Bearing block, oil cavity cleaning and lubricating system and method for bearing block, and mineral engineering machinery

A technology for lubrication systems and bearing seats, applied in cleaning methods and tools, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems affecting the performance of lubricants, the difficulty of bearing seat cleanliness, and the effect of lubricating grease on lubrication, etc. problems, achieve automatic continuous cleaning and lubrication, improve versatility and scope of application, and have good cleaning and lubrication effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

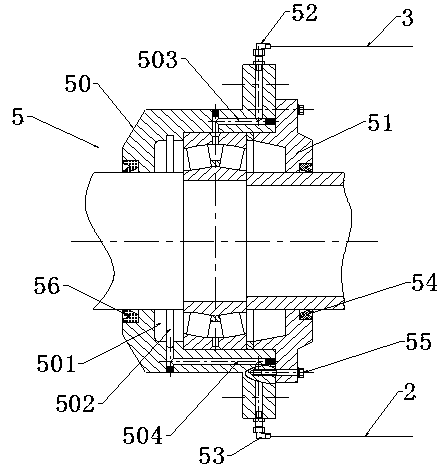

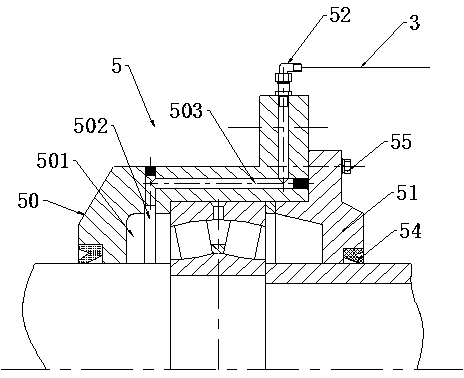

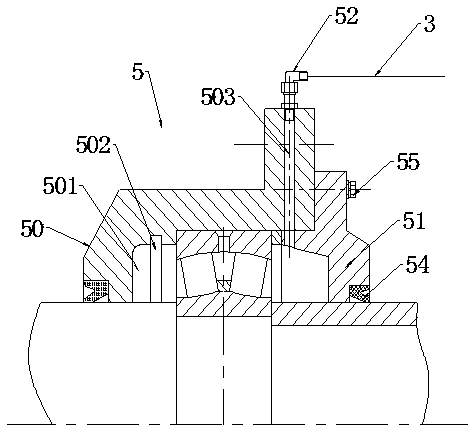

[0048] The purpose of the present invention is to provide a bearing seat, which has a simple structure, and can realize the cleaning of the oil chamber in the bearing seat without disassembling the bearing seat, bearing and related parts, and makes it possible to clean the bearing seat oil The method of removing impurities in the cavity is relatively simple. The second object of the present invention is to provide a bearing seat oil chamber cleaning and lubrication system based on the above-mentioned bearing seat. The bearing seat oil chamber cleaning and lubrication system has a simple structure, is safe and reliable, and has good cleaning and lubrication effects, and can realize the cleaning and lubrication of the bearing seat. Automatic cleaning and lubrication operations. The third object of the present invention is to provide a method for applying the above-mentioned bearing seat and its cleaning and lubricating system, which has the characteristics of simple operation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com