Steel plate for precision welded pipe with 400MPa-grade yield strength and manufacturing method thereof

A technology of yield strength and manufacturing method, which is applied in the field of iron-based alloys to achieve stable performance, fill the gap in the industry, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

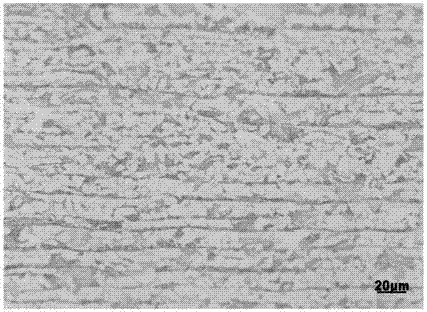

Image

Examples

Embodiment Construction

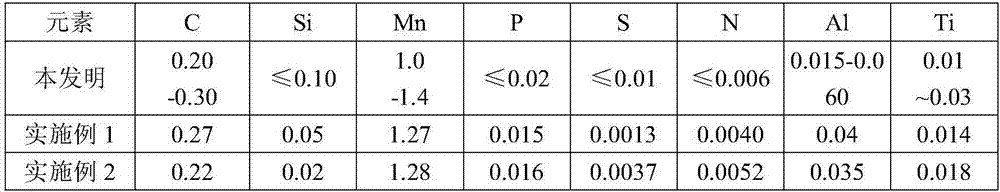

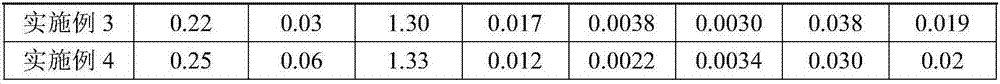

[0041] The present invention will be further described below in conjunction with Examples 1-4, as shown in Tables 1-3.

[0042] Table 1 is the chemical composition (by weight percentage) of the steel of the embodiment of the present invention, and the balance is Fe and unavoidable impurities.

[0043] Table 1 Chemical composition of the steel of the embodiment of the present invention, unit: weight percent.

[0044]

[0045]

[0046] According to the design requirements of the material composition of the present invention, pre-desulfurization of molten iron is adopted, top-bottom combined blowing of converter, LF blowing Ar treatment, and at the same time, an appropriate amount of calcium wire is fed for calcium treatment. , cast into continuous casting slabs.

[0047] After the continuous casting slab is heated by the heating furnace, it is rolled on the hot tandem rolling mill. taken to produce hot-rolled coils, and the thickness of the finished hot-rolled steel plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com