An energy-saving and emission-reducing filter capable of prolonging the service life of lubricating oil

An energy-saving emission reduction and filter technology, applied in the field of filters, can solve problems such as self-damage of oil products and engine sour candles, achieve good lubrication effect, improve lubrication effect, and prolong the effect of overhaul period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

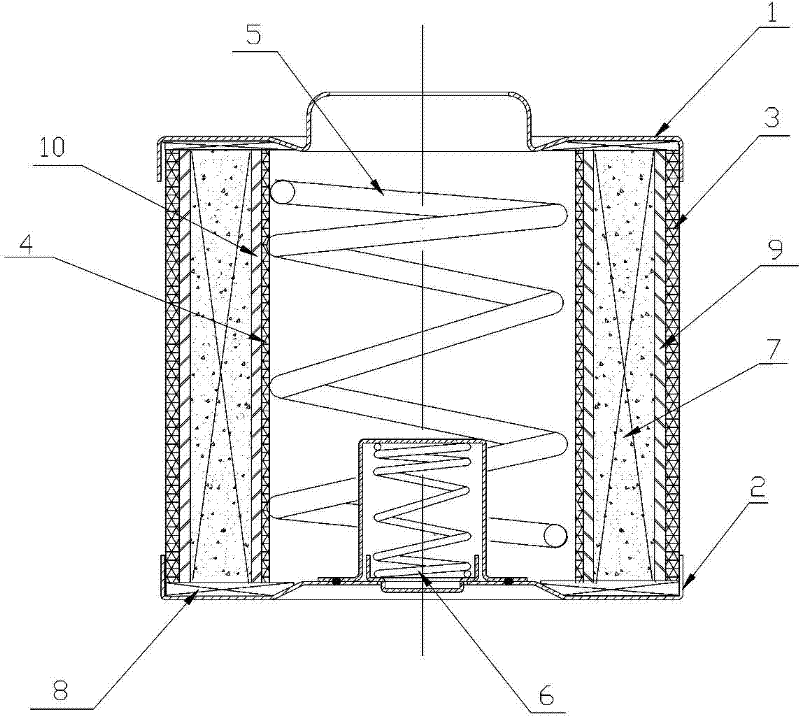

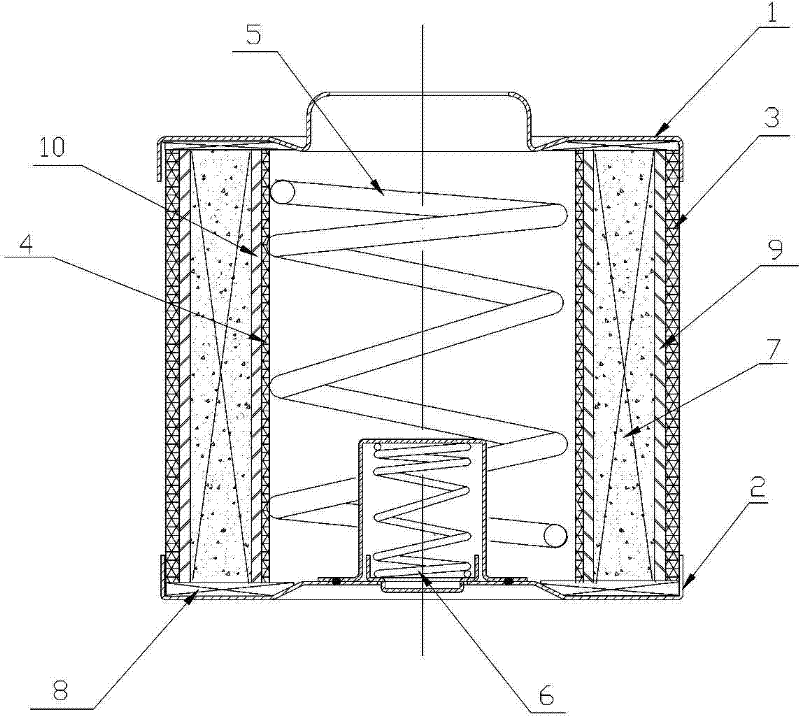

[0036] Such as figure 1 As shown, the present invention provides an energy-saving and emission-reducing filter capable of prolonging the service life of lubricating oil. The upper end cover 1 and the lower end cover 2 of the filter are respectively connected with an inner mesh cylinder holder 3 made of metal mesh and an outer mesh cylinder frame. The net cylinder holder 4, the outer surface of the inner net cylinder holder and the inner surface of the outer net cylinder holder are respectively connected with the inner net protection cloth 10 and the outer net protection cloth 9 made of 120 order copper wire mesh cloth, which are made of 120 order copper wire mesh. The annular space formed by the inner net protective cloth and the outer net protective cloth is filled with a water-absorbing cellulose resin filter layer 7, and a spring 5 is provided as a supporting reinforcement in the inner cavity of the inner net cylinder frame.

[0037] A bypass safety valve 6 is arranged ...

Embodiment 2

[0049] Such as figure 1 As shown, in this embodiment, the inner net cylinder holder 3 and the outer net cylinder holder 4 made of high-temperature modified nylon are respectively connected between the upper end cover 1 and the lower end cover 2 of the filter, and the outer surface of the inner net cylinder holder and the inner surface of the outer net cylinder rack are connected with the inner net protective cloth 10 and the outer net protective cloth 9 made of 150 mesh high temperature resistant nylon mesh respectively, and the annular space formed by the inner net protective cloth and the outer net protective cloth is filled with water-absorbing A permanent cellulose resin filter layer 7, and a spring 5 is provided as a supporting reinforcement in the inner cavity of the inner net cylinder holder. A bypass safety valve 6 is arranged in the lower end cover, and the end faces of the inner and outer net cylinder frames and the filter layer 7 are connected with the upper and low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com