-70 degrees centigrade low-temperature steel welding bar

A low-temperature steel and welding rod technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of low low-temperature impact value, reduced welding toughness, instability, etc., to reduce sulfur content and improve low-temperature impact Toughness, segregation reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

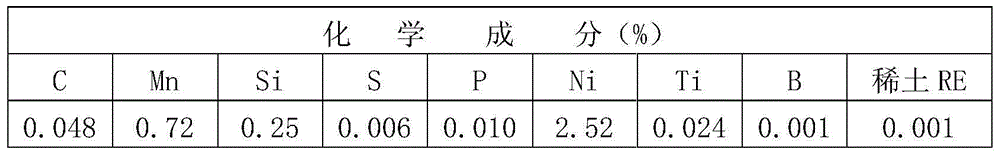

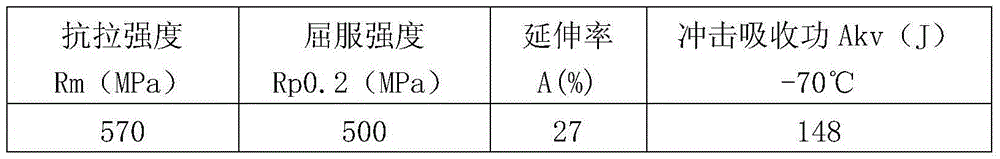

Embodiment 1

[0019] Embodiment 1: each component of drug skin and the mass percentage of each component are shown in the following table:

[0020] Raw material name

mass percentage

Raw material name

mass percentage

marble

43.8%

Atomized ferrosilicon

5%

23%

Rare earth ferrosilicon

2%

6%

ferro-titanium

6%

2%

0.5%

2%

nickel powder

7.5%

0.5%

Teflon

0.2%

1.5%

[0021] According to the above ratio, it is mixed into the electrode coating material, and the potassium and sodium mixed water glass is added to the electrode coating material, which is coated on the H04E special high-quality low-carbon and low-sulfur steel welding core by the electrode press coating machine, and then passed through the dryer. Drying and shaping to make we...

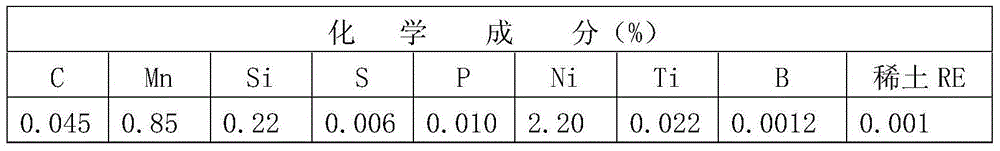

Embodiment 2

[0028] Embodiment 2: each component of drug skin and the mass percent of each component are shown in the following table:

[0029] Raw material name

mass percentage

Raw material name

mass percentage

marble

53.5%

Atomized ferrosilicon

3%

16%

Rare earth ferrosilicon

3%

3%

ferro-titanium

3%

3%

1%

3%

nickel powder

6.5%

1%

Teflon

1%

manganese metal

3%

[0030] According to the above ratio, it is mixed into the electrode coating material, and the potassium and sodium mixed water glass is added to the electrode coating material, which is coated on the H04E special high-quality low-carbon and low-sulfur steel welding core by the electrode press coating machine, and then passed through the dryer. Drying and shaping to make welding rods ...

Embodiment 3

[0037] Embodiment 3: each component of drug skin and the mass percent of each component are shown in the following table:

[0038] Raw material name

mass percentage

Raw material name

mass percentage

marble

48%

Atomized ferrosilicon

4%

18.4%

Rare earth ferrosilicon

2%

4%

ferro-titanium

4%

quartz

3%

0.7%

Potassium titanate dehydrate

5%

nickel powder

7%

1.5%

Teflon

0.4%

manganese metal

2%

[0039]According to the above ratio, it is mixed into the electrode coating material, and the potassium and sodium mixed water glass is added to the electrode coating material, which is coated on the H04E special high-quality low-carbon and low-sulfur steel welding core by the electrode press coater, and then passed through the dryer. Drying and shaping to make welding rods of var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com