Heavy-duty self-repairing open gear grease

A gear grease, self-healing technology, applied in the field of grease, can solve the problem that the grease does not have self-healing performance, and achieve the effect of good metal adhesion performance, small friction coefficient and preventing excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

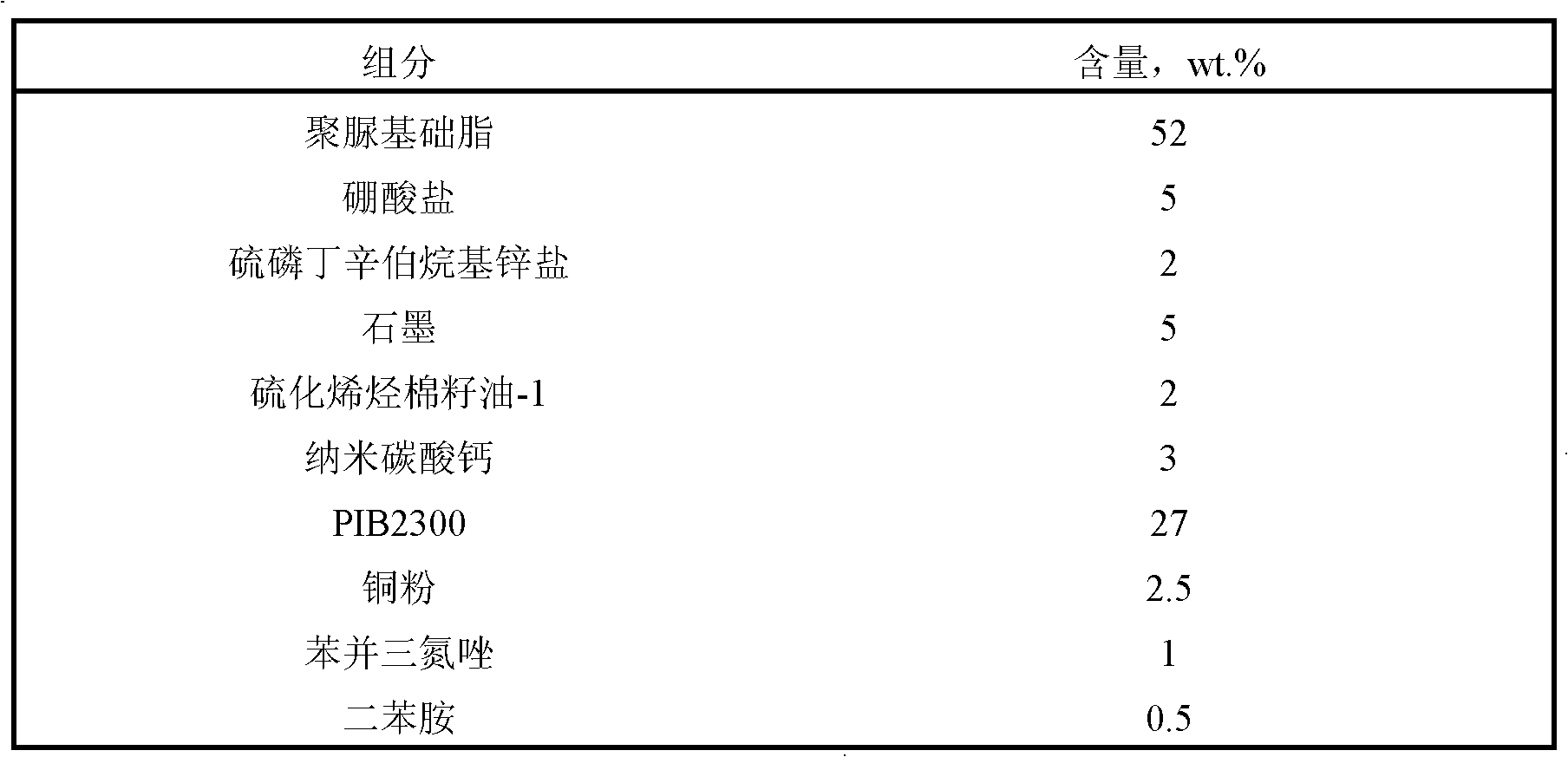

[0017] Example 1: Open gear grease composition comprising:

[0018] Table 1 Example 1

[0019]

[0020] Experimental conditions: Mix and stir for not less than 60 minutes at a temperature of 80-110°C.

[0021] The specific measurement data are shown in Table 4

Embodiment 2

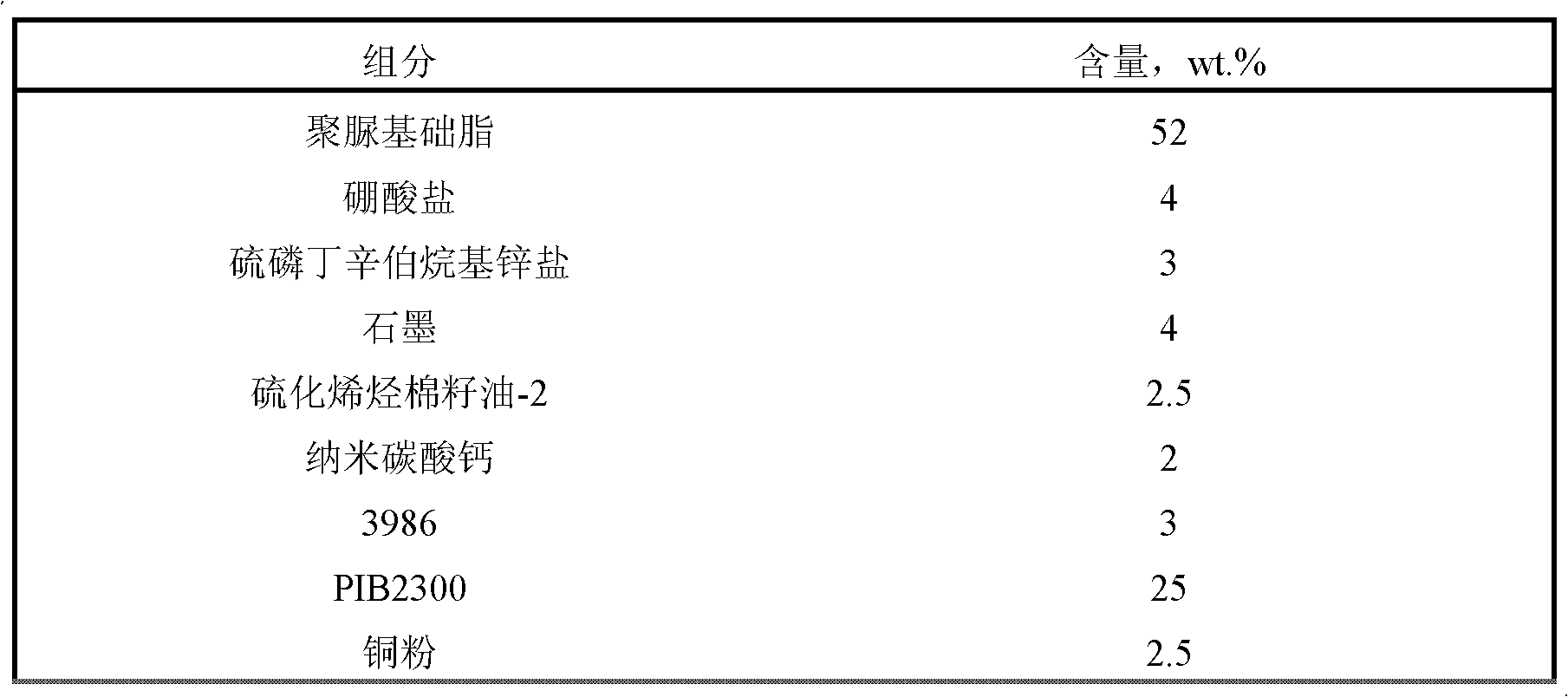

[0022] Example 2: An open gear lubricant composition comprising:

[0023] Table 2 Example 2

[0024]

[0025]

[0026] Experimental conditions: Mix and stir for not less than 60 minutes at a temperature of 80-110°C.

[0027] The specific measurement data are shown in Table 4

Embodiment 3

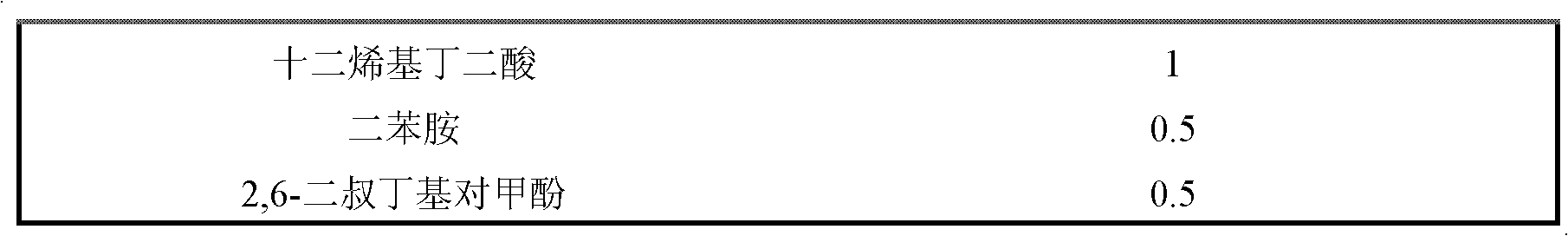

[0028] Example 3: An open gear lubricant composition comprising:

[0029] Table 3 Example 3

[0030]

[0031] Experimental conditions: Mix and stir for not less than 60 minutes at a temperature of 80-110°C.

[0032] The specific measurement data are shown in Table 4

[0033] The polyurea base grease component of above embodiment 1, embodiment 2, embodiment 3 is shown in table 4

[0034] Table 4 Polyurea Grease Components

[0035]

[0036] After testing, the performance indicators of the above three heavy-duty self-repairing open gear greases are shown in Table 4.

[0037] Table 4 Performance of heavy-duty self-repairing open gear grease

[0038]

[0039] Note: The self-repairing test method adopts SRV-IV fretting friction and wear testing machine (Optimol Grease Company of Germany), MicroXAM interferometric non-contact surface profiler (ADE Company of the United States), MH-5-VM microhardness tester, and surface roughness measurement The frequency of the fixed fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com