A double-pipe SAGD long horizontal well uniform steam injection numerical simulation method considering coupling of an oil reservoir and a shaft

A technology for long horizontal wells and numerical simulation, applied in wellbore/well components, earthwork drilling, electrical digital data processing, etc., can solve the problems of unusable, predictable, unusable simulation calculations, etc., and achieve the goal of improving the uniformity of heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

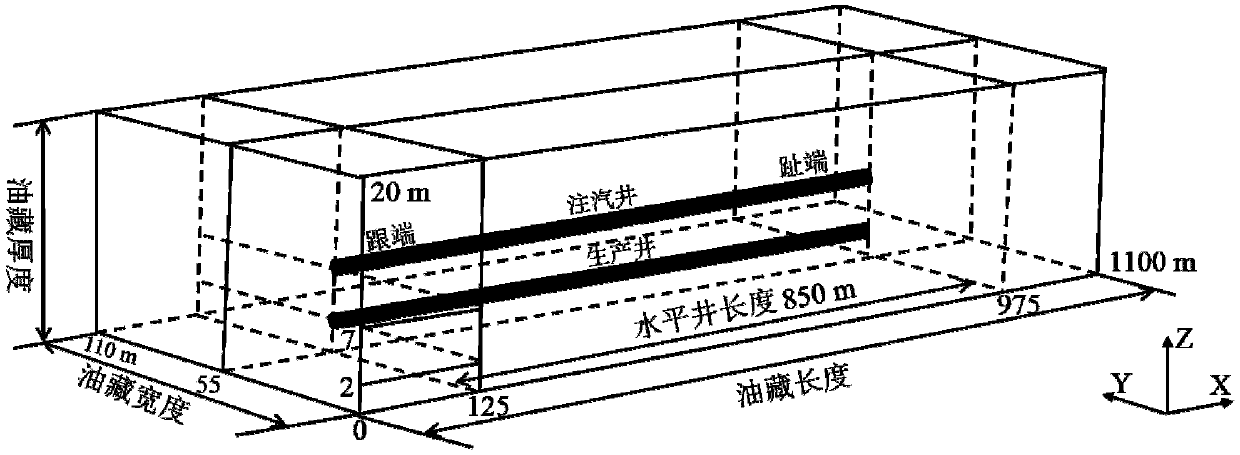

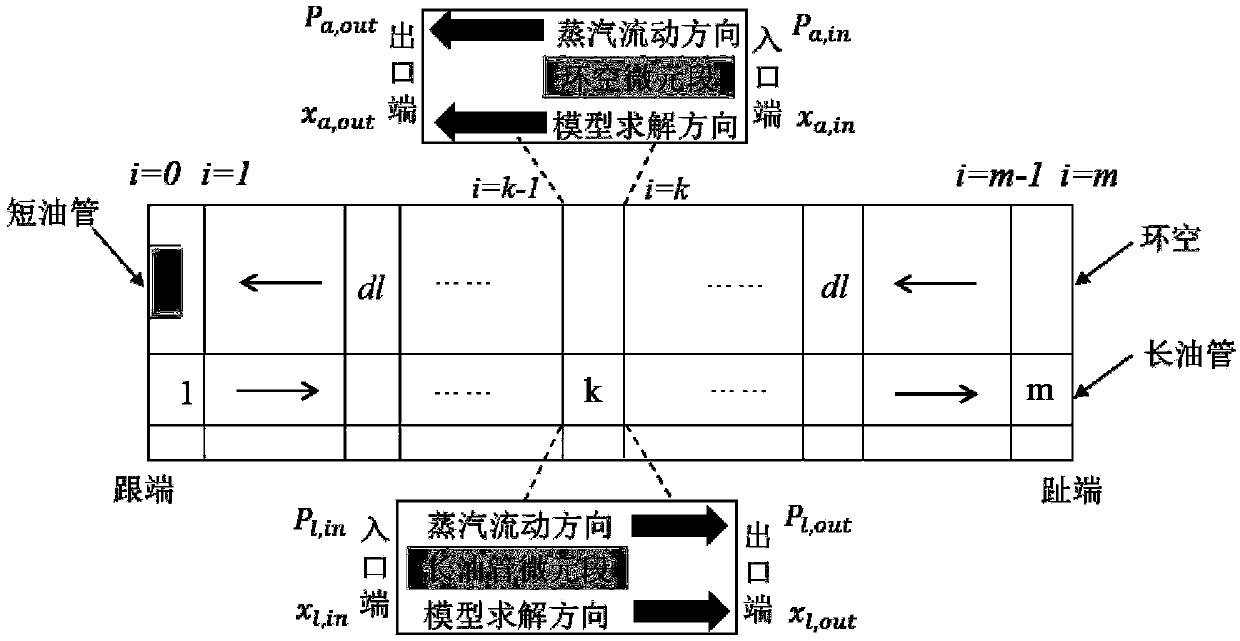

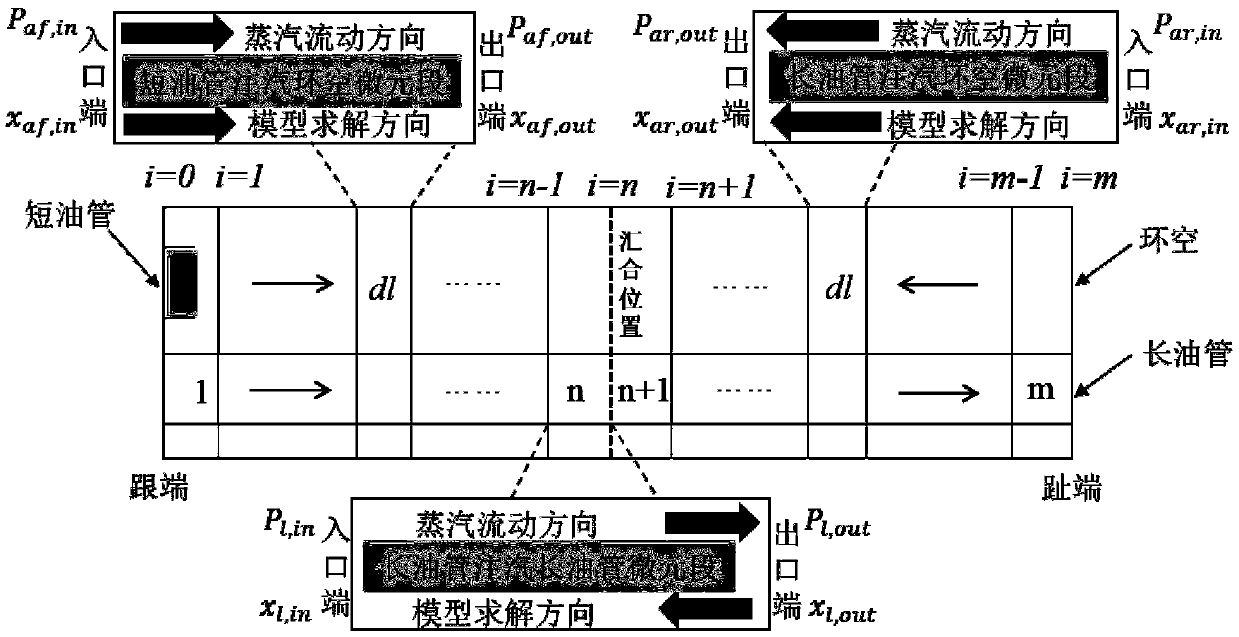

Embodiment 1

[0146] A numerical simulation method for uniform steam injection in double-tube SAGD long horizontal wells considering the coupling of reservoir and wellbore, such as Figure 8 As shown, the double-tube SAGD long horizontal well pair includes a steam injection well and a production well. Both the steam injection well and the production well are mainly composed of long tubing, short tubing and slotted screen. The long tubing is run into the toe of the horizontal well. The short tubing is run into the heel of the horizontal well, and the reservoir conditions before the injection-production well starts production are the initial formation conditions. The toe enters the annulus of the horizontal well, and flows from the annulus toe to the heel. The length of the horizontal section of the horizontal well is 460m, and 177.8mm slotted screen is used for completion. Absolute roughness 0.00005m, thermal conductivity 0.8W / (m K), oil layer thermal conductivity 1.73W / (m K), oil layer the...

Embodiment 2

[0253] As described in Example 1, a double-tube SAGD long horizontal well uniform steam injection numerical simulation method considering the coupling of the reservoir and the wellbore, the difference is that the buried depth of the reservoir is 180m, the thickness of the oil layer is 20m, the porosity is 0.33, and the lateral permeability The vertical permeability is 2700mD, the vertical permeability is 1890mD, the original formation pressure is 0.22MPa, the original formation temperature is 10℃, the oil saturation is 0.75, the length of the horizontal section of the horizontal well is 800m, the inner diameter of the screen is 209.1mm, the outer diameter is 219.1mm, 44.85W / (m·K); the inner diameter of the short tubing is 77.9mm, the outer diameter is 88.9mm, the absolute roughness is 0.00005m, the thermal conductivity is 0.8W / (m·K); the thermal conductivity of the oil layer is 5.2W / (m·K).

[0254] In Example 2, the double-pipe SAGD conventional steam injection model is used to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com