Automatically-flowing and automatically-supplying circulating water cooling automobile brake drum water seal

A circulating water cooling and automobile braking technology, which is applied in the field of auto parts, can solve the problems of non-circulation of cooling water, hidden dangers of driving safety, damage to road surfaces, etc., and achieve the effects of eliminating safety hazards, protecting the environment and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

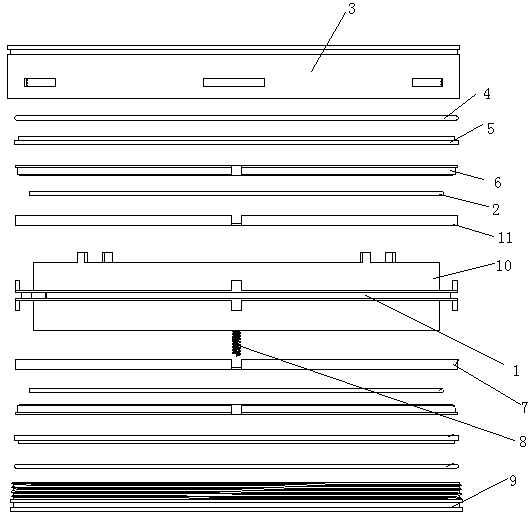

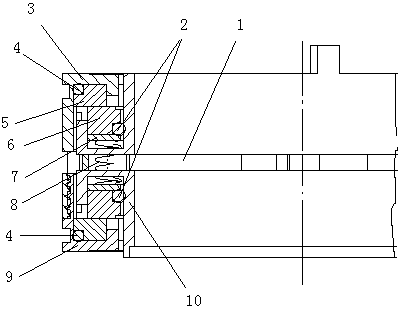

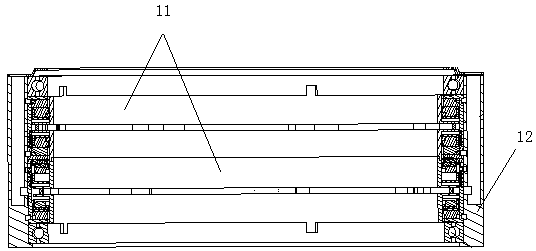

[0016] Such as figure 1 , figure 2 As shown, the automobile brake drum water seal of the present invention is composed of inner skeleton 10, upper outer skeleton 3 and lower outer skeleton 9, sealing ring, upper and lower wear-resistant rings; the two ends of inner skeleton 10 are respectively equipped with wear-resistant rings Skeleton 7,11, seal ring 2, lower wear ring 6 and upper wear ring 5, seal ring 4. Outside the sealing ring at one end is the upper exoskeleton 3, and outside the sealing ring at the other end is the lower exoskeleton 9, and the upper exoskeleton and the lower exoskeleton are screwed together to form a whole. There is an inner skeleton water tank 1 in the middle of the skeleton. There are several holes (about 18 to 20) on one end of the inner skeleton. Springs (reset) are installed in the holes. There are multiple water inlets and outlets on the outer skeleton. Multiple water inlets and outlets. Blades (forming impellers) can be arranged in the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com