Patents

Literature

71results about How to "Extended overhaul cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

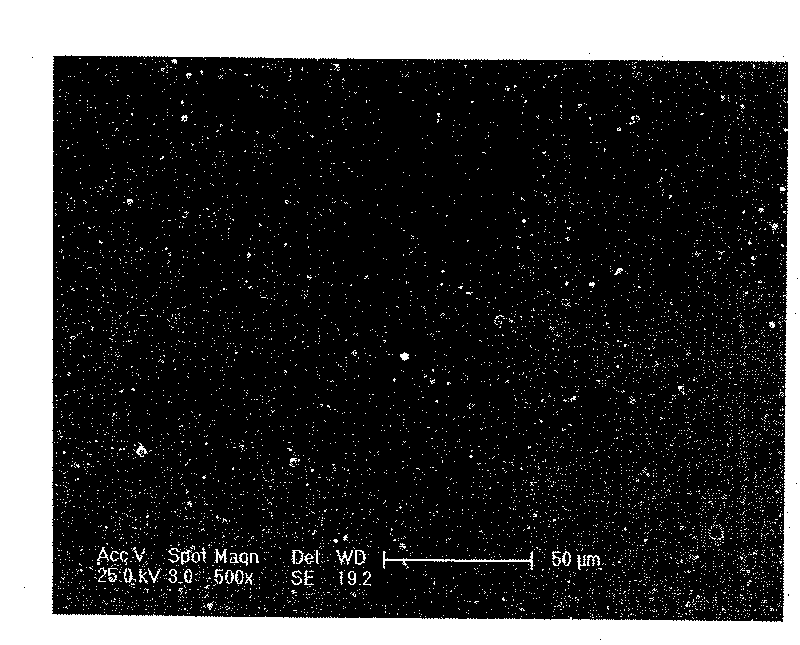

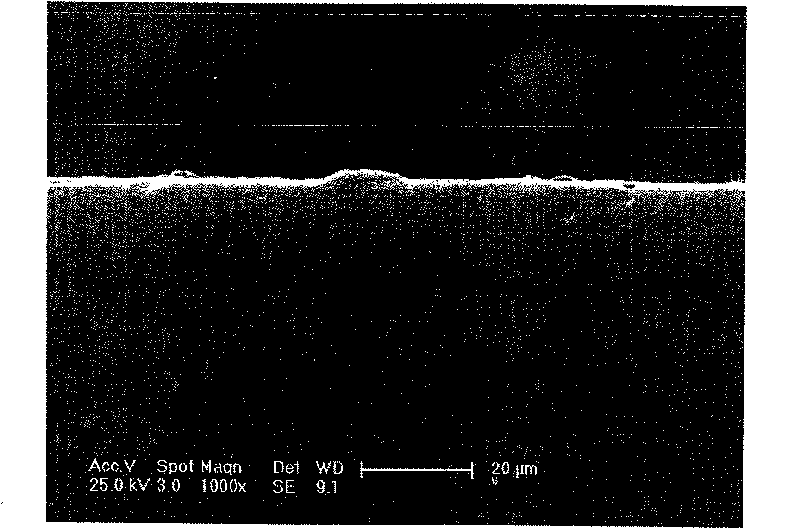

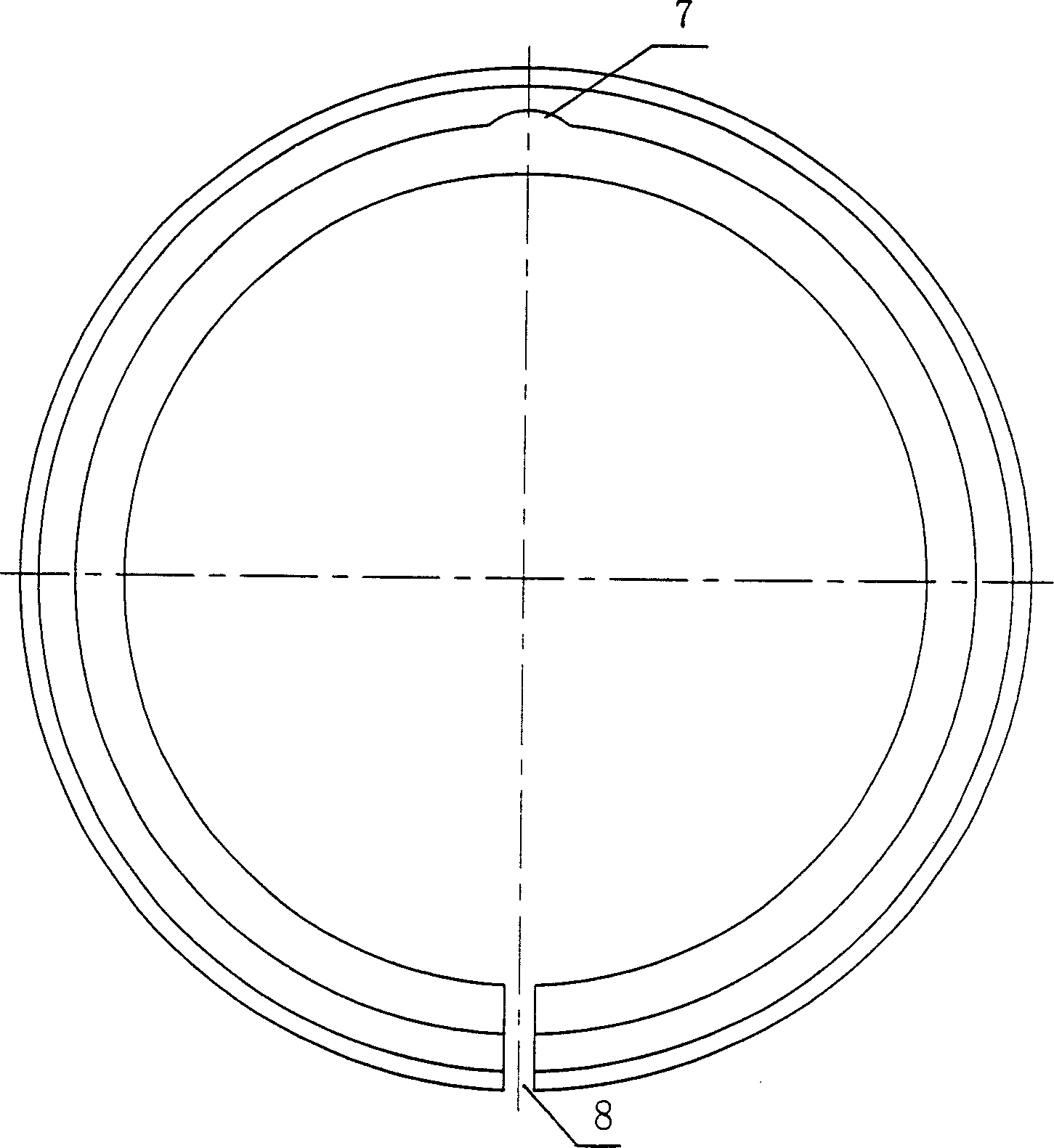

PVD chromium based ceramic composite coating piston ring and method for producing the same

InactiveCN101430004AOvercome the hardnessOvercome uniformity issuesPiston ringsVacuum evaporation coatingCeramic compositePiston ring

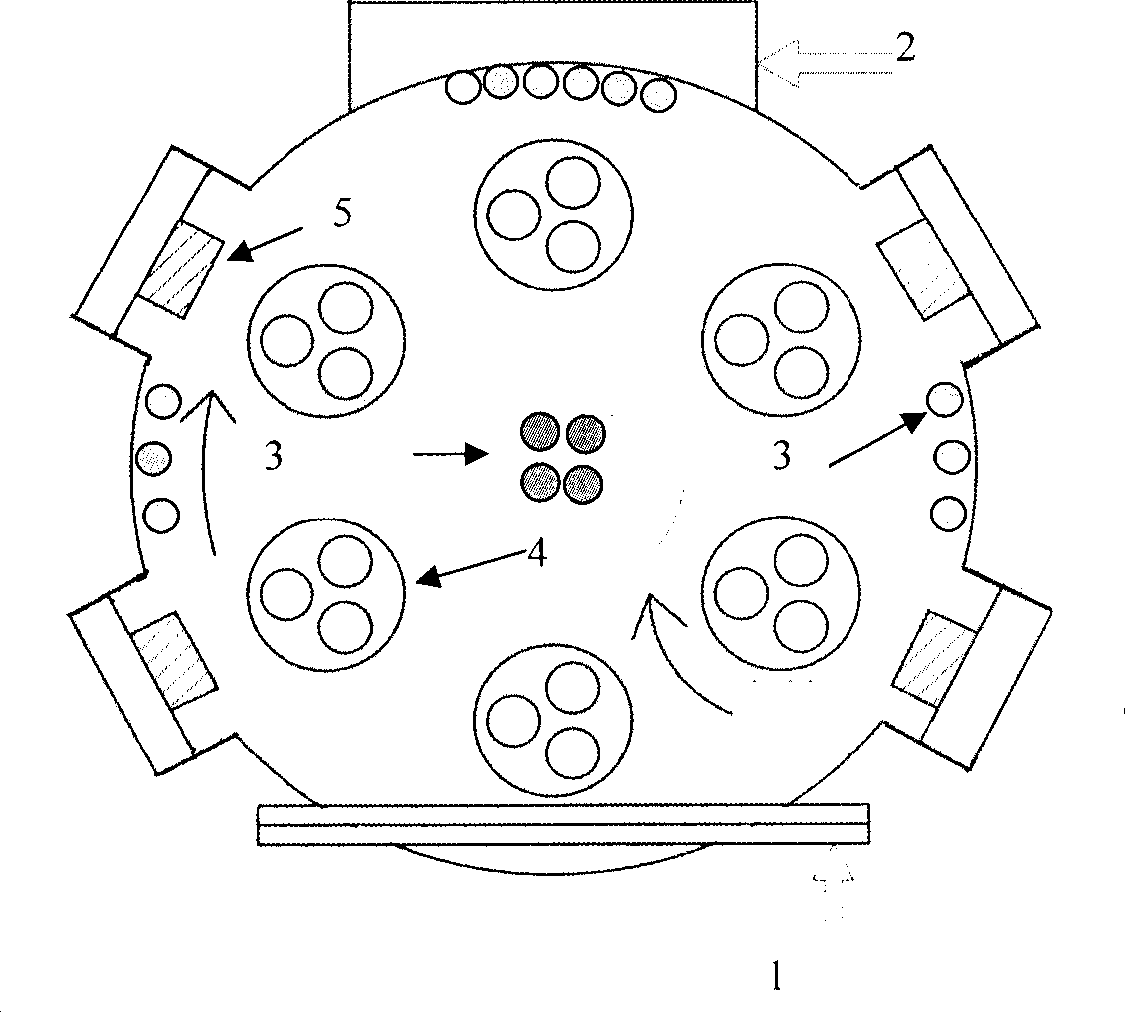

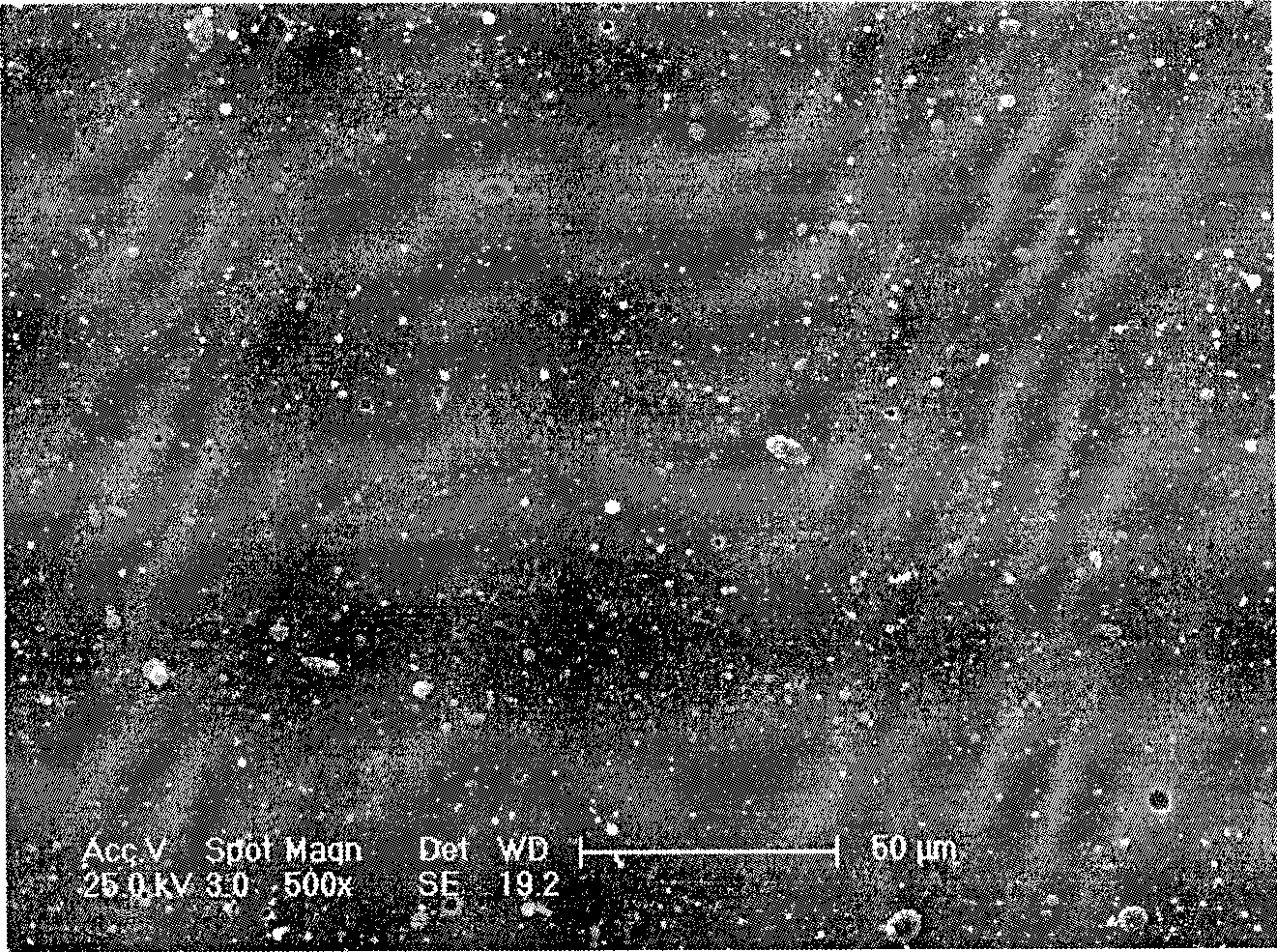

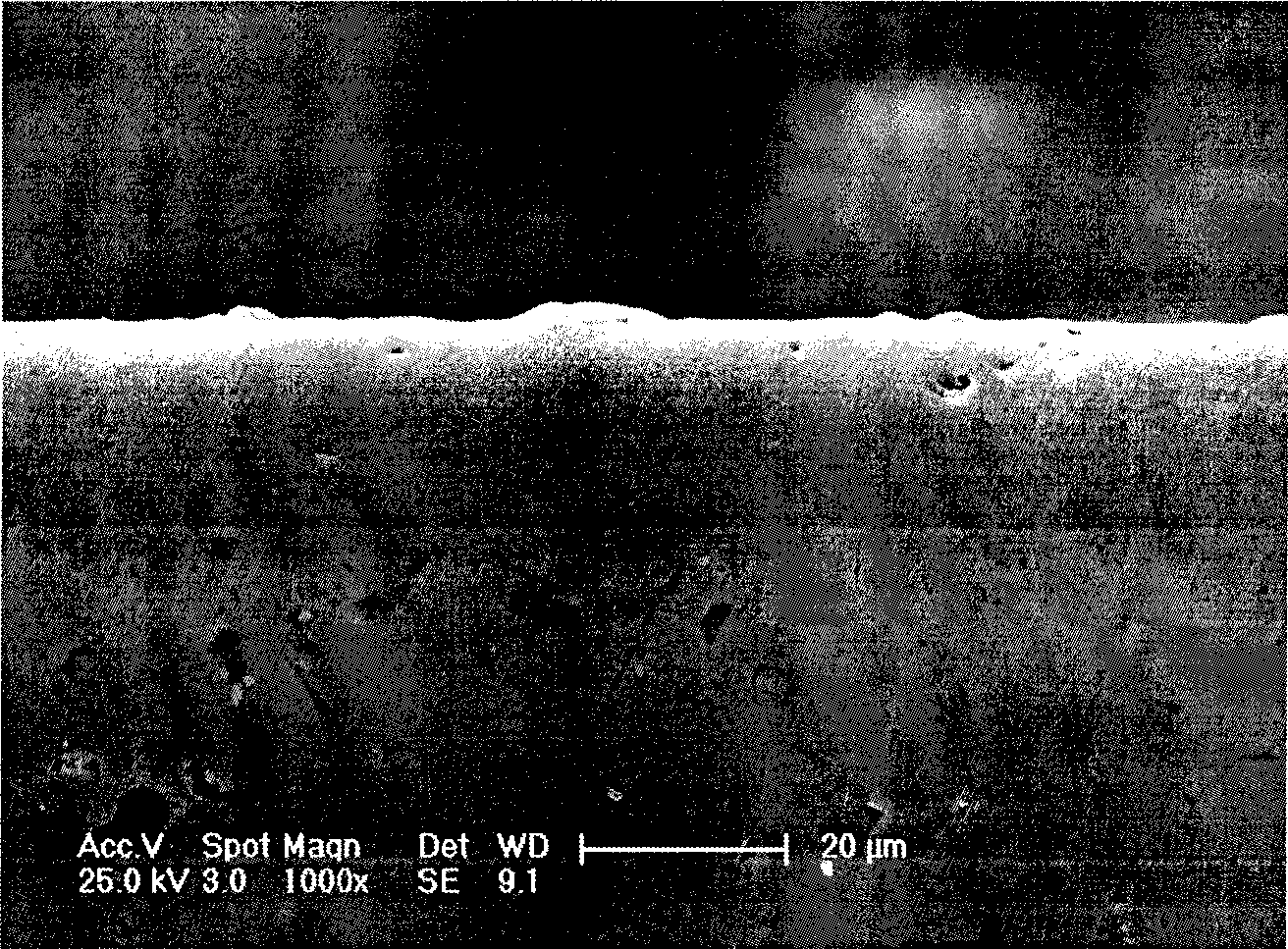

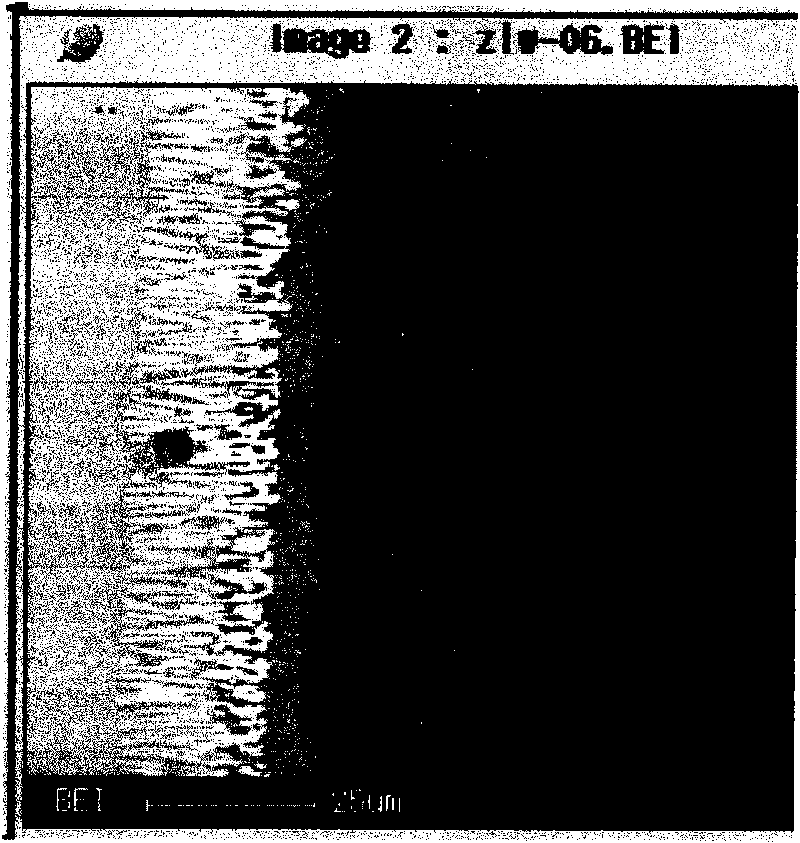

The invention discloses a PVD chromium base ceramic composite coating piston ring and a preparation method thereof, and the piston ring is manufactured by plating a chromium base ceramic composite coating on a basal body of the piston ring which is treated by nitriding by adopting high power electric arc discharge method; the chromium base ceramic composite coating is composed of a bonding layer, a main wearing layer and an anti-attrition layer, wherein, the bonding layer is binded with the basal body of the piston ring in a metallurgical way, the main wearing layer is arranged on the bonding layer, and the anti-attrition layer is positioned on the surface of the main wearing layer; the bonding layer is Cr, the main wearing layer is a Cr / CrN multilayer coating formed by the Cr and the CrN which are alternately arranged, and the anti-attrition layer is a Cr / Cr2O3 multilayer coating formed by the Cr and the Cr2O3 that are alternately arranged. The coating structure has reasonable design, and the manufactured coating has good cementing property, high hardness and good lubricating property. Furthermore, the method used for manufacturing the piston ring has no pollution in the preparation process, and overcomes the serious problem of environmental pollution of the conventional electrodeposited chromium; as the manufactured coating has better abrasion resistant and corrosion resistant performance compared with the electrodeposited chromium, the service life of the piston ring is greatly prolonged.

Owner:WUHAN UNIV

High-temperature preventive coating process

InactiveCN101724809AAchieve local preparationImprovement of working conditions in coating processSolid state diffusion coatingChromium trioxidePhosphoric acid

The invention relates to a high-temperature preventive coating process which is characterized by comprising the process flows of: preparing a caking agent, preparing slurry, spraying, solidifying and heating in a vacuum furnace, wherein the caking agent comprises the following ingredients in mass ratio: 700 to 900g of water, 60 to 90g of chromium trioxide, 70 to 90g of magnesium oxide and 270 to 400g of phosphoric acid; a preparation process of the caking agent comprises the following steps of: adding the phosphoric acid in water, adding the magnesium oxide and fully dissolving, and adding the chromium trioxide, wherein the step of adding the magnesium oxide and fully dissolving adopts a principle of adding in small amount and a plurality of times, that is to say, adding in small amount and then adding again after the solution become clear. The invention changes the traditional process flow, improves the coating performance, can be applied to components and parts that work for a long time in severe environment, and is particularly suitable for a gas turbine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Ship lock mushroom head, mushroom head cap and processing method thereof

InactiveCN101215670AImprove wear resistanceGuaranteed safe operationBarrages/weirsSolid state diffusion coatingEconomic benefitsEngineering

The invention belongs to the field of metal materials, and relates to the selecting of the materials of a mushroom head and a mushroom headgear of a bottom hinge of a ship lock gate and the improvement for processing technology. The material of the mushroom head for the bottom hinge of the ship lock gate is 40 chromium or 4 chromium 13, and the material of the mushroom headgear which is engaged with the mushroom head is 38 CrMoAlA or QT 600-3. The mushroom head uses 40 Cr and 4Cr13 materials, whose hardness value is 45, the mushroom headgear uses 38CrMoAlA materials, whose hardness value is 900, and the hardness value of the QT 600-3 materials is 600. The invention provides the machining process of the above materials, the materials of the mushroom head and the mushroom headgear and the surfaces use a reasonable treatment process, and the hardness value of the materials of the mushroom head and the mushroom headgear which are engaged are reasonably collocated, thereby greatly improving the wear resistance of friction pair and playing a key role to guarantee the safe operation of a ship lock and prolong the repair cycle of the ship lock, and the economic benefits is remarkable.

Owner:JIANGSU PROVINGIAL TRANSPORTATION ENG GRP

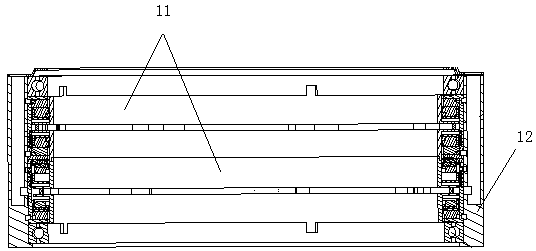

Bearing block, oil cavity cleaning and lubricating system and method for bearing block, and mineral engineering machinery

ActiveCN103867581AAchieve cleaningImprove cleaning efficiencyHollow article cleaningLubrication elementsSystem structureScrew thread

The invention discloses a bearing block, which comprises a bearing sleeve and a bearing cap, wherein a flange is arranged at one end of the bearing sleeve, and a through shaft hole is formed in the other end of the bearing sleeve; a threaded hole is also formed in the flange, is connected with an oil inlet hole passage, and is communicated with a bearing hole through the oil inlet hole passage; an oil outlet threaded hole and an oil outlet hole passage are also formed in the flange, and the oil outlet hole passage is communicated with a transition section of the bearing sleeve to form a loop, so that an oil cavity of the bearing block is cleaned; the oil inlet hole passage and the oil outlet hole passage can be flexibly formed, so that the universality of the bearing block is improved, and the application range of the bearing block is widened. In addition, the invention discloses a bearing-block-based bearing block cleaning and lubricating system and a bearing-block-based bearing block cleaning and lubricating method. The system has the advantages of simple structure, safety, reliability, good cleaning and lubricating effects, capability of automatically cleaning and lubricating the bearing block and high applicability. Moreover, the invention provides mineral engineering machinery based on the bearing block and the bearing block oil cavity cleaning and lubricating system.

Owner:江苏京冶海上风电轴承制造有限公司

Biodegradable lubricating oil

InactiveCN103773555AEmission reductionExtend oil change intervalsAdditivesCopper oxideCleansing Agents

The invention discloses biodegradable lubricating oil. The biodegradable lubricating oil comprises base oil, an anti-oxidant, a rusting inhibitor, an anti-foaming agent, a metal deactivator, a demulsification agent, an antiwear agent, a cleaning agent, a viscosity index improver, copper oxide powder and magnesium metal powder. The anti-oxidant is a mixture of diarylamine and dithiocarbamate. The rusting inhibitor is an alkylsuccinic acid derivative. The anti-foaming agent is a dimethyl siloxane polymer. The metal deactivator is triazole. The demulsification agent is polyalkoxypolyphenol. The antiwear agent comprises alkyl phosphate ester and salt. The cleaning agent is calcium petroleum sulfonate. The viscosity index improver is an ethylene-propylene copolymer. The biodegradable lubricating oil is prepared by a simple method, has high quality, a long use period, improved extreme pressure resistance, and completely improved oxidation resistance, corrosion resistance and foaming resistance, can be degraded biologically and completely exceeds environmental protection requirements on the same type of products.

Owner:TIANJIN ZEYA TECH

High-strength and high-hardness online heat treatment rare-earth steel rail material and production method thereof

InactiveCN110951944AExtended service lifeExtended overhaul cycleFurnace typesHeat treatment furnacesChemical compositionHeat treating

The invention discloses a high-strength and high-hardness online heat treatment rare-earth steel rail material. The high-strength and high-hardness online heat treatment rare-earth steel rail materialcomprises the following chemical components in percentage by mass: 0.93-1.0% of C, 05-0.6% of Si, 0.9-1.0% of Mn, not more than 0.020% of P, not more than 0.020% of S, 0.15-0.3% of Cr, 0.01-0.05% ofNb, 0.15-0.5% of Ni, 0.001% of Ce, and the balance Fe and inevitable impurities. The invention further discloses a production method of the high-strength and high-hardness online heat treatment rare-earth steel rail material. The prepared steel rail material has the tensile strength not less than 1330 MPa, the elongation not less than 9%, and the steel rail tread hardness not less than 400 HB.

Owner:BAOTOU IRON & STEEL GRP

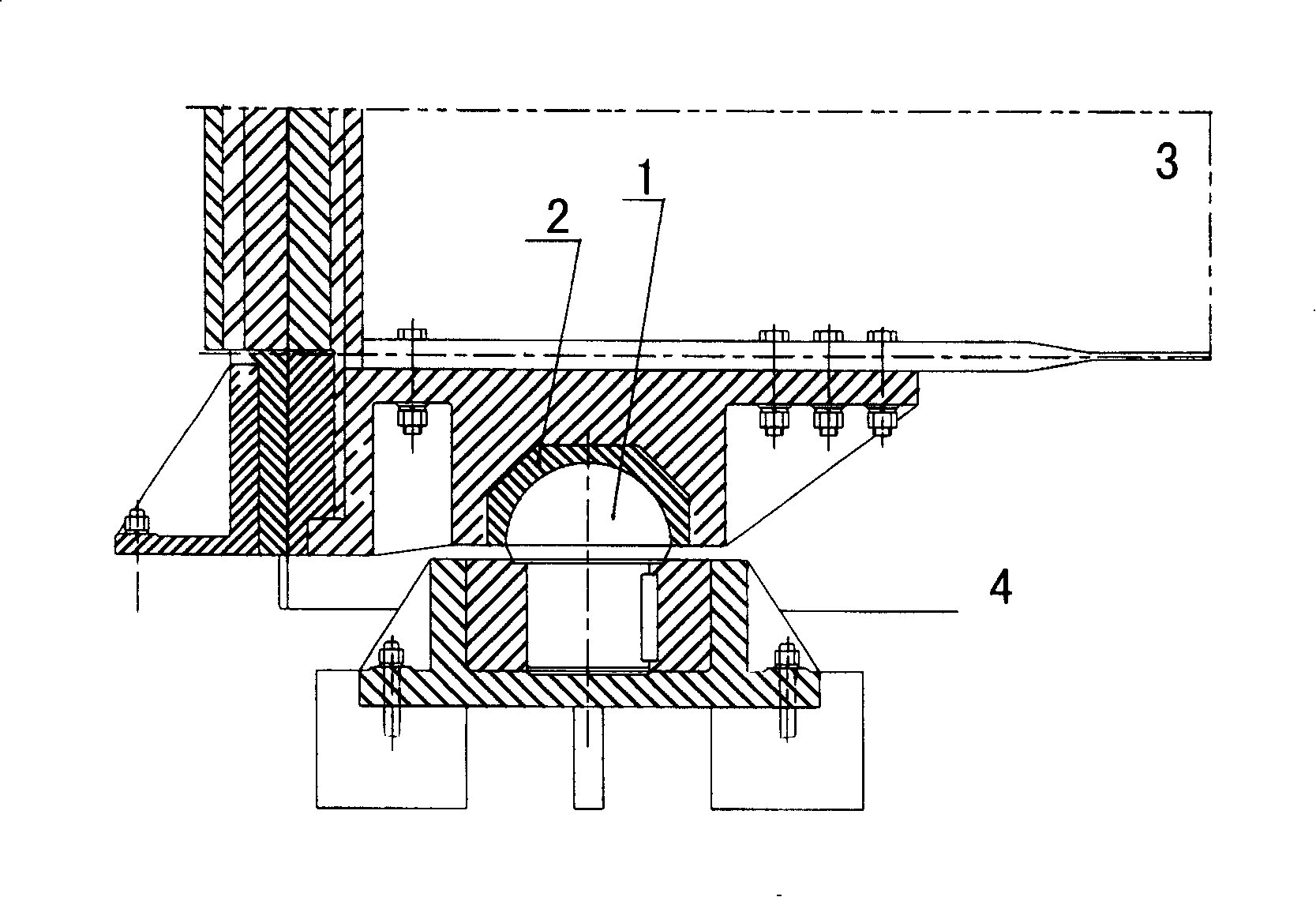

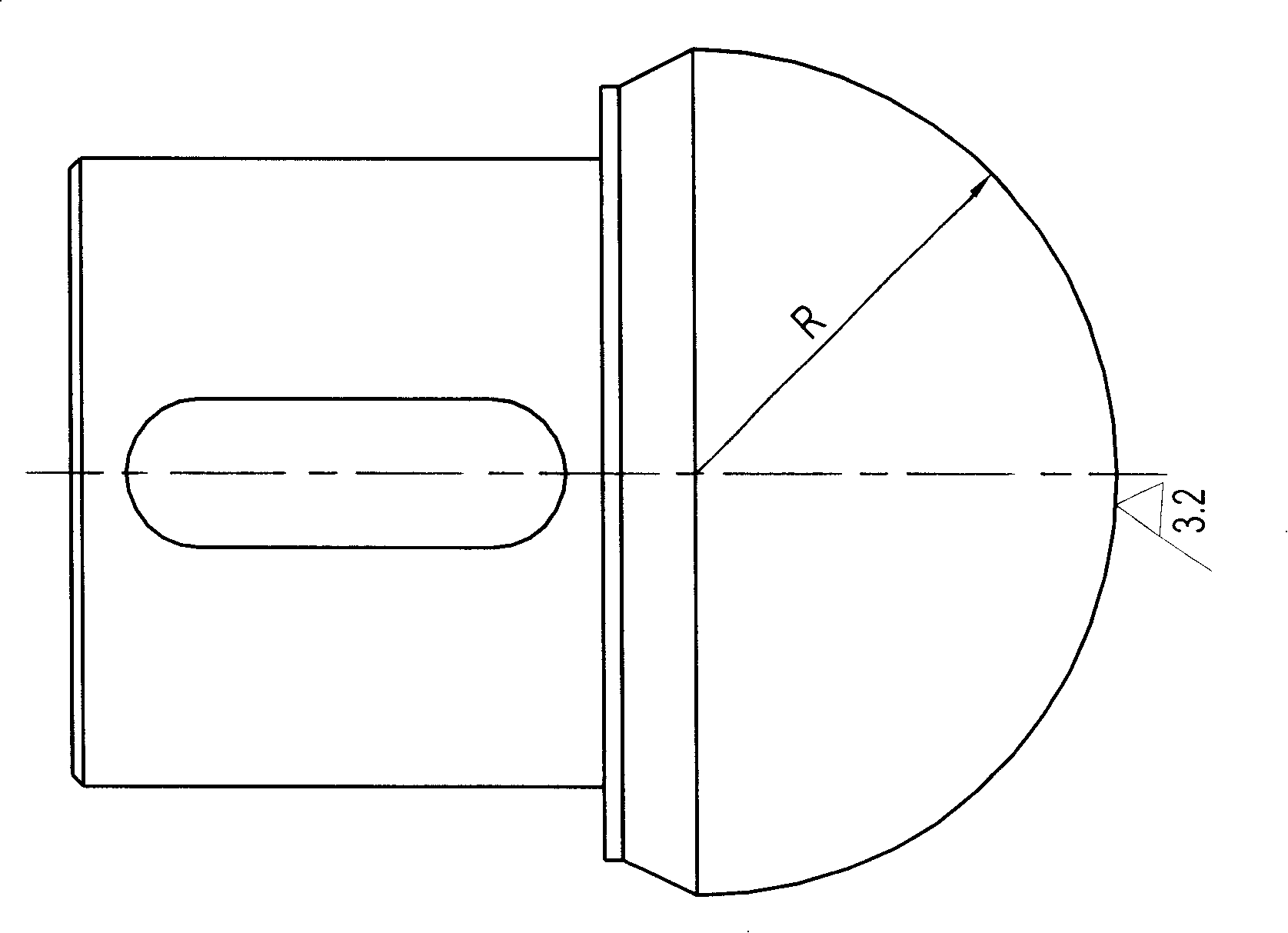

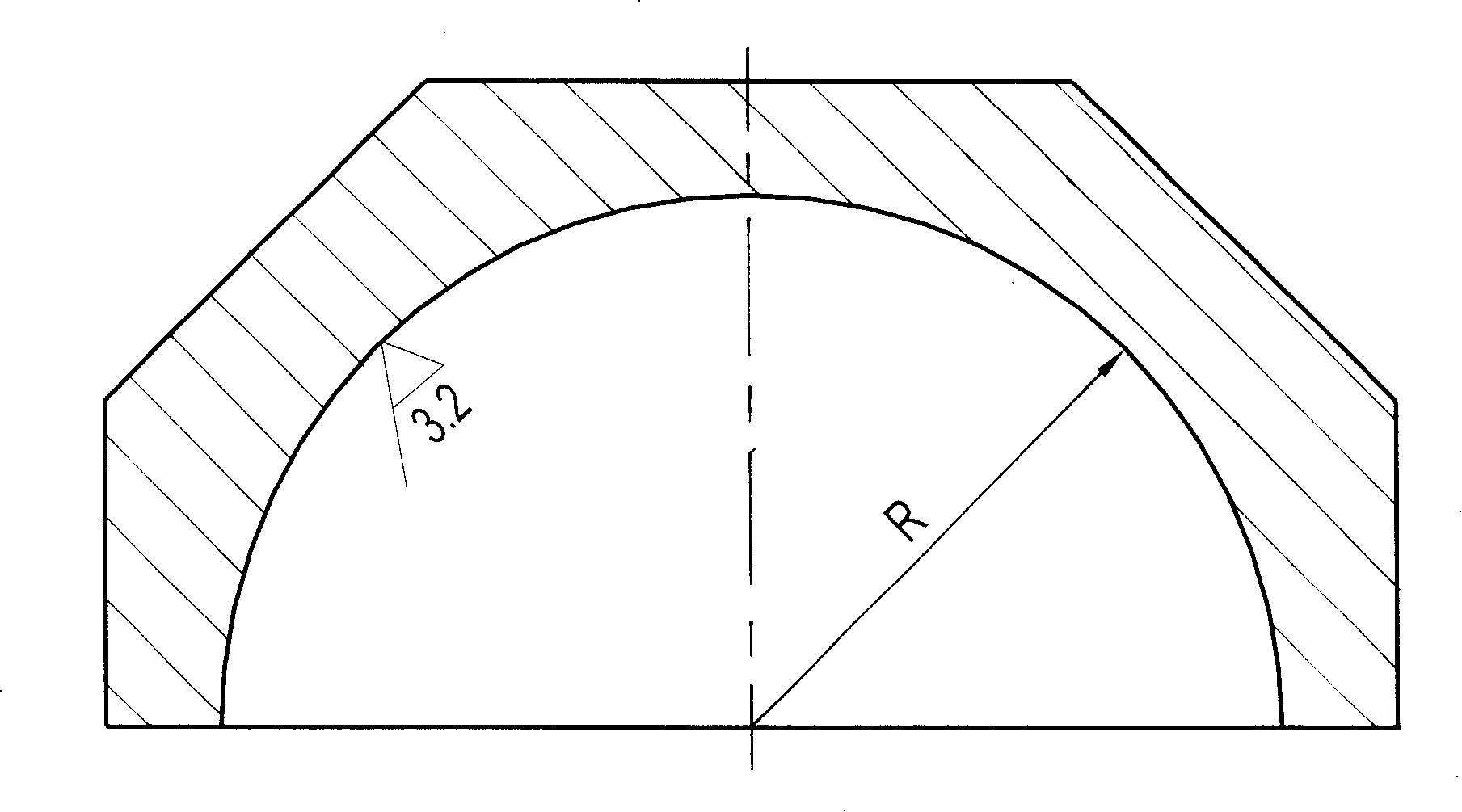

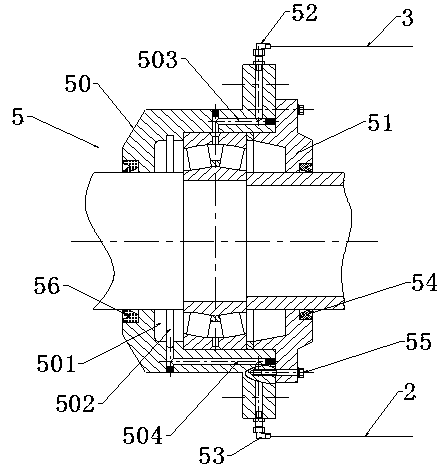

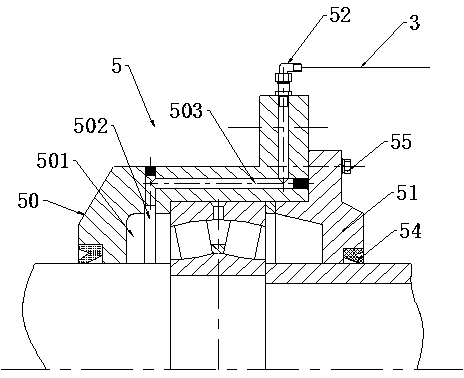

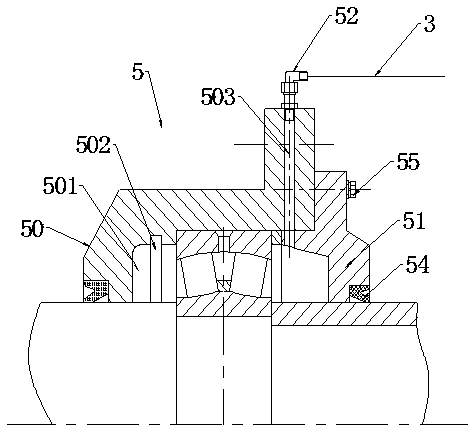

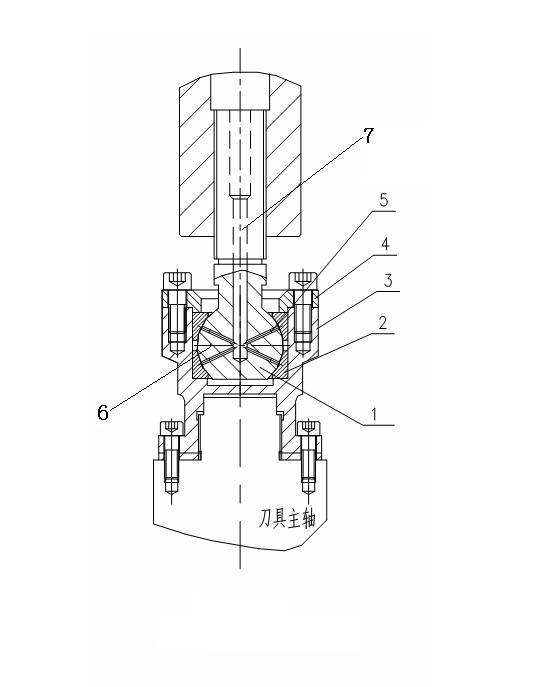

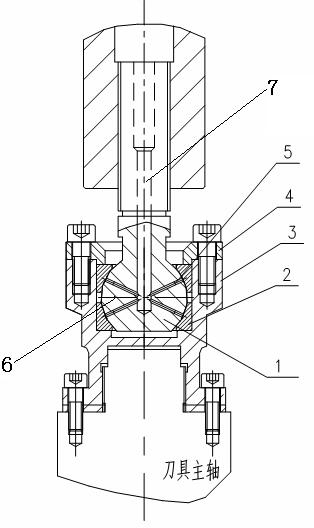

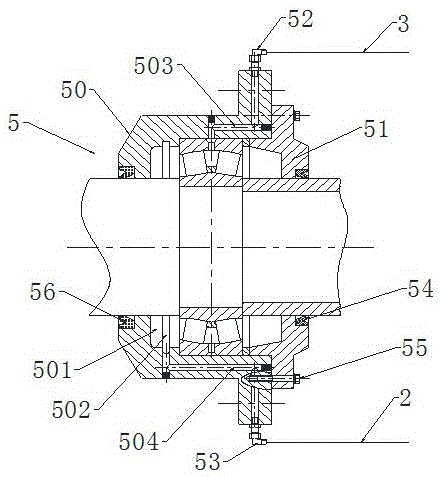

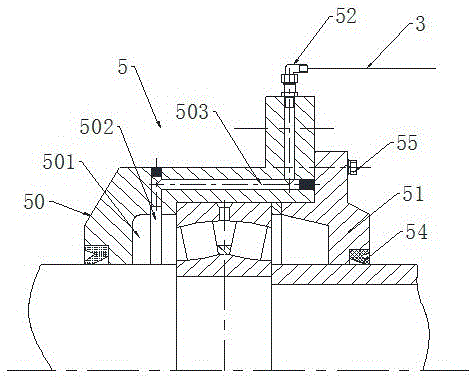

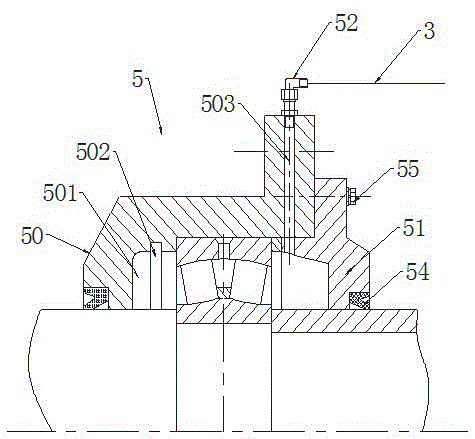

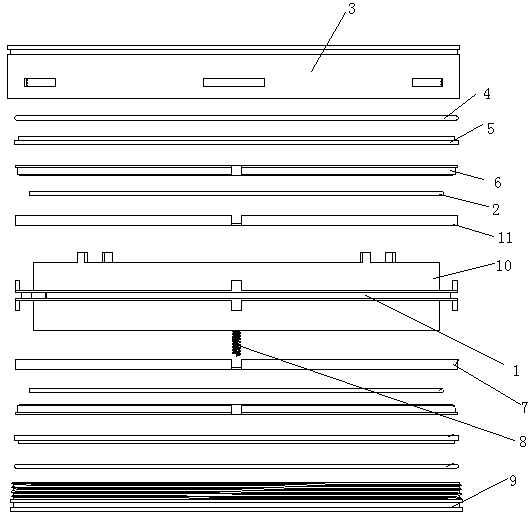

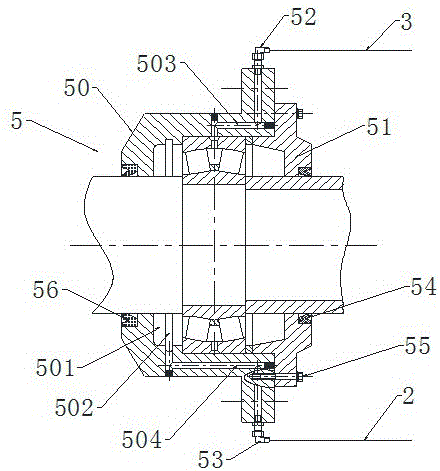

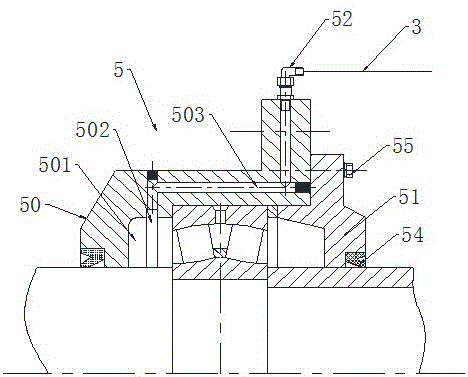

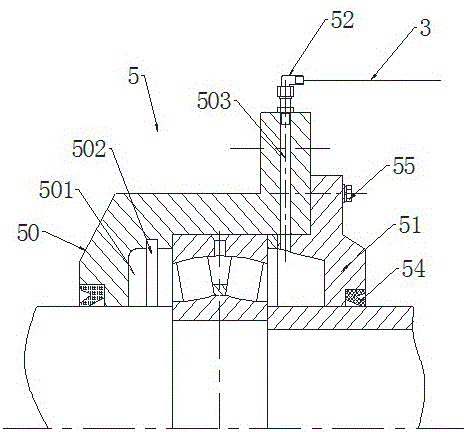

Dynamic and static pressure ball socket bearing structure for high speed gear shaper

ActiveCN102221039AImprove mean time between failuresImprove the lubrication effectPivotal connectionsGear-cutting machinesEngineeringAxial force

The invention relates to a dynamic and static pressure ball socket bearing structure for a high speed gear shaper. The structure comprises a ball rod (1), a ball socket (2) and a shell (3), wherein the lower end of the shell (3) is connected with a cutter spindle; a ball main body (6) at the lower end of the ball rod (1) is positioned in the ball socket (2); the ball socket (2) is arranged in an installation seat of the shell (3) and is positioned and subjected to gap adjustment along the axial direction of the ball rod (1) through a pressing ring (4); and the upper end of the ball rod (1) stretches out of the pressing ring (4) and is connected with a crank. The structure is characterized in that: an oil injection hole (7) is formed in the center of the ball rod (1) and reaches the ball center of the ball main body (6); the ball main body (6) is provided with a throttler (5) along the radial direction; and the oil inlet end of the throttler (5) is communicated with the oil injection hole (7) which reaches the ball center, and the oil outlet end of the throttler (5) is communicated with an annular shallow cavity on the surface of the ball main body (6), so that the shallow cavity generates dynamic pressure bearing force and static pressure bearing force due to a step effect to bear upper and lower axial forces from a gear shaping spindle when the ball main body (6) moves. The structure is simple and has a good lubricating effect and long service life.

Owner:南京二机齿轮机床有限公司

Biodegradable lubricating oil

InactiveCN103194299AGood emissionExtend oil change intervalsLubricant compositionWorking temperatureCopper oxide

The invention relates to a biodegradable lubricating oil. The biodegradable lubricating oil is composed of base oil, an antioxidant, a corrosion inhibitor, an antifoaming agent, a metal deactivator, a demulsifier, an anti-wear agent and copper oxide powder, wherein the base oil is composed of synthetic base oil poly(alpha-olefin), synthetic base oil synthetic fat and synthetic base oil polyether; the antioxidant is anyone or a mixture of diarylamine and sterically hindered phenol, wherein the weight ratio of diarylamine to sterically hindered phenol in the mixture is 1:1; the corrosion inhibitor is a salt formed through using fatty acid and amine; the antifoaming agent is polydimethylsiloxane; the metal deactivator is a toluyltriazole derivative; the demulsifier is polyalkoxyphenol; the anti-wear agent is sulfurated triphenyl phosphate; and the copper oxide powder is nanometer powder, and the particle granularity of the powder is 25-35nm. The biodegradable lubricating oil has the advantages of simple preparation method, scientific and environmentally-friendly preparation scheme, degradability, high work temperature range, good lubricating characteristic, long service life, good protection to parts, high comprehensive performances, reasonable cost, realization of above 90% biodegradation of waste oil, extremely low gas discharge, and obvious energy saving effect.

Owner:陈冬梅

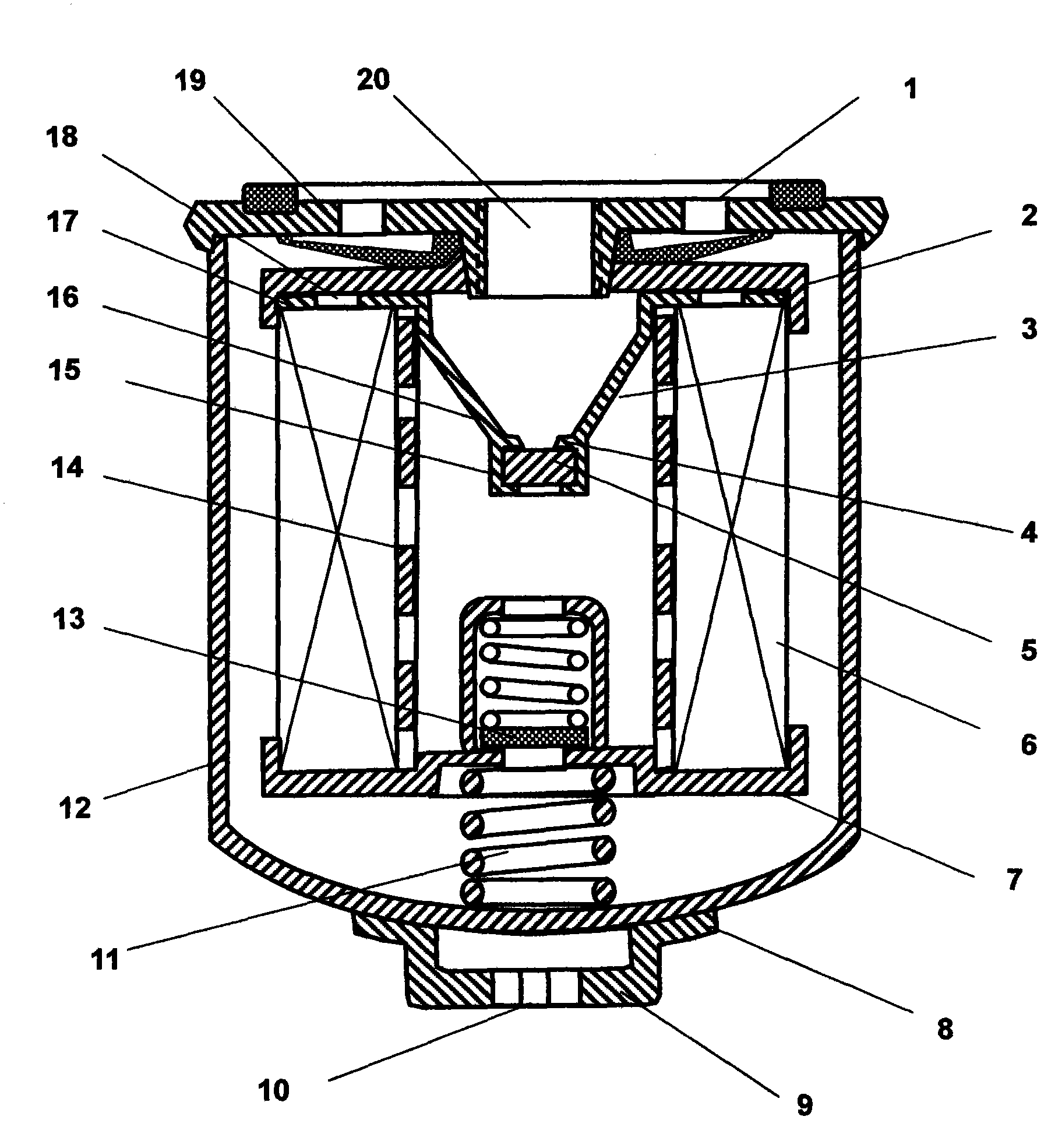

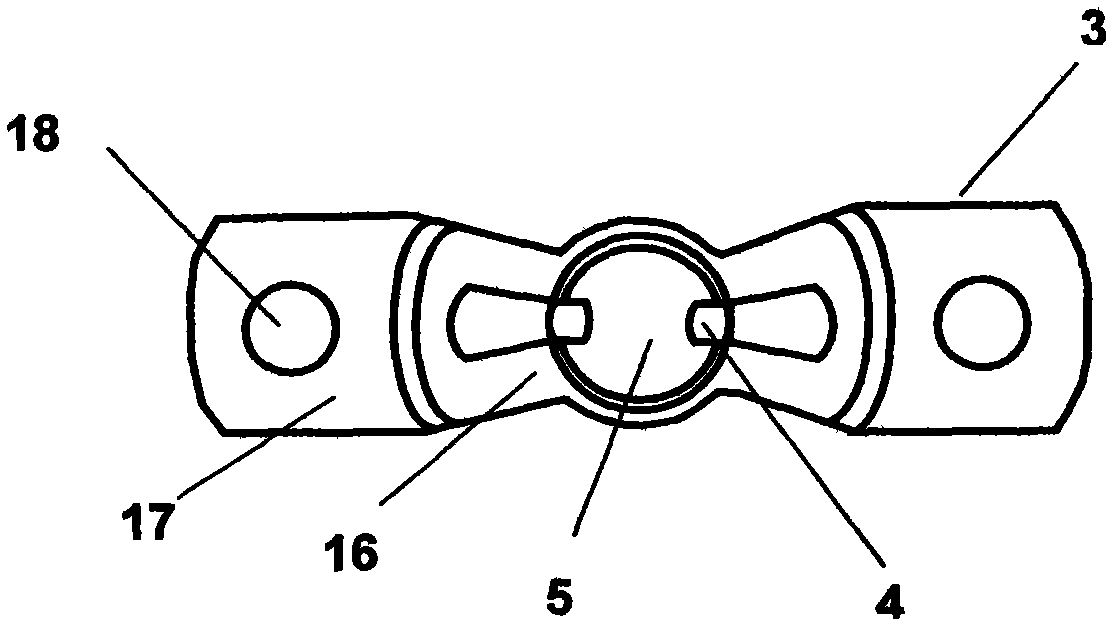

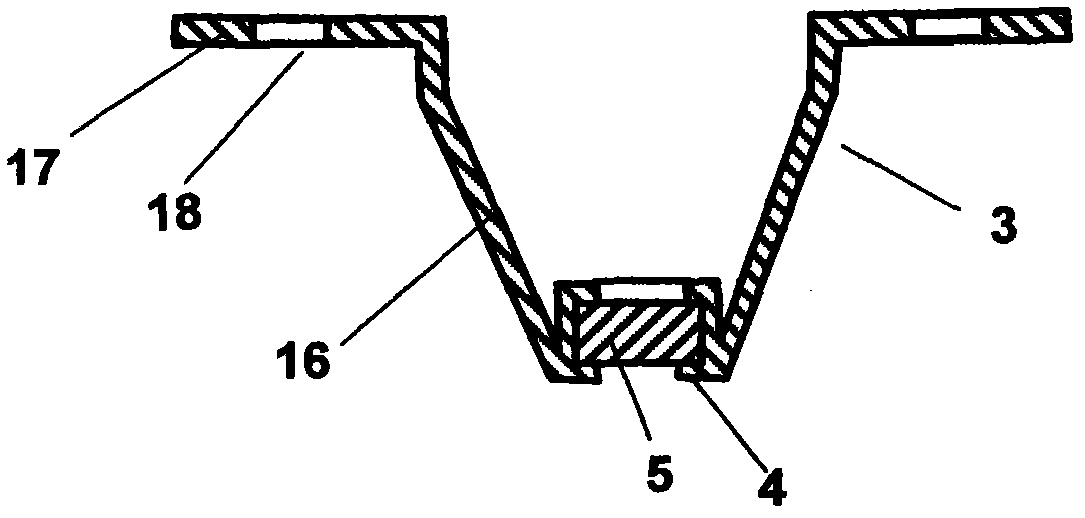

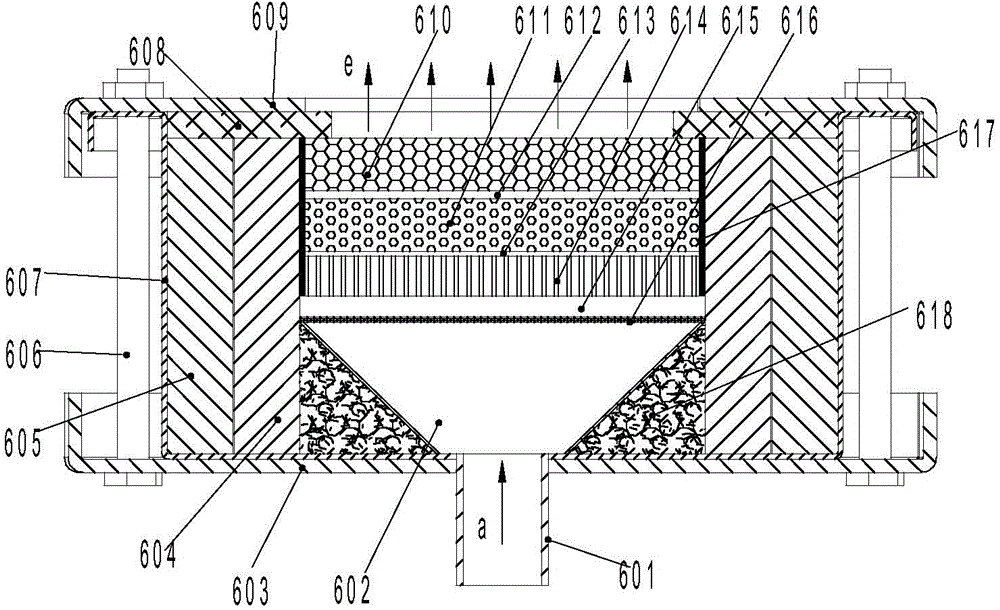

Fluid high-intensity magnetic integrated filter

A fluid high-intensity magnetic integrated filter relates to the field of fluid filters, comprises all fluid filters that filter ferromagnetic substances, and is characterized in that: a screwed covering plate is sealedly disposed on a housing of the filter; a fluid inlet and a fluid outlet are disposed on the screwed covering plate; a filter core is disposed inside the housing; the filter core comprises a filter central tube, a filter core upper end cover and a filter core lower end cover; a V-shaped magnet fixing device is fixedly disposed between a filter core end surface and the filter core upper end cover; a magnet fixing pit is disposed in the middle of the V-shaped magnet fixing device; a magnet is disposed in the magnet fixing pit; a support spring is disposed between the filter core bottom and the filter housing; with the spring, the filter core is sealedly connected with the screwed covering plate; and the main body of the filter core separates the fluid inlet from the fluid outlet. The fluid filter designed with the above scheme effectively filters ferromagnetic substances in fluid, prevents equipment wearing, prolongs service life of the equipment, enables fluid magnetization, and improves fluid use value.

Owner:四平大吉强磁滤清器有限公司

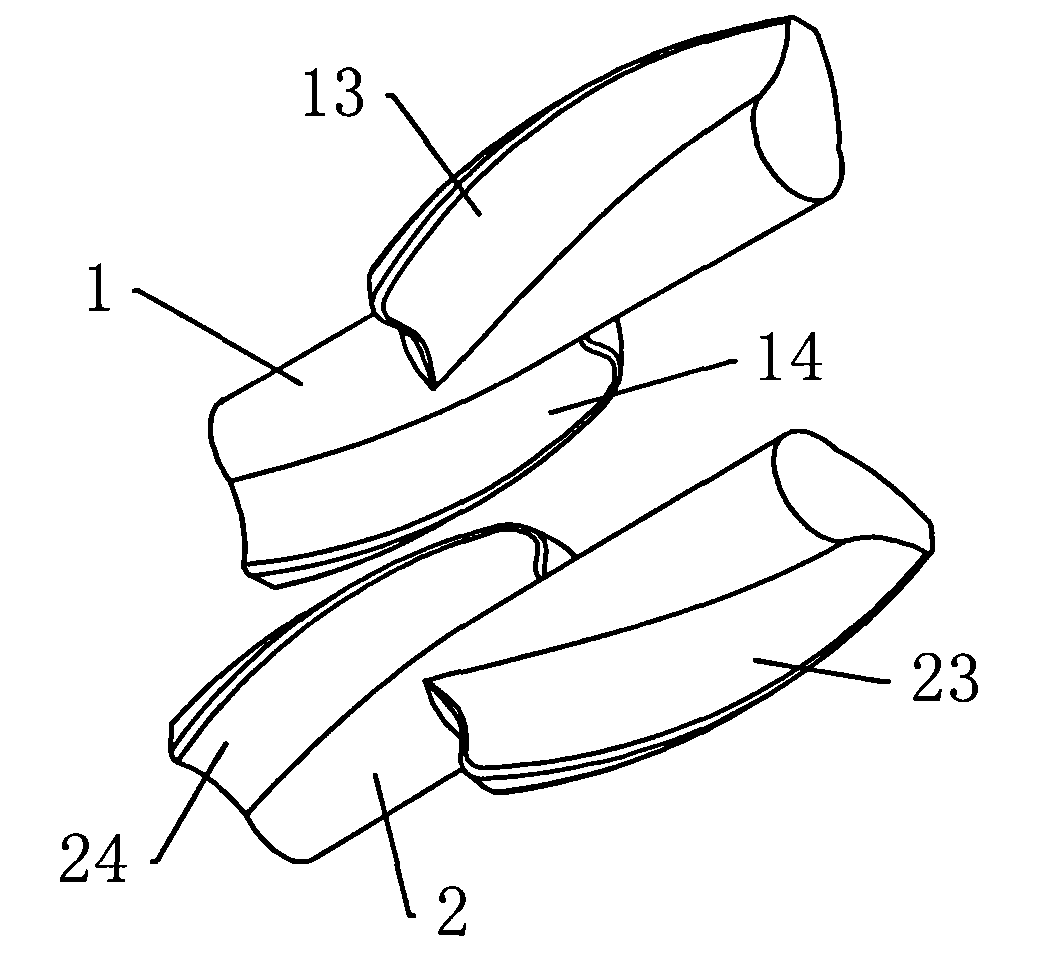

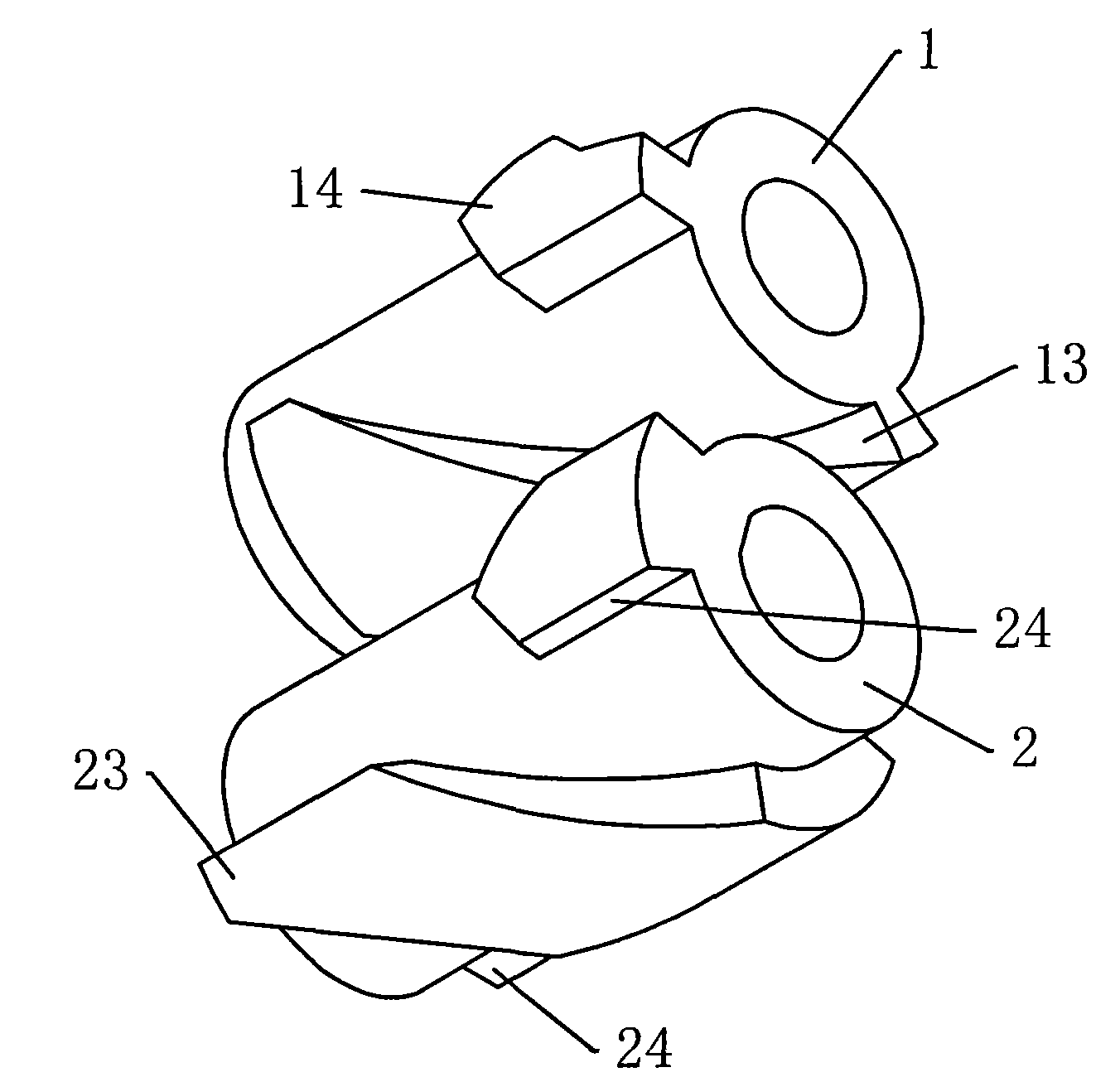

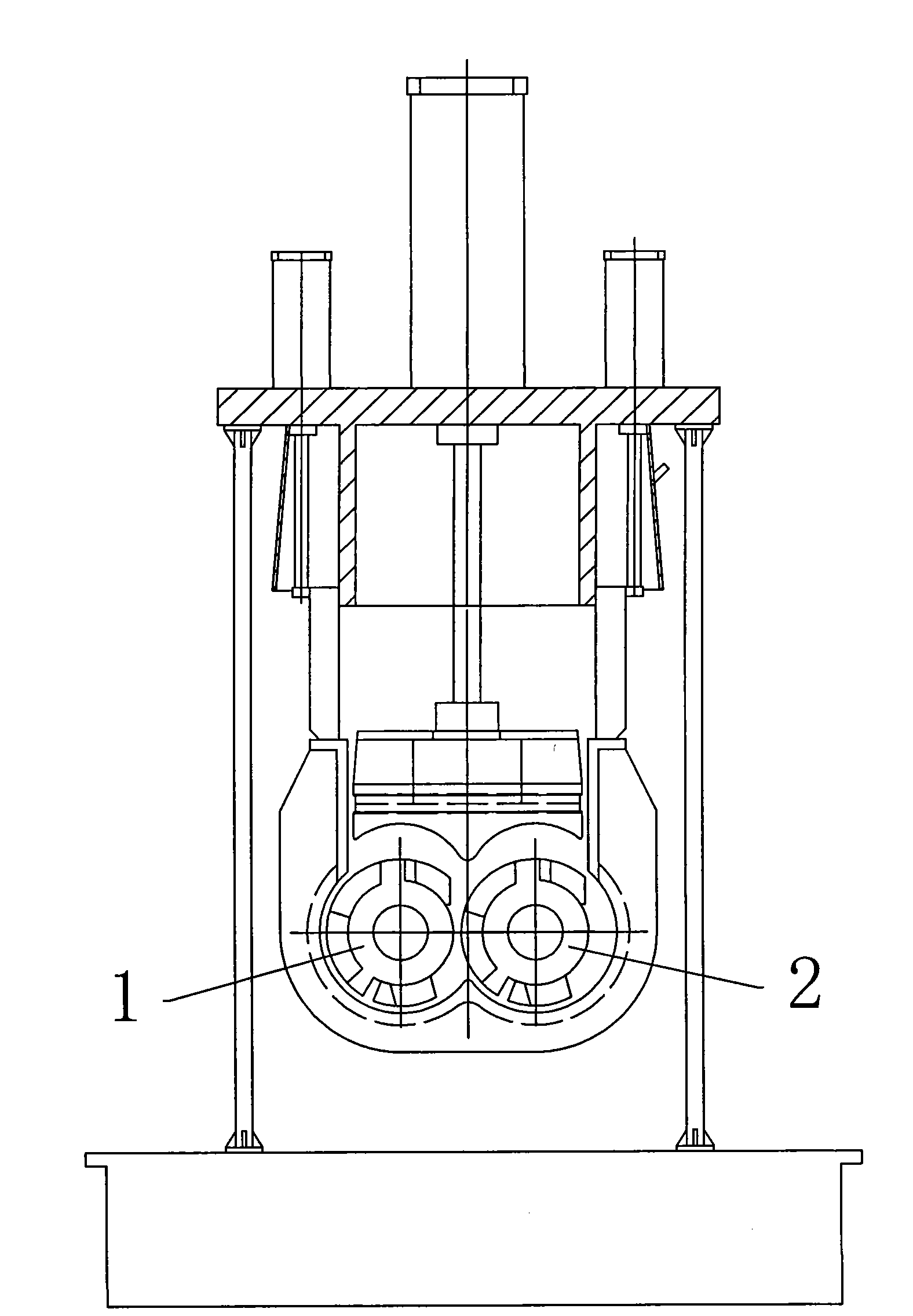

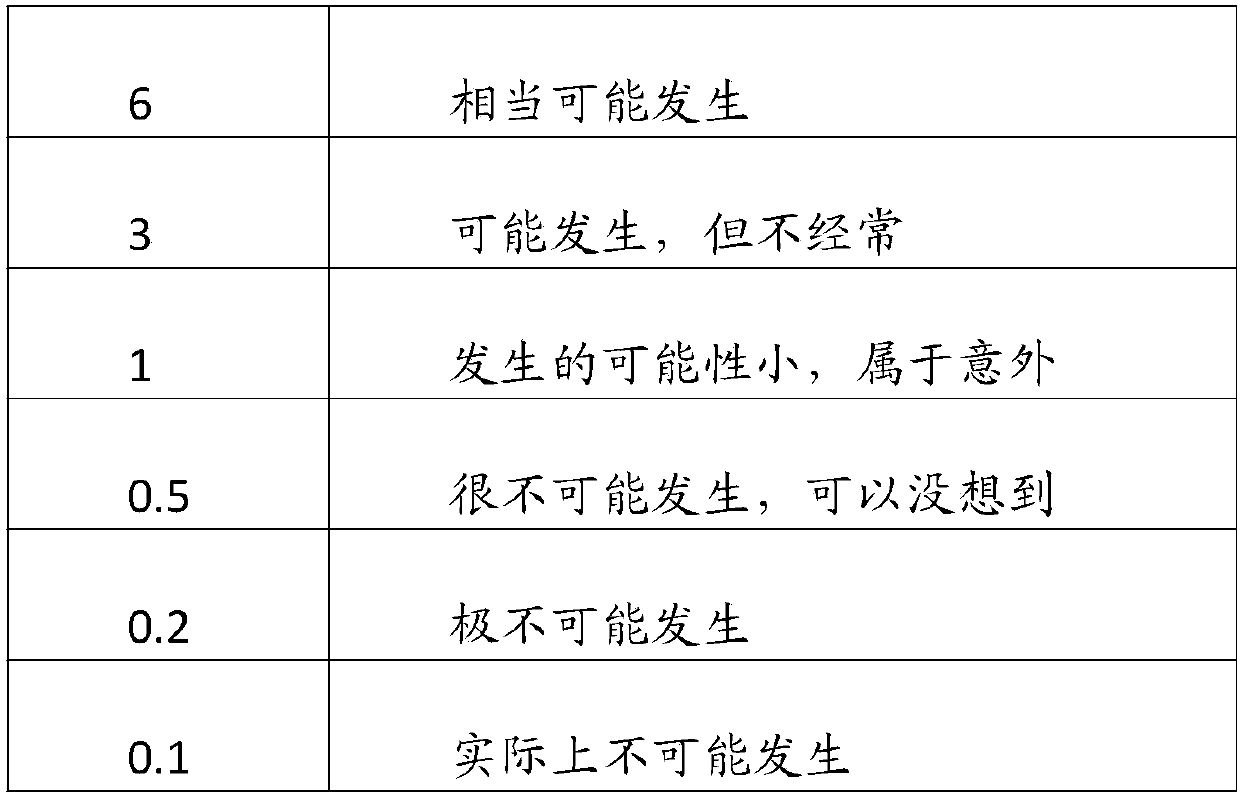

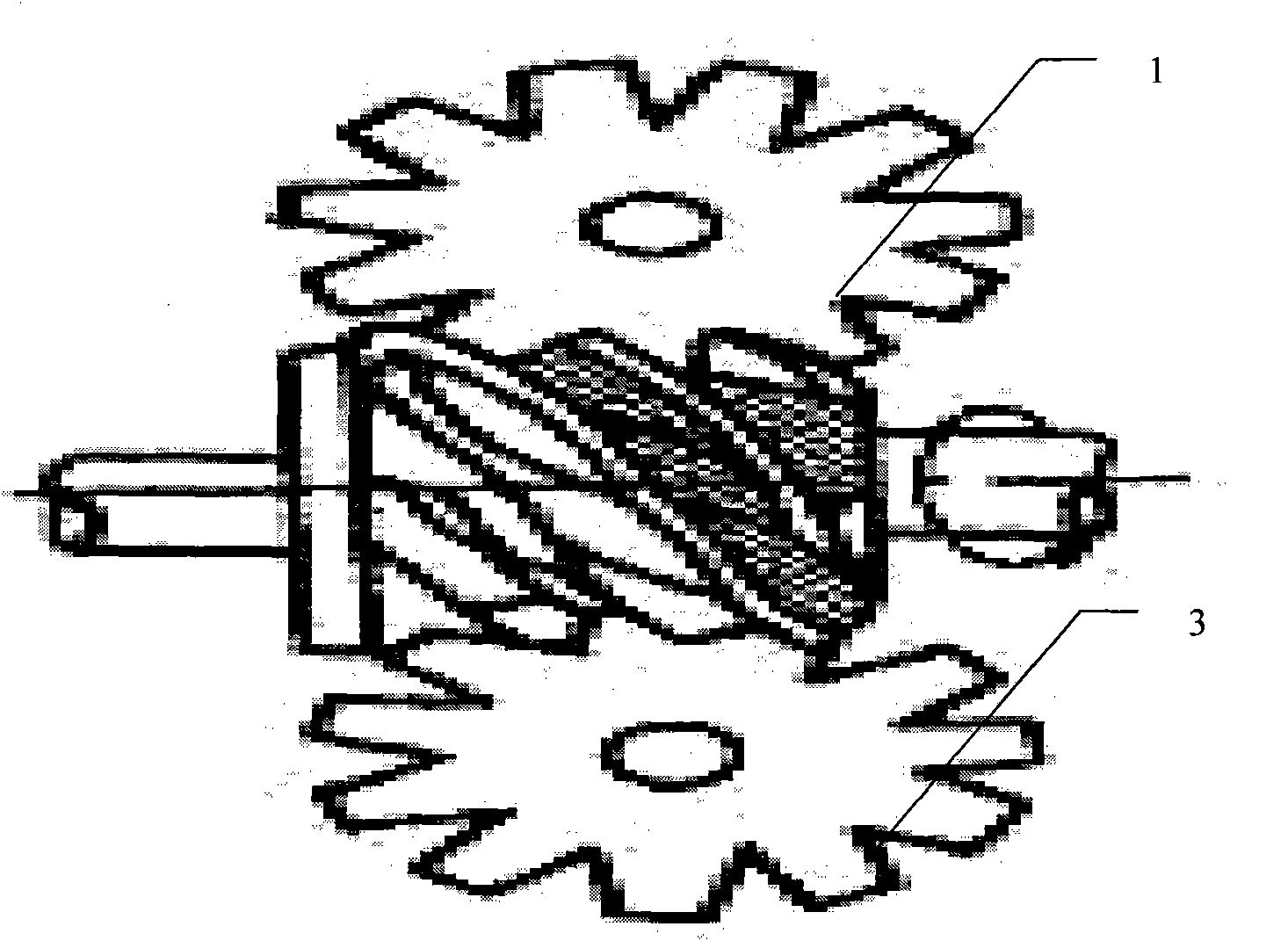

Stirring shaft of banburymixer

The invention aims to provide a stirring shaft of an energy-saving banburymixer, which can make the uniformity of mixing molecules higher, shorten mixing period and improve production efficiency. The stirring shaft is provided with two rotors which have a meshing type prism structure in synchronous opposite rotation; and the aim of mixing is achieved by linear speed difference. The stirring shaft comprises two parallel rotors which are driven by a power unit to rotate relatively; the cylindrical surfaces of the two rotors are all provided with spiral ribs, and the cylindrical surfaces of the two rotors at two ends are all provided with lug bosses; and when the two rotors rotate relatively, the lug bosses and the spiral ribs on one rotor extend into clearances between the spiral ribs and the lug bosses on the other rotor in turn.

Owner:南京凯驰机械有限公司

Bearing block, system for cleaning oil chamber of bearing block, mineral engineering machine and engineering machine

InactiveCN105570318AAchieve cleaningImprove cleaning efficiencyHollow article cleaningLubrication elementsThermodynamicsScrew thread

The invention discloses a bearing block, which comprises a bearing sleeve and a bearing cap; the bearing sleeve is of a structural form with a flange; a shaft through hole is formed in the other end of the bearing sleeve; the flange is also provided with a structure that a threaded hole is connected with an oil inlet way and communicates with a bearing hole; the flange is also provided with a structure that an oil outlet threaded hole, an oil outlet way and a transition section of the bearing sleeve communicate to form a loop, therefore cleaning on an oil chamber of the bearing block is realized; moreover, the oil inlet way and the oil outlet way can be arranged in a comparatively flexible manner, so that universality of the bearing block is increased and an applicable range of the bearing block is broadened. In addition, the invention also discloses a bearing block-based system and a bearing block-based method for cleaning and lubricating the bearing block; the system and the method are capable of realizing automatic operation of cleaning and lubricating the bearing block, and are high in applicability. Moreover, the invention also provides a mineral engineering machine and an engineering machine which apply the bearing block and the system for cleaning and lubricating the oil chamber of the bearing block.

Owner:长沙贤正益祥机械科技有限公司

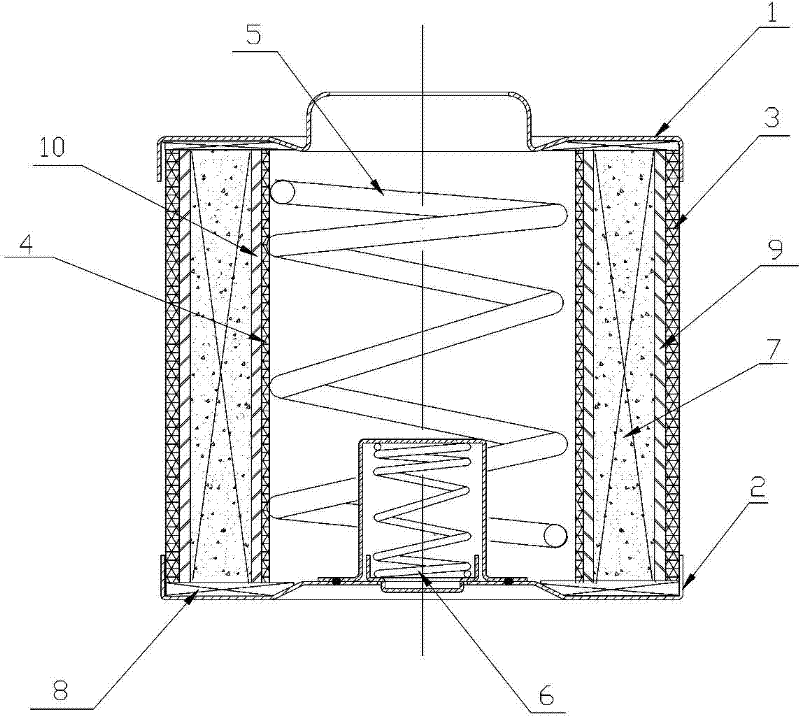

An energy-saving and emission-reducing filter capable of prolonging the service life of lubricating oil

ActiveCN102287248AReduce wearExtended maintenance cycleLubricant mounting/connectionPressure lubricationCelluloseFuel oil

The invention discloses an energy-saving emission-reducing filter capable of prolonging service life of lubricating oil. An inner screen frame (4) and an outer screen frame (3) are connected between an upper end cover and a lower end cover of the filter; the outer surface of the inner screen frame and the inner surface of the outer screen frame are connected with inner screen protective cloth (10) and outer screen protective cloth (9); an annular space formed by the inner screen protective cloth and the outer screen protective cloth is filled with a water absorption cellulose resin filter layer (7); and a support reinforcing member (5) is arranged in an inner cavity of the inner screen frame. The filter has effects of absorbing water entering an engine and engine oil, filtering various impurities in the lubricating oil and keeping the lubricating function of the lubricating oil for a long time by utilizing physical and chemical properties of solid and liquid additives in a filter element, greatly prolongs the service life of the lubricating oil, prolongs a replacement cycle of the lubricating oil, also prolongs an overhaul period of the engine, and saves fuel oil by 5 to 8 percent.

Owner:齐李豹

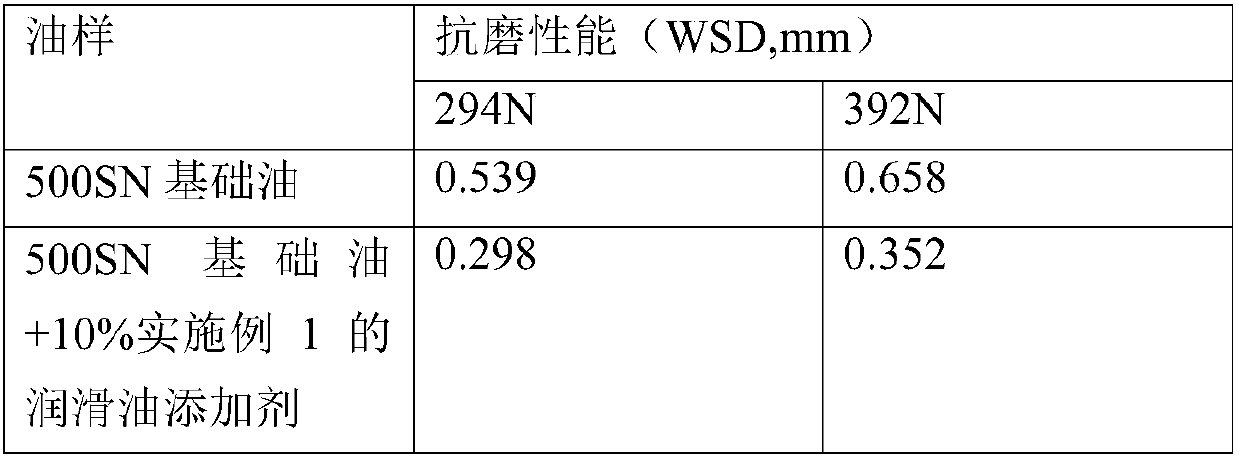

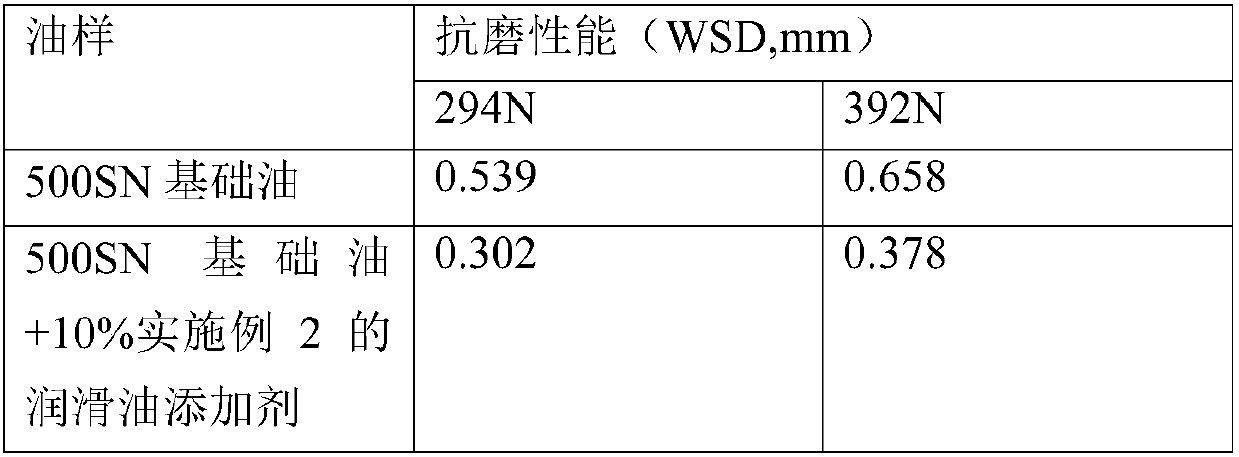

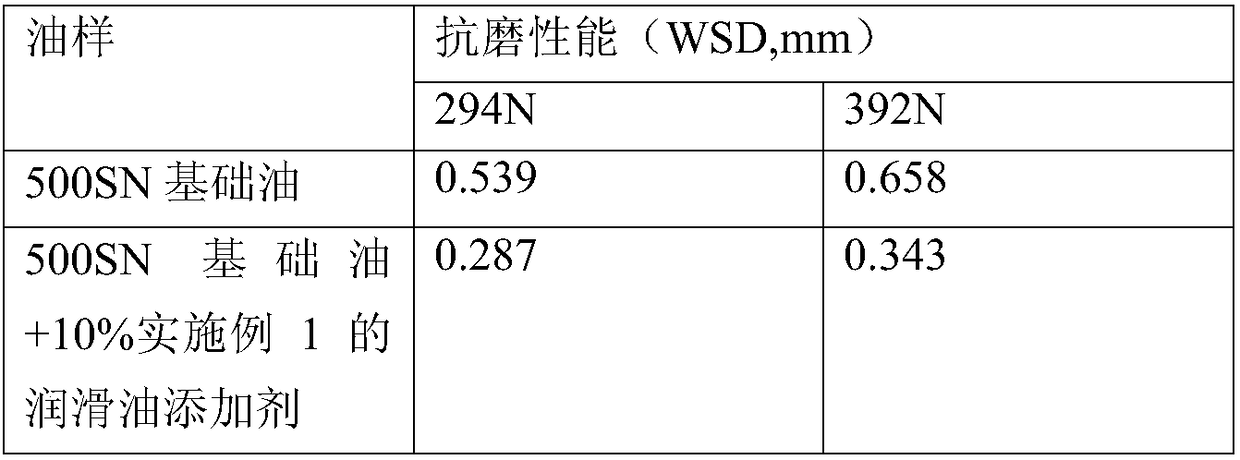

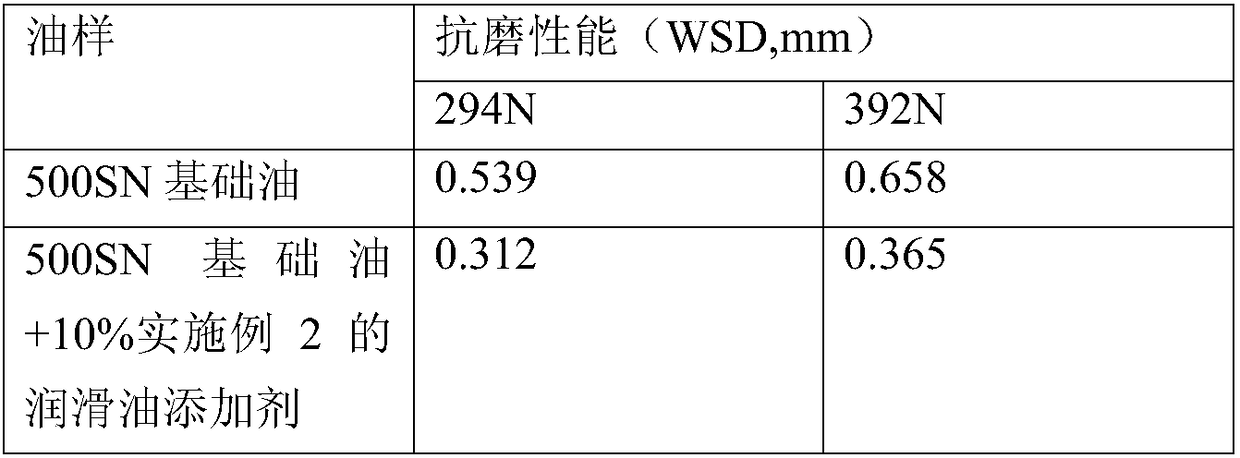

Wear-resistant additive for lubricating oil and preparation method of additive

The invention relates to a wear-resistant additive for lubricating oil. The additive comprises the following components in parts by mass: 1-5 parts of nano calcium carbonate, 2-4 parts of nano boron nitride, 3-6 parts of nano molybdenum disulfide, 2-8 parts of expanded graphite, 3-6 parts of nano cerium borate, 1-5 parts of nano zirconium oxide, 2-8 parts of nano aluminum oxide, 1-6 parts of nanotitanium dioxide, 1-8 parts of nano silicon dioxide, 3-5 parts of N,N'-di-sec-butyl-p-phenylenediamine, 4-6 parts of di-tert-butyl-p-cresol, 2-5 parts of polyvinyl alcohol, 2-8 parts of methyl acrylate, 1-5 parts of pentaerythritol, and 2-8 parts of nano zinc oxide. The ceramic-like layer formed by the additive for the lubricating oil provided by the invention has ultra-high hardness and super wear resistance, and the overhaul period of an engine is prolonged; and the additive has the advantages of having good lubricating performance, saving oil, reducing jitter, reducing engine noise, promoting power, alleviating or thoroughly treating the phenomenon of burning engine oil, and reducing harmful gases in tail gases.

Owner:颜洪

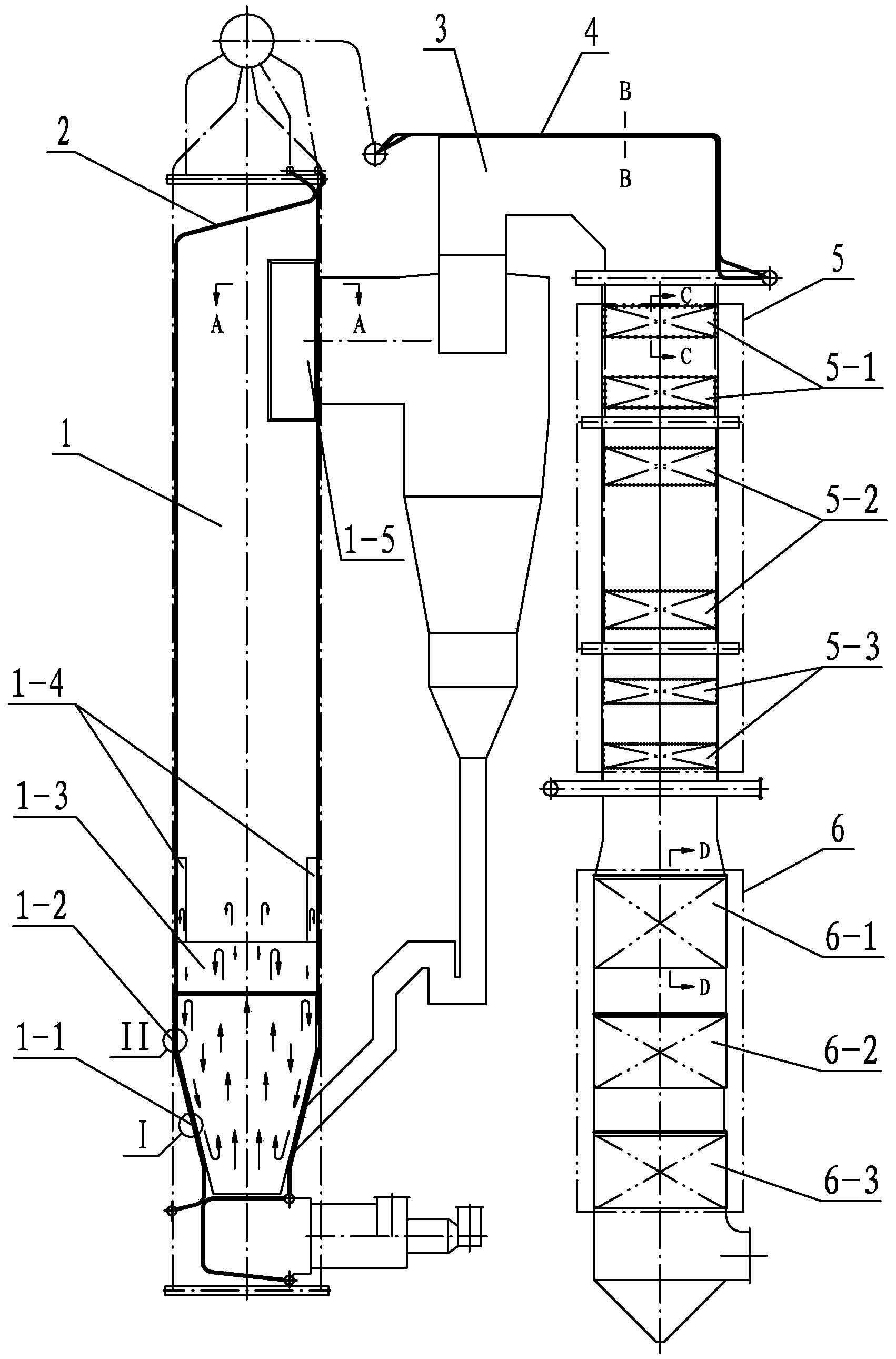

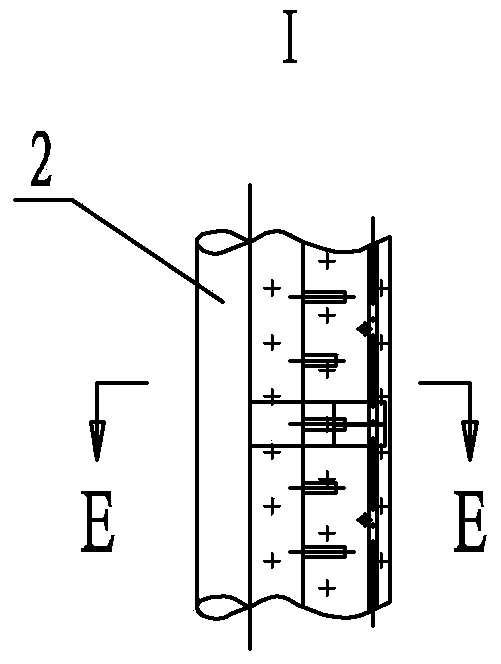

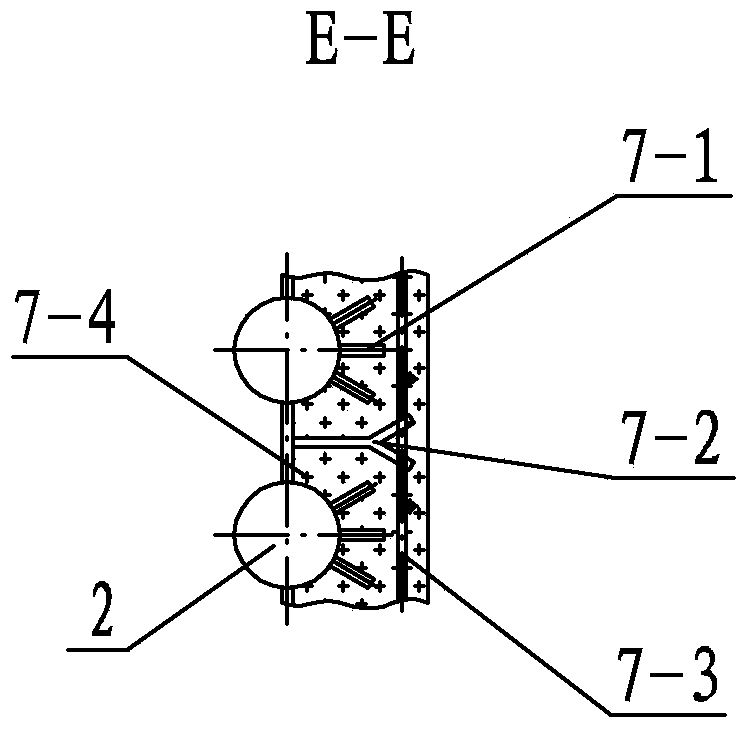

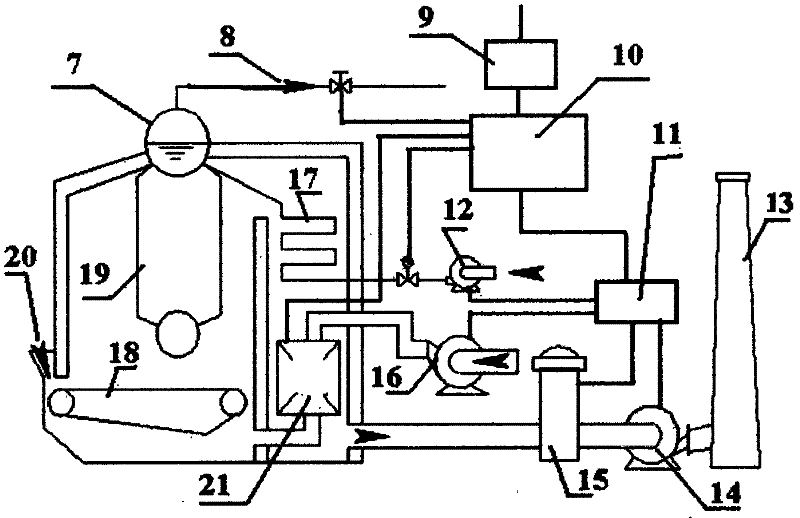

Circulating fluidized bed hot-water boiler free of abrasion and corrosion

ActiveCN103712205AReduce harmAvoid high temperature oxidationFluidized bed combustionWater heatersAir preheaterEngineering

The invention relates to a circulating fluidized bed hot-water boiler free of abrasion and corrosion, and relates to a circulating fluidized bed hot-water boiler. The circulating fluidized bed hot-water boiler solves the problem that pipe burst is generated because the heated surface of a boiler is reduced in thickness by suffering from the abrasion and the corrosion since fuel coal generates a high-temperature flue gas when being combusted in a furnace body, the flue gas contains sulfides, high-temperature high-pressure fuel particles and dust and the flue gas generate great impact accompanied by invasion, namely high-temperature oxidation, fly ash erosion and low-temperature dew-point corrosion, on the heated surface of a boiler in a boiler body in the using process of the traditional high-capacity circulating fluidized bed hot-water boiler. The circulating fluidized bed hot-water boiler free of abrasion and corrosion comprises a hearth, a water-cooled wall, a flue, a coal economizer cladding tube, a coal economizer, an air preheater, a plurality of pins, a plurality of clasp nails, a plurality of steel grids, composite material refractory concrete and an anti-abrasion cover. The circulating fluidized bed hot-water boiler disclosed by the invention is used for industrial and agricultural heating and urban centralized heating.

Owner:哈尔滨红光锅炉总厂有限责任公司

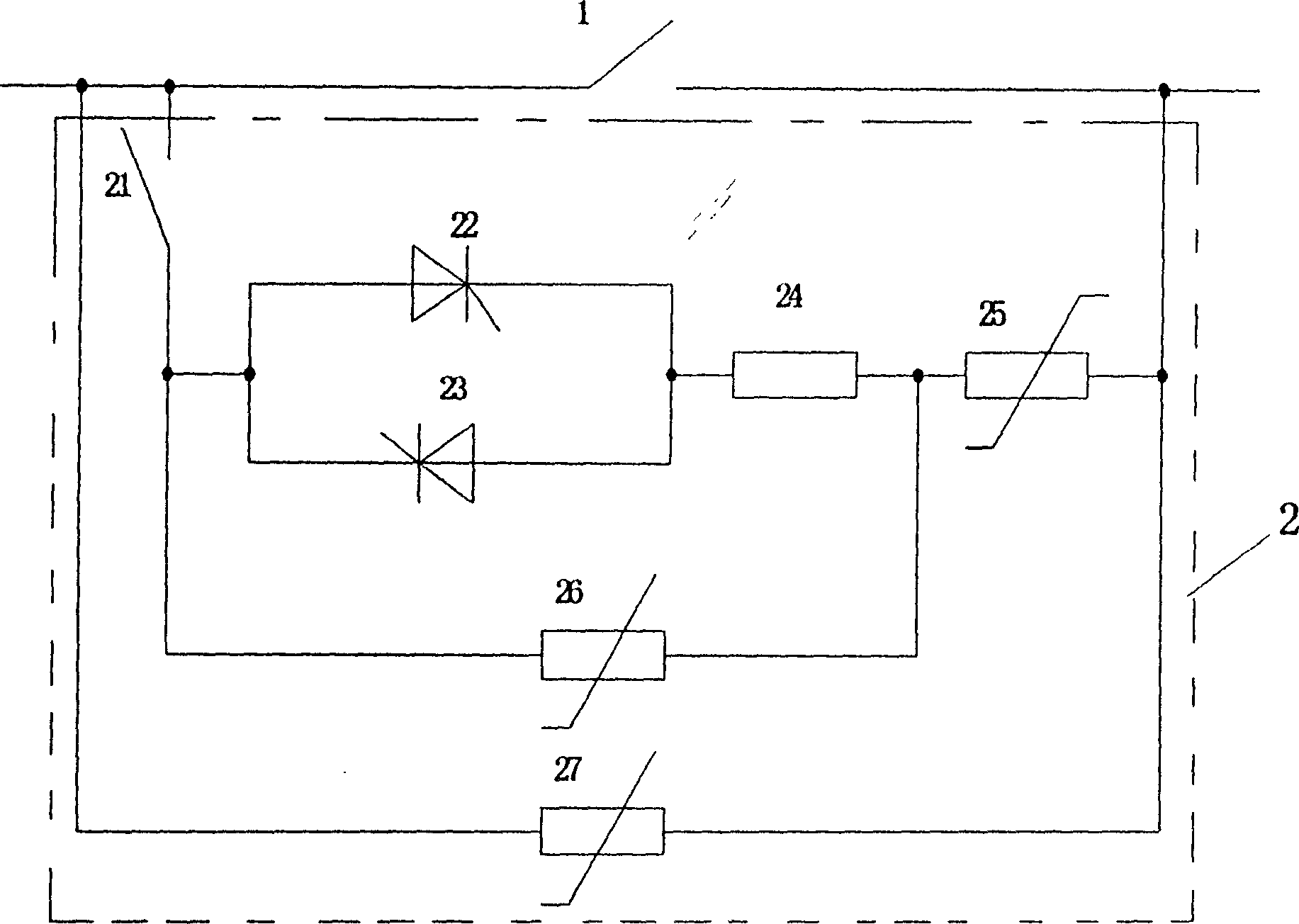

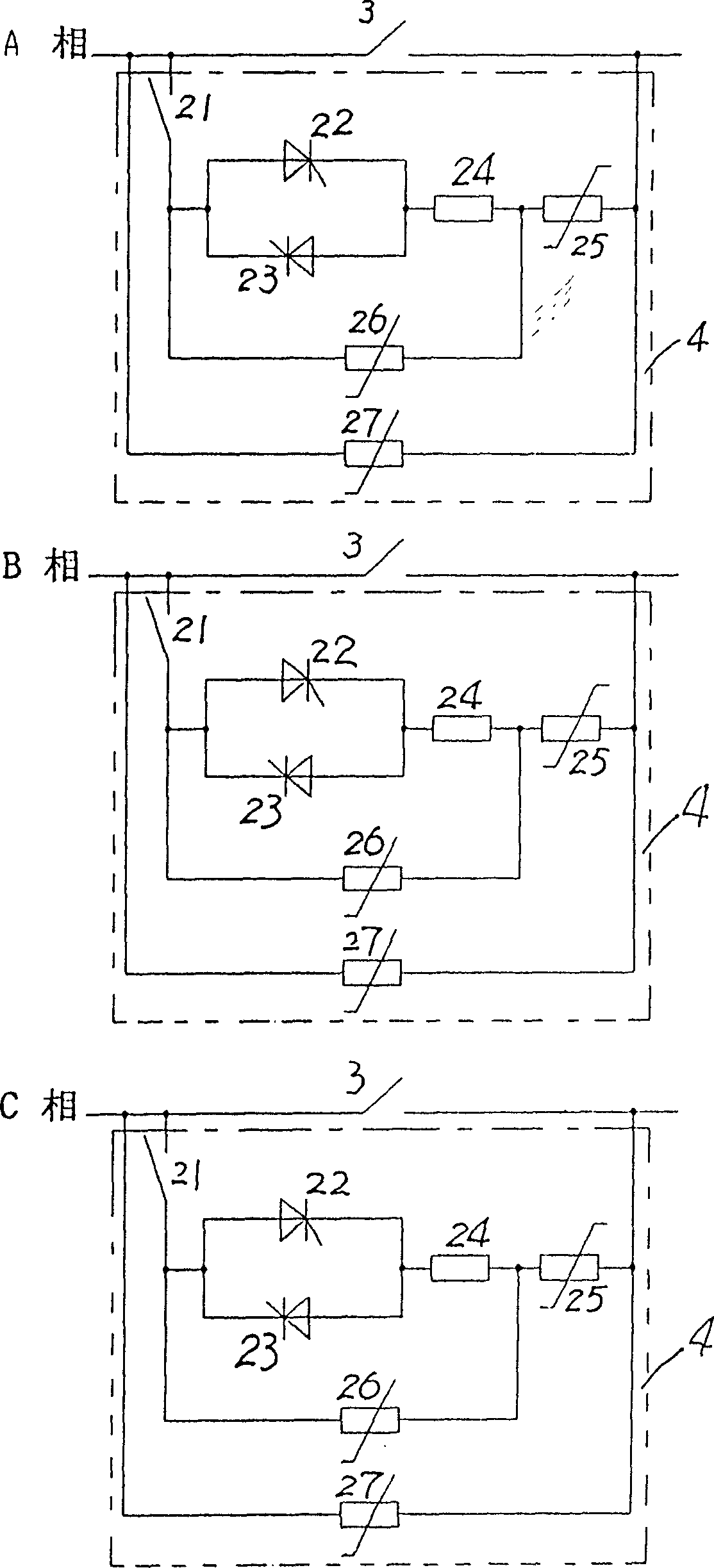

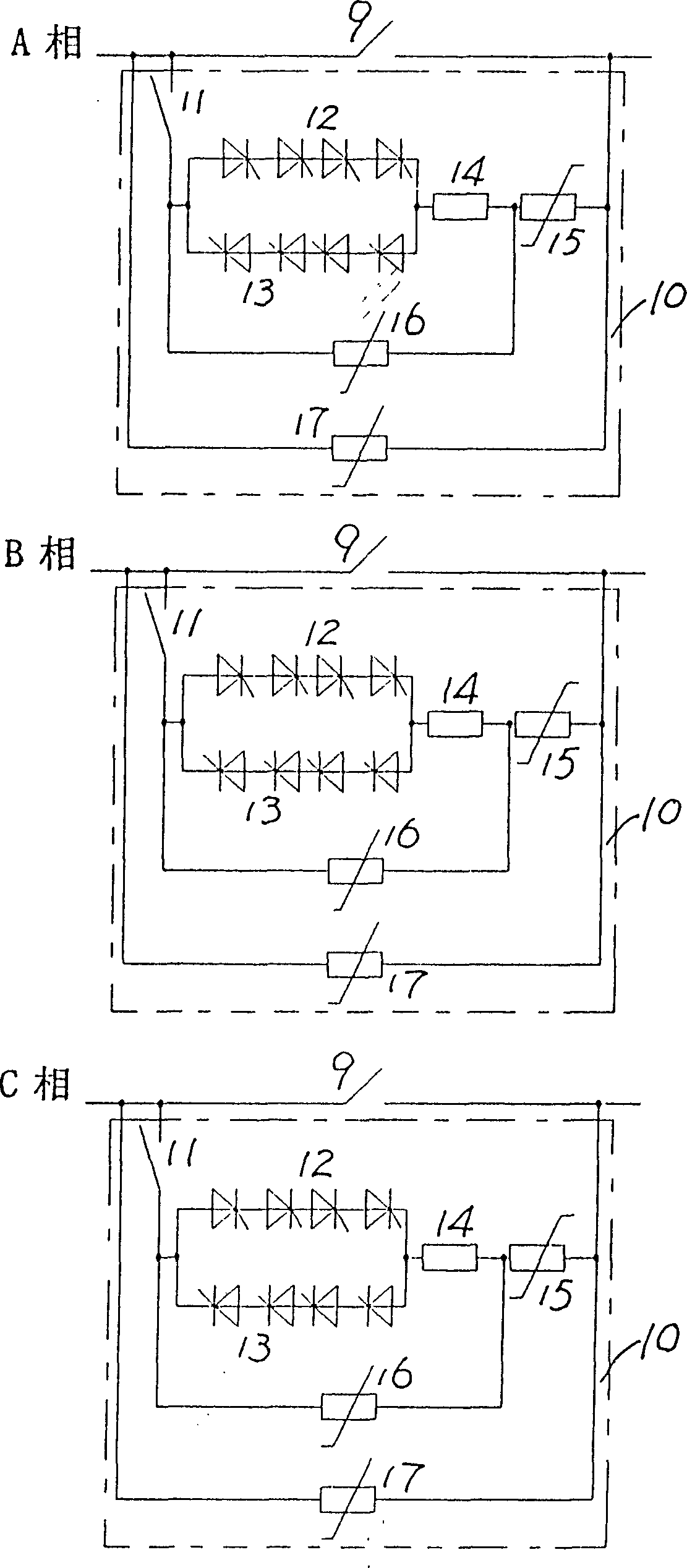

Arc-less switching circuit and method for switch apparatus

InactiveCN1567495AAvoid interceptionAvoid opening and closing accidentsElectric switchesThyratronHeat sensitive

The invention is a no-arc switching circuit of switching device and its method, including a primary contactor and a current commutating circuit, and its characteristic: in the current commutating circuit, a switch is connected in serial with a pair of reverse-parallel thyristors, sampling resistance, a PTC thermal sensitive resistance group and then connected in parallel with the primary contactor, and a voltage clamper is also connected in parallel with the primary contactor; the other voltage clamper is connected in parallel with the serial reverse-parallel thyristor pair and sampling resistance ; because of the protection of the voltage clampers, especially as switching overload or short-circuit current, assuring the thyristors normally working, thus effectively eliminating or inhibiting electric arc, protecting the contactor against melting or burning and assuring the switching reliability of the switching device.

Owner:SHANGHAI KETER POLYMER MATERIAL

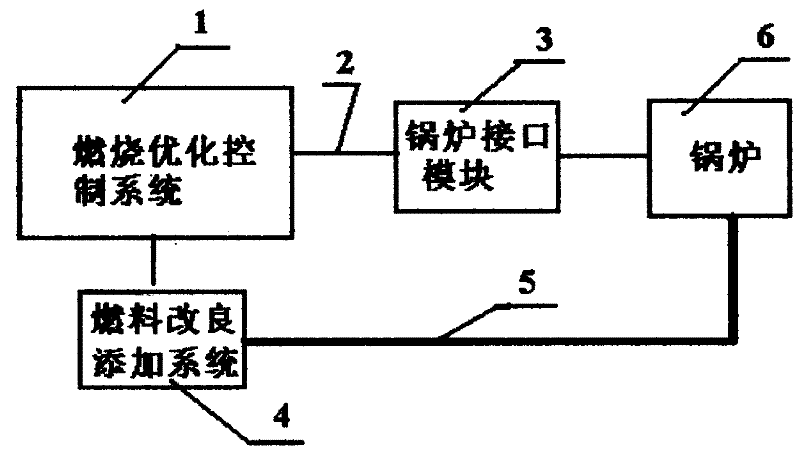

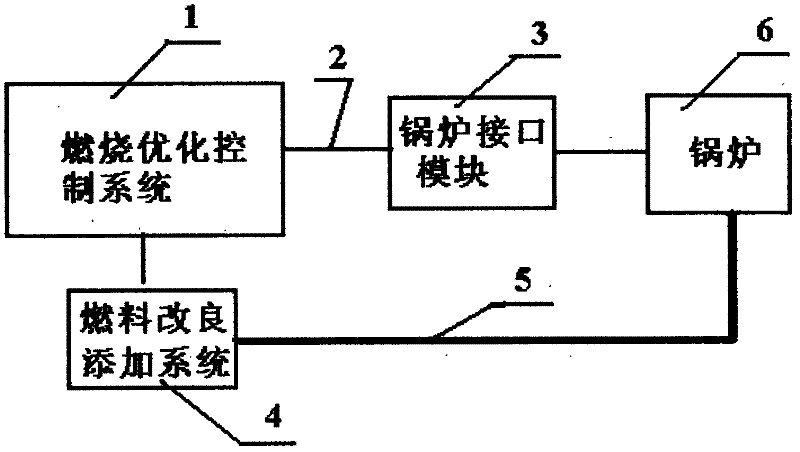

A Generalized Boiler Combustion Overall Optimization and Energy Saving Composite Control System

InactiveCN102297452ASolve the problem of maximum combustion efficiencyReduce carbon contentIndirect carbon-dioxide mitigationCombustion regulationAir preheaterCombustion

The present invention relates to a generalized boiler combustion overall optimization and energy-saving composite control system, including a combustion optimization control system, a boiler and a fuel improvement and addition system, the combustion optimization control system and the boiler are connected through a boiler interface module, and the fuel improvement and addition system It is connected with a combustion optimization control system through a signal line, and the fuel improvement adding system is connected with a boiler through a transmission line, and a control system, a data acquisition system and an air preheating device are arranged in the boiler. The invention solves the problem of how to maximize the combustion efficiency of the boiler under the existing conditions - the fully automatic combustion optimization technology can increase the thermal efficiency of the boiler by 2-5%, and significantly reduce the amount of fly ash and the carbon content of the fly ash, and the thermal efficiency of the limited site Can be higher than 5%.

Owner:宋群

Graphene lubricating oil additive and preparation method thereof

InactiveCN108165346AExtended overhaul cycleGood lubricityCarbon compoundsAdditivesP-PhenylenediaminePolyvinyl alcohol

The invention relates to a graphene lubricating oil additive. The graphene lubricating oil additive comprises, by mass, 5-20 parts of a graphene oxide suspension, 1-5 parts of nanometer calcium carbonate, 2-4 parts of nanometer boron nitride, 3-6 parts of nanometer molybdenum disulfide, 2-8 parts of expanded graphite, 1-5 parts of nano-zirconia, 2-8 parts of nano-aluminua, 1-6 parts of nanometer titanium dioxide, 1-8 parts of nano-silica, 3-5 parts of N,N'-di-sec-butyl-p-phenylenediamine, 4-6 parts of di-tert-butyl-p-cresol, 2-5 parts of polyvinyl alcohol, 2-8 parts of methyl acrylate, 1-5 parts of pentaerythritol and 2-8 parts of nanometer zinc oxide. A ceramic-like layer formed by the lubricant additive has the advantage of ultrahigh hardness, super wear resistance, prolongation of the overhaul life of an engine, good lubricating performance, fuel saving, vibration reduction, engine noise reduction, power increase, reduction or eradication of the burning oil phenomenon and reductionof harmful gases in tail gas.

Owner:刘燕飞

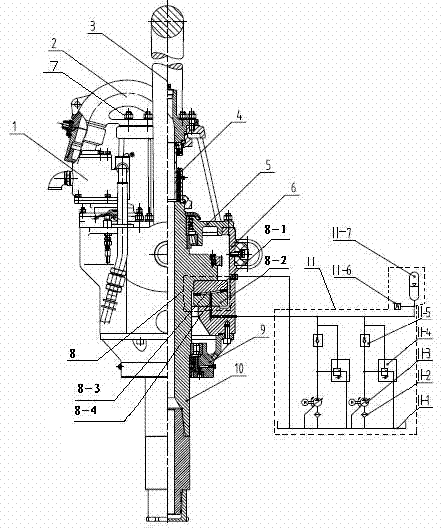

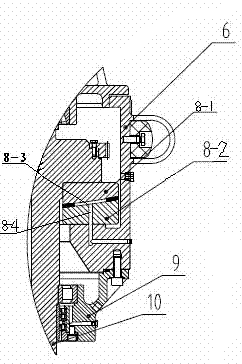

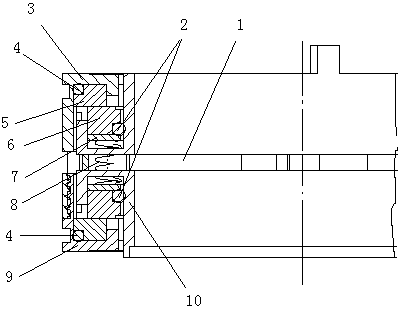

Water tap device for oil rig

ActiveCN102330542AImprove carrying capacityExtended service lifeFlushingSlider bearingStructural engineering

The invention relates to a water tap device for an oil rig. The water tap device comprises a motor device, a gooseneck tube device, a packing device, a center tube and a casing, wherein the lower end of the gooseneck tube device is connected with the upper end of the packing device; the lower end of the packing device is connected with the center tube; the upper part of the center tube is connected with the motor device; the middle of the center tube is arranged in the casing; and a sliding bearing connected with the center tube is also arranged in the casing. A main load is born by the sliding bearing comprising a thrust disc and a thrust pad; the bearing capacity of the sliding bearing is strong; the service life of the sliding bearing is prolonged by multiple times compared with that of a thrust tapered roller bearing; the overhaul cycle of the water tap device is prolonged; the safe reliability of the water tap device is enhanced; and the operation performance of the oil rig is improved.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Degradable lubricating oil

InactiveCN103773569AHigh viscosityImprove low temperature fluidityLubricant compositionCopper oxideCleansing Agents

The invention discloses degradable lubricating oil. The degradable lubricating oil comprises base oil, an anti-oxidant, a rusting inhibitor, an anti-foaming agent, a metal deactivator, a demulsification agent, an antiwear agent, a cleaning agent, a viscosity index improver, copper oxide powder and magnesium metal powder. The anti-oxidant is a mixture of diarylamine and zinc dialkyl dithiophosphate. The rusting inhibitor is ethoxyphenol. The anti-foaming agent is an alkyl methacrylate copolymer. The metal deactivator is benzotriazole. The demulsification agent is polyalkoxypolyol. The antiwear agent is dialkyl dithiophosphate. The cleaning agent is sulfurized calcium alkyl phenolate. The viscosity index improver is poly(alkyl methacrylate). The degradable lubricating oil is prepared by a simple method, has high quality, a long use period and improved extreme pressure resistance, can be degraded biologically and completely exceeds environmental protection requirements on the same type of products.

Owner:TIANJIN ZEYA TECH

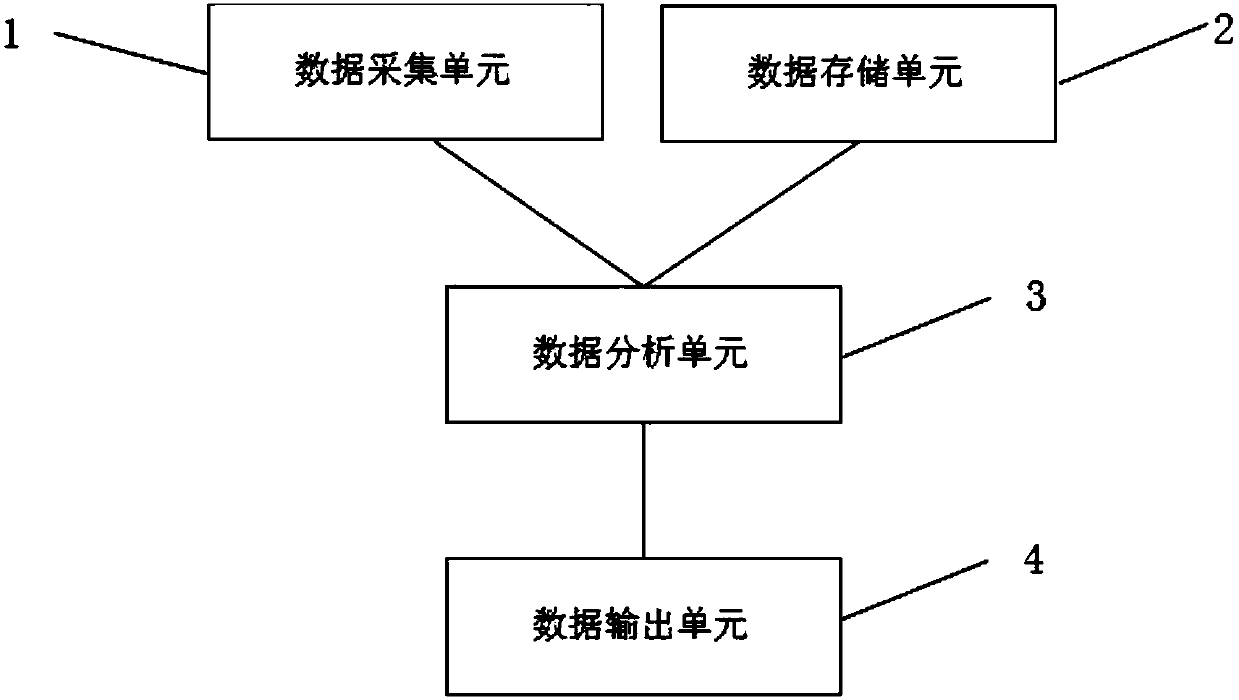

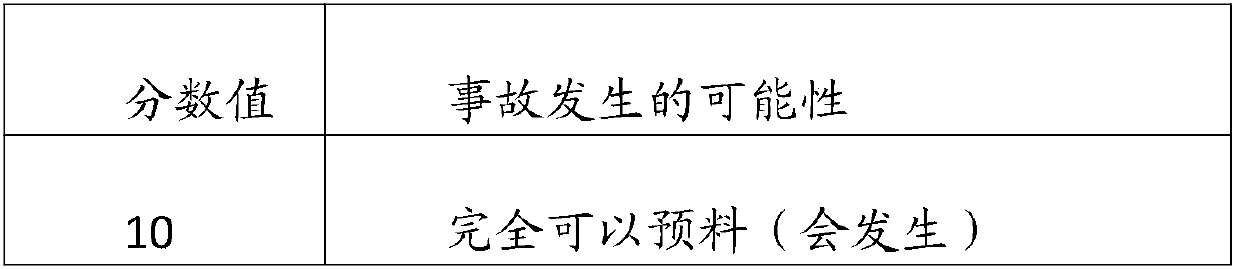

Active safety production risk assessment device and method

The invention discloses an active safety production risk assessment device and method. The active safety production risk assessment device comprises a data acquisition unit, a data storage unit, a data analysis unit, and a data output unit; the data acquisition unit is used to collect personnel real-time location information, real-time image information, equipment health real-time information andpersonnel health real-time information, and send to the data analysis unit; the data storage unit stores safety management data information and assessment rule information, and sends the safety management data information and assessment rule information to the data analysis unit; the data analysis unit analyses and obtains the safety production information and sends to the data output unit; and the data output unit is used to output the safety production information. The active safety production risk assessment device improves the management level of the safety production risk assessment to anew height. By means of the active safety production risk assessment device, the casualty accident is reduced by more than 95%, the cost of equipment operation and maintenance is reduced by 30%, the overhaul cycle of the mainframe is lengthened, the physical and mental health assessment level is improved, and the energy consumption index and environmental emission index of the equipment can be greatly reduced.

Owner:北京必可测科技股份有限公司

PVD chromium based ceramic composite coating piston ring and method for producing the same

InactiveCN101430004BReduce coefficient of frictionImprove the lubrication effectPiston ringsVacuum evaporation coatingCeramic compositePiston ring

The invention discloses a PVD chromium base ceramic composite coating piston ring and a preparation method thereof, and the piston ring is manufactured by plating a chromium base ceramic composite coating on a basal body of the piston ring which is treated by nitriding by adopting high power electric arc discharge method; the chromium base ceramic composite coating is composed of a bonding layer,a main wearing layer and an anti-attrition layer, wherein, the bonding layer is binded with the basal body of the piston ring in a metallurgical way, the main wearing layer is arranged on the bondinglayer, and the anti-attrition layer is positioned on the surface of the main wearing layer; the bonding layer is Cr, the main wearing layer is a Cr / CrN multilayer coating formed by the Cr and the CrNwhich are alternately arranged, and the anti-attrition layer is a Cr / Cr2O3 multilayer coating formed by the Cr and the Cr2O3 that are alternately arranged. The coating structure has reasonable design,and the manufactured coating has good cementing property, high hardness and good lubricating property. Furthermore, the method used for manufacturing the piston ring has no pollution in the preparation process, and overcomes the serious problem of environmental pollution of the conventional electrodeposited chromium; as the manufactured coating has better abrasion resistant and corrosion resistant performance compared with the electrodeposited chromium, the service life of the piston ring is greatly prolonged.

Owner:WUHAN UNIV

Biodegradable wear-resistant lubricating oil

InactiveCN103773554AEmission reductionExtend oil change intervalsAdditivesWear resistantImidazoline derivatives

The invention discloses biodegradable wear-resistant lubricating oil. The biodegradable wear-resistant lubricating oil comprises base oil, an anti-oxidant, a rusting inhibitor, an anti-foaming agent, a metal deactivator, a demulsification agent, an antiwear agent, a cleaning agent, a viscosity index improver, copper oxide powder and magnesium metal powder. The anti-oxidant is a mixture of sterically hindered phenol and acrylate. The rusting inhibitor is an imidazoline derivative. The anti-foaming agent is a dimethyl siloxane polymer. The metal deactivator is benzotriazole. The demulsification agent is polyalkoxypolyamine. The antiwear agent is a metal dialkyldithiocarbamate. The cleaning agent is a phenolate. The viscosity index improver is polyalkylmethacrylate. The biodegradable wear-resistant lubricating oil is prepared by a simple method, has high quality, a long use period, improved extreme pressure resistance, and completely improved oxidation resistance, corrosion resistance and foaming resistance, can be degraded biologically and completely exceeds environmental protection requirements on the same type of products.

Owner:TIANJIN ZEYA TECH

Automatically-flowing and automatically-supplying circulating water cooling automobile brake drum water seal

InactiveCN102705409AExtended service lifeExtended overhaul cycleBraking elementsStructural engineeringMechanical engineering

The invention relates to an automatically-flowing and automatically-supplying circulating water cooling automobile brake drum water seal, which is characterized by consisting of an inner frame, an upper outer frame, a lower outer frame, seal rings, an upper wearing ring and a lower wearing ring; a wearing ring frame, one seal ring, the upper wearing ring, the lower wearing ring and the other seal ring are arranged at two ends of the inner frame in sequence; the upper outer frame is arranged outside the seal ring at one end of the inner frame; the lower outer frame is arranged outside the seal ring at the other end of the inner frame; the upper outer frame and the lower outer frame are connected to form a whole; an inner frame water channel is arranged in the middle of the inner frame; a plurality of water inlets and outlets are arranged in the inner diameter of the inner frame; a plurality of water inlets and outlets are arranged on the outer frame; a plurality of holes are arranged on an end face of the inner frame; and springs are arranged in the holes. According to the invention, the automatically-flowing and automatically-supplying circulating water cooling automobile brake drum water seal is used for an automatically-flowing and automatically-supplying separator and can circularly use the braking cooling water, so that the brake performance can be greatly improved, and the service life of the brake drum is prolonged.

Owner:李智

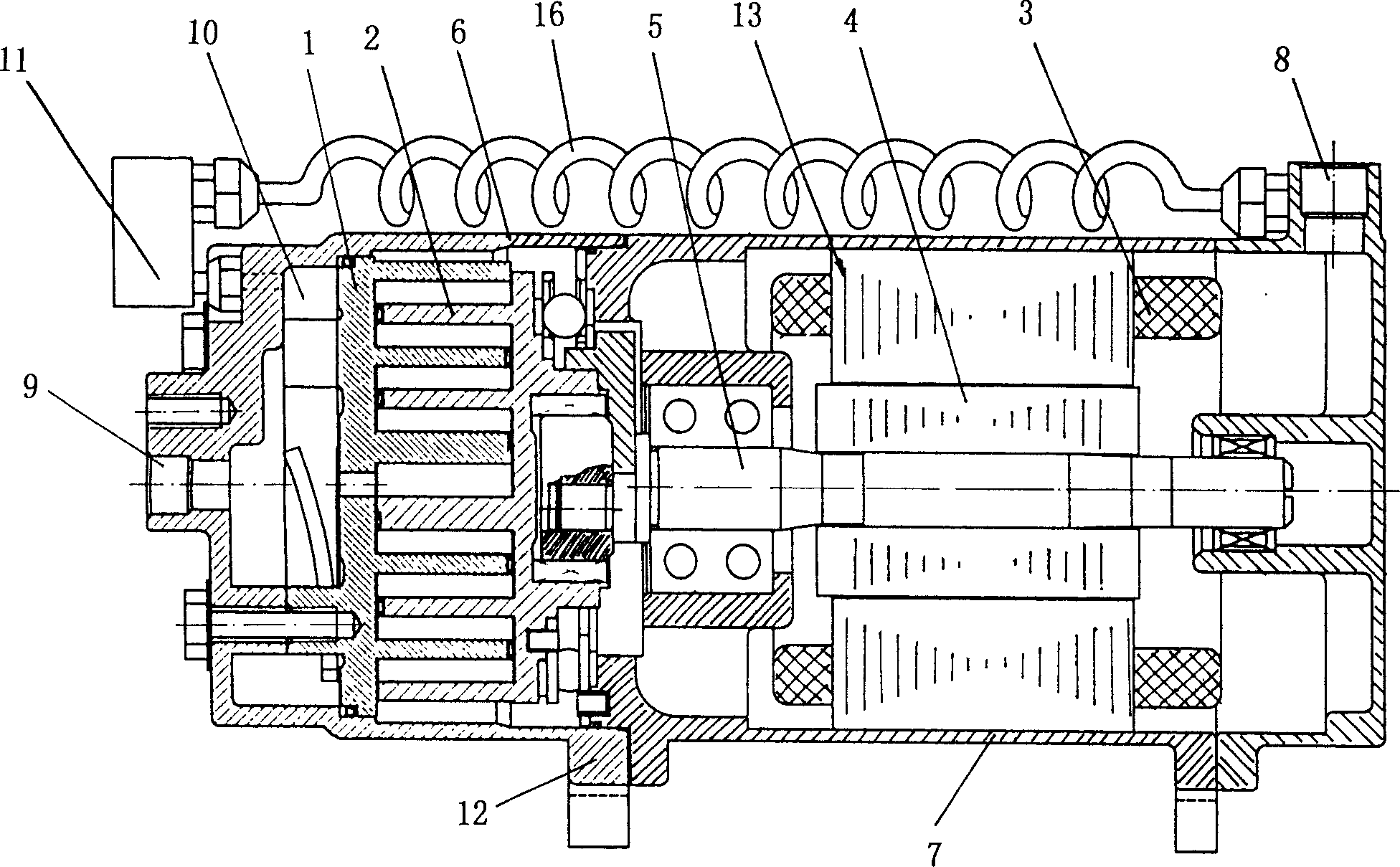

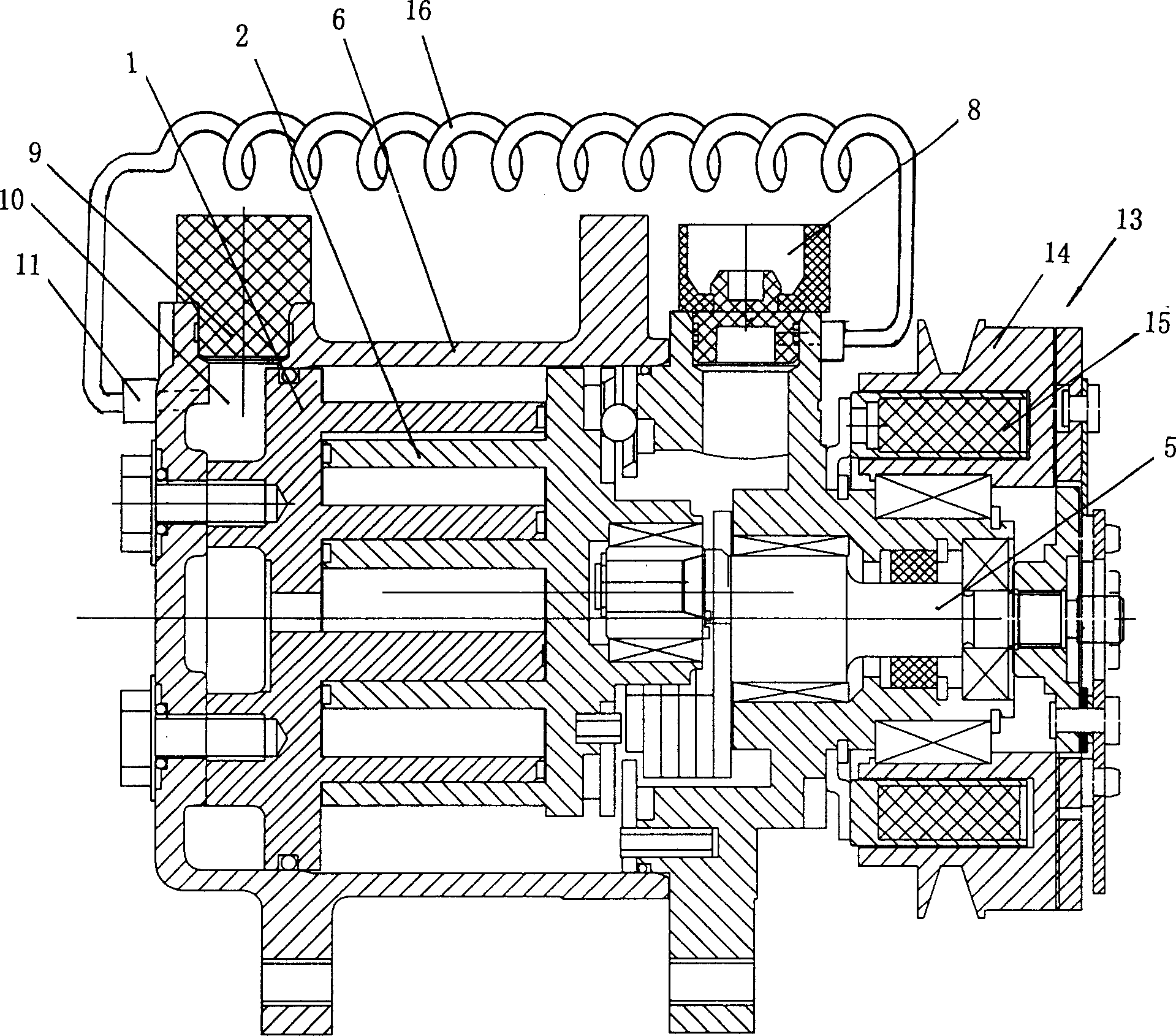

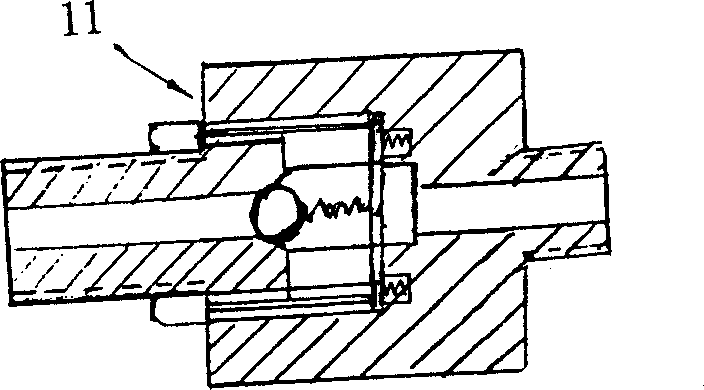

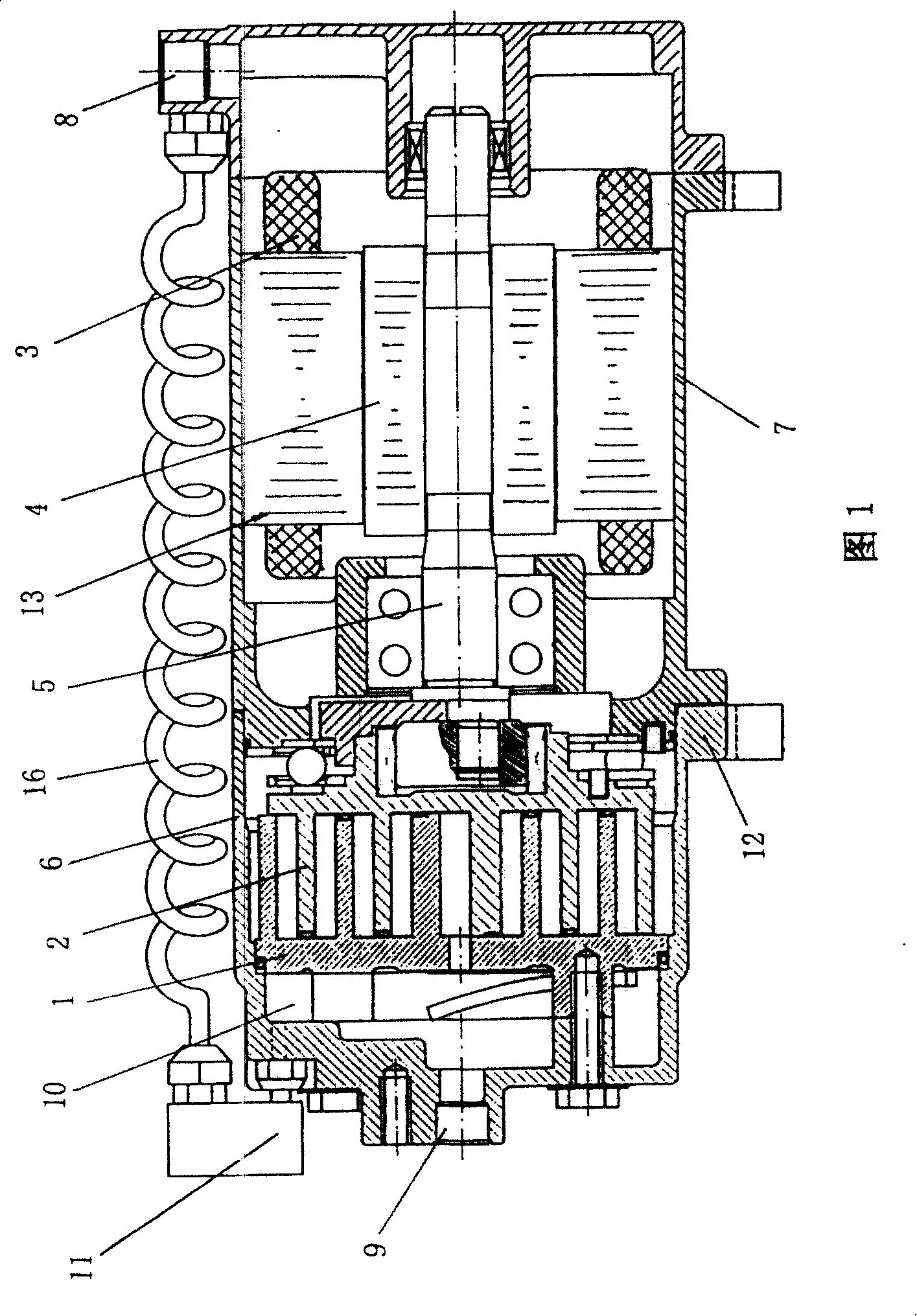

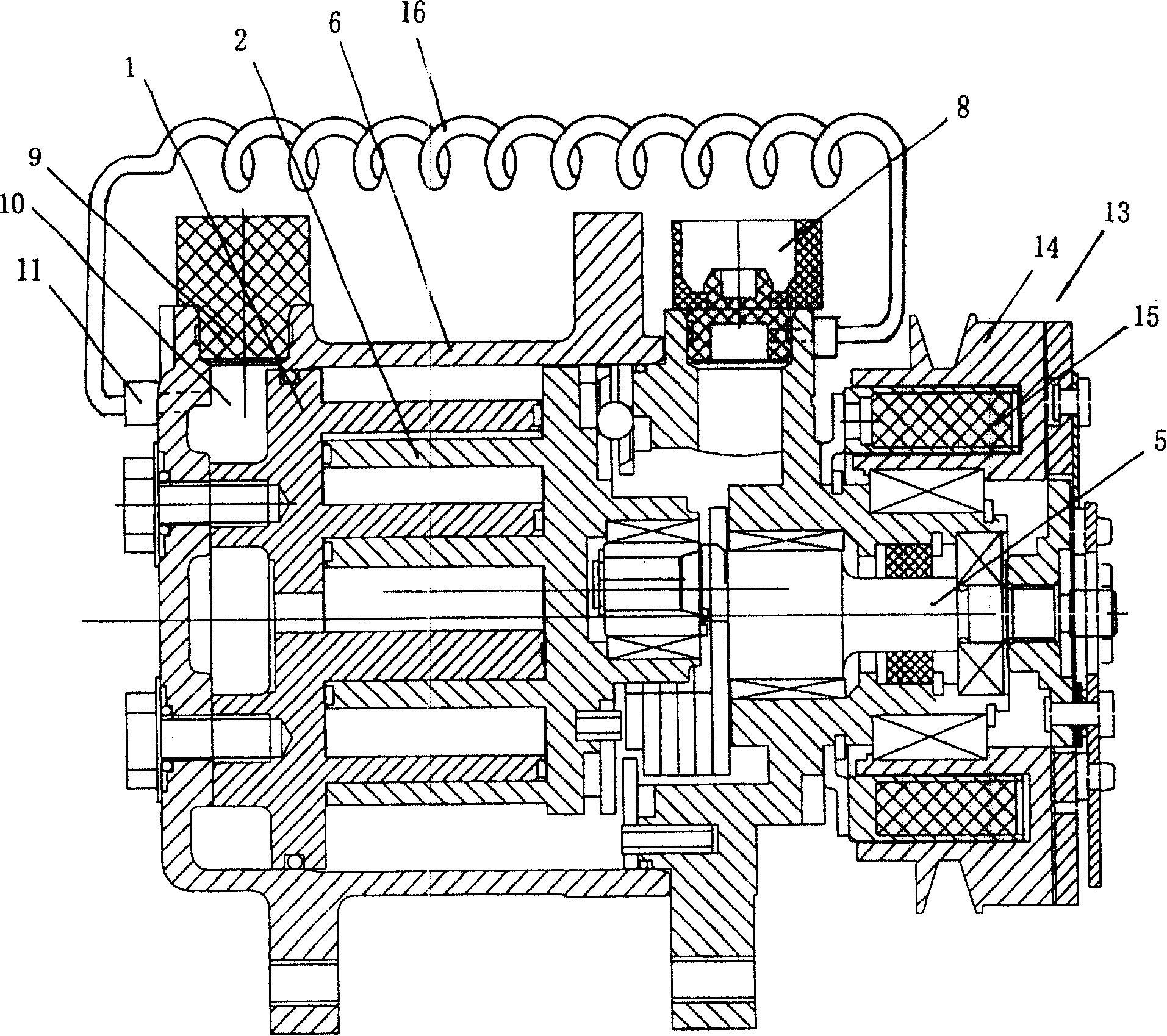

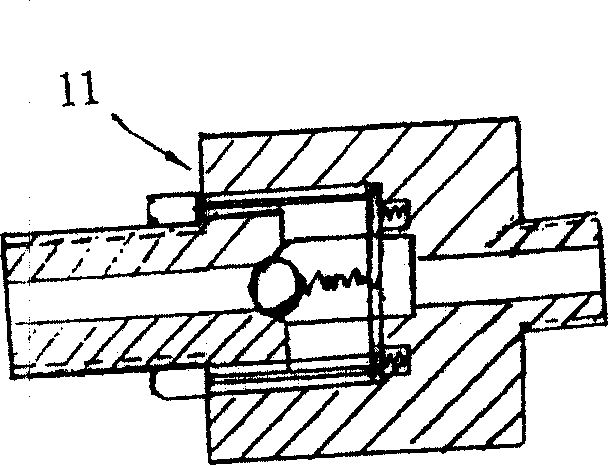

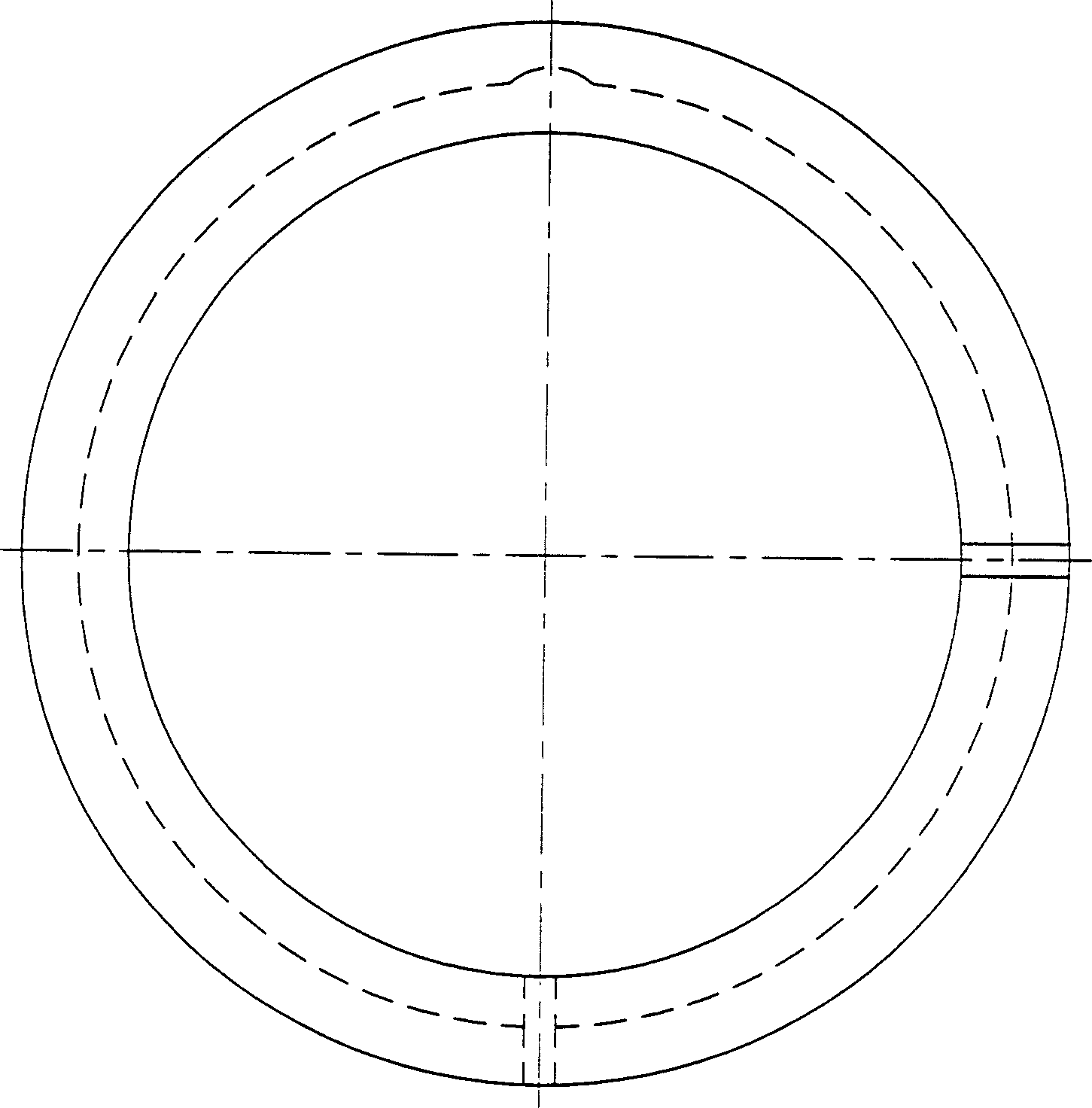

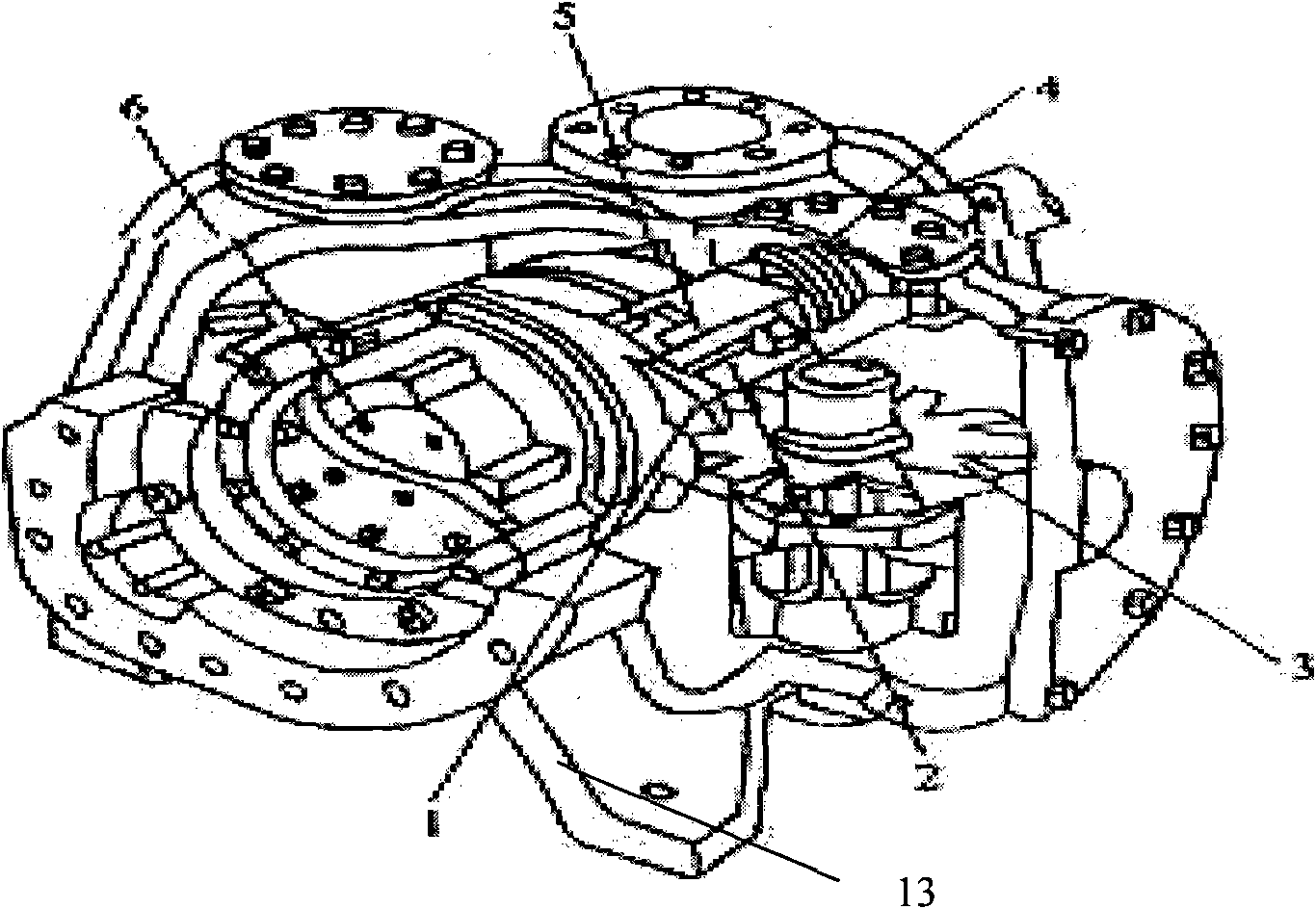

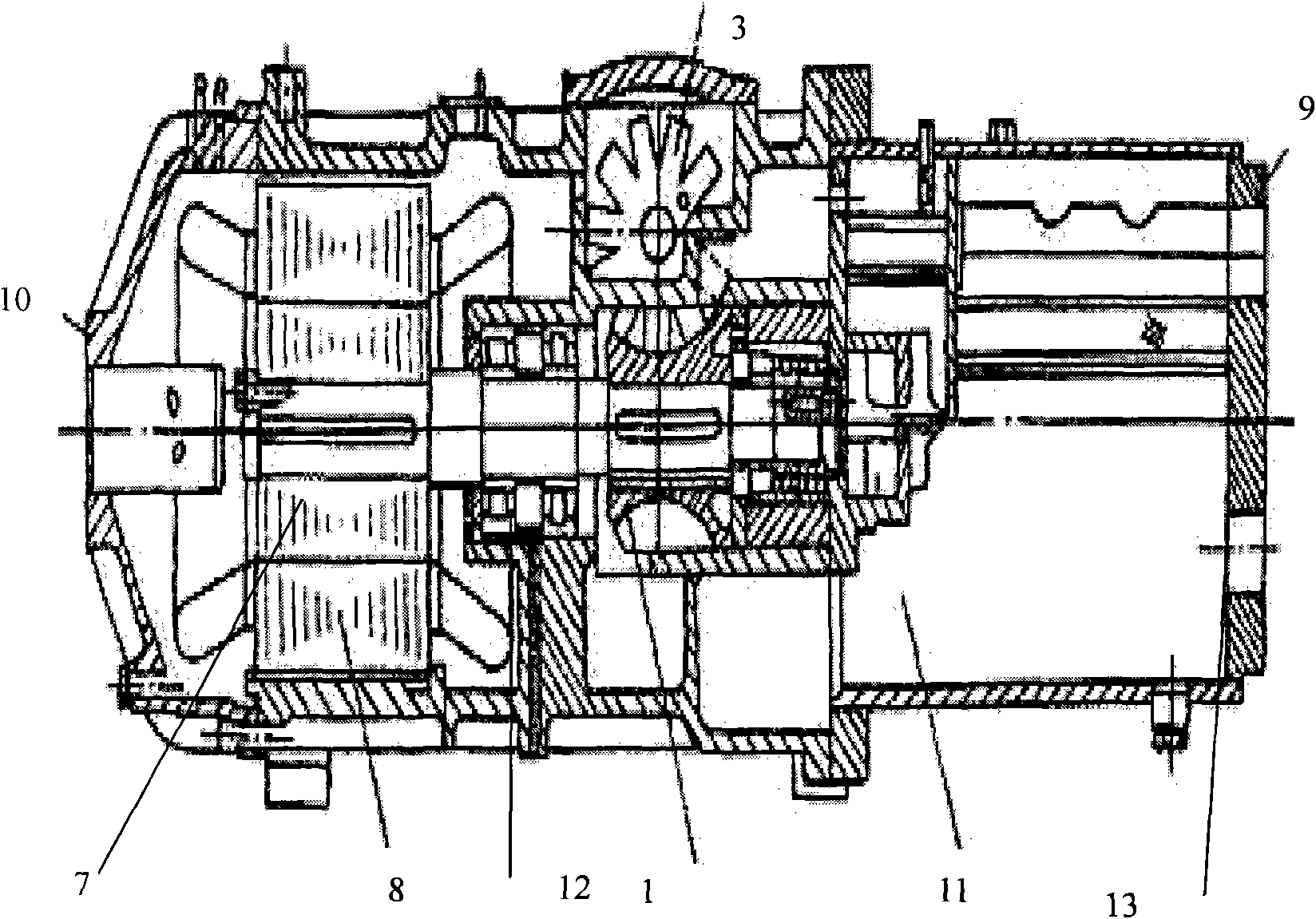

Vehicular constant-pressure fully-closed vortex compressor

ActiveCN1851272ASolve environmental problemsSolve overpressure discharge problemsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringHigh pressure chamber

Owner:NANJING AOTECAR NEW ENERGY TECH

Vehicular constant-pressure fully-closed vortex compressor

ActiveCN100386522CSolve environmental problemsSolve overpressure discharge problemsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringHigh pressure chamber

The invention discloses car-using constant pressure type closed cycle vortex compressor. It includes static plate, movable plate, and crank shaft. The static plate is set in shell body. The movable plate is cut into the static and connected with the crank shaft. The crank shaft is connected to driving gear. One end of the shell body is set exhaust port connected with high pressure chamber. And its end is set suction port. Its features are as follows: the high pressure chamber is connected to zoom-type unloading valve and interlinked to its air inlet end. Its air out end is interlinked to the suction port. The advantages are constant pressure and environment protecting. And it can be used in fuel or electric motor car.

Owner:NANJING AOTECAR NEW ENERGY TECH

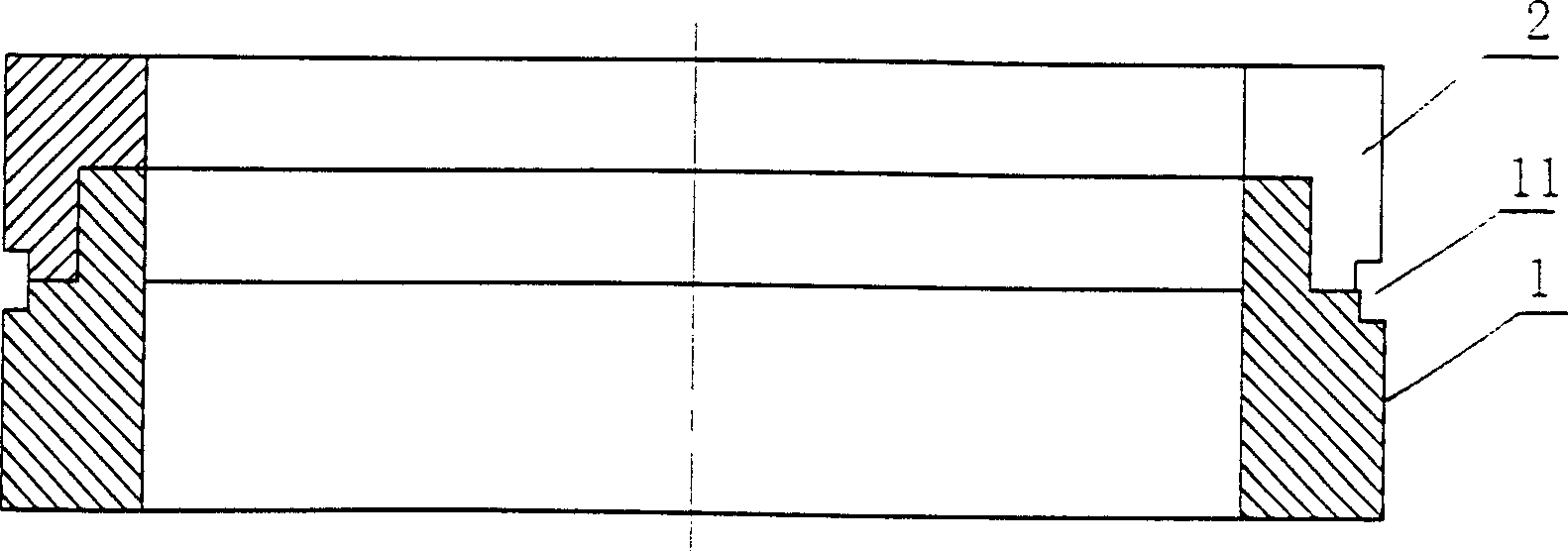

Combined sealing piston ring

InactiveCN1488849AIncrease horsepowerHigh strengthPiston ringsMachines/enginesCombustionExternal combustion engine

The present invention relates to a combined packing piston ring used in the piston machines of internal combustion engine and air compressor, etc. Said combined packing piston ring includes subring A and subring B, said two subrings have open-end respectively. Said invention also provides the assembly method of said two subrings and concrete steps. The adoption of said invention can raise cylinder compression ratio, can make full combustion, raise power of internal combustion engine, save fuel oil and can prolong the service life of piston ring.

Owner:徐楠

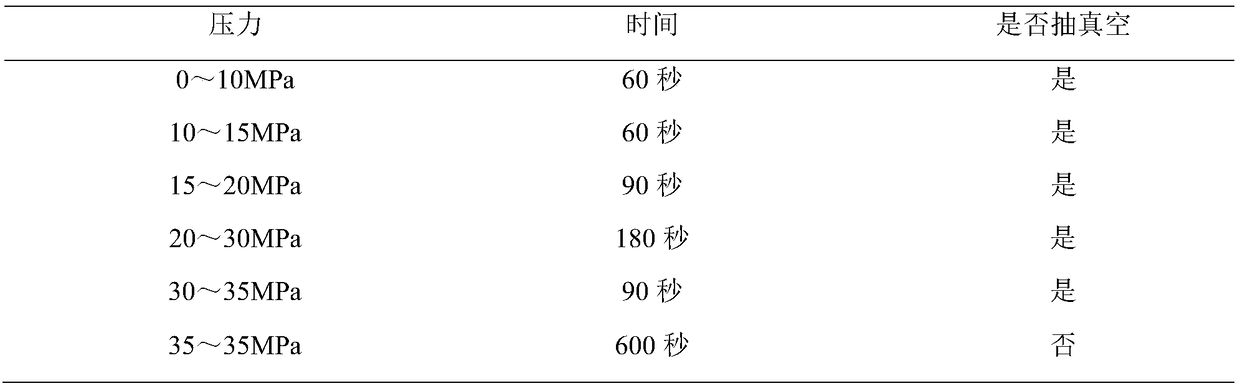

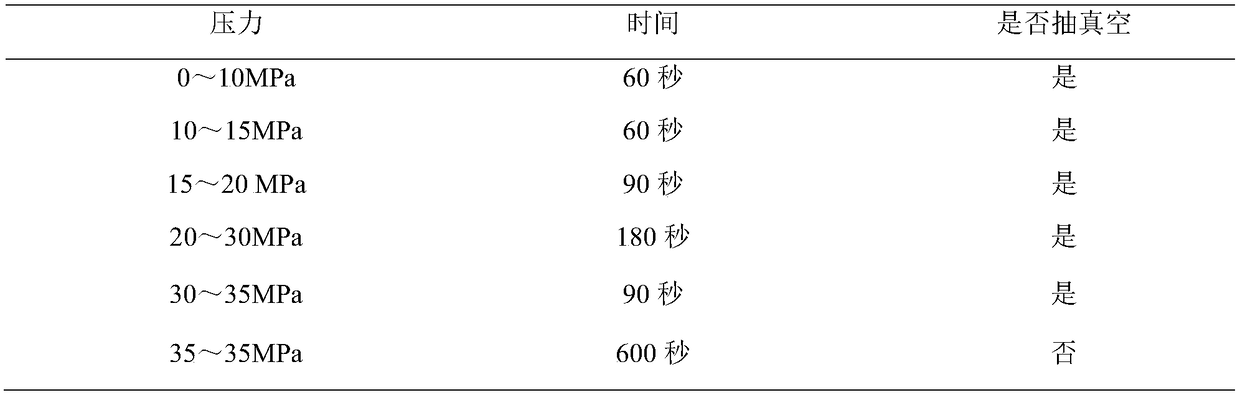

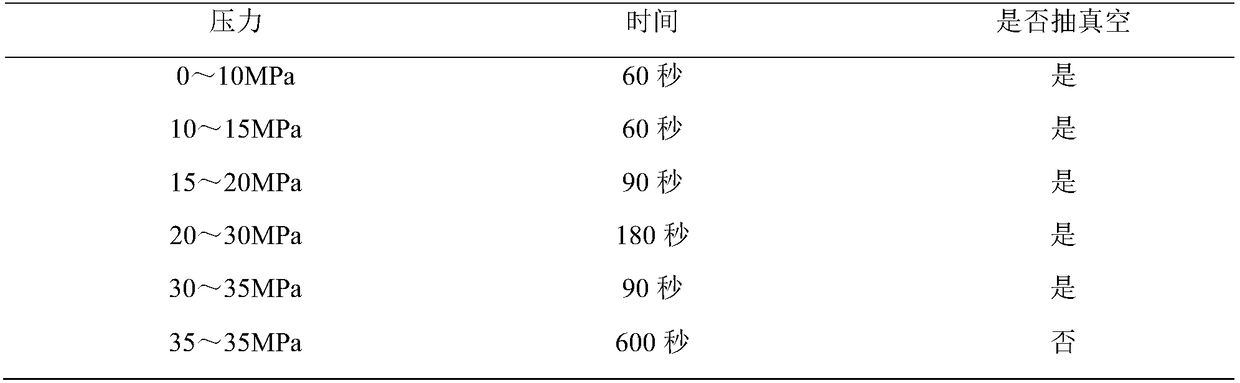

Ceramic matrix tread sweeper grinder and production method thereof

InactiveCN109336473AImprove high temperature resistanceHigh strengthVehicle cleaningSlagFerrosilicon

The invention discloses a ceramic matrix tread cleaner grinder and a production method thereof, and belongs to the field of urban rail transit equipment. The ceramic matrix tread cleaner grinder is prepared from the following ceramic raw materials: a silicon carbide whisker, ferrosilicon nitride, quartz powder, alumina powder, titanium oxide and zirconia powder. The production method comprises thefollowing steps: pouring the raw materials into a mixer, adding modified phenolic resin for premixing, then adding tetrahydrofuran and water for continuous mixing and producing particles with the diameter of about 2 to 3 mm, drying, carrying out vacuum hot-pressing molding and curing. According to the production method disclosed by the invention, hot-pressing molding is carried out on the grinderby improving a formula and a process and using modified phenolic resin as a binder; with reasonable hot pressing pressure and heat treatment time, the toughness and thermal stability of the grinder can be improved; in addition, slag is not easy to fall off and the service life can be effectively prolonged; besides, certain social benefits for environmental protection also can be played.

Owner:马鞍山市雷狮轨道交通装备有限公司

Bearing pedestal oil cavity cleaning system and method, mineral engineering machine and engineering machine

InactiveCN105822679AAchieve cleaningImprove cleaning efficiencyCleaning using liquidsBearing unit rigid supportLubricantAutomation

The invention discloses a bearing pedestal oil cavity cleaning system which comprises a bearing pedestal, an oil supplying system, an oil return pipeline, an oil storing device, an electronic monitoring device and an oil pipe. The bearing pedestal comprises an oil inlet hole way, a threaded hole connected with the oil inlet hole way and provided with a lubricating connector, an oil outlet hole way, and an oil outlet threaded hole connected with the oil outlet hole way. A pipe connector is installed at the oil outlet threaded hole. The oil supply system provides a lubricating agent in the oil storing device for the bearing pedestal. The oil return pipeline recovers lubricating oil output by the pipe connector at the oil outlet threaded hole and conveys the lubricating oil to the oil storing device. The electronic monitoring device is used for monitoring the working state of the oil supply pipeline. The invention further provides a cleaning and lubricating method of a bearing pedestal oil cavity. Automation operation of cleaning and lubricating of the bearing pedestal oil cavity is achieved. In addition, the invention provides a mineral engineering machine and an engineering machine adopting the bearing pedestal oil cavity cleaning and lubricating system or method.

Owner:长沙贤正益祥机械科技有限公司

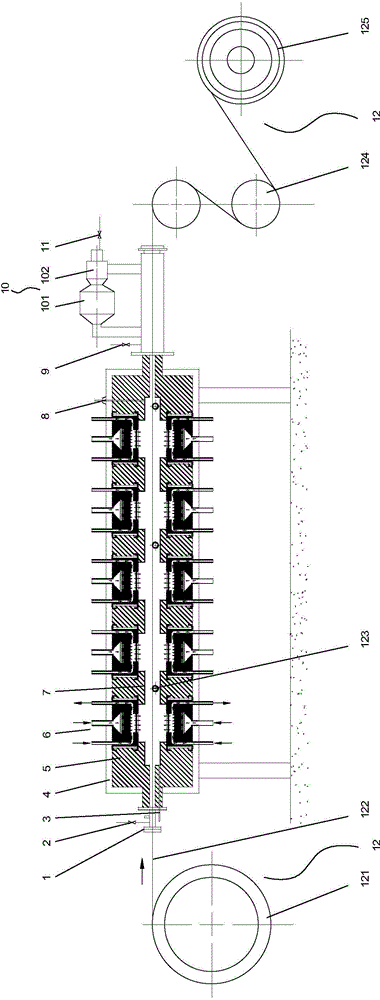

Single-screw fluid power generator and generating method

InactiveCN102102541AAchieving hybrid power generationBroaden applicationEngine of intermeshing engagement typeSafety/regulatory devicesOrganic Rankine cycleMechanical energy

The invention aims to provide a fluid motor of a single-screw fluid power generator. The fluid motor is characterized by converting the energy of motion of the fluid to mechanical energy by a single-screw expansion structure and converting the mechanical energy to electric energy through motions of stators and rotors, wherein the fluid is one or a mixture of liquid, gas, supercritical fluid and plasma. The invention also aims to provide a method for converting the energy of motion of the fluid to electric energy. The method is characterized by converting the energy of motion of the fluid to mechanical energy by a single-screw expansion structure and converting the mechanical energy to electric energy through motions of stators and rotors. The generator and method are especially suitable for small-sized power generating equipment, can generate power of 1w-3000kw, preferably 50-3000kw, is suitable for generating power by utilizing the low-grade heat energy of solar energy, waste heat, excess pressure and terrestrial heat and is suitable for generating power by sampling low-temperature organic working media, especially by organic Rankine cycle.

Owner:BEIJING WISWORD HI TECH

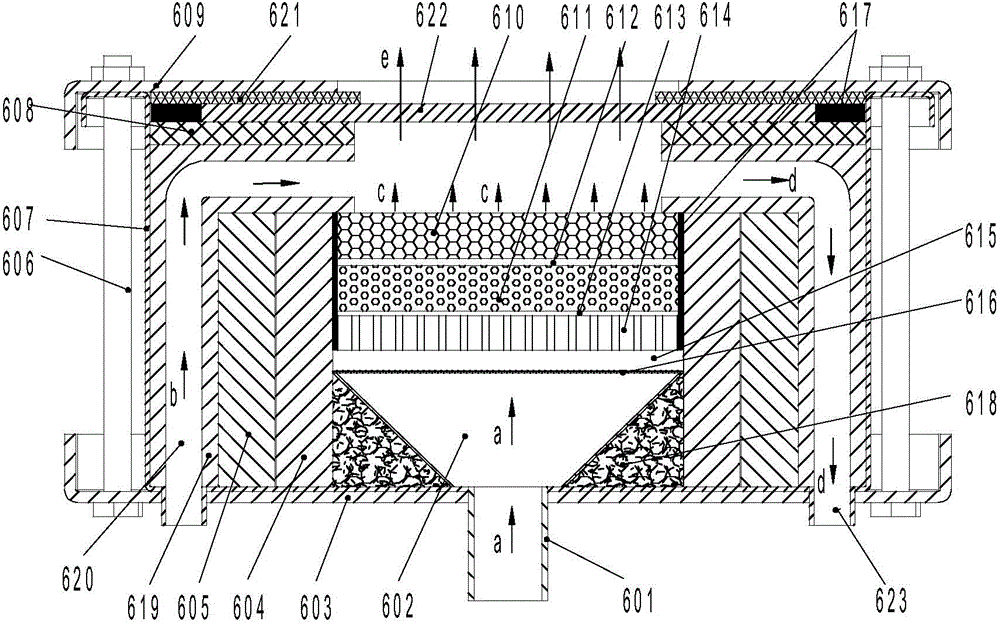

Gas catalytic flameless near-infrared heating annealing furnace

ActiveCN104962716AImprove thermal efficiencyEvenly distributedFurnace typesHeat treatment furnacesFurnace temperatureCombustor

The invention relates to a gas catalytic flameless near-infrared heating annealing furnace, and relates to an annealing furnace. The gas catalytic flameless near-infrared heating annealing furnace comprises a furnace shell, a furnace liner, a heating system, a cooling system and a transport system, wherein a fire-resisting material layer is arranged between the furnace shell and the furnace liner, the heating system is embedded in the fire-resisting material layer and is a gas catalytic flameless near-infrared heating porous medium burner, the heating system comprises a burner body, a heat preservation layer and a refractory brick layer, a pre-mixed gas dispersing chamber, a perforated plate, a pre-mixed gas homogenizing chamber, a flame-preventing screen plate and a foam ceramic plate are arranged in the refractory brick layer, the bottom of the pre-mixed gas dispersing chamber is communicated with a pre-mixed gas supply pipe, and heat-preserving cotton is arranged between the periphery of the pre-mixed dispersing chamber and the refractory brick layer; the upper end surface and the lower end surface of the burner body are connected together by virtue of an upper pressing plate, a lower pressing plate and a connecting piece. The gas catalytic flameless near-infrared heating annealing furnace is high in heat efficiency, complete in burning, low in pollutant emission and applicable to the annealing process needing the protection of atmosphere in the furnace, has characteristics of high temperature, low energy consumption, high yield, low repair cost and the like and is likely to popularize and use.

Owner:北京秦冶众智科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com