Combined sealing piston ring

A sealing piston and combined technology, which is applied in the field of piston rings, can solve the problems of trapezoidal inclined surface processing of trapezoidal inclined surface split rings, affecting the service life of piston rings, affecting the service life of cylinders, etc., to achieve fuel saving, uniform thickness, and service life prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

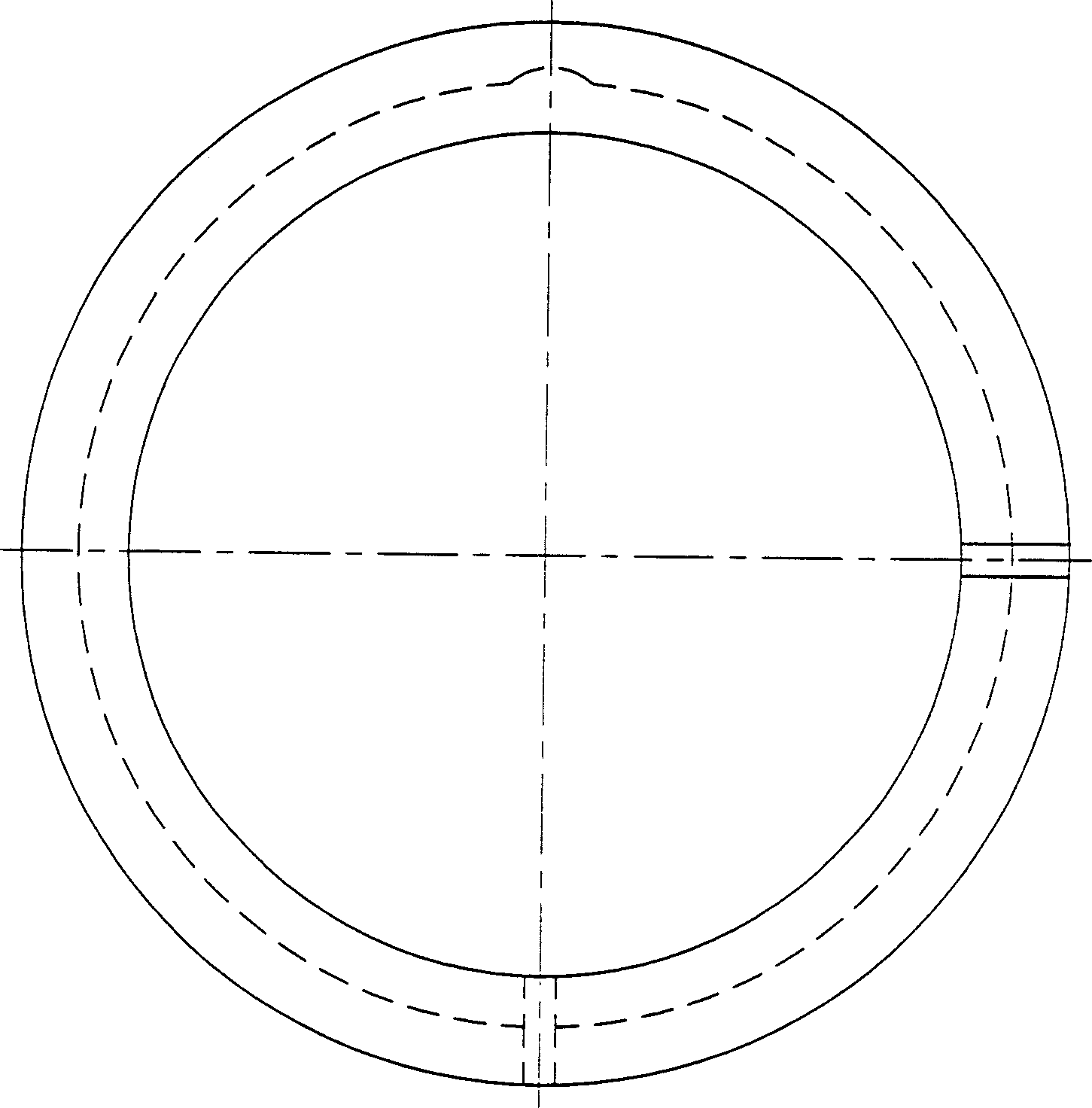

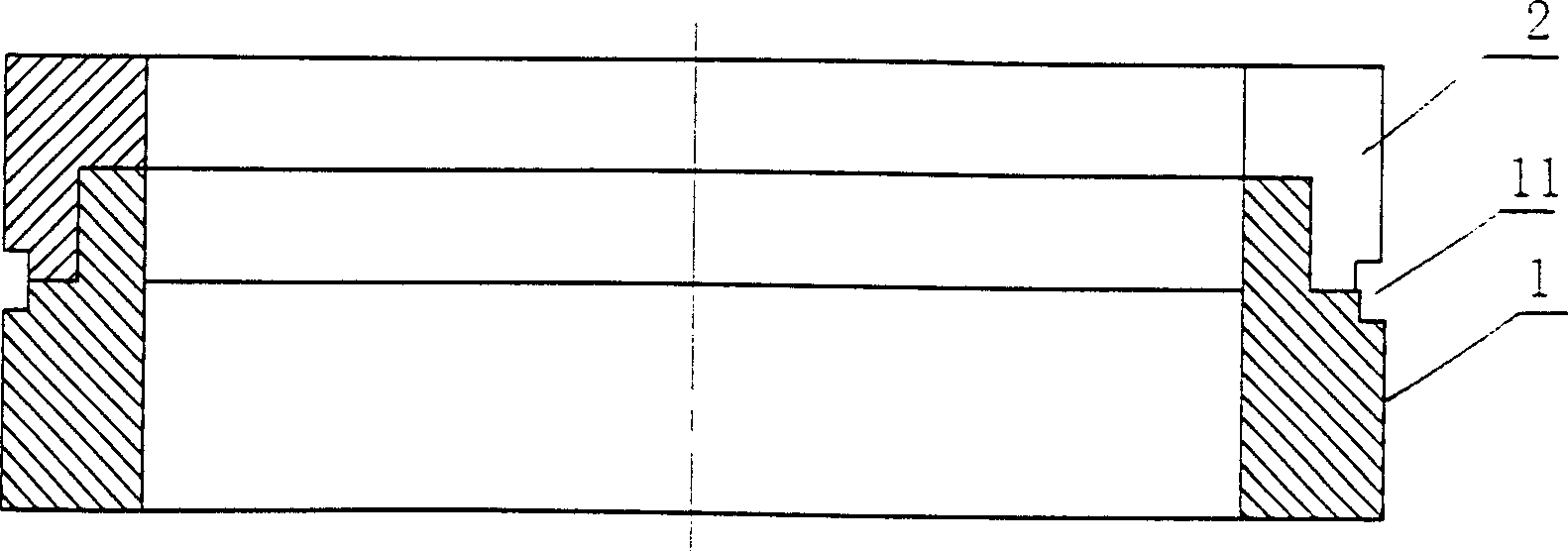

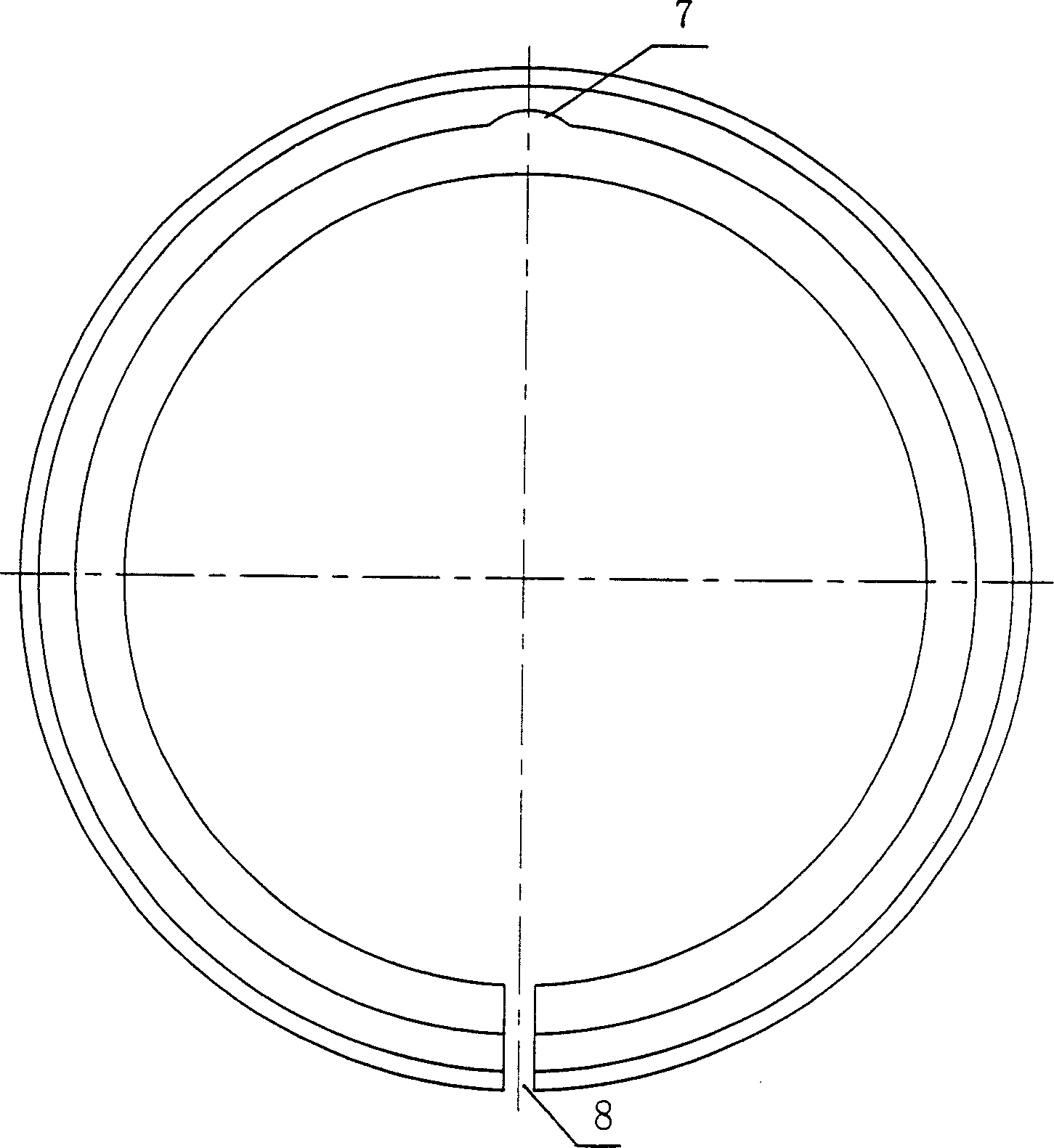

[0038] attached Figure 1~6 It is the accompanying drawing of the first embodiment of the present invention.

[0039]In the accompanying drawing, the combined piston ring includes sub-ring I1 and sub-ring II2 with the same thickness. Both sub-ring I1 and sub-ring II2 have openings. There is a concave shoulder 3 on the sub-ring II2. The circumferential surface of the concave shoulder 3 is in line with the The inner and outer circles of the sub-ring II2 are concentric, and there is a slightly concave arc-shaped depression 4 on the inner concave shoulder 3, and the depression is at an angle of 180° to the opening 5 on the sub-ring II2, and there is an outer convex shoulder 6 on the sub-ring I1, The peripheral surface of the outer convex shoulder 6 is concentric with the inner and outer circles of the sub-ring I1, and the outer convex shoulder 6 has an arc-shaped protrusion 7 whose shape matches the depression 4 on the inner concave shoulder of the sub-ring II2. 7 and the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com