Gas catalytic flameless near-infrared heating annealing furnace

A gas-catalyzed, near-infrared technology, which is applied to heat treatment furnaces, furnaces, and furnace types, can solve problems such as high maintenance costs, low site utilization, and short furnace overhaul periods, and achieve high thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

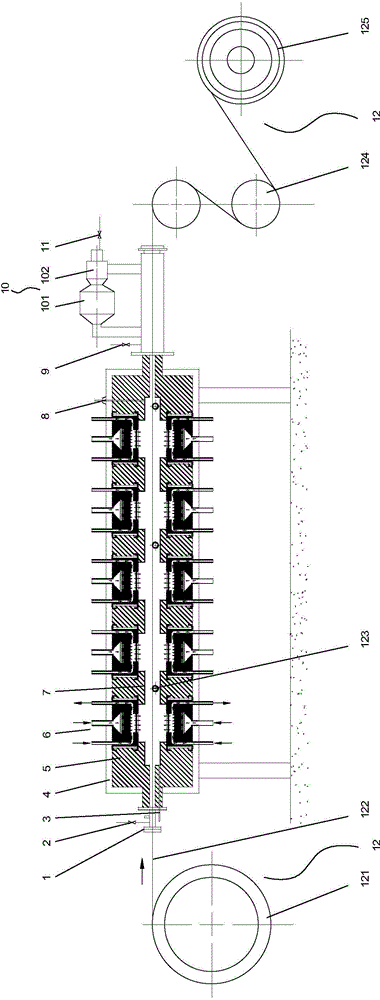

[0058] A gas-fired catalytic flameless near-infrared heating annealing furnace (see figure 1 ), the annealing furnace is used for bright annealing of stainless steel strips that need to ensure the atmosphere in the furnace. It includes a furnace shell 4, a furnace lining 7, a heating system, a cooling system 10, and a conveying system 12. The furnace shell is a high-temperature section, and the cooling system is a cooling part;

[0059] The cooling system 10 is installed at the rear end of the furnace shell 4. The cooling system 10 includes a heat exchanger 101 and a forced cooling fan 102. The rear end of the cooling system 10 is provided with a protective gas outlet 11;

[0060] The conveying system 12 includes an uncoiler 1201, stainless steel belt rollers 1203, S rollers 1204, and a coiler 1205 in the furnace. One end of the stainless steel belt 1202 is wound on the uncoiler 1201, and the other end passes through the furnace shell 4 and cooled in turn. System 10 , S roll ...

Embodiment 2

[0071] A gas-fired catalytic flameless near-infrared heating annealing furnace, which is used for annealing stainless steel strips that do not need to ensure the atmosphere in the furnace, the basic structure of the annealing furnace is the same as that of Embodiment 1, the difference lies in: (1) cooling system The rear end of 10 is not provided with a protective gas outlet 11; the front end of the furnace shell 4 is not provided with an inlet sealing device 1, a front protective gas release port 2, and a protective gas inlet 3 in the furnace chamber, and the rear end of the furnace shell 4 is not provided with a rear protective gas release Mouth 9.

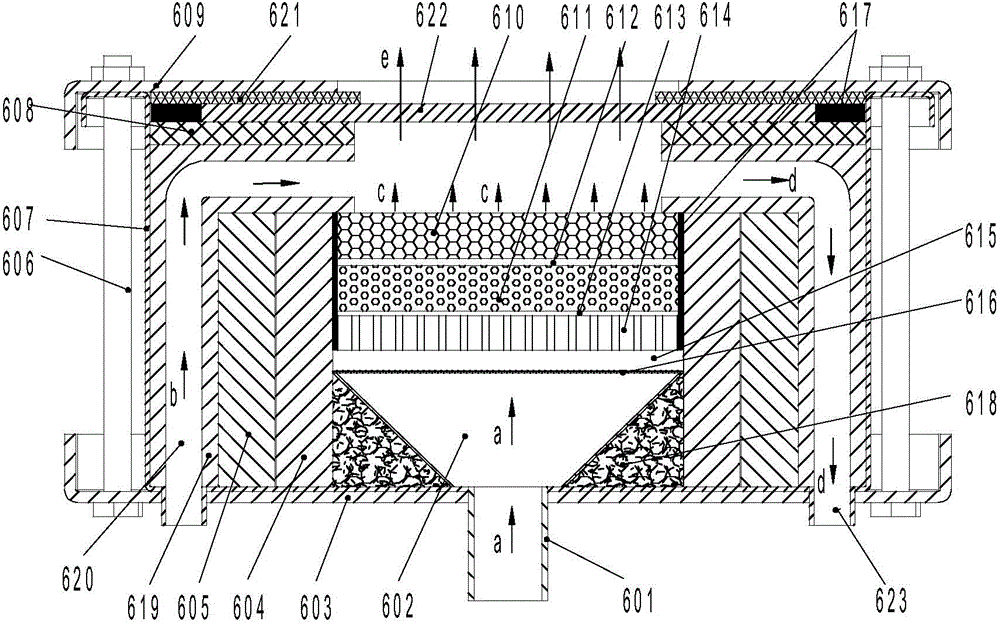

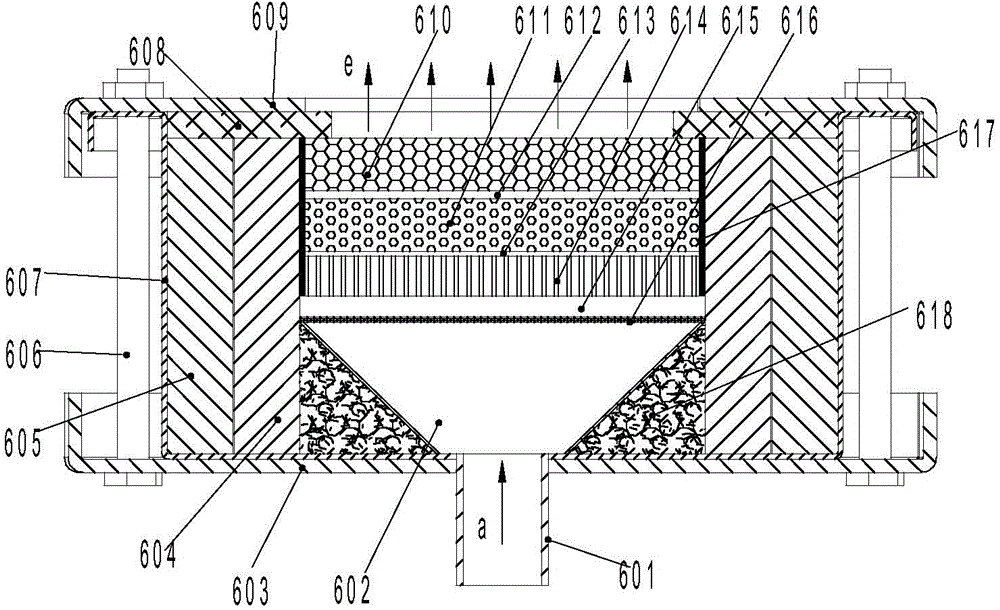

[0072] (2) The gas-fired catalytic flameless near-infrared heating porous media burner 6 is a gas-fired catalytic flameless near-infrared direct heating porous media burner (see image 3 ), which includes a burner body 607, an insulating layer 605, and a refractory brick layer 604. The refractory brick layer 604 is located in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com