Vehicular constant-pressure fully-closed vortex compressor

一种涡旋压缩机、全封闭的技术,应用在旋转活塞式机械、机械设备、用于弹性流体旋转活塞式/摆动活塞式的泵组合等方向,能够解决压力不稳等问题,达到减少损耗、节约成本、延长大修周期的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

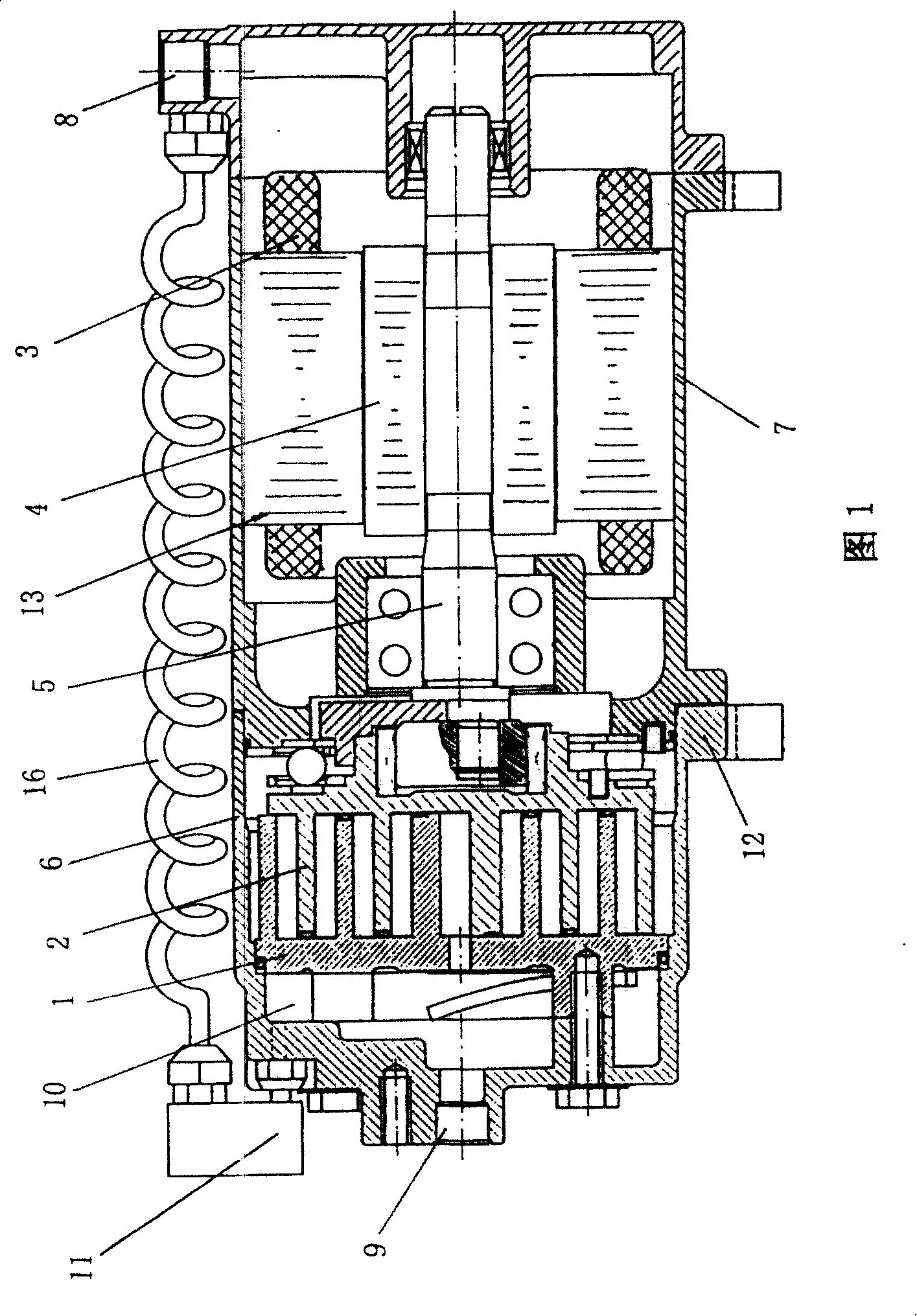

[0019] As shown in Figures 1 and 3.

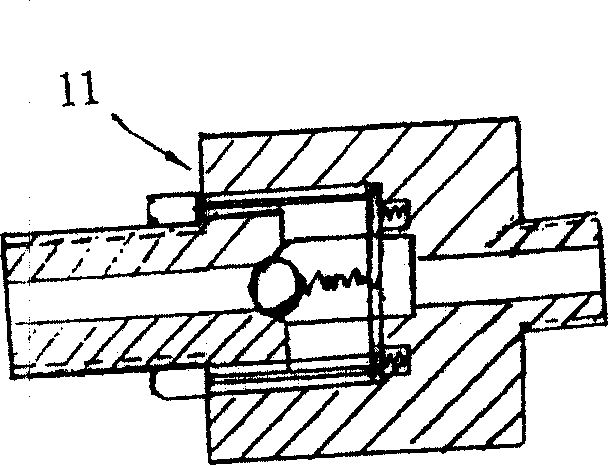

[0020] A constant-pressure fully enclosed AC-DC scroll compressor for electric vehicles, comprising a static disk 1, a moving disk 2, a motor stator 3, a motor rotor 4, and a crankshaft 5, the static disk 1 is fixed in a housing 6, and the moving disk 2 The end of the profile line is inserted into the static disk 1, the other end of the moving disk 2 is connected with the crankshaft end of the crankshaft 5, the other end of the crankshaft 5 is connected with the motor rotor 4, the supporting structure of the crankshaft 5 is the same as that of the prior art, and the bearing support can be used structure, the motor rotor 4 is installed in the motor stator 3, and the motor stator 3 is installed in the motor housing 7, the housing 6 and the motor housing 7 can be an integral structure, or a split structure, when they are split In the structure, the opposite end can adopt a flange connection structure, wherein the flange 12 is either located o...

Embodiment 2

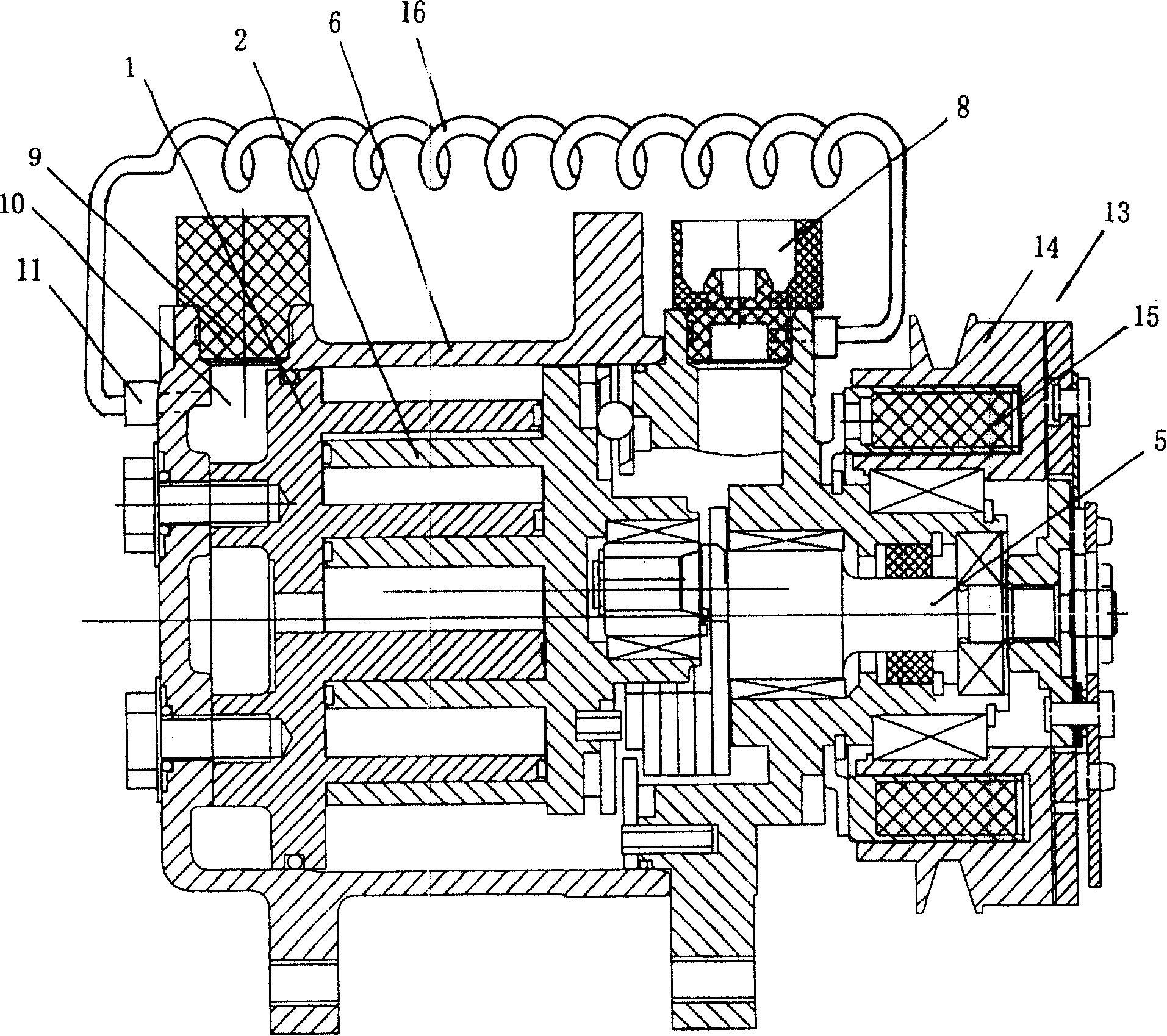

[0023] like figure 2 , 3 shown.

[0024] A constant-pressure fully-enclosed scroll compressor for fuel vehicles, comprising a static disk 1, a moving disk 2, and a crankshaft 5, the static disk 1 is fixed in a housing 6, and the molded end of the moving disk 2 is inserted into the static disk 1, The other end of the moving plate 2 is connected with the crankshaft end of the crankshaft 5, and the other end of the crankshaft 5 stretches out of the housing 6 and is connected with the driving 14. The belt pulley 14 is driven by the automobile engine, and the work of the belt pulley 14 is installed on the outside of the belt pulley. The clutch 15 is controlled, the support structure of the crankshaft 5 is the same as the prior art, and the bearing support structure can be used; the suction port 8 is located at the end of the housing 6 close to the pulley 14, and the exhaust port 9 is located at the end of the housing 6 close to the static disc 1, the exhaust port 9 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com