Patents

Literature

1081results about How to "Improve heating uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

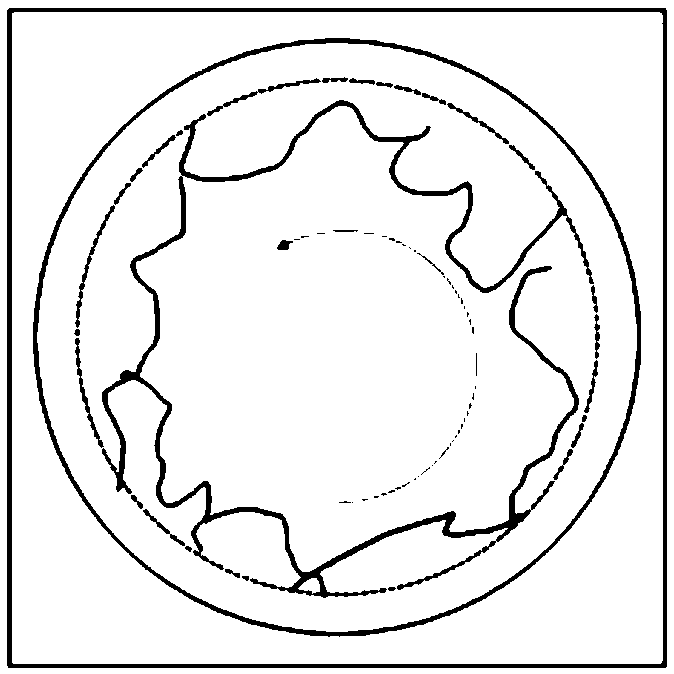

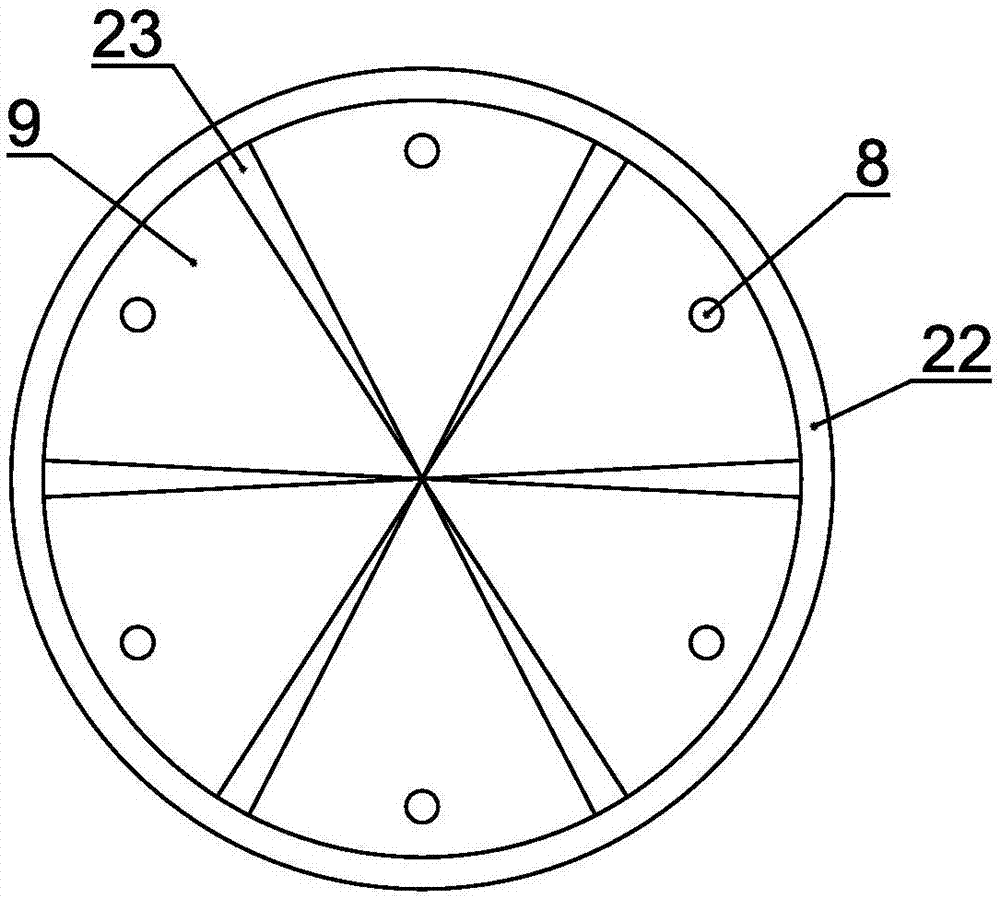

Device for controlling delivery and uniform distribution of reaction gases in MOCVD reaction chamber

ActiveCN101914761AReduce manufacturing costControl consumptionChemical vapor deposition coatingSystem capacityEngineering

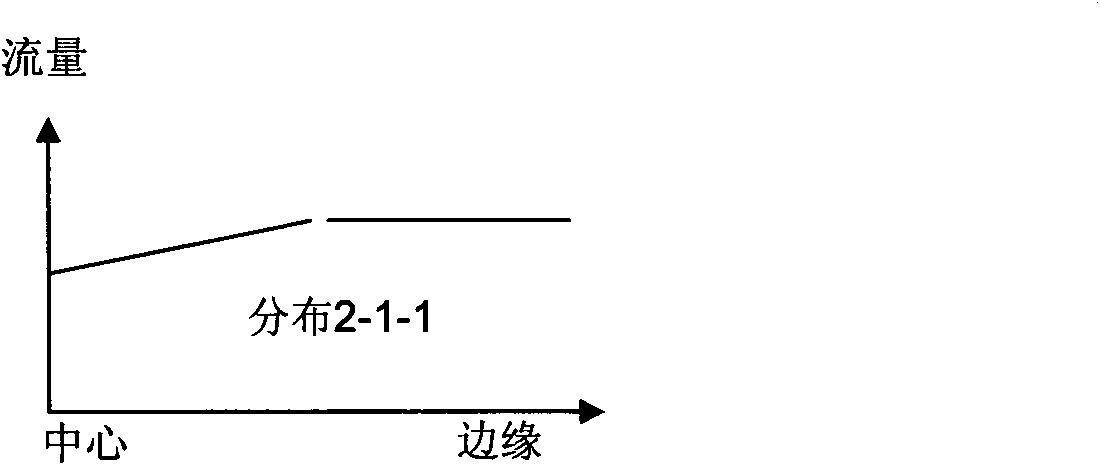

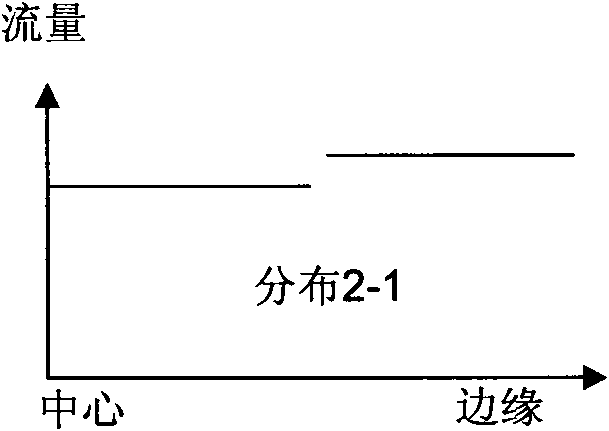

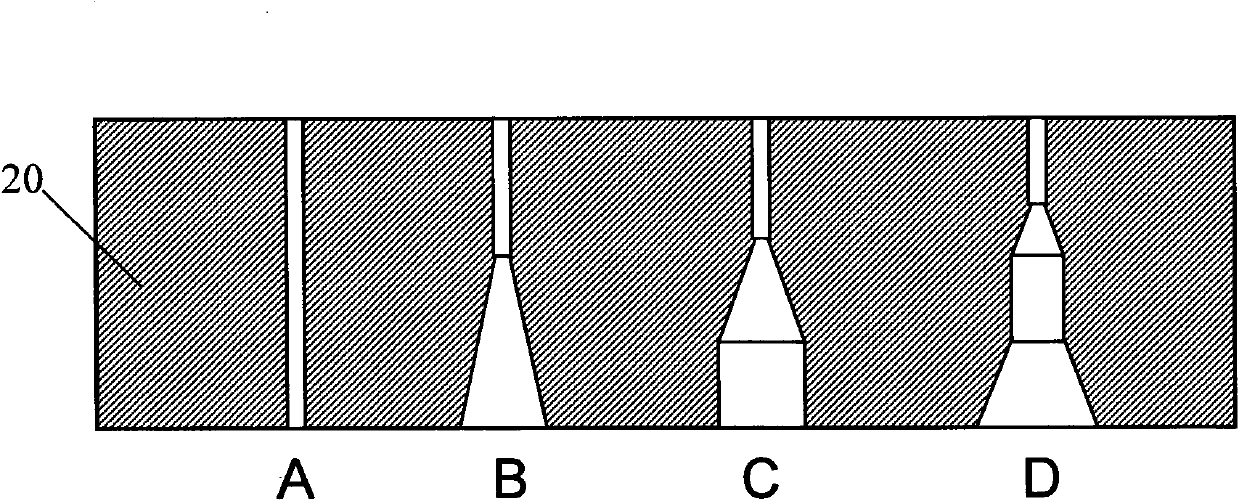

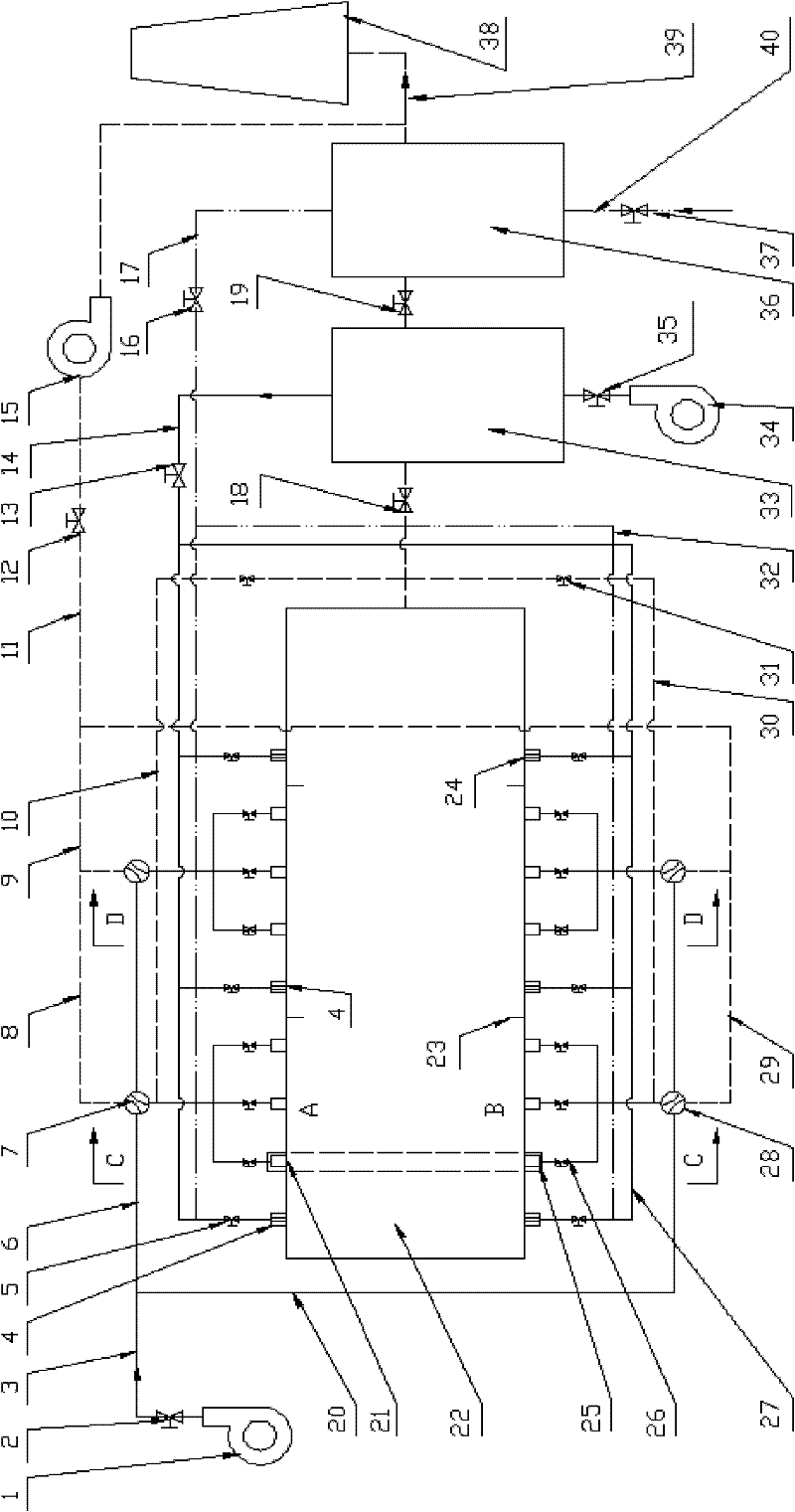

The invention discloses a device for controlling the delivery and the uniform distribution of reaction gas in a MOCVD reaction chamber. By respectively controlling the flow of gas passages non-uniformly distributed radially on a front gas homogenizing plate and input passages at different positions, at least two reaction gases are respectively introduced into two paths which are radially and axially crossed on a spray header, and can be secondarily distributed by nozzles in different shapes, so the uniformly distributed boundary layer concentration, speed and temperature required are achieved on the surface of a rotary epitaxial wafer, the quality of massively produced epitaxial films and the finished product ratio of massively produced epitaxial wafers are improved, the consumption of expensive reaction gases can be effectively controlled and the epitaxial production cost is reduced. By properly increasing the distance between the surface of the spray header and the epitaxial wafer, deposits generated on the surface of the spray header and the nozzles in the epitaxial growth are reduced, the cleaning period is prolonged, and the production efficiency and system capacity are improved. The device also can reduce the processing difficulty and manufacturing cost of the nozzles of the spray header and cooling medium passages.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

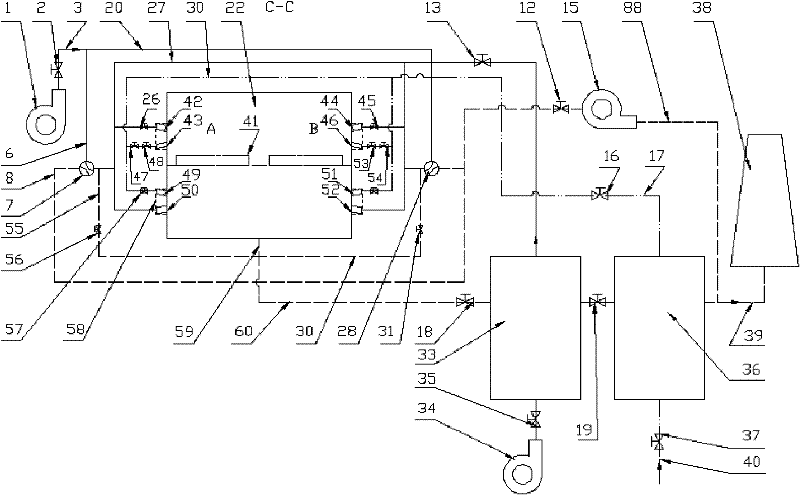

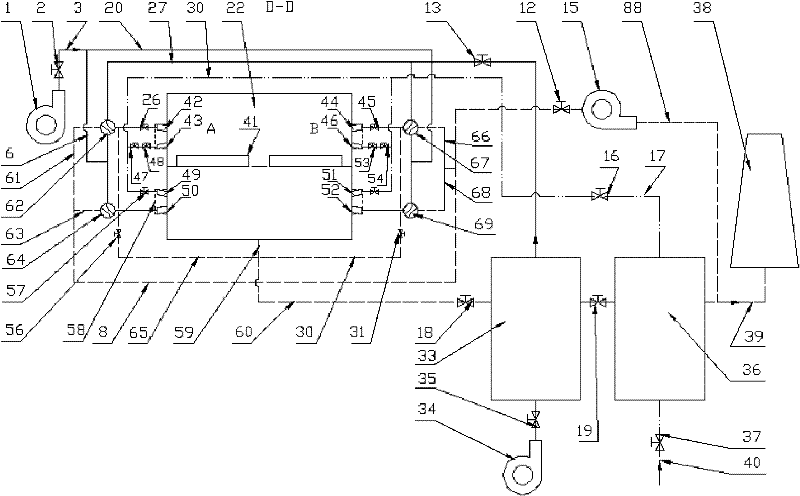

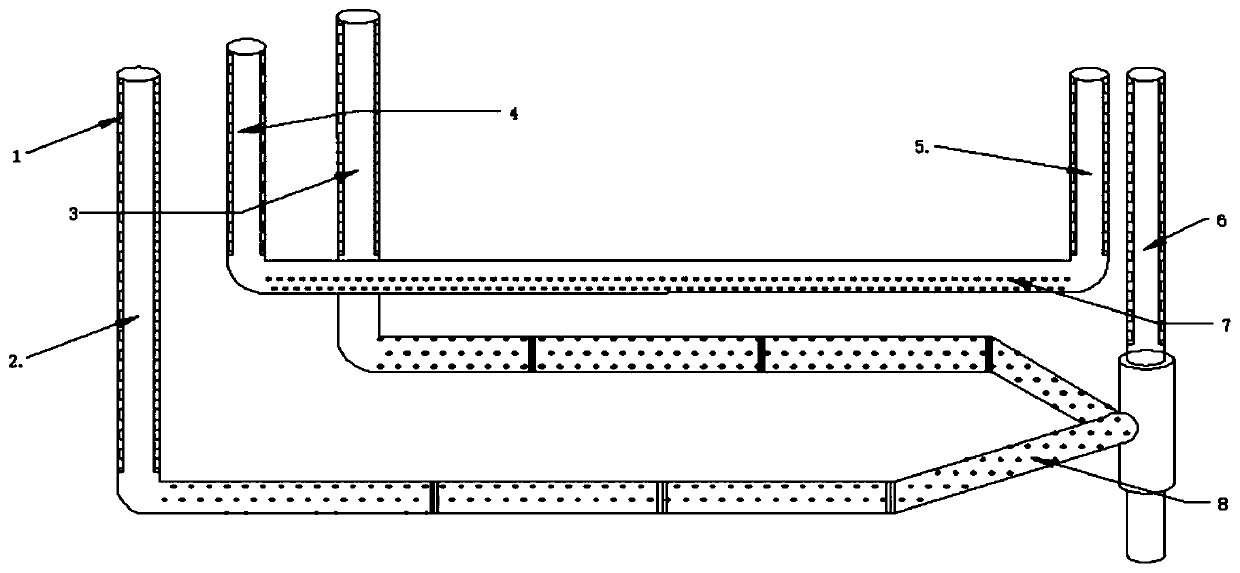

Heating device for improving heating quality of steel billets and using method thereof

ActiveCN102242249AImprove heating uniformityImprove uneven flow fieldFurnace typesHeat treatment furnacesHeat pipe heat exchangerGas pipeline

The invention relates to a heating device for improving heating quality of steel billets and a using method thereof. The heating device comprises a heating furnace, a heat storage system blower, a flat flame system blower, a combustion-supporting air pipeline, a gas pipeline, a heat storage system draught fan, an air heat exchanger, a gas heat pipe exchanger, a smoke exhaust pipeline and a chimney. 2-4 ignition burners are arranged at a preheating section of a heating furnace, and 12-30 pairs of heat storage type burners and 4-12 flat flame burners are respectively arranged at a heating section and a soaking zone. The using method comprises the following steps of reasonable distribution of combustion-supporting air and gas flow rate of the heat storage type burners and the flat flame burners, sectional configuration of furnace temperature and heating time, preheating of combustion-supporting air and gas temperature through a high-temperature smoke gas and furnace tail gas in grades, alternative furnace feeding of cold and heat steel billets, intermittent movement of the steel billets, and vaporization cooling of the steel billets. The flow field in the furnace is modified through the system, the optimal configuration of flow rates of air and gas in the burner is realized through reasonable arrangement of gas and air pipeline systems, and the waste heat of high-temperature smoke gas of the heating furnace is gradiently utilized, thus the in-furnace time is shortened, the uniformity of heating the steel billets is improved, and the high-efficiency heating of the steel billets is realized.

Owner:SHOUGANG CORPORATION

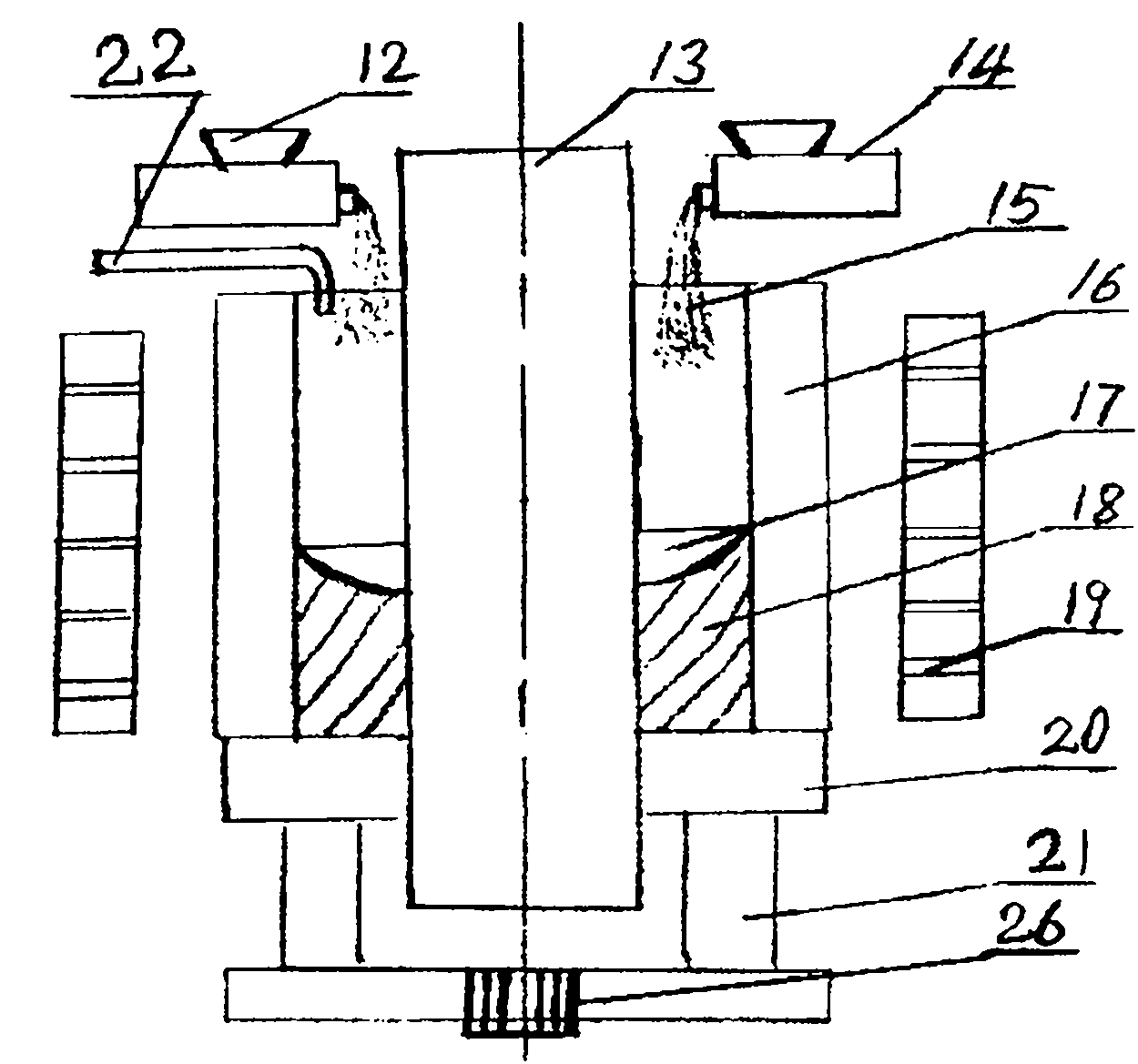

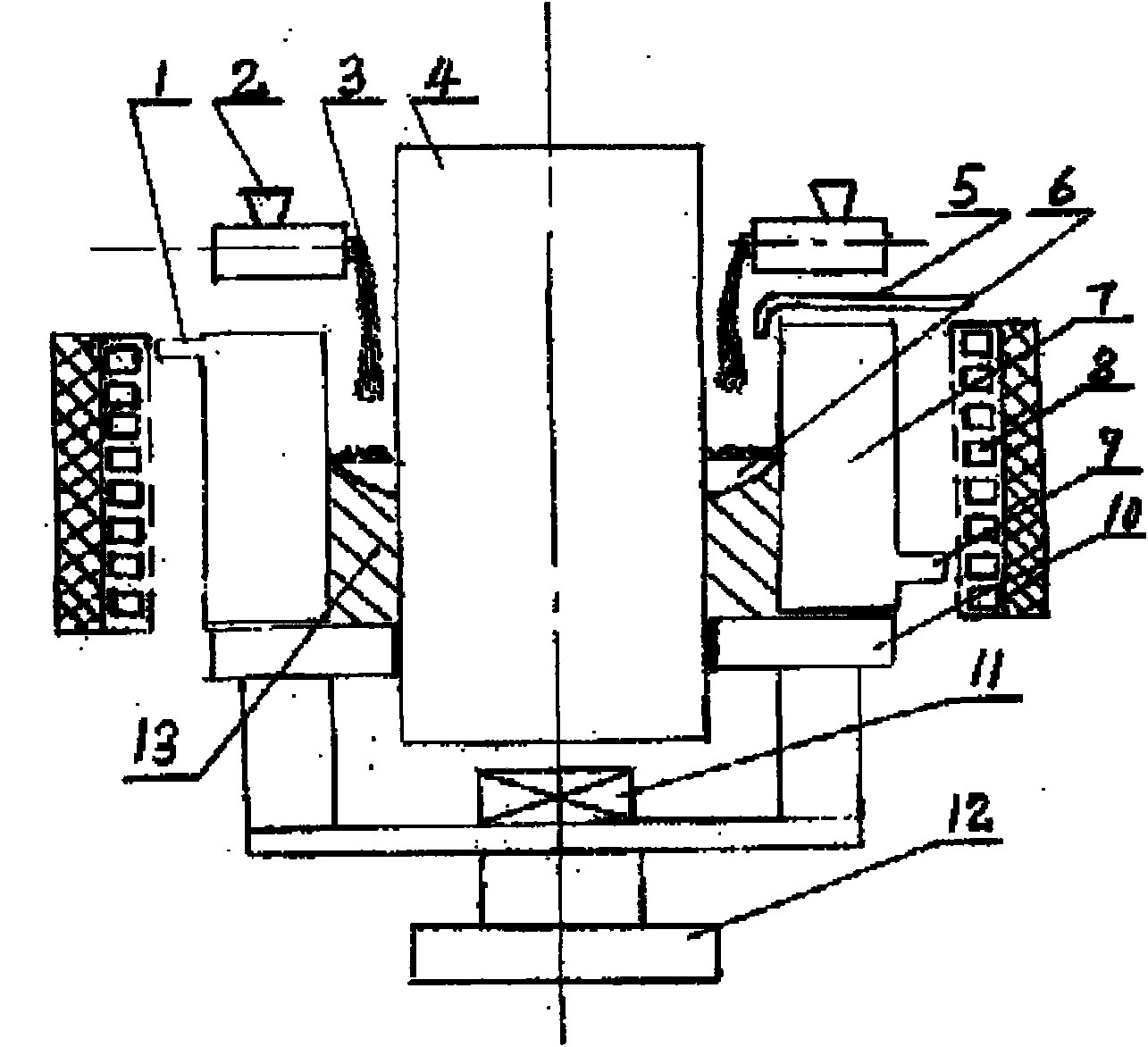

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

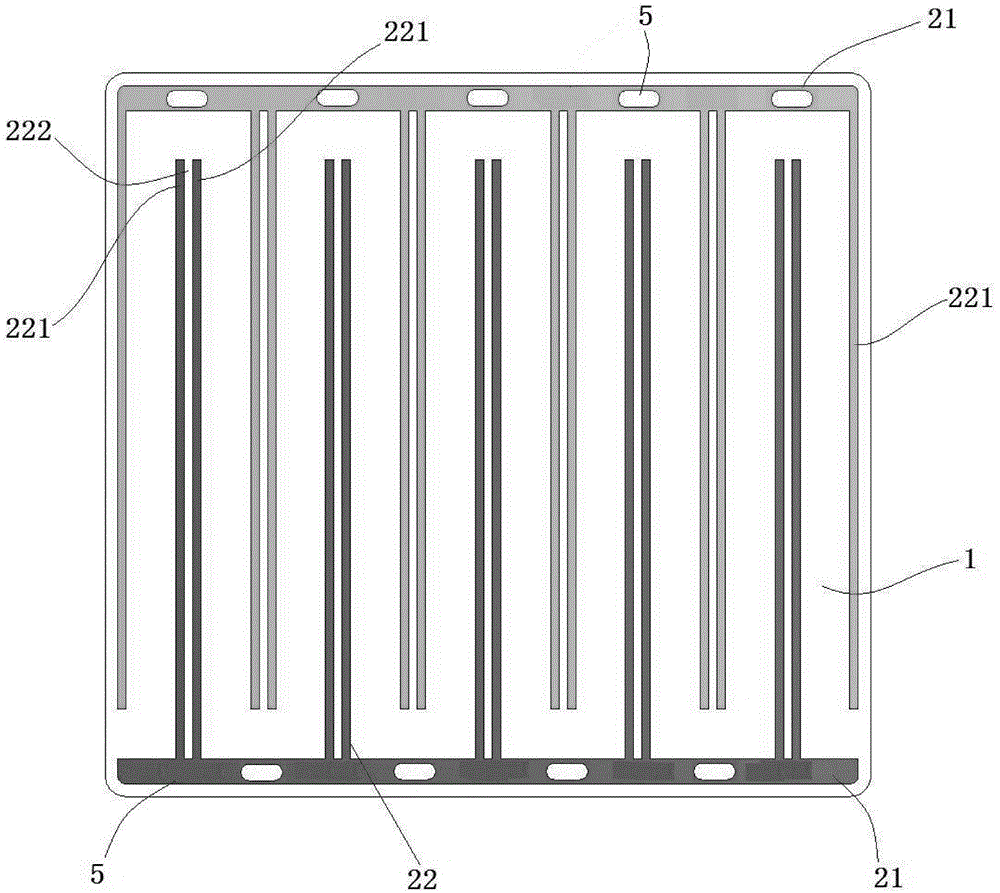

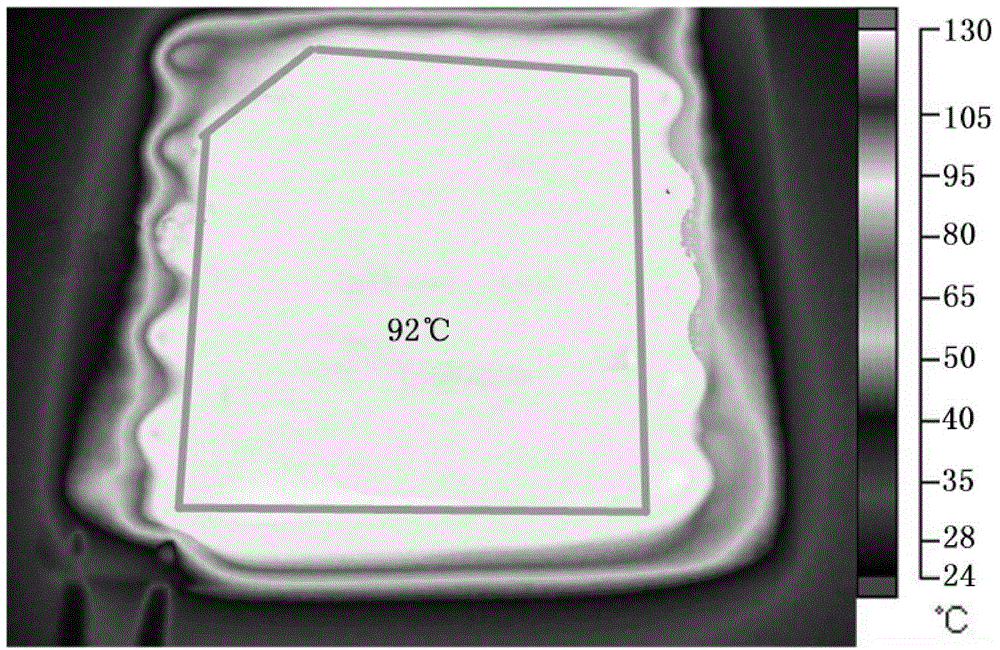

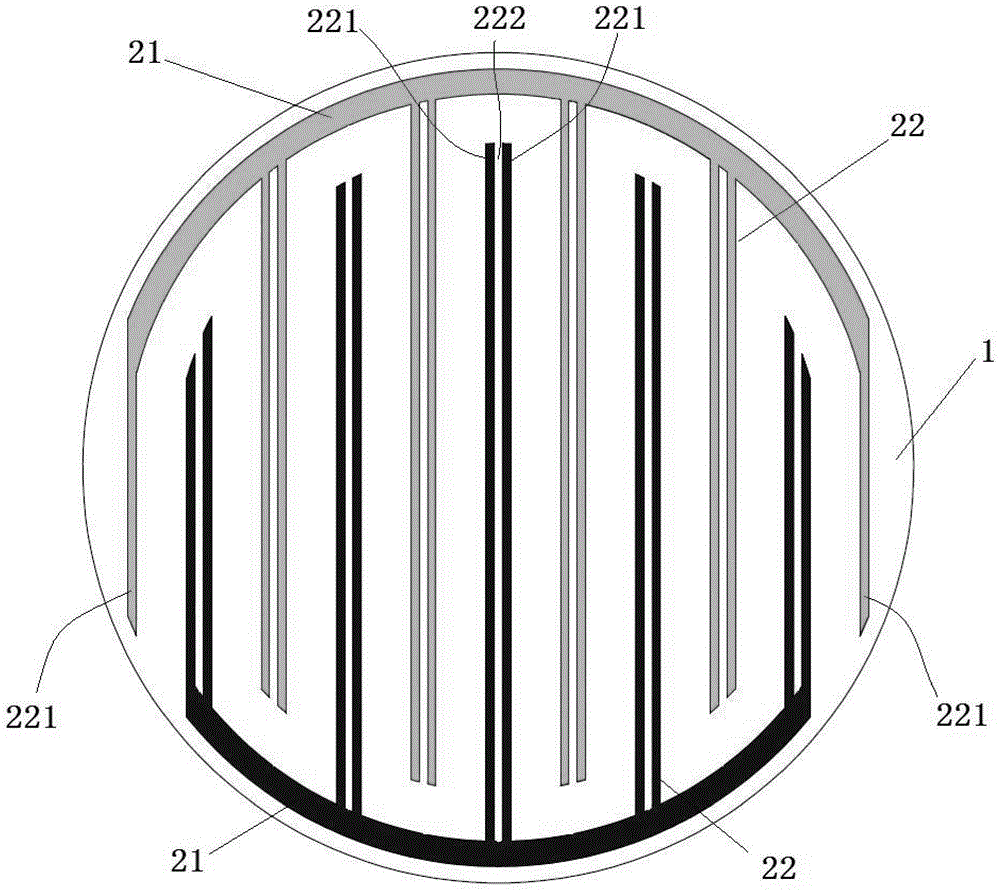

Low-voltage transparent electrothermal film

ActiveCN104883760ALower resistanceHeating fastTransparent/reflecting heating arrangementsElectrical resistance and conductanceElectricity

The invention discloses a low-voltage transparent electrothermal film, including a transparent base material, a transparent conducting layer and electrodes. The transparent conducting layer is formed on at least one side of the transparent base material; the electrodes are formed by bus bars and inner electrodes, and the inner electrodes extend oppositely from the bus bars to form interdigital electrodes; the bus bars are connected with a positive electrode or a negative electrode of a power supply, so that the two adjacent inner electrodes are opposite in polarity, and in energization, current provided by the positive electrode bus bar flows from the positive inner electrodes into the corresponding negative inner electrodes and finally all converges into the negative electrode bus bar; and the electrodes are located on the transparent conducting layer and is in electrical contact with the transparent conducting layer. The low-voltage transparent electrothermal film is provided with the bus bars and the inner electrodes, an interval of two electrodes is reduced to enable resistance of the transparent conducting layer between the two electrodes to be reduced, thus low voltage can be used to supply power, and normally, the low-voltage transparent electrothermal film can be heated to 90 to 180 DEG C rapidly by adoption of voltage of a lithium battery of everyday use. Two sets of electrodes can be arranged on two sides of graphene, and the inner electrodes of the two sets of electrodes are staggered at a certain distance, thereby further ensuring heating uniformity, and improving heating temperature under the same low voltage.

Owner:GRAHOPE NEW MATERIALS TECH INC +1

Cigarette column applicable to low-temperature cigarettes

ActiveCN105614945AEasy to addEasy to removeTobacco treatmentTobacco devicesHeat conductingEngineering

The invention discloses a cigarette column applicable to low-temperature cigarettes. The cigarette column comprises the following components in parts by weight: 100 parts of tobacco particles, 0.05-2.0 parts of tobacco essence, 1-15 parts of heat-conducting component and 1-20 parts of bonding agent. The cigarette column is wholly cylindrical or disc-shaped, the size of the cigarette column is slightly smaller than that of a tobacco filling cavity of the existing smoking set for the low-temperature cigarettes, so that the addition is easy, and the removal is also easy; a large amount of pores are formed inside, so that the suction is easy, simultaneously the heated area and the heated uniformity of the suctioning material can be improved and smoke can be rapidly formed at a lower temperature; and the cigarette column contains the heat-conducting component, so that the heat conduction in the cigarette column can be greatly accelerated in suction, and the cigarette column is beneficial to improving the heat uniformity and rapidly forming smoke.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Technology for processing high strength large hexagon-headed bolt used for steel structure

InactiveCN101934466AImprove heating uniformityFast heatingBoltsFurnace typesHigh intensityElectrical current

The invention provides a technology for processing high strength large hexagon-headed bolt used for steel structure. The invention relates to a technology for processing high strength connecting piece. High frequency induction current hot forging and cold extruding are adopted, so as to produce a bolt. The invention is on the basis of patent application with patent application number of 200810020090.5, high frequency induction heating is adopted in hot forging, frequency thereof is controlled to be 20000-50000Hz, and the advantages of high frequency induction heating that speed is fast and heating is uniform are utilized, so that work piece surface can obtain uniform tissue and properties from center part to the surface, heating uniformity of work piece is improved, better crystal phase structure can be obtained, and high strength bolt with better property can be obtained.

Owner:扬州狮鹤高强度螺栓有限公司

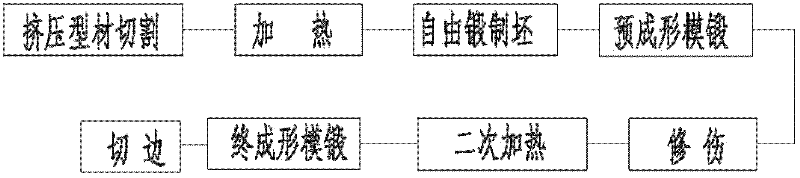

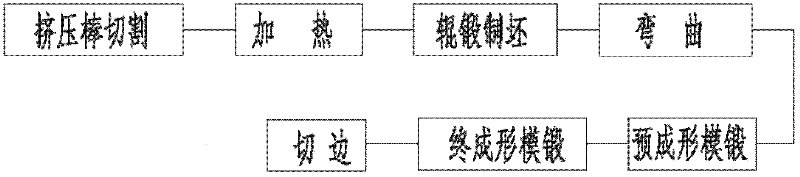

Manufacturing process for lambdoidal control arm

InactiveCN102500740AReduce preprocessing timeIncrease profitRailway componentsMetal-working apparatusProduction rateControl arm

The invention discloses a manufacturing process for a lambdoidal control arm. The manufacturing process comprises the following steps of: sawing an extruded bar; heating the extruded bar; rolling and forging the extruded bar to form a blank; bending to form the blank; preforming a forged die; finally forming the forged die; and trimming the forged die. In the manufacturing process, the extruded bar is taken as a raw material; the blank is heated to 440 DEG C-480 DEG C through electric induction; the blank is rolled and forged twice by a forging roll to realize volume distribution; the processes of bending to form the blank, preforming the forged die and finally forming the forged die are carried in sequence; and the trimming process is carried out in a thermal cutting manner. Compared with the prior art, a repairing process and a secondary heating process are reduced, the processing steps for the lambdoidal control arm are simplified, production cost for the product can be lowered, production rate can be increased, and product performances can be ensured.

Owner:芜湖禾田汽车工业有限公司

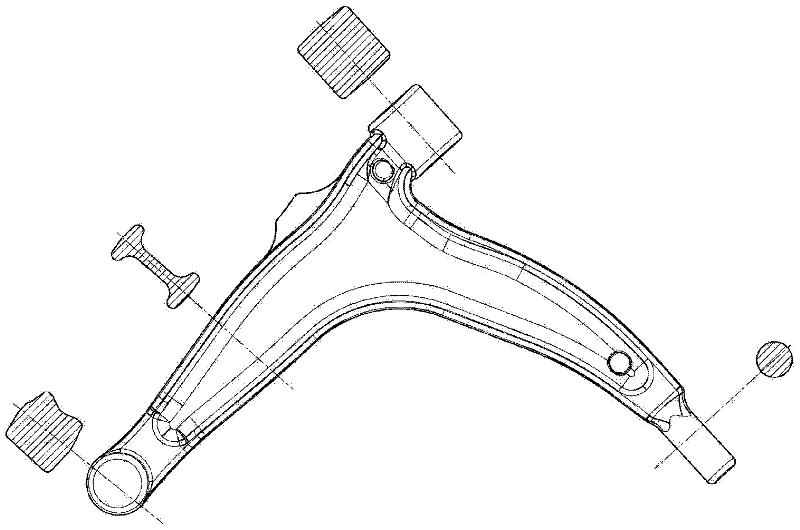

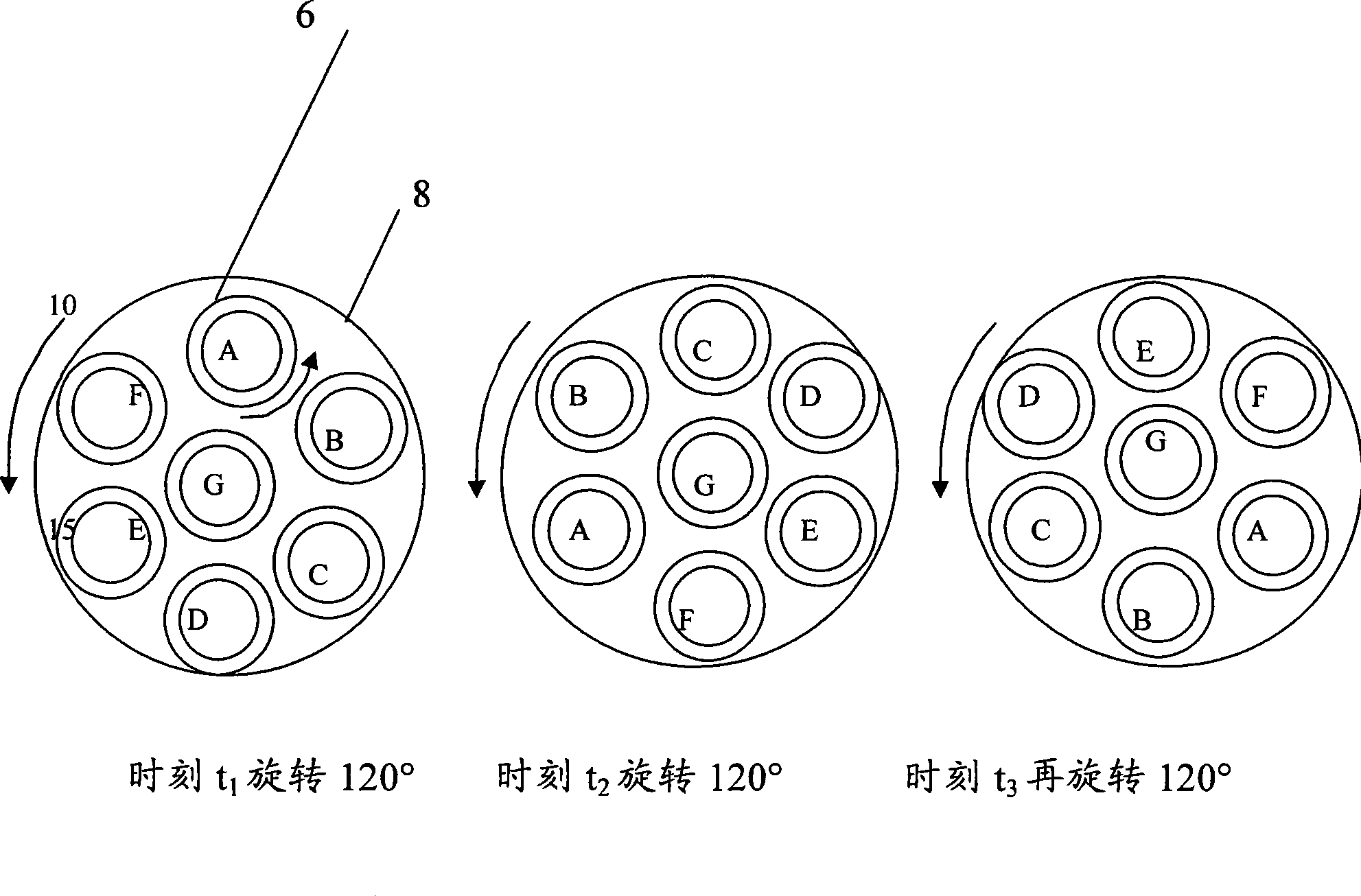

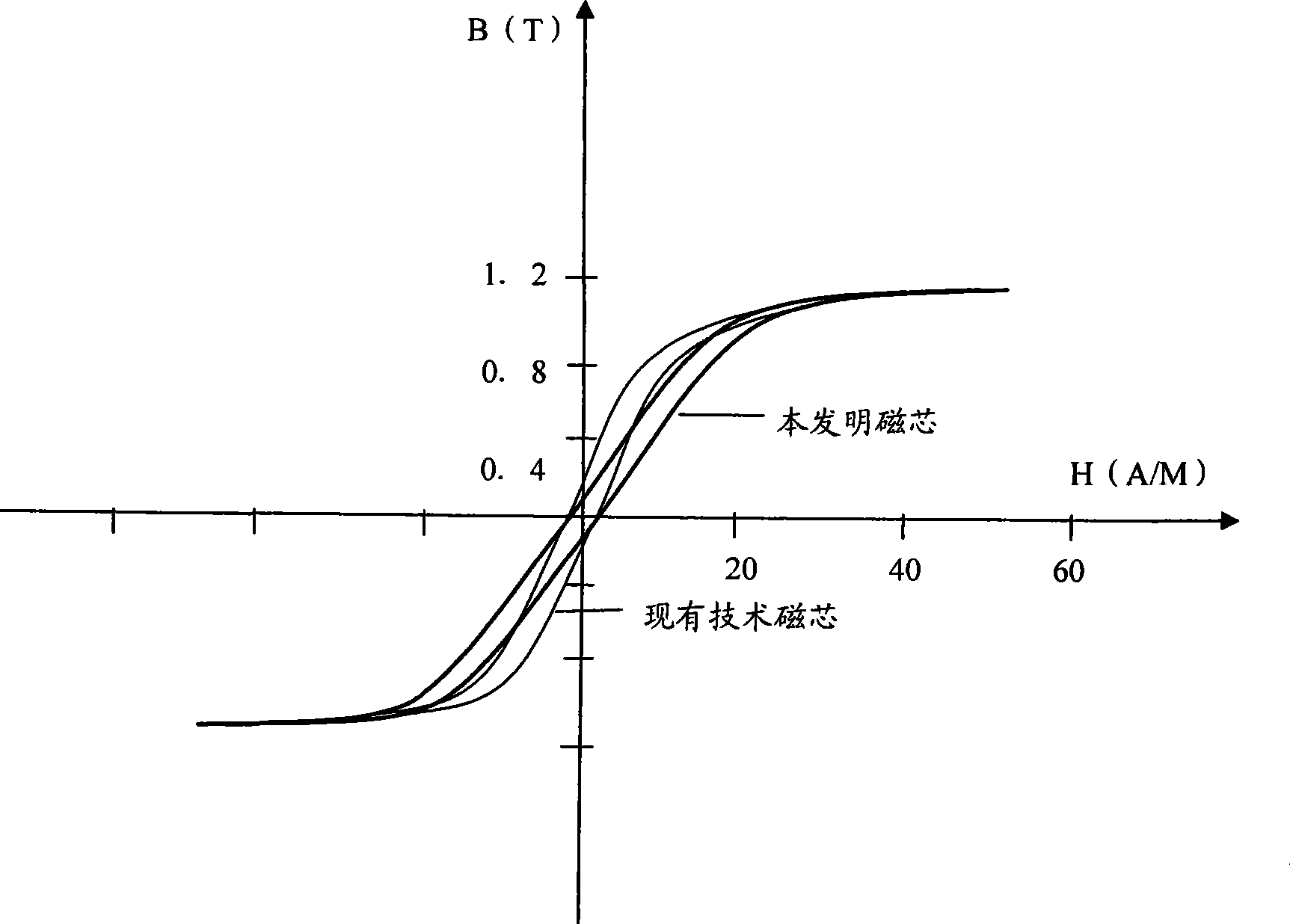

Iron based nanocrystalline magnet core for large power inverter power source and production method

ActiveCN101477868AGood tape making processReduce lossInorganic material magnetismTransformers/inductances magnetic coresPower inverterDownstream processing

The invention relates to a soft magnetic core used for a high-power inverter power supply, and a manufacturing method thereof. The magnetic core is made of an Fe-based amorphous nano-crystalline belt material through winding , and comprises components according to weight percentages as follows: 81%-85% of Fe, 0.01%-5% of Co, 7%-9% of Si, 1.5%-2.5% of B, 1%-2% of Cu, 4%-7% of M, and 0.001%-0.04% of M', wherein M is one or more of Nb, Mo, V, W and Ta, and M' is at least one of Al and Ti. The magnetic core is subjected to anneal in a protective atmosphere or a vacuum; when in anneal, the position of the magnetic core in a furnace is movable or rotatable, a holding temperature is 520-600 DEG C, the holding time is 1-2 hours, and a temperature rise speed is 100 DEG C per hour. The magnetic core manufactured by adopting the method has lower loss, better manufacturing technique properties, and good soft magnetic characteristics; moreover, the downstream processing after the heat treatment is applicable to various technique methods.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

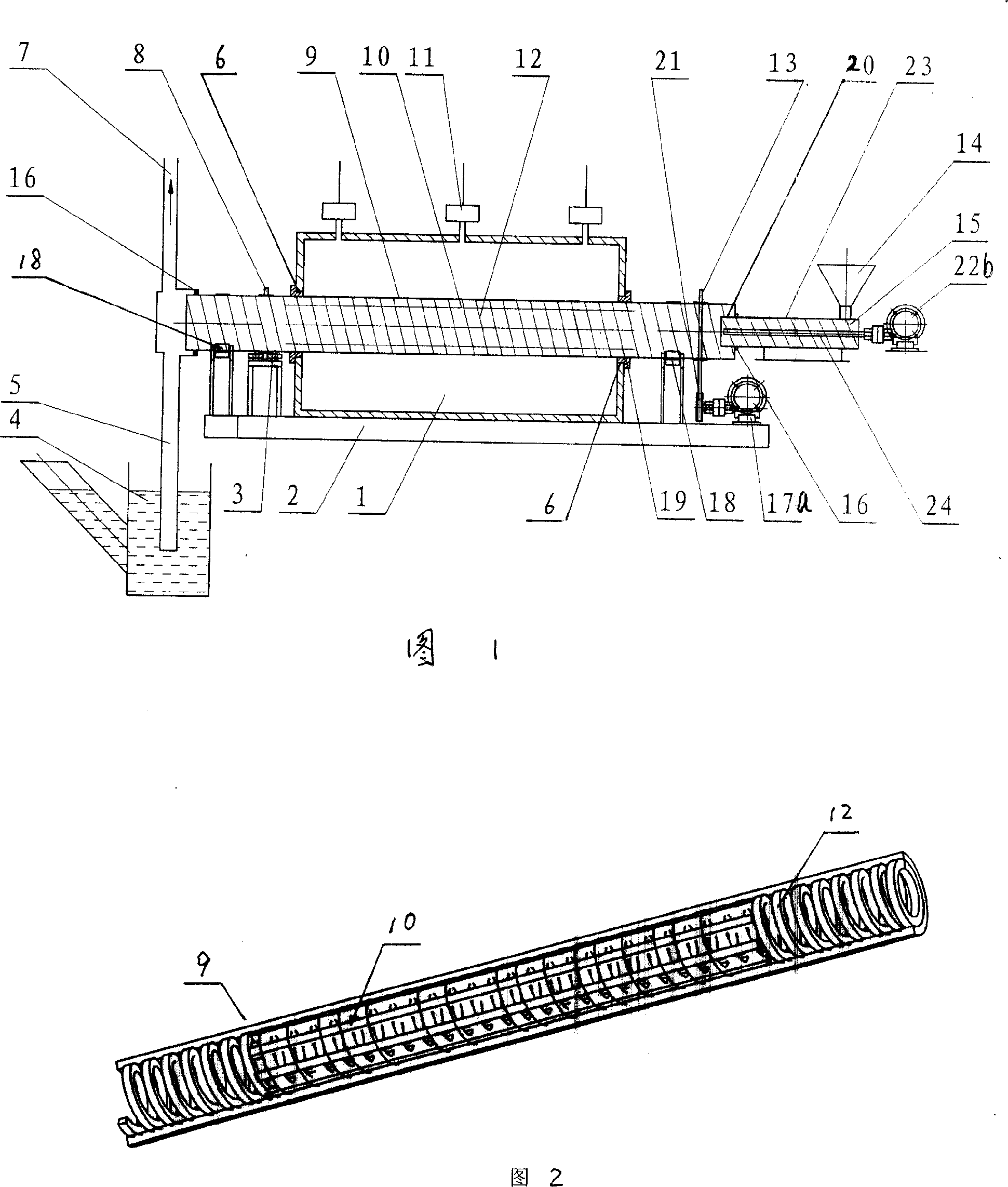

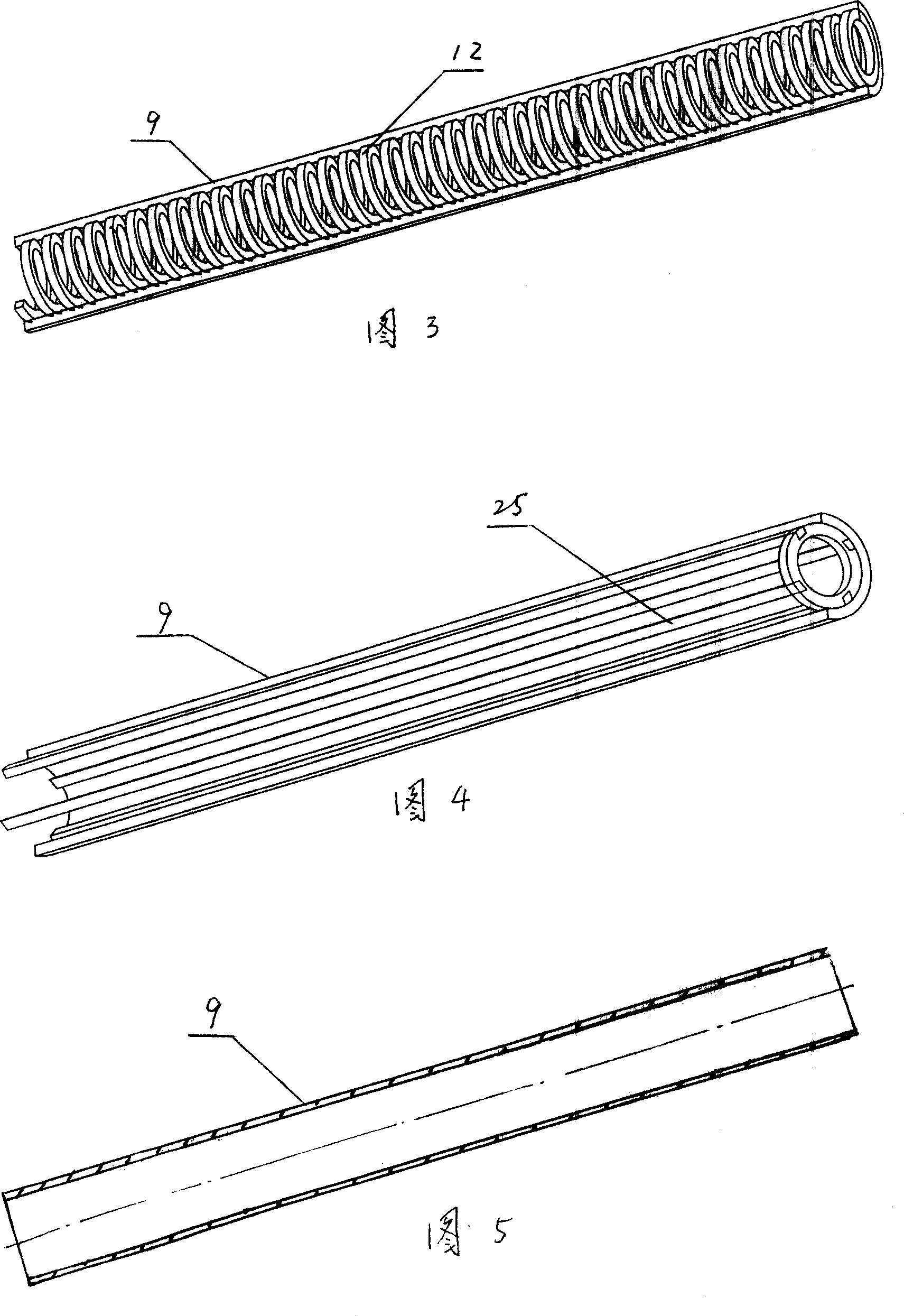

Microwave drum dry distiller and its application in dry distilling and pyrolyzing oil shale

InactiveCN101020828AFast heatingRapid responseSpecial form destructive distillationMicrowave ovenSlag

The present invention relates to carbon material pyrolyzing and dry distilling technology, and is especially one kind of microwave drum dry distiller and its application in dry distilling and pyrolyzing oil shale. The microwave drum dry distiller includes one microwave oven, and one inner screw drum on supporting rolls. The inner screw drum set on the microwave oven has material inlet, slag discharging barrel, gas exhausting pipe, and discharging port connected to the spiral conveyer. Granular oil shale entering to the microwave oven spirally through the inner screw drum absorbs microwave for dry distilling and pyrolysis so as to produce shale oil, fuel gas and semi-coke. The present invention has simple structure, convenient operation, fast dry distilling, high energy utilizing rate, environment friendship and other advantages.

Owner:NORTHEAST DIANLI UNIVERSITY +1

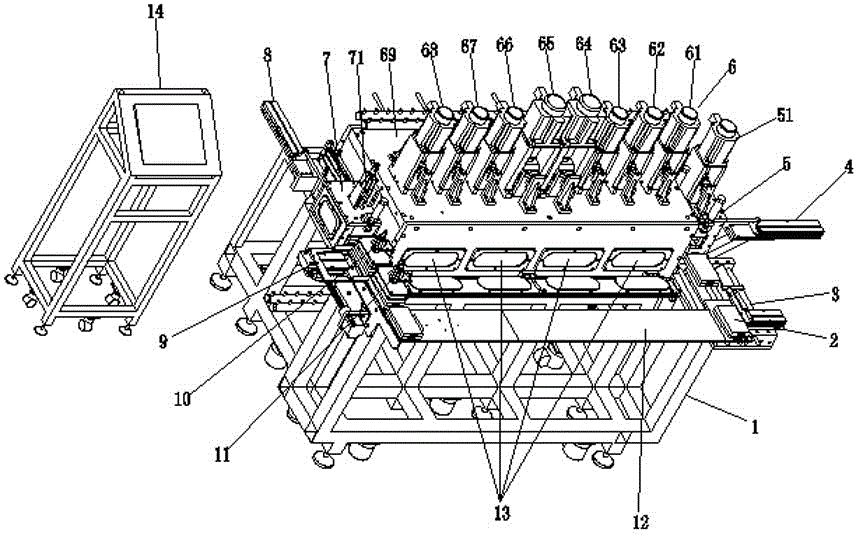

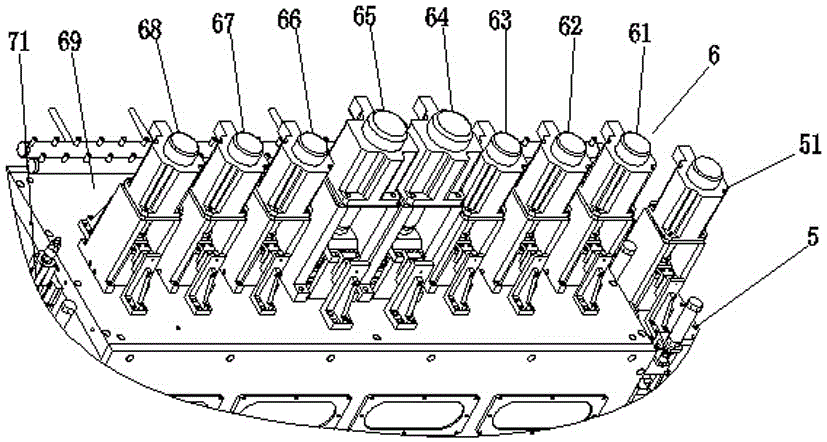

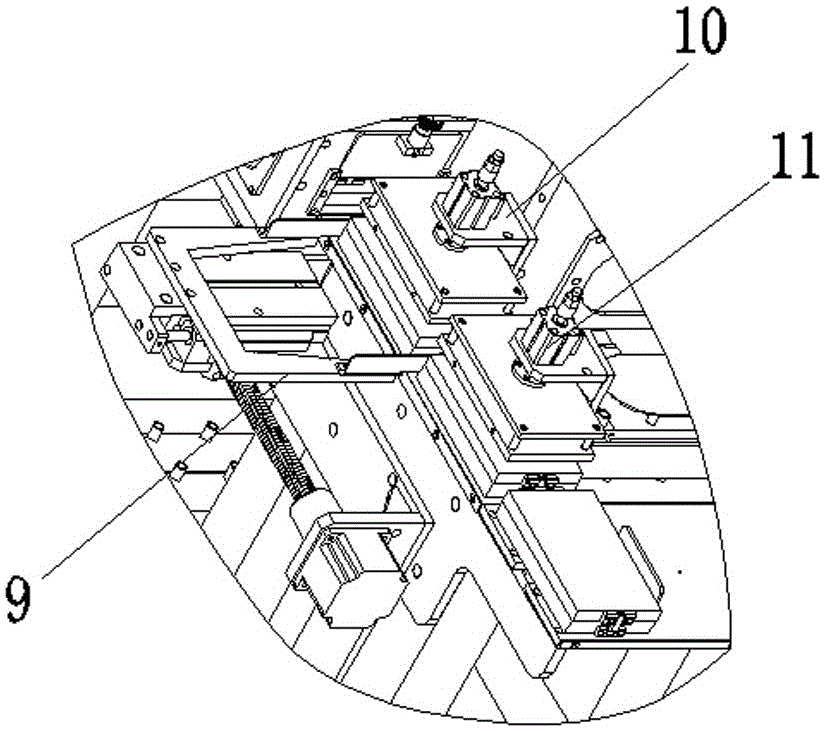

Hot-bending forming machine for mobile phone glass and watch surface covers

InactiveCN106316081AUniform heating effectImprove production continuityGlass reforming apparatusEngineeringHeating effect

The invention discloses a hot-bending forming machine for mobile phone glass and watch surface covers. The hot-bending forming machine comprises a rack and an operation console, wherein a forming part is arranged on the rack and comprises a forming bin, mold preheating mechanisms, a forming mechanism, a shaping mechanism, mold precooling mechanisms and a mold first cooling mechanism are sequentially arranged from an inlet end to an outlet end in the forming bin, and a forking and conveying mechanism for conveying a mold to each mechanism is arranged on the back side of the forming bin; a transition bin is arranged outside the inlet end of the forming bin, a mold feeding mechanism is arranged in front of the transition bin, a mold pushing mechanism is arranged on the outer side of the transition bin, and a first mold preheating mechanism is arranged in the transition bin; a discharging bin is arranged outside the outlet end of the forming bin, a second mold cooling mechanism is arranged in the discharging bin, a discharged material pushing mechanism is arranged on the back side of the discharging bin, a secondary cooling mechanism is arranged in front of the discharging bin, and a discharging cooling and conveying mechanism is arranged on the outer side of the secondary cooling mechanism. The hot-bending forming machine for the mobile phone glass and the watch surface covers has the advantages of uniform heating effect, good production continuity, high production efficiency and the like.

Owner:饶武良

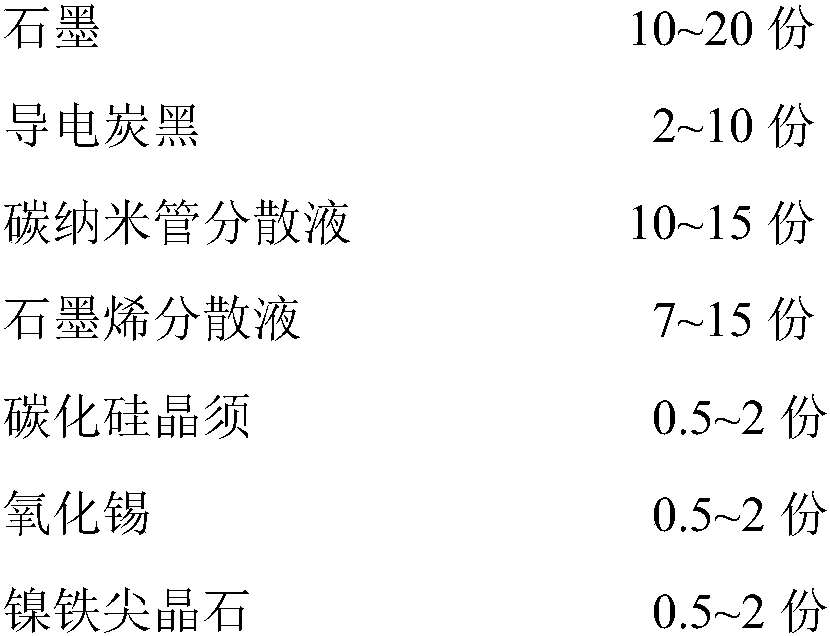

Electric heating paint and preparation method and application thereof

ActiveCN108084823AImprove ductilityImprove heating uniformityChemical industryPolyurea/polyurethane coatingsWeather resistanceCarbon black

The invention provides novel electric heating paint and a preparation method thereof. Ink is prepared from, by mass, 10-20 parts of graphite, 2-10 parts of conductive carbon black, 10-15 parts of carbon nanotube dispersion liquid, 7-15 parts of graphene dispersion liquid, 0.5-2 parts of silicon carbide whiskers, 0.5-2 parts of tin oxide, 0.5-2 parts of ferronickel spinel, 16-37 parts of water-based resin linking agent, 20-40 parts of water and 2.3-8 parts of addition agent. The invention relates to an electric heating sizing agent containing the conductive composition and a preparation methodthereof. In addition, the conductive ink has the advantages of being high in heating uniformity, electricity-heat conversion efficiency and heating speed, light, good in flexibility, high in adhesiveforce, good in weather resistance and aging resistance, high in safety, environmentally friendly and the like, can be used as heating products for buildings and can also be processed into various electric heating products.

Owner:张昊 +3

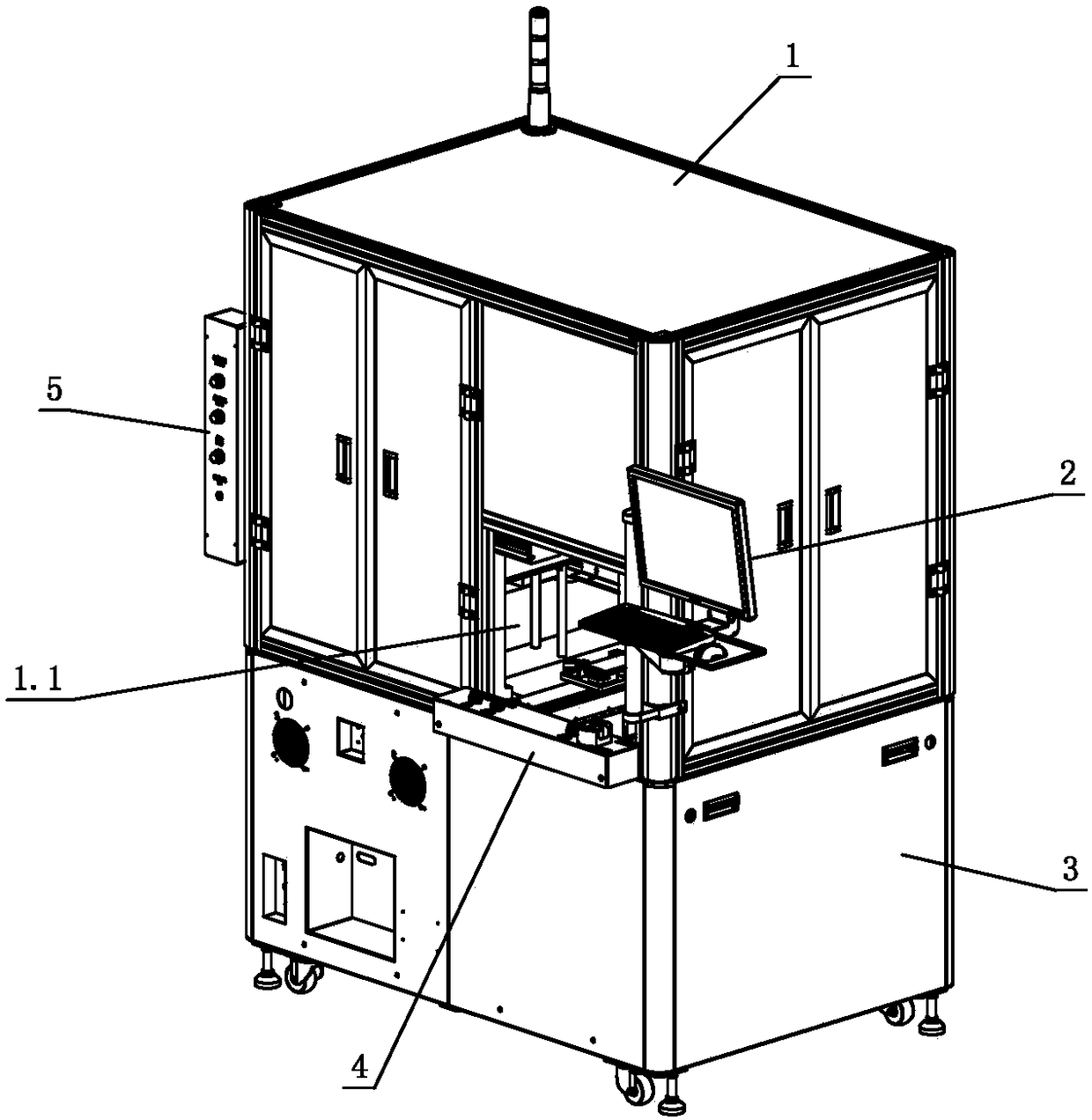

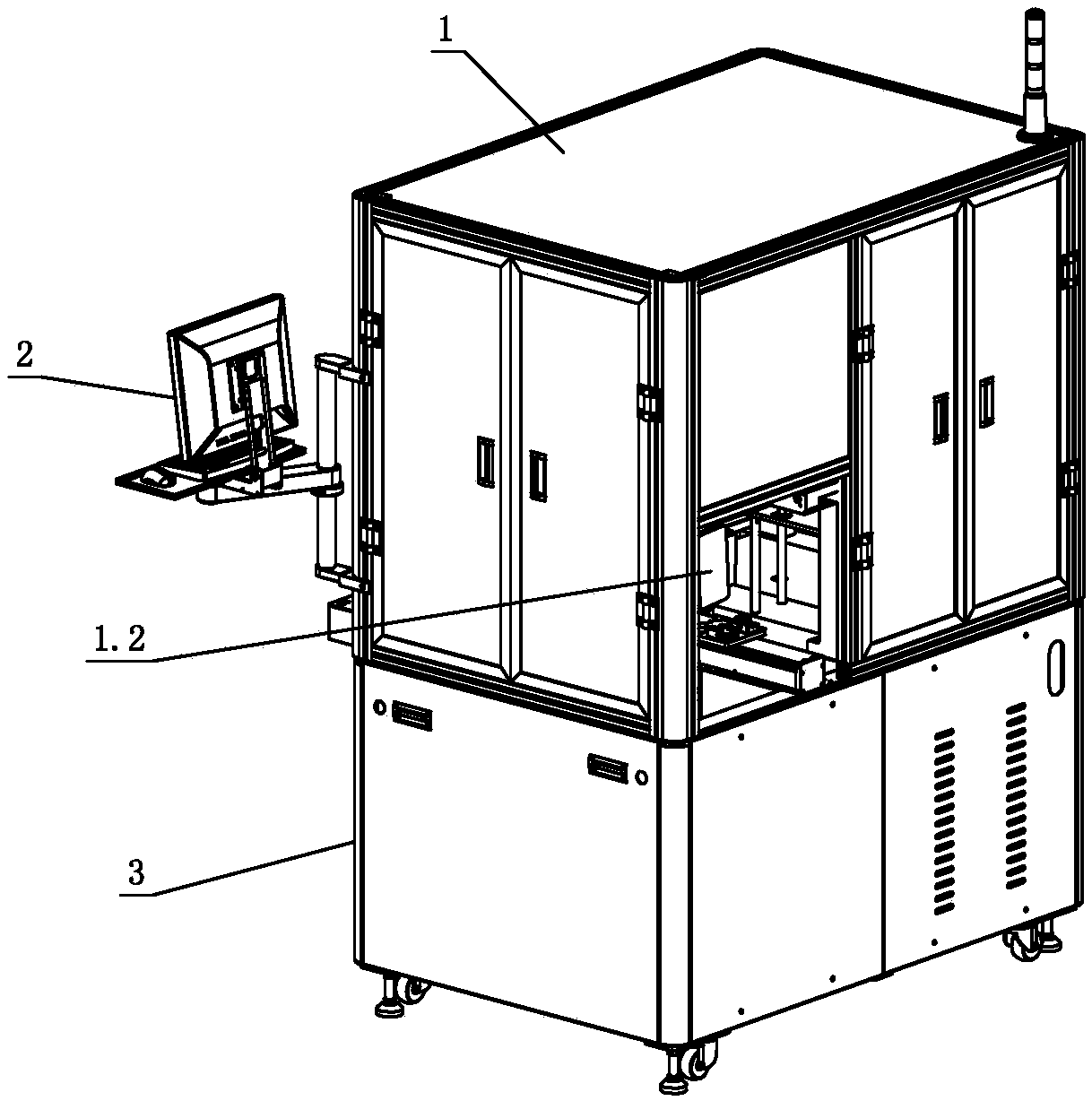

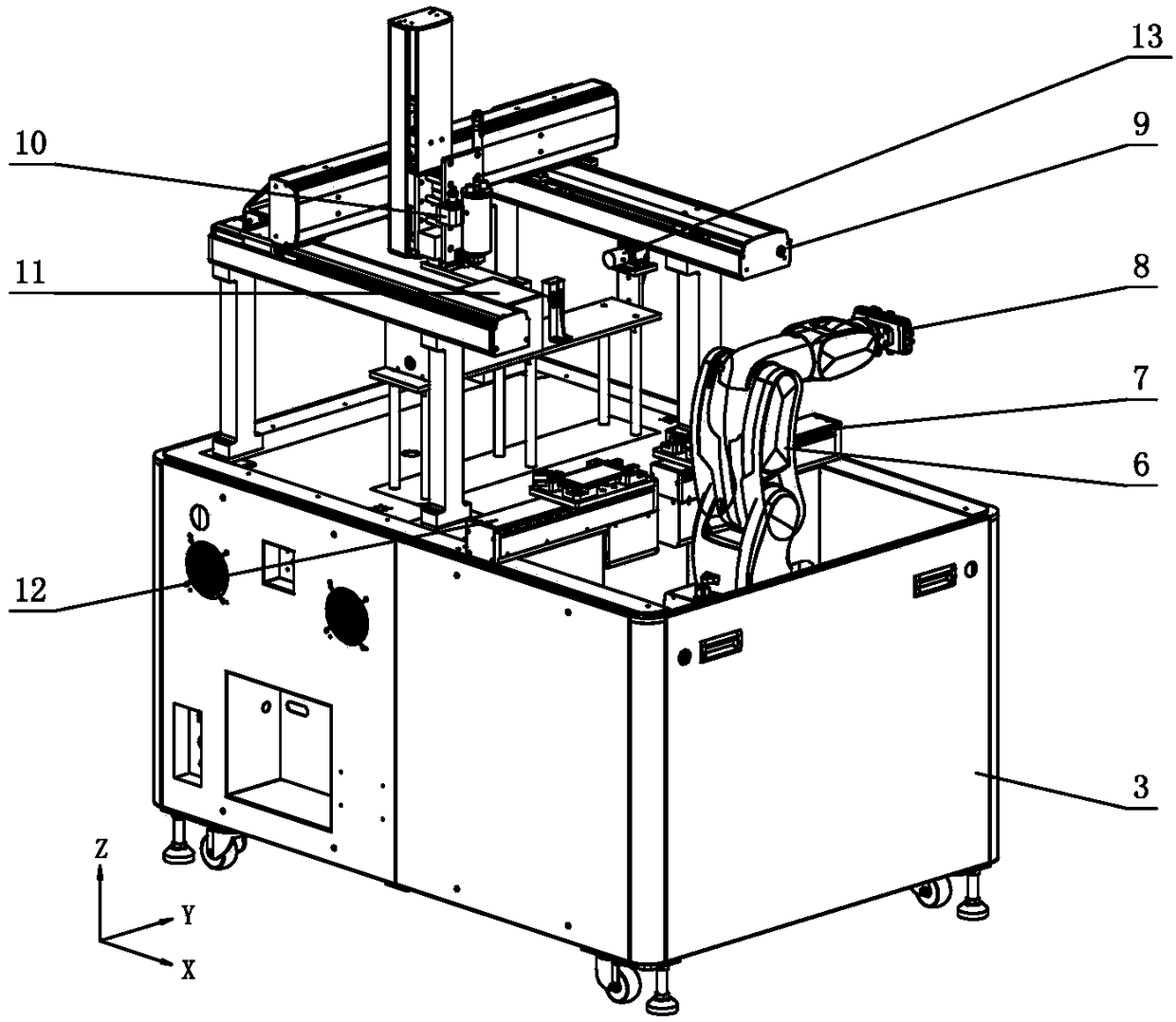

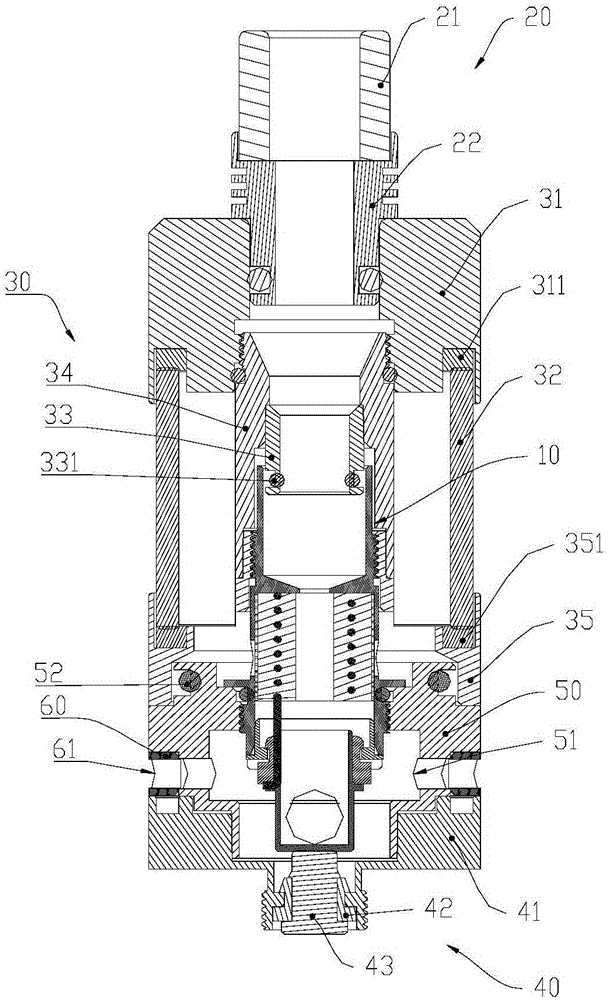

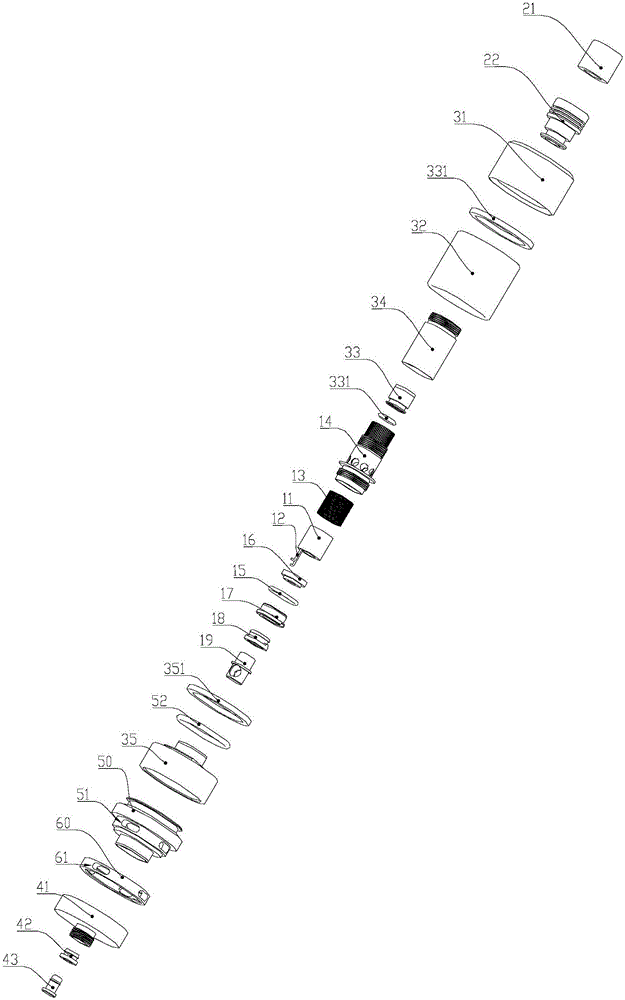

Automatic dispensing equipment

ActiveCN108284044AImprove heating efficiency and heating uniformityImprove dispensing qualityLiquid surface applicatorsCoatingsWorking rangeHot-melt adhesive

The invention provides automatic dispensing equipment. The automatic dispensing equipment comprises an equipment console, wherein a dispensing mechanism, a triaxial correcting mechanism, a feeding mechanism, a discharging mechanism and a transferring robot are arranged on the equipment console; the conveying starting end of the feeding mechanism is located in the material swinging area, and the conveying tail end of the feeding mechanism is located in the feeding area; the conveying starting end of the discharging mechanism is located in the feeding area, and the conveying tail end of the discharging mechanism is located in the material taking area; and the dispensing and transferring track of the transferring robot is programmed by an off-line programming software, and the working range of the feeding area at least covers the feeding area and the discharging area. The dispensing mechanism, the feeding mechanism and the discharging mechanism are integrated on the same device, and a six-axis transfer robot is adopted for grabbing products to carry out dispensing operation, so that the dispensing quality and efficiency can be improved, and the automatic dispensing equipment can be applied to dispensing of a space curve track, such as coating hot melt adhesive between a mobile phone screen and a middle frame gap, so that the protection level of a mobile phone can be improved, andabattery back cover of a hyperboloid screen phone can be subjected to hot melt adhesive operation and the like.

Owner:GUANGDONG LXD ROBOTICS CO LTD

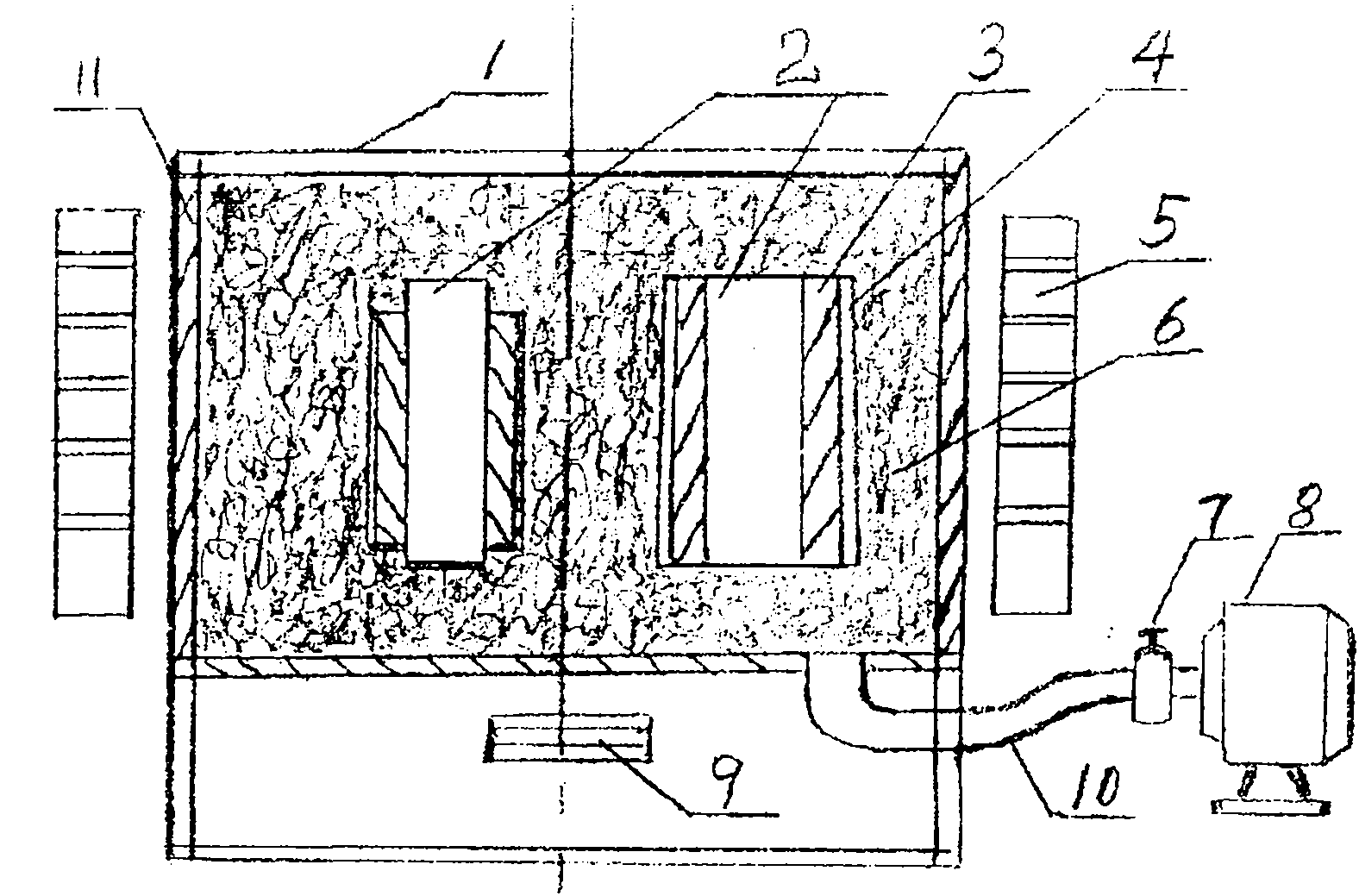

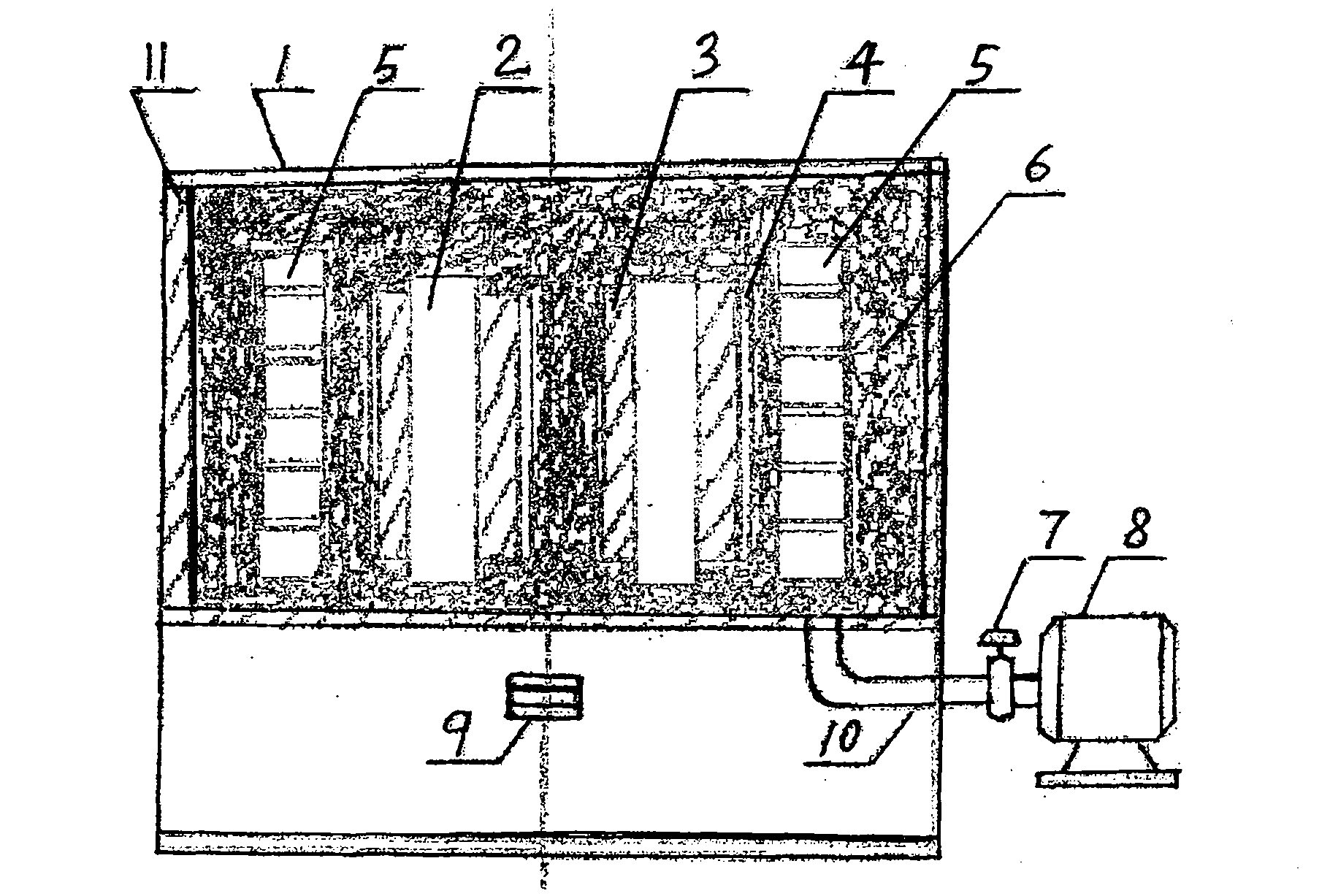

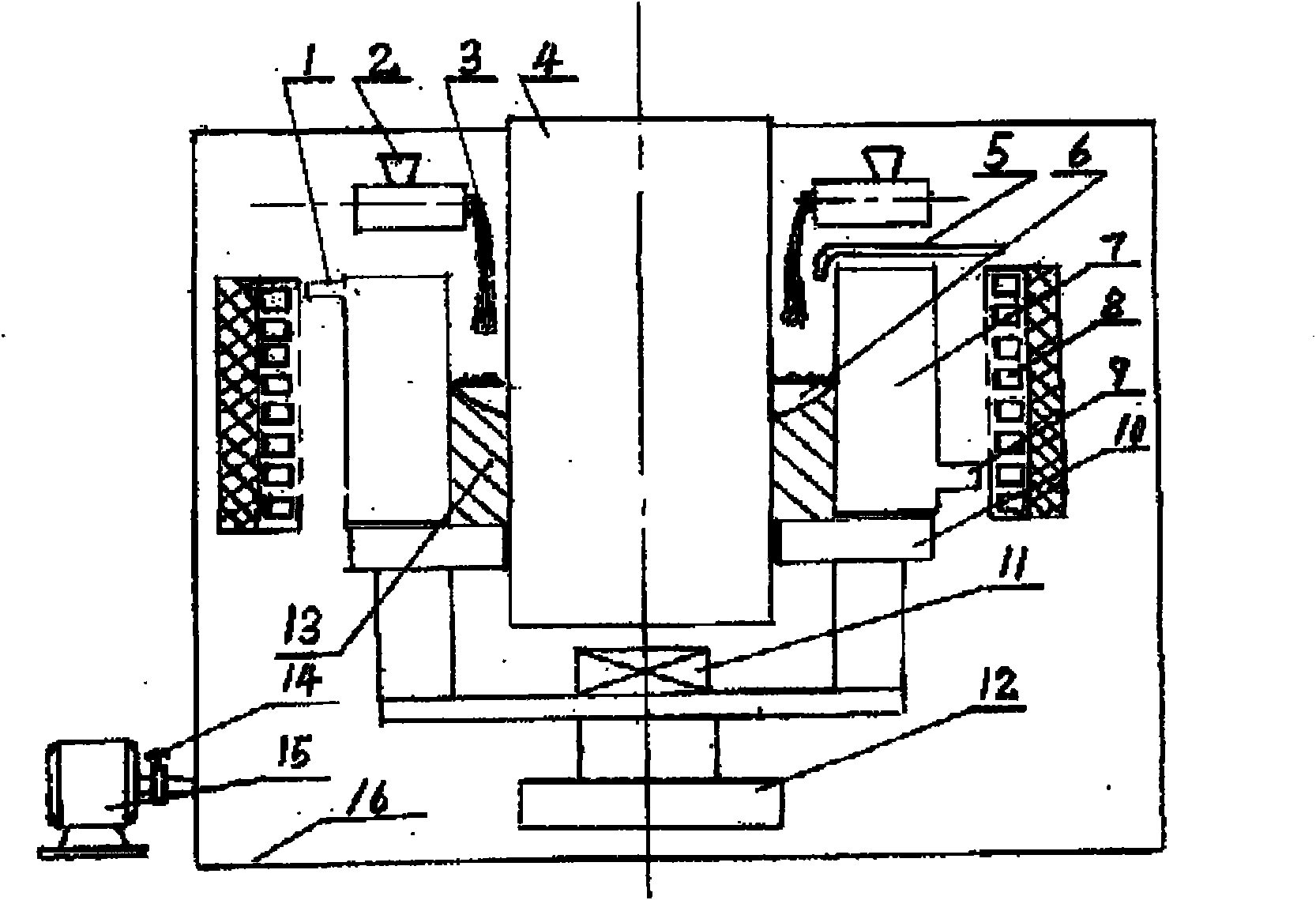

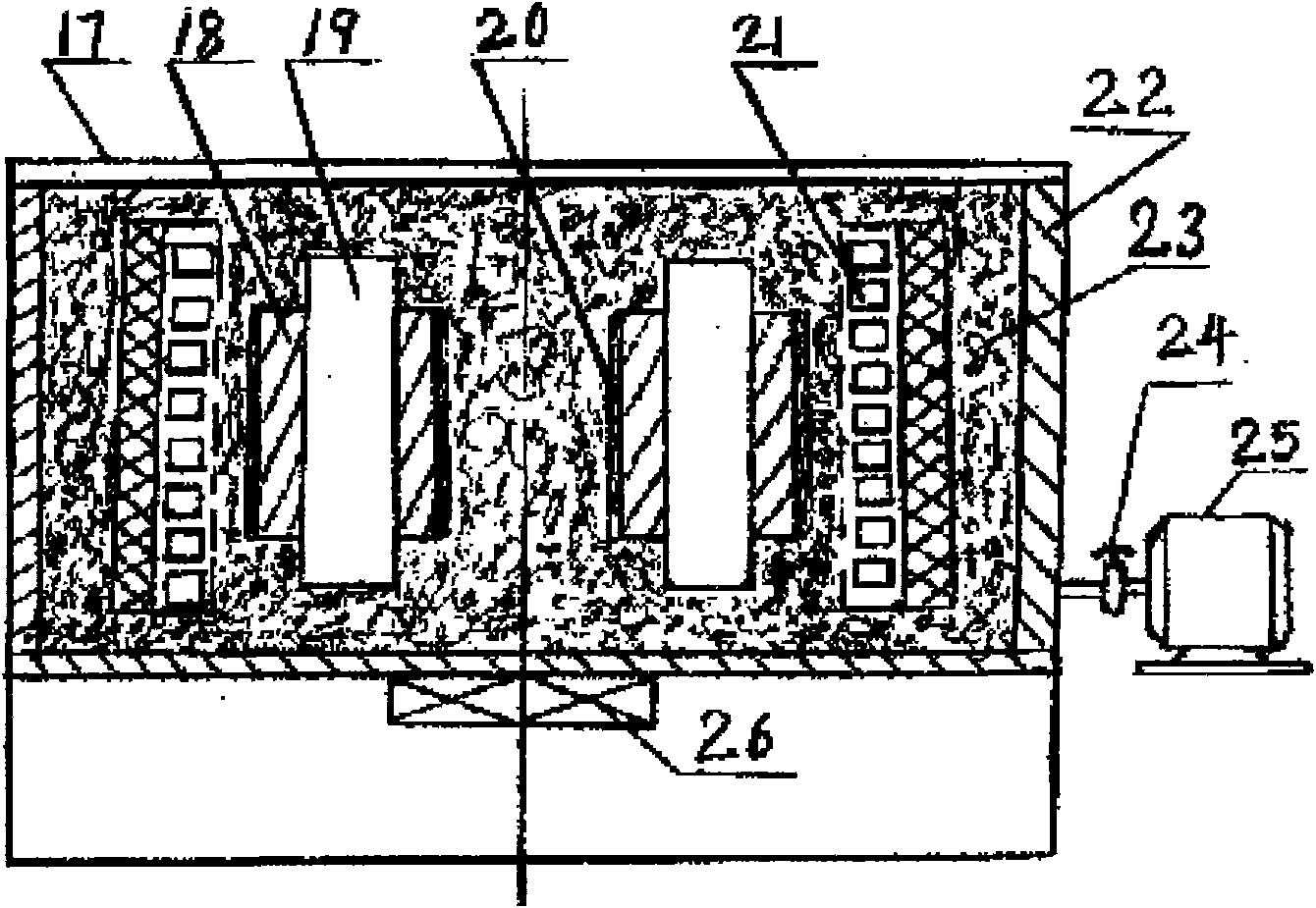

Micro-nano-alloy bimetal composite material preparation technique and device thereof

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

Preparation method of p-CuO/n-CdS/ZnS composite semiconductor photochemical catalyst

InactiveCN102125858AExtended service lifeImprove photocatalytic efficiencyPhysical/chemical process catalystsHydrogen productionDistillationUltrasonic dispersion

The invention discloses a preparation method of a p-CuO / n-CdS / ZnS composite semiconductor photochemical catalyst, which comprises the steps of: firstly, with an ammonium salt, a zinc salt, a cadmium salt, thiocarbamide and deionized water as raw materials, sequentially carrying out treatments such as microwave reaction, ultrasonic dispersion, heating reaction, washing, ultrasonic dispersion, filtering, drying, roasting, grinding and the like to obtain CdS / ZnS solid powder; and secondly, with the CdS / ZnS solid powder, a copper salt, alkali and deionized water as raw materials, sequentially carrying out treatments such as reaction, ultrasonic dispersion, decompression distillation, thermal treatment, washing, ultrasonic dispersion, filtering, drying, roasting, grinding and the like to obtain the p-CuO / n-CdS / ZnS composite semiconductor photochemical catalyst. Through compounding a p-type semiconductor CuO with n-type semiconductor CdS and ZnS, oxidization of holes to the CdS can be effectively reduced, the light corrosion rate of the CdS is decreased; and photoproduced electronics are effectively separated from the holes, thus the service life of the CdS is prolonged, and the photochemical catalysis efficiency of the p-CuO / n-CdS / ZnS composite semiconductor photochemical catalyst is increased. The method is simple, convenient and practical, and is beneficial to popularization.

Owner:NANJING FORESTRY UNIV

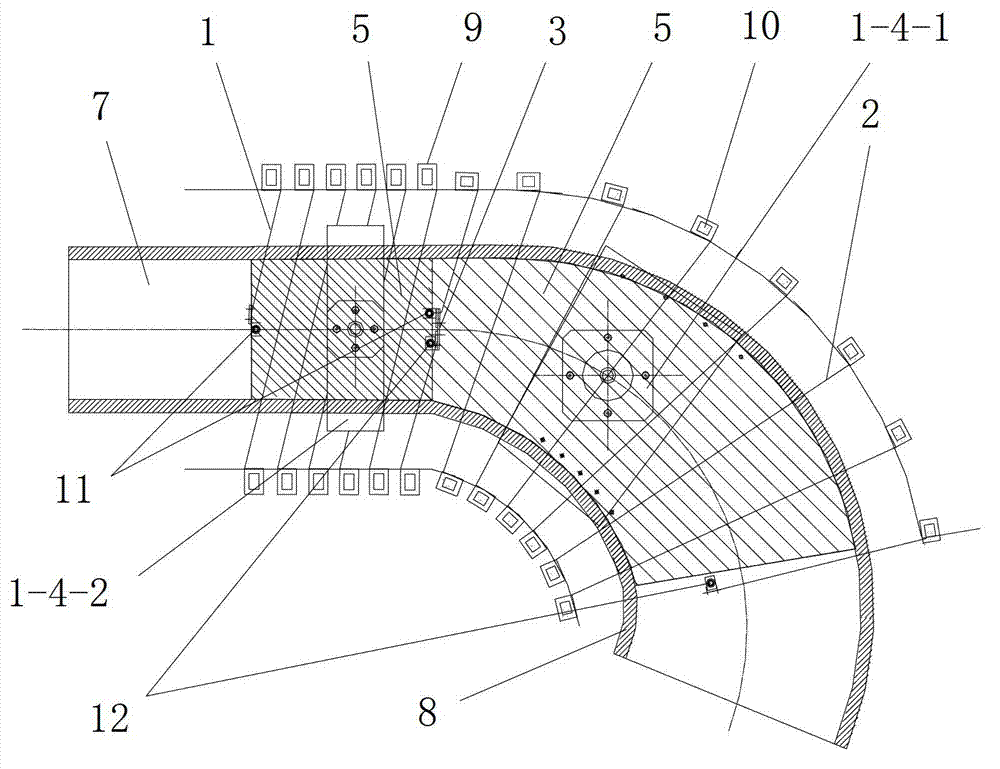

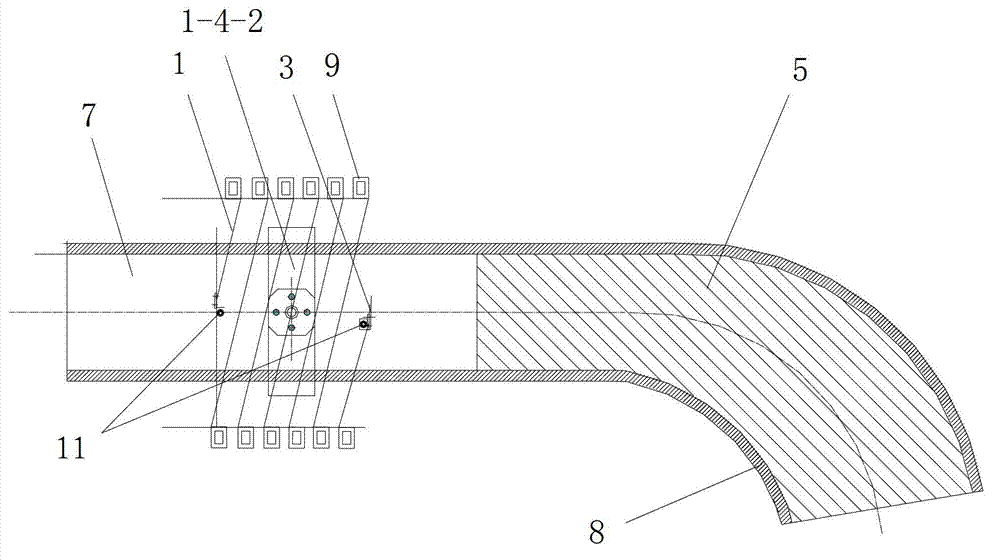

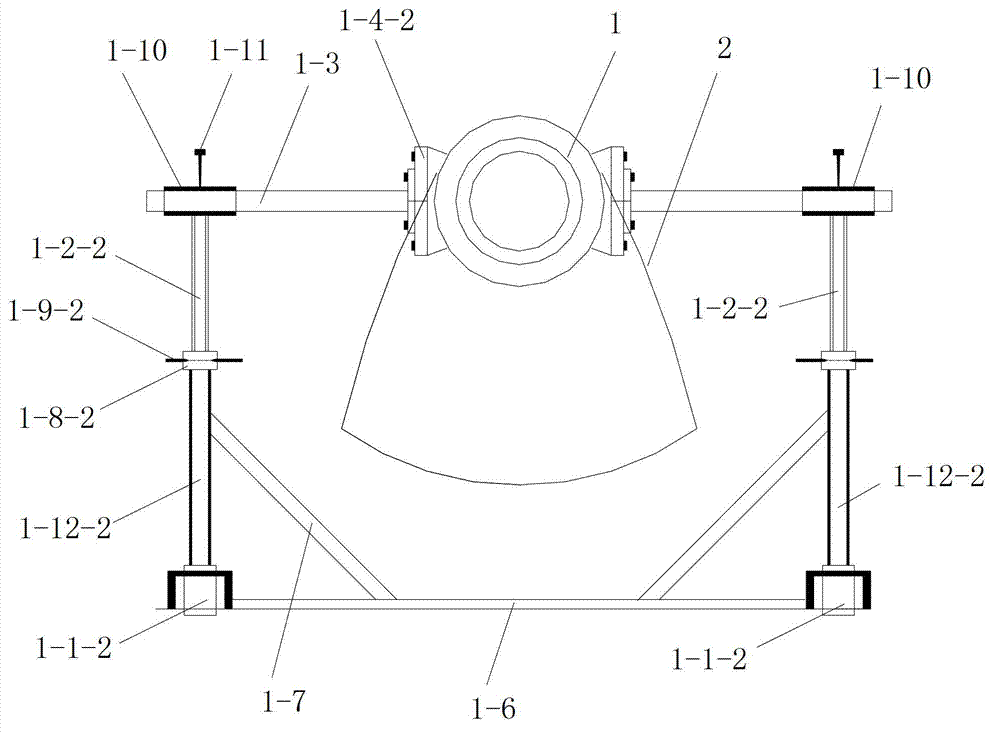

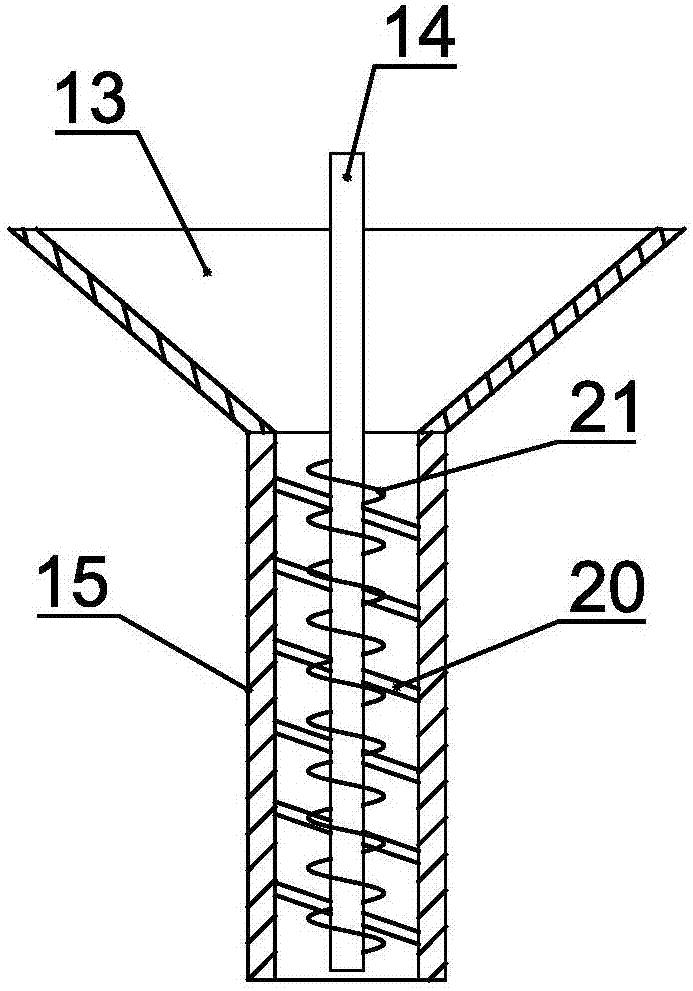

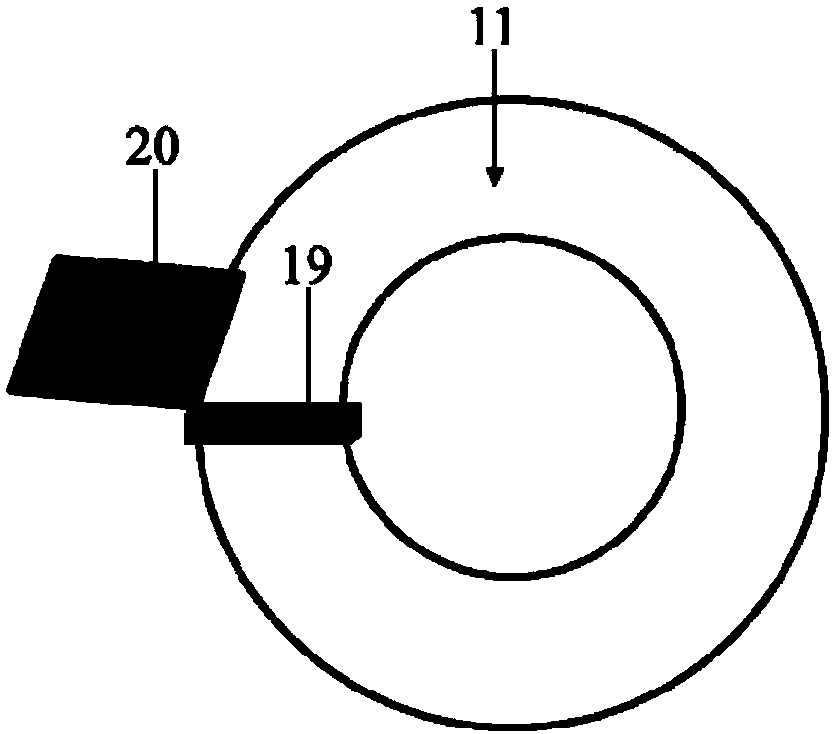

Detachable electromagnetic induction heater for diameter-expanded bend-pushed large-diameter elbow

The invention discloses a detachable electromagnetic induction heater for diameter-expanded bend-pushed large-diameter elbow, which comprises a detachable electromagnetic induction heating coil, wherein a molding core head for expanding diameter and pushing bend is sleeved with the detachable electromagnetic induction heating coil; a central axis of the detachable electromagnetic induction heating coil is coincident with a central axis of the molding core head; the molding core head is a cleat-shaped core head that comprises an extension section, a deformation section and a shaped section; the detachable electromagnetic induction heating coil comprises a straight line section heating coil and a bended section heating coil; the straight line section heating coil and the bended section heating coil are connected by copper bars; the straight line section heating coil is annularly wound on the extension section; and the bended section heating coil is annularly wound on the deformation section and the shaped section. The detachable electromagnetic induction heater is simple in structure, reasonable in design, simple and convenient to use and operate, strong in operability, good in using effect, not only can improve the pipe blank feeding efficiency when expanding the diameter and pushing the bend of the large-diameter elbow, and also can improve the heating efficiency and the uniformity of the pipe blank.

Owner:西安秦钛智造科技有限公司

Electro-conductive concrete with nano charcoal black

The invention relates to a nano carbon black conductive concrete which is prepared by using silicate cement and sand as the basic material and using nano carbon black as the conductive phase, wherein the constituents of the conducting material comprise (by weight percent) nano carbon black 0.05-3, nano carbon black dispersing agent 0-3, concrete dehydragent 0-0.75.

Owner:WUHAN UNIV OF TECH

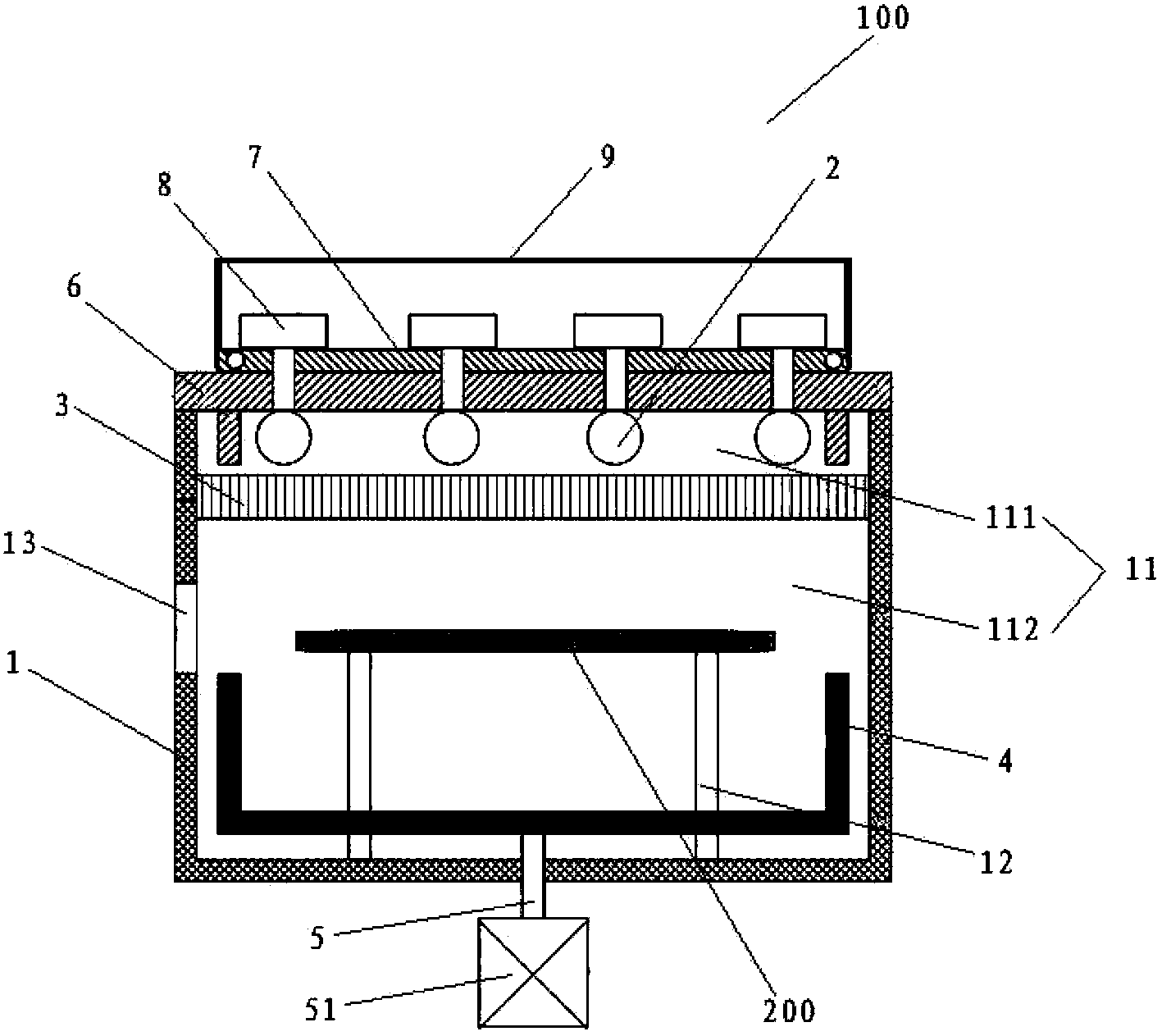

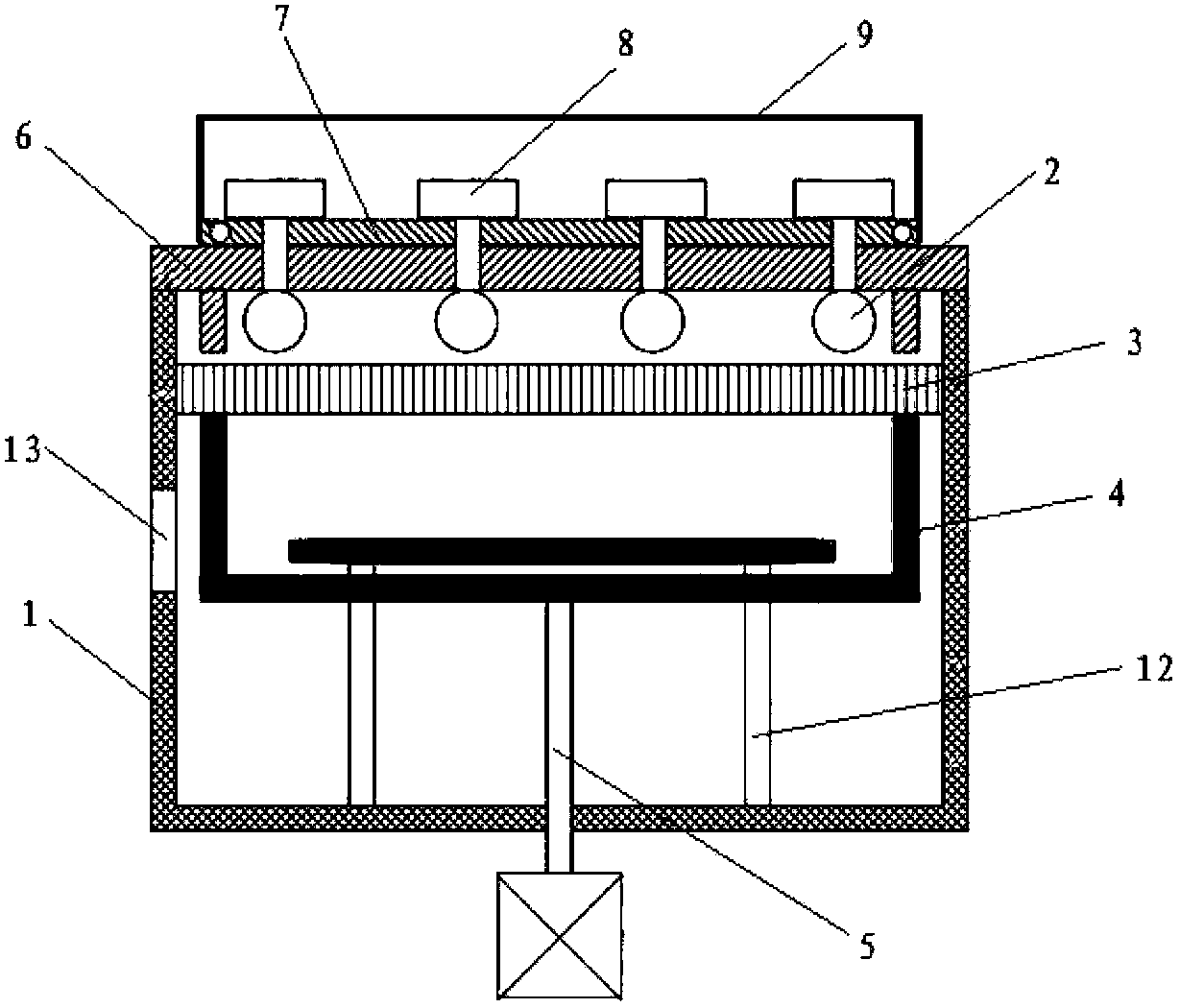

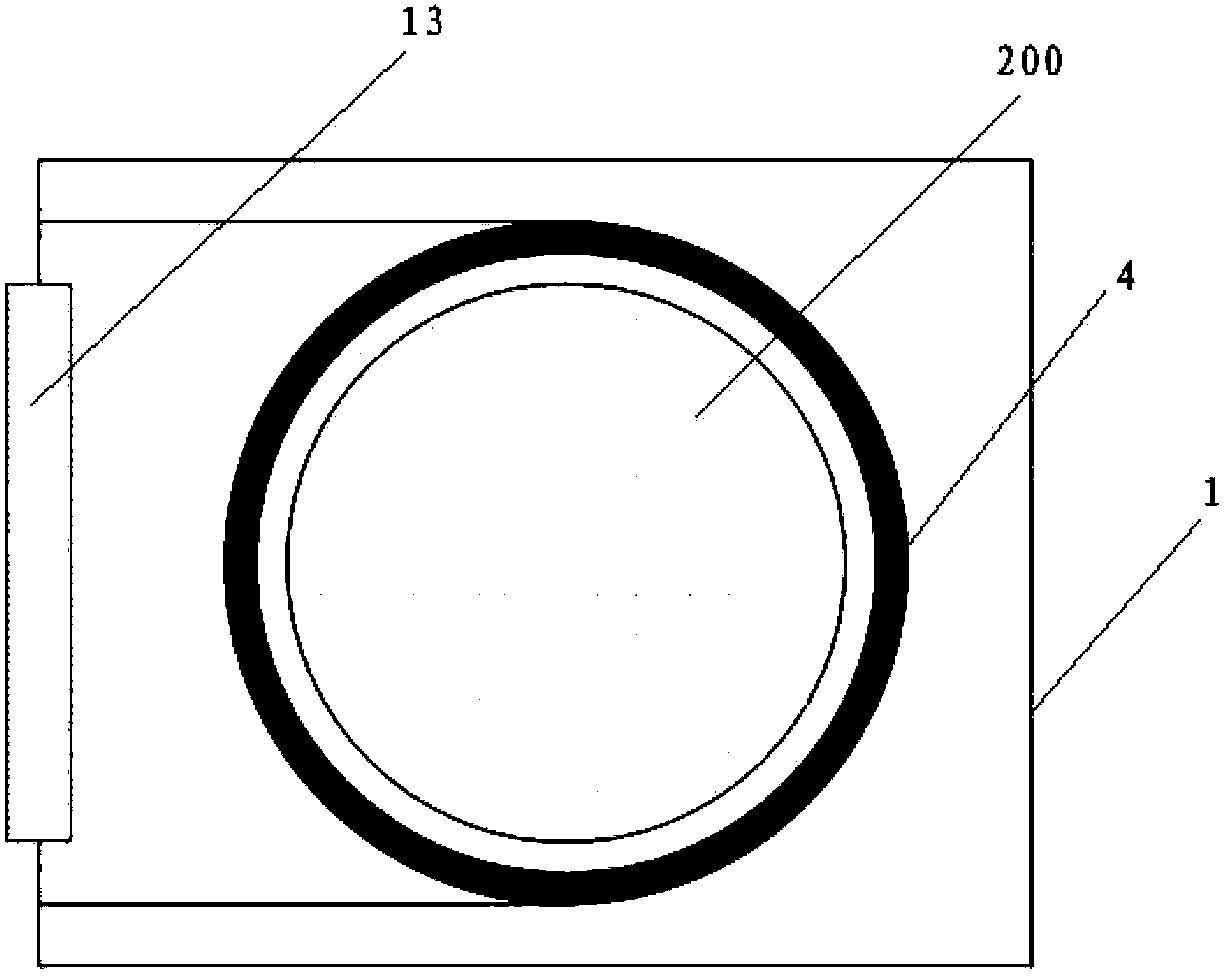

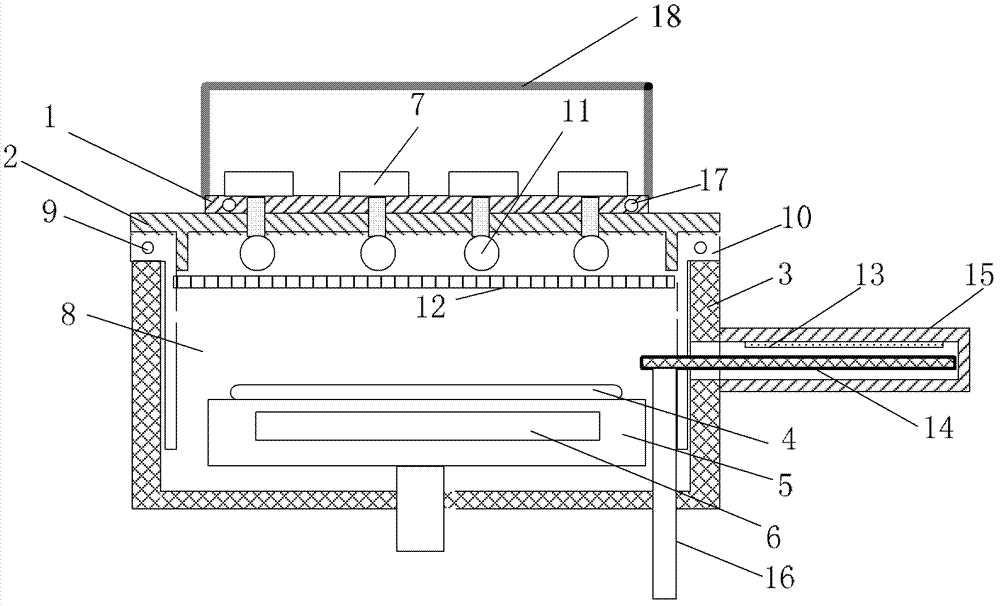

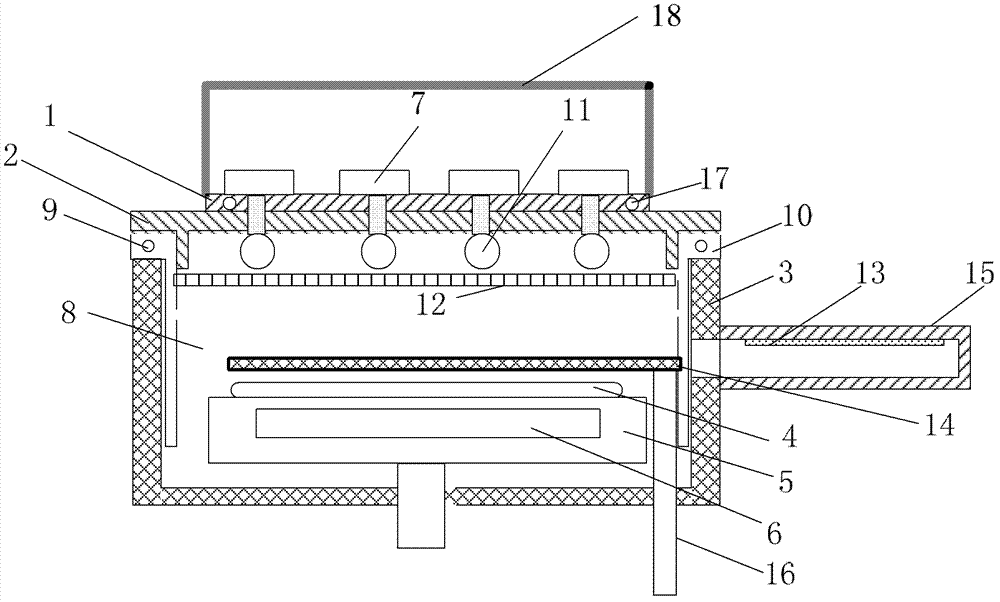

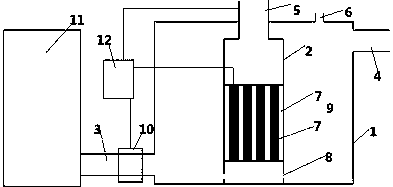

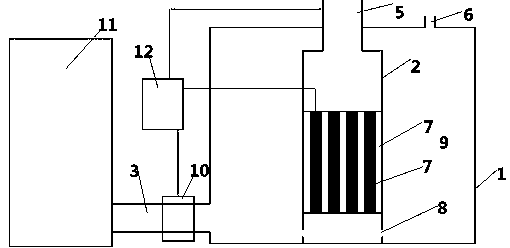

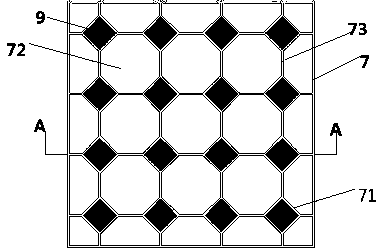

Physical vapor deposition equipment and physical vapor deposition process

ActiveCN103572211AImprove heating efficiencyImprove heating uniformityVacuum evaporation coatingSputtering coatingGas phaseEngineering

The invention discloses a physical vapor deposition device which comprises a reaction chamber, wherein the reaction chamber comprises a medium window arranged in the reaction chamber and used for dividing the reaction chamber into an upper chamber and a lower chamber, a substrate support component in the lower chamber, a heating component arranged on the top wall of the upper chamber and used for heating a to-be-processed substrate, a substrate sending port arranged on the side wall of the lower chamber and used for sending out the processed substrate from the lower chamber or sending the to-be-processed substrate in the lower chamber, and a heating constraint bucket arranged in the lower chamber and can be lifted in the lower chamber through a lifting mechanism. The medium window has light transmission and is used for sealing the lower chamber. The physical vapor deposition equipment disclosed by the invention is capable of greatly improving the uniformity when the substrate is heated and improving the degassing effect of the substrate. The invention further discloses a physical vapor deposition process.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Heating pot capable of increasing heating efficiency

PendingCN107595153ARealize three-dimensional heatingImprove heating uniformityRoasters/grillsHeating effectEngineering

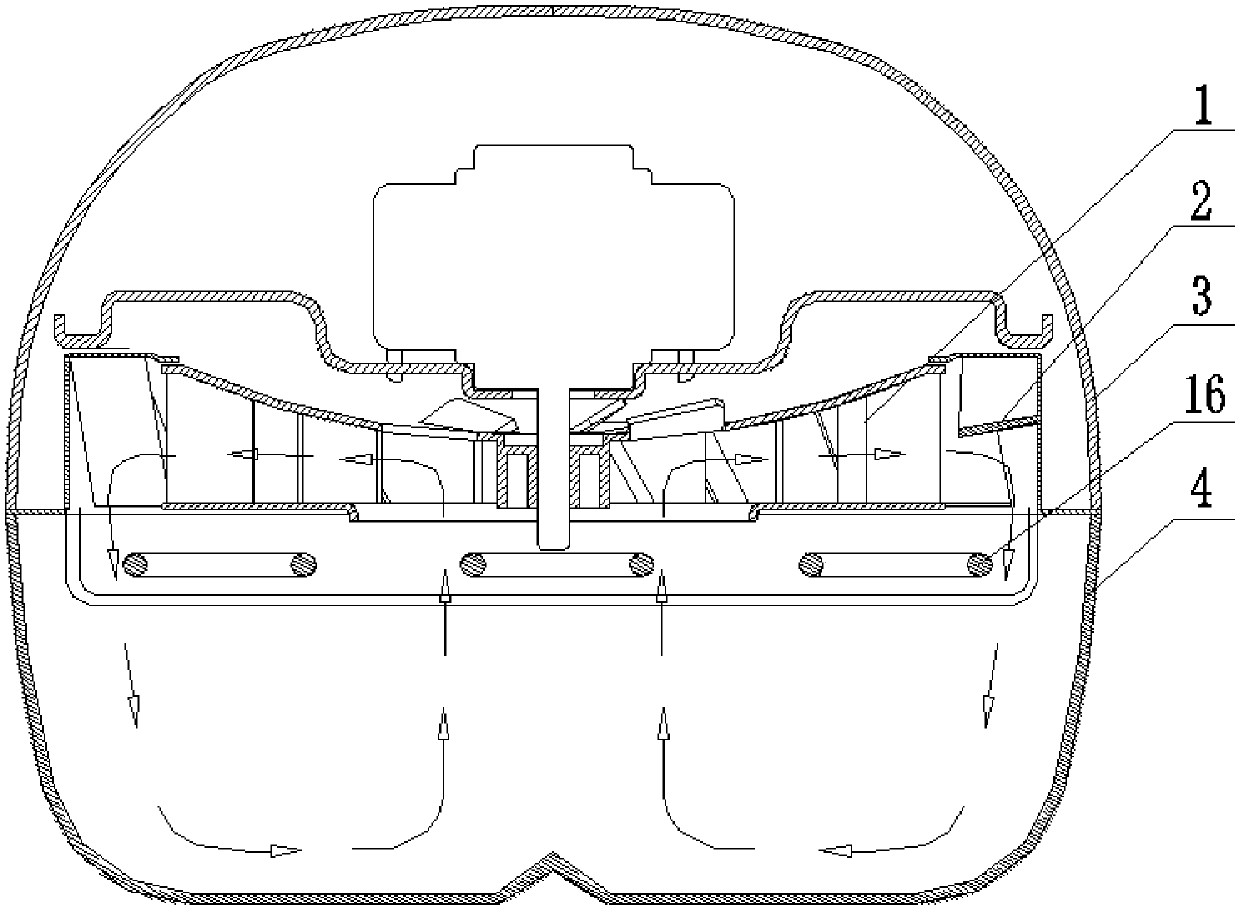

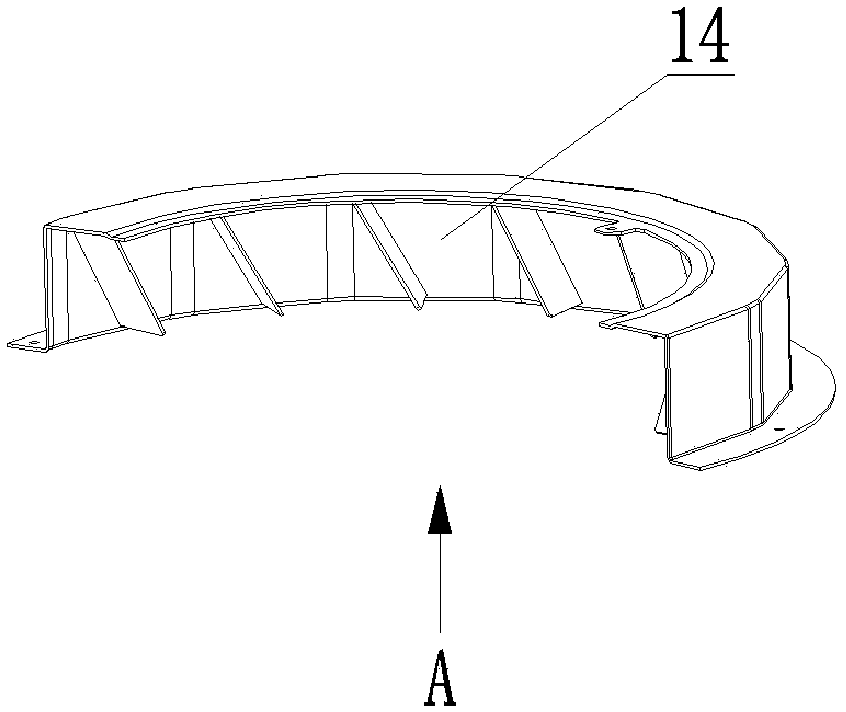

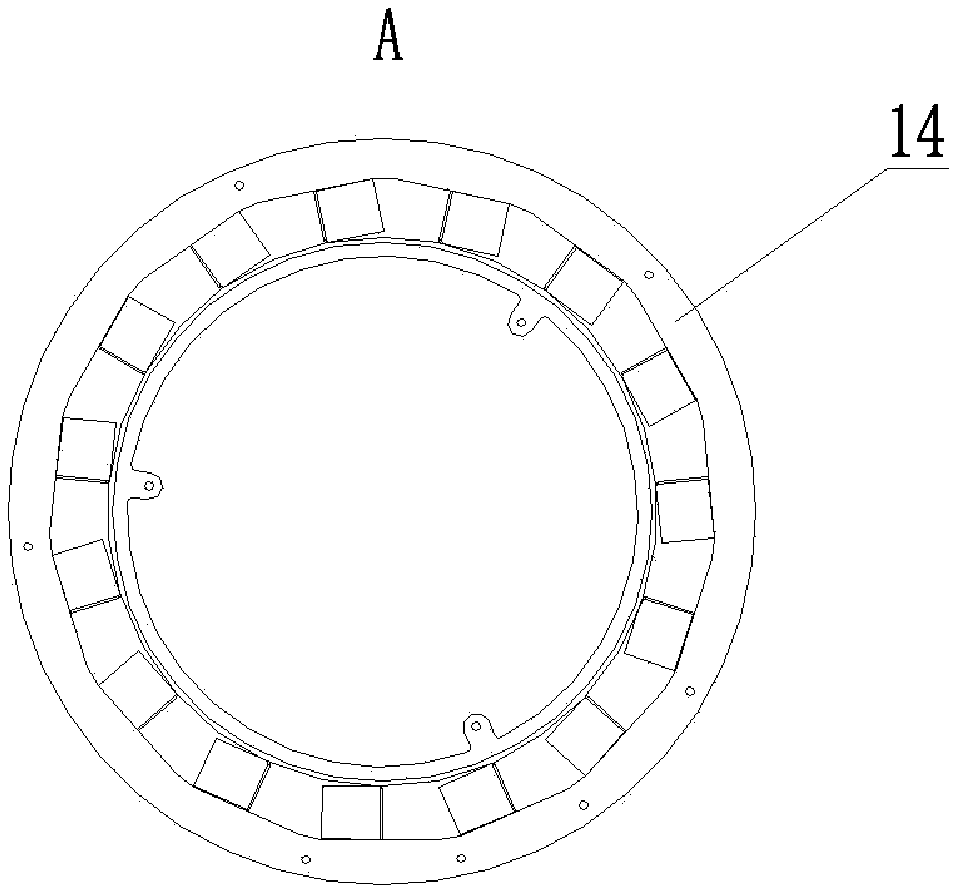

The invention provides a heating pot capable of increasing the heating efficiency. The heating pot includes a pot body and a cover, the cover comprises a heating element, a centrifugal fan and a windguiding piece arranged in the circumferential direction of the centrifugal fan and used for guiding airflow. According to the scheme, since the wind guiding piece is arranged in the circumferential direction of the centrifugal fan or below the centrifugal fan, the heating air can be blown out of the centrifugal fan, and then blown to food in a spiral blowing mode after flowing through the wind guiding piece, and therefore a three-dimensional heating effect on the food can be achieved, and the heating efficiency and the heating uniformity of the food are improved.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

Superheat water vapor in-situ pyrolysis oil-rich coal efficient oil extraction method

The invention relates to a superheat water vapor in-situ pyrolysis oil-rich coal efficient oil extraction method. In the method, the well spacing manner of two horizontal heat injection wells and onehorizontal production well is adopted, and hydrofracture / supercritical carbon dioxide fracture / controllable shock wave fracture technology is adopted, a large-scale grid fractures is formed inside thecoal layer, and blended grout of iron ore and lime is injected in the fractures to improve the thermal conductivity of oil-rich coal and heat uniformity of the oil-rich coal; and low-temperature plasma electrodes are planted in the horizontal sections of the two heat injection wells, and auxiliary pyrolysis to oil-rich coal is carried out through adopting the low-temperature plasma technology. According to the invention, a reliable heat source is provided, the heat conduction efficiency is improved, underground pyrolysis temperature is maintained while increasing the capability of gas bearingand oil gas bearing, and the pyrolysis oil preparation efficiency and light oil proportion of the oil-rich coal are improved.

Owner:XIAN UNIV OF SCI & TECH

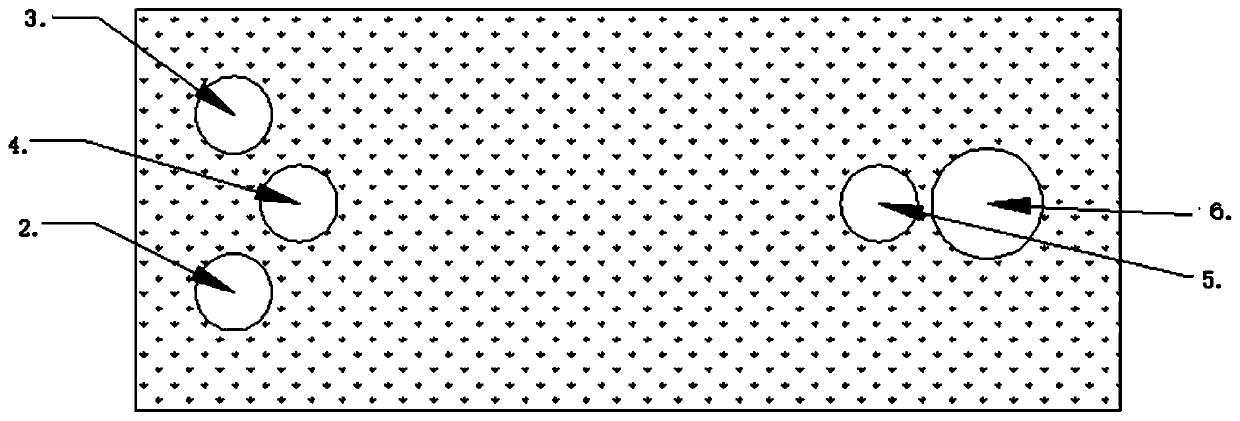

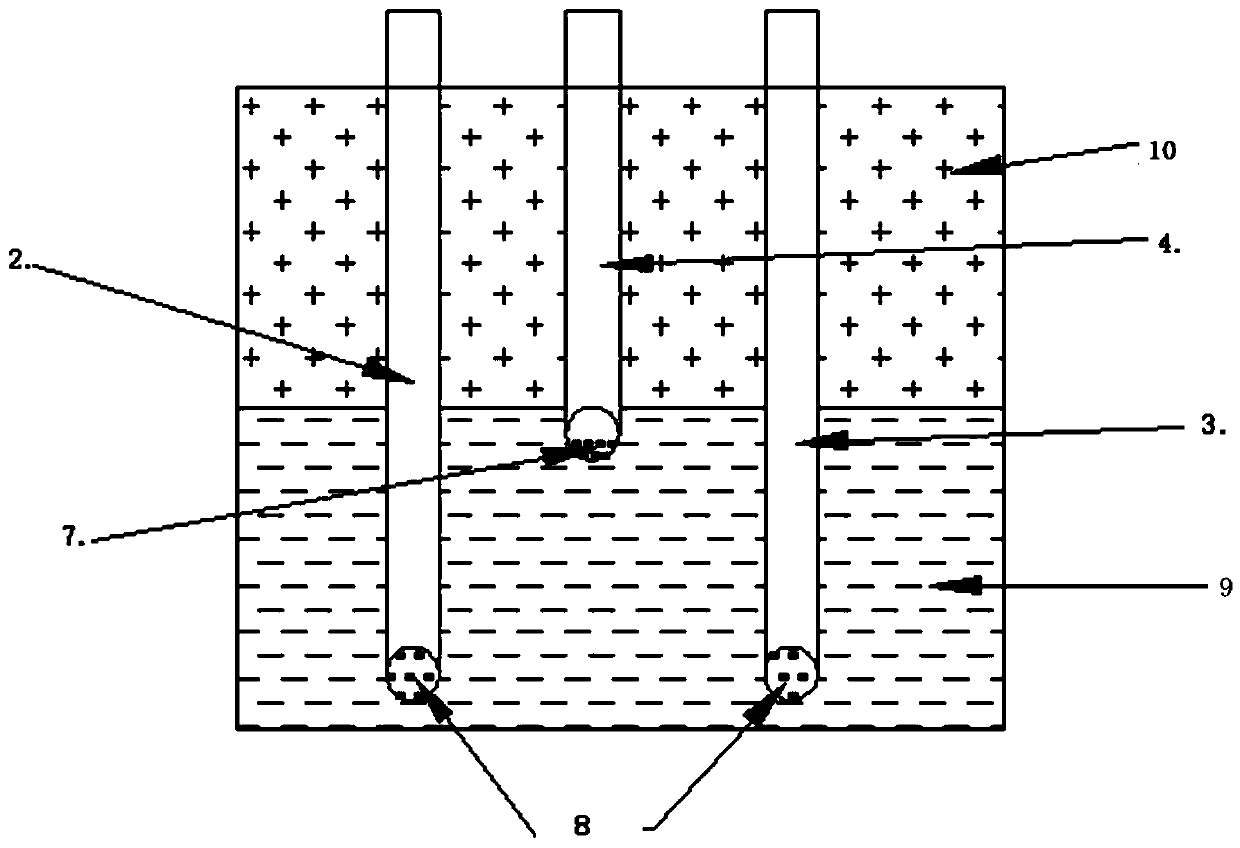

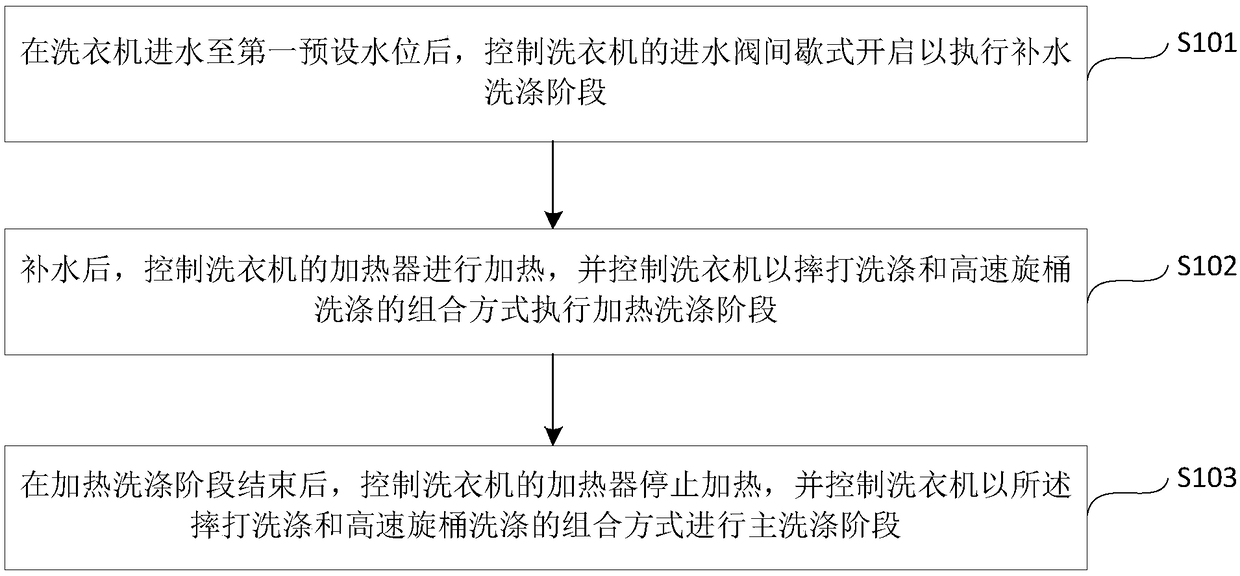

Washing machine control method and device and washing machine

ActiveCN108660682AHigh mechanical strengthImprove heating uniformityControl devices for washing apparatusTextiles and paperMachine controlInlet valve

The invention provides a washing machine control method and device and a washing machine. The method includes controlling a water inlet valve of the washing machine to intermittently open to perform awater supplementing washing stage after water is fed into the washing machine to the first preset water level; after water supplementing, controlling a heater of the washing machine to conduct heating and controlling the washing machine to perform a heating washing stage in a combination of beat washing and high speed barrel spinning washing; after the heating washing stage, controlling the heater of the washing machine to stop heating and controlling the washing machine to perform a main washing stage in the combination of the beat washing and the high speed barrel spinning washing. By meansof combination of the different washing modes, the washing effect of clothes is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Substrate processing equipment and cavity chamber device thereof and substrate heating method

ActiveCN103094156AHeating evenlyImprove heating uniformitySemiconductor/solid-state device manufacturingEngineeringThermal radiation

The invention discloses substrate processing equipment and a cavity chamber device thereof and a substrate heating method. The cavity chamber device comprises a cavity chamber body, a heating part, a bearing platform and an even heating plate, wherein a processing cavity chamber is limited in the cavity chamber body, the heating part is arranged on the top of the interior of the processing cavity chamber, the bearing platform is arranged in the processing cavity chamber and used for bearing a substrate, the upper surface of the bearing platform is relative to the heating part, and the even heating plate can move between a holding position and an even heating position. When the even heating plate is in the even heating position, the even heating plate is arranged between the heating part and the bearing platform, and when the even heating plate is in the holding position, the even heating plate departs between the heating part and the bearing platform. According to the cavity chamber device, thermal homogenization generated by the heating part is transmitted to the substrate through manners, such as a thermal radiation manner and a thermal convection, and therefore, even hearting on the substrate can be achieved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

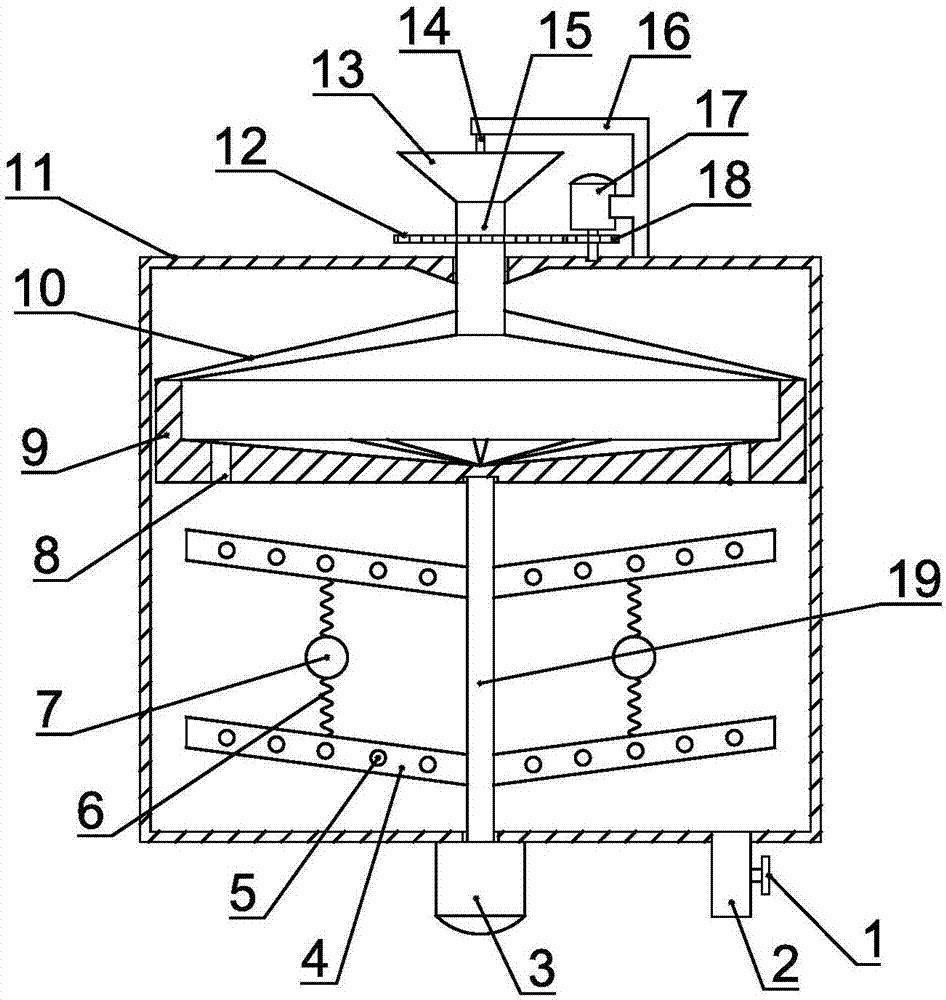

Centrifugal stirring device for artificial butter

InactiveCN107469675AImprove the mixing effectImprove heating uniformityRotary stirring mixersTransportation and packagingRadiation modeEngineering

The invention discloses a centrifugal stirring device for artificial butter. The device includes a tank body, the center of the top of the tank body is provided with a feeding pipe, a driven gear on the feeding pipe is in gear engagement with a driving gear installed on an output shaft of a second driving motor, an electric heating strip is installed on an installation shaft inside the feeding pipe, a centrifugal material disk is arranged on the upper portion of the inner side of the tank body, and an annular baffle is arranged on an outer ring on the top of the centrifugal material disk; a plurality of flow diversion trenches are formed in the center of the top portion of the centrifugal material disk in a radiation mode, multiple discharging holes are formed in the outer ring of the centrifugal material disk, the feeding pipe is fixedly connected with the annular baffle by a plurality of oblique supporting rods, an output shaft of a first driving motor on the bottom of the tank body is connected with the stirring shaft arranged in the tank body, and a stirring mechanism is arranged on the stirring shaft inside the tank body. The centrifugal stirring device for the artificial butter is novel in structure and reasonable in design, the flow directions of raw materials are more diversified during stirring, and the processing effect and efficiency are improved.

Owner:张册

Steam generator for intelligently controlling heating power

InactiveCN109780520AAvoid lostProvide quicklySteam generation heating methodsBoiler controlEngineeringHeating power

The invention provides a steam generator. The steam generator comprises a box, and an inner tube, the inner tube comprises an outer tube and a core arranged in the outer tube, the steam generator further comprises a steam utilization device, the steam generated by heating in the box enters the steam utilization device through a steam outlet, and recycled to a water tank after the thorough heat exchange in the steam utilization device, and the water enters the box from the water tank through a water pump. According to the steam generator, the fact that the outlet temperature meets the requirement is ensured by controlling the heating power, and the fact that the loss of the heat is caused due to the too high outlet temperature, and the heat does not meet the actual requirements due to the too low outlet temperature are avoided.

Owner:ZHONGBEI UNIV

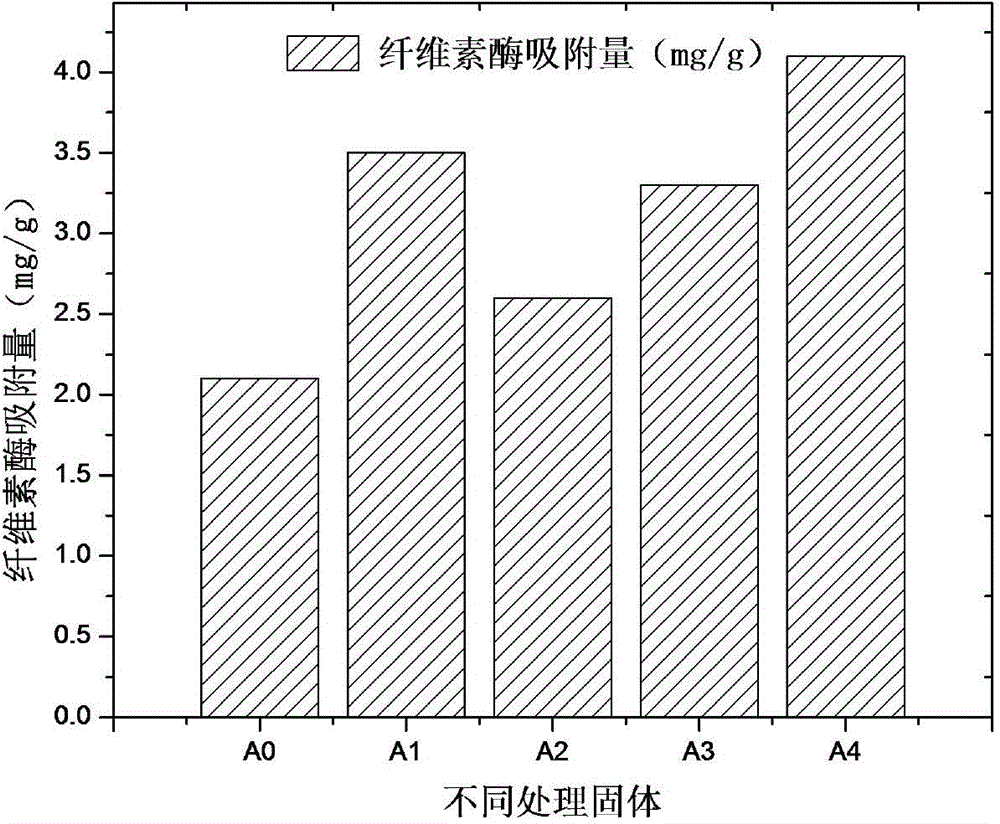

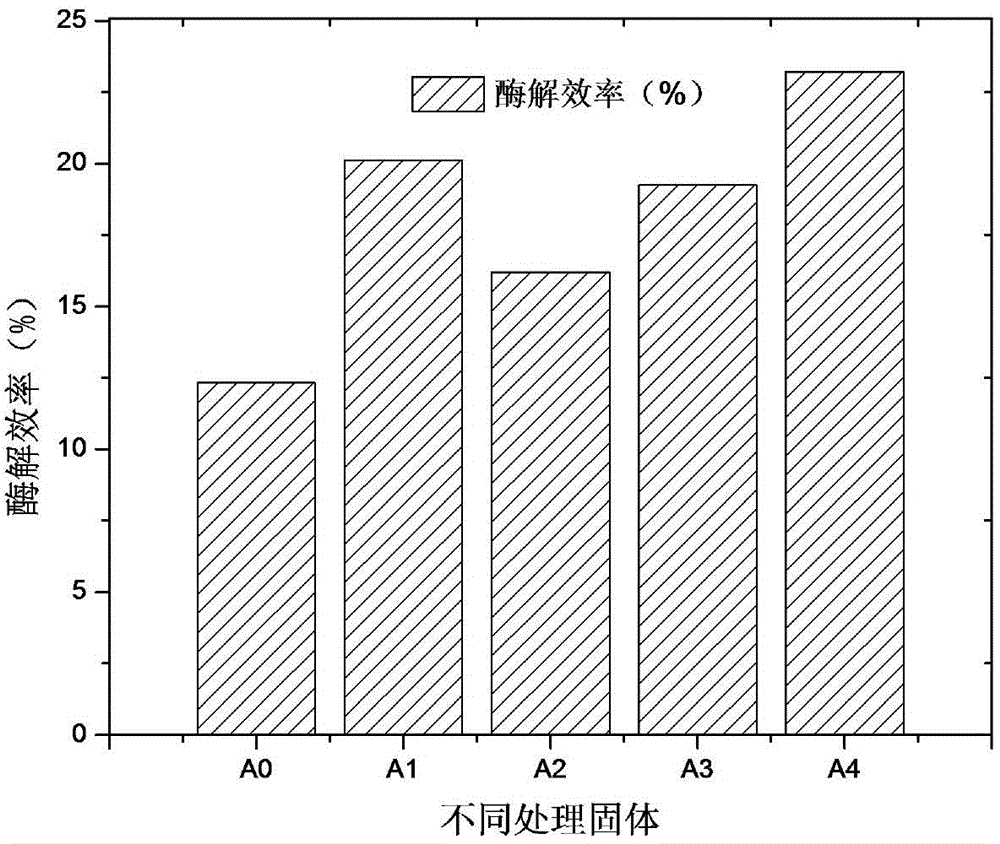

Pretreatment method of lignocellulose by using microwave-assisted alkaline sodium sulfite

The invention discloses a pretreatment method of lignocellulose by using microwave-assisted alkaline sodium sulfite, belonging to the technical fields of biomass resource utilization and agricultural waste comprehensive utilization. The method comprises the following steps: by using lignocellulose as a raw material, pulverizing, screening, and pretreating by using microwave-assisted alkaline sodium sulfite to lower the alkali consumption and enhance the pretreatment effect of the alkaline sodium sulfite; and carrying out solid-liquid separation, flushing the solid residue with an alkaline sodium sulfite solution, and washing with water to obtain the lignocellulose pretreatment product with favorable enzymolysis effect. The method can better remove lignin and reduce the inhibition effect of lignin on cellulose degradation, thereby effectively enhancing the conversion efficiency from lignocellulose to monosaccharide. The method reduces the chemical reagent consumption, is beneficial to environmental protection, and lowers the production cost, thereby generating higher economic value.

Owner:JIANGNAN UNIV

Heating wire assembly, atomizer and electronic cigarette

InactiveCN105054308AIncrease the amount of atomizationMeet the needs of large smoke volumeTobacco devicesElectronic cigaretteEngineering

The invention discloses a heating wire assembly used in an electronic cigarette atomizer. The heating wire assembly comprises an oil guide body and a heating wire. The heating wire is nested in the oil guide body in a winding and circuitous mode. The two tail ends of the heating wire are located outside the oil guide body. Due to the fact that the heating wire is nested in the oil guide body in the winding and circuitous mode, the heating wire can make full contact with the oil guide body, the heating uniformity is improved, the atomization amount of tobacco tar is increased, and the demand for the large smoke volume of an electronic cigarette of part of consumers can be met. The invention further discloses an atomizer containing an atomization core and the electronic cigarette.

Owner:SHENZHEN HANGSEN STAR TECH +1

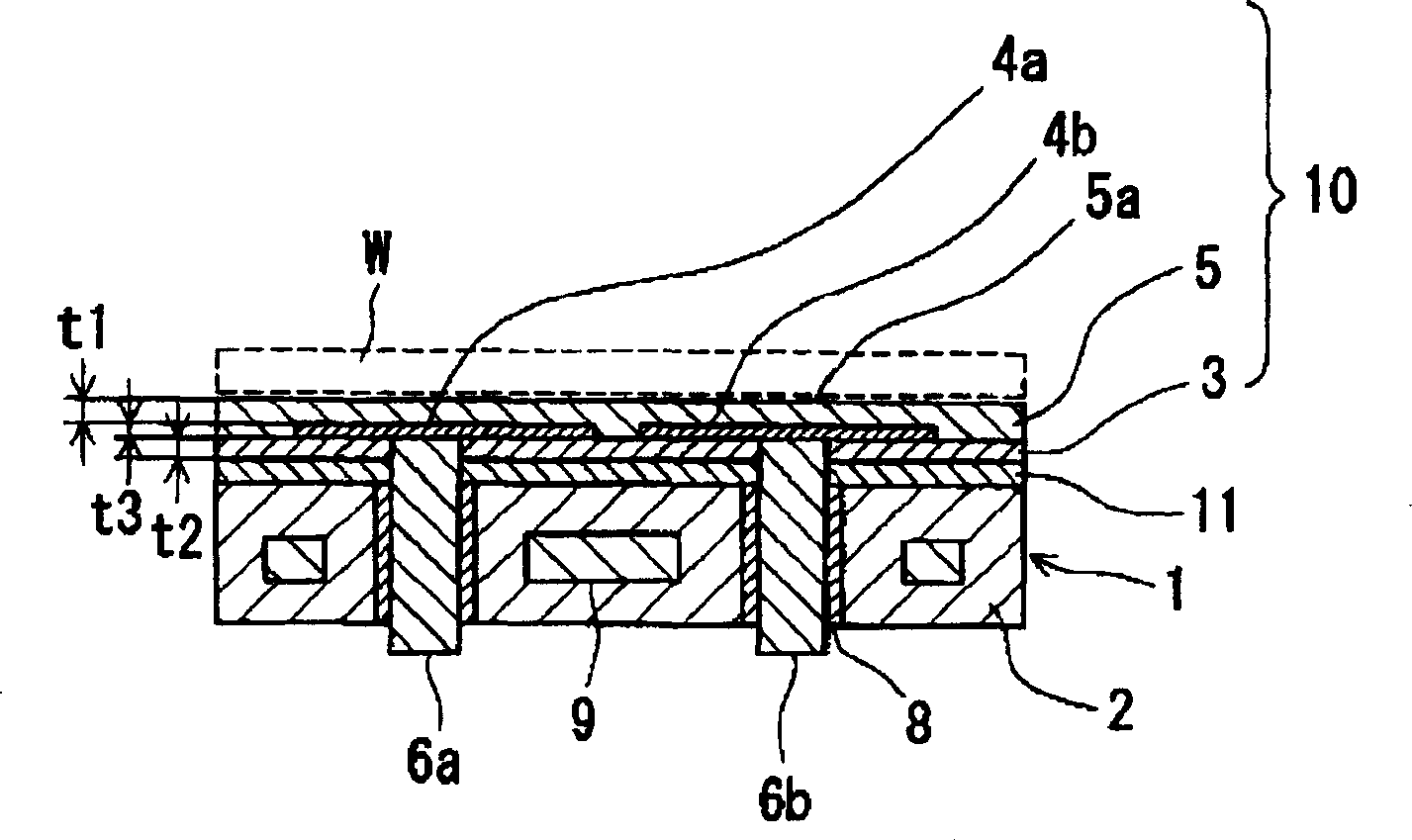

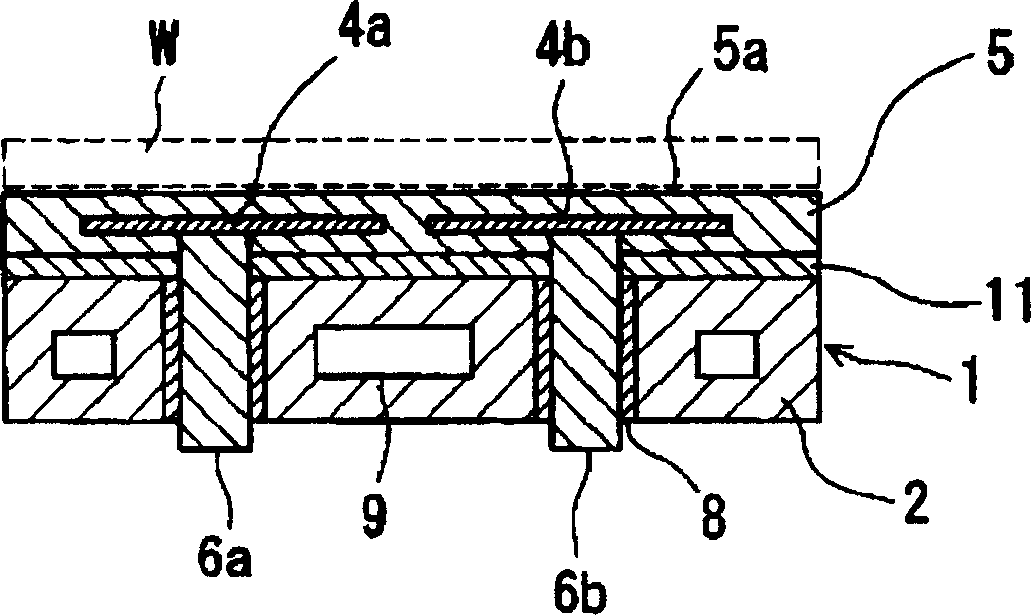

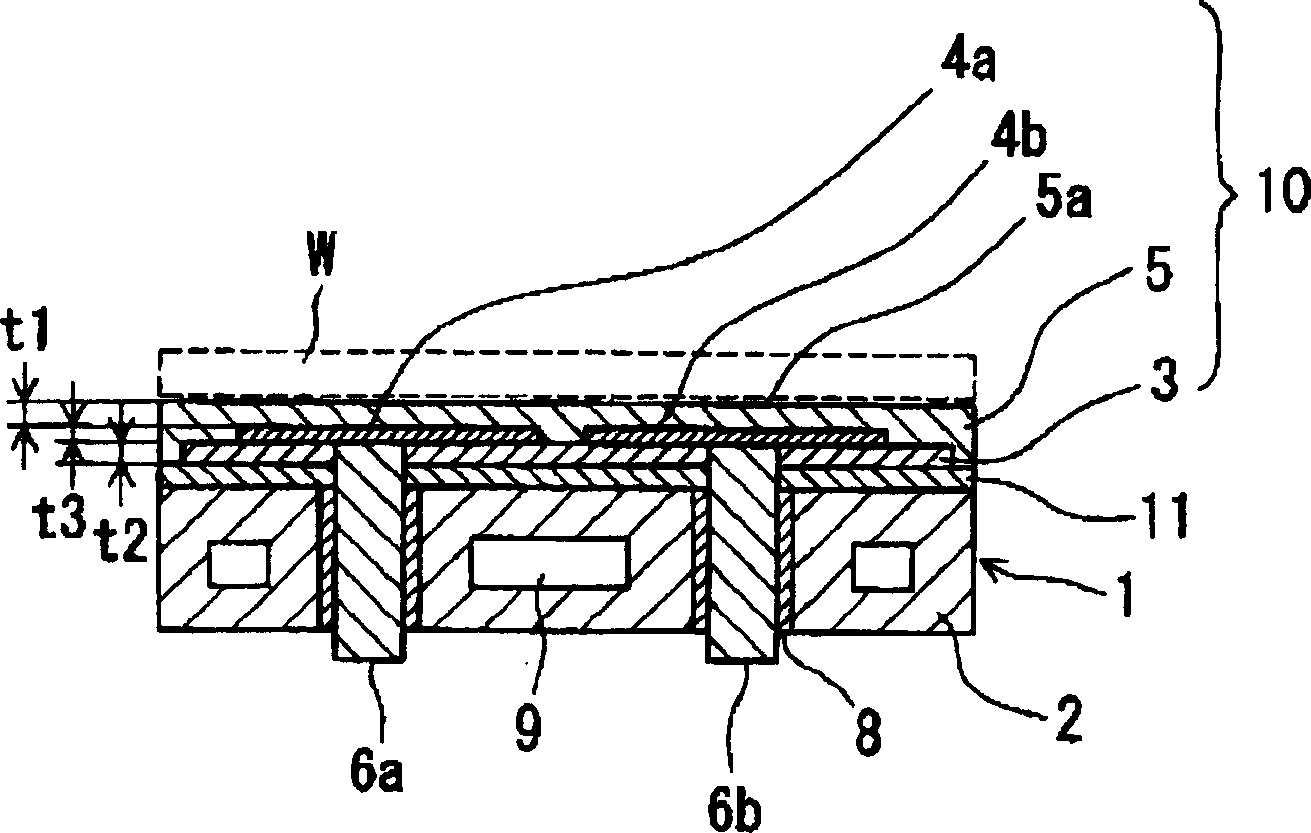

Wafer supporting member

ActiveCN1674247AImprove heating uniformityReduce temperature differencePassenger spaceSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The present wafer supporting member includes a supporting part composed of a planar insulating sheet having a pair of main surfaces, one serving as a mounting surface for mounting a wafer and the other having an adsorption electrode; a resin layer part provided below the adsorption part and a conductive base part provided below the resin layer part wherein the adsorption part has a thickness in a range of 0.02 to 10.5 mm, preferably 0.02 to 2.0 mm.

Owner:KYOCERA CORP

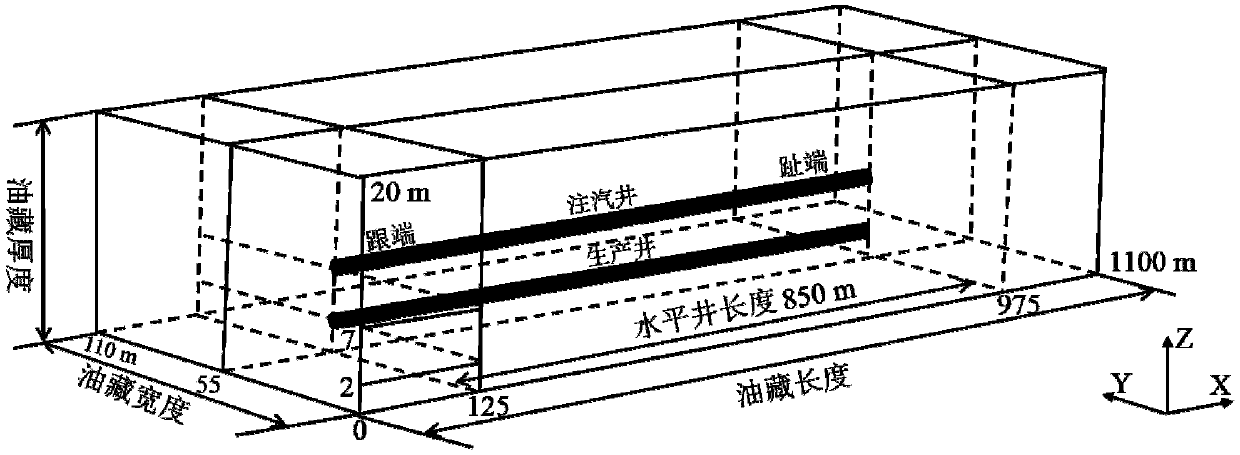

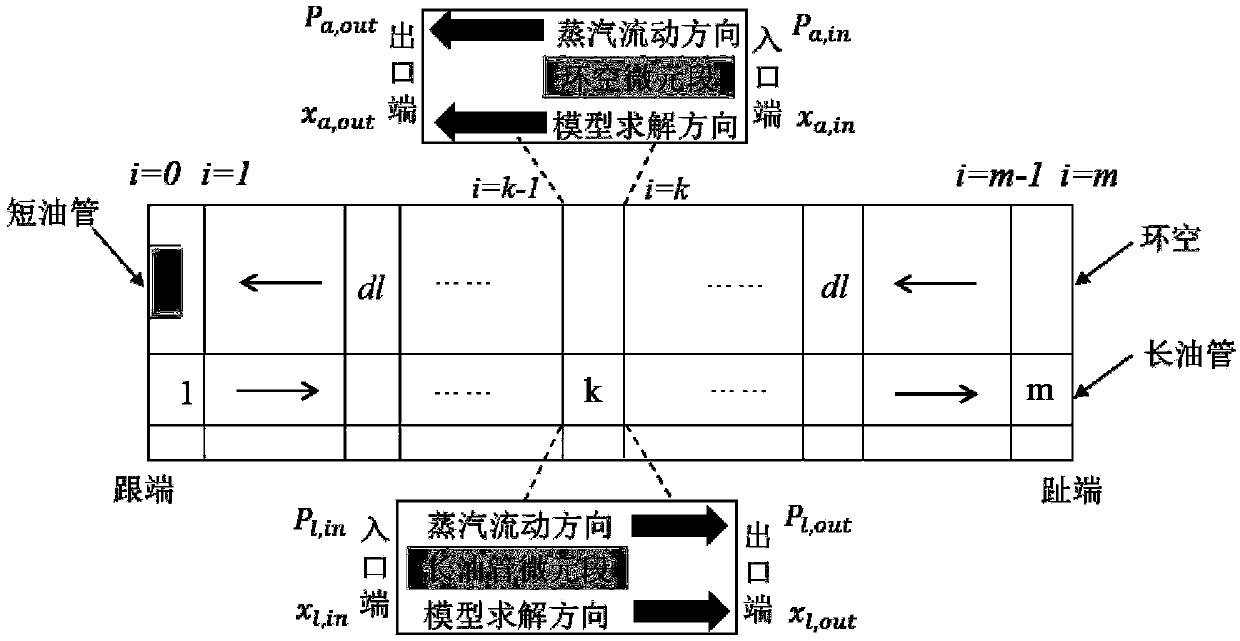

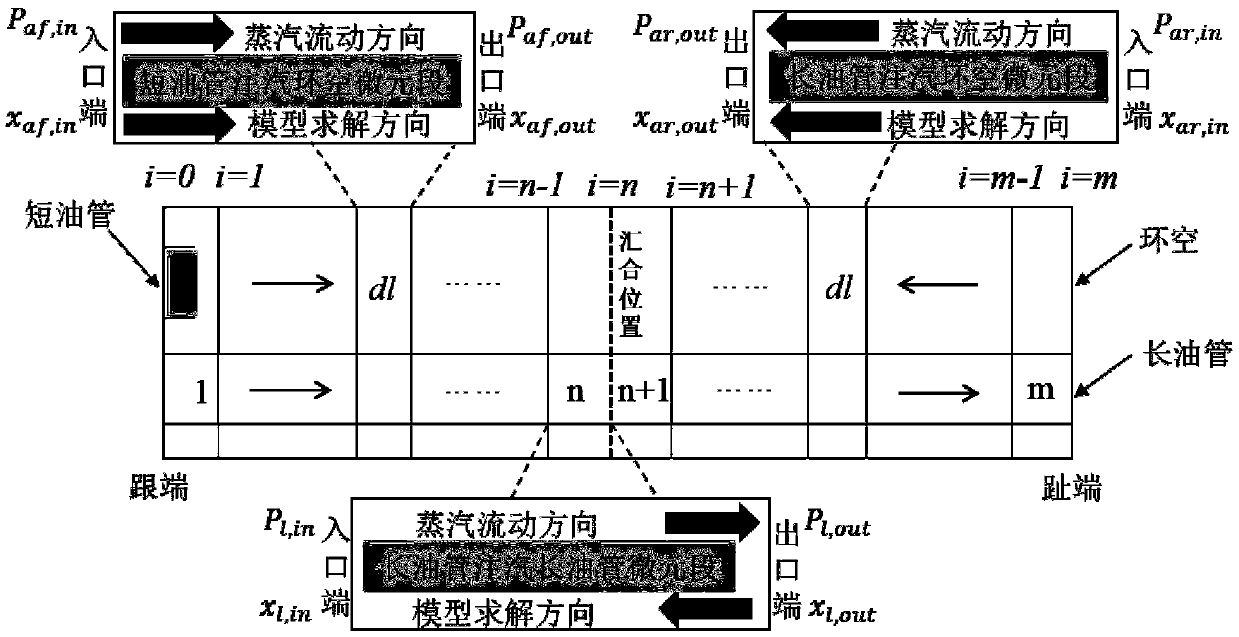

A double-pipe SAGD long horizontal well uniform steam injection numerical simulation method considering coupling of an oil reservoir and a shaft

ActiveCN109598099AImprove the uniformity of heatingImprove heating uniformityFluid removalDesign optimisation/simulationDistribution ruleFinite difference method

The invention relates to a double-pipe SAGD long horizontal well uniform steam injection numerical simulation method considering coupling of an oil reservoir and a shaft, and the method comprises thesteps: establishing a reservoir internal seepage and heat transfer mathematical model in a three-dimensional three-phase heavy oil reservoir double-pipe steam injection development process from the aspects of mass conservation and energy conservation; And establishing a flowing and heat transfer mathematical model in the wellbore in the steam injection process according to the variable-mass bidirectional convergence flow characteristic of the fluid in the wellbore and the structural characteristics of the slotted screen pipe column. The method is based on pressure and temperature continuity principles. the wellbore model and the reservoir model are coupled; the model is solved by adopting a fully implicit finite difference method and an iteration technology; By means of the model, the distribution rule of parameters such as pressure, temperature, steam inflow and wellbore on-way steam pressure, temperature and dryness at any moment in the simultaneous steam injection process of the double-pipe SAGD long pipe and the double-pipe SAGD short pipe can be predicted, proper steam injection parameters are selected, the stratum heating uniformity degree is improved, and a reasonable development scheme is made.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Low-temperature smoke formation body

ActiveCN105815815AEasy to storeDoes not affect the feeling of smokingTobacco treatmentTobacco devicesHeat conductingMass ratio

The invention discloses a low-temperature smoke formation body. The low-temperature smoke formation body comprises a carrier and tobacco extract adsorbed on the carrier, wherein the carrier is composed of a plant adsorption material, a heat-conducting component and an adhesion agent; and the mass ratio of the plant adsorption material to the tobacco extract in the low-temperature smoke formation body is no more than (1:1). The low-temperature smoke formation body disclosed by the invention is molded according to the size of a smoking set heating cavity, subjected to tobacco tar adsorption and sealed and packaged, so that the low-temperature smoke formation body can be stored for a long period and a smoking feeling is not influenced; and meanwhile, the low-temperature smoke formation body is easy to add and clean. The low-temperature smoke formation body disclosed by the invention has a loose structure, is internally provided with a plurality of pores and is easy to smoke; meanwhile, the heating area and heating uniformity of a smoking material can be improved, and a very good satisfaction feeling can be given to consumers; and meanwhile, the low-temperature smoke formation body is made from cheap raw materials, is safe and environmentally friendly, and can be taken as disposable consumption goods.

Owner:CHINA TOBACCO HUNAN INDAL CORP

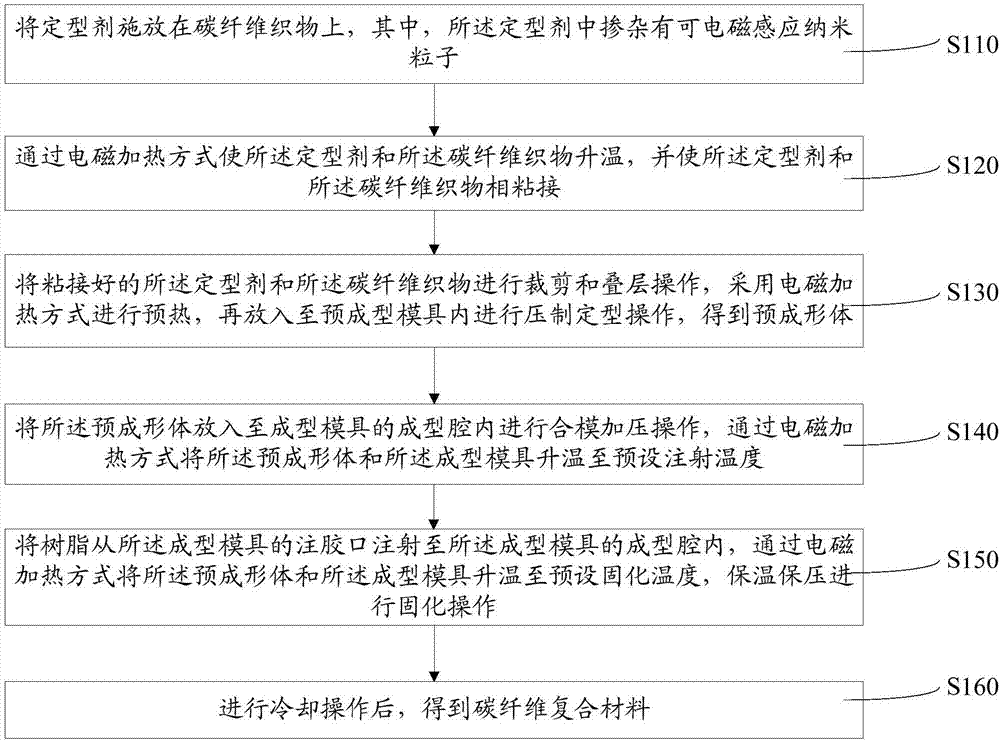

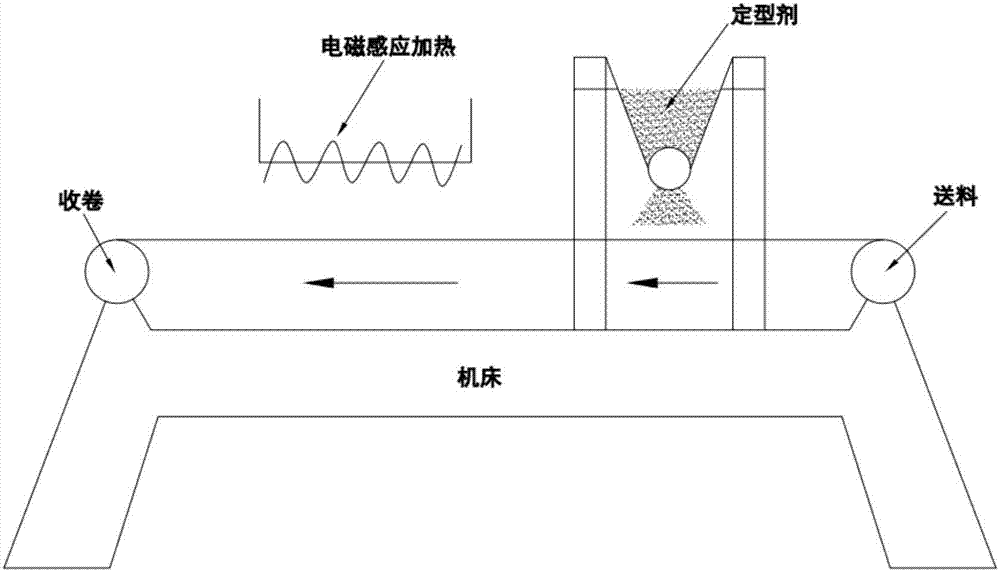

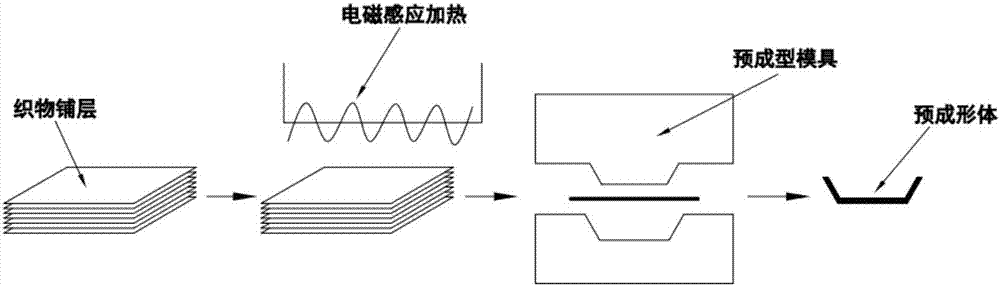

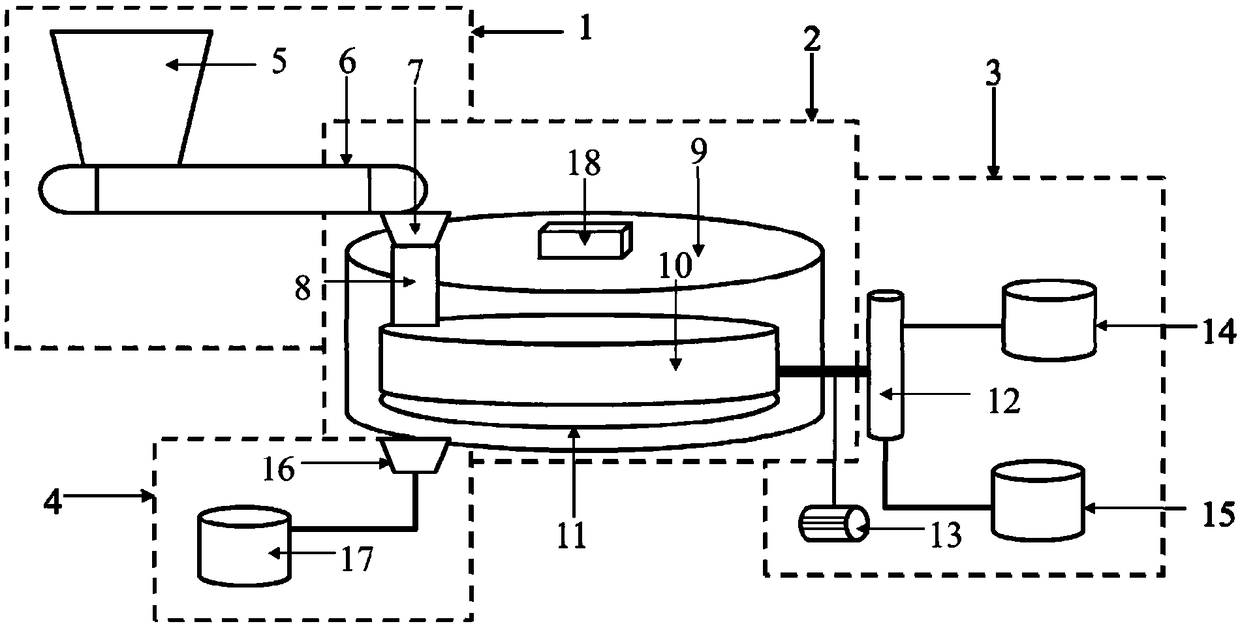

Manufacturing method for carbon fiber composite material

The invention discloses a manufacturing method for a carbon fiber composite material. The manufacturing method comprises the steps that a sizing agent is applied on carbon fiber fabrics, wherein electromagnetic-induction nano particles are doped in the sizing agent; the sizing agent and the carbon fiber fabrics are heated in an electromagnetic heating mode and are enabled to adhere to each other; the bonded sizing agent and carbon fiber fabrics are subjected to cutting and laminating operation, are preheated by adopting the electromagnetic heating mode and then are put into a pre-forming mold to be subjected to pressing shaping operation so as to obtain a pre-formed body; the pre-formed body is placed into a forming mold to be subjected to mold closing pressurization operation, and the pre-formed body and the forming mold are heated to a preset injection temperature in the electromagnetic heating mode; resin is injected into the forming mold, and the pre-formed body and the forming mold are heated to a preset curing temperature in the electromagnetic heating mode; and after curing molding cooling, demoulding is carried out to obtain the carbon fiber composite material. The method has the advantages that the rate of temperature increase by heating is high, the product manufacturing efficiency is high, and the energy consumption and the manufacturing cost are low.

Owner:惠州市海龙新材料科技有限公司

Oil-based drill cutting continuous microwave pyrolysis device and process

ActiveCN108203217APrevent leakageAvoid contactSludge treatment by pyrolysisByproduct vaporizationThermodynamicsMicrowave pyrolysis

The invention discloses an oil-based drill cutting continuous microwave pyrolysis device. The device comprises a feeding device, a microwave reaction device, an oil and gas cooling recovery device anda pyrolysis residue cooling device. The feeding device comprises a feeding bin and a belt conveyor. The microwave reaction device comprises a microwave reaction chamber, a waveguide feed port is arranged at the top end of the microwave reaction chamber, and a quartz chamber is arranged inside the microwave reaction chamber. The quartz chamber is composed of a fixed ring wall and a rotating tray,and the top end of the quartz chamber is open. A feeding buffer bin is disposed below the end of the belt conveyor and communicated with the quartz chamber through a chute. A discharging port is arranged on the fixed ring wall at the position above the corresponding discharge buffer bin. The discharging port is provided with a scraper plate, and the scraper plate is connected to the discharge buffer bin through a chute. The device can achieve continuous uniform feeding and continuous discharging without blockage in the closed environment, prevents leakage of microwaves, and prolongs service life.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com