130KSI-grade and 135KSI-grade corrosion-resistant drill tool steel for oil and gas fields and manufacturing method thereof

A manufacturing method and oil and gas field technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of design, production, and manufacturing difficulties, and achieve the effects of saving production processes and costs, excellent strength and toughness, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

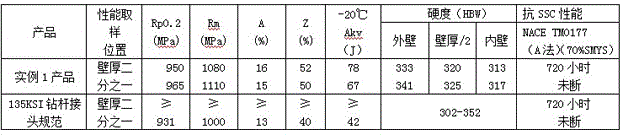

Embodiment 1

[0052] The diameter of the drilling tool steel bar used in the development of oil and gas fields involved in this example is 170 mm, and the contained element components and their mass percentages are: C: 0.28%, Si: 0.25%, Mn: 0.97%, P: 0.007%, S : 0.002%, Cr: 1.42%, Mo: 0.88%, V: 0.08%, Nb: 0.027%, Ni: 0.13%, Cu: 0.12%, Al: 0.027%, Ca: 0.0027%, the balance is Fe and impurities element.

[0053] The production process of the above-mentioned bars is as follows:

[0054] The smelting raw materials are configured according to the chemical element composition of the above-mentioned steel, followed by KR molten iron pretreatment-converter primary smelting-LF furnace refining-RH furnace vacuum degassing-continuous casting of 390×510mm rectangular billet-slab slow cooling-casting billet shot blasting -Continuous heating furnace heating-high pressure water descaling-continuous rolling-bar slow cooling-stress relief annealing-peeling-ultrasonic flaw detection + surface flaw detection ...

Embodiment 2

[0069] The diameter of the steel bar used in oil and gas field development involved in this example is 230mm, and the components and their mass percentages are: C: 0.29%, Si: 0.27%, Mn: 0.98%, P: 0.007%, S: 0.002% , Cr: 1.37%, Mo: 0.86%, V: 0.06%, Nb: 0.026%, Ni: 0.15%, Cu: 0.13%, Al: 0.025%, Ca: 0.0024%, and the balance is Fe and impurity elements.

[0070]The smelting, continuous casting, rolling and annealing processes of this implementation example are basically the same as those of Example 1 (wherein the size of the continuous casting slab produced is 600mm round slab), the main difference lies in the difference of subsequent products.

[0071] Round steel materials are used to manufacture heavy-duty drill pipe products. The specific production process is as follows: Round steel—fine straightening—normalizing + quenching + tempering—inner drilling—outer turning—comprehensive testing (hardness, mechanical properties, etc.)—inner Circular expansion drilling—ultrasonic flaw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com