Clearing robot for pipeline surface adhesive contaminants

A technology of attachments and robots, applied in the directions of manipulators, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of limitation, waste of manpower and material resources, threats to safety production, etc., and achieve the effect of high performance, rich development and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

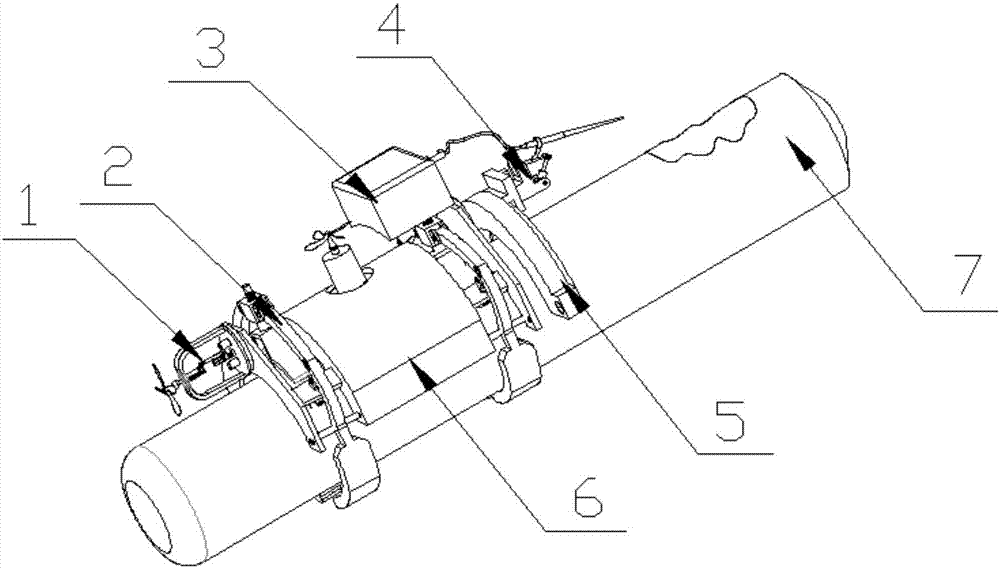

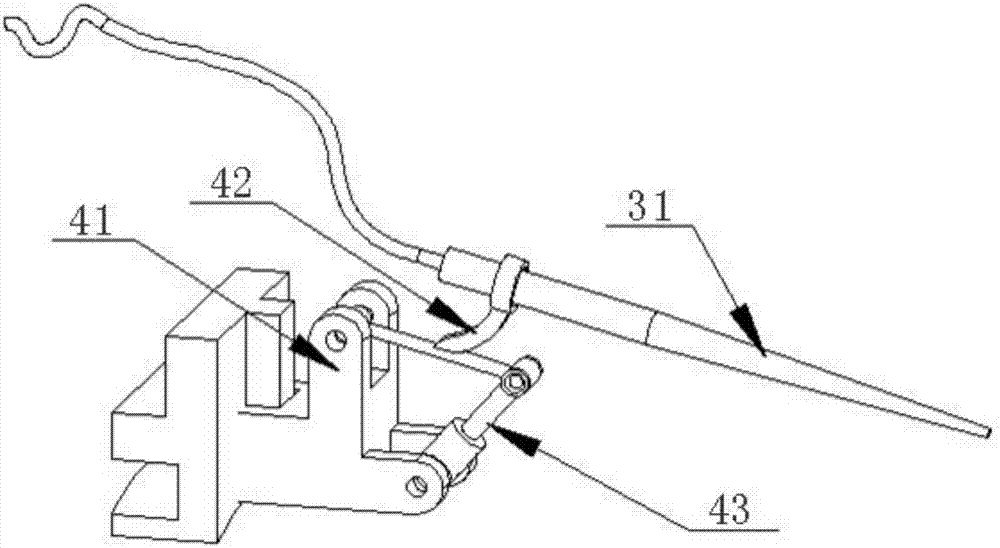

[0035] like Figure 1-5Shown is a schematic diagram of the structure of the pipeline surface attachment cleaning robot. This example includes an arc-shaped housing. The inner side of the arc-shaped housing is provided with a wheel-type moving mechanism 6 for moving the arc-shaped housing on the pipeline 7 to be cleaned. The vector propulsion mechanism 1 moving along the pipeline 7 to be cleaned, the fixing device 2 for fixing the arc-shaped shell on the pipeline 7 to be cleaned, the high-pressure water gun system for cleaning the pipeline 7 to be cleaned 3, the The water gun rotary mechanism 5 used to adjust the water gun 32 of the high-pressure water gun system 3 in the radial position of the pipeline 7 to be cleaned and the water gun position adjustment mechanism 4 arranged on the water gun rotary mechanism 5 for adjusting the position of the water gun.

[0036] Further, the water gun rotary mechanism 5 includes an arc-shaped rotary bracket 51 arranged on the head of the ar...

Embodiment 2

[0045] Such as Figure 3-4 , 6-8, the second embodiment has many similarities with the first embodiment. There are three main differences.

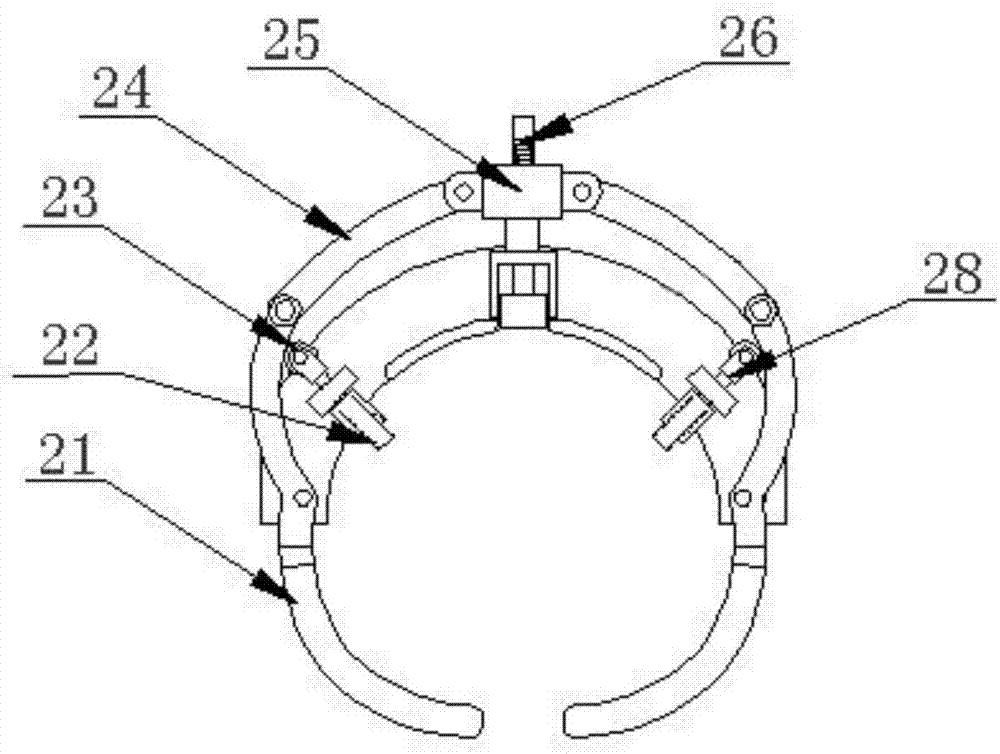

[0046] One is that the fixing device 2' is a permanent magnetic adsorption device, which includes a plurality of adsorption units, and each adsorption unit consists of two permanent magnets 22' and a yoke 21' to form a B-shaped magnetic circuit; through this device, the surface of the pipeline can be made The attachment cleaning robot is adsorbed on the pipeline 7' to be cleaned.

[0047] Its two, be on the design of wheel type moving mechanism 6 ', comprise arc housing 65 ', two universal rollers 61 ' are respectively installed on the left and right sides of arc housing 65 '; Four universal rollers 61 ' and When the pipeline 7' to be cleaned is in contact, it can roll along the pipeline to be cleaned under the action of external force.

[0048] The third is that the vector propulsion mechanism 1' is a parallel vector propulsion mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com