Patents

Literature

564results about How to "Improve low temperature fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

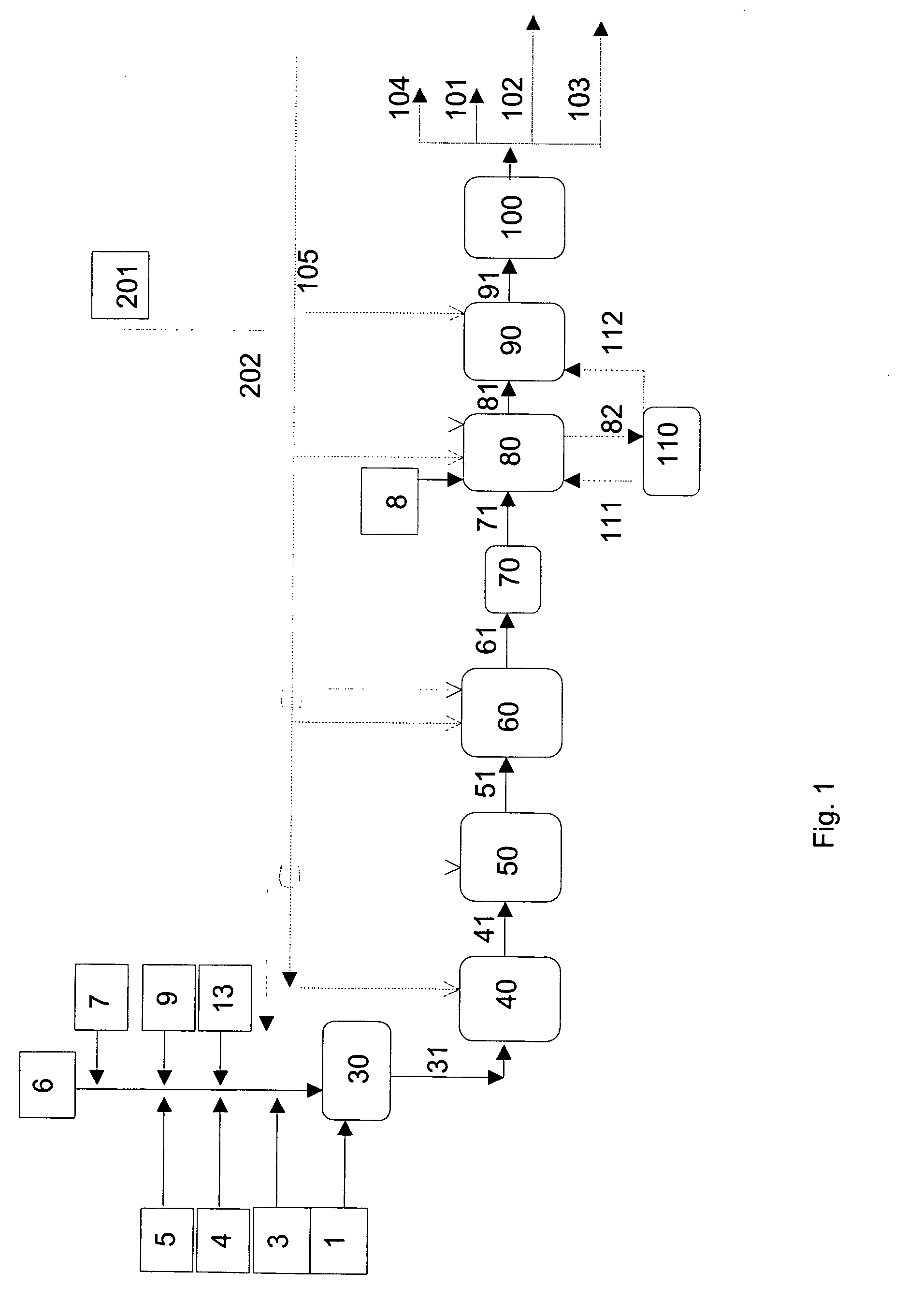

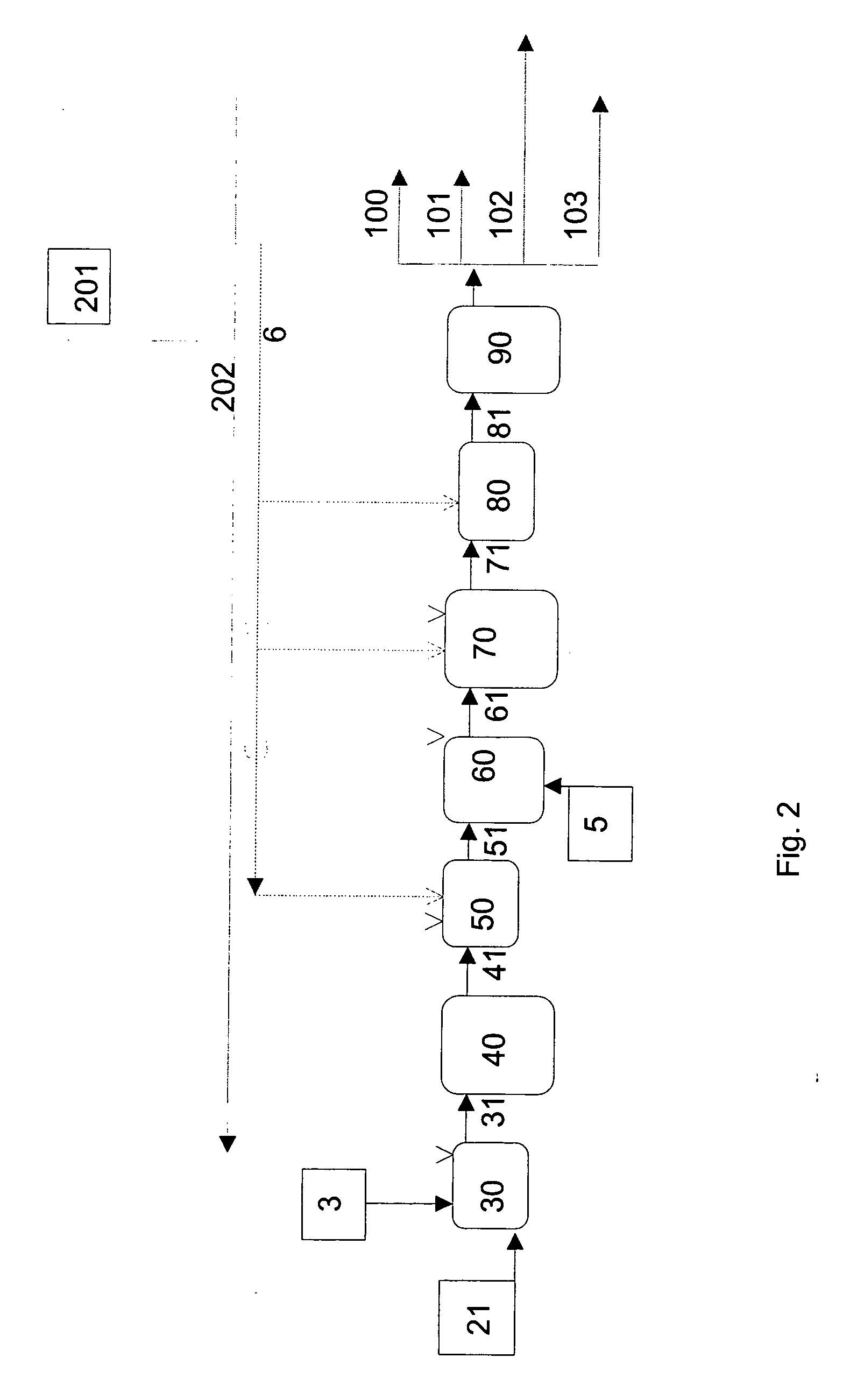

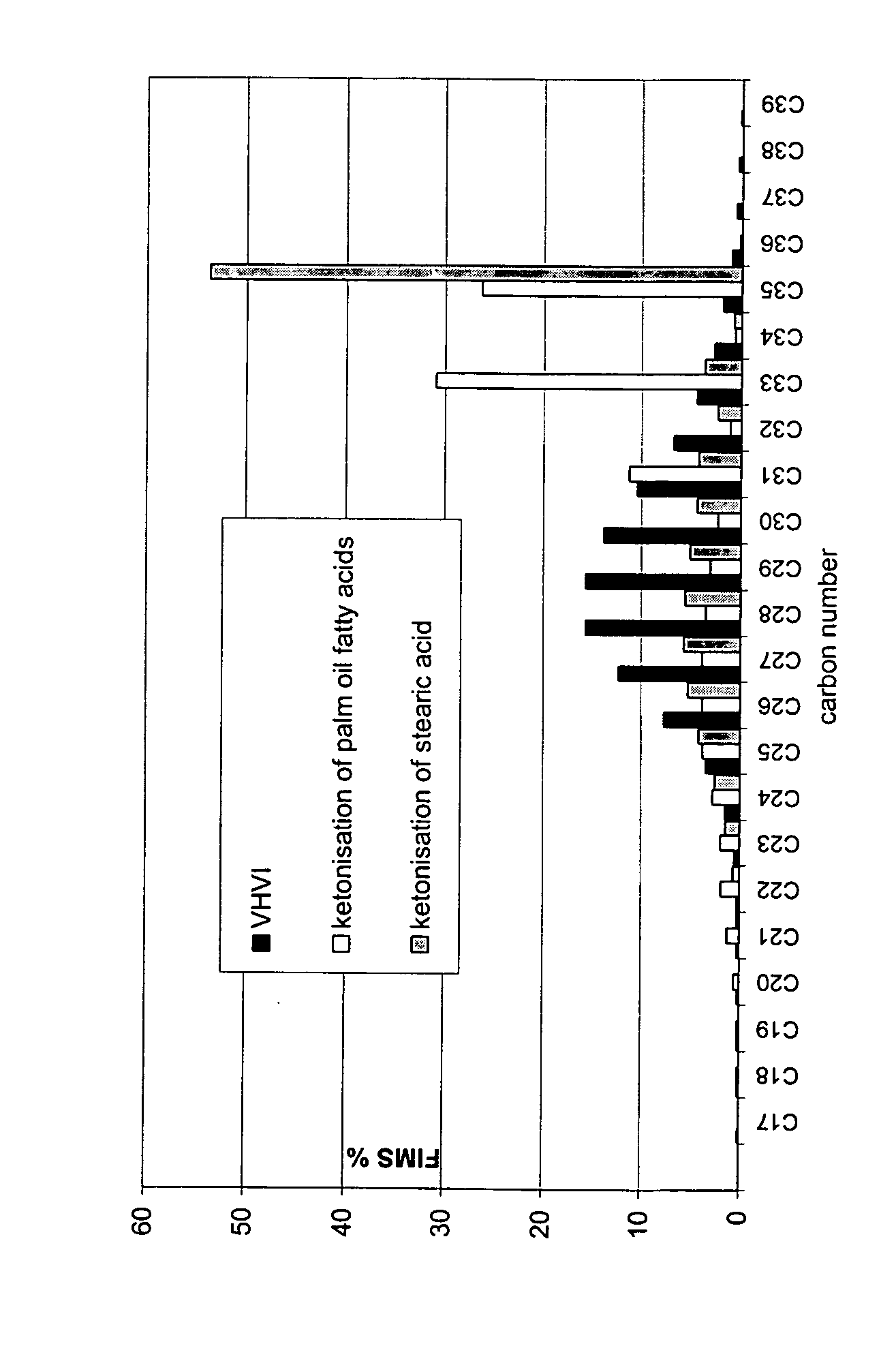

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

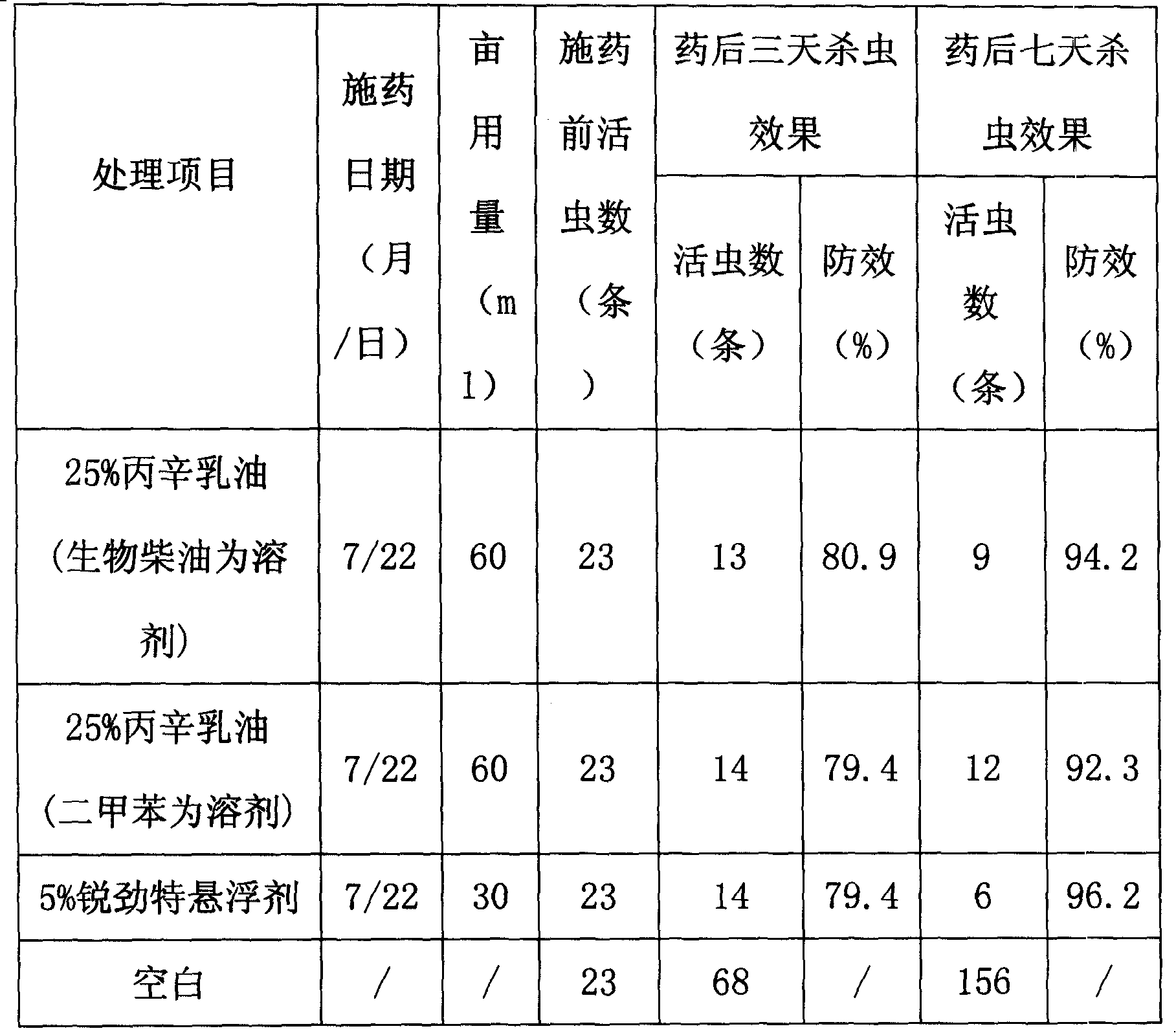

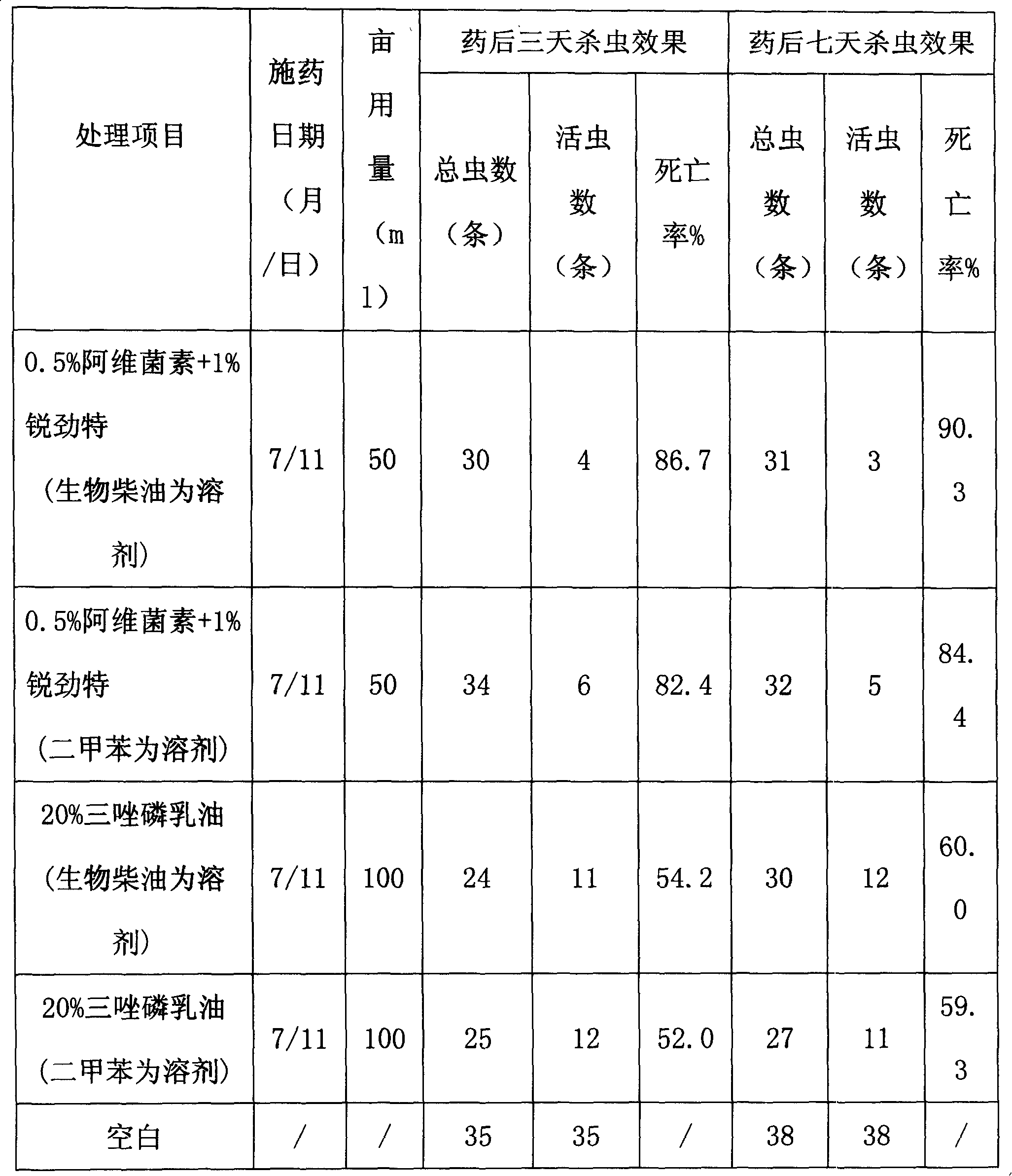

Pesticide missible oil preparation containing biological diesel oil solvent

InactiveCN101194606AImprove low temperature fluidityWide application areaBiocideAnimal repellantsBiodieselAdditive ingredient

The invention relates to an agricultural chemical missible oil preparation with biological diesel oil dissolvent, the ingredient comprises agricultural chemical original raw pesticide, dissolvent, and emulsifying agent, wherein the dissolvent is biological diesel oil or is mixed dissolvent which is mixed by biological diesel oil and conventional agricultural chemical in any proportion. The invention uses biological diesel oil as dissolvent to replace or partially replace conventional dissolvent in the prior art, which has the advantages of high efficiency, safety, environmental protection, and low toxicity, and can reduce the cost of agricultural chemical.

Owner:湖南万家丰科技有限公司

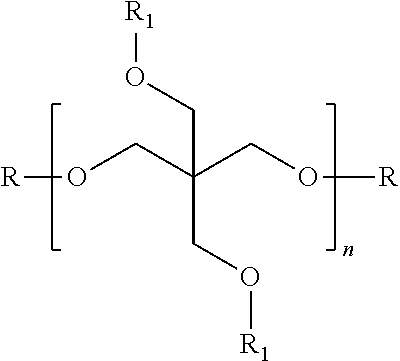

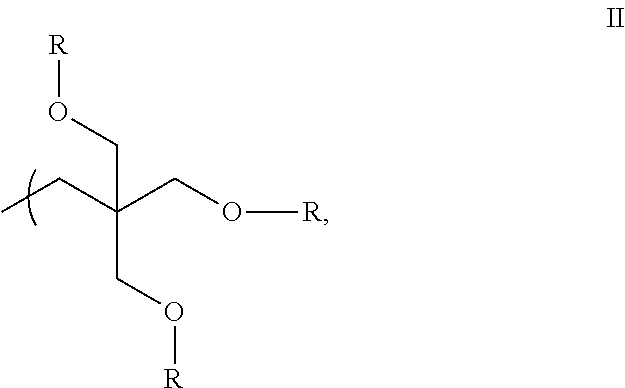

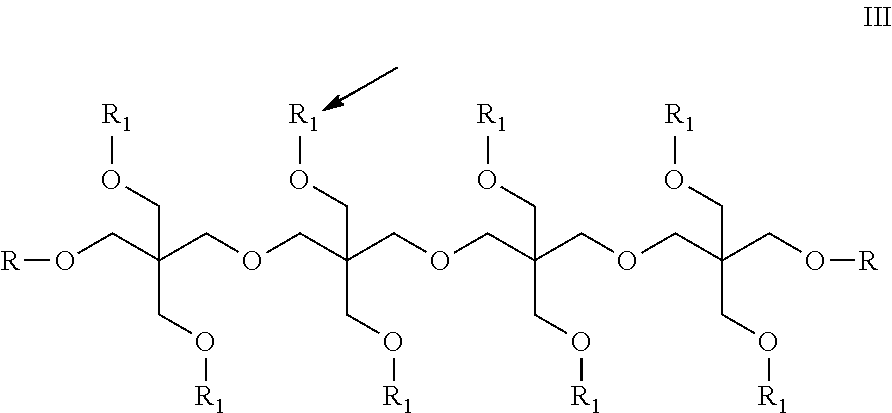

Refrigeration Oil and Compositions with Carbon Dioxide Refrigerant

ActiveUS20110240910A1High than expected CO miscibilityConducive to loadLiquid carbonaceous fuelsHeat-exchange elementsCarboxylic acidMonomer

Lubricant compositions comprising certain mixtures of esters of pentaerythritol, di-pentaerythritol, tri-pentaerythritol and higher pentaerythritol oligomers are ideally suited for use with CO2 as refrigerant in heat transfer devices provided that at least 30% by weight of the esters are esters of pentaerythritol oligomers containing 4 or more pentaerythritol monomer units and wherein a majority of the alkylcarboxylate groups are straight chain C3-6 alkanoyl groups, such as n-pentanoyl. Said mixture of alkylcarboxylate esters are shown to not only have higher than expected viscosity and exceptional CO2 miscibility, but also possess excellent lubricity, film building properties and load bearing properties even as part of a lubricant / CO2 solution.

Owner:LANXESS SOLUTIONS US INC

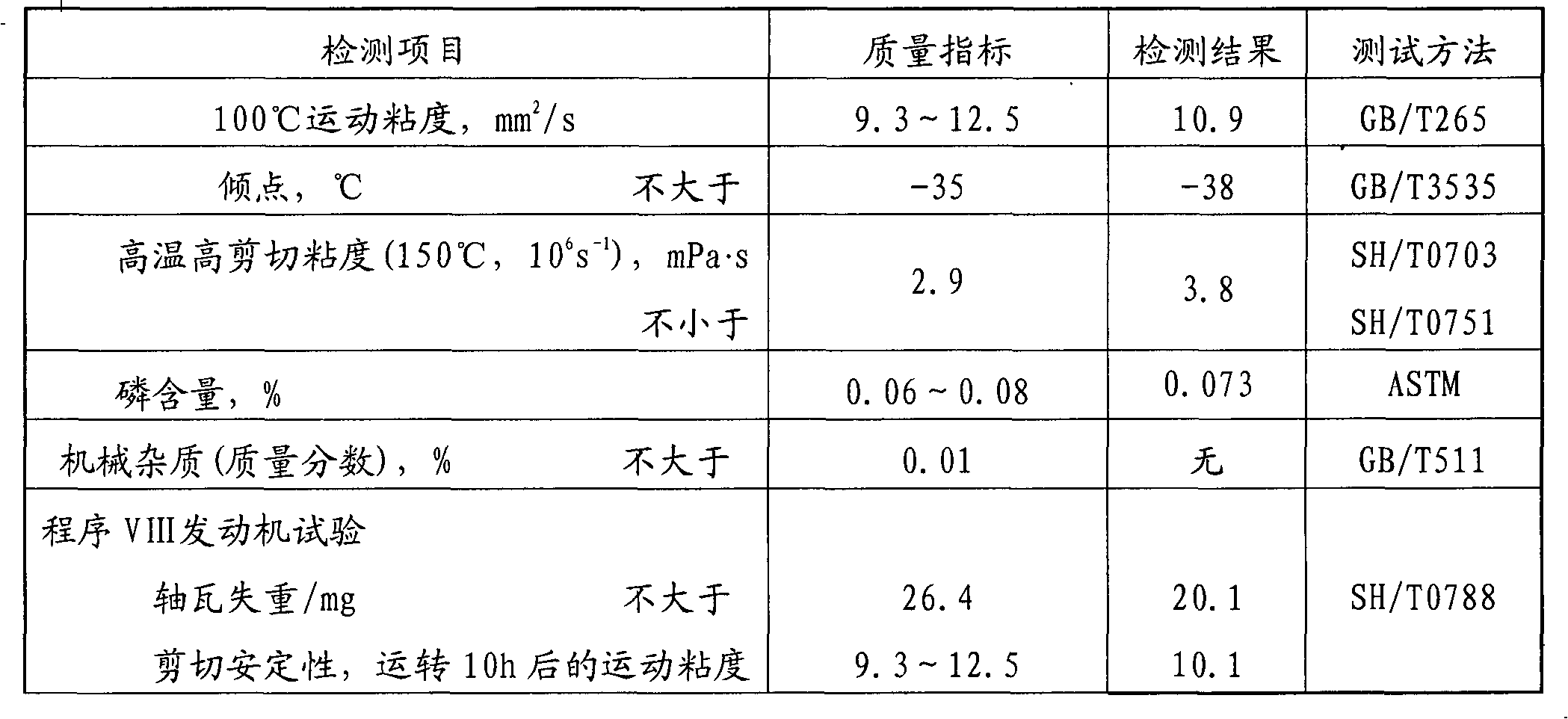

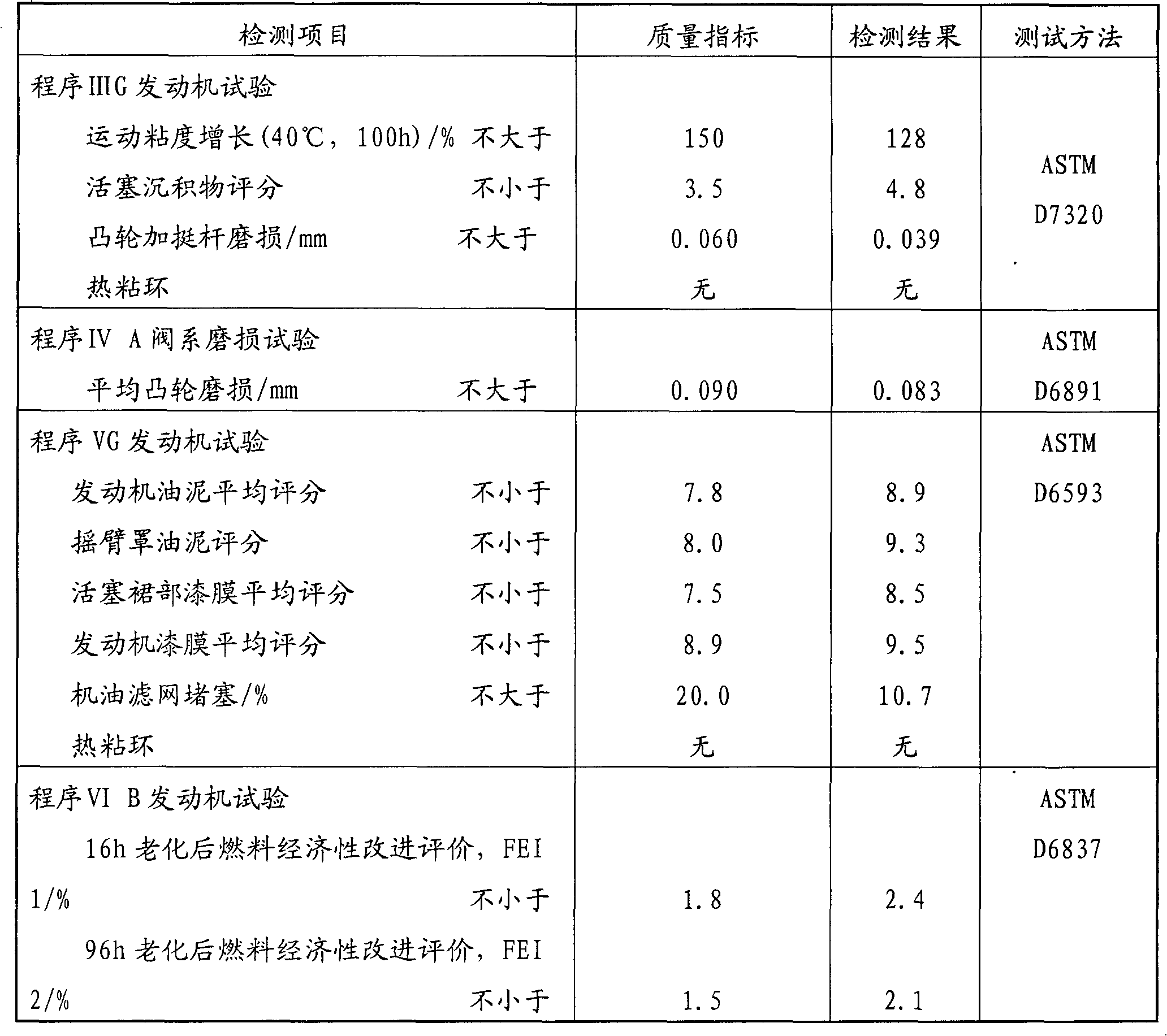

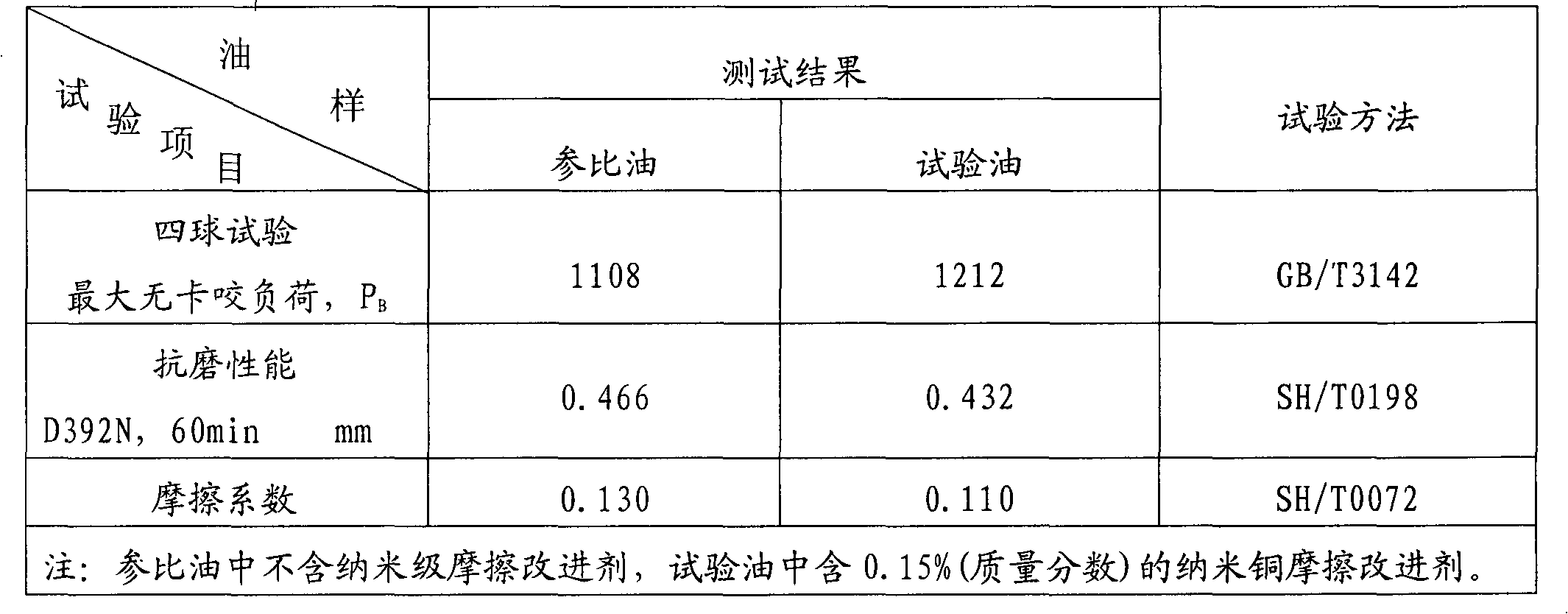

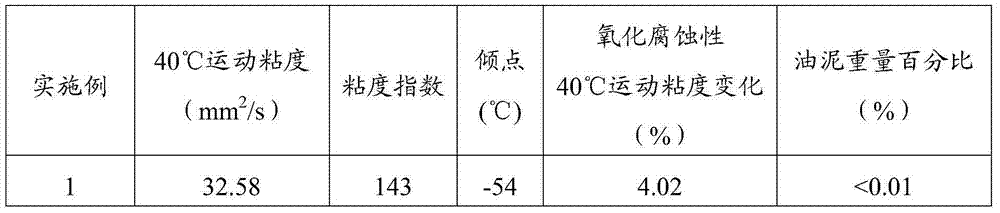

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

Compositions and processes for nanoimprinting

InactiveUS20080277826A1Mass productionImprove low temperature fluidityNanoinformaticsSynthetic resin layered productsResistNanoimprint lithography

The invention is directed to new nanoimprint resist and thin-film compositions for use in nanoimprinting lithography. The compositions permit economical high-throughput mass production, using nanoimprint processes, of patterns having sub-200 nm, and even sub-50 nm features.

Owner:CHOU +3

Method for improving low-temperature fluidity of lubricating oils using high-and low-molecular weight polymer additive mixtures

InactiveUS6458749B2Improve low temperature fluidityWide applicabilityLiquid carbonaceous fuelsBase-materialsMethacrylatePolymer science

A method for improving the low temperature fluidity of lubricating oil compositions based on addition to lubricating oils of a mixture of selected high molecular weight and low molecular weight alkyl (meth)acrylate copolymers is disclosed. Combinations of low molecular weight alkyl (meth)acrylate polymers containing zero to 25 weight percent (C16-C24)alkyl (meth)acrylate with high molecular weight alkyl (meth)acrylate polymers containing 25 to 70 weight percent (C16-C24)alkyl (meth)acrylate are especially effective at satisfying different aspects of low temperature fluidity properties simultaneously for a broad range of base oils.

Owner:EVONIK ROHMAX ADDITIVES GMBH

High-temperature chain oil and preparation method thereof

InactiveCN101117609AHigh temperature thermal oxidation performanceReduce evaporation lossAdditivesPentaerythritolEvaporation

The present invention discloses high temperature chain oil, the components and the contents are: high temperature antioxygen 1 to 5 percent, extreme pressure / anti-wear agent 1 to 10 percent, corrosion inhibitor 0.01 to 0.5 percent, and high temperature detergent dispersant 1 to 20 percent, the rest is base oil; the components and the contents of the base oil (weight ratio) are: dipentaerythritol ester 50 to 90 percent, and aromatic ester 10 to 50 percent. The preparation is as follows: the dipentaerythritol ester and the aromatic ester are mixed together according to the above ratio to prepare the base oil, a certain volume of the high temperature antioxygen, the extreme pressure anti-wear agent, the high temperature detergent dispersant and the corrosion inhibitor is added into the base oil, then the base oil is heated to 80 to 100 DEG C, and is agitated at the constant temperature for 0.5 to 1 hour, and is filtrated, thus the product is got. The present invention is characterized in that the coking volume can be obviously reduced, the anti-high temperature coking performance and the high temperature detergency performance can be improved, the product can be used under the 280 DEG C high temperature condition, the evaporation loss is little, and the coking volume is little, the lubrication performance and the high temperature detergency and dispersing performance is good.

Owner:中国石油天然气股份有限公司大连润滑油研究开发中心

Air compressor oil and preparation method thereof

InactiveCN104263481AGuaranteed safe operationAvoid cloggingLubricant compositionGas compressorAntioxidant

The invention provides air compressor oil which comprises the following components in parts by weight: 75-94 parts of synthetic hydrocarbon base oil, 5-20 parts of synthetic ester base oil and 1-5 parts of functional additive, wherein the functional additive comprises a purification dispersant, an antiwear agent, a metal deactivator, an antirust agent, an antioxidant, a pour point depressant, a demulsifying agent and an anti-foaming agent. The invention provides a preparation method of the air compressor oil. The preparation method comprises the step of mixing the synthetic hydrocarbon base oil, the synthetic ester base oil and the functional additive at the temperature of 60-80DEG C to obtain the air compressor oil. According to the air compressor oil provided by the invention, the synthetic oil is used as the base oil and the compound type functional additive is added, so that the air compressor oil provided by the invention has low oil sludge property. In addition, the air compressor oil provided by the invention also has the advantages of better thermal oxidation stability, low-temperature fluidity and higher viscosity index, and the use requirement of an air compressor is met.

Owner:CHINA PETROLEUM & CHEM CORP

Fuel oil base and aviation fuel composition containing same

ActiveUS20140323777A1Excellent life cycle COImprove low temperature fluidityRefining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsAlkaneVegetable oil

The aviation fuel oil base of the present invention is obtained by hydrotreating an oil to be treated containing an oxygen-containing hydrocarbon compound derived from an animal or vegetable oils and fat and a sulfur-containing hydrocarbon compound and then hydroisomerizing the resultant hydrotreated oil, wherein a yield of a fraction having a boiling range of 140 to 300° C. is 70 mass % or more; an isoparaffin content is 80 mass % or more; a content of isoparaffin having 2 or more branches is 17 mass % or more; an aromatic content is less than 0.1 vol %; an olefin content is less than 0.1 vol %; a sulfur content is less than 1 mass ppm; and an oxygen content is less than 0.1 mass %.

Owner:JX NIPPON OIL & ENERGY CORP

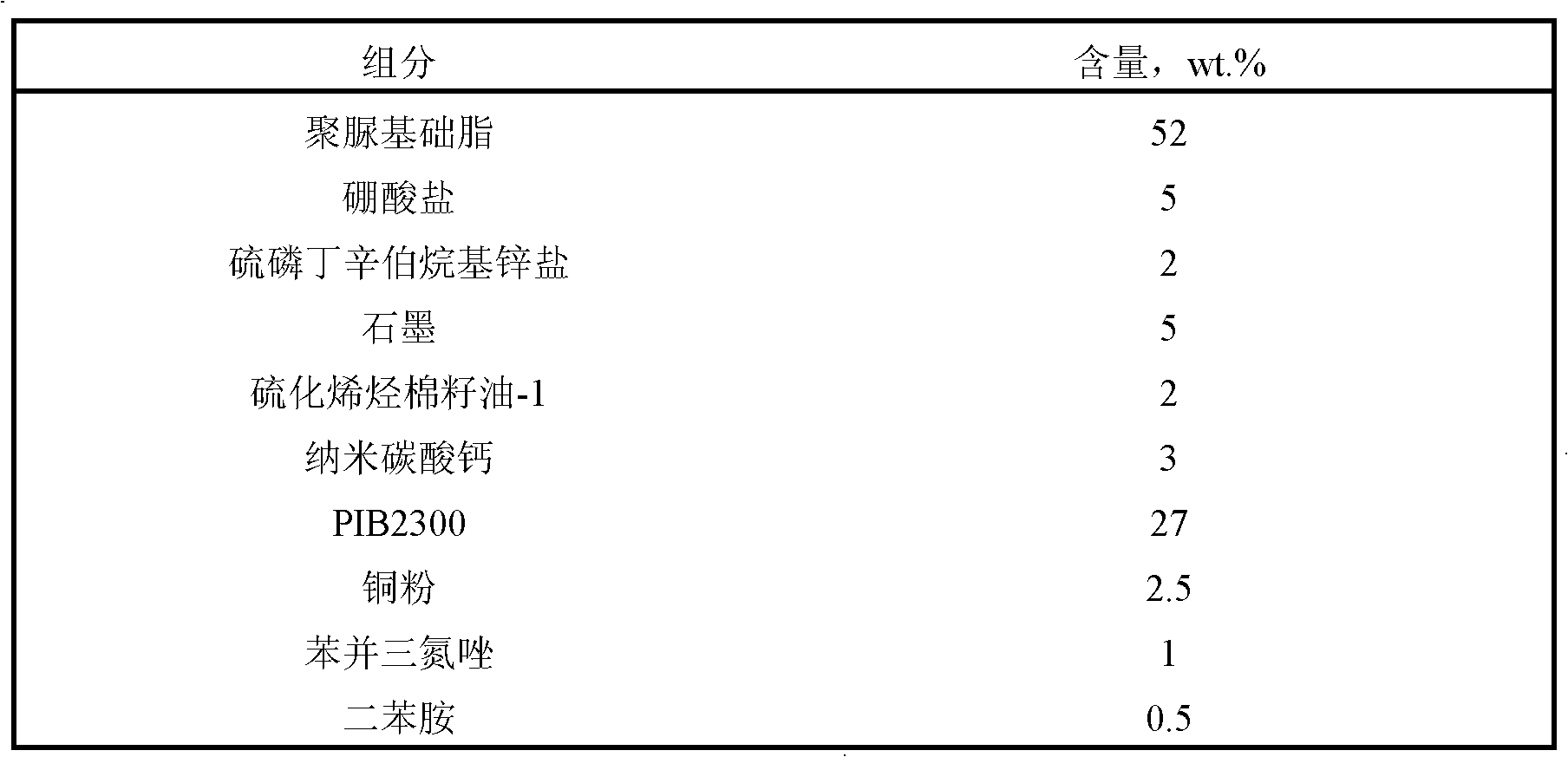

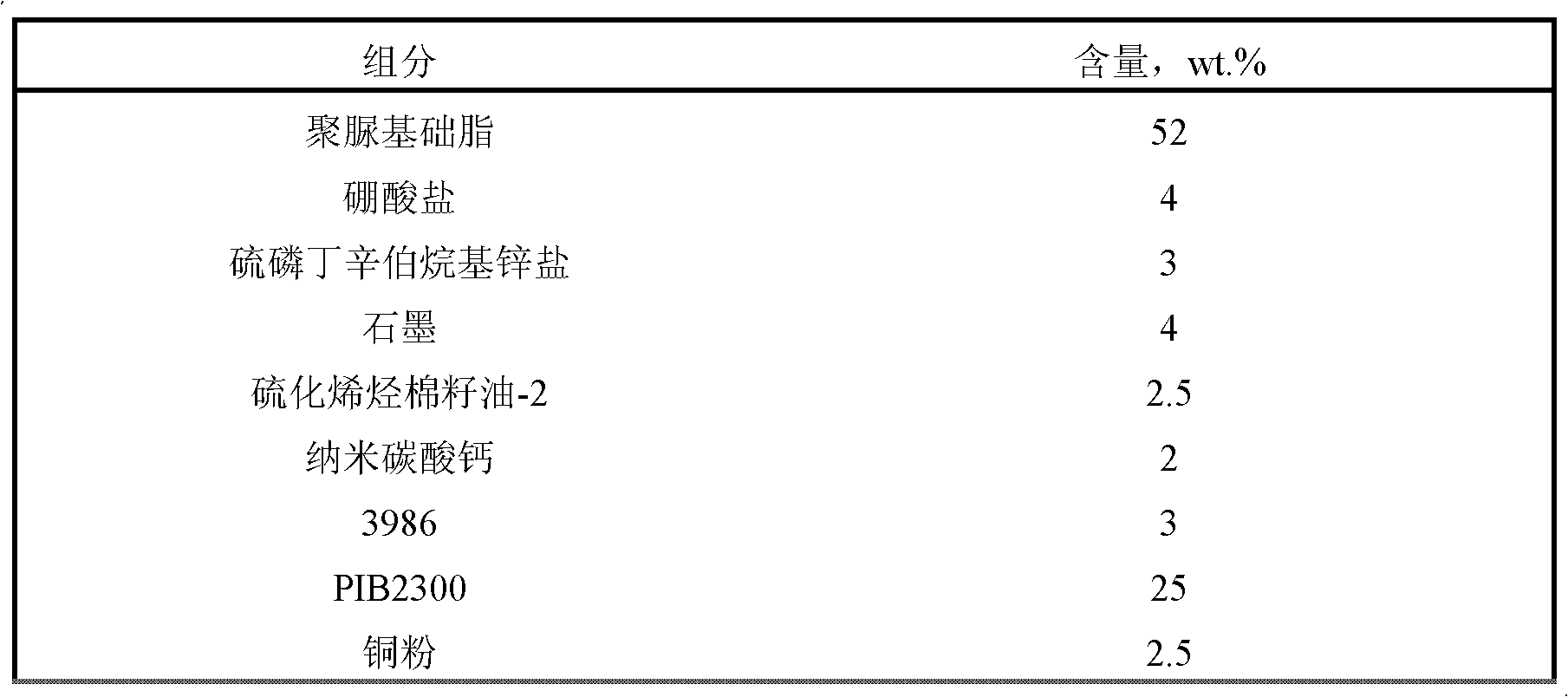

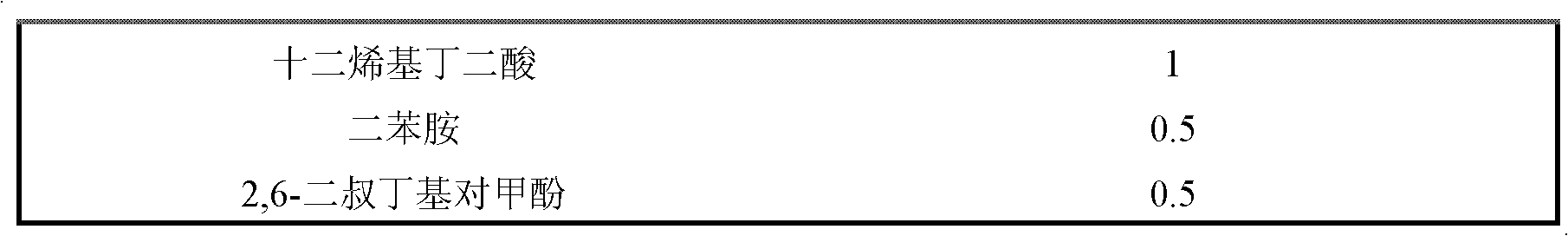

Heavy-duty self-repairing open gear grease

The invention discloses a clean-type heavy-duty open gear grease with self-repairing function. The product is composed of a lubricating grease base grease prepared from an organic compound thickening mineral oil containing carbamido in molecules or synthetic oil, and additives. A base grease thickener is composed of an MDI and organic amine in a molar ratio of 1:1-3; and the base oil is mineral oil or poly alpha olefin synthetic oil. The heavy-duty open gear grease comprises the following components, calculated by the weight of the base grease: 50-60wt% of base grease, 4-8wt% of a extreme pressure antiwear agent, 1-4wt% of an oily agent, 6-8wt% of a solid additive, 0.5-1.5wt% of an antirust agent, 25-35wt% of a tackifier, 2-4wt% of a self-repairing additive, and 0.3-1.0wt% of an antioxidant. The invention adopts borate as the extreme pressure antiwear agent added with an extreme pressure agent containing a small amount of sulfur phosphorus, so as to improve the extreme pressure anti-wear performance of the lubricating grease, as well as realize low toxicity, tastelessness and environment-friendliness of the grease. Besides, soft metal Cu nanoparticles employed by the invention endow good self-repairing performance on the grease. Compared with a traditional open gear lubricant product, the heavy-duty open gear grease provided by the invention has characteristics of excellent lubrication performance, self repairing, tastelessness and environment-friendliness, and can be widely used for lubricating of open gears.

Owner:PETROCHINA CO LTD

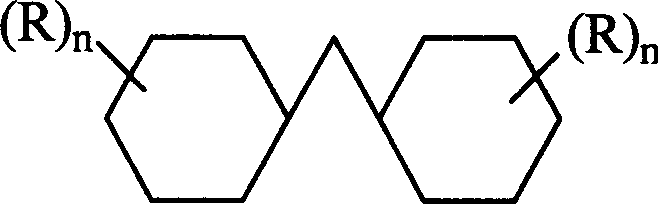

Transmission liquid composition for stepless speed gear

ActiveCN101007982AHigh viscosity indexHigh traction coefficientAdditivesAlkaline earth metalAlicyclic Hydrocarbons

The invention provides a stepless variable device transmission fluide compound. It comprises following components with their percentage on base oil weight: (1) bicyclo alicyclic hydrocarbon base oil, (2) alkali metal salt detersive, 0.05- 3%, (3) ashless dispersant 1- 15%, (4) phenol or amine anti- oxidant, 0.01- 1%, (5) antiwear agent, 0.05- 2%, (6) friction improver. 0.05- 3%, (7) viscosity index improver, 0-20%, (8) antifoam agent, 0- 1000ppm. The transmission fluide is characterized by good viscosity-temperature characteristic and low- temperature flowability, high drag coefficient at normal temperature, good comprehensive performance, and satification for CVT use requirement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving low-temperature fluidity of lubricating oils using high-and-low-molecular weight polymer additive mixtures

InactiveUS20010056044A1Low-temperature fluidity be improveLow temperature fluidityLiquid carbonaceous fuelsBase-materialsMeth-Methacrylate

A method for improving the low temperature fluidity of lubricating oil compositions based on addition to lubricating oils of a mixture of selected high molecular weight and low molecular weight alkyl (meth)acrylate copolymers is disclosed. Combinations of low molecular weight alkyl (meth)acrylate polymers containing zero to 25 weight percent (C16-C24)alkyl (meth)acrylate with high molecular weight alkyl (meth)acrylate polymers containing 25 to 70 weight percent (C16-C24)alkyl (meth)acrylate are especially effective at satisfying different aspects of low temperature fluidity properties simultaneously for a broad range of base oils.

Owner:EVONIK ROHMAX ADDITIVES GMBH

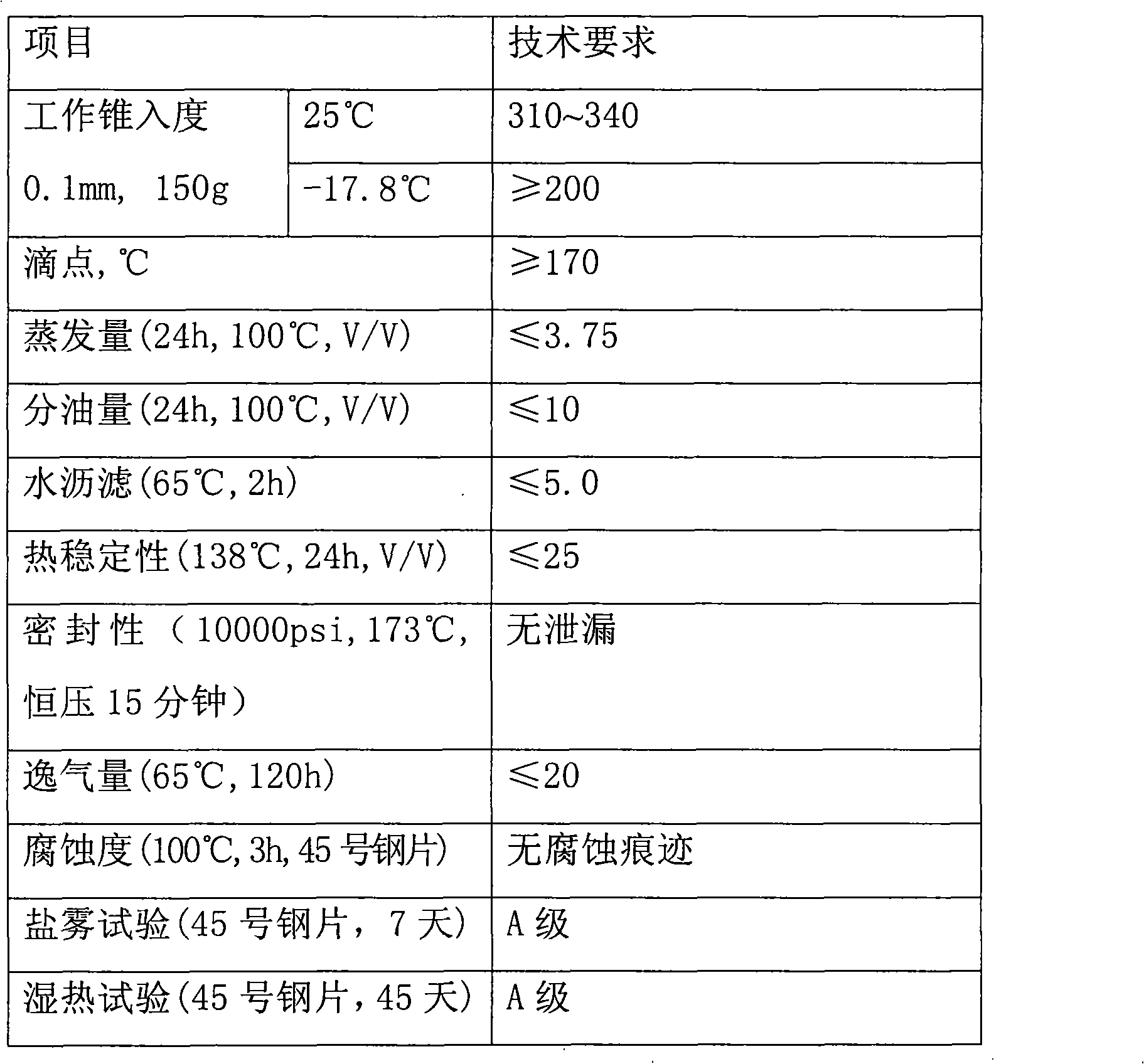

API oil sleeve thread sealing grease composite and preparation method thereof

ActiveCN101565648AImprove low temperature fluidityMechanical automatic spraying effect is goodOther chemical processesAdditivesWear resistantPetroleum

The invention provides an API oil sleeve thread sealing grease composite. The components of the composite include 40-50 percent of basic grease, 5-10 percent of dimethyl silicon oil, 16.5-20 percent of crystalline graphite powder, 6-9 percent of polyfluortetraethylene, 0.5-1.0 percent of expansion graphite powder, 1-2 percent of white carbon black, 3-4 percent of sericite in powder, 3-4 percent oflight calcium carbonate and 10-15 percent of tin bronze powder according to the percentage accounting for in the weight of the sealing grease composite. The invention also provides a preparation method of the API oil sleeve thread sealing grease composite. The invention has the beneficial effects that among the components of the sealing grease composite, synthetic oil is taken as a substitute formineral oil, and therefore the low temperature fluidity of the basic grease is improved to facilitate the brush application in winter. The addition of high performance antirust to the basic grease ensures that pipe threading does not rust when oil sleeves and pipes are stored outside in long term. Without zinc powder added but with the consumption of copper powder increased and other wear-resistant materials added, the high temperature lubricity of the grease is guaranteed and the pipe threading of the oil sleeves and pipes is prevented from thread gluing when screwing together. With novel high efficiency sealing materials added in the components of the sealing grease composite, the leak tightness of the grease is guaranteed.

Owner:TIANJIN PIPE GROUP CORP

Lubricant composition

InactiveUS20090312211A1Low viscosityProlong lifeGroup 5/15 element organic compoundsLiquid carbonaceous fuelsOxidation stabilityViscosity index

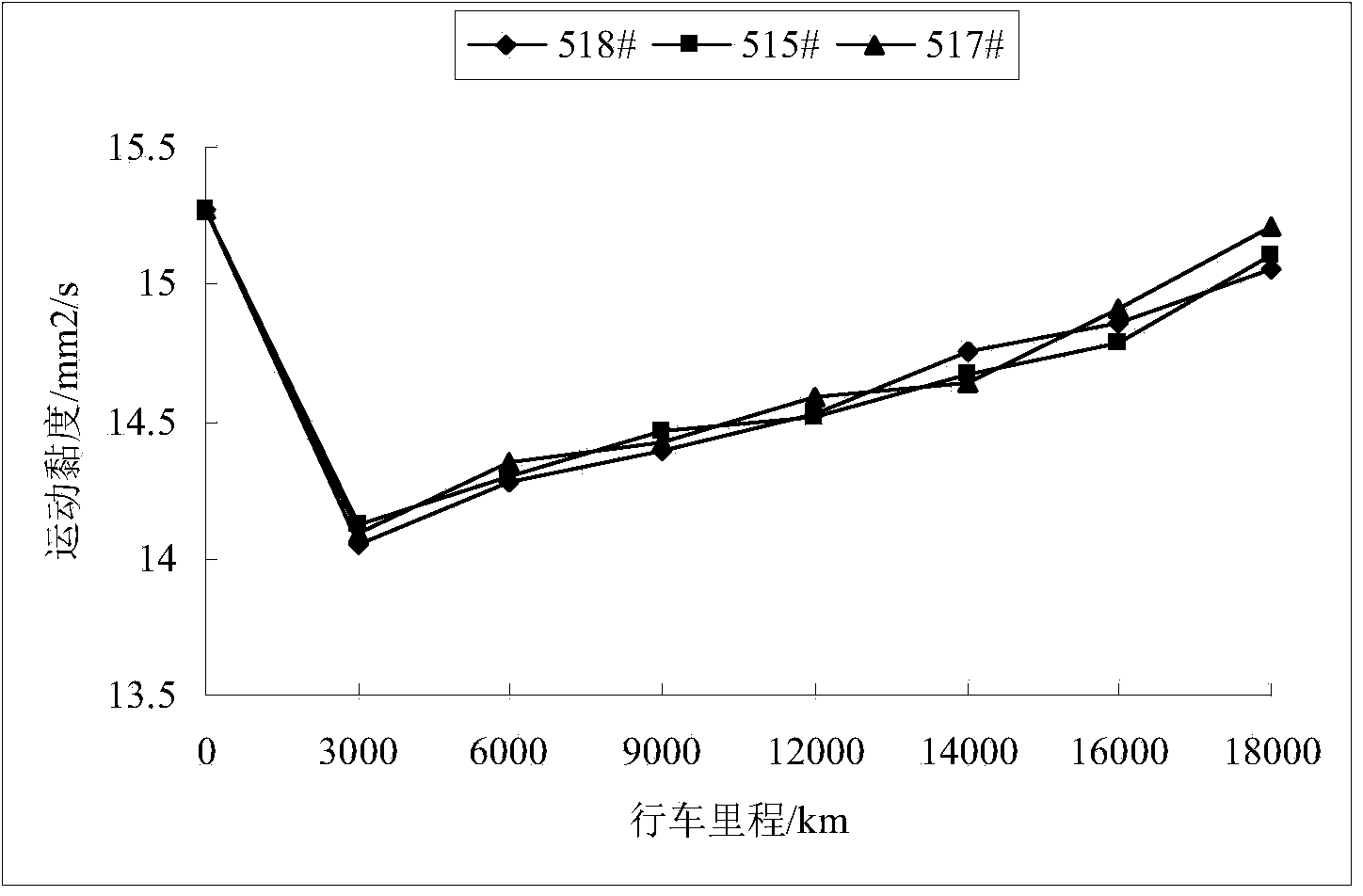

Provided is a lubricant composition containing a lubricant base oil and 0.5 to 10 mass % of (A) an ethylene / α-olefin copolymer having a number average molecular weight of 2,800 to 8,000, in which the lubricant base oil used here has a kinematic viscosity at 100° C. of 1.5 to 40 mm2 / s, a viscosity index of 100 or more, a pour point of −25° C. or lower, and a sulfur content of 0.01 mass % or less, and the lubricant composition has low viscosity and a long metal fatigue life, while being excellent in low-temperature fluidity and oxidation stability, thereby being particularly suitable as a lubricant for automobile transmissions or the like.

Owner:IDEMITSU KOSAN CO LTD

Special lubricating oil for fuel gas engine of public transport automobile

ActiveCN104342266AAntioxidant time is longImprove protectionLubricant compositionThiadiazolesPolyisobutylene succinimide

The invention discloses special lubricating oil for a fuel gas engine of a public transport automobile. The special lubricating oil is prepared from blended base oil, binary ethylene-propylene rubber, polymethacrylate, alkylphenol calcium sulfide, high-base-number calcium alkylbenzenesulfonate, polyisobutylene succinimide, boronated polyisobutylene succinimide, alkylated phenyl-alpha-naphthylamine, p,p'-dioctyl diphenylamine, a hindered phenol type antioxidant, dialkyl molybdenum dithiocarbamate, copper nanoparticle anti-wear additives, methyl silicone oil and thiadiazole polysulfide. According to the lubricating oil composition oil product, the sulfate ash content is lower than 0.5%, the content of phosphorus is lower than 0.03%, and the base number is 3-8mgKOH / g. According to the special lubricating oil for the fuel gas engine of the public transport automobile, aiming at the special requirements of the public transport automobile on engine oil, different additive varieties and charging sequences are adopted, so that physical and chemical indicators and use performance of the special lubricating oil are better than natural gas engine lubricating oil of the same grade, and the special lubricating oil has excellent cleaning and dispersion properties, lubricating property, abrasion resistance and oxidation resistance.

Owner:陕西通用润滑科技有限公司

Lubricant composition

InactiveCN101495607AImprove fatigue lifeLow viscosityAdditivesBase-materialsOxidation stabilityViscosity index

Disclosed is a lubricant composition containing a lubricant base oil and 0.5-10% by mass of an ethylene / a-olefin copolymer (A) having a number average molecular weight of 2,800-8,000. A lubricant base oil having a kinematic viscosity at 100 DEG C of 1.5-40 mm / s, a viscosity index of not less than 100, a pour point of not more than -25 DEG C, and a sulfur content of not more than 0.01% by mass is used in this lubricant composition. This lubricant composition has low viscosity and long metal fatigue life, while being excellent in low-temperature fluidity and oxidation stability. Consequently, this lubricant composition is particularly useful as a lubricant for automobile transmissions or the like.

Owner:IDEMITSU KOSAN CO LTD

Coagulation-reducing viscosity-reducing agent for high-coagulation thickened oil

ActiveCN102618243AReduce viscosityGood depressing effectFluid removalDrilling compositionPolyacrylamideSODIUM DODECYL BENZENE SULFONATE

The invention relates to a coagulation-reducing viscosity-reducing agent for high-coagulation thickened oil. By weight percentage, the coagulation-reducing viscosity-reducing agent for the high-coagulation thickened oil comprises the following materials: 0.1% to 0.2% of anion polyacrylamide, 5% to 10% of sodium acrylate-setanol acrylate copolymer, 5% to 15% of sodium dodecyl benzene sulfonate, 1%to 2% of mixture of hexafluoropropylene oxide dipolymer amide sulphobetaine and hexafluoropropylene oxide dipolymer amide amine oxide, 1% to 2% of sodium hydroxide and the balance water. The coagulation-reducing viscosity-reducing agent can disperse high-coagulation thickened crude oil, reduces the freezing point of the crude oil to above 0 DEG C and enables the viscosity of the crude oil to be smaller than 300mPa*s at the normal temperature. The using concentration of the coagulation-reducing viscosity-reducing agent can be controlled at 0.1% to 0.5%, is lower by one magnitude order than that (3% to 7%) of a traditional surfactant, is not limited by hydrophile-lipophile balance values and phase inversion temperature (PIT) and can emulsify the high-coagulation thickened oil at the temperature above the freezing point of the crude oil.

Owner:PETROCHINA CO LTD

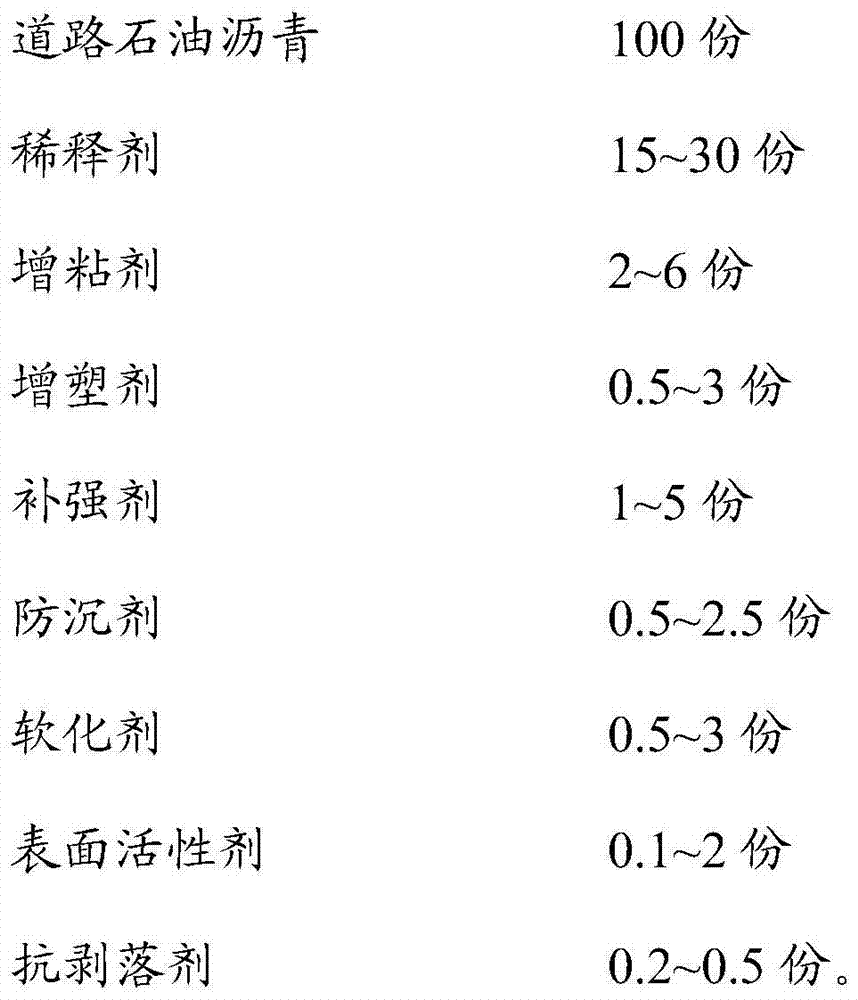

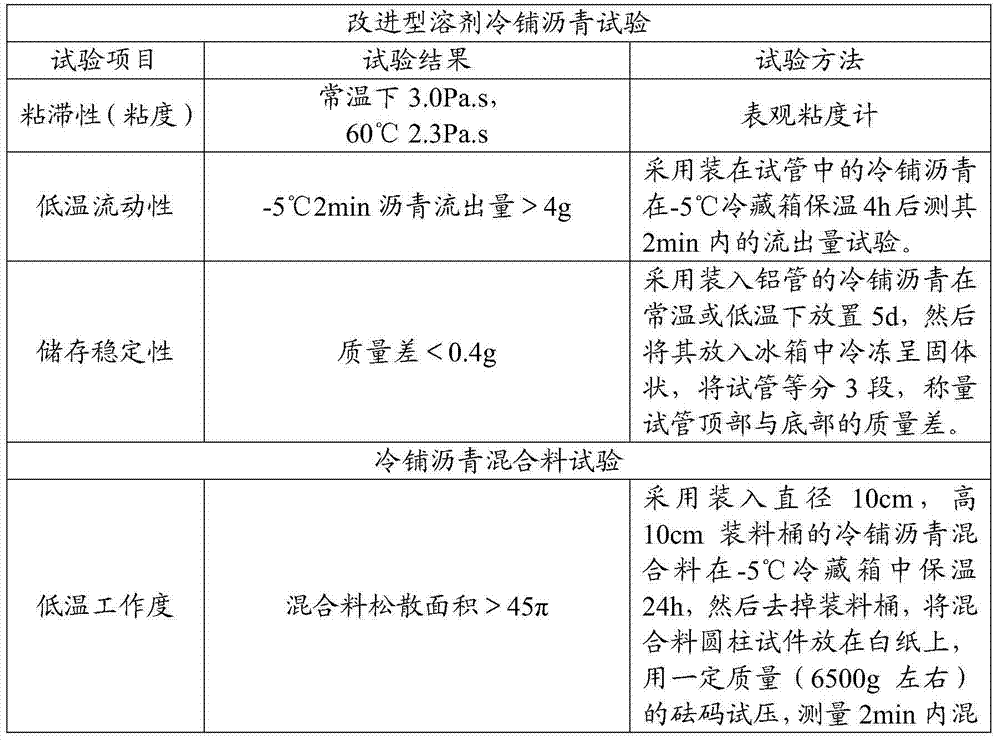

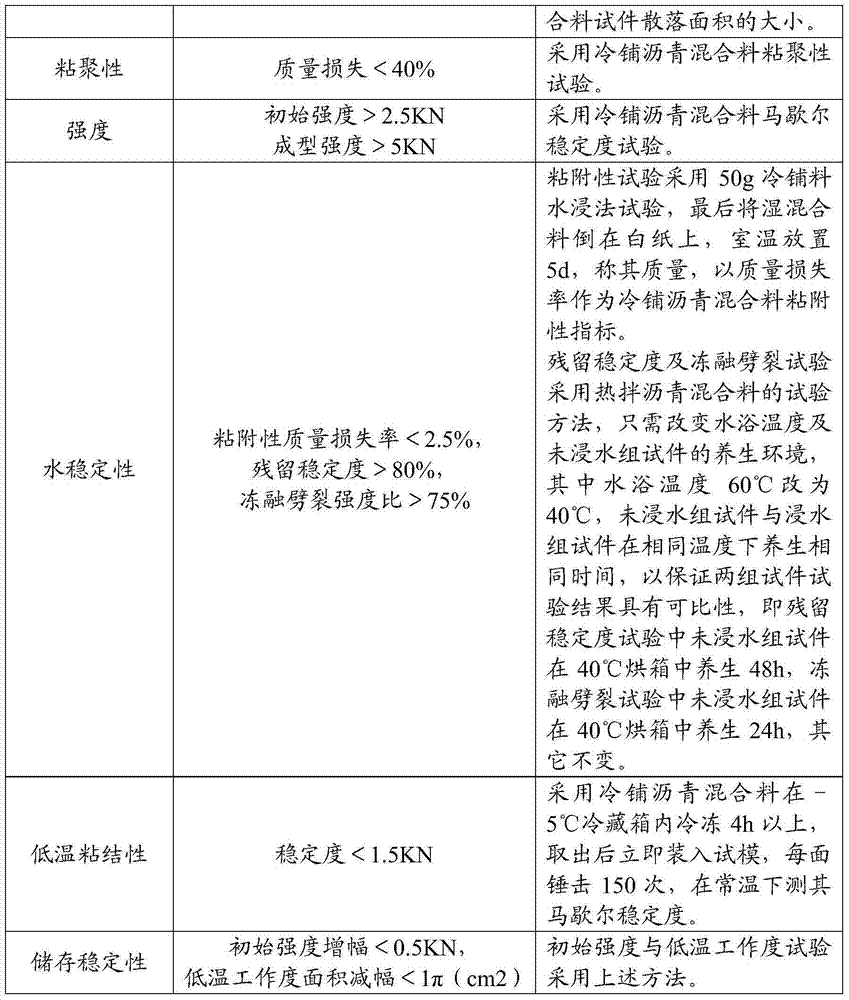

Improved solvent cold laid asphalt as well as preparation process and using method thereof

InactiveCN103923475AImprove adhesionImprove liquidityIn situ pavingsBuilding insulationsLiquid stateEngineering

The invention discloses an improved solvent cold laid asphalt as well as a preparation process and using method thereof. The improved solvent cold laid asphalt is at a liquid state under normal temperature or low temperature; cold oil and cold materials can be directly blended for construction on the spot without heating, and the construction can be carried out at high / low temperature seasons and rain / snow weather, and a large number of machinery and labor are not required in the construction process, the construction is simple and convenient and the repair effect is good; traffic can be immediately opened after repair without affecting the travel of people; the improved solvent cold laid asphalt is usually used for daily maintenance, such as pot slot repair and emergency repair; meanwhile, the improved solvent cold laid asphalt has the advantages of no deterioration, no layering and the like after being stored for a long time.

Owner:CHANGAN UNIV

Diesel fuel pour-point depressant dispersant and preparation method thereof

ActiveCN101709233AIncreased sensitivityImprove pour point depressing effectLiquid carbonaceous fuelsFuel additivesPolyethylene glycolDepressant

The invention discloses a diesel fuel pour-point depressant dispersant and a preparation method thereof. The dispersant comprises the following components by weight percentage: 0-20% of Tween, 0-20% of polyethylene glycol, 0-10% of vinyl alcohol butyl ether, 0-10% of polar nitrogenous compounds and 50-80% of Span-80. The raw materials are weighed and mixed according to the weight percentage, and then the materials are stirred in a stirring tank with the speed of 100rpm for 30 min at the temperature of 50 DEG C, and the dispersant is prepared. In the invention, a new dispersant mixture is prepared by combining and mixing various kinds of dispersants uniformly, and then is used with the pour-point depressant according to a certain proportion, thereby improving the sensitivity of the pour-point depressant and the effect of pour point depression.

Owner:SHANGHAI INST OF TECH

Anti-wear energy-saving engine lubricating oil

InactiveCN103923728AHigh viscosityImprove low temperature fluidityAdditivesThermodynamicsProcess engineering

The invention relates to anti-wear energy-saving engine lubricating oil, which comprises basic oil and an additive serving as raw materials, wherein the basic oil is hydrogenated isodewaxed III type basic oil; the additive is an anti-wear agent MODDP, namely, molybdenum dialkyldithiophosphate. The complex system has a good synergistic effect, so that the wear reduction, anti-wear, carbon deposit reduction, oil sludge dispersion and anti-wear energy-saving effects become more remarkable. Under the condition of high temperature and high pressure, MODDP is decomposed to form an MoS2 protective film, and meanwhile a novel metal produced by friction undergoes a friction chemical reaction to generate FePO4 and FeS reaction films, so that unique 'anti-wear, repair, energy-saving and environmental protection' effects are achieved on an engine, remarkable repairing and maintaining functions are realized, and the service lives of equipment such as engines are prolonged; equipment such as engines is protected, and the worn inner cylinder wall of equipment can be repaired automatically; a cylinder body can be kept clean, continuous protection is provided, and the service life is prolonged.

Owner:山东力牌石油化学有限公司

Oil-based viscosity reducer for raw oil conveyed through pipeline

ActiveCN101845187AIncrease polarityReduce associationPipeline systemsChemical industryDiethylenetriamine

The invention relates to high molecular synthesis technology, in particular to an oil-based viscosity reducer for raw oil conveyed through a pipeline, and belongs to the technical field of chemical industry. The oil-based viscosity reducer is mainly used for reducing the viscosity of the raw oil conveyed through a long-distance pipeline and is prepared by the following steps of: synthesizing terpolymer by using higher alcohol acrylate, maleic anhydride and acrylamide in a molar ratio of 20-70 percent to 10-50 percent to 10-50 percent; synthesizing amide by using oleic acid and diethylenetriamine in a molar ratio of 20-80 percent to 20-80 percent; heating and uniformly mixing ethylene vinyl acetate copolymer, terpolymer, amide and another surfactant in a molar ratio of 0-80 percent to 0-80 percent to 5-60 percent to 5-60 percent in a compounding mode; and then cooling the obtained product and crushing the product into grains to obtain the oil-based viscosity reducer product.

Owner:CHINA PETROLEUM & CHEM CORP +2

Process for synthesizing pentaerythritol oleate

InactiveCN1381437ASimple processLess side effectsOrganic compound preparationCarboxylic acid esters preparationOrganic acidPentaerythritol

A process for synthesizing pentaerythritol oleate from pentaerythritol and oleic acid as raw materials includes dewatering condensation reaction under the action of organic acid as catalyst and removing residual acid under 20-100 Pa to obtain the pentaerythritol oleate. Its advantages are simple process, little by-reaction, low cost and high output rate. The said product has good high-temp. resistance, good lubricating performance, excellent viscosity-temp. characteristic and low-temp. flowability.

Owner:王伟松

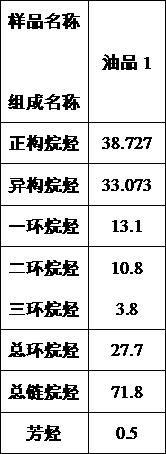

Synthetic base drilling fluid base oil

InactiveCN105505347ALow aromatic contentPromote degradationDrilling compositionCyclic alkanePhysical chemistry

The invention relates to a base oil used during drilling operation, wherein the base oil is a synthetic base drilling fluid base oil with characteristics of environmental protection, low toxicity, high safety and low-temperature fluidity. According to the present invention, the synthetic base drilling fluid base oil is formed by mixing Fischer-Tropsch synthetic oil and non-conventional petroleum-derived fine chemical base oil, and contains at least 35% by mass of a variety of C9-C20 n-alkanes, at least 60% by mass of a variety of C9-C20 branched or cyclic alkanes, and less than 0.5% by mass of aromatic hydrocarbon, the kinematic viscosity of the synthetic base drilling fluid base oil at the temperature of 40 DEG C is 2-3 mm<2> / s, the pour point is -10 to -30 DEG C, and the flash point is 50-80 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

Open type gear lubricating grease

ActiveCN1970706AIncrease stickinessImprove comprehensive wear indexAdditivesBase-materialsSolventAgricultural engineering

The invention discloses a solvent-diluted open-typed gear lubricant, which is characterized by the following: the basic oil is high-viscosity synthesized oil; the thickener is composite calcium sulfonate; the additive is auxiliary extreme-pressure agent, anti-oxidant and diluent; the lucribant possesses superior high-low temperature adaptability (low-temperature fluidity and high-temperature adhesive), which is not easy to volatilize under normal temperature.

Owner:辽宁海华科技股份有限公司

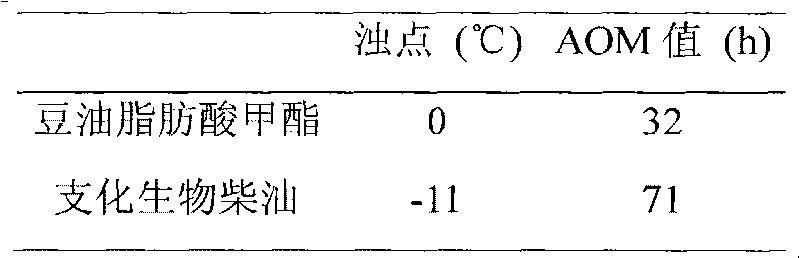

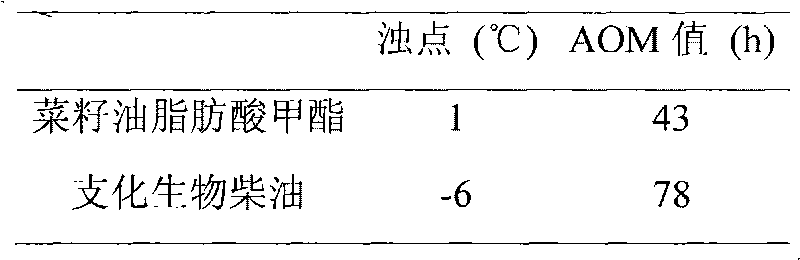

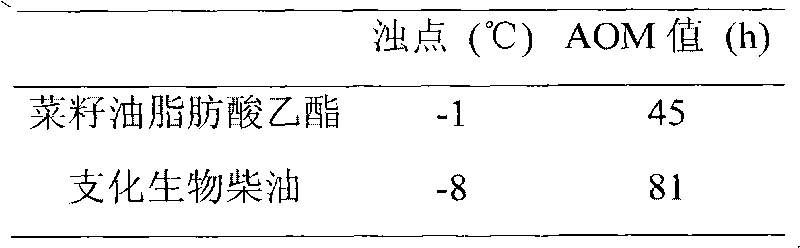

Method for producing branched biodiesel

InactiveCN101760328AImprove oxidation stabilityImprove low temperature fluidityFatty acid isomerisationBiofuelsProcess equipmentBiodiesel

The invention relates to a method for producing branched biodiesel, which belongs to the technical field of new energy production. The method is characterized in that the method adopts two steps of reaction to convert biodiesel into branched biodiesel. In the epoxidation process, biodiesel is mixed with formic acid, stirred and heated, the mixture of catalyst and hydrogen peroxide is dripped, reacted mixture is transferred into a separating funnel after reaction is finished, the upper layer of liquid is taken and washed by water until becoming neutral, and thereby epoxidized biodiesel is obtained; in the ring-opening reaction, the epoxidized biodiesel is mixed with fatty alcohol, added with catalyst and stirred for reaction, 5 percent of Na2CO3 is added, mixture is washed and then poured into the separating funnel, so that an ester layer is separated out, and after low-boiling point components are evaporated, the branched biodiesel is obtained. The invention improves the oxidative stability and low-temperature fluidity of biodiesel at the same time, has the advantages of low requirement on processing equipment, simple operation, mild reaction condition and the like, and is suitable for industrialized mass production.

Owner:DALIAN UNIV OF TECH

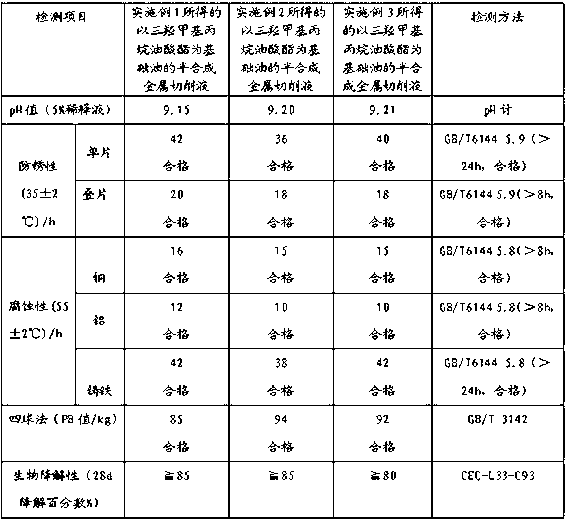

Semisynthetic metal cutting fluid with trimethylolpropane oleate serving as base oil and preparation method of semisynthetic metal cutting fluid

The invention discloses semisynthetic metal cutting fluid with trimethylolpropane oleate serving as base oil and a preparation method of the semisynthetic metal cutting fluid. The semisynthetic metal cutting fluid comprises the trimethylolpropane oleate, nonionic surfactants, anionic surfactants, antirust agents, cosolvents, extreme pressure agents, defoaming agents, bacteriacide and water. The preparation method of the semisynthetic metal cutting fluid includes: adding the extreme pressure agents into the base oil with uniform stirring so that solution A is obtained; then sequentially adding the defoaming agents, the antirust agents, the cosolvents and the bacteriacide into the water with uniform stirring so that solution B is obtained; and mixing the solution A with the solution B, and stirring while slowly dropwise adding the nonionic surfactants and the anionic surfactants so that a homogeneous and clarified micro-emulsion system, namely, the semisynthetic metal cutting fluid with the trimethylolpropane oleate serving as the base oil is obtained finally. The semisynthetic metal cutting fluid has good lubricity and biological degradability, has low-toxicity and low-harm to human bodies and the environment and is suitable for metal machining of most materials.

Owner:上海樱花化研化工科技有限公司

Open gear oil composition and preparation method thereof

ActiveCN106701284AExcellent anti-wear propertiesImprove carrying capacityLubricant compositionWater resistantMetal

The invention provides an open gear oil composition and a preparation method thereof. The open gear oil composition is prepared from 85.5-99.56%, preferably 90.9-98.37%, more preferably 92-96% of ester synthetic oil, 0.1-8%, preferably 1-6% of anti-wear reagent at extreme pressure, 0.03-3.0%, preferably 0.1-1.5% of oil-based antiabrasive agent, 0.01-0.5%, preferably 0.03-0.1% of metal deactivator and 0.3-3.0%, preferably 0.5-1.5% of antioxygen according to the total weight of the open gear oil composition being 100%. The open gear oil composition has good antiabrasive and abrasion-resistant performance, extremely high bearing capacity and high anti-rust and water-resistant performance, further has excellent low-temperature fluidity and high-temperature adhesion and excellent shear stability, and has the wide application range, and no oil is shed when the open gear oil composition is used for a long time.

Owner:埃优诺特种新材料科技(山东)有限公司

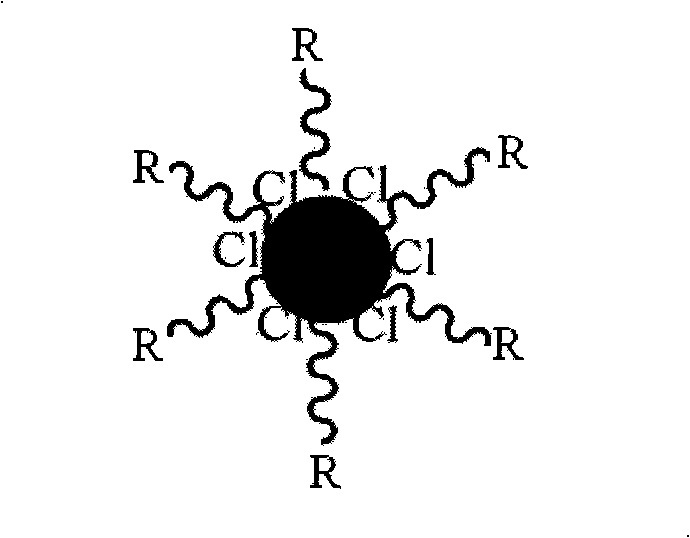

Star poly-(methyl)acrylate long-chain ester polymer and preparation method thereof

InactiveCN101691417AMelt strength adjustment and improvementHigh degree of polymerizationPolymer scienceAtom-transfer radical-polymerization

The invention discloses a star poly-(methyl)acrylate long-chain ester polymer and a preparation method thereof. In the method, through atom transferring radical polymerization, the poly-(methyl)acrylate long-chain ester polymer with a star molecular structure is synthesized in one step by using a simple and economical method of arm first and core later; and arm length and arm number are controlled by adjusting a ratio of a monomer (methyl) acrylates long-chain ester to a catalyst to a ligand, and the adding time and dosage of a crosslinking agent methylacrylic acid gylcol ester (EGDMA) during a polymerization reaction so as to obtain the star polymer with high yield, adjustable and controllable molecular weight, and narrow molecular weight distribution. The preparation method can synthesize the (methyl)acrylate long-chain ester star polymer of which the weight-average molecular weight reaches up to a million and the yield reaches over 85 percent, and has important significance for theory and practical application.

Owner:EAST CHINA UNIV OF SCI & TECH

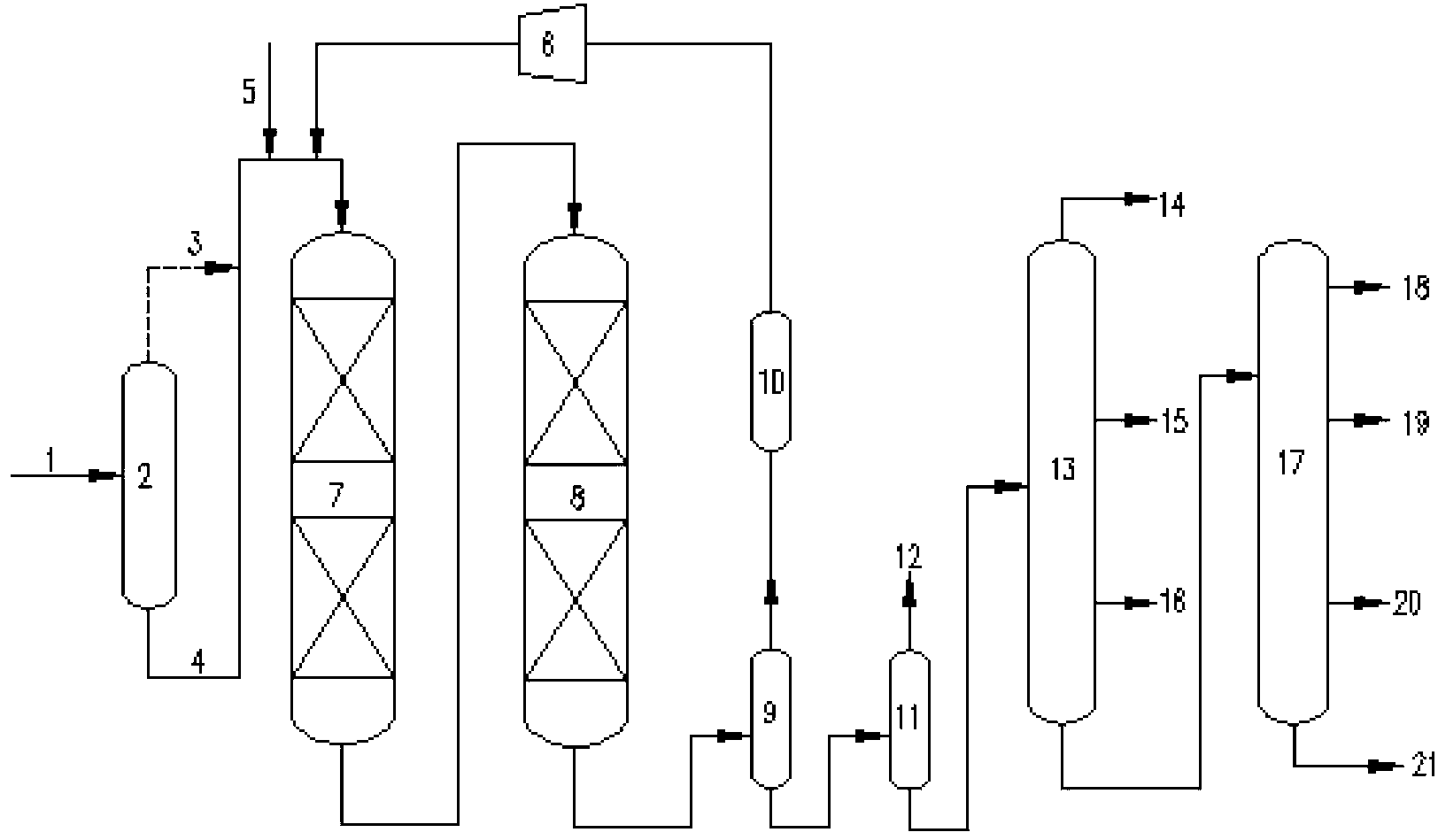

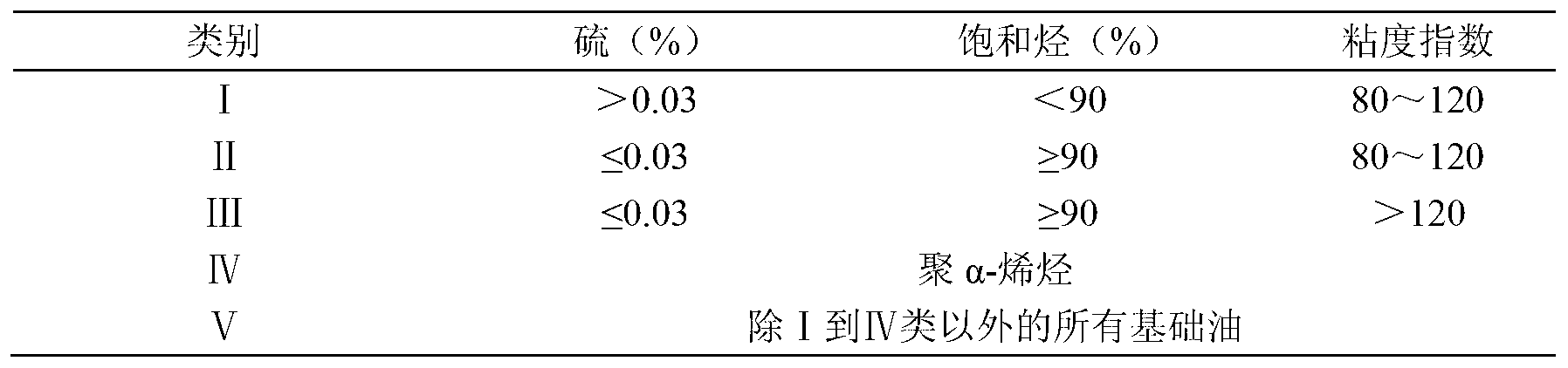

Method for producing high-grade lubricant base oil through hydrogenating of hydrocracking tail oil

ActiveCN103305267AHigh selectivityIncreased production flexibilityTreatment with hydrotreatment processesMixed feedingHydrogen

The invention discloses a method for producing high-grade lubricant base oil through hydrogenating of hydrocracking tail oil. The method comprises the steps of: by taking the hydrocracking tail oil as a raw material, firstly carrying out decompression pre-fractionation to obtain NO.4 base oil stock with final boiling point of less than or equal to 430 DEG C and NO.6 base oil stock with initial boiling point of more than 430 DEG C; leading in the NO.4 base oil stock and NO.6 base oil stock into an isodewaxing reactor and a supplementary refining reactor together with hydrogen by adopting a feeding switching mode or respective feeding mode, so as to carry out hydrogenation isodewaxing reaction and supplementary refining reaction, wherein the isodewaxing reactor and the supplementary refining reactor are connected in series; after reaction is finished, separating out gas from liquor to obtain a liquor phase, and fractionating the liquor phase to obtain the high-grade lubricant base oil. By adopting a method of switching or independently feeding plus mixed feeding, the selectivity of raw materials and the flexibility of production can be improved. The base oil produced can achieve the requirement of API II type and III type lubricant base oil, and the yield of the obtained API III base oil is high.

Owner:SINOPEC NANJING ENG & CONSTR +1

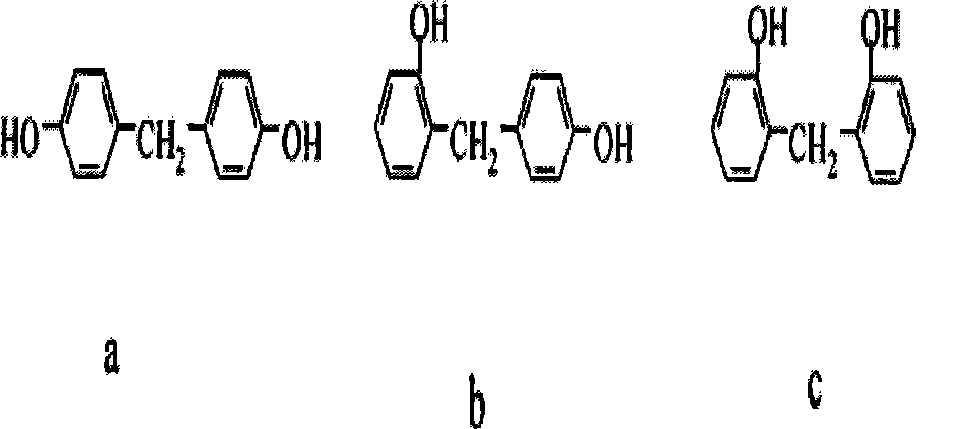

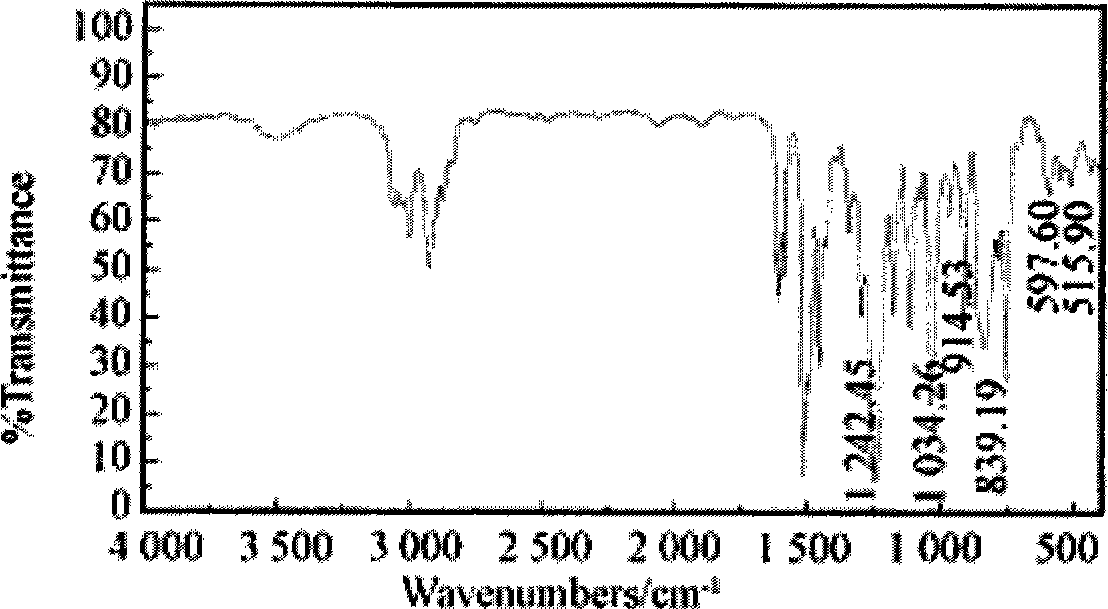

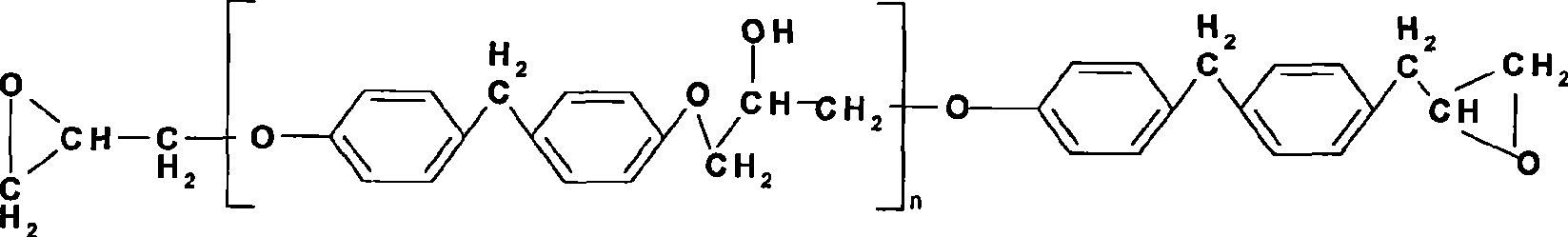

Process for producing wind electricity grade of bisphenol F epoxy resin

The invention provides a comprehensive preparation technology for preparing bisphenol F with high para isomeride content first and then preparing wind-power bisphenol F epoxy resin with high epoxide number and low viscosity through the bisphenol F. The comprehensive preparation technology is as follows: formaldehyde and phenol are taken as raw materials, subjected to phenol formaldehyde condensation in a methanol solvent by adoption of a phosphoric acid as catalyst, and subjected to toluene recrystallization and freezing to obtain the bisphenol F with high para 4, 4'-isomer content; the bisphenol F and epichlorohydrin are taken as raw materials, added with dichlorohydrin, and subjected to ring-opening addition etherification reaction in the presence of catalyst hyamine benzyltrim-ethy-lammonium chloride, so as to generate a bisphenol F dichloro-alcohol ether intermediate; the bisphenol F dichloro-alcohol ether intermediate is added with solid alkali in batch, subjected to primary ring-closure epoxidation dechlorination reaction, and added with adequate diluted liquid alkali and adequate toluene solvent for secondary ring-closure epoxidation dechlorination reaction after separation of superfluous epichlorohydrin; and the bisphenol F dichloro-alcohol ether intermediate is subjected to crystallization of the toluene solvent, hot-water washing, vacuum drying and so on to obtain the bisphenol F epoxy resin product with high epoxide number and low viscosity.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com