Dynamic and static pressure ball socket bearing structure for high speed gear shaper

A technology of spherical hinge bearings and gear shaping machines, which is applied in the direction of gear cutting machines, gear teeth, mechanical equipment, etc., can solve the problems that the structure and lubrication method of spherical hinge bearings cannot meet the gear shaping speed, etc., so as to avoid abnormal damage, easy to realize, The effect of extended overhaul period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

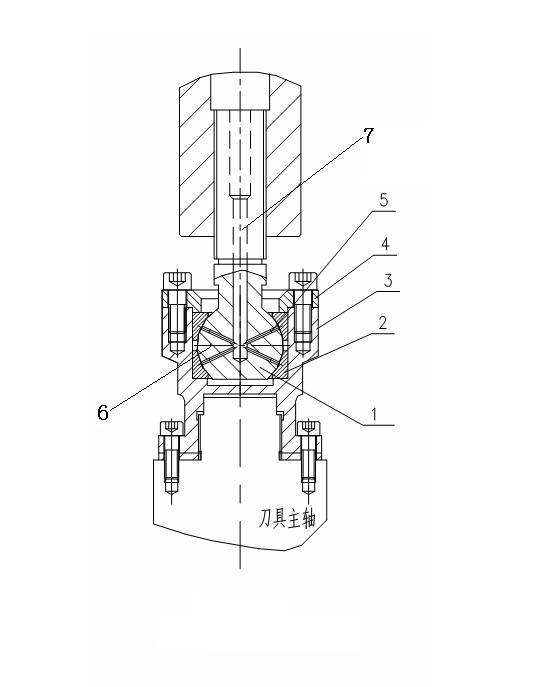

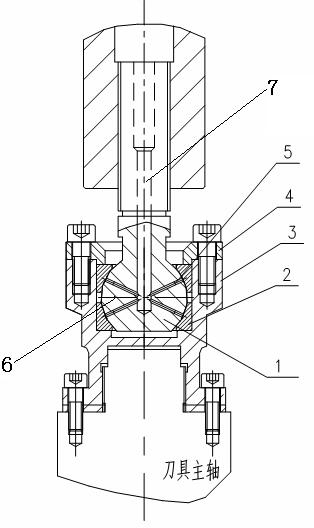

[0021] Such as figure 1 shown.

[0022] A dynamic and static pressure ball joint bearing structure for a high-speed gear shaping machine, comprising a ball rod 1, a ball joint seat 2 and a shell 3, the lower end of the shell 3 is connected to the tool spindle, and the ball joint seat 2 can be directly made of ceramic materials, In order to improve its wear resistance, it can also be manufactured by depositing a wear-resistant metal layer (such as zirconia, aluminum oxide) or a wear-resistant non-metal layer (such as silicon nitride, silicon carbide) on the surface of the base metal material. The ball body 6 at the lower end of the club 1 is located in the ball joint seat 2. The diameter of the ball body 6 is 50-60 mm. Orientation and gap adjustment, the upper end of the club 1 stretches out of the pressure ring 4 and is connected with the crank, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com