Ceramic matrix tread sweeper grinder and production method thereof

A cleaner and ceramic-based technology, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of affecting safe use, poor thermal stability, and easy to generate slag, so as to prevent slag from falling, improve toughness, Good toughness and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

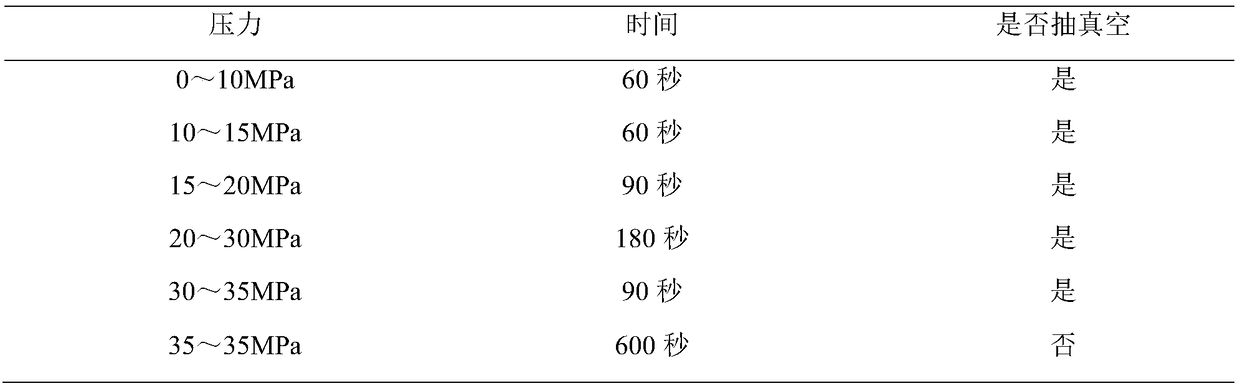

[0031] A grinding wheel for a ceramic-based tread cleaner of the present embodiment and a manufacturing method thereof, specifically include the following steps:

[0032] (1) According to the following ratio for ingredients

[0033] Silicon carbide whiskers 8%, ferrosilicon nitride 10%, quartz powder 18%, ρ-Al 2 o 3 10%, nanometer titanium oxide 8%, calcium yttrium composite zirconia powder 20%, silane coupling agent modified phenolic resin 15%, tetrahydrofuran 6%, water 5%, of which W (silicon carbide whiskers) + W (quartz powder) + W (titanium oxide) + W (zirconia powder) + W (ferrosilicon nitride) + W (alumina powder) and the ratio of the amount of W (modified phenolic resin) is 4.9:1;

[0034] (2) Put the above-mentioned ceramic raw materials silicon carbide whisker, ferrosilicon nitride, quartz powder, alumina powder, nanometer titanium oxide, calcium yttrium composite zirconia powder into the mixer, and add modified Phenolic resin premix;

[0035] (3) After premixing...

Embodiment 2

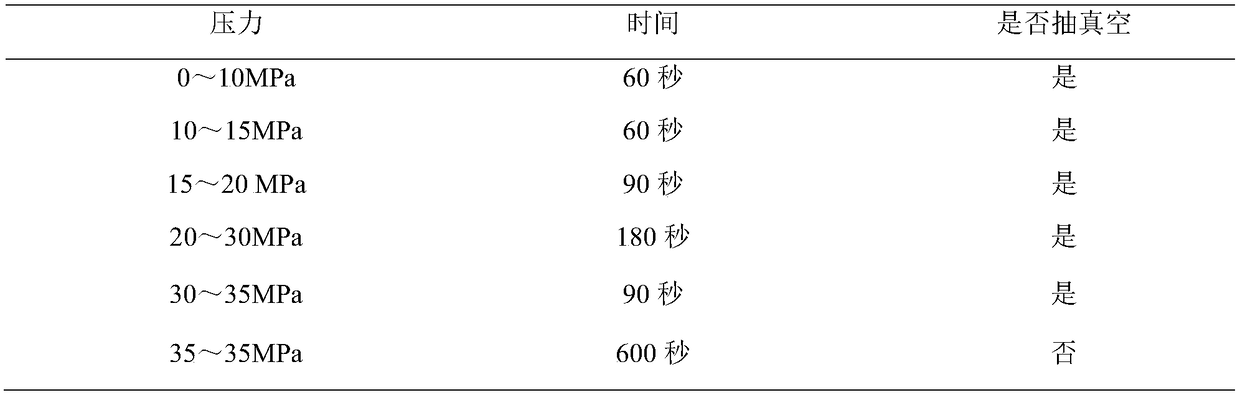

[0044] A grinding wheel for a ceramic-based tread cleaner of the present embodiment and a manufacturing method thereof, specifically include the following steps:

[0045] (1) According to the following ratio for ingredients

[0046] Silicon carbide whiskers 5%, ferrosilicon nitride 15%, quartz powder 12%, ρ-Al 2 o 3 10%, nanometer titanium oxide 7.9%, calcium yttrium composite zirconia powder 20%, phenolic resin modified by silane coupling agent 20%, tetrahydrofuran 5%, water 5%, copper powder 0.1%;

[0047] (2) Put the above-mentioned ceramic raw materials silicon carbide whisker, ferrosilicon nitride, quartz powder, alumina powder, nanometer titanium oxide, calcium yttrium composite zirconia powder into the mixer, and add modified Phenolic resin premix;

[0048] (3) After premixing is completed, add tetrahydrofuran and water to continue mixing to form particles with a diameter of about 3mm;

[0049] (4) Put the granulated mixture into a drying oven to dry for 2 hours, an...

Embodiment 3

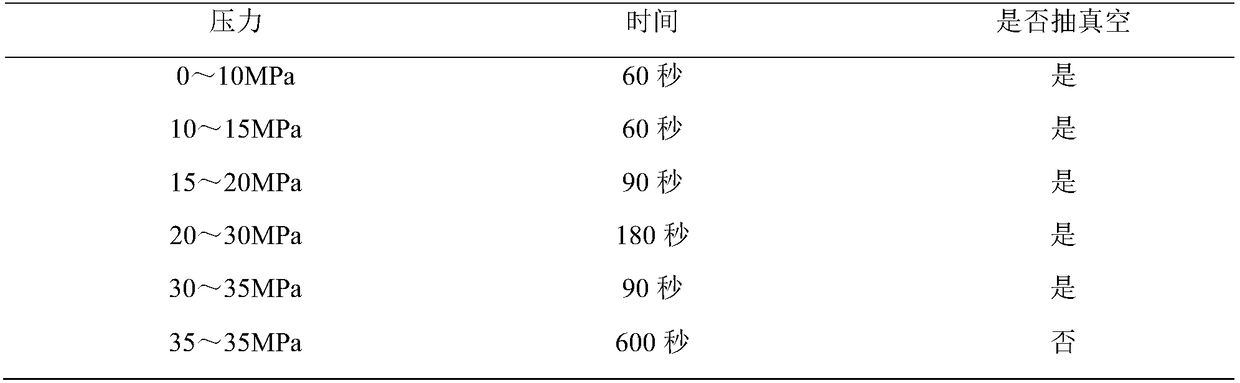

[0055] A grinding wheel for a ceramic-based tread cleaner of the present embodiment and a manufacturing method thereof, specifically include the following steps:

[0056] (1) According to the following ratio for ingredients

[0057] Silicon carbide whiskers 10%, ferrosilicon nitride 8%, quartz powder 15%, ρ-Al 2 o 3 8%, nanometer titanium oxide 5%, calcium yttrium composite zirconia powder 24.8%, silane coupling agent modified phenolic resin 16%, tetrahydrofuran 6%, water 7%, copper powder 0.2%, wherein W (silicon carbide whisker ) + W (quartz powder) + W (titanium oxide) + W (zirconia powder) + W (ferrosilicon nitride) + W (alumina powder) and the ratio of the total amount of W (modified phenolic resin) is 4.4:1;

[0058] (2) Put the above-mentioned ceramic raw materials silicon carbide whisker, ferrosilicon nitride, quartz powder, alumina powder, nanometer titanium oxide, calcium yttrium composite zirconia powder into the mixer, and add modified Phenolic resin premix;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com