Patents

Literature

62results about How to "Strong resistance to moisture absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyborosiloxane fire retardant for polycarbonate and preparing method thereof

InactiveCN101033330AImprove heat resistanceStrong resistance to moisture absorptionAcetic acidSilanol

The invention discloses a flame retardant of boron polysiloxane, including the following steps: (1)adding acetic acid or hydrochloric acid into water, adjusting pH from 1.8 to 5.0, then adding silane mixture which molar ratio with water is 1:3~20, stirring for hydrolysis at 60~90deg.C for 0.5~5 hours, generating silicon alcohol, adding solvent for extraction to separate the organic phase, (2)adding boric acid into the organic phase for reaction at 70~110deg.C for 2~16 hours, conducting vacuum distillation to remove solvent to obtain the flame retardant of boron polysiloxane, in which, the molar ratio of oxygen in silanol and boric in boric acid is 1:0.3~3.0. Adding 3% to 5% of this fire retardant into polycarbonate can raise the flame retardant level of UL94 to V0, and the flame-retardant polycarbonate has good mechanical properties, high transparency, brushing tolerance, non-corrosive, without harm to the environment.

Owner:HANGZHOU NORMAL UNIVERSITY

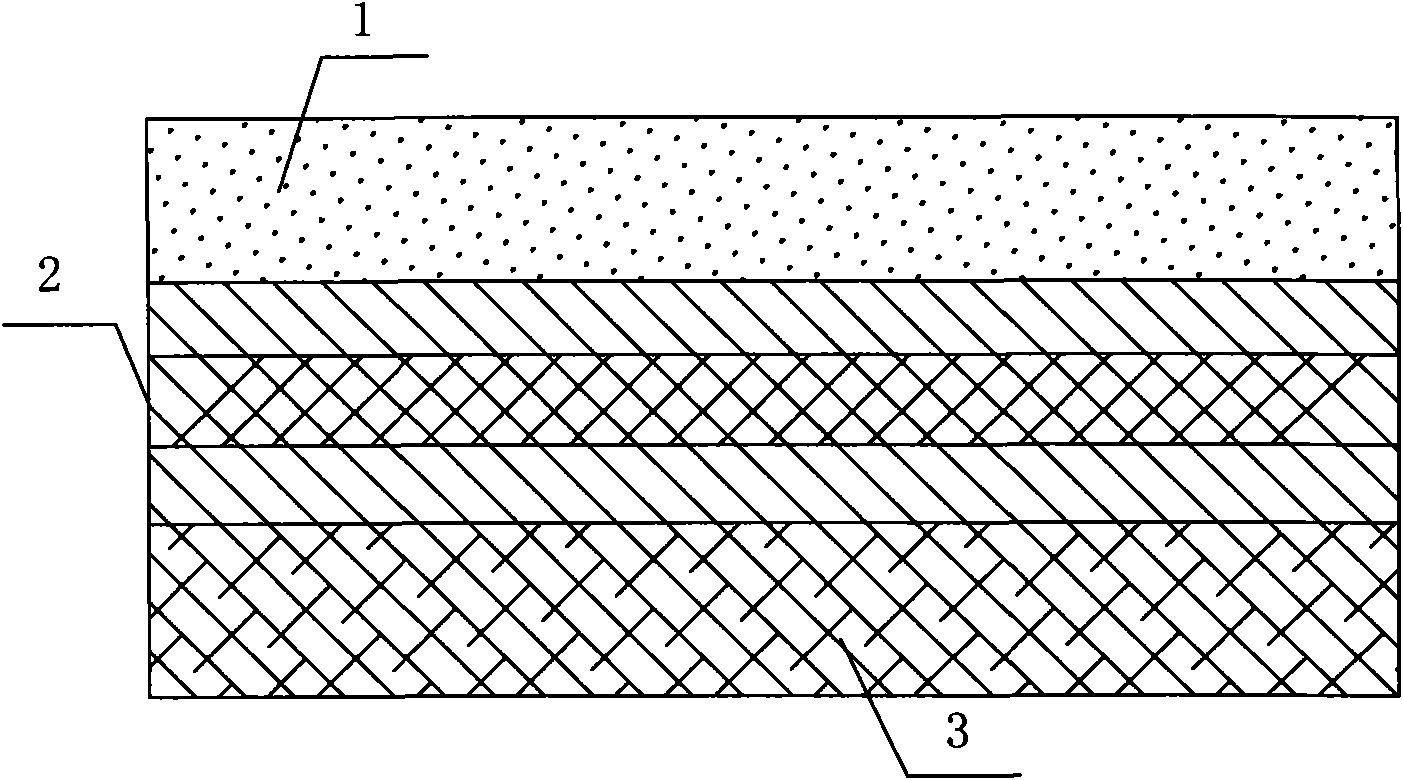

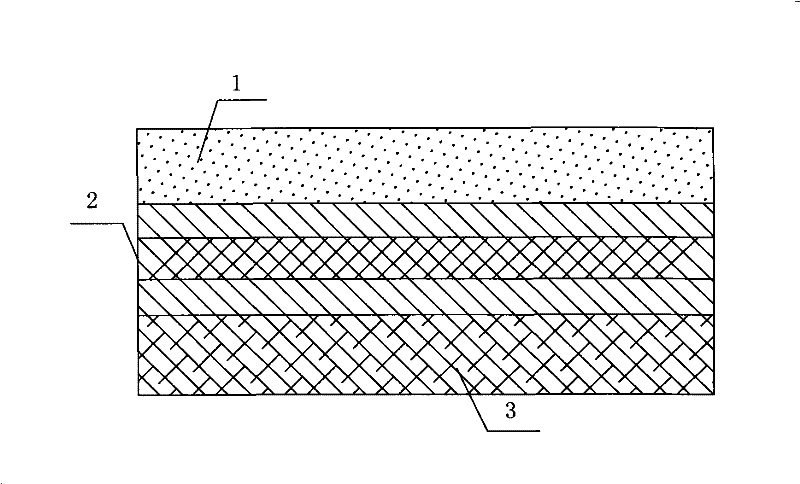

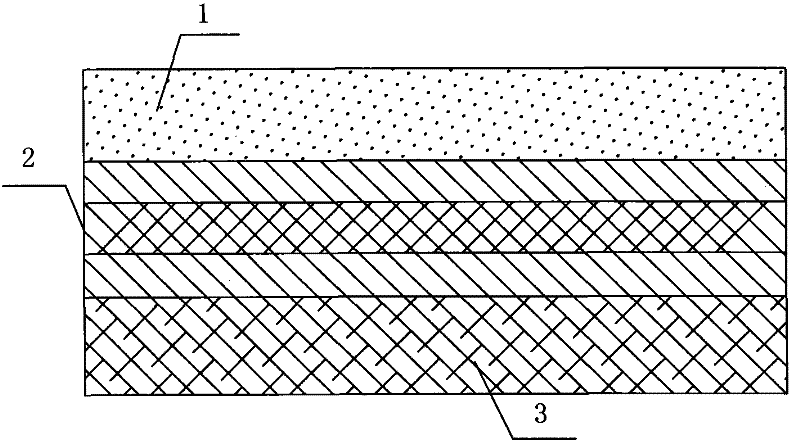

Composite sound-proof formed foaming automobile carpet and preparation method thereof

ActiveCN101574938AStrong composite fastnessGood formabilityVehicle arrangementsSynthetic resin layered productsPolyesterFiber

The invention discloses a composite sound-proof formed foaming automobile carpet and a preparation method thereof. The carpet is made of three layers of materials, namely a fabric layer, a middle multi-layer co-extrusion film layer and a bottom material layer, wherein the fabric layer is made of polyester fiber; the middle multi-layer co-extrusion film layer is made of PE / PE / AD / NYLON / AD / PE / PE multi-layer co-extrusion films; and the bottom material layer is made of polyester fiber. The sound-proof formed foaming automobile carpet provided by the invention has good sound insulation effect, can effectively prevent PU foaming breakdown, and has no toxic odor such as formaldehyde and the like and no penetrating odor; the fabric of the carpet has elegant color and the loop appearance can be adjusted; and the composite sound-proof formed foaming automobile carpet is an environment-friendly carpet with high sound insulation performance. The method for preparing the composite sound-proof formed foaming automobile carpet provided by the invention has simple process, high efficiency, strong operability, high qualification rate of finished products, and can be suitable for mass production.

Owner:江苏中联地毯有限公司

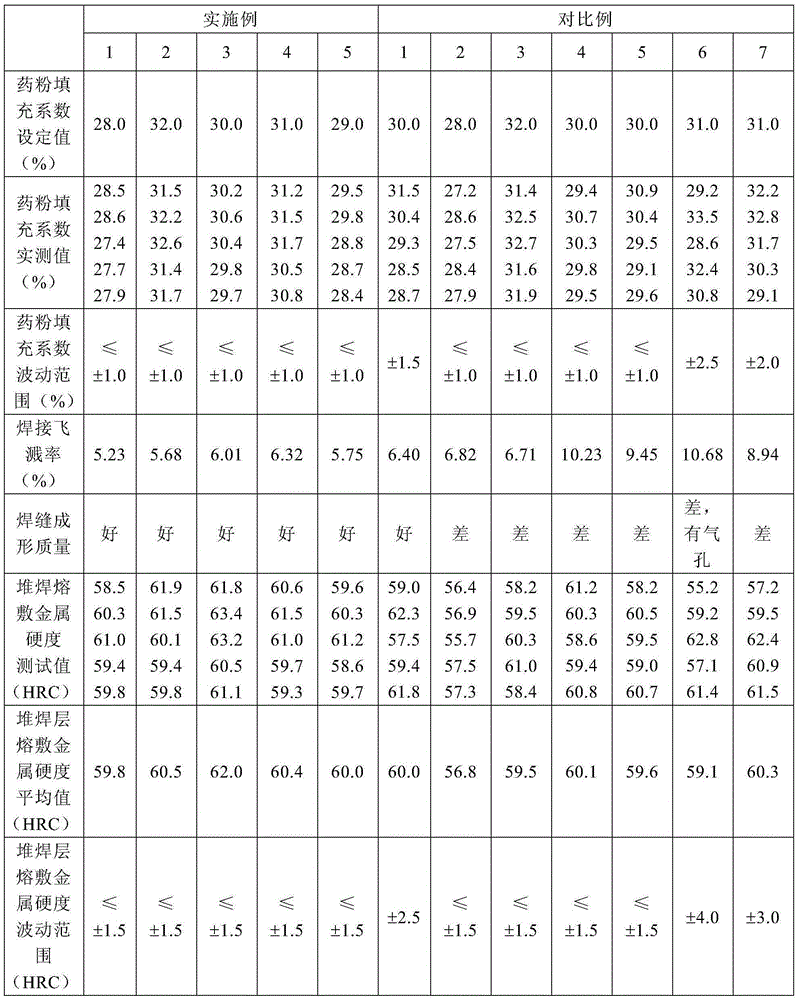

High-niobium high-chromium alloy cast ion self-protection flux-cored wire for grinding roller surfacing and preparation method thereof

ActiveCN105312795AReduce liquidityReduced service lifeArc welding apparatusWelding/cutting media/materialsSodium titanateHigh stress

The invention discloses a high-niobium high-chromium alloy cast ion self-protection flux-cored wire for grinding roller surfacing and a preparation method thereof. The flux-cored wire is composed of a ferrite stainless steel band and flux powder wrapped with the ferrite stainless steel band. The flux powder is prepared from, by weight, 42.0-48.0% of high-carbon chromium iron, 13.0-16.0% of niobium iron, 4.5-5.0% of graphite, 1.5-2.0% of silicon iron, 2.0-3.0% of electrolytic manganese, 1.5-2.0% of medium-carbon ferroboron, 1.0-2.0% of aluminum-magnesium alloy, 0.5-1.0% of cryolite, 0.5-1.0% of fluorite, 1.0-1.5% of lithium carbonate, 0.5-1.0% of zircon sand, 1.0-1.5% of potassium titanate, 1.5-2.0% of sodium titanate and the balance iron powder. The preparation method includes the steps that the flux powder is added into a U-type tank after being preprocessed; and four times of continuous drawing and diameter reducing are sequentially carried out after the opening of the U-type tank is closed, and the flux-cored wire is obtained. The flux-cored wire has the advantages that the hardness of deposited metal of a surfacing layer is stable, welding spatter is little and high-stress abrasive wear resistance is good, and is particularly suitable for surfacing repair and remanufacturing of cement grinding rollers.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

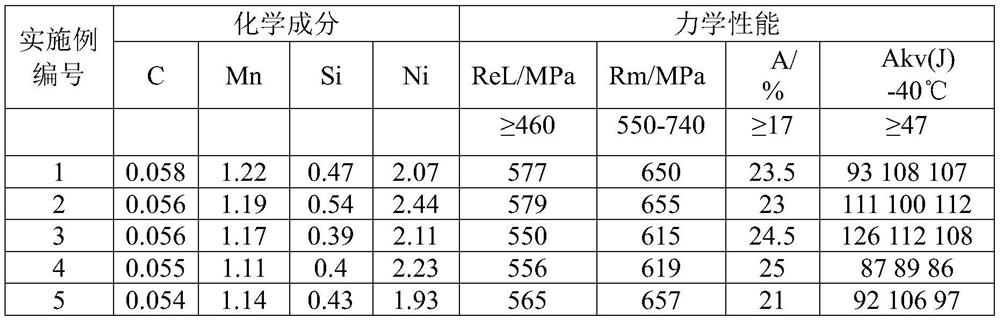

Low-hydrogen high-toughness seamless flux-cored wire for low-temperature steel and preparation method of low-hydrogen high-toughness seamless flux-cored wire

ActiveCN109623193AImprove impact toughnessLow melting pointWelding/cutting media/materialsSoldering mediaSilicon alloyMagnetite

The invention discloses a low-hydrogen high-toughness seamless flux-cored wire for low-temperature steel. The seamless flux-cored wire is composed of low-carbon steel strip skin and flux core powder and used for welding of the low-temperature steel adopted in a LPG ship and a liquefied petroleum storage tank. The low-hydrogen high-toughness seamless flux-cored wire is formed by mixing, by mass percentage, 30-40% of rutile, 0.5-1% of sodium fluoride, 10-16% of manganese-silicon alloy, 1-2% of zircon sand, 5-9% of rare earth silicon iron, 10-12% of nickel powder, 3-5% of magnesium powder, 0.3-0.6% of ferroboron, 1-5% of titanium powder, 2-4% of potassium titanate, 0.5-1% of magnesia, 1-2% of magnetite and 12-14% of iron powder. The seamless flux-cored wire is high in impact toughness at thelow temperature, applicable to all-position welding, good in welding manufacturability and meanwhile good in seawater corrosion resistance and ultralow in diffusible hydrogen; and the low-hydrogen high-toughness seamless flux-cored wire is mainly applied to welding of the low-temperature steel of the LPG ship, the liquefied petroleum storage tank and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

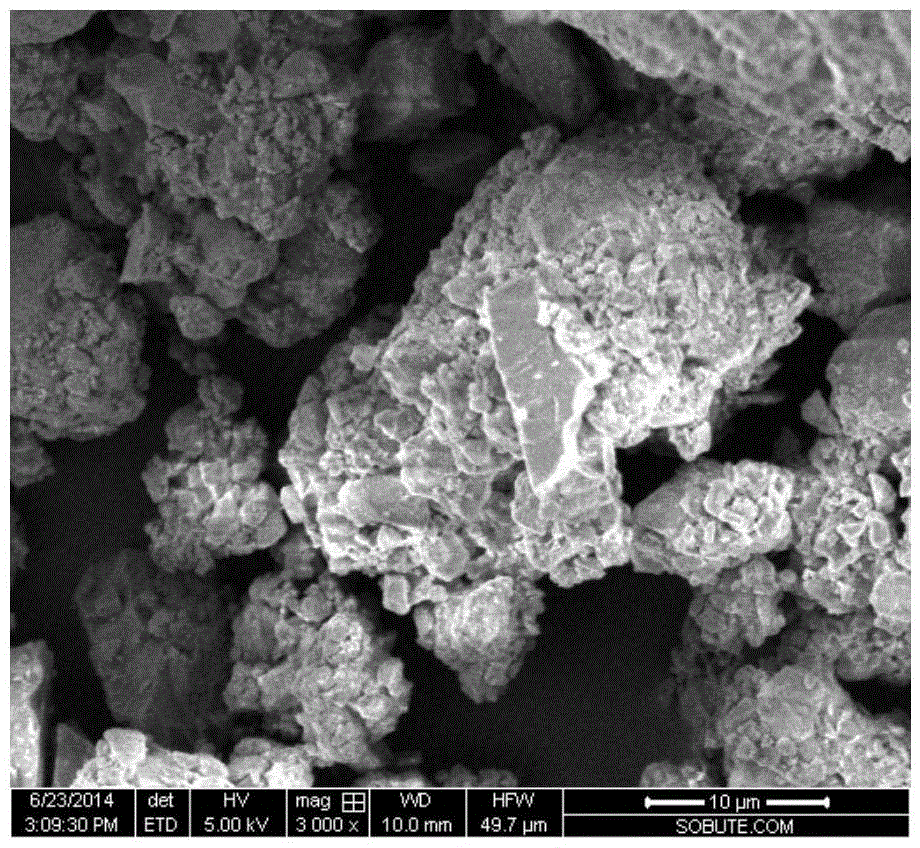

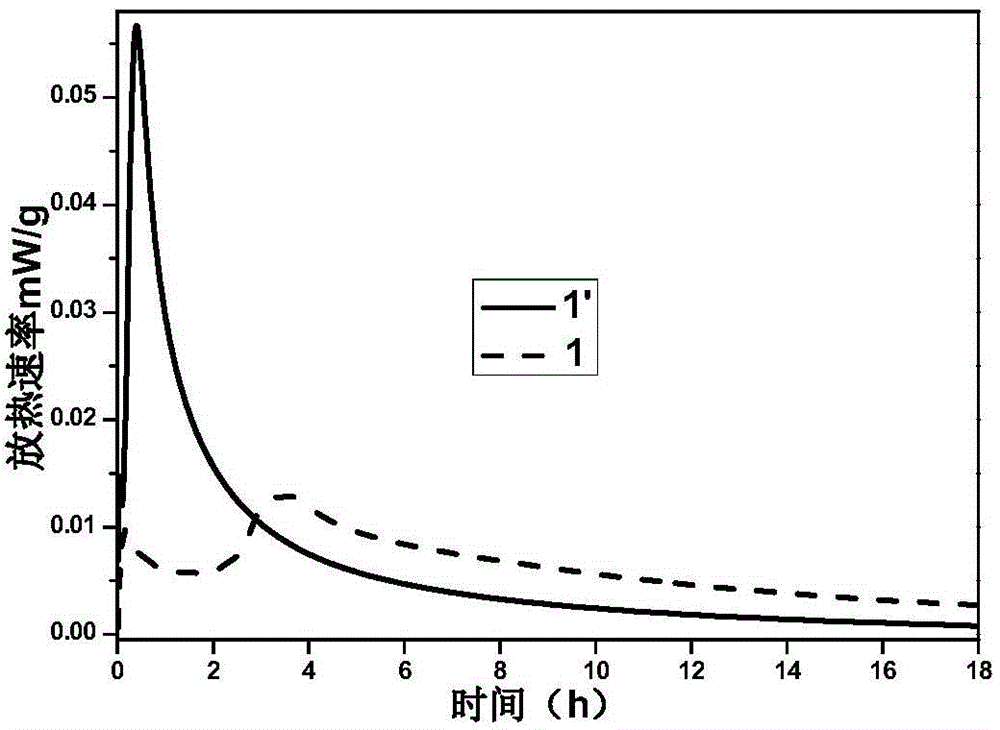

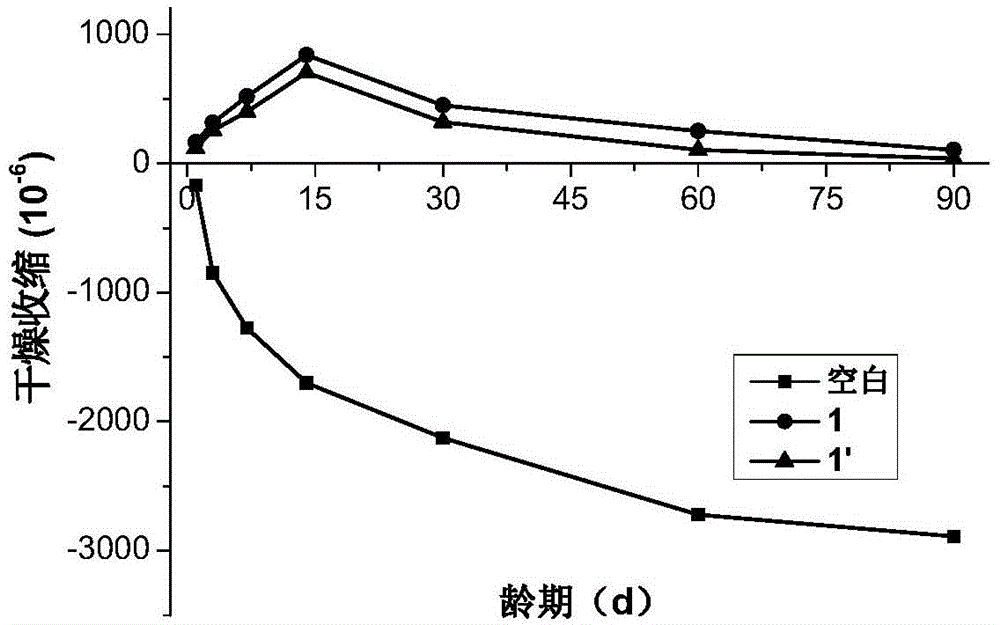

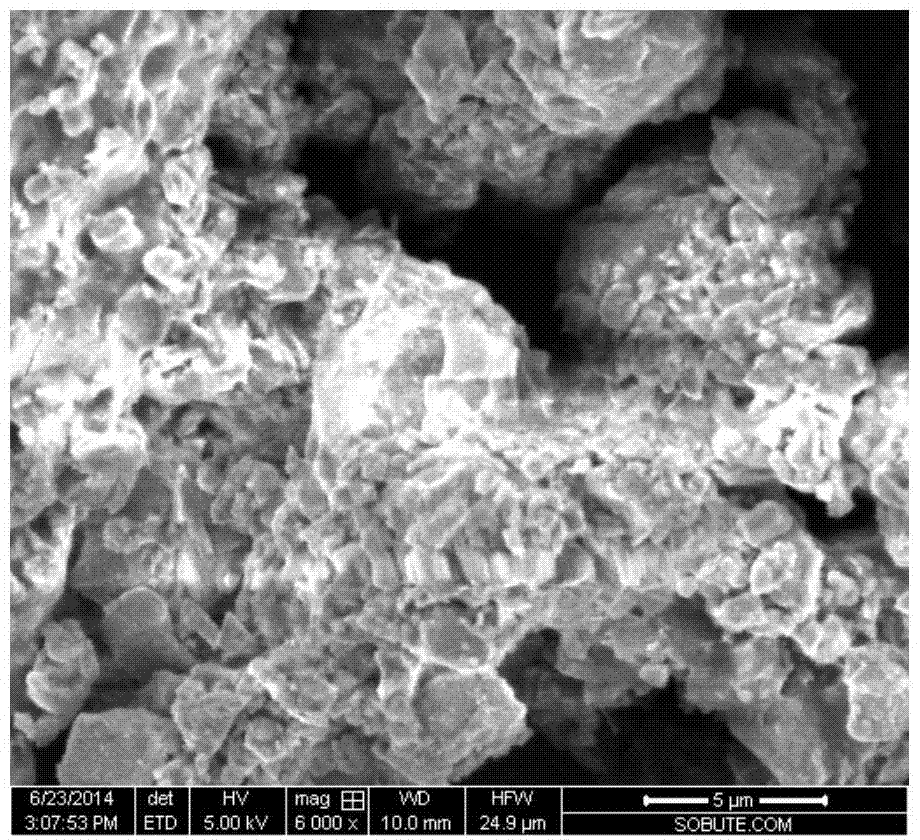

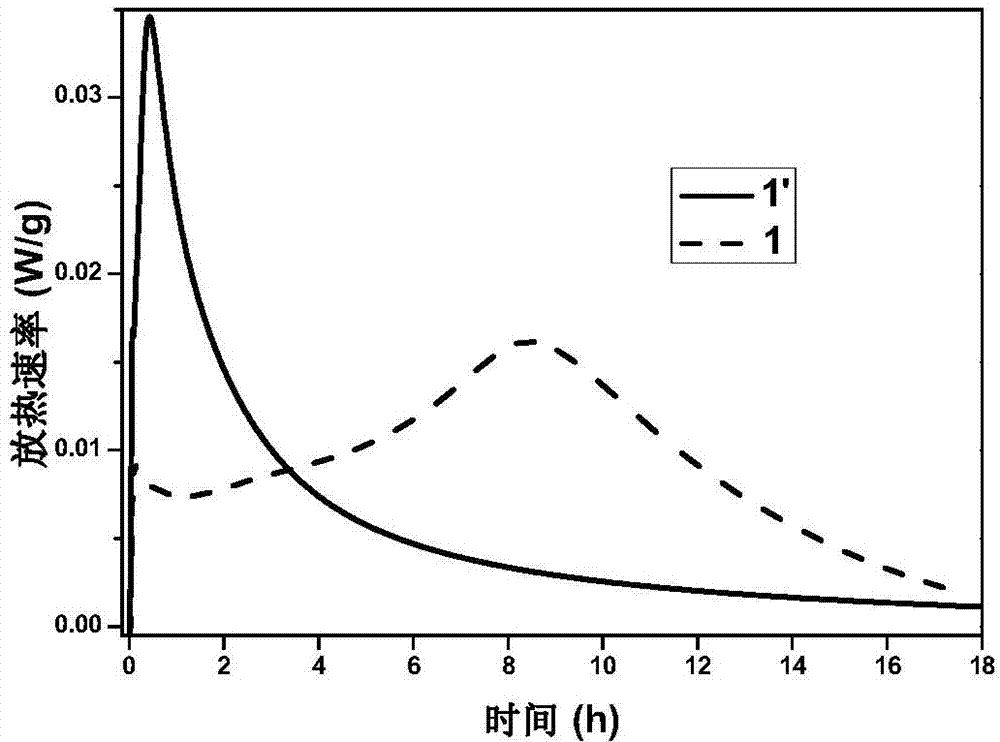

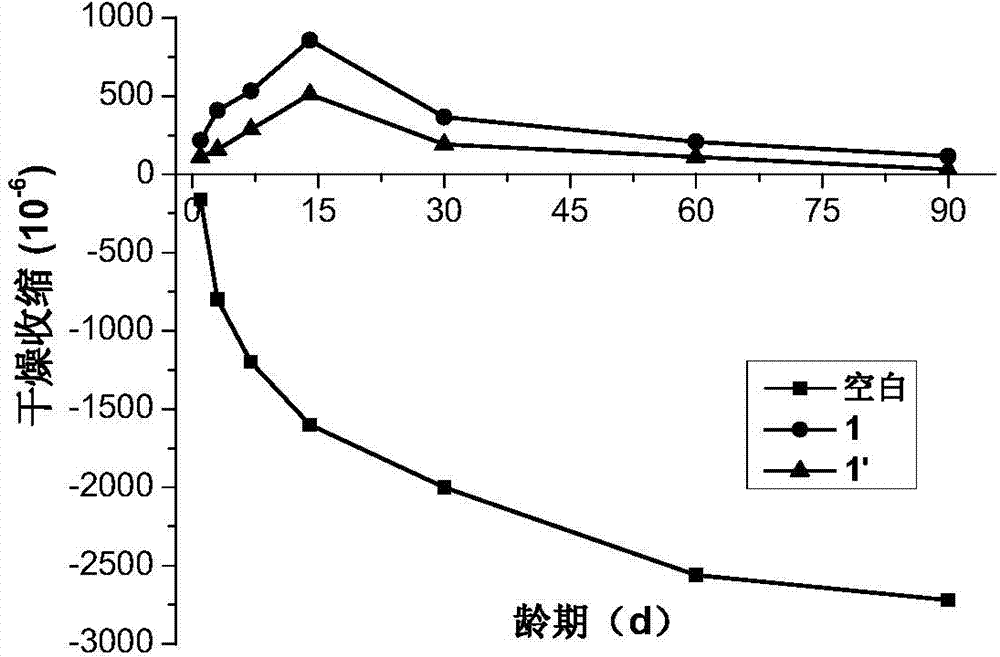

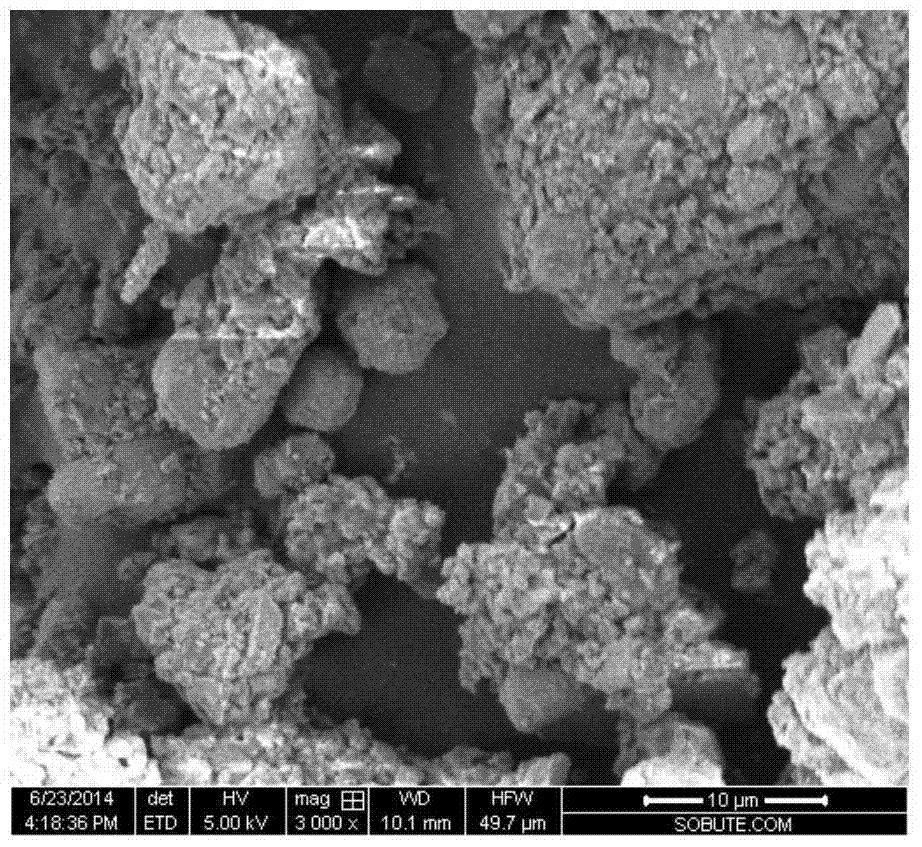

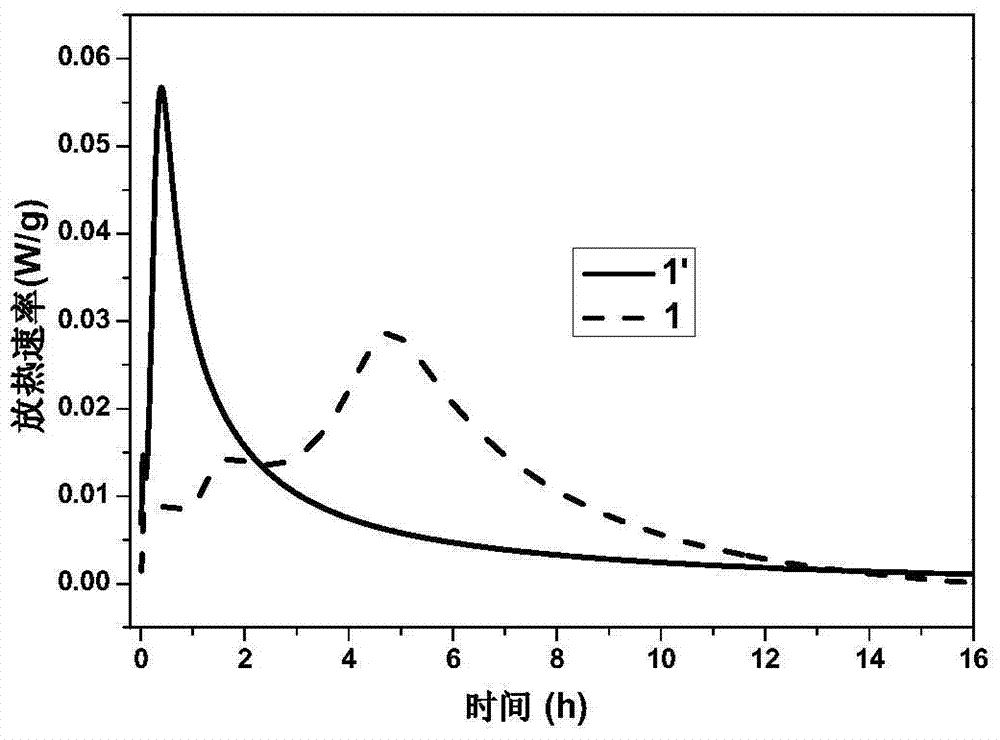

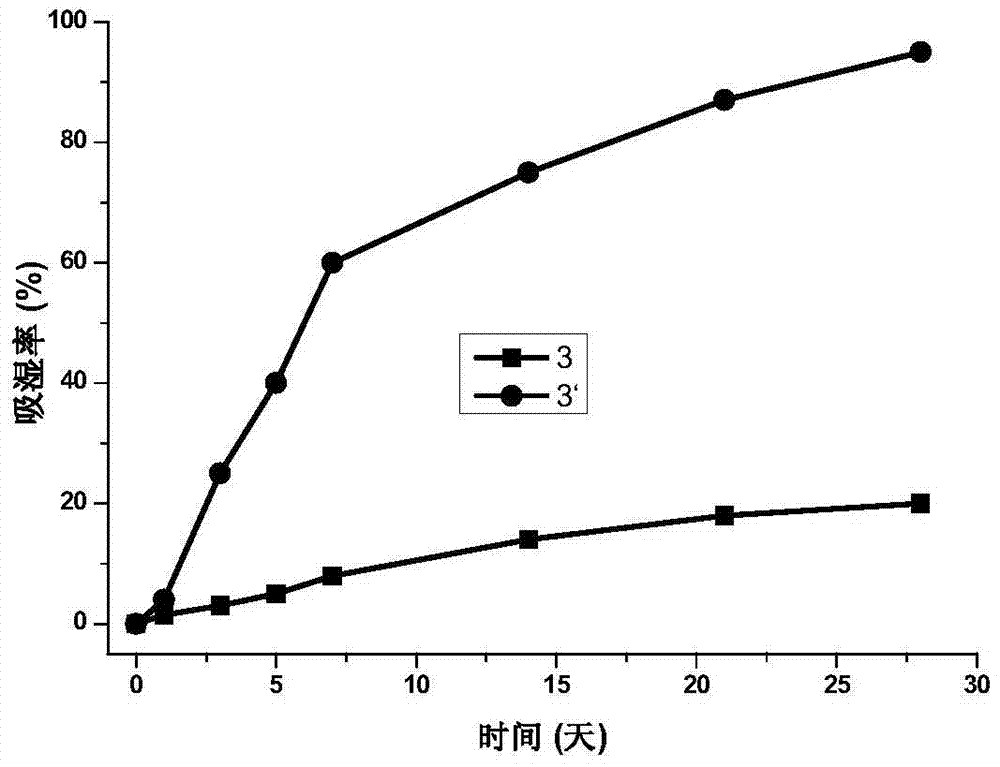

Modified calcium oxide expansion agent for cement concrete and preparation method of modified calcium oxide expansion agent

The invention provides a modified calcium oxide expansion agent for cement concrete. The modified calcium oxide expansion agent for the cement concrete has the specific surface area of 100-600m<2> / kg and is prepared from a degradable high polymer and calcium oxide expansion clinker. According to the modified calcium oxide expansion agent for the cement concrete, provided by the invention, the invalid hydration of calcium oxide at a plastic stage of concrete is reduced, the hardened expansion quantity is increased, and the shelf life of the product can be further prolonged; the expansion agent can be applied to the crack resisting and seepage prevention of a concrete structure and can be used for greatly improving the durability of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

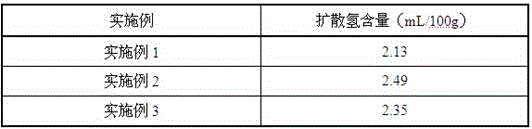

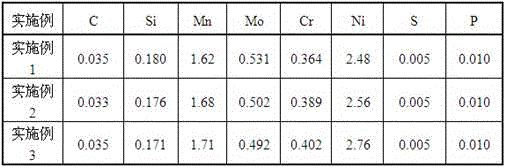

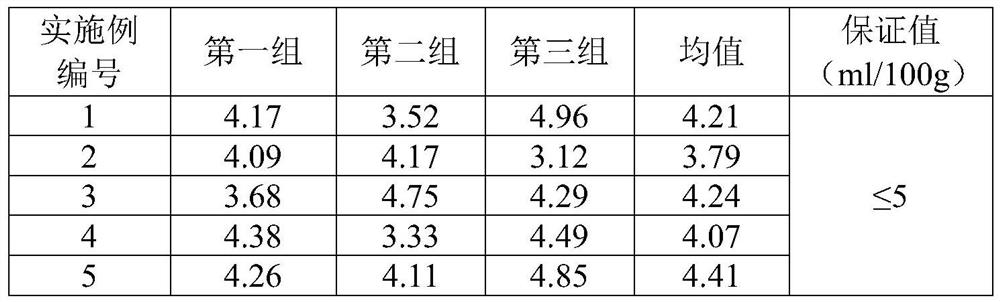

Ultralow hydrogen seamless submerged arc flux-cored wire for steel with yield strength being 690 MPa level

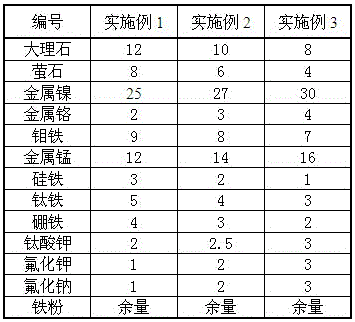

ActiveCN106141500AStrong resistance to moisture absorptionGood workmanshipWelding/cutting media/materialsSoldering mediaPotassium fluorideManganese

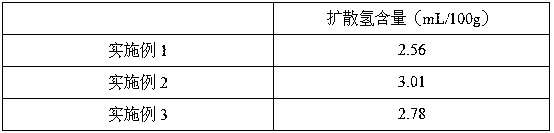

The invention discloses an ultralow hydrogen seamless submerged arc flux-cored wire for steel with yield strength being the 690 MPa level. The submerged arc flux-cored wire is composed of a sheath and flux core powder. The sheath is made of a low-carbon steel strip. The flux core powder is prepared from, by mass percent, 8%-12% of marble, 4%-8% of fluorite, 25%-30% of metal nickel, 2%-4% of metal chromium, 7%-9% of ferromolybdenum, 12%-16% of electrolytic manganese, 1%-3% of ferrosilicon, 3%-5% of ferrotitanium, 2%-4% of ferro-boron, 2%-3% of potassium titanate, 1%-3% of potassium fluoride, 1%-3% of sodium fluoride and the balance ferrous powder. The ultralow hydrogen seamless submerged arc flux-cored wire for the steel with the yield strength being the 690 MPa level is high in moisture absorption resisting property, and excellent in processing property of being matched with fluorine and alkali sintered flux SR-SJ613, diffusible hydrogen is extremely low (smaller than or equal to 4 mL / 100 g), minus 40 DEG C charpy impact energy reaches over 100 J, and the wire can be applied to welding of a steel plate with the yield strength being the 690 MPa level in the ocean engineering field.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Core-making sand composition of warm core box and sand making method

InactiveCN104439041AWide variety of sourcesLow priceFoundry mouldsMoulding machinesSilicon oxideAtmospheric pressure

The invention discloses a core-making sand composition of a warm core box and a sand making method. The composition comprises an inorganic binding agent, raw sand and non-crystallization type silicon oxide. According to the preparation method, a sand mixing machine is used for mixing, preferably a continuous sand mixing machine is adopted; the raw sand, sodium silicate and the non-crystallization type silicon oxide are automatically controlled by a pc to be fed; after the core-making sand composition is mixed, and is added into a core shooting machine sand bucket; a core-making mold is heated to 145-155 DEG C in advance to prepare the core-making sand composition; the core-making sand composition is shot into a mold cavity by a core shooting machine under the air pressure of 0.4Mpa-0.7Mpa; hot air of 120-160 DEG C is blown into a core-making cavity for 20-200 seconds; a thin core is blown for 20-40 seconds and the air blowing time is properly prolonged by a thick core; after the sand core is hardened, the box is opened and the sand core is ejected out; and the sand core can be poured on the day by assembling the box, and also can be poured by assembling the box after being stored for 3-5 days. The composition has a wide source, a high mechanical property and cheap price; and popularization and application are facilitated, the composition has no toxin and odor, and the environment protection is facilitated.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

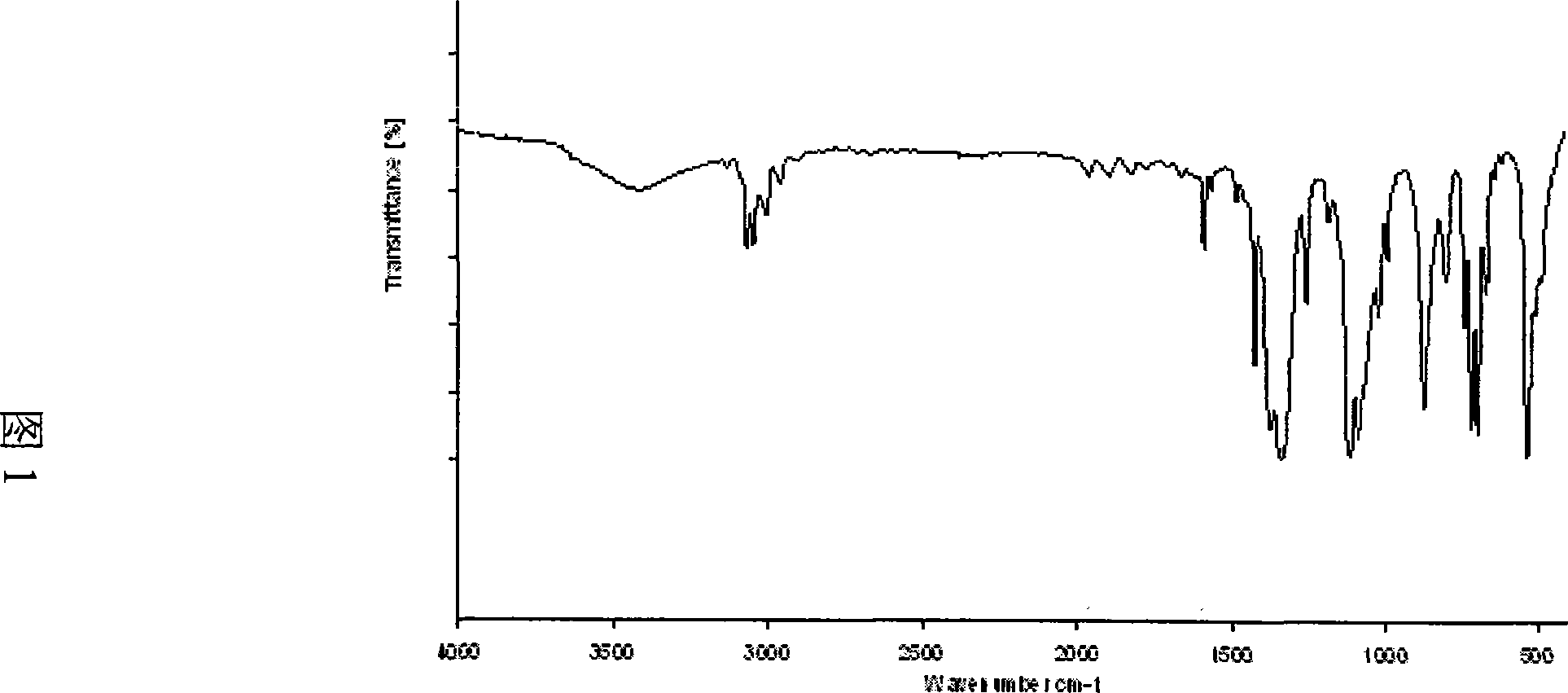

Modified calcium oxide cement concrete expansion agent and preparation method thereof

ActiveCN104710121ASmall water absorptionStrong resistance to moisture absorptionCrack resistanceAcrylic resin

The invention provides a modified calcium oxide cement concrete expansion agent and a preparation method thereof. The modified calcium oxide cement concrete expansion agent consists of acrylic resin and a calcium oxide expansion clinker, wherein the surface of the calcium oxide expansion clinker is wrapped with the acrylic resin; the mass of the acrylic resin accounts for 0.01 to 10 percent of the total mass of the modified calcium oxide cement concrete expansion agent; the specific surface area of the modified calcium oxide cement concrete expansion agent is 100 to 600m<2> / kg. According to the modified calcium oxide cement concrete expansion agent, a hydration process of the calcium oxide expansion clinker can be regulated, ineffective hydration in the plastic stage of concrete can be reduced, expansion after hardening can be increased, and the shelf life of the expansion agent product can be prolonged; the modified calcium oxide cement concrete expansion agent can be used for the crack resistance and seepage resistance of a concrete structure, and the durability of the concrete can be greatly improved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

High-toughness titanium alkaline type seamless flux-cored wire suitable for full-position welding

ActiveCN108406159ASimple processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention discloses a high-toughness titanium alkaline type seamless flux-cored wire suitable for all-position welding. The flux-cored wire is composed of a low-carbon steel strip at the peripheryand flux core powder inside; and the flux core powder comprises the following components, by weight percentage: 30-40% of rutile, 1-2% of aluminum oxide, 2-4% of dehydrated feldspar, 1-3% of quartz,1-3% of zircon sand, 1-2% of rare earth oxide, 1-2% of silicon powder, 0.2-0.4% of ferroboron, 6-8% of nickel powder, 8-15% of metal manganese, 4-9% of magnesium powder and the balance iron powder andinevitable impurities. According to the flux-cored wire, a titanium alkaline slag system is adopted, the proportion of alloy elements is optimized, the content of mineral powder is adjusted, and under the protection of CO2 gas, horizontal, transverse and vertical position welding can be realized; the mechanical property is stable, the impact power at 40 DEG C below zero reaches 100J, the crack resistance is good, diffusible hydrogen is low, the moisture resistance is strong, the seawater corrosion resistance is good, and the anti-cracking ability is good.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-energy powdery ammonium nitrate explosive with no sibium, and preparation method

A non-TNT high-energy powder explosive is prepared from composite wax (4-6%), additive (0.5-4%) and ammonium nitrate (rest) through changing the oxidant and combustible agent to liquid state, mixing, airflow atomizing for dewatering, granulating, drying and cooling in sealed water cooler. Its advantages are no environmental pollution, and high explosion power.

Owner:云南锐达民爆有限责任公司

Plant hollow capsule

InactiveCN104127877AReduce usageReduce pollutionCapsule deliveryMacromolecular non-active ingredientsEthyl hydroxybenzoateDisease

The invention discloses a plant hollow capsule which comprises the following ingredients by mass: 20 to 30 parts of hydroxypropyl methyl cellulose, 20 to 30 parts of carrageenan, 10 to 25 parts of alginate, 10 to 25 parts of guar gum, 6 to 12 parts of algal polysaccharides, 2 to 6 parts of carboxyl methyl glucomannan, 1 to 3 parts of a soybean isolate protein, 2 to 6 parts of a malt extract, 1 to 4 parts of starch, 40 to 60 parts of ethyl alcohol, 2 to 5 parts of triethyl ester, 1 to 4 parts of glycerin, 0.5 to 1.5 parts of titanium dioxide, 2 to 5 parts of magnesium stearate, 0.1 to 0.5 part of ethyl hydroxybenzoate, 2 to 5 parts of methyl p-hydroxybenzoate, 0.2 to 0.6 part of methyl silicone oil, 1 to 3 parts of an edible pigment, and 70 to 100 parts of purified water. The plant hollow capsule can reduce environmental pollution, prevents and treats the transmission of diseases, and improves the capsule security.

Owner:ZHEJIANG YILI CAPSULE

Method for fabricating seamless tube welding wire containing rutile cored powders by mild-carbon steel strip

ActiveCN103753055AReduce the incidence of cracksImprove porosity resistanceWelding/cutting media/materialsSoldering mediaCopper platingManganese

Disclosed is a method for fabricating a seamless tube welding wire containing rutile cored powders by a mild-carbon steel strip. The method includes that by weight, 30%-50% of rutile, 2%-5% of dehydrated feldspar, 5%-10% of silicon iron, 1%-8% of ferrotitanium, 5%-15% of manganese metal, 2%-5% of zircon sand, 3%-8% of mineral magnesia, 2%-6% of quartz, 0.5%-2% of zirconium metal and the balance iron powders are fully and uniformly stirred to form the rutile cored powders, and the rutile cored powders are stored in a feeding device for stand-by, the mild-carbon steel strip is rolled to form a U-shaped steel strip, the cored powders are filled in the U-shaped steel strip at a rolling speed of 2-10m / s, the filling rate is controlled within 14%-18%, then a seamed tube in the diameter of D is formed by rolling, a seamless tube welding wire tube blank is formed by on-line welding of a laser-beam welding machine or a high-frequency welding machine, the seamless tube welding wire tube blank is subjected to high frequency annealing at 500-1200 DEG C, then the diameter of the seamless tube welding wire tube blank is reduced by a cold-drawn machine to form a D1 seamless tube welding wire, and then the D1 seamless tube welding wire is copperized so as to form the seamless tube welding wire containing the rutile cored powders.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Flux-cored welding rod for stainless steel welding

ActiveCN111168273AImprove conductivityStrong resistance to moisture absorptionWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceCrack resistance

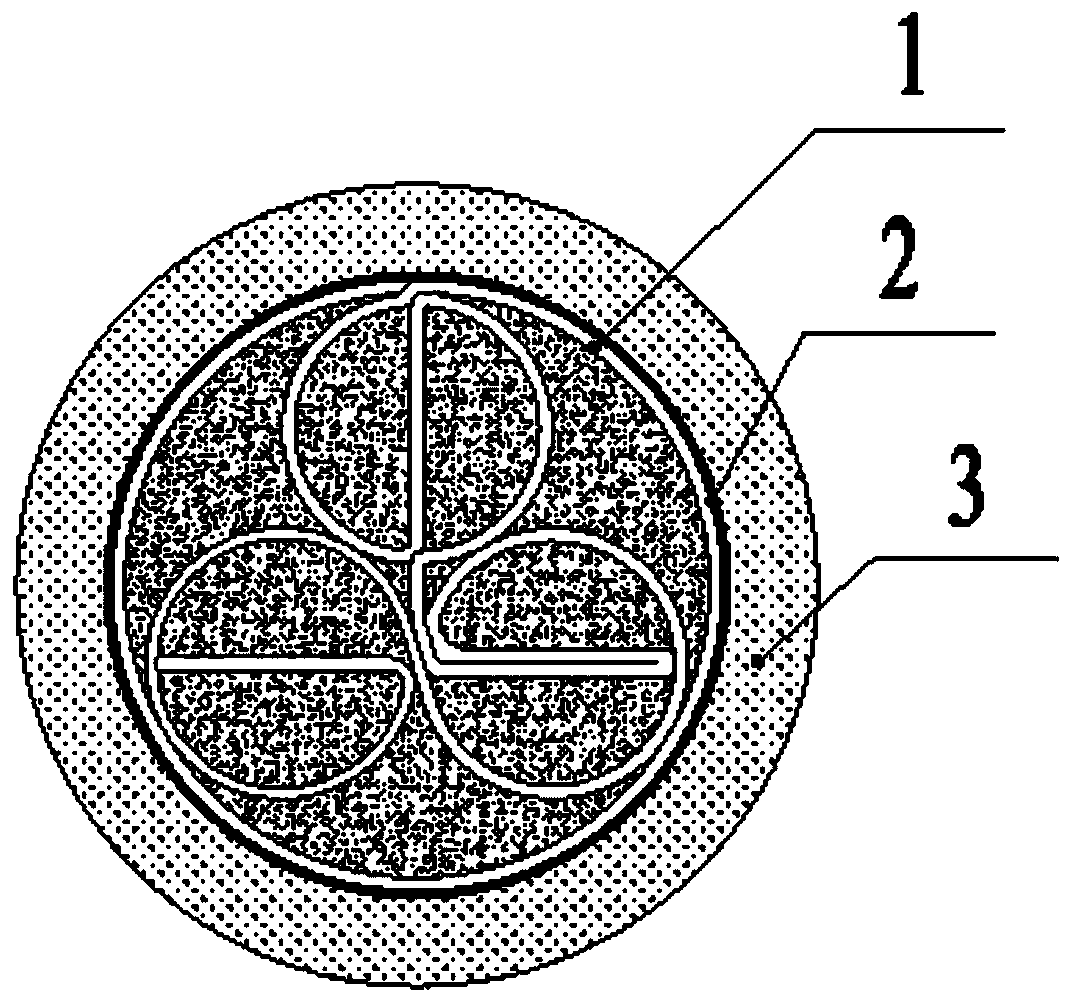

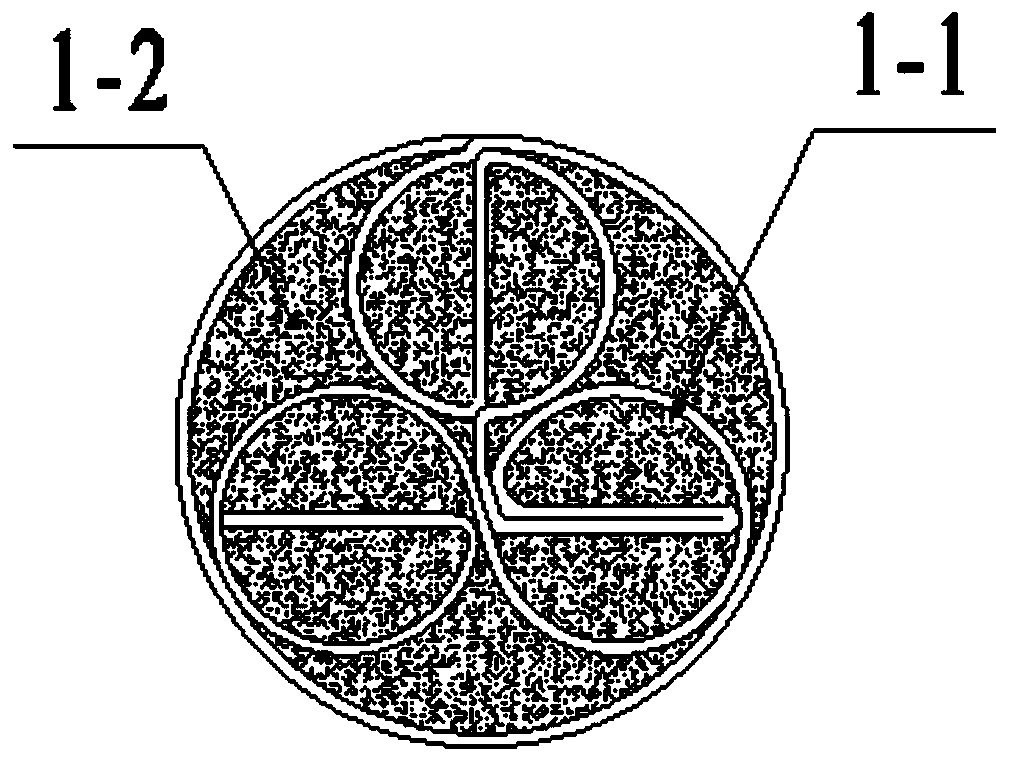

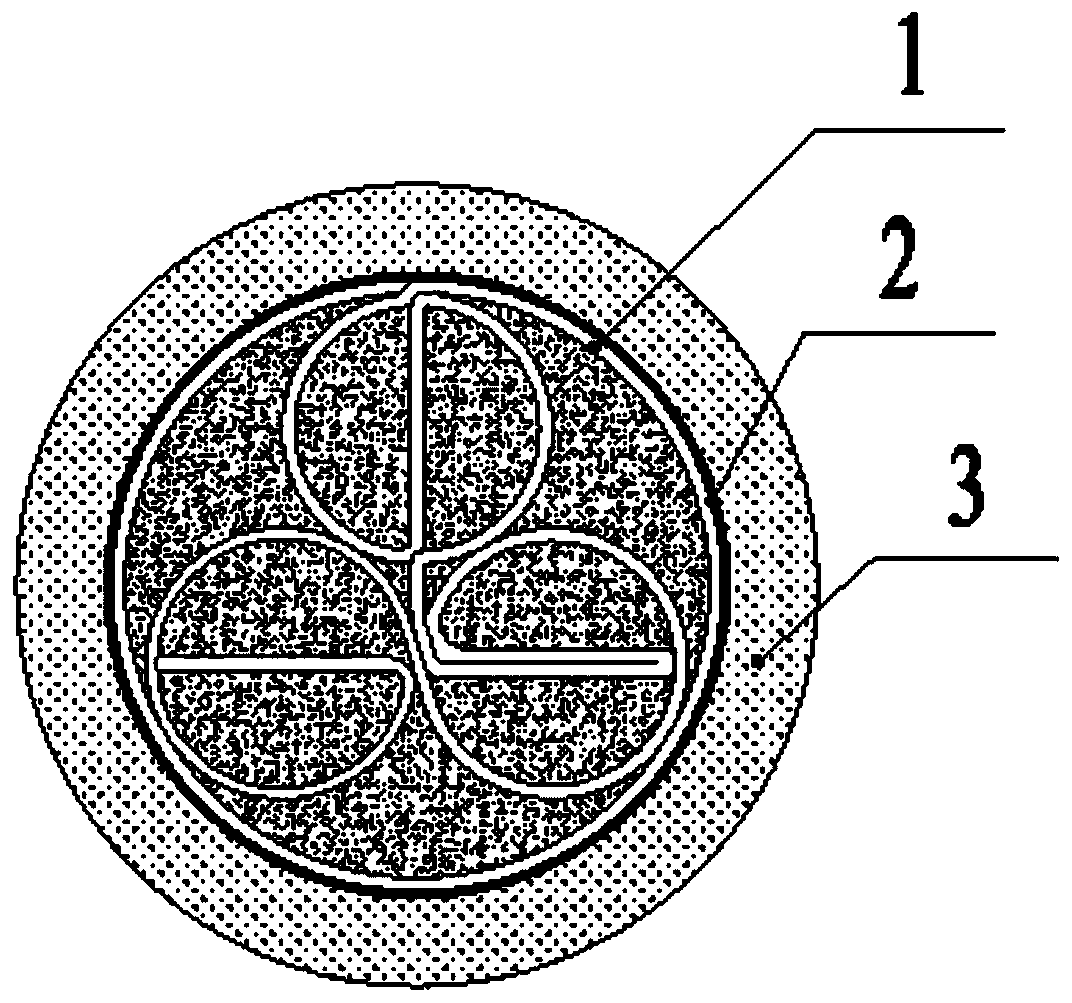

The invention belongs to the field of welding materials, and particularly relates to a flux-cored welding rod for stainless steel welding. The flux-cored welding rod comprises a flux-cored welding core, a nano graphene coating and a coating from inside to outside, the flux-cored welding core is of a structure similar to a cable, a nickel strip is sequentially bent into three e-shaped circles whichare externally tangent pairwise and are equal in diameter, then is wound into a circular ring which is internally tangent to the e-shaped circles, and is closed to form the flux-cored welding core, gaps in the closed circular ring are filled with flux core, and modified potassium titanate is adopted in the flux core to serve as an arc stabilizer. According to the welding rod, during welding, thecenter of the welding core is high in electrical conductivity and stable in electric arc, resistance heat generated by the flux-cored welding core is small, the heat conduction performance of the welding core is high, the volume expansion of the welding core is small, and the reddening and cracking resistance of the coating is good. The use length of the welding rod is 88% or above of the length of the coating, the utilization rate of the welding rod is increased, deposited metal is uniform in chemical component, the comprehensive mechanical property is good, and the welding rod is an innovation in the aspect of flux-cored welding rods for stainless steel welding.

Owner:ZHENGZHOU UNIV

Seamless submerged arc flux-cored wire for welding high manganese steel LNG storage tank

ActiveCN110653515AExcellent solderabilityAvoid changes in the structure and properties of the fusion zoneWelding/cutting media/materialsSoldering mediaChromium carbideFerrosilicon

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Seamless submerged arc flux-cored wire capable of realizing postweld heat treatment

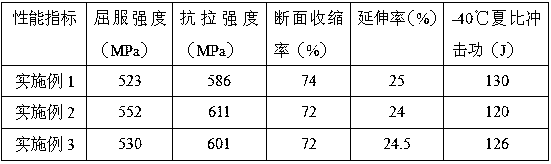

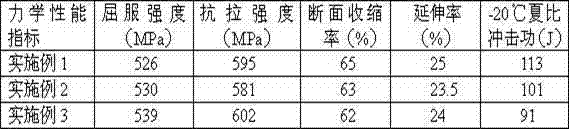

InactiveCN110125572ASimple welding processHigh elongationWelding/cutting media/materialsSoldering mediaPotassiumRare earth

The invention discloses seamless submerged arc flux-cored wire capable of realizing postweld heat treatment and belongs to the technical field of welding materials. The seamless submerged arc flux-cored wire is composed of an outer skin and flux-cored powder, the flux-cored powder comprises the following components in percentage by mass: 8-12% of nickle powder, 0.5-1.5% of ferromolybdenum, 12-20%of manganese metal, 3-7% of rare earth ferrosilicon, 1-2% of ferrotitanium, 1-3% of ferroboron, 0.5-1% of potassium fluosilicate, 0.5-1% of graphite and the balance of iron powder and unavoidable impurities. After heat treatment, low-alloy high-strength steel welded by adopting the seamless submerged arc flux-cored wire has low diffusible hydrogen content, stable mechanical property and proper strength, and the impact energy at minus 50 DEG C can reach 110 J or above; and in addition, after welding and heat treatment, welding seam metal welded by adopting the seamless submerged arc flux-coredwire has high toughness, so that the seamless submerged arc flux-cored wire is suitable for welding of low-alloy high-strength steel needing postweld heat treatment.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Mixed flammable incense and production method thereof

ActiveCN104207613AStrong moisture resistanceStrong resistance to moisture absorptionReligious equipmentBarium nitrateAdhesive

The invention relates to mixed flammable incense and a manufacturing method thereof. The mixed flammable incense comprises an igniting raw material and an incense burning main body raw material, wherein the proportion of the igniting raw material and the incense burning main body raw material is (1:99)-(1:20), the igniting raw material is formed by 15-30 parts of potassium perchlorate, 8-15 parts of antimony sulfide, 3-8 parts of aluminum powder, 0.5-2 parts of barium nitrate, 0.8-1.5 parts of manganese dioxide and 2-3 parts of adhesive, the incense burning main body raw material is formed by aggregate, a binding material, spice, pigment and rosin, and the mixed flammable incense is prepared through squeezing after the igniting raw material and the incense burning main body raw material are completely mixed. The mixed flammable incense disclosed by the invention has the characteristics that the igniting is easy, the burning is full, the adaptive surface is wide, and the like.

Owner:钟发

Sterilization and smoke suppression halogen-free wood fire retardant

InactiveCN106363742AImprove photocatalytic activityGood killing effectWood treatment detailsWood impregnation detailsDecabromodiphenyl etherMoisture absorption

The invention discloses a sterilization and smoke suppression halogen-free wood fire retardant. The sterilization and smoke suppression halogen-free wood fire retardant is composed of, by mass, 40-80 parts of guanyl urea phosphate, 30-50 parts of urea, 10-20 parts of zinc borate, 5-10 parts of ammonium molybdate, 3-10 parts of pentaerythritol, 1-20 parts of ammonium dihydrogen phosphate, 12-25 parts of silica sol, 3-15 parts of decabromodiphenyl ether, 5-10 parts of fatty alcohol-polyoxyethylene ether, 1-20 parts of hexadecyltrimethoxysilane, and 1-20 parts of nanometer titania modified by one of Pt, Ag and Fe<3+>. The sterilization and smoke suppression halogen-free wood fire retardant is good in flame retardant property, high in anti-moisture absorption property and leaching resistance, good in stability, completely non-poisonous and low in cost and has the smoke suppression and sterilization effects.

Owner:GUANGXI UNIV

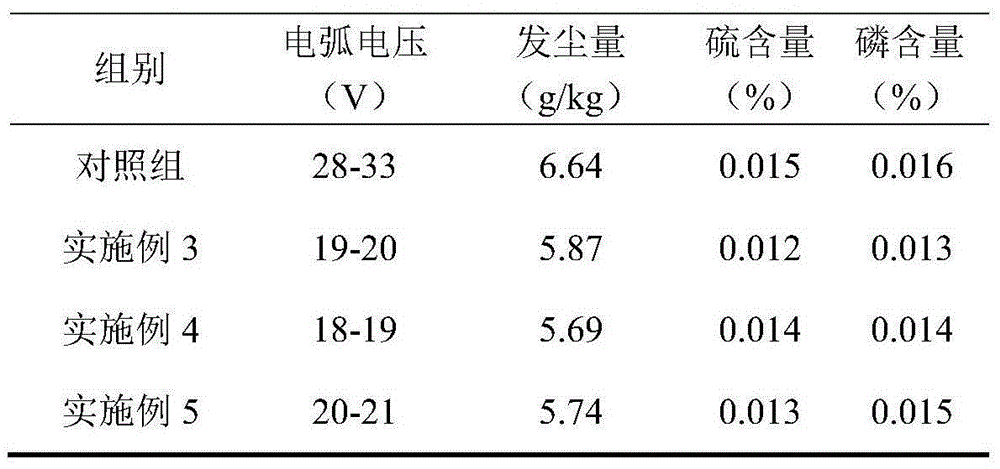

Potassium titanate welding rod material and preparation method thereof

ActiveCN105057921AImprove liquidityStrong resistance to moisture absorptionWelding/cutting media/materialsSoldering mediaChromium carbideTitanium dioxide

The invention discloses a potassium titanate welding rod material and a preparation method thereof. The welding rod material is mainly composed of components of, by weight, 50 parts of potassium carbonate, 40-60 parts of titanium dioxide, 1-7 parts of carbon nano tubes, 5-15 parts of kieselguhr, 1-9 parts of tungsten carbide, 2-8 parts of chromium carbide and 0.5-1.5 parts of nano silica. Compared with the prior art, the welding rod material is used as an additive of welding chemicals, the advantages of both good mobility and high anti-moisture absorption property in the prior art are achieved, most importantly, arc voltage can be reduced apparently, arcs are stabilized, spattering is reduced, and the content of sulphur and phosphorus of the welding rod material is reduced apparently.

Owner:句容亿格纳米材料厂

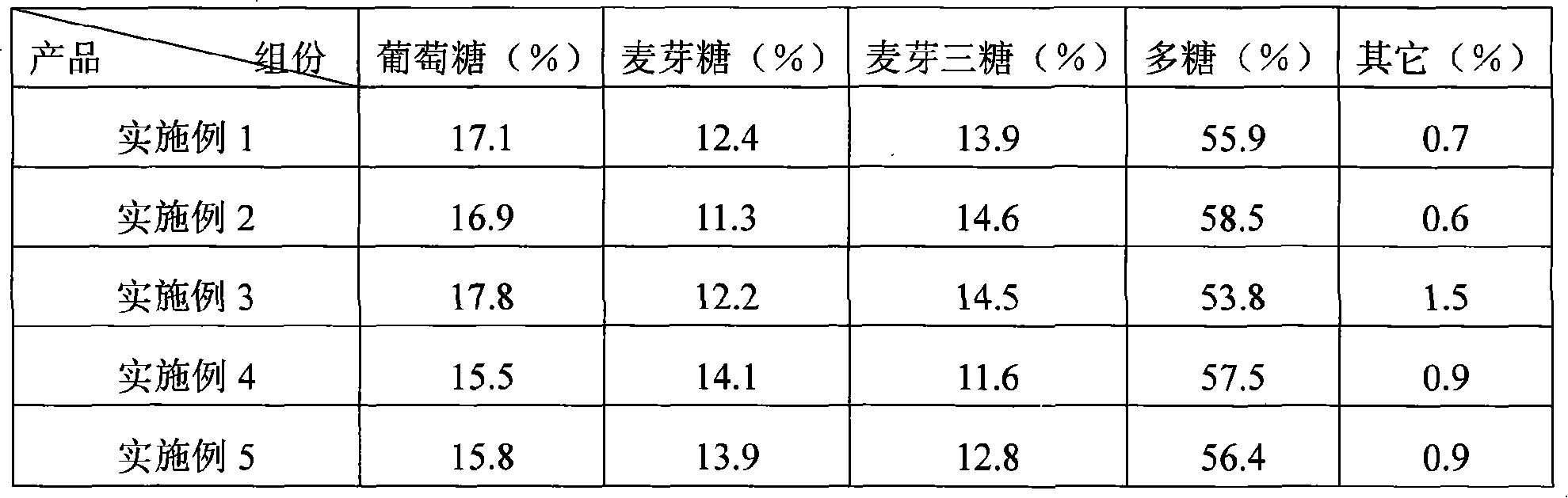

Method for preparing syrup used for sweety

The invention discloses a preparation method of syrup for candies, pertaining to the production field of syrup, and is characterized in that a two enzymes (heat-resistant Alpha-amylase, composite liquefied enzyme) method is adopted and enzyme types, time of adding enzyme and enzyme dosage are controlled so as to prepare the syrup used for candies production. Compared with the prior art, the syrup for candies produced by the preparation method of the invention is characterized by excellent and stable performance, conformance to requirements of the candies production and can be widely applied to the production of various candies and chocolates, thus having good value of popularization and application.

Owner:BAOLINGBAO BIOLOGY

550 MPa-grade flux-cored wire with excellent moisture resistance

ActiveCN112917044AImprove moisture resistanceSimple welding processWelding/cutting media/materialsSoldering mediaShielding gasFerrosilicon

The invention belongs to the technical field of welding materials, and particularly relates to a 550 MPa-grade flux-cored wire with excellent moisture resistance. The flux-cored wire comprises a carbon steel sheath and a flux core. The flux core comprises the following components in percentage by mass: 34-42% of rutile, 2-6% of electrolytic manganese, 10-15% of silicon-manganese alloy, 14-18% of nickel powder, 2-6% of ferrotitanium, 1-5% of aluminum-magnesium alloy, 1-3% of sodium fluoride, 1-4% of zircon sand, 4-8% of ferroboron, 1-3% of potassium titanate, 2-6% of silicon iron, 1-6% of magnesium powder, 2-5% of feldspar, 1-5% of fluorinated ethylene propylene and the balance iron powder. According to the 550 MPa-grade flux-cored wire with the excellent moisture resistance, pure CO2 serves as shielding gas, the 550 MPa-grade flux-cored wire can be used in a maritime work construction working environment, the impact toughness requirement at -40 DEG C is met, the diffusible hydrogen content is lower than 5 ml / 100 g, the yield strength grade of the flux-cored wire is 460 MPa grade, the tensile strength grade reaches 550 MPa grade, and the flux-cored wire is good in cold crack resistance, extremely high in moisture absorption resistance and high in pore resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Nickel-saving high-nitrogen austenitic stainless steel gas-shielded flux-cored wire and preparation method thereof

ActiveCN113146097AReduce nickel contentSimple welding processWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention discloses a nickel-saving high-nitrogen austenitic stainless steel gas-shielded flux-cored wire and a preparation method thereof, and belongs to the technical field of welding materials and welding material manufacturing processes. The technical problem that when high-nitrogen low-nickel austenitic stainless steel is welded at present, the low-temperature impact toughness of a welding joint is not high is solved. The flux-cored wire is prepared from flux core powder and a stainless steel skin wrapping around the flux core powder, the flux core powder is formed by mixing rutile, potassium feldspar, zircon sand, fluorite, cryolite, copper powder, aluminum-iron alloy, electrolytic manganese, atomized ferrosilicon, silicon-calcium alloy, metal nickel, ferromolybdenum, ferrocolumbium, ferrotitanium and nitrided metal chromium. the method comprises the following steps that the mineral powder is dried in batches and mixed with the dried alloy powder, then the outer skin is filled with the mixture, rolling and drawing diameter reducing are conducted, and the flux-cored wire is obtained. According to the nickel-saving high-nitrogen austenitic stainless steel gas-shielded flux-cored wire and the preparation method thereof, the welding wire is excellent in low-temperature mechanical property.

Owner:BEIJING JINWEI WELDING MATERIAL +2

Composite sound-proof formed foaming automobile carpet and preparation method thereof

ActiveCN101574938BStrong composite fastnessGood formabilityVehicle arrangementsSynthetic resin layered productsPolyesterFiber

The invention discloses a composite sound-proof formed foaming automobile carpet and a preparation method thereof. The carpet is made of three layers of materials, namely a fabric layer, a middle multi-layer co-extrusion film layer and a bottom material layer, wherein the fabric layer is made of polyester fiber; the middle multi-layer co-extrusion film layer is made of PE / PE / AD / NYLON / AD / PE / PE multi-layer co-extrusion films; and the bottom material layer is made of polyester fiber. The sound-proof formed foaming automobile carpet provided by the invention has good sound insulation effect, can effectively prevent PU foaming breakdown, and has no toxic odor such as formaldehyde and the like and no penetrating odor; the fabric of the carpet has elegant color and the loop appearance can be adjusted; and the composite sound-proof formed foaming automobile carpet is an environment-friendly carpet with high sound insulation performance. The method for preparing the composite sound-proof formedfoaming automobile carpet provided by the invention has simple process, high efficiency, strong operability, high qualification rate of finished products, and can be suitable for mass production.

Owner:江苏中联地毯有限公司

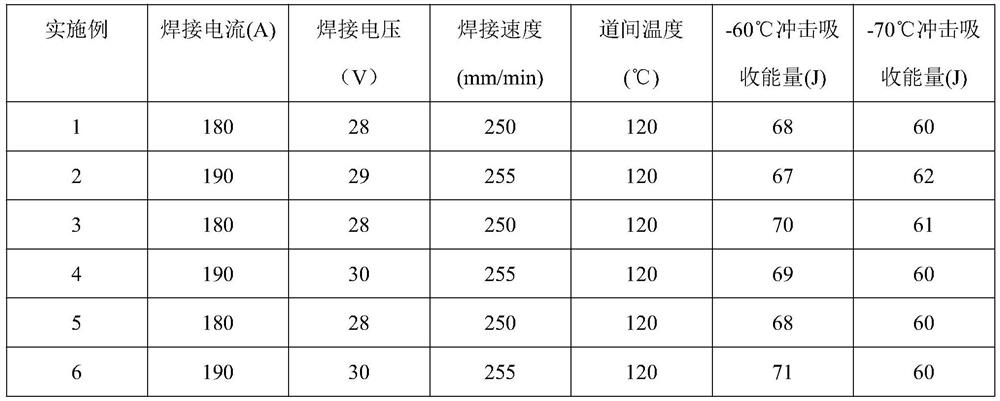

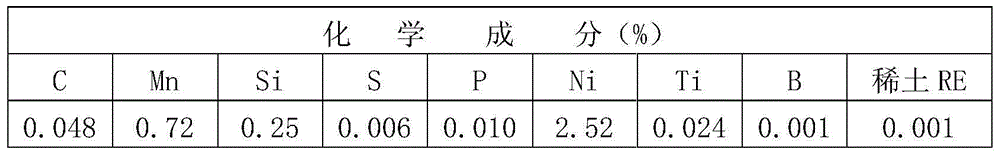

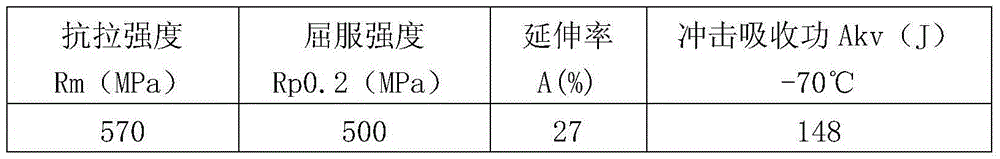

-70 degrees centigrade low-temperature steel welding bar

ActiveCN104551455AReduce segregationDecreased low temperature toughnessWelding/cutting media/materialsSoldering mediaSlagMolten bath

The invention discloses a -70 degrees centigrade low-temperature steel welding bar. The -70 degrees centigrade low-temperature steel welding bar comprises a welding core and a coating, the coating of the welding bar is composed of 44-54% of marble, 15-24% of fluorite, 3-6% of barium carbonate, 2-5% of quartz, 2-5% of dehydration potassium titanate, 0.5-1.5% of borax, 1-3% of manganese metal, 3-6% of atomized ferrosilicon, 1-3% of rare earth ferrosilicon, 3-6% of ferrotitanium, 0.5-1.0% of silicon calcium alloy, 6.0-8.0% of nickel powder and 0.2-1.0% of Teflon. The -70 degrees centigrade low-temperature steel welding bar is featured with low nickel content, less splashing, good molten bath fluidity, uniform slag cover, soft electric arc sound, beautiful weld joint appearance, easiness in sediment separation and good welding technique, the content of diffusible hydrogen in the weld joint metal is within 5ml / 100 g (mercury process), and this meets the standard super-low-hydrogen welding bar requirement.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

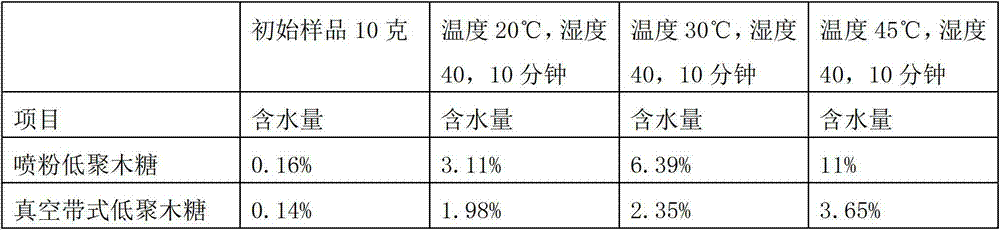

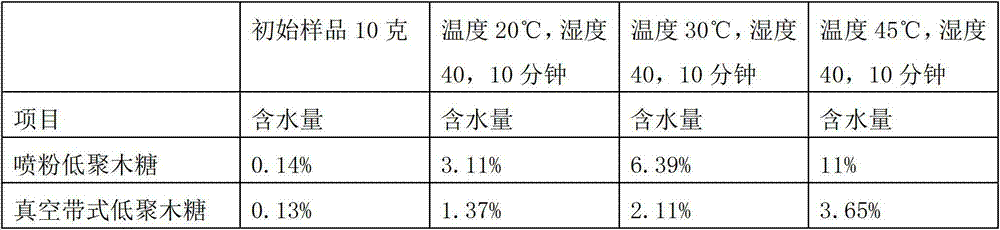

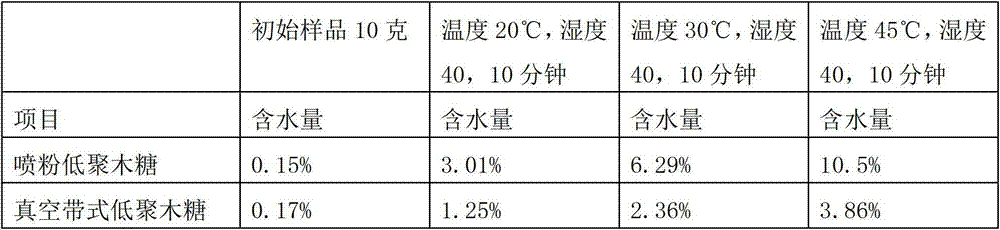

Preparation method of energy-saving moisture-absorption-resisting xylooligosaccharide powder

ActiveCN103045766AGood liquidityStrong resistance to moisture absorptionSaccharides productionChemistryActive carbon

The invention discloses a preparation method of energy-saving moisture-absorption-resisting xylooligosaccharide powder. The preparation method comprises the following steps of: (1) taking an xylooligosaccharide solution, adding active carbon, stirring and decolorizing, filtering after the decolorizing, so as to obtain a decolorizing solution, and adding de-ionized water in the decolorizing solution, so as to obtain the xylooligosaccharide solution after passing through resin for purifying; (2) placing the xylooligosaccharide solution into an evaporator, so as to obtain an xylooligosaccharide concentrated solution; and (3) throwing the xylooligosaccharide concentrated solution into a vacuum belt drier for dry, and then milling, so as to obtain the moisture-absorption-resisting xylooligosaccharide powder. The preparation method provided by the invention comprises the advantages that (1) the process is simple, and the operation and the adjustment are convenient; (2) the moisture absorption resisting capability of the obtained product is high, the storage and the transportation are convenient, and the relatively good flowing property is kept; (3) the intelligent degree of automatization is high, the labour is saved, and the labour intensity is reduced; and (4) the energy consumption is low, and the cost is low.

Owner:山东绿健生物技术有限公司

A modified calcium oxide cement concrete expansion agent and its preparation method

The invention provides a modified calcium oxide expansion agent for cement concrete and a preparation method of the modified calcium oxide expansion agent. The modified calcium oxide expansion agent for the cement concrete is prepared from an ethylene-vinyl acetate copolymer and calcium oxide expansion clinker, wherein the surface of the calcium oxide expansion clinker is coated with the ethylene-vinyl acetate copolymer, and the ethylene-vinyl acetate copolymer accounts for 0.05-10% the total mass of the modified calcium oxide expansion agent for the cement concrete; the specific surface area of the calcium oxide expansion clinker is 100-600m<2> / kg. According to the modified calcium oxide expansion agent for the cement concrete, provided by the invention, the hydration process of the calcium oxide clinker can be adjusted, the invalid hydration of a plastic stage of the concrete is reduced, the hardened expansion quantity is increased, and the shelf life of the expansion agent product is prolonged; the expansion agent can be applied to the crack resisting and seepage prevention of a concrete structure and can be used for greatly improving the durability of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

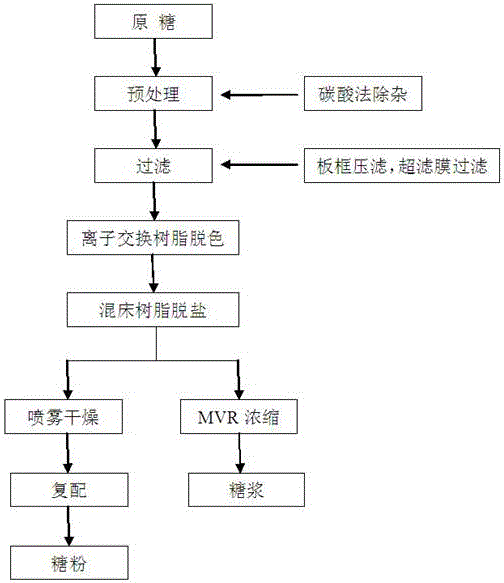

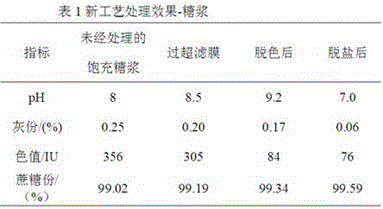

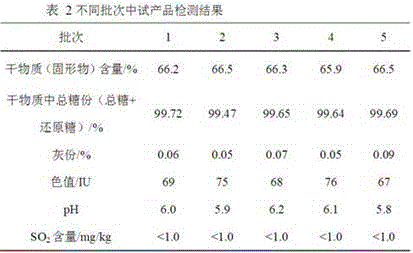

Preparation method of high-quality syrup and powdered sugar

InactiveCN106755606AReduce color valueLow ashSugar productsPurification using alkaline earth metal compoundsIcing sugarFiltration

The invention relates to the technical field of the making of sugar, and particularly discloses a preparation method of high-quality syrup and powdered sugar. According to the preparation method of the high-quality syrup and powdered sugar, raw sugar is used as a raw material. The preparation method is characterized by comprising the following steps of dissolving the raw sugar by using water, so as to obtain raw-sugar syrup, introducing lime milk and the raw-sugar syrup together into a purification system, slowly introducing carbon dioxide into the purification system to carry out carbonation, making carbonated syrup enter a filtration system, and making the carbonated syrup first enter a clarifier and then pass through a hyperfiltration membrane, so as to finally obtain clear juice; subjecting the clear juice to discoloration, desalination and condensation treatment in sequence, so as to obtain target syrup; carrying out spray drying on the desalinated clear juice, so as to obtain the powdered sugar, cooling the powdered sugar, and then compounding the powdered sugar, so as to obtain a final product. The preparation method has the characteristics that the operation is simple (crystallization, evaporation and dissolution are not needed); the energy consumption is low; the cost is low; the product quality is stable and favorable.

Owner:山东星光生物科技有限公司

A kind of water-based self-drying/quick-drying sand casting coating and preparation method thereof

ActiveCN103878302BStrong resistance to moisture absorptionReduce consumptionFoundry mouldsFoundry coresDry sandSand casting

The invention provides a water-based self-drying / quick-drying sand casting paint with fast drying speed, little / no pollution, safe use, low production cost and high sintering peeling rate and a preparation method. The present invention uses natural refractory materials such as zircon powder, chromite powder or zirconium-containing composite silicate powder as the base material without calcination or electric melting treatment, and adopts normal temperature curing type modified high molecular polymer as the main normal temperature Self-drying / low-temperature quick-drying binder, while using quick-drying silicate binder as the main high-temperature binder, using a high-efficiency composite suspension dispersant with high refractoriness and low thermal shrinkage, and adding an appropriate amount of high-efficiency Water reducer and defoamer to produce high solids (non-volatile content), low permeability water-based quick-drying / self-drying coatings for cast steel and cast iron series, which have excellent thixotropy and brushability and fast drying Performance, to achieve the purpose of saving energy, improving the environment, and improving the quality of castings. The invention can be applied to the field of casting coatings.

Owner:广东省铸力铸材科技有限公司 +1

Nano-scale dietary fiber hard capsule and preparation method

InactiveCN101406293BThe interference effect is not significantGreat tasteFood shapingFood preparationCelluloseDietary fiber

The invention discloses a nanometer dietary fiber hard capsule and a preparation technology thereof, wherein a dietary fiber raw material is prepared into a particle which is subjected to film coating, and the coated particle is filled into a cellulose ester capsule shell. The nanometer dietary fiber hard capsule adopts PVA as a coating material of a main film-forming material, has good coating effect, has unobvious interference effect on release of dietary fibers, is economic and accessible, and has better mouthfeel. Adults can directly swallow the capsule; and children and the elderly who are subjected to dysmasesia can break the capsule and directly take the particle in the capsule, the mouthfeel is suitable and the compliance is good. Moreover, after film coating, the phenomena of moisture absorption, bonding and even mildewing of the particle which are usually generated during the storing process can be prevented. The used capsule shell is not the prior gelatin capsule shell but the cellulose ester capsule shell, and has superior heat resistance and flexibility.

Owner:孟繁宇

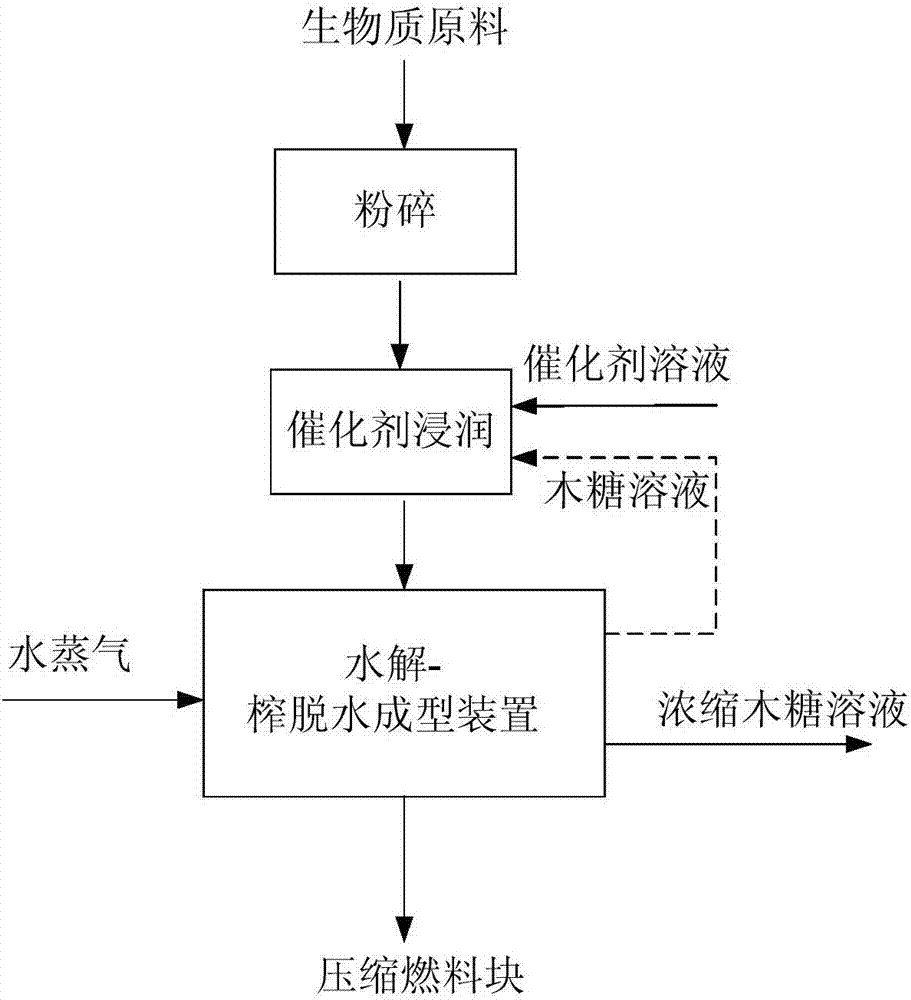

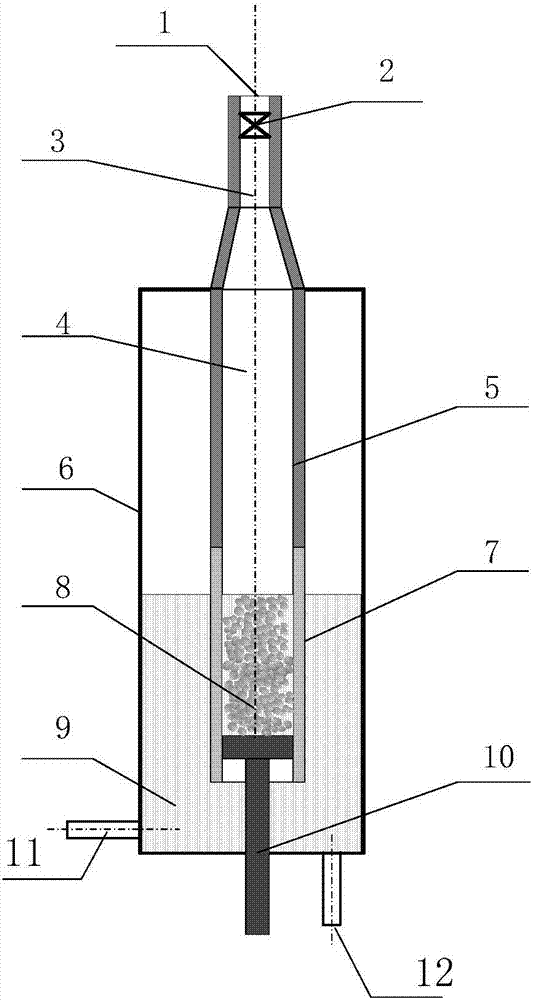

Integrated method for preparing xylose mother liquor from biomass through hydrolysis and of compression molding of residues

InactiveCN107447059AIncrease concentrationReduce moisture contentOrganic chemistrySolid fuelsBrickMoisture

The invention relates to an integrated method for preparing xylose mother liquor from biomass through hydrolysis and for dehydration and compression molding of residues. In a reactor capable of realizing continuous hydrolysis, extrusion dehydration and compression molding of biomass, the biomass is hydrolyzed to produce xylose at first, then undergoes extrusion to remove water and is then subjected to compression molding so as to obtain xylose mother liquor and a compression-molded fuel brick. The method realizes integrated operation of hydrolysis, dehydration and compression molding of biomass raw materials, and can continuously produce xylose mother liquor and the compression-molded fuel brick. The method is advanced in that removal of hemicellulose from biomass, preparation of xylose and dehydration and compression molding of hydrolysis residues are realized at the same time. Through hydrolysis, hemicellulose in the biomass is removed and converted into xylose on one hand; and on the other hand, the interior structure of biomass is opened, lignin is softened, and biomass can be more easily compressed and bonded. Through compression molding, moisture and dissolved xylose are extruded on the one hand, and the compression-molded fuel brick is formed on the other hand.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Traditional Chinese medicine granules for treating cataract and preparation method thereof

InactiveCN107536911AGuaranteed curative effectReduce daily dosageSenses disorderGranular deliveryDiseaseCurative effect

The invention relates to traditional Chinese medicine granules for treating cataract and other eye diseases and a preparation method thereof. Effective constituents of the traditional Chinese medicinegranules are traditional Chinese medicine extract powder which is prepared from, by weight, 15-25 parts of rehmanniae radix praeparata, 10-20 parts of lycii fructus, 9-15 parts of semen plantaginis,10-20 parts of cuscutae semen, 10-14 parts of lycii cortex, 15-25 parts of poria and 10-14 parts of camomile. The traditional Chinese medicine granules are prepared through a secondary granulation technology, have the advantages of being uniform in granule size, high in shaping rate, low in hygroscopicity, convenient to take and precise in curative effect, and are suitable for industrial production and clinical application.

Owner:NINGXIA MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com