Patents

Literature

351results about How to "Organizational stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

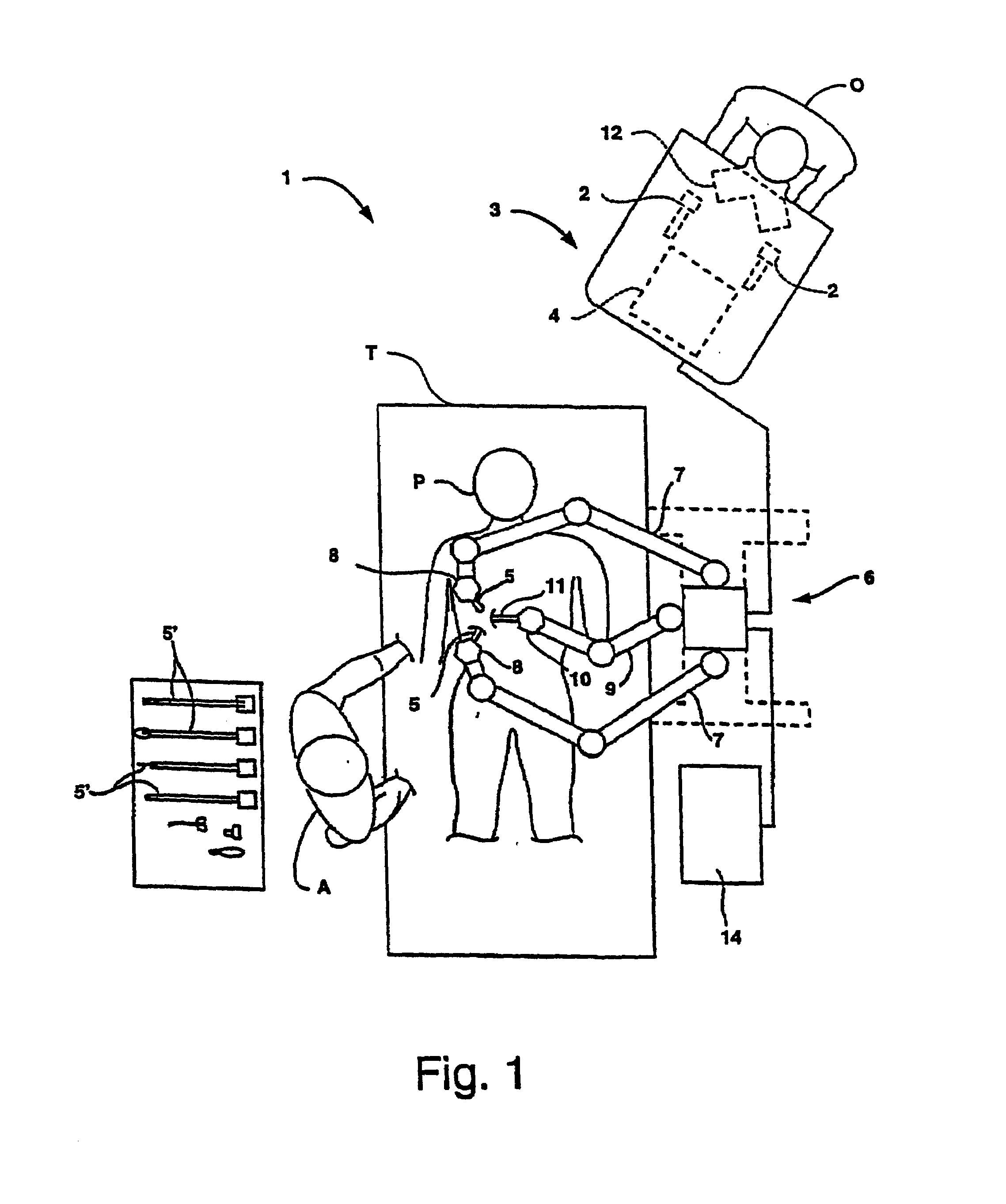

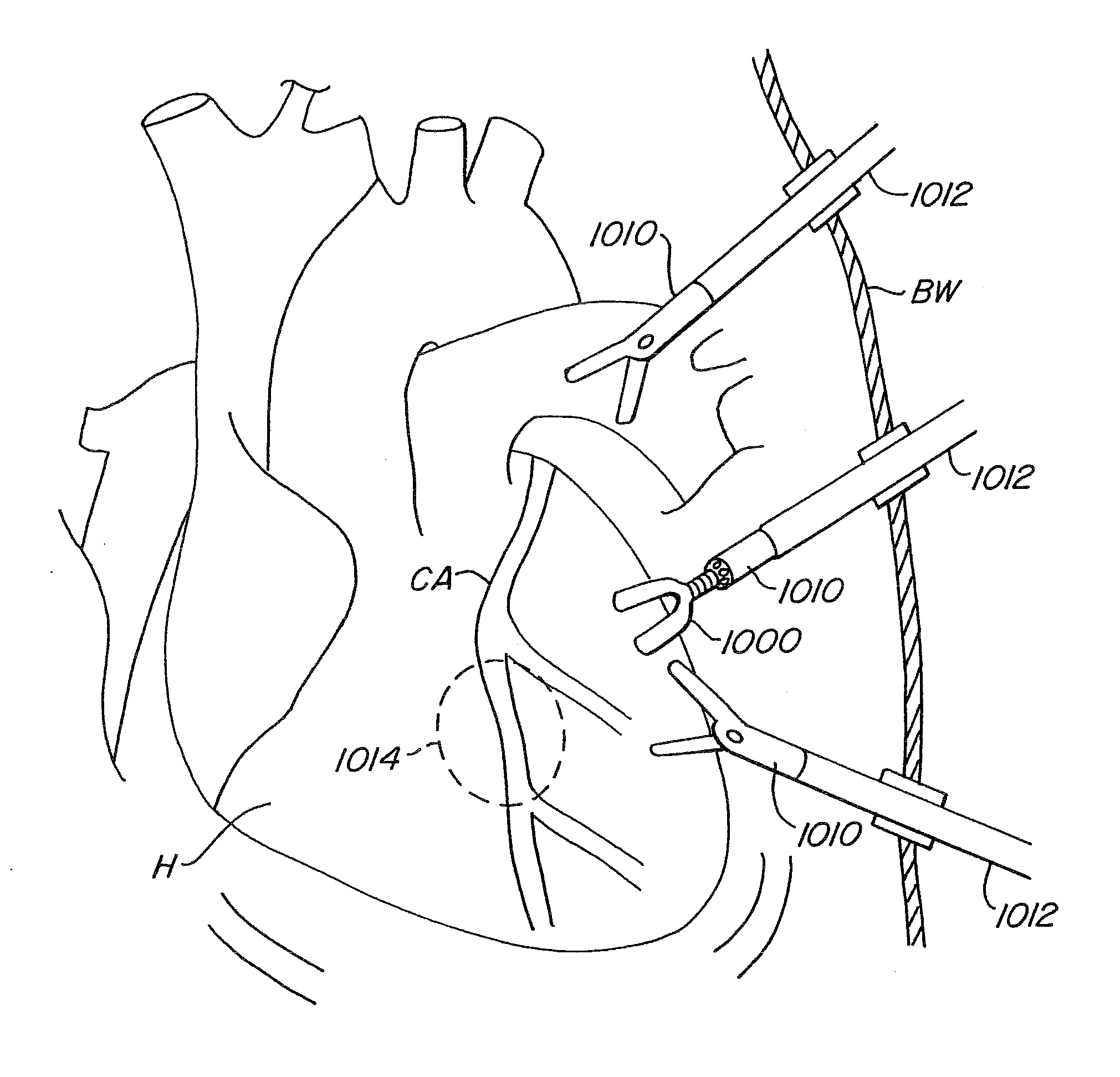

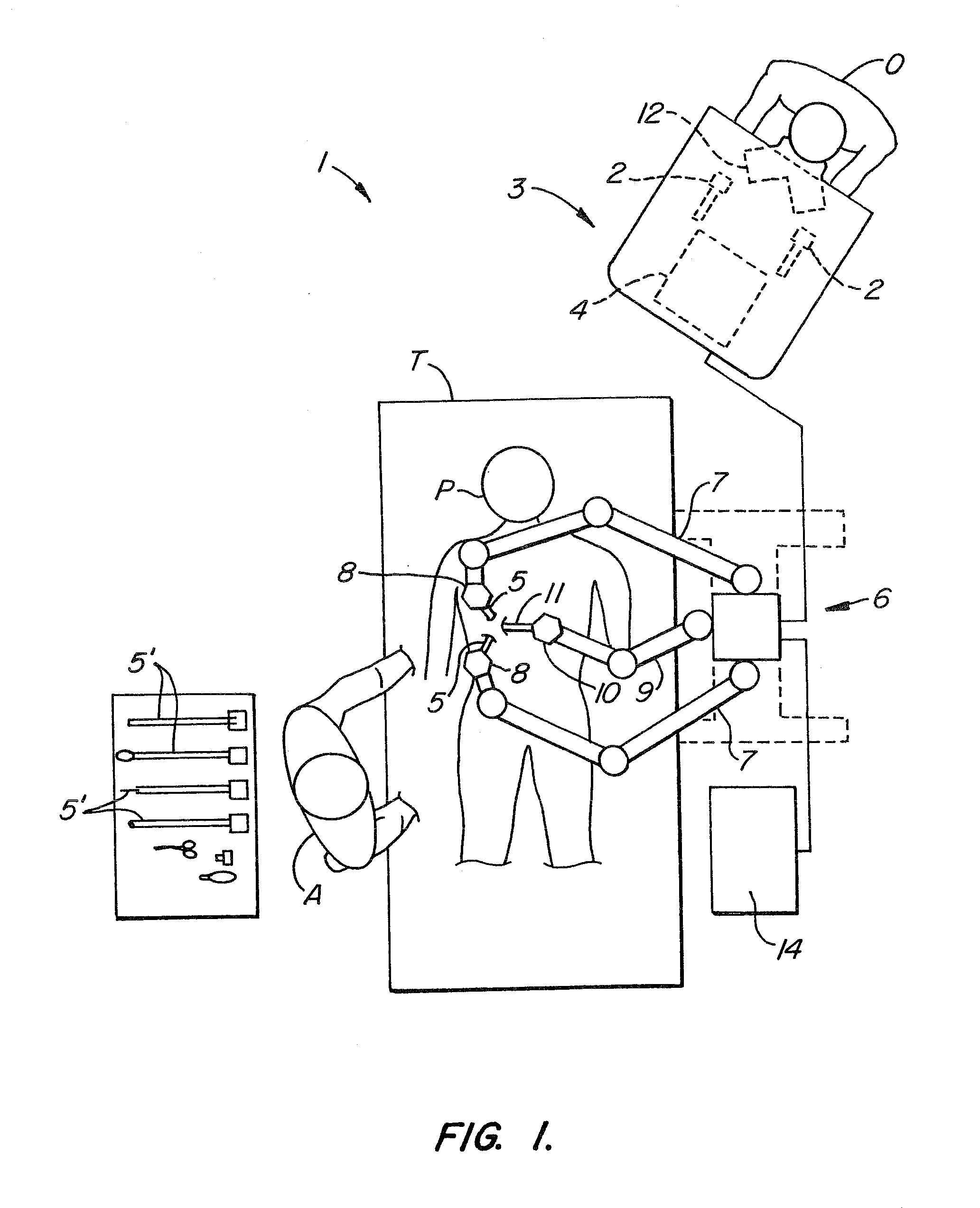

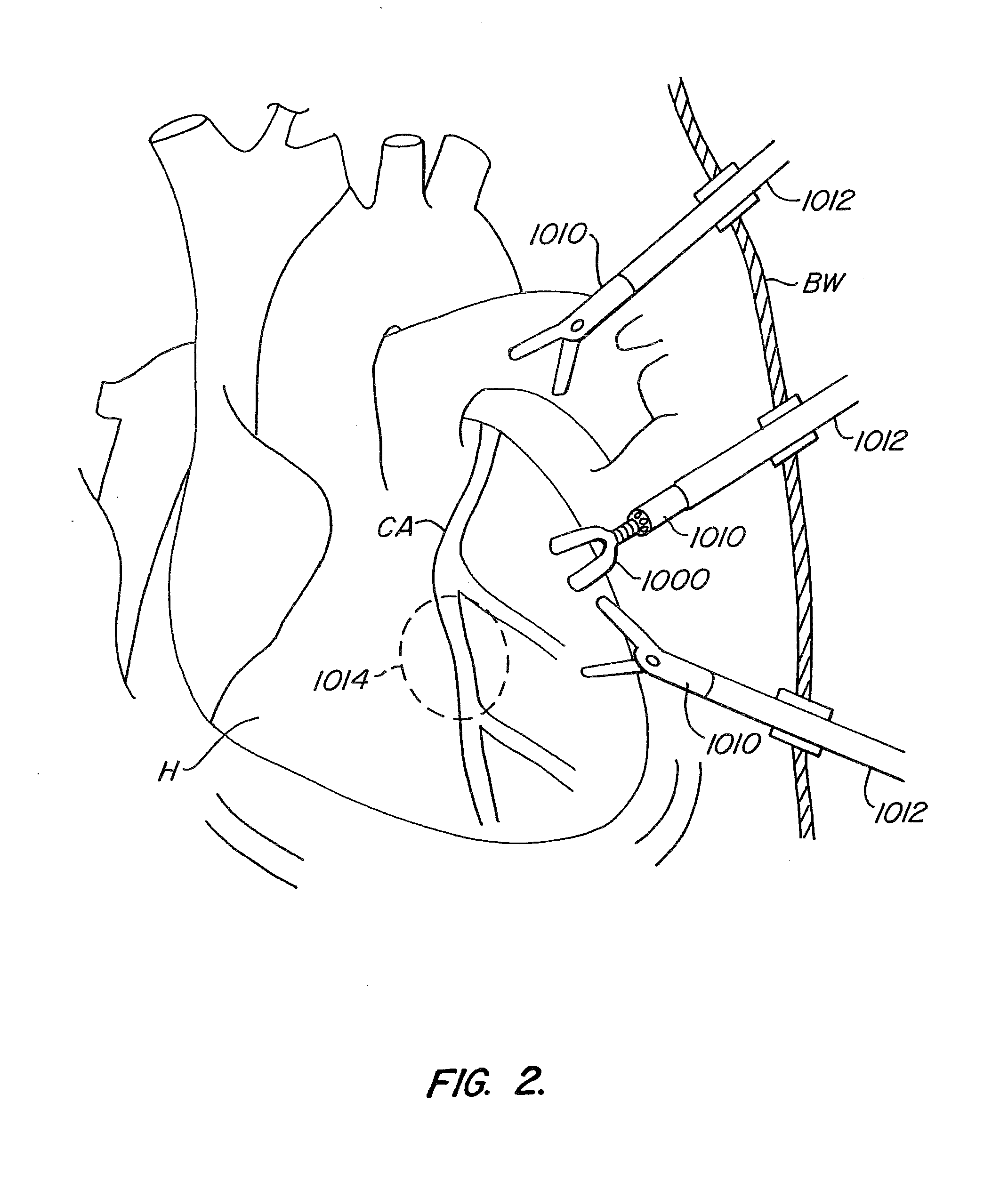

Endoscopic beating-heart stabilizer and vessel occlusion fastener

InactiveUS7250028B2Physiological motion of stabilizedAvoid relative motionSuture equipmentsDiagnosticsSurgical operationSurgical department

Owner:INTUITIVE SURGICAL OPERATIONS INC

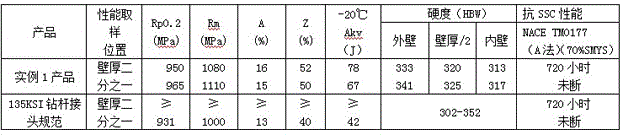

130KSI-grade and 135KSI-grade corrosion-resistant drill tool steel for oil and gas fields and manufacturing method thereof

ActiveCN107177797AImprove strength and toughnessMeet anti-H

<sub>2</sub>

S corrosion characteristics requirementsFurnace typesHeat treatment furnacesMechanical propertyContinuous rolling

The invention relates to high-toughness and hydrogen sulfide corrosion resistant round steel and a manufacturing method thereof. The round steel comprises, by mass, 0.25-0.40% of C, 0.20-0.45% of Si, 0.95-1.50% of Mn, 1.35-1.90% of Cr, less than or equal to 0.002% of S, less than or equal to 0.008% of P, 0.75-1.30% of Mo, 0.10-0.30% of Ni, 0.05-0.25% of V, 0.010-0.050% of Nb, 0.10-0.30% of Cu, less than or equal to 0.050% of Al, 0.0005-0.005% of Ca, and the balance Fe and unavoidable impurity elements. The hot-rolled round steel is produced through a process route of continuous casting-continuous rolling-annealing, the round steel is subjected to heat treatment directly, or a machined semi-finished drill tool is subjected to heat treatment. On the premise that related 130KSI and 135KSI synthesized mechanical properties are met correspondingly, according to an America NACE TM0177 standard hydrogen-sulfide-resistant stress corrosion test, a product is not broken for 720 hours under the condition that 70% of nominal yield stress is pre-loaded in a saturated H2S solution. The material is suitable for 130KSI-strength-grade and 135KSI-strength-grade drill tools under the mining environment of acidic oil and gas fields.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Fresh and cool enzymolysis grain beverage and preparation method thereof

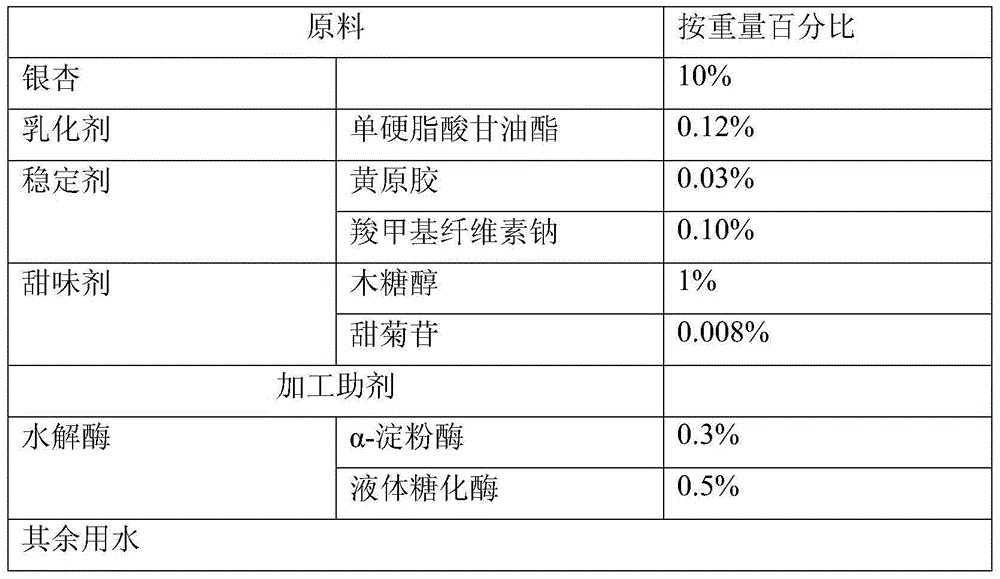

The invention provides a fresh and cool enzymolysis grain beverage and a preparation method thereof, relating to a non-alcoholic beverage. The invention aims to provide a fresh and cool enzymolysis grain beverage which retains original nutrition and functional components of grains and is fine, fresh and cool in taste, stable in product composition and low in viscosity, and a preparation method thereof. The beverage is prepared from the following raw materials: 8-12% of grains, 0.01-0.2% of sodium citrate, 0.01-0.4% of emulsifier, 0.05-0.5% of stabilizer, 1.0-2.3% of processing auxiliary agent and the balance of water. The preparation method comprises the steps of: pre-cooking or baking the grains, carrying out colloid milling and homogenizing, adding the processing auxiliary agent, carrying out enzymolysis, then inactivating the enzyme, separating, and filtering to obtain coarse fiber and a material liquid C; adding the material liquid C, sodium citrate, emulsifier and stabilizer to hot water, diluting to certain volume with blending water to obtain a blended liquid, cooling, then conveying to an ultrahigh-temperature instantaneous sterilizing system, preheating, degassing, homogenizing, and then carrying out ultrahigh-temperature instantaneous sterilizing; and filling the blended liquid after ultrahigh-temperature instantaneous sterilizing, and then packaging.

Owner:XIAMEN HUIERKANG FOOD

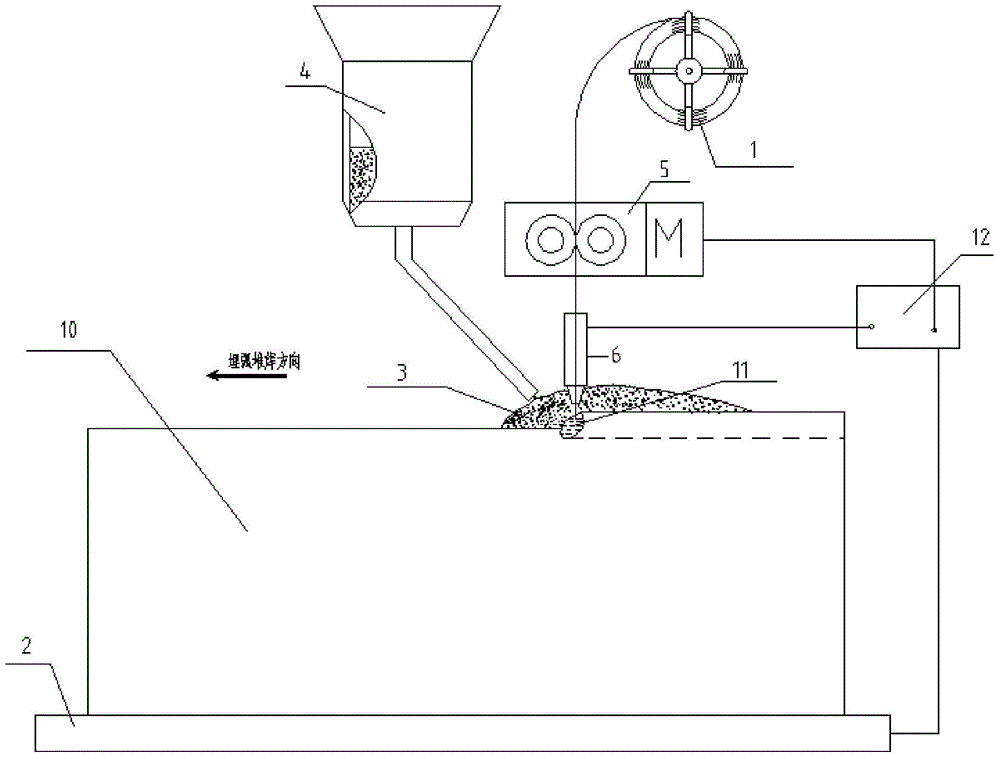

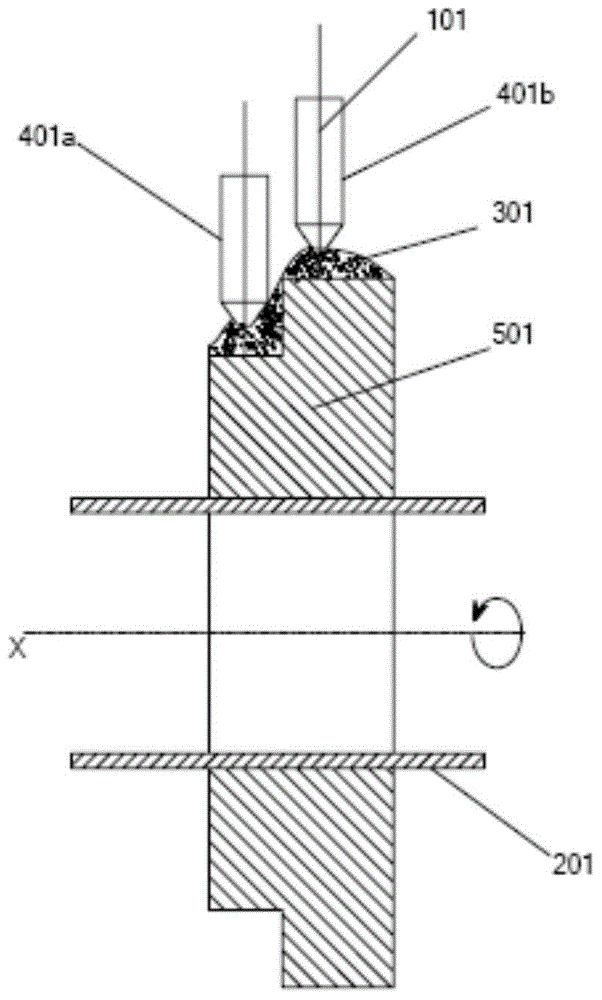

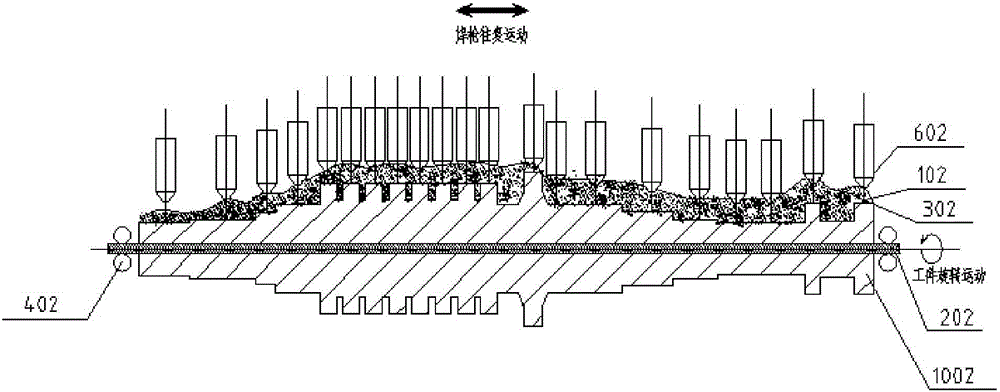

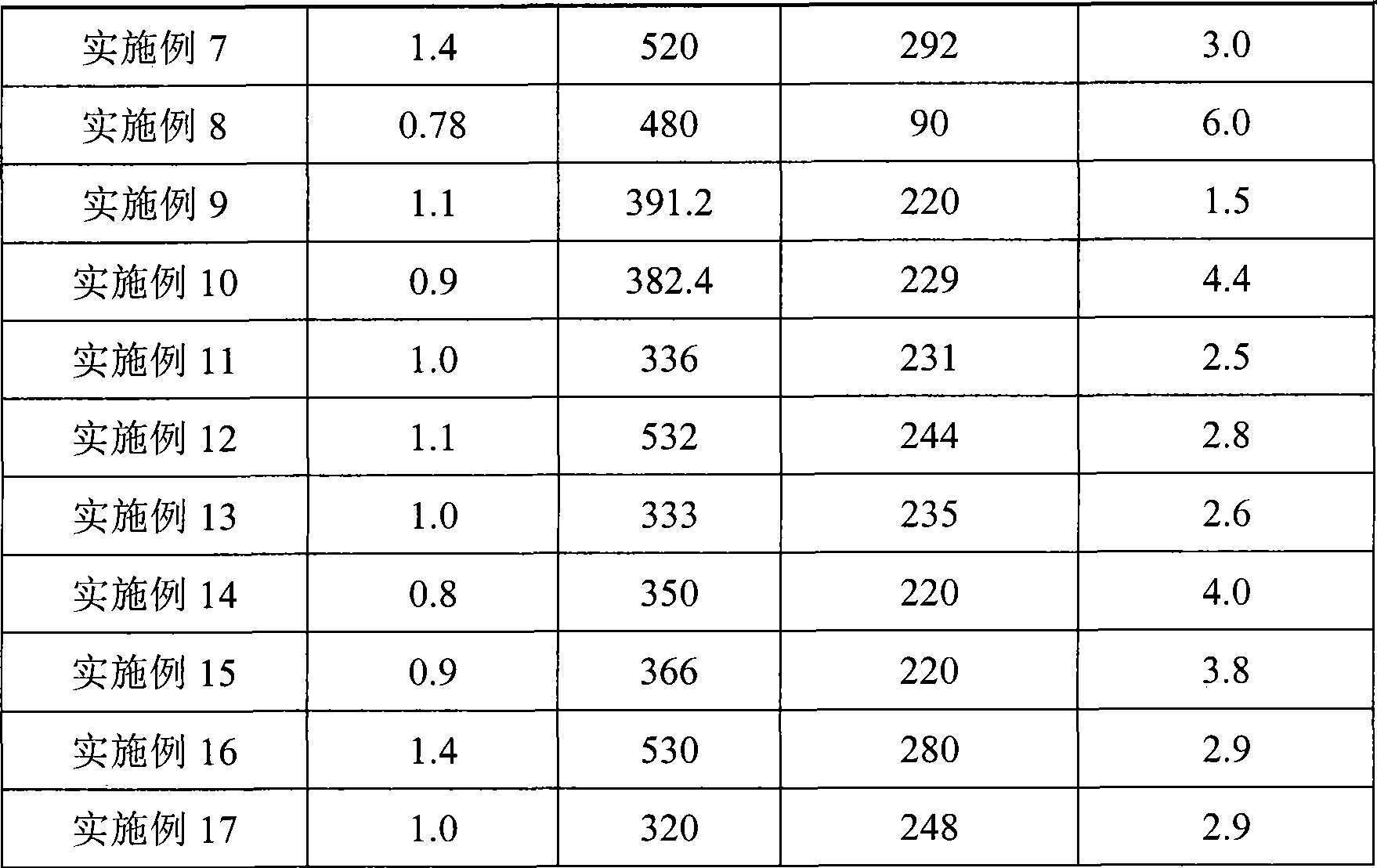

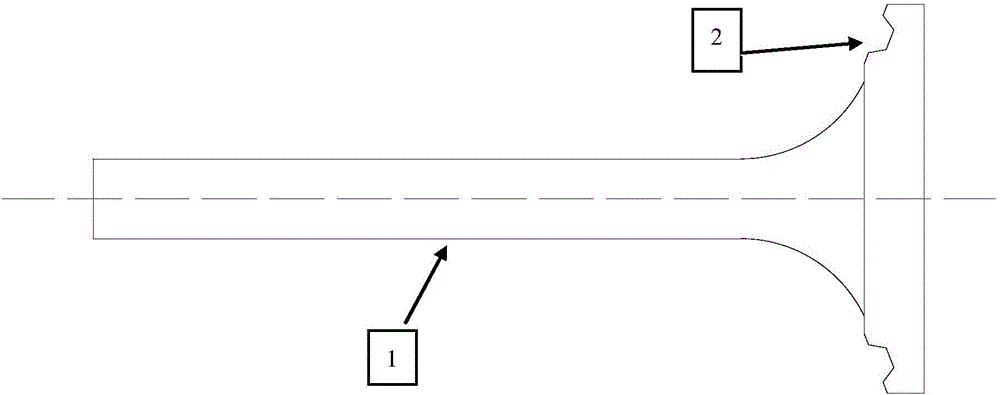

Metal component submerged arc overlay welding forming method

ActiveCN104526114AUniform tissueOrganizational stabilityArc welding apparatusElectric arcEngineering

The invention provides a high efficient submerged arc additive manufacturing method for a metal component with good mechanical property. The metal component submerged arc overlay welding forming method is as follow: two poles of a welding power supply are connected with a welding gun and a base material respectively, a particle-shaped welding flux and a metal welding wire are synchronously conveyed to the surface of the base material, the power is switched on, an electric arc is generated between the welding wire and the base material under the coverage of the welding flux, so that the surfaces of the welding wire and the base material locally melt, a weld pool is formed on the surface of the base material, the welding wire and the welding flux are continuously conveyed, the relative movement track of the welding gun and the base material is controlled according to the component digital to analog data, and a metal component is formed through layer-by-layer overlay welding deposition on the base material.

Owner:NANFANG ADDITIVE MFG TECH

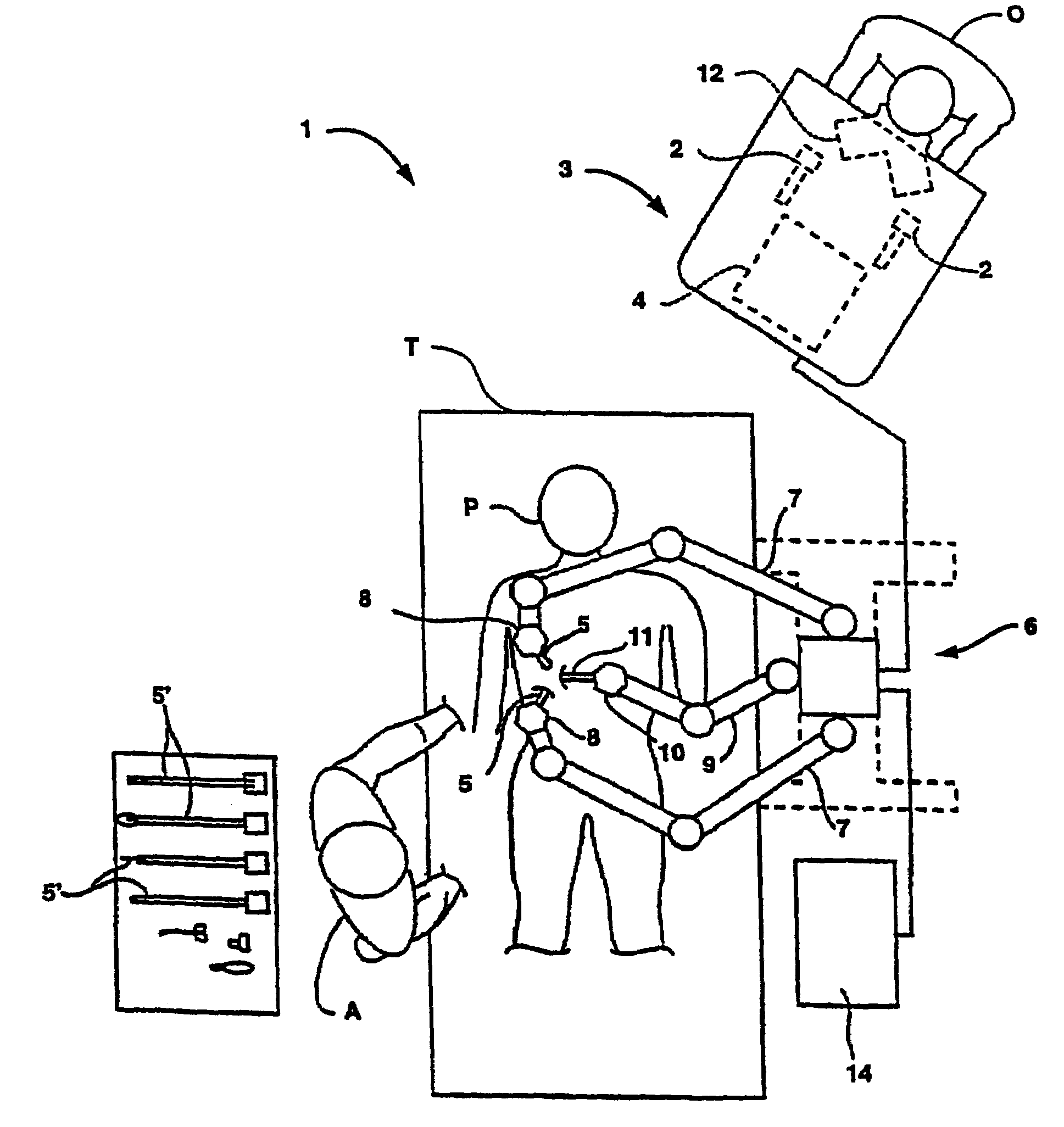

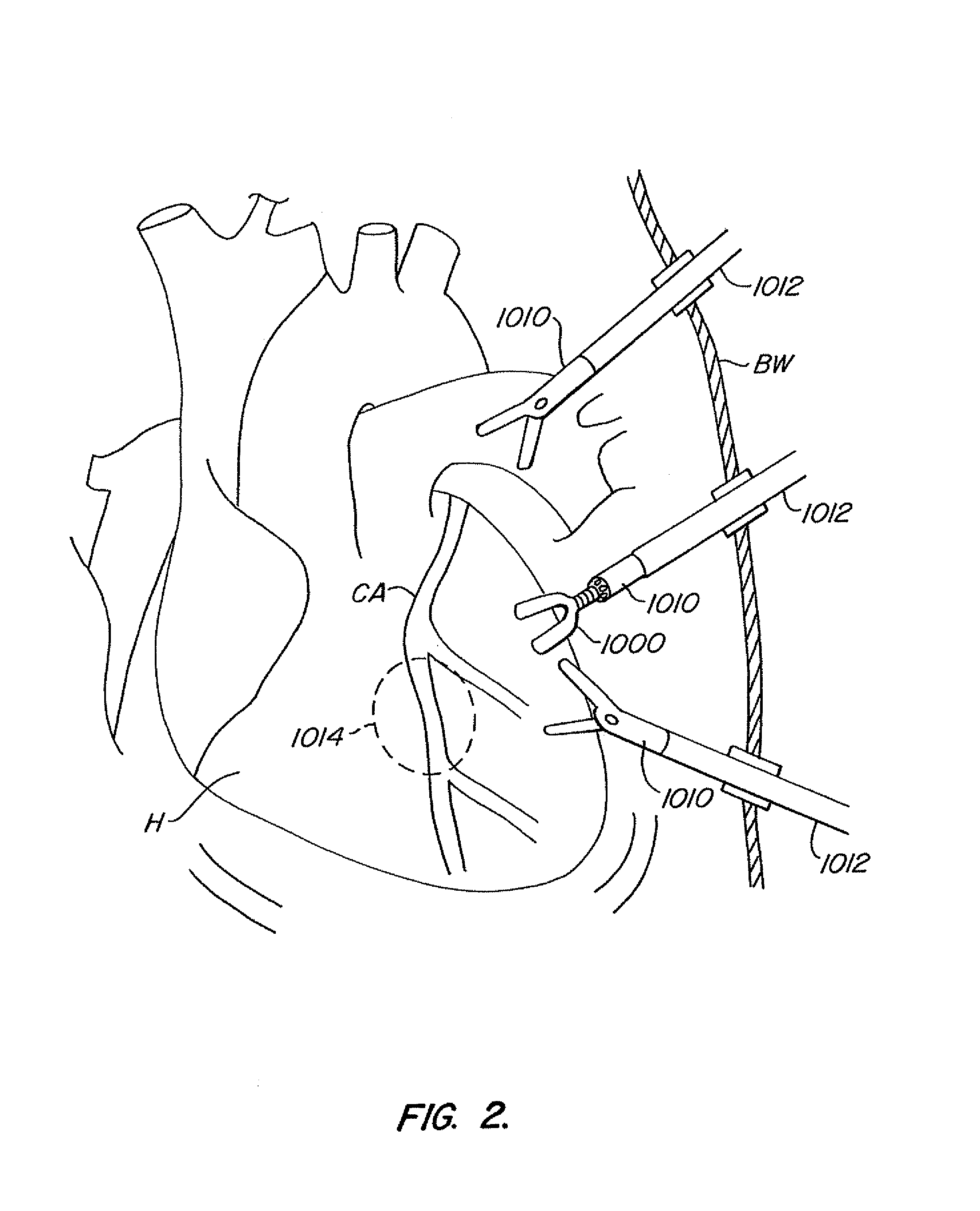

Endoscopic beating-heart stabilizer and vessel occlusion fastener

ActiveUS20070208223A1Smooth motionAvoid relative motionSuture equipmentsEndoscopesSurgical operationTarget tissue

Devices, systems and methods related to endoscopic surgery, particularly related to robotic surgical operations, provide a tissue stabilizer for endoscopically stabilizing a target tissue within a patent's body. For stabilizing a beating heart during a closed-chest coronary artery bypass grafting procedure, a stabilizer is inserted through an endoscopic cannula and provides sufficient surface area to contact the heart and effectively stabilize the target tissue area. The stabilizer can straddle a blood vessel, such as a coronary artery, which is targeted for an anastomosis. Vessel occlusion fasteners may occlude the target blood vessel prior to the anastomosis procedure.

Owner:INTUITIVE SURGICAL OPERATIONS INC

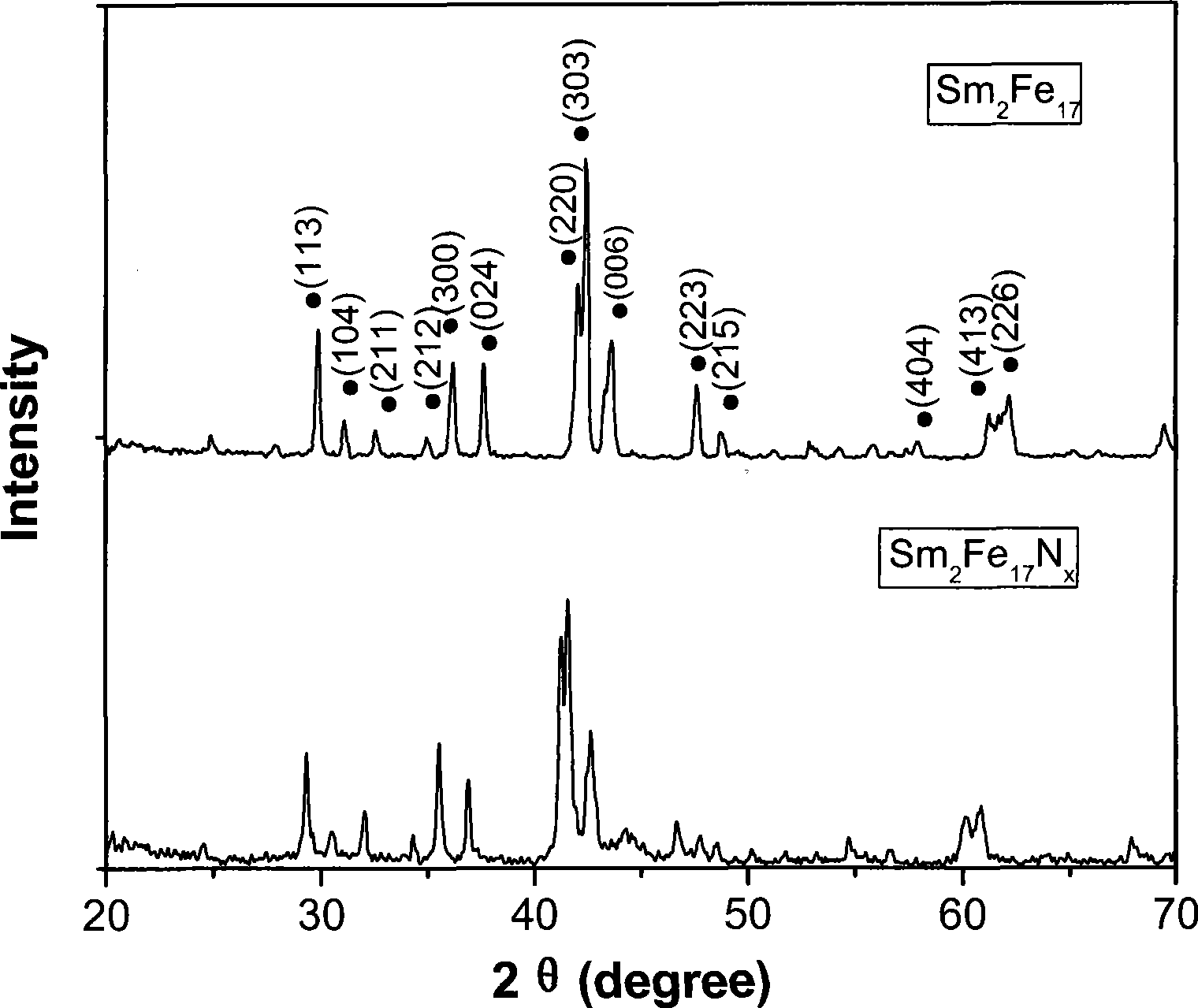

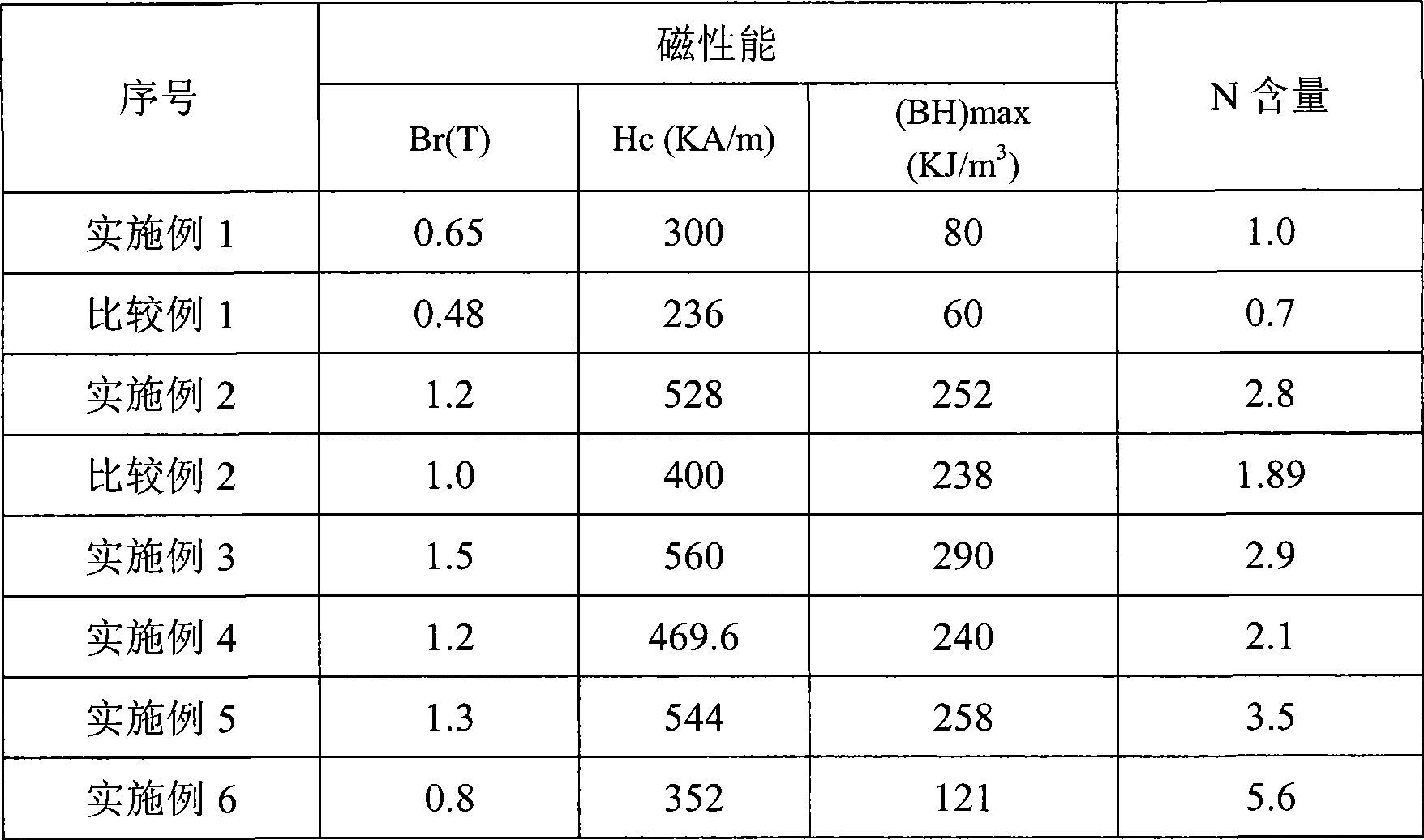

Nitrogen-containing rare-earth magnetic powder and preparation method thereof

ActiveCN101546642AIncrease the speed of diffusionPromote decompositionInorganic material magnetismRare-earth elementLanthanide

The invention discloses a nitrogen-containing rare-earth magnetic powder prepared by taking ferrocene, cyclopentadienyl lanthanide, metallic iron and rare earth as the main raw materials. The nitrogen-containing rare-earth magnetic powder comprises the following component of R2Fe17-xMxNy, wherein the R is one or more kinds of 17 kinds of rare earth elements including Sc and Y, the M includes transitional elements except for Fe and is one or more kinds of Al, Ga, In, Si, Ge, Sn, Pb, Mg and Ca, the x is equal to 0 to 5, and the y is equal to 1 to 6; and the preparation method comprises the following steps: working procedure of preparation of the R2Fe17-xMx compound powder; working procedure of nitridation; and working procedure of magnetic powder refining and nitriding.

Owner:GUOKE RE ADVANCED MATERIALS CO LTD

Welding technology for nickel base alloy build-up welding of marine low-speed machine air valve sealing face

InactiveCN106112204AReduce manufacturing costIncrease productivityArc welding apparatusWelding/cutting media/materialsShielding gasWelding power supply

The invention discloses a welding technology adopting consumable electrode pulse gas-shielded welding for nickel base alloy build-up welding of a marine low-speed machine air valve sealing face according to the base material characteristics of an air valve, the weldability of nickel base alloy, an annular ship type welding groove of the air valve sealing face and the use condition of the air valve. The consumable electrode pulse gas-shielded welding mode is adopted, the welding power, the welding parameters and the shielding gas constituents are proportioned, factors such as forming of welding liens, globular transferring, arc striking, arc quenching, the overlap amount, preheating and the interlayer temperature are controlled, and the welding defects such as air holes, incomplete fusion and porosity of nickel base alloy build-up welding of the sealing face can be overcome in the existing producing and machining process of the air valve of a marine diesel engine. Thus, the high-quality air valve can be obtained, the production cost of enterprises can be effectively lowered, and the production efficiency of the enterprises can be improved.

Owner:NANJING INT MARINE EQUIP & SPARES

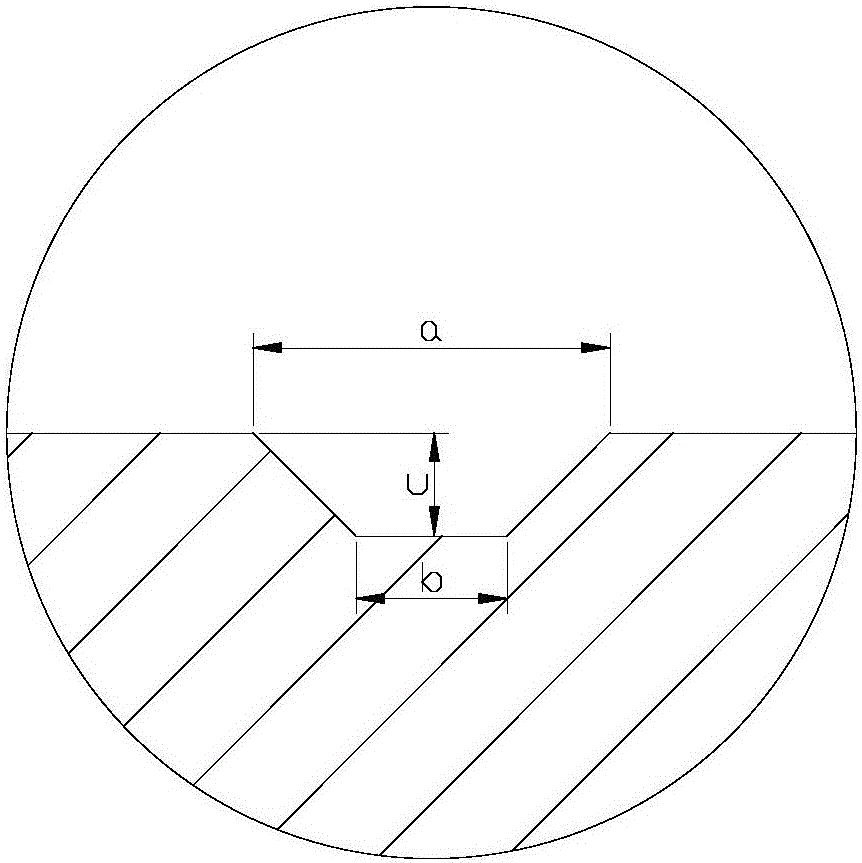

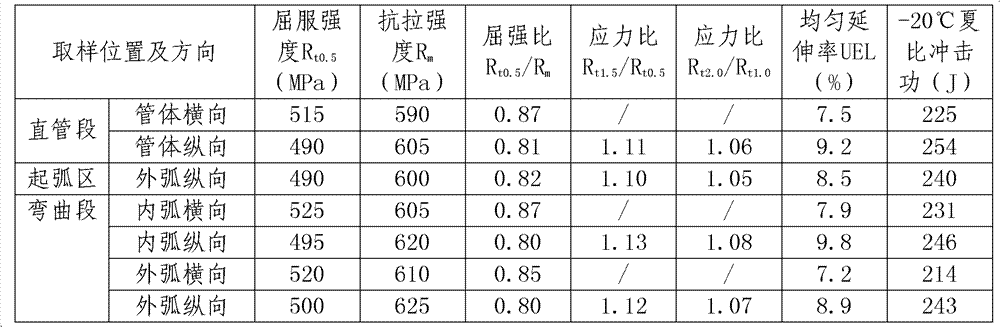

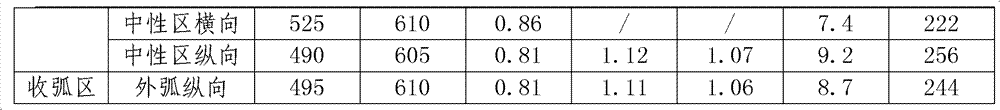

Manufacturing method of X70 large-deformation steel fire-bent pipe

InactiveCN103088270AUniform tissueOrganizational stabilityFurnace typesHeat treatment furnacesTemperingHeat conservation

The invention discloses a manufacturing method of an X70 large-deformation steel fire-bent pipe. The manufacturing method comprises the following steps of 1, utilizing a straight seam submerged-arc welding steel pipe made by steel plate controlled-rolling and controlled-cooling as a base pipe, 2, carrying out medium-frequency induction heating bending of the main pipe by an integral heating quenching bending technology under the conditions of an induction heating temperature of 950 to 1050 DEG C and a feeding rate of 40 to 80mm / min, and cooling at a cooling rate greater than or equal to20DEG C / s by an external spray cooling method, and 3, putting the fire-bent pipe obtained by the step 2 into a heating furnace, carrying out integral heating at a temperature of 700 to 850 DEG C, carrying out heat preservation for 1.0 to 2.0 hours, carrying out quenching, and carrying out integral tempering under the conditions of a tempering temperature of 350 to 550 DEG C and tempering heat preservation time of 1.5 to 2.5 hours. The X70 large-deformation steel fire-bent pipe obtained by the manufacturing method has bent pipe strength and toughness satisfying X70 standard requirements, a high longitudinal tensile stress ratio, a high uniform elongation percentage, and a good longitudinal deformation capability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Mineral high-strength wear-resistant material and preparation method thereof

The invention discloses a mineral high-strength wear-resistant material which is prepared from the following raw materials in percentage by weight: 0.30-0.50% of C, 0.10-0.65% of Si, less than or equal to 1.0% of Mn, 1.0-4.5% of Cr, 0.05-3% of Ni, 0.15-1.5% of Mo, 0.05-0.5% of V, 0.010-0.5% of Nb, 0.01-0.5% of Al, less than or equal to 0.025% of P, less than or equal to 0.015% of S and the balanceof Fe. A chain wheel manufactured from the mineral high-strength wear-resistant material is excellent in alloy element proportion, is pure in steel, is uniform in structure, has excellent comprehensive performance, is high in chain gear hardness, is uniform in hardness and is good in wear resistance; and meanwhile, a base body part has good impact toughness and strength. The defects that a commonChinese chain wheel is poor in comprehensive performance and is low in coal passing amount are solved. The mineral high-strength wear-resistant material greatly improves the coal passing amount of the chain wheel, reduces chain wheel use cost, and improves economic benefits.

Owner:YINGKOU SPECIAL STEEL FORGING

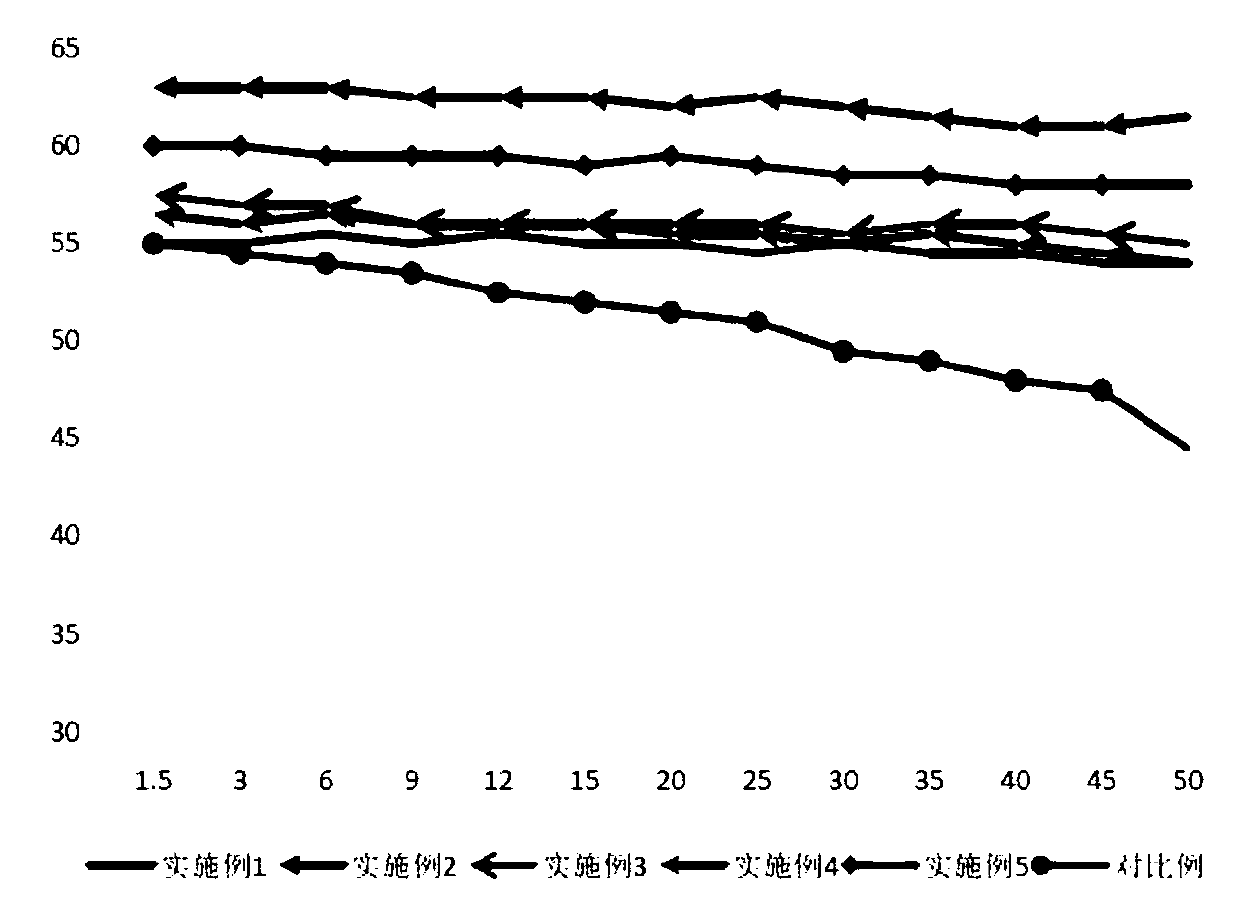

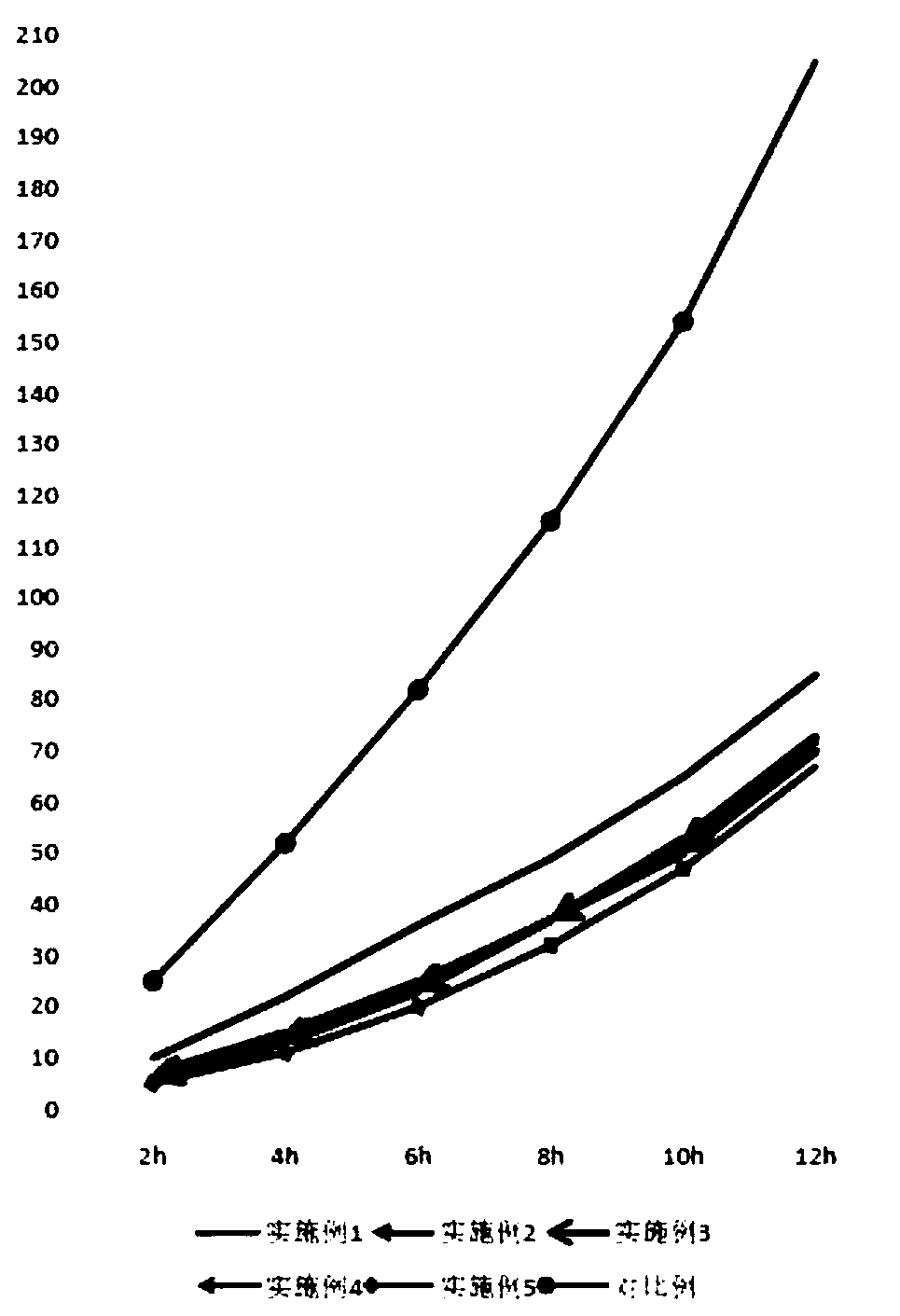

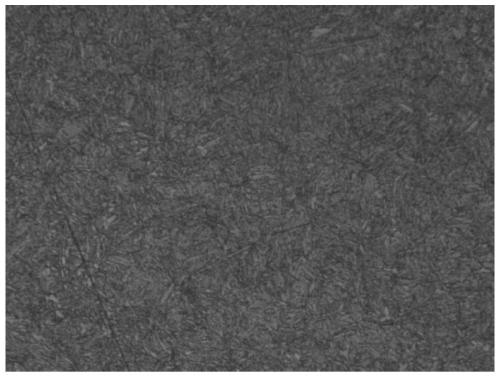

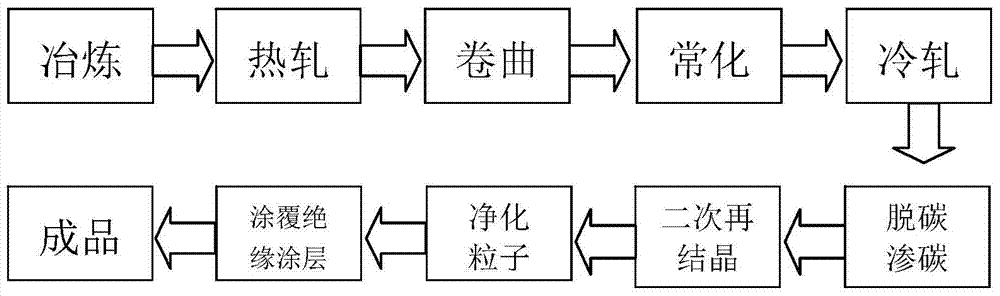

Thin-gauge, ultra-low iron loss, low-noise and high-magnetic induction oriented silicon steel sheet and production method thereof

The invention discloses a production technology of a thin-gauge, ultra-low iron loss, low-noise and high-magnetic induction oriented silicon steel sheet. The oriented silicon steel sheet comprises the following components in percentage by weight: 0.003-0.05 percent of C, 4.1-9 percent of Si, 0.05-0.5 percent of Mn, 0.02-0.06 percent of Al, 0.01-1 percent of Sn, 0.05-0.1 percent of Mo, 0.2-1 percent of Cu, 0.003-0.02 percent of N, 0.002-0.06 percent of P, 0.001-0.008 percent of S and the balance of iron and other inevitable impurities. The high-magnetic induction oriented silicon steel sheet which is produced through hot rolling, cold rolling and annealing processes and the like has the superior performances such as ultra-low iron loss, high flux density, low magnetostriction coefficient and small thickness, has the advantages of simple process, stable texture and capabilities of greatly saving the materials and saving the resources while guaranteeing that the capacity of a transformer is unchanged, and is the best candidate material for manufacturing high-grade power transmission and distribution transformer cores at present.

Owner:STATE GRID CORP OF CHINA +2

Method for producing welding materials by using offcut of steel plate

ActiveCN1947924ASimple production processLow costTemperature control deviceFurnace typesSheet steelButt welding

A technology for using the leftover of steel plate to prepare the welding material includes such steps as choosing the leftover of steel plate, hot rolling and butt welding to obtain coiled rod, or adding alloying element and smelting to obtain coiled rod, cold drawing, slitting, straightening, and coating chemical flux to obtain welding electrodes, or cold drawing and plating copper to obtain welding wire.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

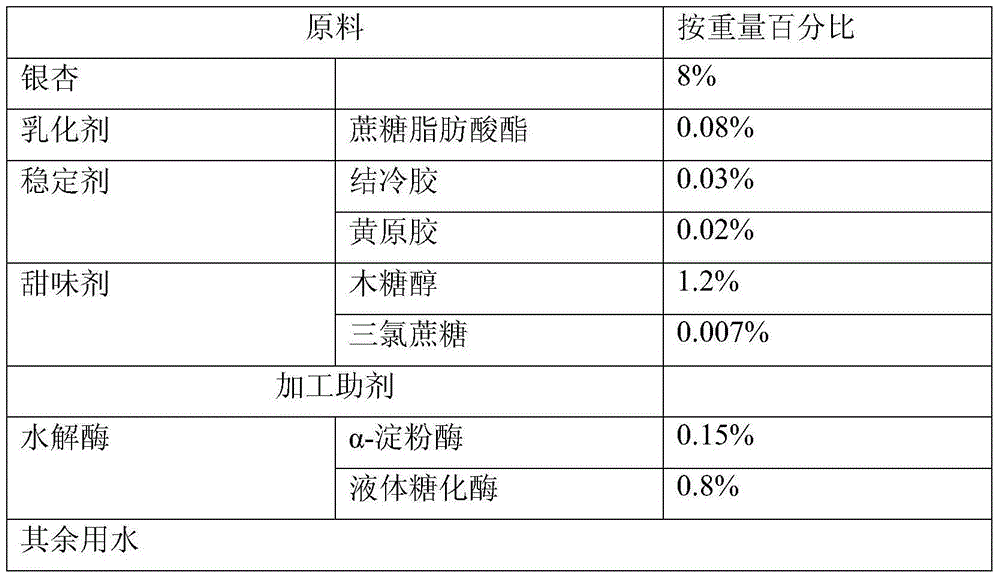

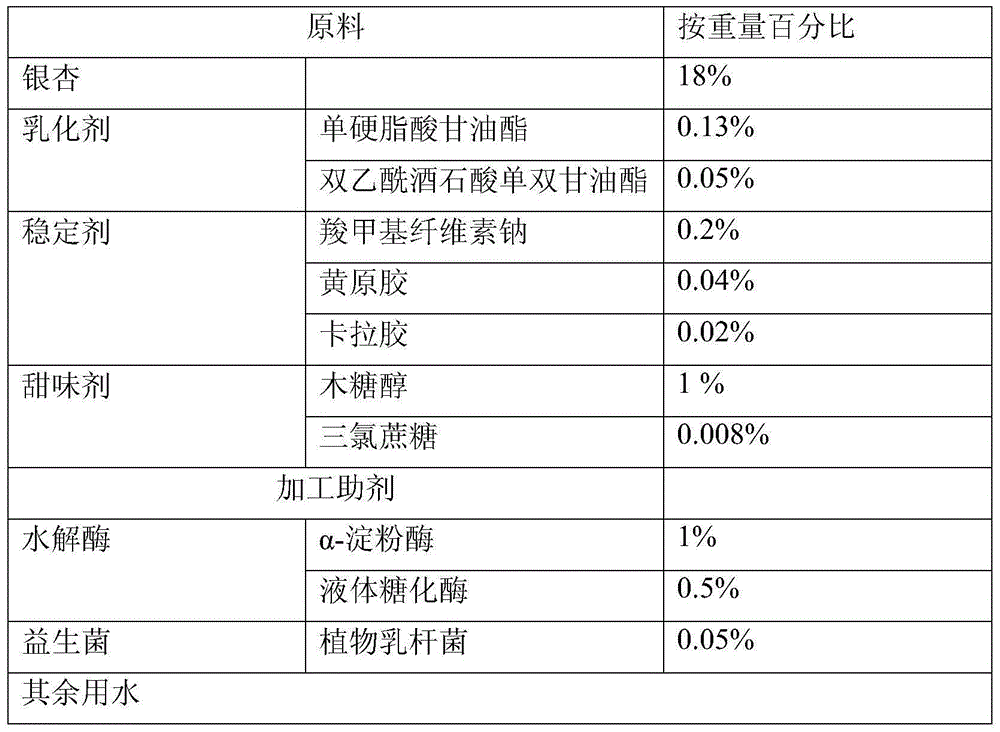

Gingko beverage and preparation method thereof

ActiveCN104473273AReduce contentIncrease contentFood ingredient as emulsifierAdditive ingredientEndopleura

The invention discloses a gingko beverage and a preparation method thereof, belonging to the technical field of processing of food beverages, and providing a novel process for preparing a gingko beverage by using a modern biotechnology. According to the gingko beverage and the preparation method thereof, by adopting conventional processes of shelling, cooking for detoxicating, removing endopleura, colloid-milling, homogenizing and the like and a modern enzymolysis technology, or a preparation method further matched with an enzymolysis technology and a probiotic fermentation technology, on the basis of preserving organic nutrients and flavor of gingko, the problems of high viscosity and poor taste of the gingko beverage are solved; the prepared gingko beverage is cool and fine in taste, delicious in sour and sweetness, relatively excellent in palatability, and stable in tissues; nutritional ingredients are relatively preferably absorbed by a human body; meanwhile, the gingko beverage is rich in effective ingredients such as abundant ginkgetin and ginkgo terpene lactones, and has a relatively excellent health function.

Owner:石药集团中诺药业(泰州)有限公司

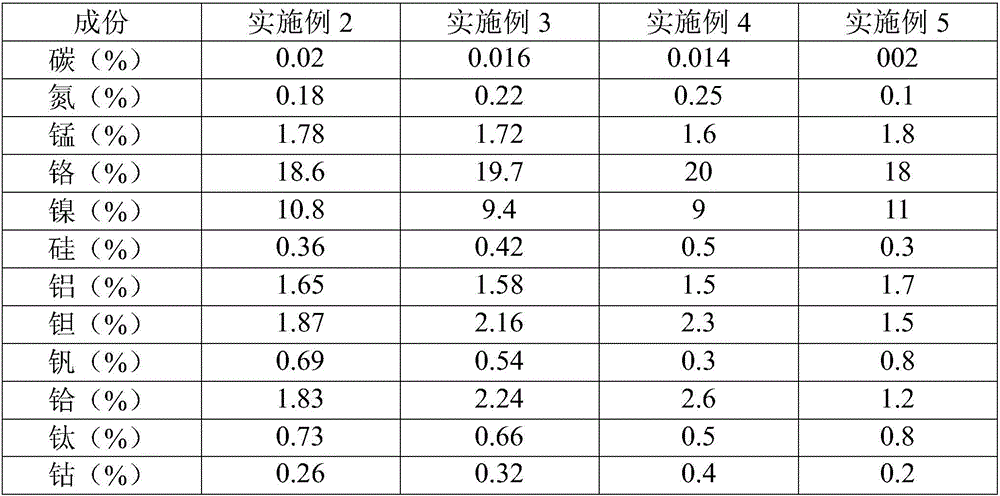

Corrosion-resistance seamless stainless steel pipe and preparation method thereof

InactiveCN106282845AMake up for the lack of strengthImprove corrosion resistanceFurnace typesHeat treatment furnacesManganeseHafnium

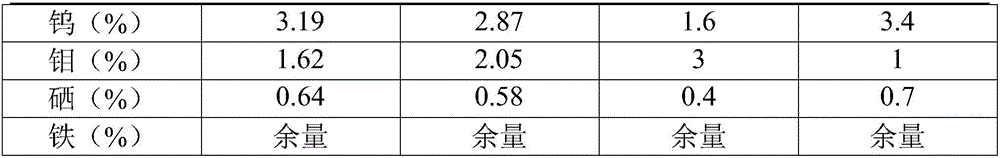

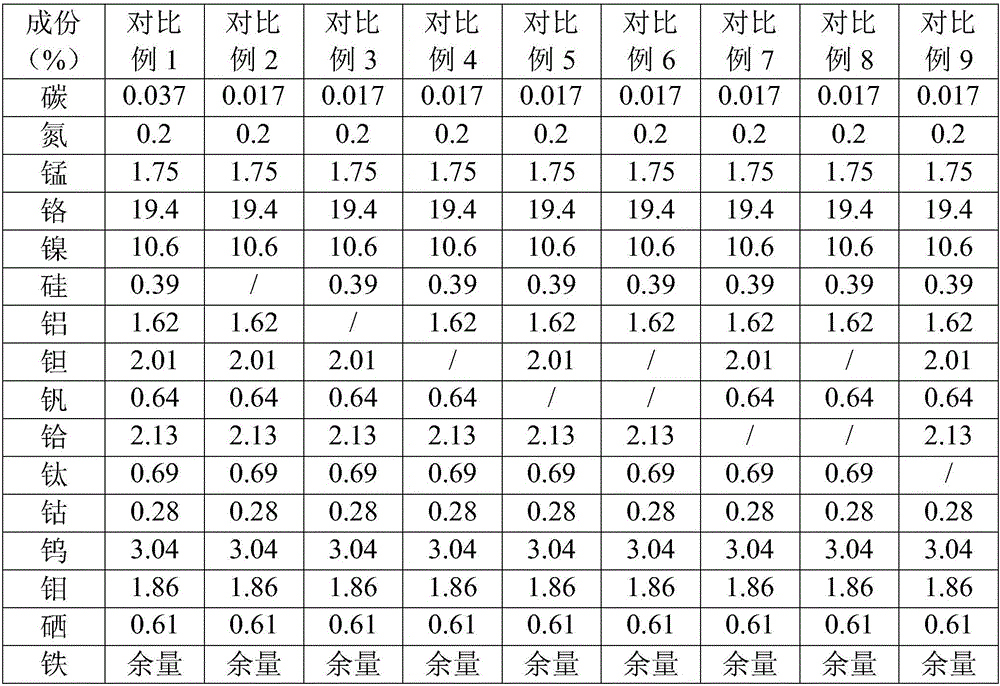

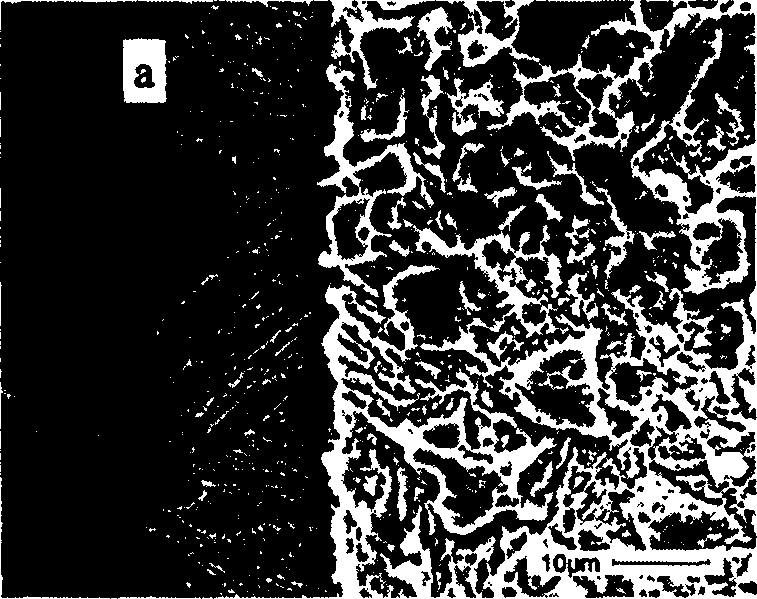

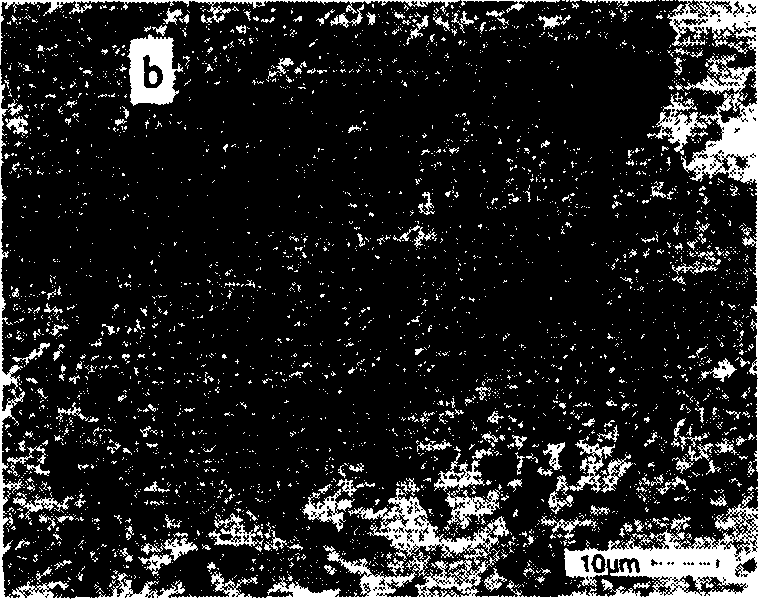

The invention discloses a corrosion-resistance seamless stainless steel pipe and a preparation method thereof. The corrosion-resistance seamless stainless steel pipe comprises the following chemical components in percentage by mass: carbon not more than 0.02%, 0.1-0.25% of nitrogen, 1.6-1.8% of manganese, 18-20% of chromium, 9-11% of nickel, 0.3-0.5% of silicon, 1.5-1.7% of aluminum, 1.5-2.3% of tantalum, 0.3-0.8% of vanadium, 1.2-2.6% of hafnium, 0.5-0.8% of titanium, 0.2-0.4% of cobalt, 1.6-3.4% of tungsten, 1-3% of molybdenum, 0.4-0.7% of selenium, and the balance of iron. Tantalum, hafnium and tungsten are added in austenitic stainless steel, and the chemical components can improve the performances of corrosion resistance, hardness, strength and high-temperature resistance of the austenitic stainless steel, so that the austenitic stainless steel is rich in high ductility and toughness.

Owner:ZHEJIANG HENGYUAN STEEL CO LTD

Flame spray welding process for titanium alloy surface wearable coating

InactiveCN1603450AOptimize the pretreatment processIncrease surface galvanizing activation processMolten spray coatingLiquid stateSurface roughness

One kind of titanium alloy surface wear-resisting coating flame spurts welds the technique, this craft through increases the surface in the superficial pretreatment craft to soak the zinc activation working procedure, and gater two into one, the surface decontamination working procedure with it; Simultaneously had reasonably determined in the technological process essential parameter, is concrete is: Treats spurts the surface roughness is Ra25~~12.5, the preheating temperature is 230~~270deg.C, when heavy melt the liquid state resident time is 20~~60S; And after spurts welds carries on 'to it the tempering' heat treatment, the heat treatment temperature range is 200~~600deg.C, guarantees the wet time is 0.5~~2H and so on a series of crafts measure, successfully brings to completion in the titanium alloy surface preparation gathers the performance fine flame to spurt welds the wear-resisting coating, better solution project practice implementation flexible question.

Owner:JIANGSU UNIV

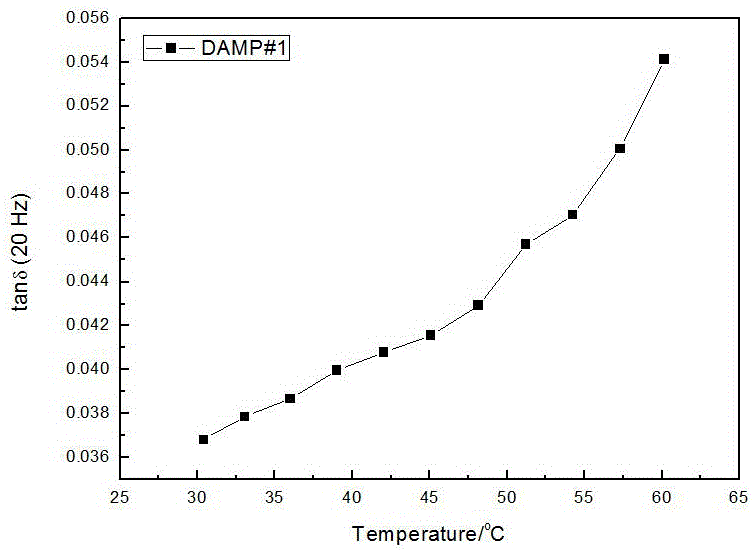

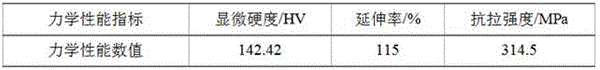

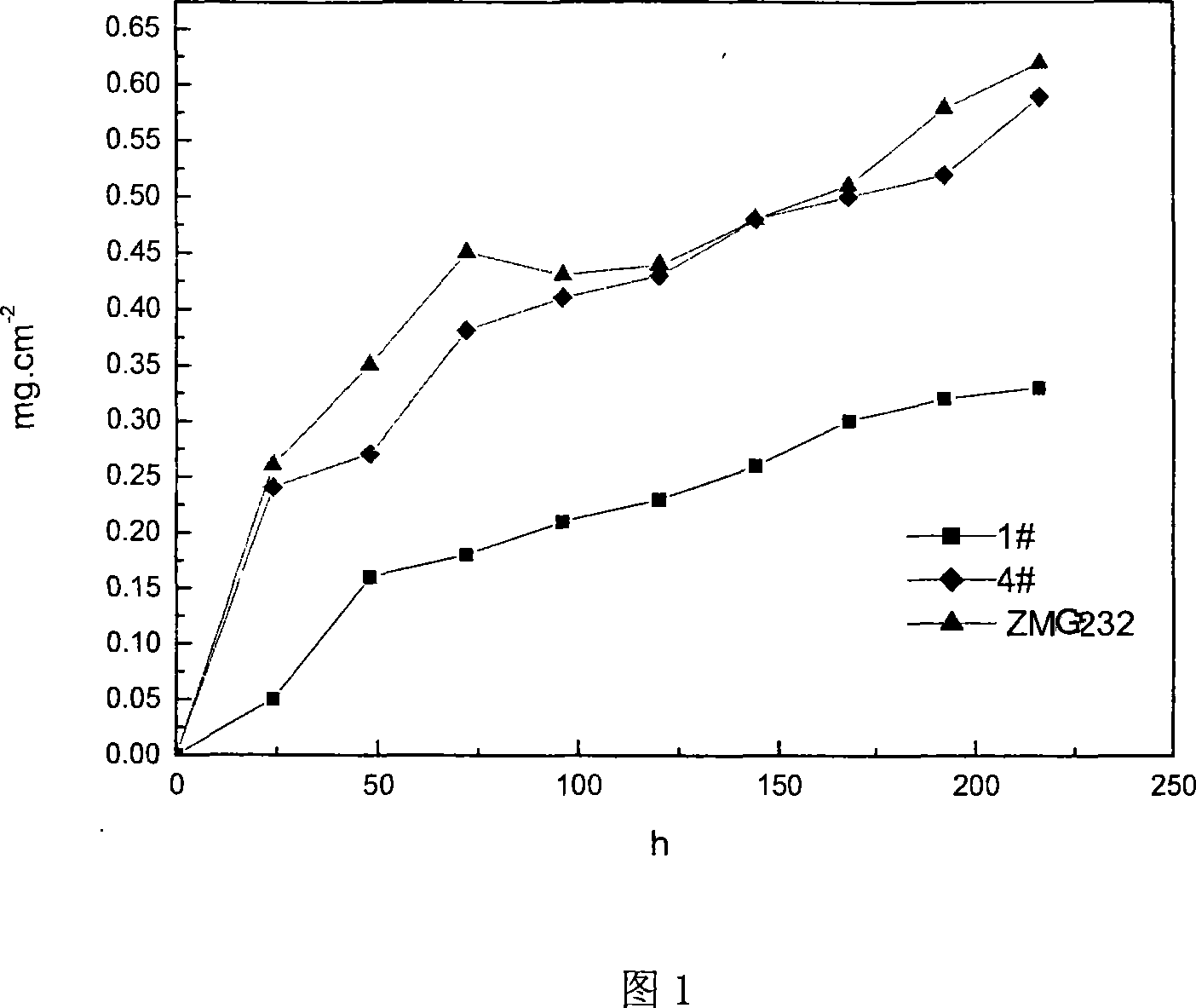

Environmental-friendly zinc-aluminum damping alloy and preparation method thereof

The invention discloses an environmental-friendly zinc-aluminum damping alloy and a preparation method of the environmental-friendly zinc-aluminum damping alloy. The alloy is made of, by weight percentage, 15%-27% of Al, 0.01%-0.1% of Ti, 0.1%-0.2% of rare earth, 0.02%-0.62% of Cu, 0.01%-0.5% of Mg and the balance Zn, and the sum of the weight percentages is 100%. Through the alloying and heat treatment processes, the microstructure of the alloy is obviously refined and uniformized, and the mechanical property of an existing zinc-aluminum alloy is improved. Compared with the existing zinc-aluminum damping alloy, according to the environmental-friendly zinc-aluminum damping alloy, alloy compositions do not contain silicon and lead, machining and cutting are easy, the alloy is not broken easily, environmental protection and zero pollution are achieved, and the alloy has good damping performance. The novel zinc-aluminum damping alloy can be used as a shock absorbing material and is widely used in the fields of building materials, electronics, general machines and the like.

Owner:FUZHOU UNIV

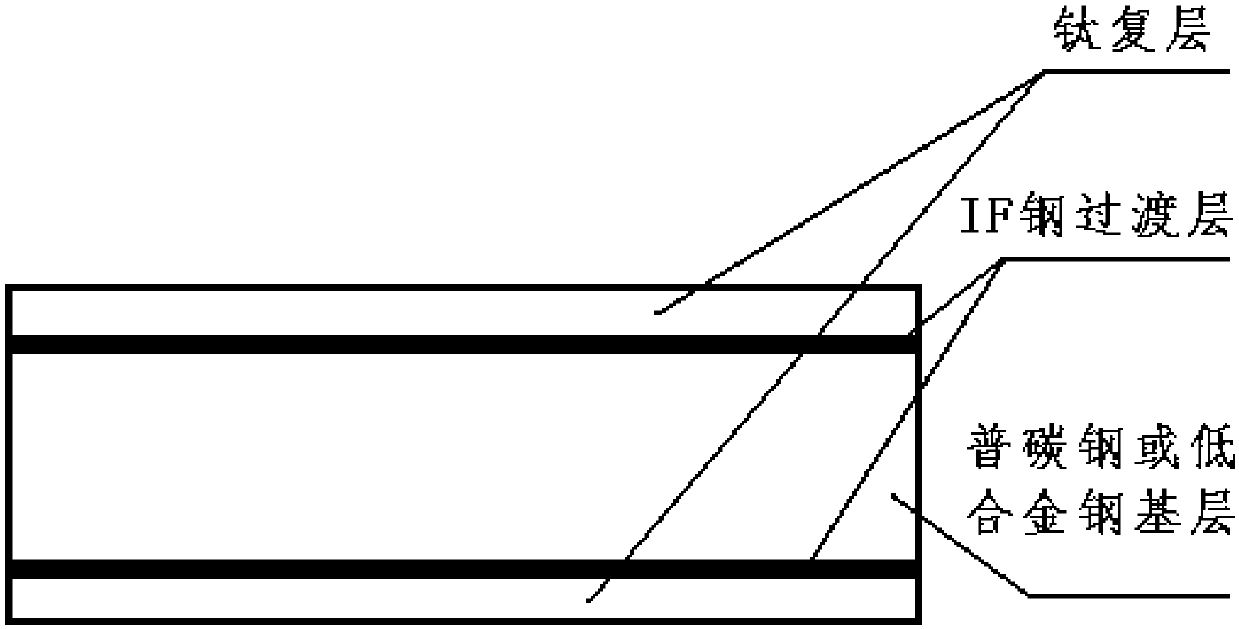

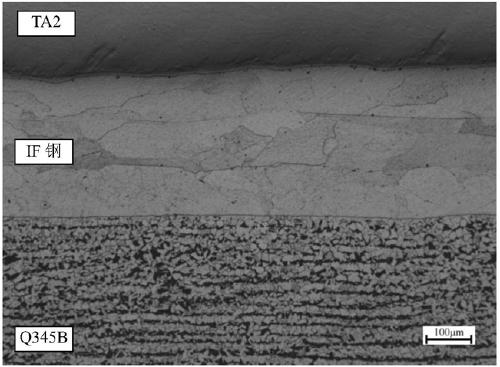

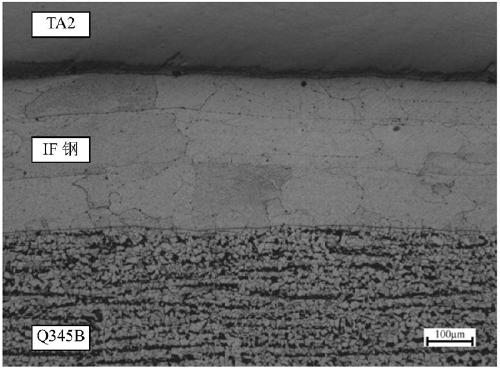

Double-sided titanium steel composite plate taking IF steel as transition layer and high-temperature preparation method thereof

ActiveCN109695000AImprove distributionImprove and enhance bond qualityMetal layered productsComposite plateMechanical property

The invention discloses a double-sided titanium steel composite plate taking IF steel as a transition layer and a high-temperature preparation method thereof. A composite blank for preparing the composite plate comprises a base material, the IF steel and a titanium composite material, wherein the base material is plain carbon steel or low alloy steel with C less than or equal to 0.22%, the titanium composite material is industrial pure titanium TA2, the thickness ratio of the base material to the titanium composite material is 5-10, the length and width of the titanium composite material are smaller than those of the base material, and the margin between the titanium composite material and four sides of the base material is 60-100 mm; and the vacuum welded composite blank is heated to 1040-1060 EDG C for heat preservation, the heat preservation time is 1 min / mm * the total thickness of the composite blank, the initial rolling temperature is 1020-1040 DEG C, the single-pass reduction rate is 15%-25%, the total reduction rate is greater than or equal to 70%, the finish rolling temperature is greater than or equal to 850 DEG C, air cooling is carried out to a room temperature, the thickness of the rolled IF steel transition layer is 280-320 [mu]m, and the double-sided titanium steel composite plate with the thickness of 6-75 mm is obtained after plate splitting, and excellent corrosion resistance and mechanical properties are achieved.

Owner:ANGANG STEEL CO LTD

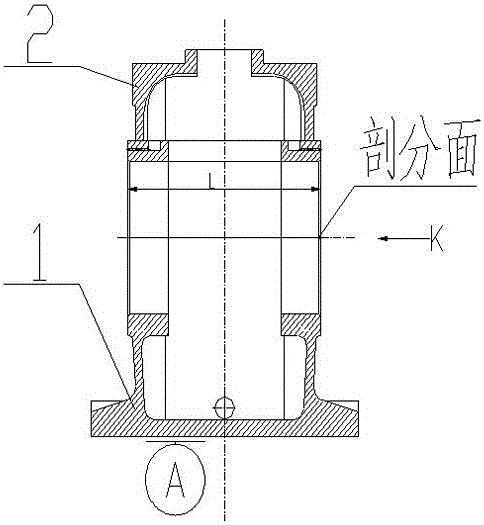

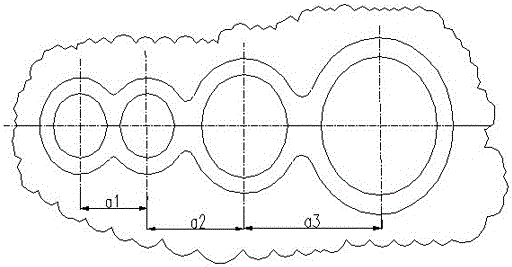

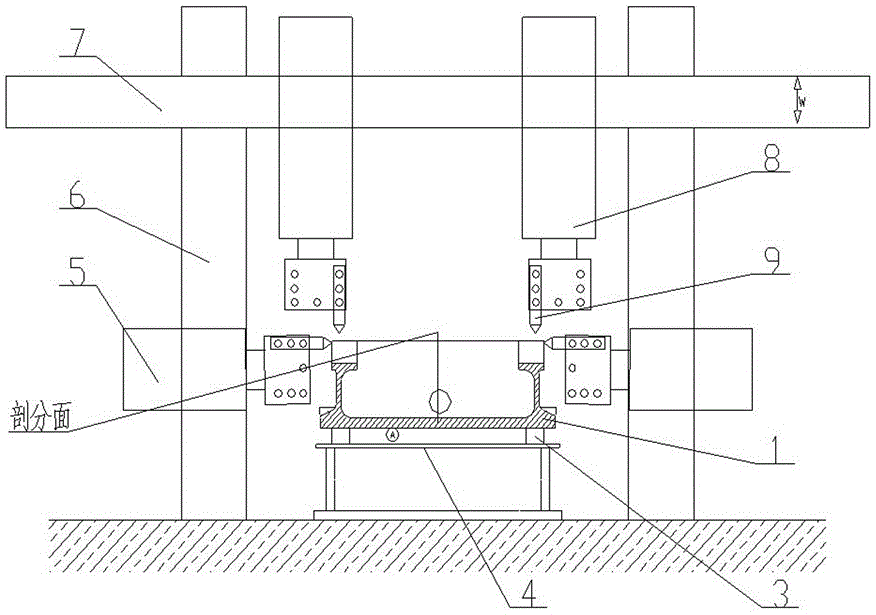

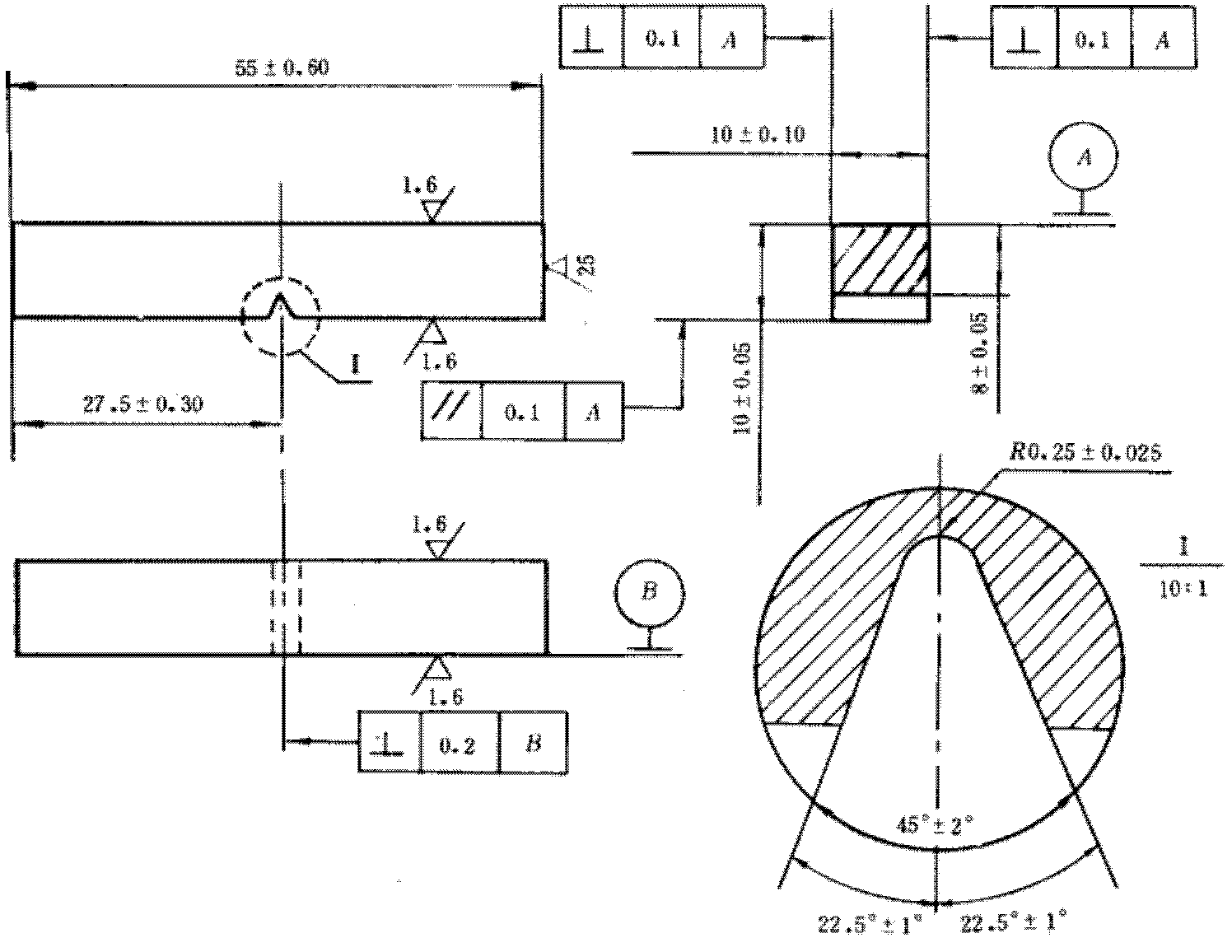

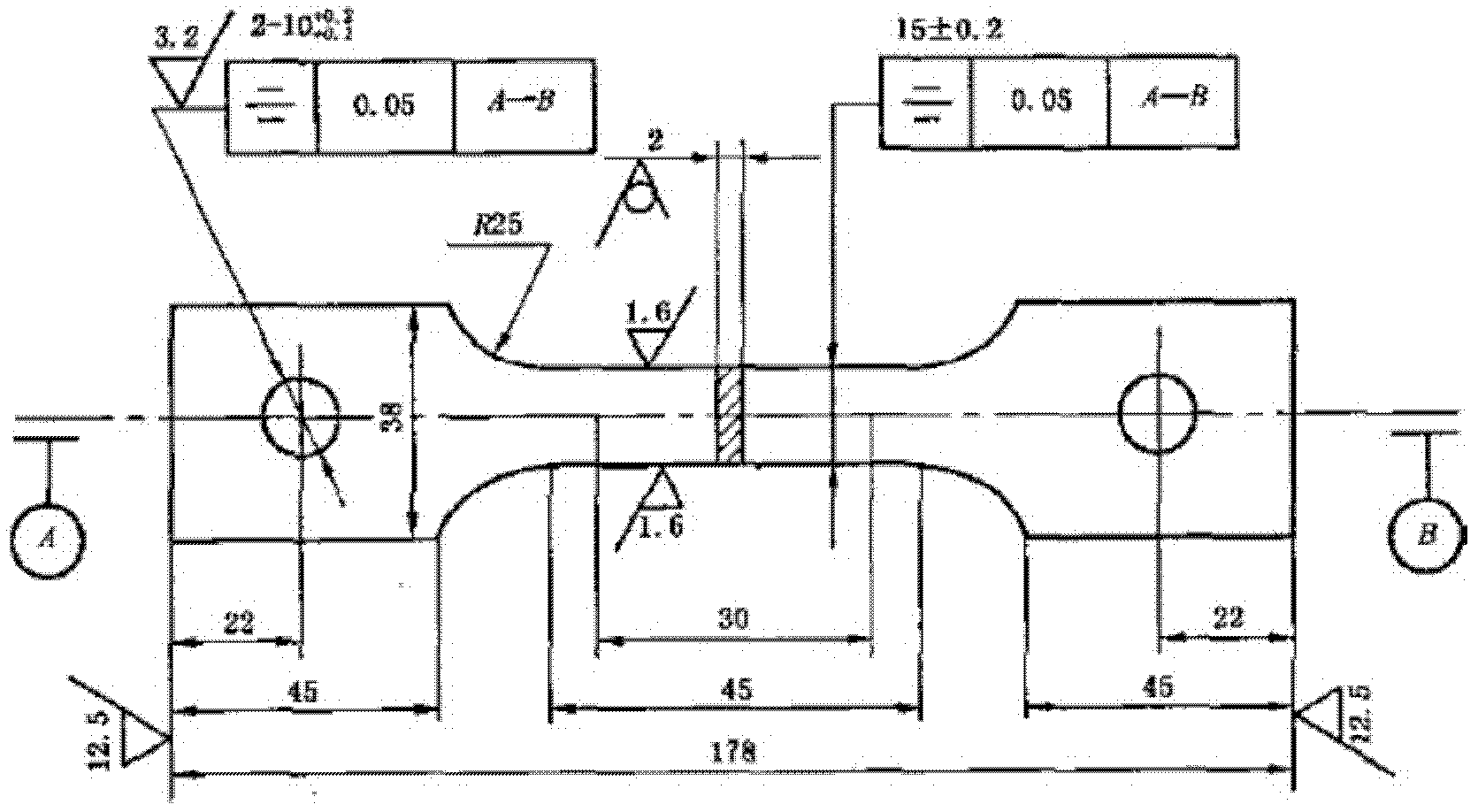

Machining method for improving form and position precision of large gearbox body device

InactiveCN105750601AImprove finishing efficiencyReduce adjustment and deformation errorsMilling equipment detailsOther workshop equipmentEngineeringMachine tool

The invention relates to a machining method for improving the form and position precision of a large gearbox body device. The processing method comprises the following steps: marking out, performing rough machining on the subdivision surface and a semi-axle hole of each separated gearbox body, performing artificial failure, marking out secondarily, carrying out semifinishing on the subdivision surface and the semi-axle hole of each separated gearbox body, performing natural failure, performing finishing on the subdivision surface of each separated gearbox body, assembling a gearbox body device, performing finishing on the axle holes of the gearbox body device, and checking finally. According to the machining method, since semifinishing and finishing of each separated gearbox body and the gearbox device are performed by the same machine tool on the same locating basis, the machining precision is greatly improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

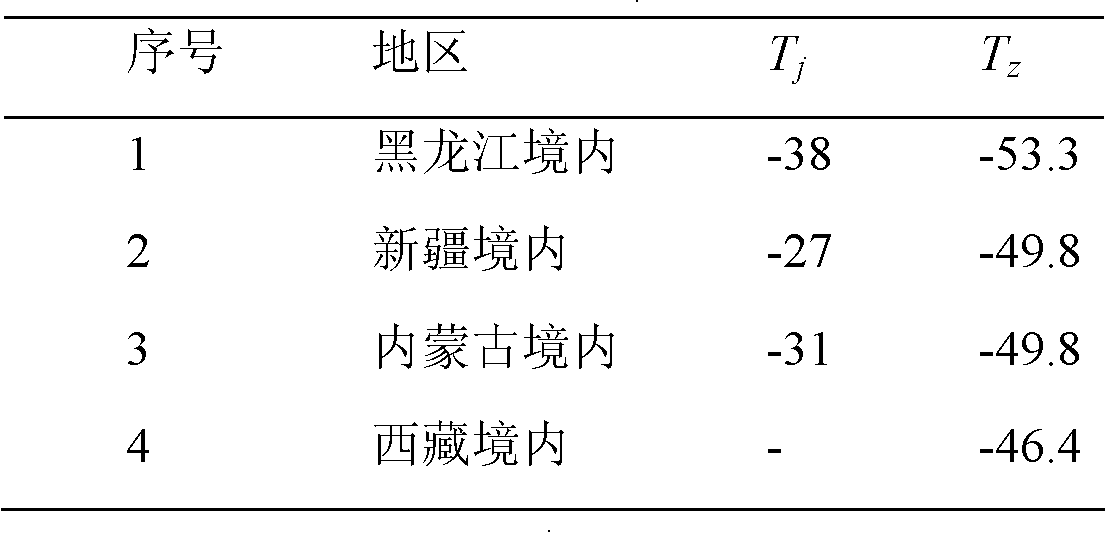

Low-temperature angle steel and manufacturing method thereof

The invention relates to a low-temperature angle steel and a manufacturing method thereof, and belongs to the field of low-temperature steels. The angle steel has excellent low-temperature toughness at the temperature of above 40 DEG C below zero, the yield strength of the angle steel reaches 350MPa, and the angle steel is suitable to be used as a power transmission iron tower material under the low-temperature conditions of high cold regions. The angle steel comprises the following chemical components in percentage by weight: 0.05 to 0.18 percent of C, 0.5 to 1.7 percent of Mn, 0.01 to 0.55 percent of Si, 0.005 to 0.01 percent of Ga, 0.01 to 0.08 percent of V, 0.02 to 0.08 percent of Nb, 0.001 to 0.005 percent of Ca, 0.005 to 0.05 percent of Ti, 0.01 to 0.06 percent of Als, 0.15 to 0.25 percent of Cu, 0.0005 to 0.002 percent of B, 0 to 0.01 percent of P, 0 to 0.005 percent of S, and the balance of Fe and inevitable impurities. The angle steel has the advantages of simplicity in process, purity, tissue stability, yield strength of more than 350MPa and excellent low-temperature toughness at the temperature of above 40 DEG C below zero; and by adopting the alloying principles of multiple elements and low quantity, the angle steel has high and low-temperature performance and low cost.

Owner:CHINA ELECTRIC POWER RES INST +1

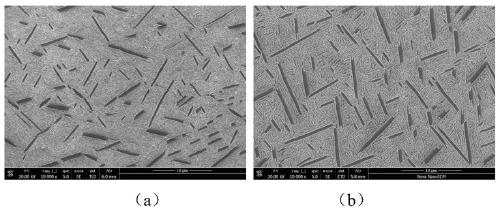

High-temperature and high-strength titanium alloy and processing method thereof

PendingCN112195364AImprove plasticityImprove thermal stabilityMetal-working apparatusFlight vehicleThermal deformation

The invention discloses a high-temperature and high-strength titanium alloy and a processing method thereof. Alloy components, a preparation method, thermal deformation, thermal treatment and other elements are included. The alloy components include, by weight, 5.00-6.70% of Al, 3.00-5.00% of Sn, 2.5-7.50% of Zr, 0.3-2.0% of Mo, 0.25-1.5% of Si, 0.30-1.00% of Nb, 0.50-2.00% of Ta, 0.20%-1.60% of W, 0.02%-0.1% of C, 0.1%-1.5% of B and the balance Ti and inevitable impurity elements. The alloy material can be obtained through a smelting method and a powder metallurgy sintering method, then a forged piece product is obtained through combination of thermal deformation and a thermal treatment process, the forged piece prepared through the process is of a double-state structure, and the materialhas high strength and good plasticity within the range from the room temperature to 700 DEG C. The alloy can be used for manufacturing aerospace key parts used for a long time at the temperature being 600-700 DEG C, and can also be used for temperature-resistant structural parts, such as aerospace crafts, used for a short time at the temperature being 700-750 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Magnesium particle macromolecule composite material and preparation method thereof

A magnesium particle macromolecule composite material is characterized in composed of macromolecule olefin polymer as substrate which is uniformly distributed with 0.5-50um magnesium alloy particles at the mass percentage of 0 C08L 23 / 06 C08L 23 / 12 C08L 27 / 06 C08K 3 / 08 1 5 1 2008 / 2 / 22 101235173 2008 / 8 / 6 000000000 Nanjing University of Information Science & Technology 210044 Zhao Haofeng Wang Ling luzhi bin 32200 The Patent Agency of the South-East University No.2 Sipailou, the City of Nanjing, Jiangsu Province 210018

Owner:NANJING UNIV OF INFORMATION SCI & TECH

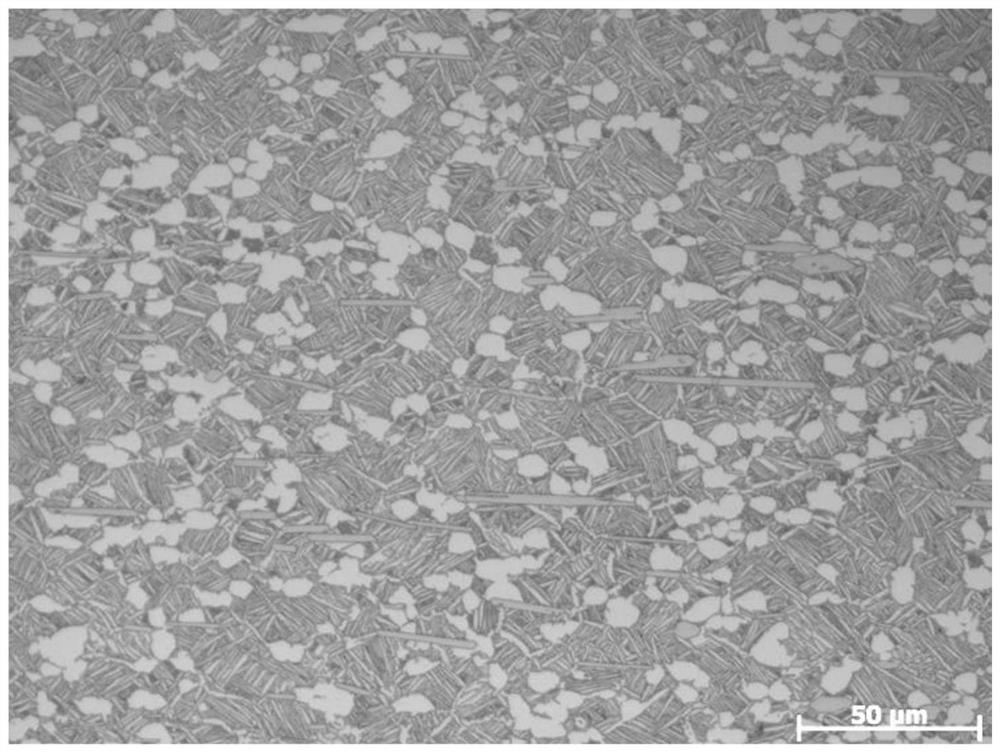

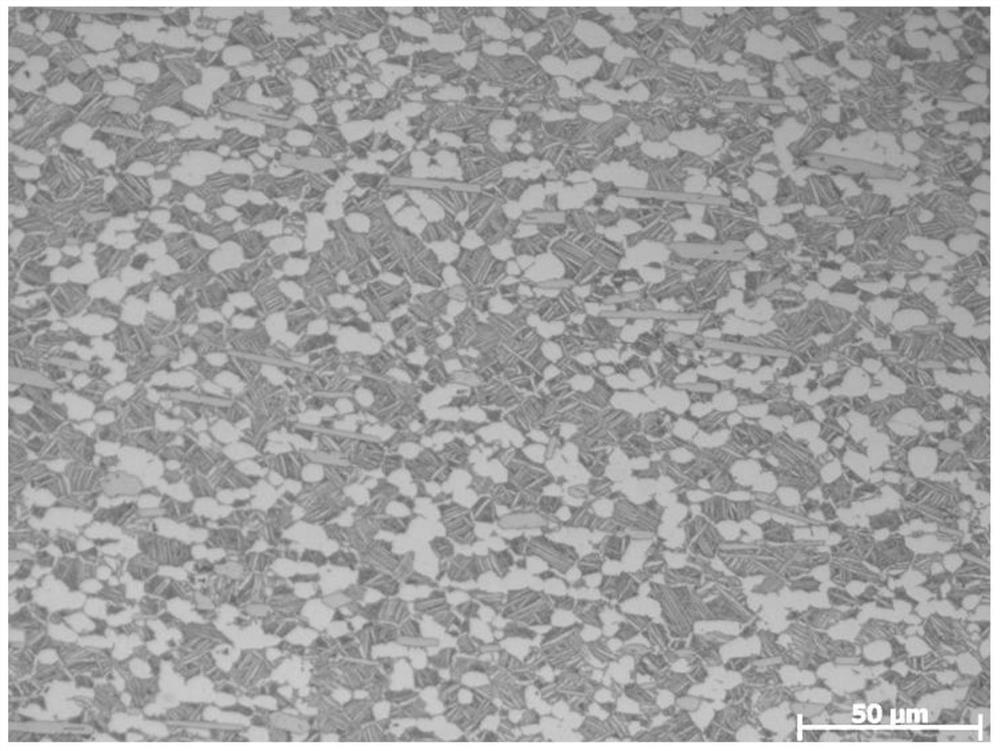

Production method of TC16 alloy disc round wire for cold heading

The invention discloses a production method of a TC16 alloy disc round wire for cold heading. The method comprises the following steps: heating a TC16 alloy precision forged blank with uniform transverse and vertical microstructure at a temperature which is a phase transition point or above, and carrying out one-heating and multi-pass rolling to form a drawn blank; heating the drawn blank at a temperature being the phase transition point or below, and carrying out multi-pass hot drawing to obtain a continuously cold-rolled wire blank; carrying out special pass cold continuous rolling on the continuously cold-rolled wire blank to obtain a special-shaped wire, and carrying out duplex roller die cold drawing on the special-shaped wire to form a round wire; and carrying out heat treatment and surface treatment on the round wire to obtain the TC16 alloy disc round wire with a bright surface. The TC16 alloy wire produced through adopting the method has the advantages of high consistence and stability in microstructure and performances, fine and uniform transverse microstructure after annealing, small and uniform vertically-drawn alpha phase, realization of the performances completely meeting corresponding material standard requirements, good consistence and stability in batches, passing processing verification of fasteners in batches and with multiple figure numbers, and excellent technologic performances of a continuous cold heading process.

Owner:西部超导材料科技股份有限公司

Ferritic stainless steel containing rare earth element yttrium for solid-oxide fuel battery

InactiveCN101195894AImprove high temperature resistanceImprove conductivityFinal product manufactureFuel cellsRare-earth elementYttrium

The invention relates to ferrite stainless steel which includes rare earth element yttrium and is used for a solid oxide fuel cell. The invention is characterized in that the invention comprises the following elements according to the mass percent: Y is 0.01 to 0.10 percent, C is lower than 0.03, Mn is 0.40 to 1.20 percent, Ni is 0.20 to 0.26 percent, Cr is 14.00 to 26.00 percent, Mo is 0.02 to 2.00 percent, W is 0.01 to 0.10 percent, P is lower than 0.04 percent, S is lower than 0.03 percent, Si is 0.01 to 0.05 percent, the residual is Fe; the thermal expansion coefficient is in the range of (11.8 to 13.0) is multiplied by 10 <-6> K at 25-1000 DEG C, and preferred in the range of (12.0 to 12.5) is multiplied by 10 <-6> K, and ferrite stainless steel alloy material is the alloy material which is particularly suitable for connecting and encapsulating the negative electrode and the positive electrode of the moderate temperature type solid oxide fuel cell, or can be used as the lighter of a vehicle engine, or can be used for high temperature boiler heating parts. The alloy is easy for the domestic industrial smelting and the processing formation, the manufacture cost is low, the alloy is suitable for the commercialization production, and has very high promotion and application value.

Owner:JILIN INST OF CHEM TECH

Filling metal particle for welding and manufacturing method therefor

InactiveCN101011783AMake full use ofSimple production processWelding/cutting media/materialsSoldering mediaChemical compositionMetal particle

A stuffing metal grain for soldering with diameter of 0.1-5.0mm, with the mass percentage of C less than 0.15%, S less than 0.035%, P less than 0.035%, oxygen less than 50ppm, nitrogen less than 50ppm, with other alloy elements like Mn being 0.1%-2.0%, Si 0.02%-1.8%, Mo less than 2.5%, Cr less than 3.5%, Ni less than 6.0%, Ti less than 0.5%, V less than 0.5%, Nb less than 0.5%, Cu less than 0.5%, and B less than 0.09%. It is simple in process, with greatly reduced cost.

Owner:SHANDONG UNIV

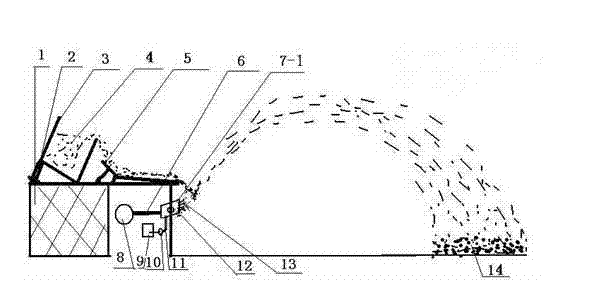

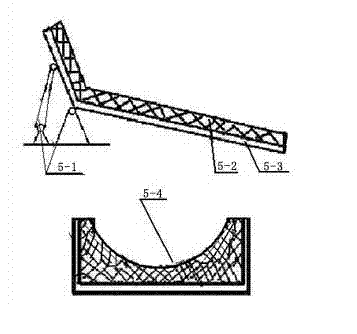

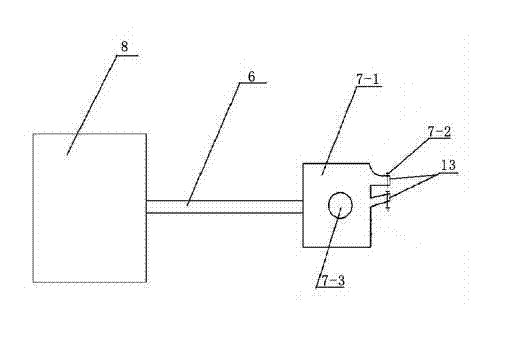

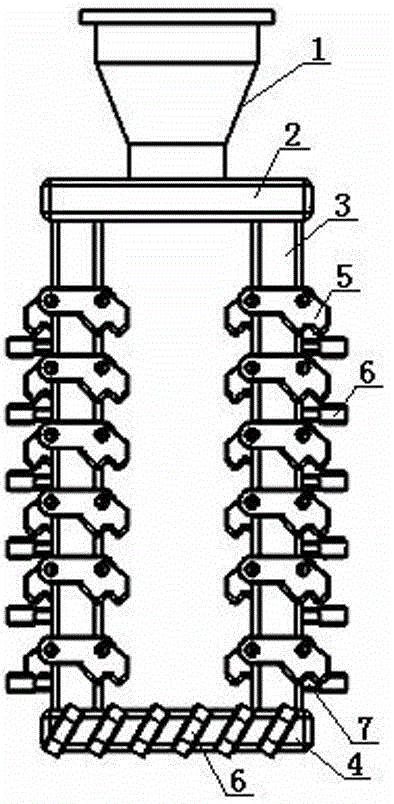

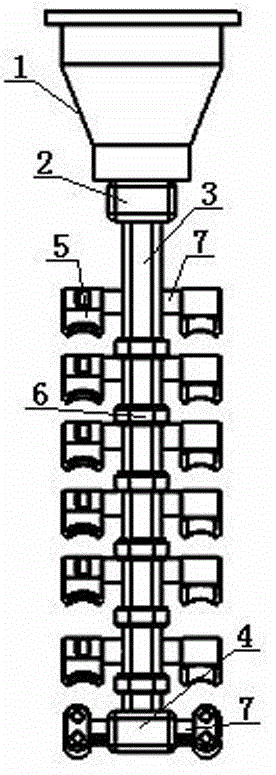

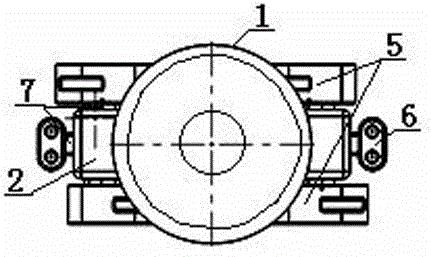

High-temperature liquid-state steel slag granulating device and process

InactiveCN102453781AImprove the efficiency of materializationFully granulatedRecycling and recovery technologiesAir volumeSlag

The invention relates to a high-temperature liquid-state steel slag granulating device and process. The high-temperature liquid-state steel slag granulating device comprises a liquid-state steel slag pouring system and a steel slag granulating system, wherein an atomizing nozzle of a cooling water spraying device in the steel slag granulating system is connected with an air cavity of an air spraying device, the air spraying device is provided with a spraying panel with an adjustable angle, the angle of the spraying panel, and air pressure in the air cavity and air quantity of an air nozzle are adjusted so that liquid-state steel slag is blown to do parabolic flight, and the liquid-state steel slag fully reacts with air and moisture in the flying process to form granulated steel slag spheres. According to the invention, a structure with upper and lower layers of nozzles is adopted, thus the steel slag is atomized twice in the flying process, atomization efficiency of the steel slag is greatly improved; explosion effect generated by cooling water and high-temperature steel slag is utilized to ensure that the steel slag is granulated more fully; meanwhile, dissociative calcium oxide and magnesium oxide can be digested, and a glass-state layer of a spinel structure is formed on the surface of the steel slag, thus tissue structure is smaller and more stable.

Owner:HENAN UNIV OF SCI & TECH

Precise CRDM part casting forming method

ActiveCN104874739AImprove yieldUniform structure and long-term wear resistanceFoundry mouldsFoundry coresStellite alloyInvestment casting

The invention discloses a precise CRDM part casting forming method. The precise CRDM part casting forming method comprises the steps that 1, a ceramic mold shell matched with design shape is manufactured in an investment mode according to the design shape of a CRDM claw and / or a connecting rod; 2, the ceramic mold shell is preheated under the condition of the temperature ranging from 850 DEG C to 1100 DEG C, the temperature is kept for 1-5 hours, and temperature uniformity of all positions of the ceramic mold shell is ensured; a stellite ingot is molten under the condition of the temperature ranging from 1400 DEG C to 1500 DEG C and is cast into the well-preheated ceramic mold shell, and a casting is formed after solidification; 3, mold shell is cleaned, and the casting is subjected to heat preservation under the condition of the temperature ranging from 850 DEG C to 950 DEG C and then is subjected to air cooling for 610 hours. The forming of the connecting rod and / or the claw part for a CRDM is reliably achieved by means of an investment casting technology, forming operation is easy, finished product rate is high, and a formed connecting rod and / or the claw part has even texture, is long-acting and abrasion-resistant, is reliable and stable in use and can effectively meet the technological requirements.

Owner:DONGFANG TURBINE CO LTD

Heat treatment method for improving mechanical property of GH738 bolt type products

InactiveCN109306399AImprove mechanical propertiesGuaranteed tensile propertiesFurnace typesHeat treatment furnacesHigh densityCarbide

The invention discloses a heat treatment method for improving mechanical property of GH738 bolt type products. The GH738 bolt type products are subjected to head molding and heading through a solid solution state material, then stabilizing treatment is conducted, then primary aging treatment is conducted, then secondary aging treatment is conducted, and thus heat treatment of the GH738 bolt type products is finished. During secondary aging treatment, much more high-density gamma' strengthening phases are separated out, so that much more gamma' strengthening phases with smaller size and large degree of dispersion and much more carbide are obtained, the alloy is strengthen sufficiently, and accordingly the mechanical property of the GH738 bolt type products is improved. By the adoption of the heat treatment method, the technical problem that the mechanical property usually cannot meet the requirements in ordinary heat treatment production is solved, and the prepared GH738 bolt type products can be applied and popularized in the field of aero-engines.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

HRB400 hot-rolled reinforcement bar production technology

The invention discloses an HRB400 hot-rolled reinforcement bar production technology, which comprises the following steps: controlling the tapping temperature T and molten steel smelting (C) of a converter, pushing off the slag and tapping, wherein the discharged slag quantity does not exceeds 4kg / t, the tapping time is not less than 3min; conveying the molten steel, which is qualified after being smelted by the converter, into an argon blowing station, wherein the temperature of the molten steel entering the argon blowing station is less than or equal to 1610DEG C, and bottom argon blowing is adopted in the whole process of the molten steel; and carrying out titanium microalloying treatment on the molten steel in a refining station through a titanium nitride feed line technology, and controlling the content of titanium in the molten steel to be 300ppm below. The continuous casting pulling speed is controlled to be less than or equal to 3.5m / min, and the overheating temperature of the molten steel is less than or equal to 30DEG C so as to guarantee the quality of a steel blank. Steel rolling adopts the controlled rolling and controlled cooling technology, and the controlled cooling temperature is less than or equal to 750DEG C. According to the HRB400 hot-rolled reinforcement bar produced by adopting the technology, the strength of steel can be enhanced, the steel performance can be improved, and cost of per ton of steel can be lowered, and the HRB400 hot-rolled reinforcement bar production technology has excellent economic benefits and market prospects.

Owner:湖南华菱涟源钢铁有限公司

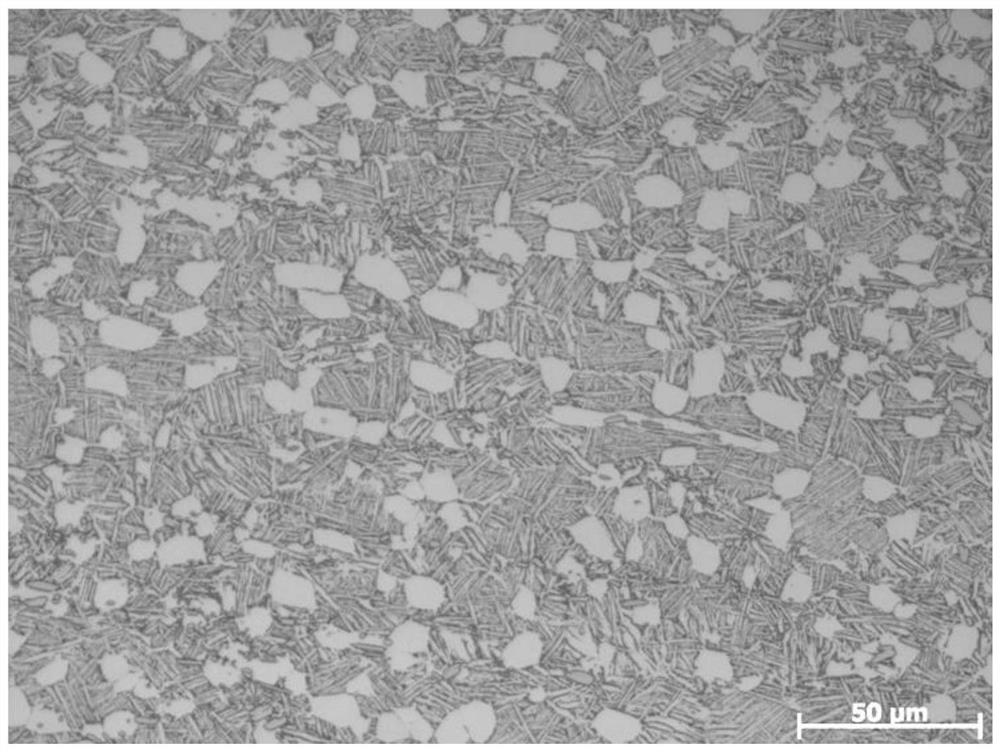

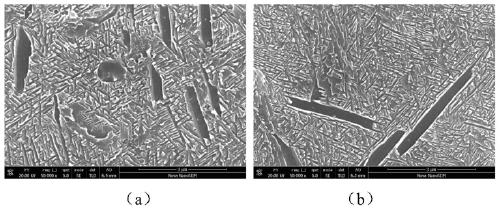

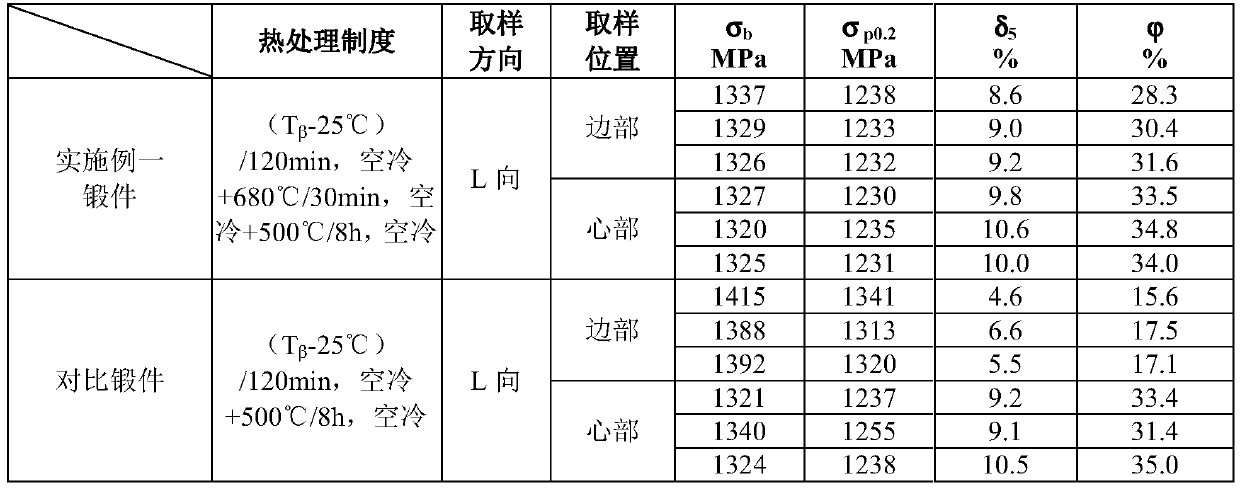

Heat treatment process of titanium alloy

The invention discloses a heat treatment process of a titanium alloy, and belongs to the technical field of material science. The heat treatment process is mainly as follows: the heating temperature T of the first heating treatment is greater than or equal to (Tbeta-50) DEG C and less than or equal to (Tbeta+60) DEG C, the holding time t is equal to eta 1*delta max, the delta max is the maximum section thickness of a titanium alloy forged piece, the eta 1 is a heating coefficient, the value of the heating coefficient is 0.6-1.5min / mm, after the heat preservation on the forged piece is completed, the forged piece is discharged from a furnace and is subjected to air cooling, wind cooling, oil cooling or water cooling to a room temperature; the heating temperature T of the second heating treatment is greater than or equal to 650 DEG C and less than 780 DEG C, the holding time t is equal to (eta 2*delta max) / 2, the delta max is the maximum section thickness of the titanium alloy forged piece, the eta 2 is a heating coefficient, the value of the heating coefficient is 0.3-1.2min / mm, after the heat preservation on the forged piece is completed, the forged piece is discharged from the furnace and is subjected to air cooling to a room temperature; and the heating temperature T of the third heating treatment is greater than or equal to 480 DEG C and less than 650 DEG C, the holding time t is greater than or equal to 240min and less than or equal to 600min, and after the heat preservation on the forged piece is completed, the forged piece is discharged from the furnace and is subjected to air cooling to a room temperature. The heat treatment process solves the problems that after near-beta, metastable beta-type and fully-stable beta-type titanium alloys are subjected to solution treatment and ageing, the side and heart of the forged piece have large difference in structure properties, and is particularly suitable for preparing the high-strength titanium alloy forged piece with uniform structure properties and a large section / variable cross section.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

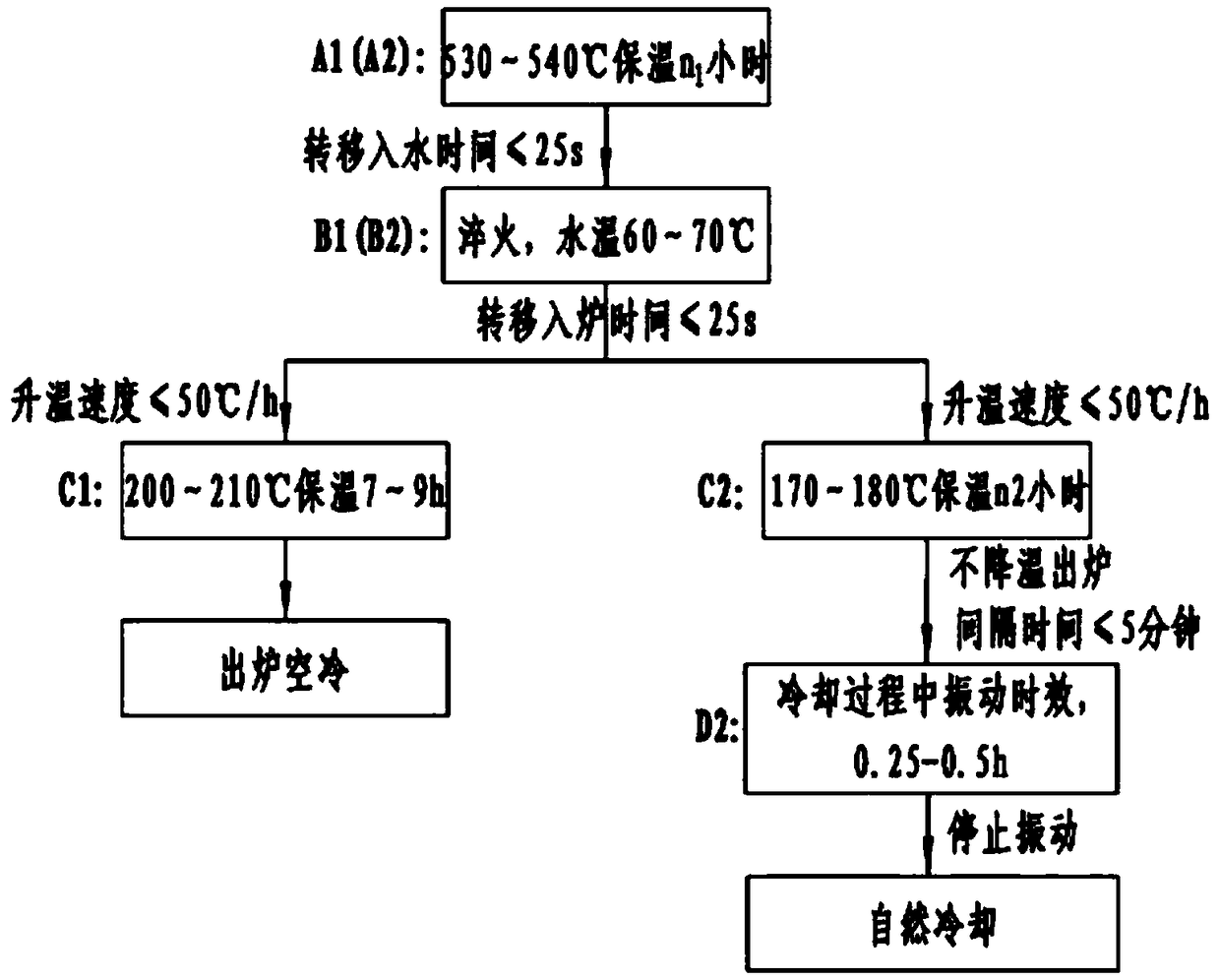

Heat treatment method for cast aluminum alloy gearbox

InactiveCN108998652AEliminate internal stressStable organization and sizeFurnace typesHeat treatment furnacesQuenchingHolding time

A heat treatment method for a cast aluminum alloy gearbox comprises the following steps that A, solid solution treatment is carried out on the cast aluminum alloy gearbox, wherein the temperature of solid solution treatment is 530-540 DEG C, the heat preservation time is n1 hours, and n1 is equal to the value obtained after dividing the largest wall thickness by 25 mm and then plus 1; B, after solid solution treatment is finished, water is immediately added into the gearbox, wherein the duration is not longer than 25 s, and the quenching temperature is 60-70 DEG C; C, after quenching is finished, the gearbox is immediately transferred into a furnace for ageing treatment in the two following modes, wherein the ageing temperature is 200-210 DEG C, and gearbox is taken out of the furnace forair-cooling after 7-9 hours of heat preservation; the ageing temperature is 170-180 DEG C, the heat preservation time is n2 hours, n2 equals to the value obtained after dividing the largest wall thickness by 25 mm and then plus 2, and vibration aging treatment in the cooling process is immediately carried out after the gearbox is discharged from the furnace. According to the method, internal stress can be fully removed while ideal high comprehensive mechanical performance is achieved, so that the structure and size of the gearbox are stable, and deformation of the subsequent finish machining size and precision cannot be caused.

Owner:ZHUZHOU JIUZHOU TRANSMISSION MACHINERY

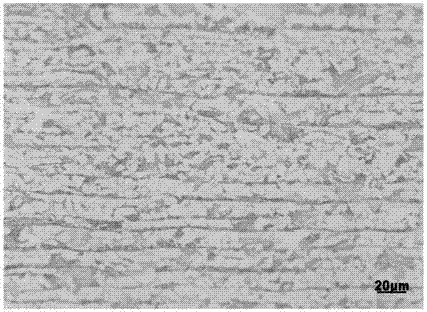

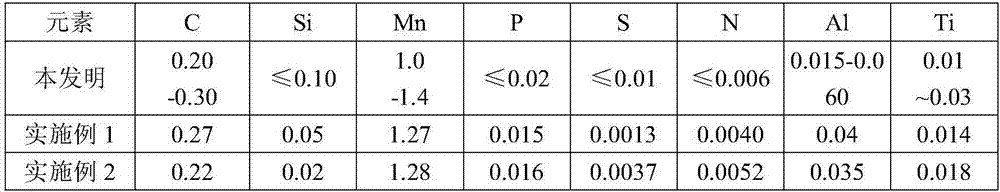

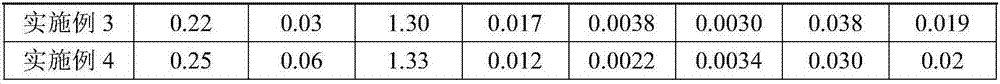

Steel plate for precision welded pipe with 400MPa-grade yield strength and manufacturing method thereof

InactiveCN107385319AReduce manufacturing costMeet the demand for yield strength improvementSheet steelUltimate tensile strength

The invention relates to a steel plate for a precision welded pipe with a yield strength of 400MPa and a manufacturing method thereof, and mainly solves the technical problem of industrial production of a hot-rolled steel plate for a precision welded pipe with a yield strength of 400MPa. The hot-rolled steel plate for precision welded pipe with a yield strength of 400MPa grade provided by the present invention has the following chemical composition weight percentages: C: 0.20-0.30%, Si≤0.10%, Mn: 1.0-1.40%, P≤0.02%, S≤0.01% , N≤0.0060%, Al: 0.015-0.060%, Ti: 0.01-0.03%, and the balance is iron and unavoidable inclusions. The yield strength of the hot-rolled steel plate is 440-550MPa, the tensile strength is 550-650MPa, and the elongation A after fracture is 25-35%. The hot-rolled steel plate of the invention is suitable for making precision welded pipes for automobile structures.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com