Manufacturing method of X70 large-deformation steel fire-bent pipe

A technology of hot-simmering pipe bending and manufacturing process, which is applied in the field of metal pipe processing and piping systems, and can solve the problem that the deformation capacity of the bending pipe cannot meet the safety requirements of the pipeline, the longitudinal tensile stress ratio, the uniform elongation decrease, and no reflection Problems such as the key indicators of the bent pipe, to achieve good longitudinal deformation ability, improved strength and toughness, and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

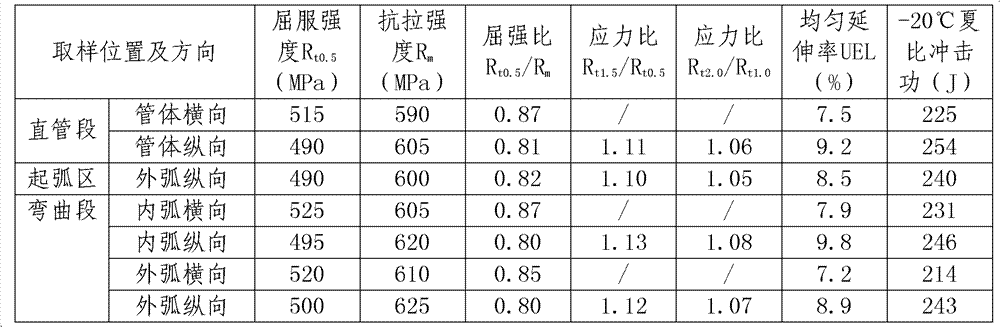

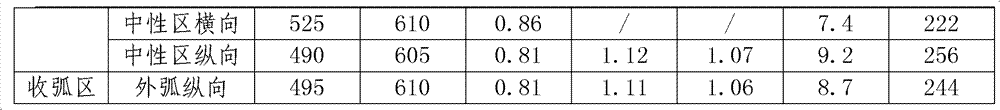

Embodiment 1

[0014] Embodiment 1. This example is to make a pipe diameter of 813mm and a wall thickness of 14mm X70 large deformation steel hot-bending pipe. The parent pipe used is a straight seam submerged arc welded steel pipe made of controlled rolling and controlled cooling steel plate. The weight percent of its composition is: C: 0.07%; Mn: 1.65%; Si: 0.21%; P: 0.010%; S: 0.004%; Nb: 0.05%; Ti: 0.02%; 0.01%; Cr: 0.12%; Mo: 0.15%; Cu: 0.16%; Ni: 0.22%; N: 0.006%; carbon equivalent Ceq: 0.43%; cold cracking coefficient Pcm: 0.19%;

[0015] Firstly, the parent tube with the above components is subjected to intermediate frequency induction heating and bending, and the overall heating and quenching bending process is used to make a 90° bend, and the bending radius is 6 times the diameter of the parent tube. Induction heating temperature is 950-1000°C, propulsion speed is 65-70mm / min, external water spray cooling, cooling speed is 20-30°C / s;

[0016] Then put the bent pipe into a heating...

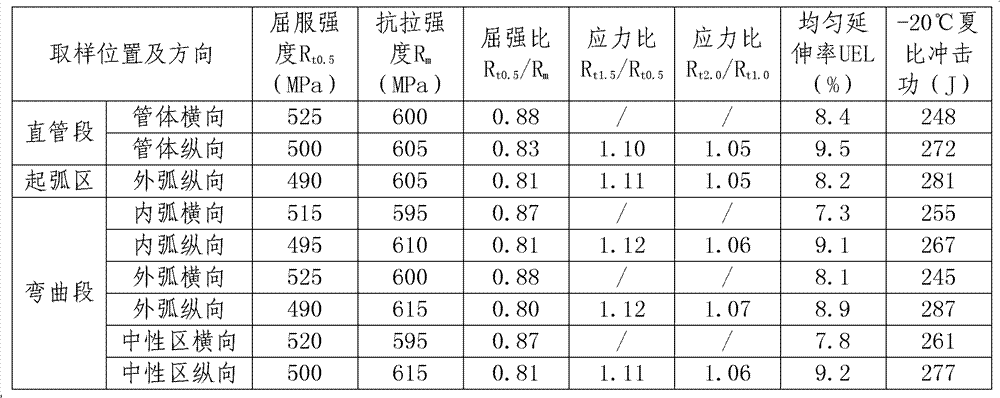

Embodiment 2

[0020] Embodiment 2. This example is to make a pipe diameter of 1016mm and a wall thickness of 21mm X70 large deformation steel hot-bending pipe. The parent pipe used is a straight seam submerged arc welded steel pipe made of controlled rolling and controlled cooling steel plate. The weight percent of its composition is: C: 0.05%; Mn: 1.68%; Si: 0.15%; P: 0.005%; S: 0.002%; Nb: 0.022%; Ti: 0.013%; 0.002%; Cr: 0.014%; Mo: 0.25%; Cu: 0.22%; Ni: 0.26%; N: 0.002%; carbon equivalent Ceq: 0.42%; Pcm: 0.18%;

[0021] Firstly, the parent tube with the above components is subjected to intermediate frequency induction heating and bending, and the overall heating and quenching bending process is used to make a 45° bend, and the bending radius is 6 times the diameter of the parent tube. Induction heating temperature is 1000~1050℃, propulsion speed is 45~50mm / min, external water spray cooling, cooling speed is 20~30℃ / s;

[0022] Then put the bent pipe into a heating furnace for overall h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com