Energy-efficient long-life gasoline engine oil

A gasoline engine oil, long-life technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of ZDDP usage reduction, loss of exhaust gas purification function, failure, etc., achieve low pour point, inhibit sludge and carbon deposition, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

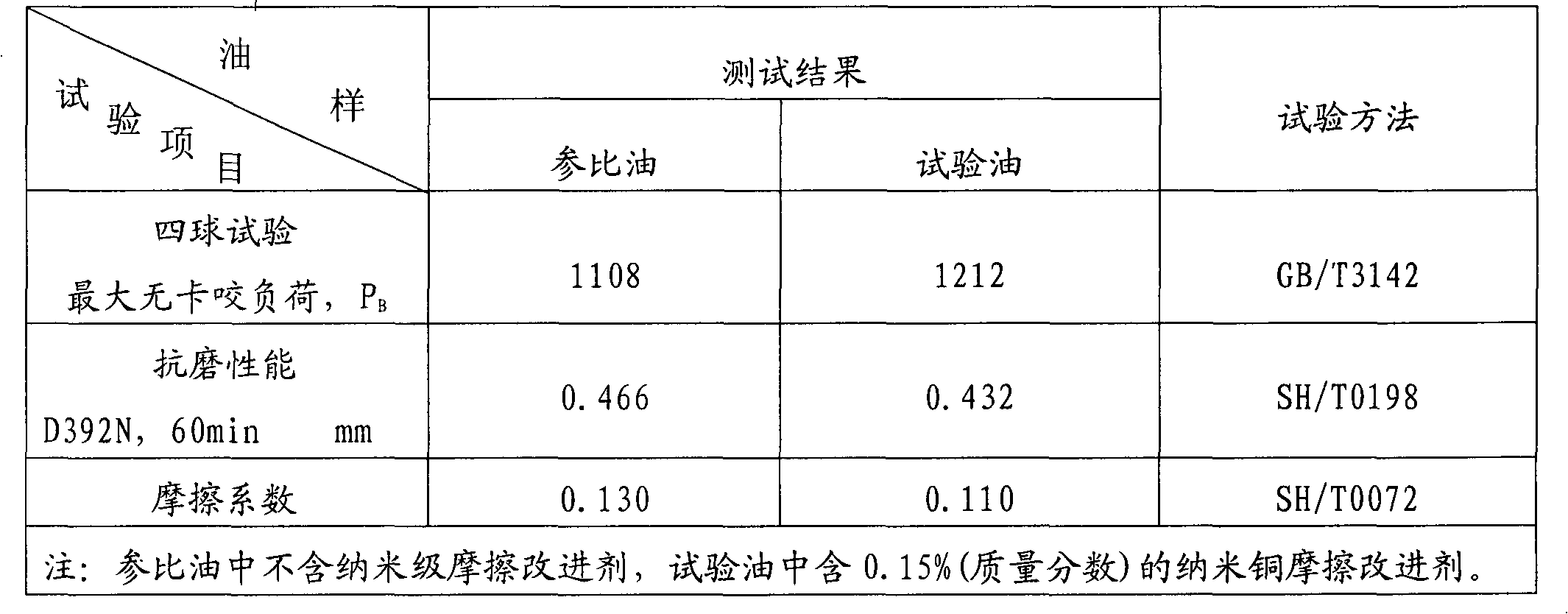

[0033] According to the ratio by weight, 88 parts of synthetic base oil (PAO8:PriEco 3004=5:2) were put into the blending kettle, and under stirring at 65°C, 10.45 parts of T80, 5.4 parts of SV260, and composite antioxidant (Ethanox 4702: LZL205 = 3: 1) 2.0 parts, high alkali value calcium salicylate 1.0 parts, T157 3.0 parts, stir evenly, add 0.15 parts of nano-copper friction modifier, keep the original temperature, stir evenly, let it settle 1 hour, that is, the finished product.

Embodiment approach 2

[0035] According to the proportion by weight, 90 parts of synthetic base oil (PAO9:PriEco 3009=3:2) were dropped into the blending kettle, and under stirring at 70°C, 0.3 parts of T814, 5.5 parts of SV261, composite antioxidant (Ethanox 4710:LZL205=4:1) 1.5 parts, high alkali value sulfurized alkylphenate calcium 0.9 parts, T161A 1.5 parts, stir evenly, add 0.3 parts of nano-molybdenum friction modifier, keep the original temperature and stir evenly, let it settle for 1.5 hours , the finished product is obtained.

Embodiment approach 3

[0037] According to the proportioning by weight, 86 parts of synthetic base oil (PAO7:PriEco 3000=8:3) were dropped into the blending kettle, and under stirring at 60°C, 0.58 parts of T814, 6.4 parts of SV277, composite antioxidant (Ethanox 4716:LZL205=5:1) 2.4 parts, 1.3 parts of high alkali value sulfurized alkylphenate calcium, 3.1 parts of T161A, stir evenly, add 0.22 parts of nano-molybdenum friction modifier, keep the original temperature and stir evenly, let it settle for 2 hours , the finished product is obtained.

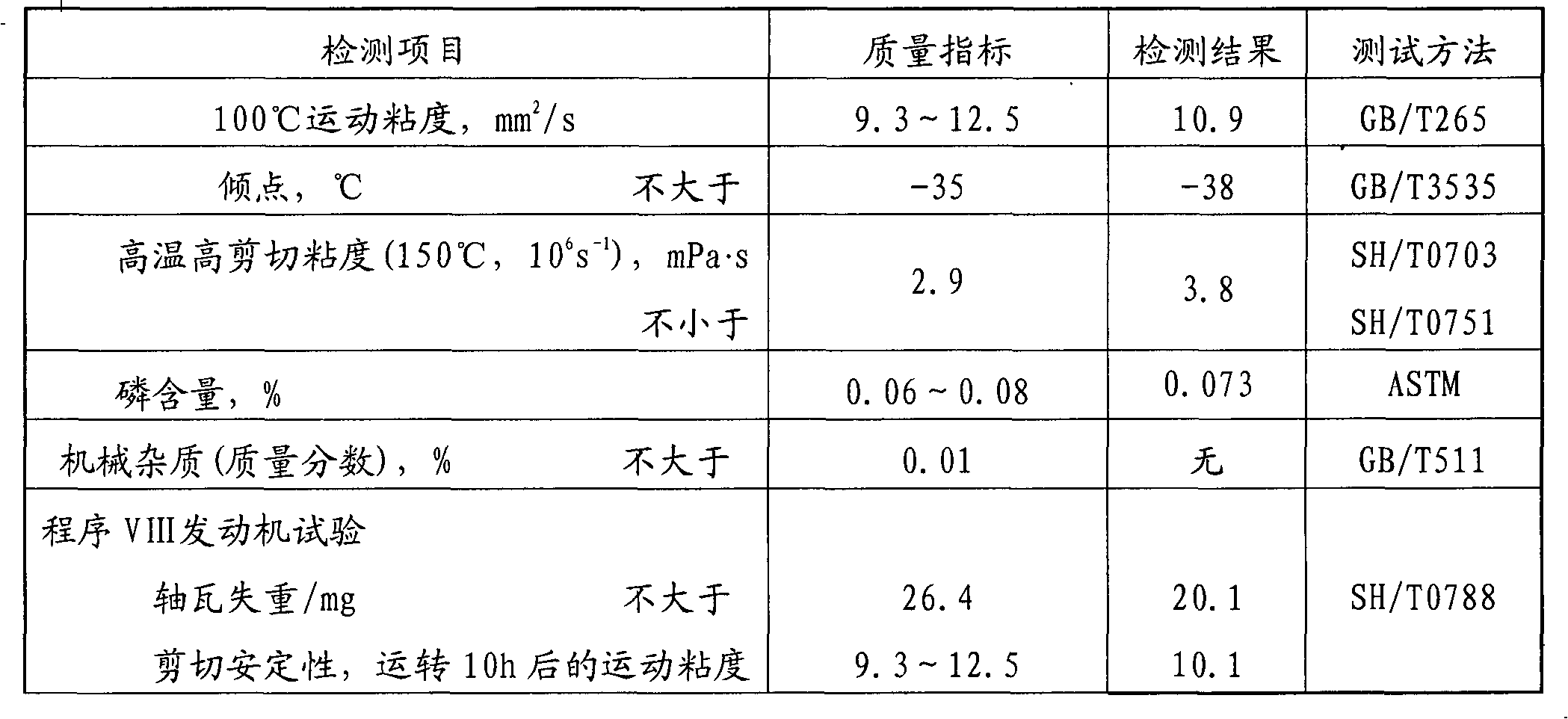

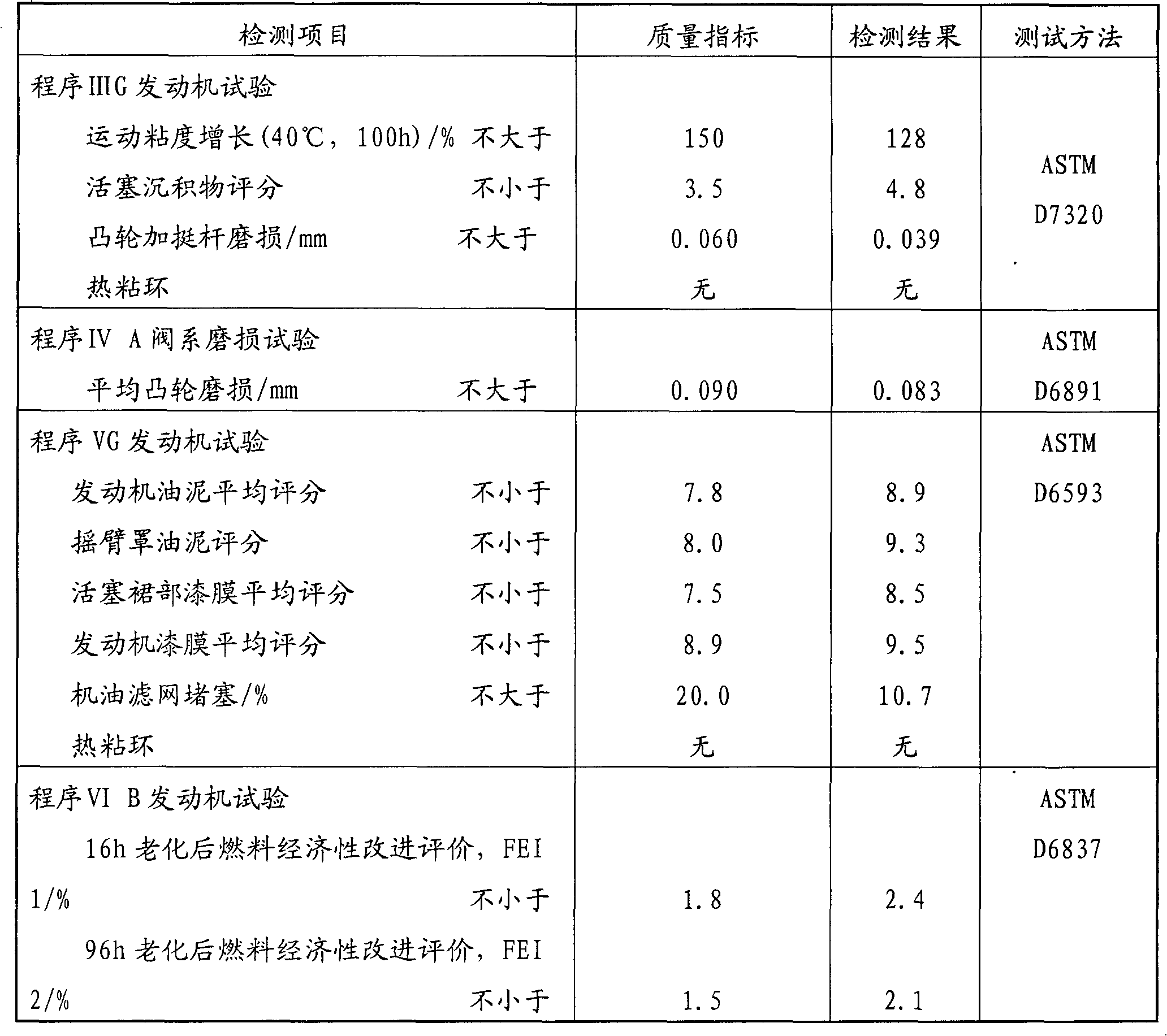

[0038] Main raw material technical indicators

[0039] 1. PAO7

[0040] Kinematic viscosity (100°C, cst): 7.0

[0041] Pour point (℃): -42

[0042] 2. PAO8

[0043] Kinematic viscosity (100°C, cst): 7.9

[0044] Pour point (℃): -55

[0045] 3. PAO9

[0046] Kinematic viscosity (100°C, cst): 9.0

[0047] Pour point (℃): -36

[0048] 4. PriEco 3000

[0049] Provided by Shanghai Daopu Chemical International Trade Co., Ltd.

[0050] Kinematic viscosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com