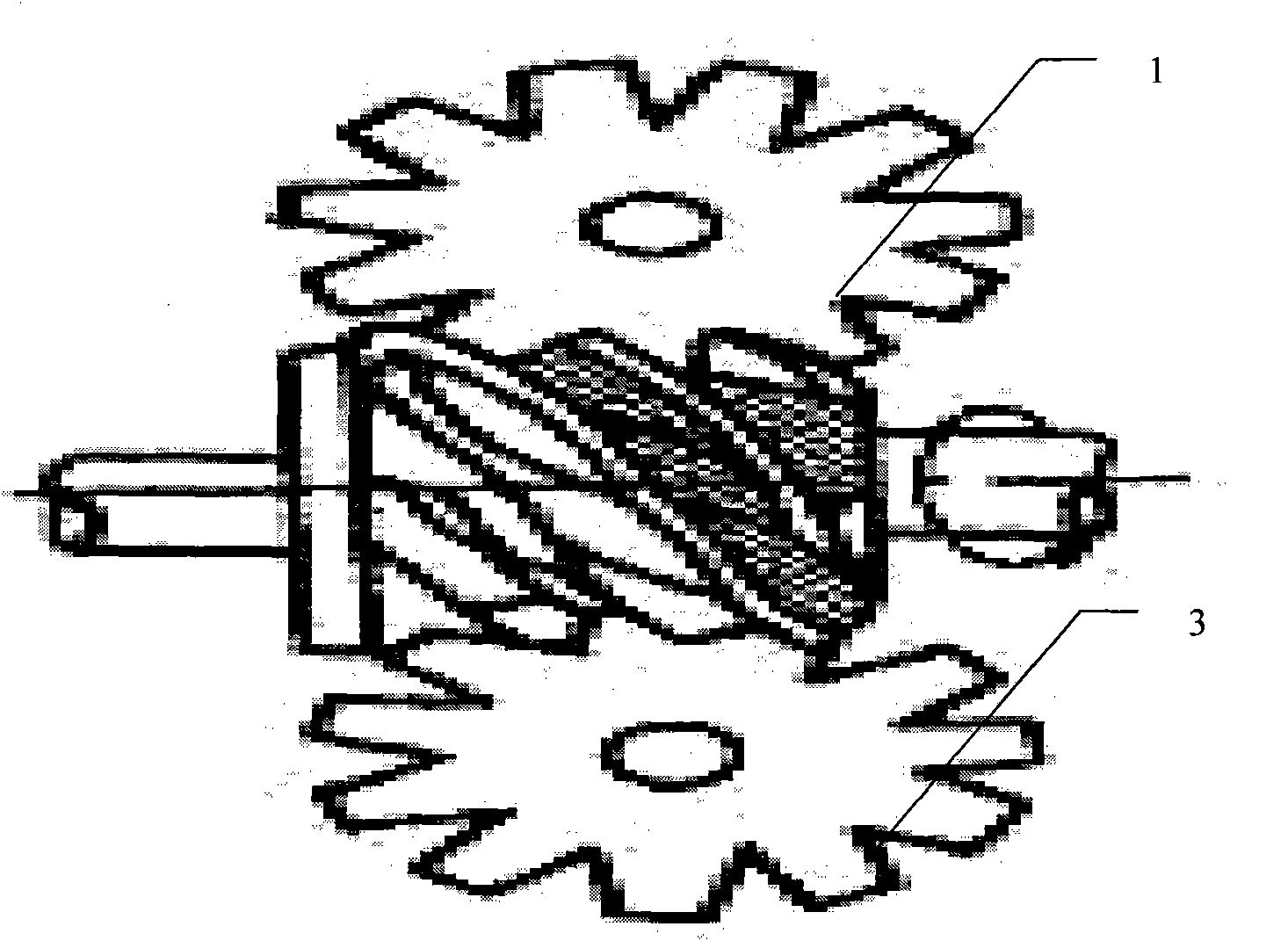

Single-screw fluid power generator and generating method

A single-screw, generator technology, applied in engine components, machines/engines, rotary piston engines, etc., can solve problems such as low power generation efficiency and thermal energy loss, and achieve expanded applications and types, reasonable structure, and large single-machine capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

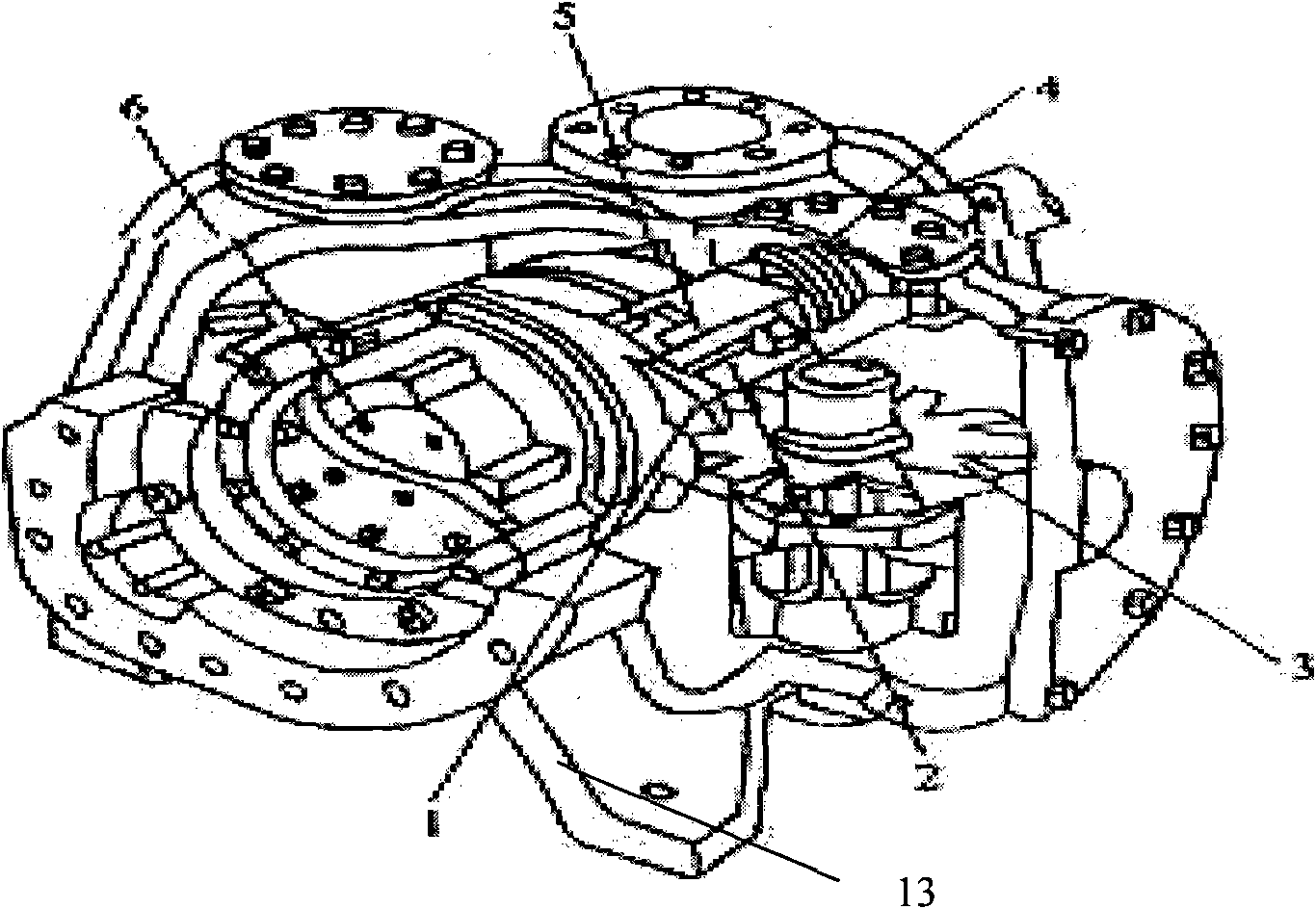

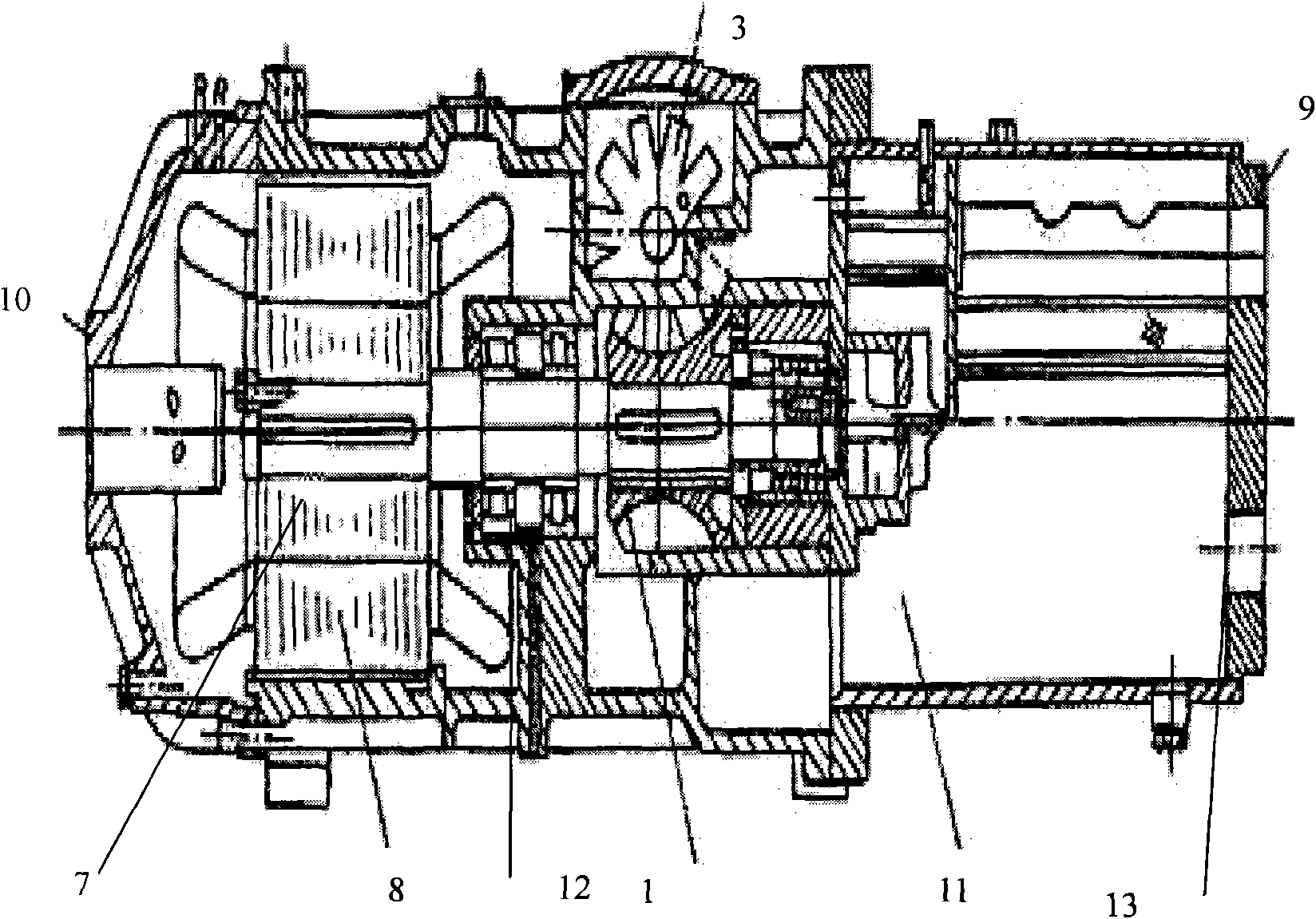

[0052] Embodiment 1: single screw generator

[0053] like image 3 As shown, in this example, the single screw 1, the star wheel 3, the generator rotor 7 and the generator stator 8 are jointly arranged inside a housing 13, the single screw 1 is placed horizontally, and the two star wheels 3 are arranged on two sides. The side is placed perpendicular to the ground, the internal volume ratio adjustment valve 2 is set around the single screw 1 and the star wheel 3 to realize the adjustment of its internal volume, and the shaft seal 4 is set outside the bearing to realize the airtightness of the bearing, and the gas transmission volume adjustment valve 5 Realize the adjustment and control of the fluid, the fluid enters the interior of the housing 13 from the fluid inlet 9, expands through the cavity formed by the single screw 1, the star wheel 3 and the housing, and converts the kinetic energy of the fluid into the mechanical energy of the single screw , the single screw and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com