Active safety production risk assessment device and method

A risk assessment and active safety technology, applied in the field of safety production, can solve the problems of oversight of work, inability to achieve unified supervision of people, equipment, and environment, and poor business operations, to reduce energy consumption and environmental emission indicators, and improve physical and mental health assessment. Level, the effect of reducing the number of non-stops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

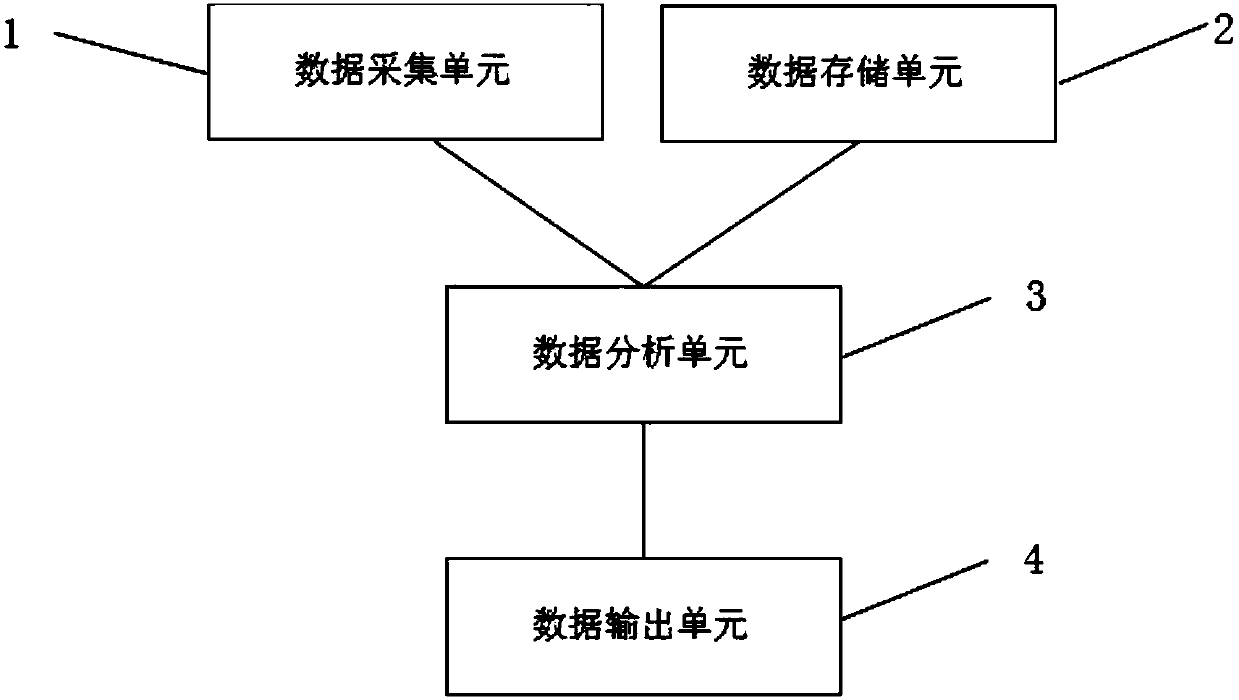

[0042] Such as figure 1As shown, an active safety production risk assessment device includes a data acquisition unit (1), a data storage unit (2), a data analysis unit (3) and a data output unit (4); the data acquisition unit (1) is used to collect Personnel real-time positioning information, real-time image information, equipment health real-time information, and personnel health real-time information are sent to the data analysis unit (3); the data storage unit (2) stores safety management data information and assessment method information, and The management data information and assessment method information are sent to the data analysis unit (3), and the data analysis unit (3) obtains the safety production information through analysis and sends it to the data output unit (4); the data output unit (4) is used to transfer the safety production information Information output.

[0043] The data acquisition unit (1) collects the real-time positioning information of personnel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com