Mesoporous silicon oxide modified polyurethane elastomer and production device thereof

A technology of polyurethane elastomer and mesoporous silica, which is applied in the chemical industry, climate sustainability, chemical instruments and methods, etc., can solve the problems of low heat transfer efficiency, improve heating efficiency, improve efficiency, and facilitate and quick adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

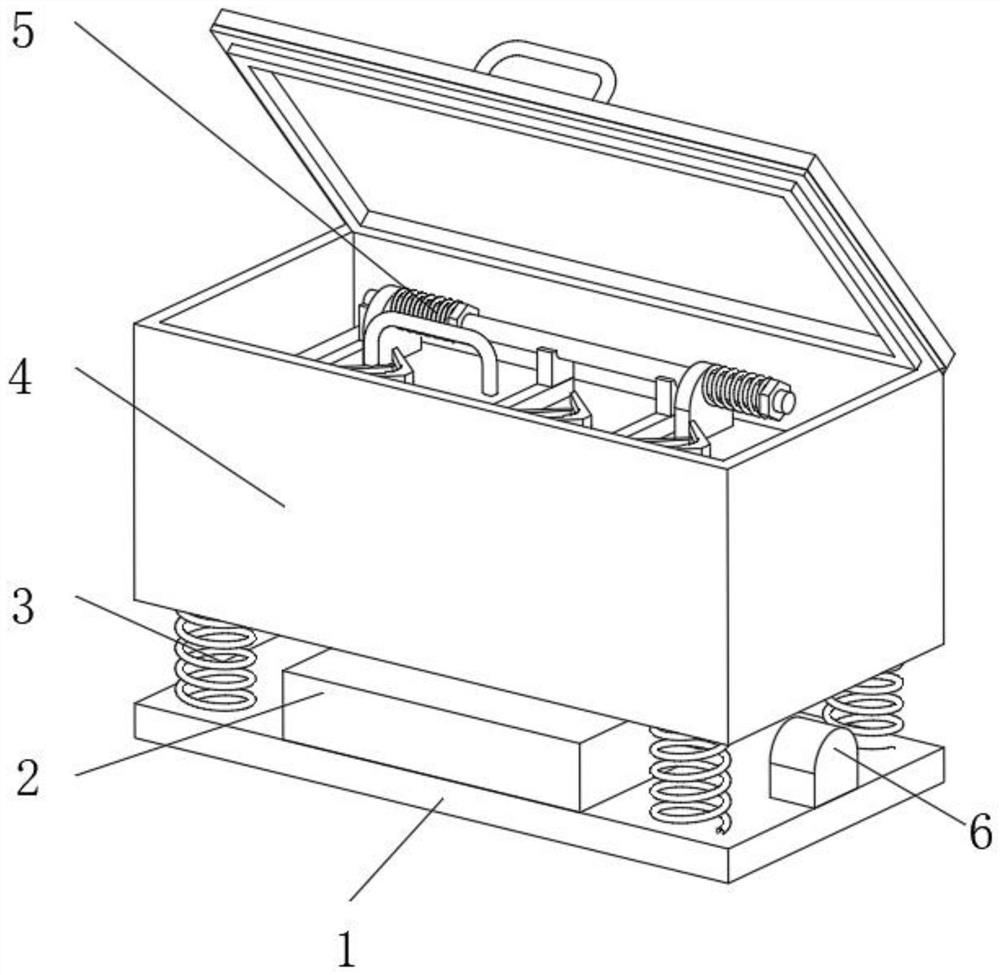

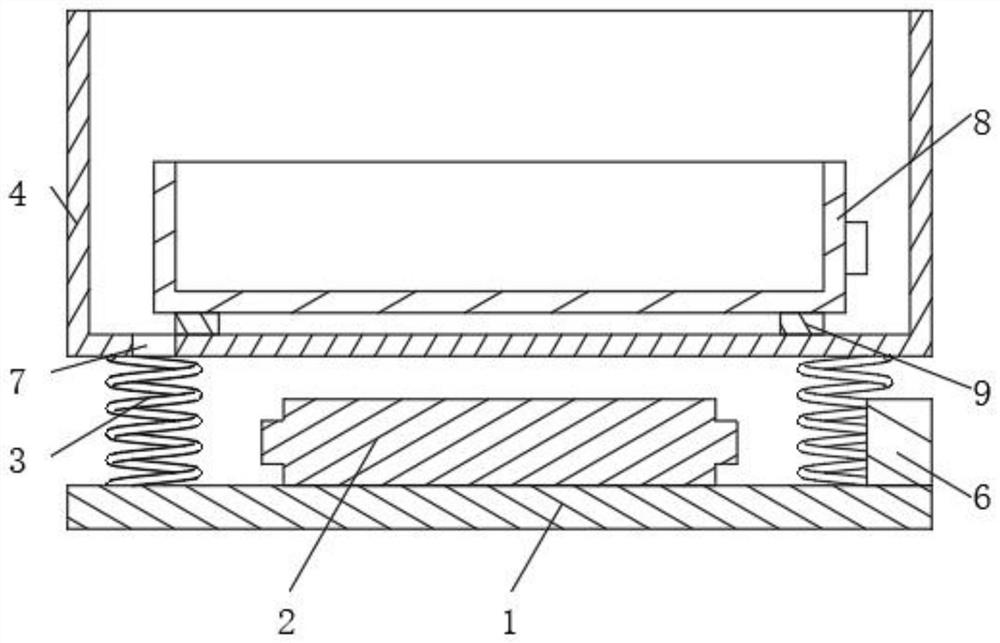

[0033] A production device for mesoporous silica modified polyurethane elastomer, such as figure 1 , 2 As shown, including a base 1, the top four-corner outer wall of the base 1 is welded with a connecting spring 3, the top outer wall of the connecting spring 3 is welded with an overflow tank 4, and the bottom inner wall of the overflow tank 4 is fixedly connected with a water bath tank through a leg 9 8. The top outer wall of the base 1 is fixed with an electric heating box 2 by bolts, the top outer wall of the base 1 is fixed with a circulation pump 6 by bolts, the inner wall of the overflow tank 4 is provided with a return hole 7, and the water bath box 8 The maximum height is lower than the maximum height of the overflow box 4, the electric heating box 2, the circulation pump 6, and the water bath box 8 are sequentially connected through water pipes, and the return hole 7 is connected with the water inlet of the electric heating box 2 through water pipes. One side outer w...

Embodiment 2

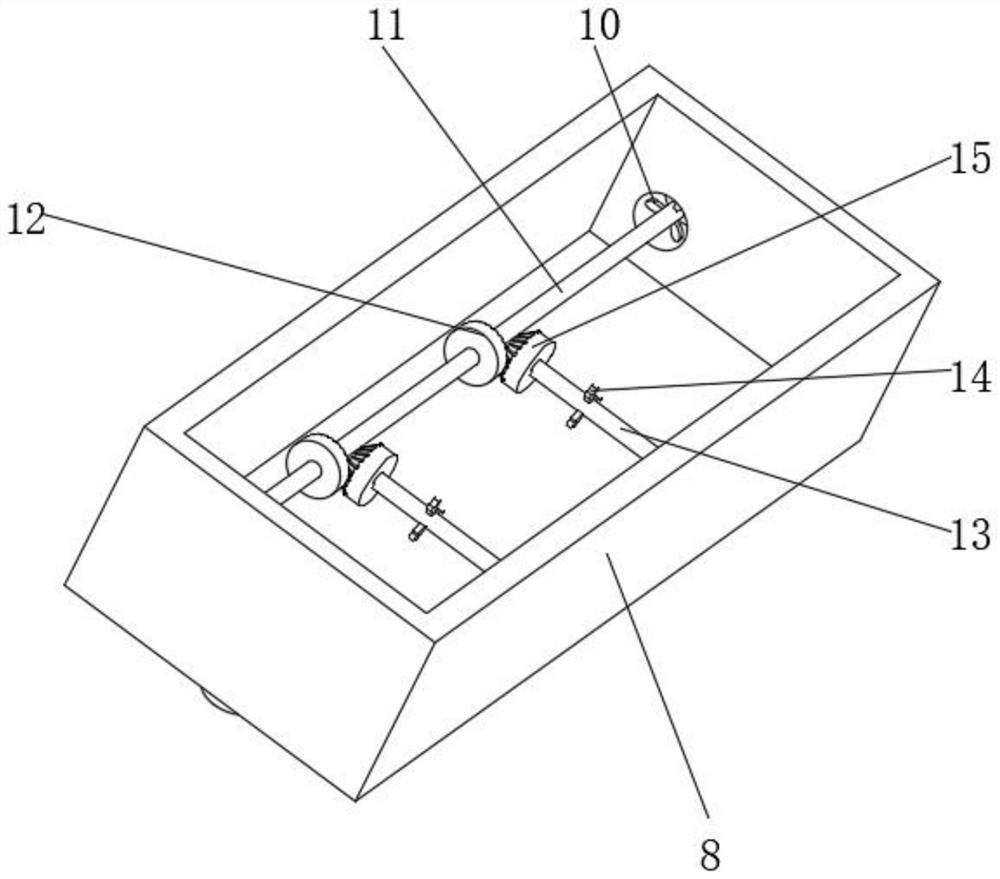

[0037] A production device for mesoporous silica modified polyurethane elastomer, such as figure 1 , 4 As shown, in order to solve the material clamping problem; the present embodiment makes the following improvements on the basis of embodiment 1: the top outer wall of the water bath box 8 is fixed with a support panel 16 by bolts, and the top outer wall of the support panel 16 is provided with a clamping mechanism 5, the clamping mechanism 5 includes three groups of movable jaws 21 and fixed jaws 22, and the three fixed jaws 22 are all fixed on the outer wall of the support panel 16 by bolts, one of the three movable jaws 21 The side outer walls are all fixed with the same slide bar 18, and the outer wall of the slide bar 18 is slidably connected with two vertical plates 17, and the two vertical plates 17 are all fixed on the top outer wall of the support panel 16 by bolts, and the slide bar 18 is close to the two vertical plates. The outer walls of each vertical plate 17 ar...

Embodiment 3

[0040] A production device for mesoporous silica modified polyurethane elastomer, such as figure 1 , 5 As shown, for the problem of water splashing; this embodiment makes the following improvements on the basis of embodiment 2: the top outer wall of the overflow box 4 is connected with a box cover 25 through a hinge, and the bottom outer wall of the box cover 25 is integrally formed with a The sealing protrusion 23 that cooperates with the inner wall of the overflow box 4, and the bottom outer wall of the box cover 25 that is in contact with the overflow box 4 is bonded with a sealing gasket 24, and the top outer wall of the box cover 25 is welded with a handle 26.

[0041] When this embodiment is in use, after clamping and fixing the bottles and cans loaded with materials, the case cover 25 is covered. At this time, on the one hand, the sealing gasket 24 provided between the case cover 25 and the overflow tank 4 can protect the hot water Play a certain sealing effect to prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com