Preparation method and application of blast furnace sintering-free cold-bonded pellets

A cold-solidified pelletizing and sintering-free technology is applied in the field of blast furnace smelting, which can solve the problems of the cold-solidified pellets failing to meet the requirements of the blast furnace charge, high carbon emissions, heavy pollution, etc., so as to reduce the amount of coke used and reduce emissions. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

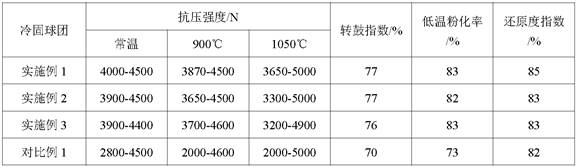

Embodiment 1

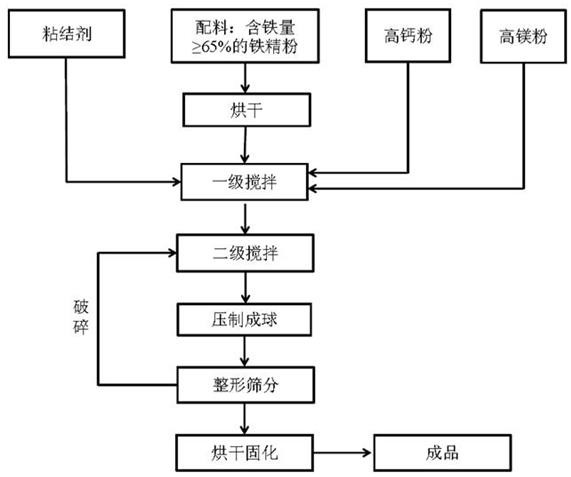

[0039] A preparation method of blast furnace-free sintering cold-set pellets, comprising the following steps:

[0040] S1. Ingredients: prepare iron powder with iron content ≥ 65% and silicon content ≤ 6%;

[0041] S2, drying the iron powder in S1 to a moisture content of 4%;

[0042]S3, the iron powder and the binder, high calcium powder, high magnesium powder in S2 are stirred and mixed uniformly in a high-efficiency strong mixer to obtain a mixture, wherein the binder is composed of the following components according to weight percentage: epoxy resin 80%, phenolic resin 10%, coupling agent 2%, magnesium chloride 2%, dextrin 4%, Yuanming powder 1%, urea-formaldehyde resin 1%, iron powder and binder, high calcium powder, high magnesium powder The mass ratio is 83:2:12:3;

[0043] S4, carrying out the secondary stirring and mixing of the mixture in a high-efficiency strong mixer;

[0044] S5. Press into a sphere in a high-pressure ball press;

[0045] S6. The spheres are s...

Embodiment 2

[0048] A preparation method of blast furnace-free sintering cold-set pellets, comprising the following steps:

[0049] S1. Ingredients: prepare iron powder with iron content ≥ 65% and silicon content ≤ 6%;

[0050] S2, drying the iron powder in S1 to a moisture content of 5%;

[0051] S3, the iron powder and the binder, high calcium powder, high magnesium powder in S2 are stirred and mixed uniformly in a high-efficiency strong mixer to obtain a mixture, wherein the binder is composed of the following components according to weight percentage: epoxy resin 78%, phenolic resin 12%, coupling agent 2%, magnesium chloride 1%, dextrin 5%, Yuanming powder 1%, urea-formaldehyde resin 1%, iron powder and binder, high calcium powder, high magnesium powder The mass ratio is 82:2:13:3;

[0052] S4, carrying out the secondary stirring and mixing of the mixture in a high-efficiency strong mixer;

[0053] S5. Press into a sphere in a high-pressure ball press;

[0054] S6. The spheres are ...

Embodiment 3

[0057] A preparation method of blast furnace-free sintering cold-set pellets, comprising the following steps:

[0058] S1. Ingredients: prepare iron powder with iron content ≥ 65% and silicon content ≤ 6%;

[0059] S2, drying the iron powder in S1 to a moisture content of 5%;

[0060] S3, the iron powder and the binder, high calcium powder, high magnesium powder in S2 are stirred and mixed uniformly in a high-efficiency strong mixer to obtain a mixture, wherein the binder is composed of the following components according to weight percentage: epoxy resin 75%, phenolic resin 14%, coupling agent 2%, magnesium chloride 1%, dextrin 4%, Yuanming powder 2%, urea-formaldehyde resin 2%, iron powder and binder, high calcium powder, high magnesium powder The mass ratio is 85:2:11:2;

[0061] S4, carrying out the secondary stirring and mixing of the mixture in a high-efficiency strong mixer;

[0062] S5. Press into a sphere in a high-pressure ball press;

[0063] S6. The spheres are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com