Wear-resistant additive for lubricating oil and preparation method of additive

A lubricating oil additive, nano molybdenum disulfide technology, applied in additives, lubricating compositions, petroleum industry and other directions, can solve problems such as corrosion, and achieve the effects of reducing noise, improving power, and prolonging overhaul period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

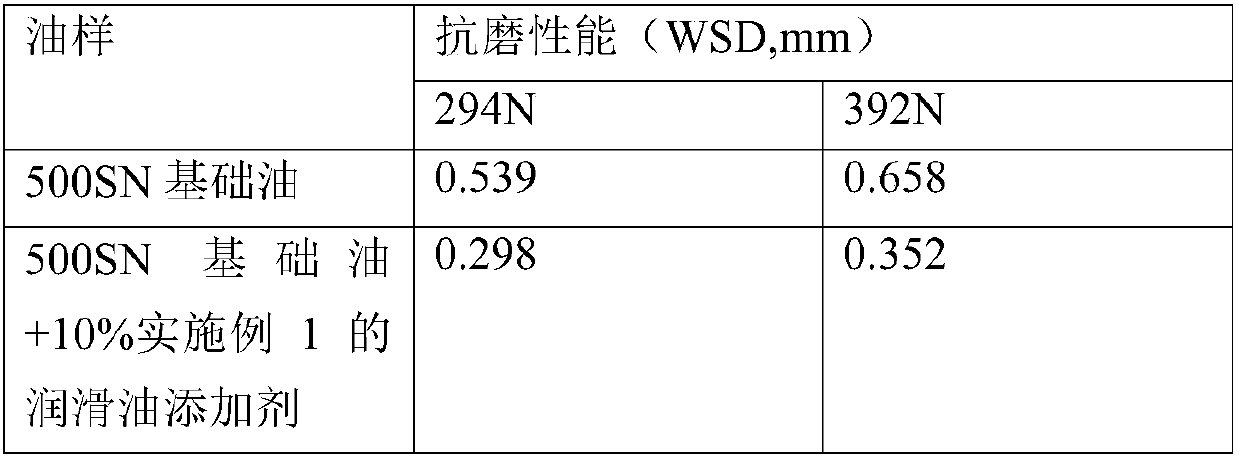

Embodiment 1

[0014] A wear-resistant lubricating oil additive, the components and mass fractions are as follows: 5 parts of nano-calcium carbonate, 4 parts of nano-boron nitride, 3 parts of nano-molybdenum disulfide, 8 parts of expanded graphite, 6 parts of nano-cerium borate, and nano-zirconia 5 parts, 2 parts of nano-alumina, 1 part of nano-titanium dioxide, 1 part of nano-silica, 5 parts of N,N'-di-sec-butyl-p-phenylenediamine, 4 parts of di-tert-butyl-p-cresol, poly 5 parts of vinyl alcohol, 2 parts of methyl acrylate, 5 parts of pentaerythritol, and 8 parts of nano-zinc oxide; nano-molybdenum disulfide is molybdenum disulfide modified by maleic anhydride, and its preparation process is as follows: get 3 parts of nano-molybdenum disulfide, 15 parts of absolute ethanol, after mixing, carry out ultrasonic dispersion, then add 10 parts of maleic anhydride at 30°C, react for 1 hour, cool to room temperature, filter with suction, wash the filter cake with ethanol for 5 times, vacuum dry and ...

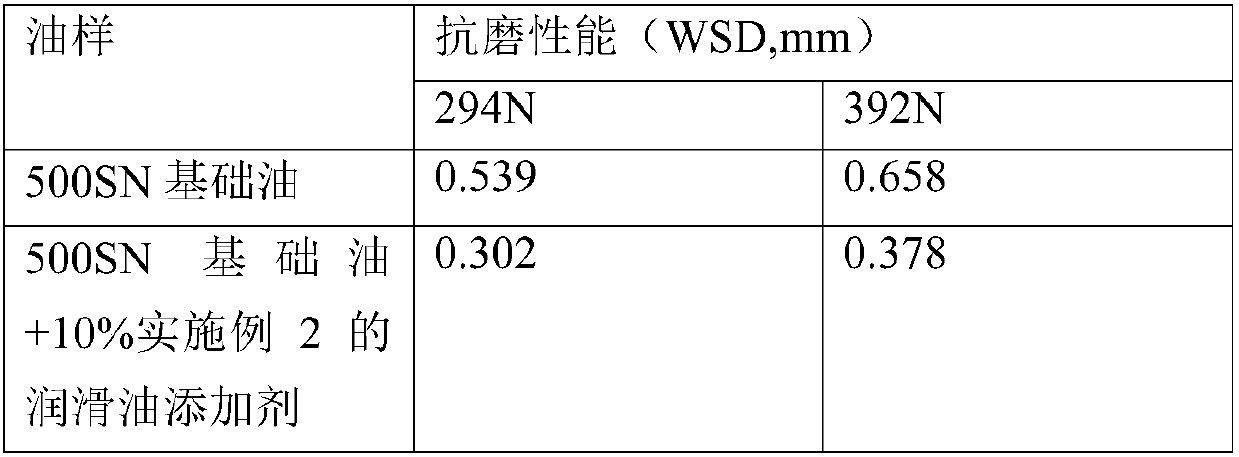

Embodiment 2

[0018] A wear-resistant lubricating oil additive, the components and mass fractions are as follows: 1 part of nano-calcium carbonate, 2 parts of nano-boron nitride, 6 parts of nano-molybdenum disulfide, 2 parts of expanded graphite, 3 parts of nano-cerium borate, and nano-zirconia 1 part, 8 parts of nano-alumina, 6 parts of nano-titanium dioxide, 8 parts of nano-silica, 3 parts of N,N'-di-sec-butyl-p-phenylenediamine, 6 parts of di-tert-butyl-p-cresol, poly 2 parts of vinyl alcohol, 8 parts of methyl acrylate, 1 part of pentaerythritol, and 2 parts of nano-zinc oxide; nano-molybdenum disulfide is molybdenum disulfide modified by maleic anhydride, and its preparation process is as follows: get 5 parts of nano-molybdenum disulfide, 10 parts of absolute ethanol, after mixing, carry out ultrasonic dispersion, then add 8 parts of maleic anhydride at 50°C, react for 2 hours, cool to room temperature, filter with suction, wash the filter cake with ethanol for 5 times, vacuum dry and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com