Patents

Literature

74results about How to "Guarantee the quality of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

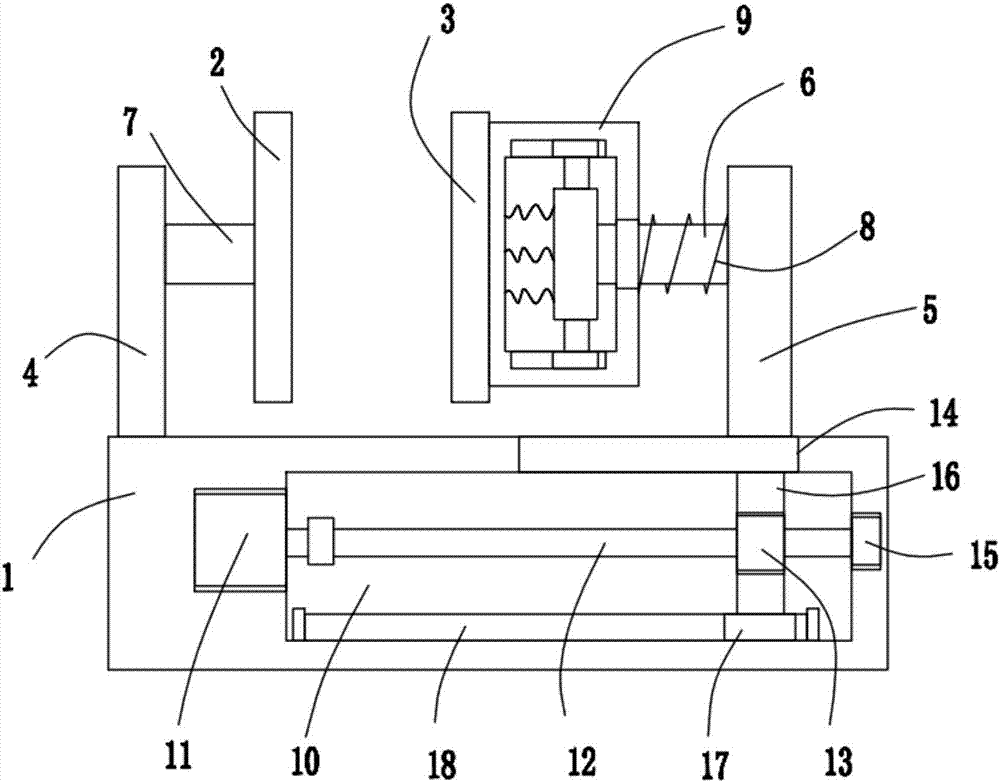

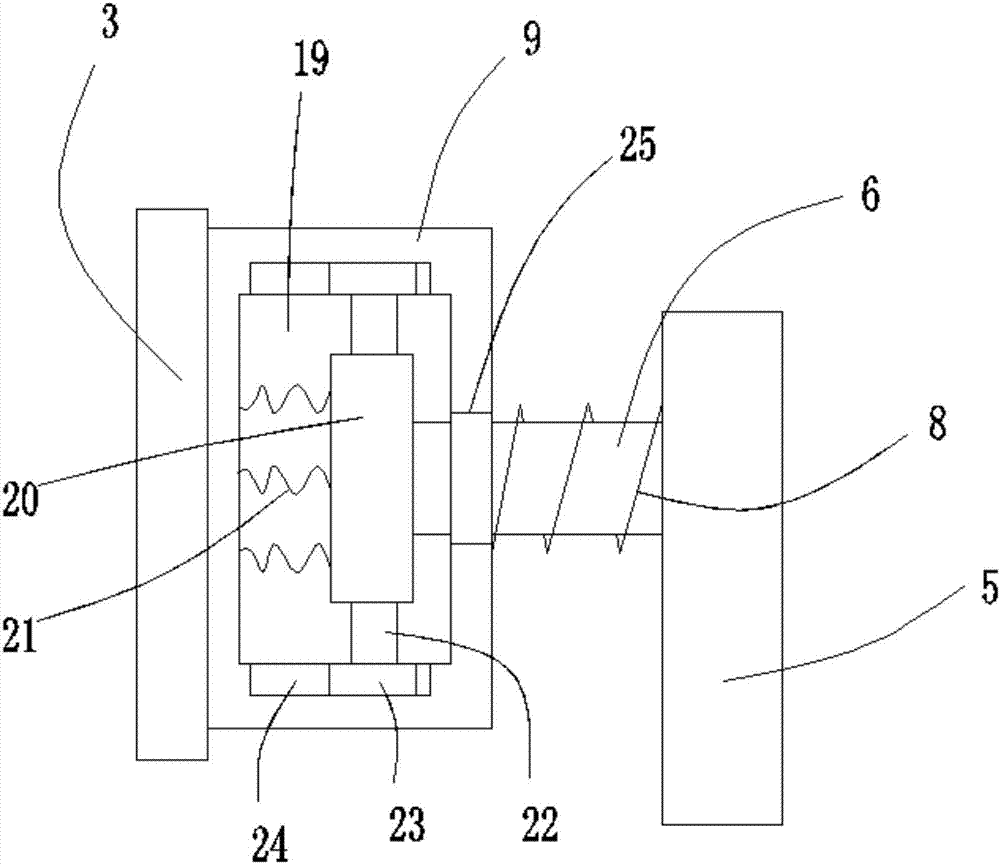

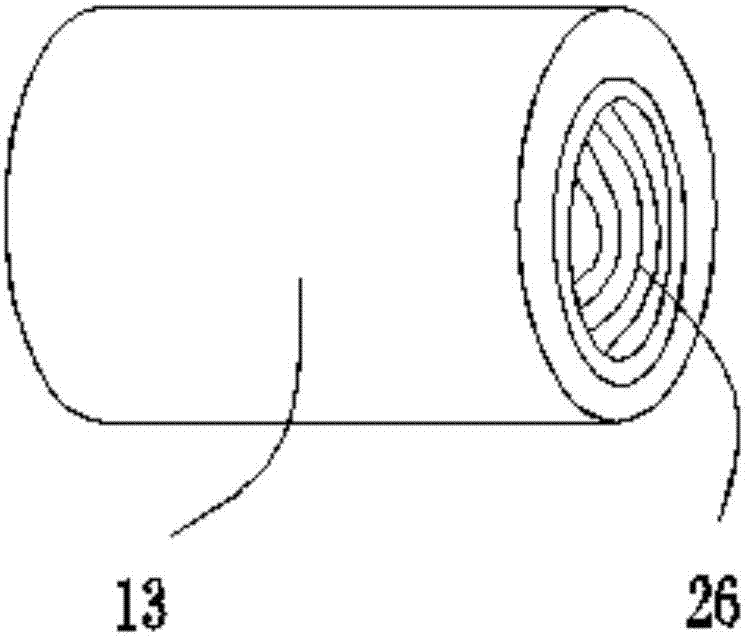

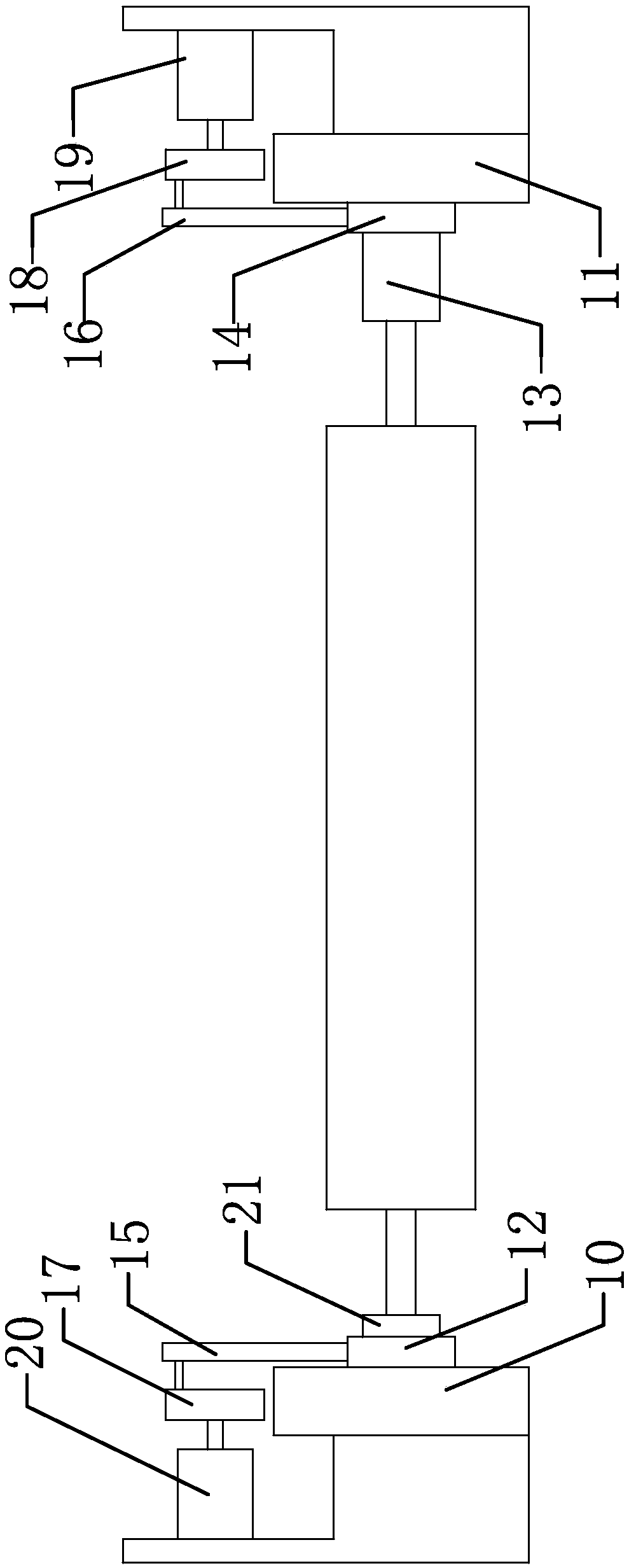

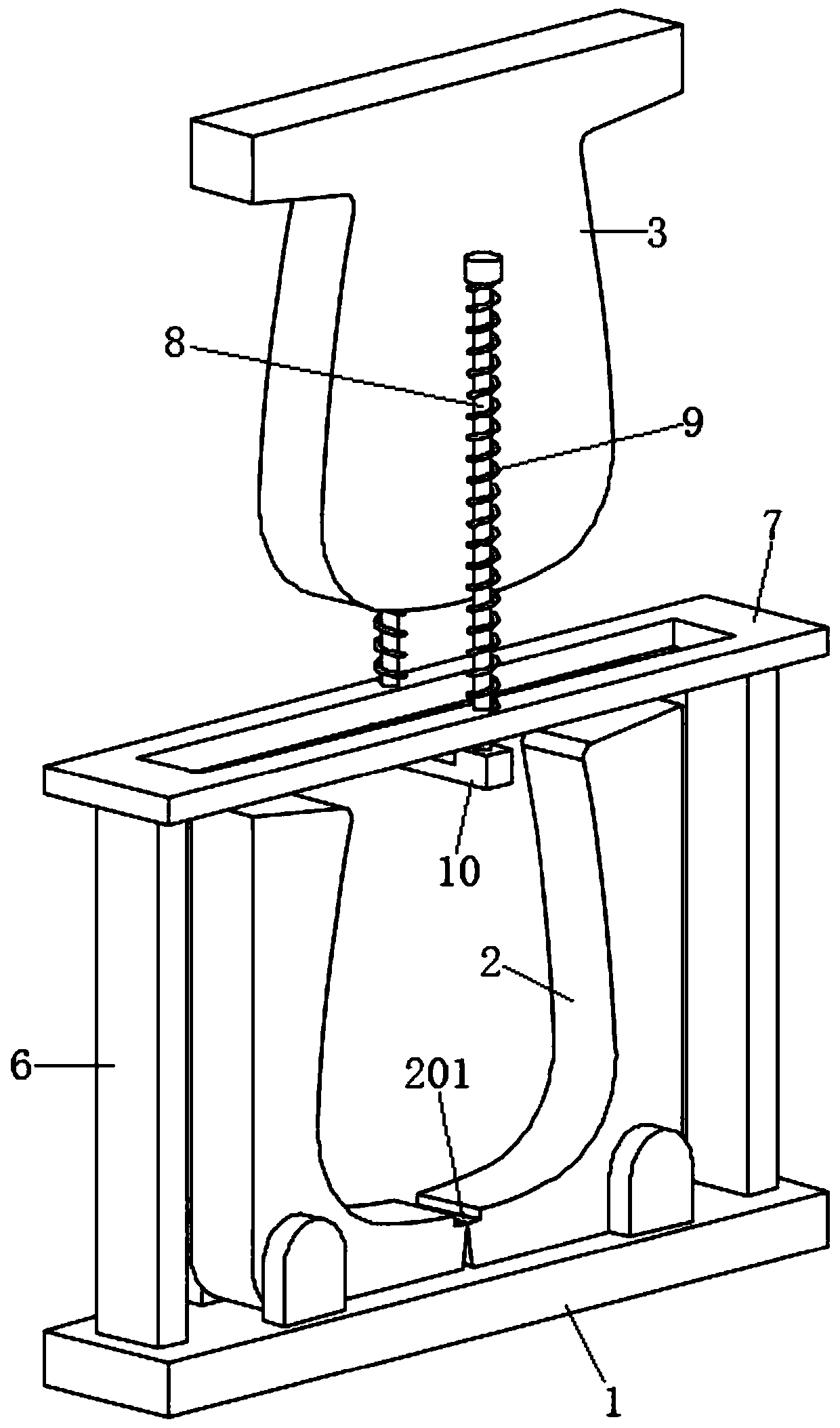

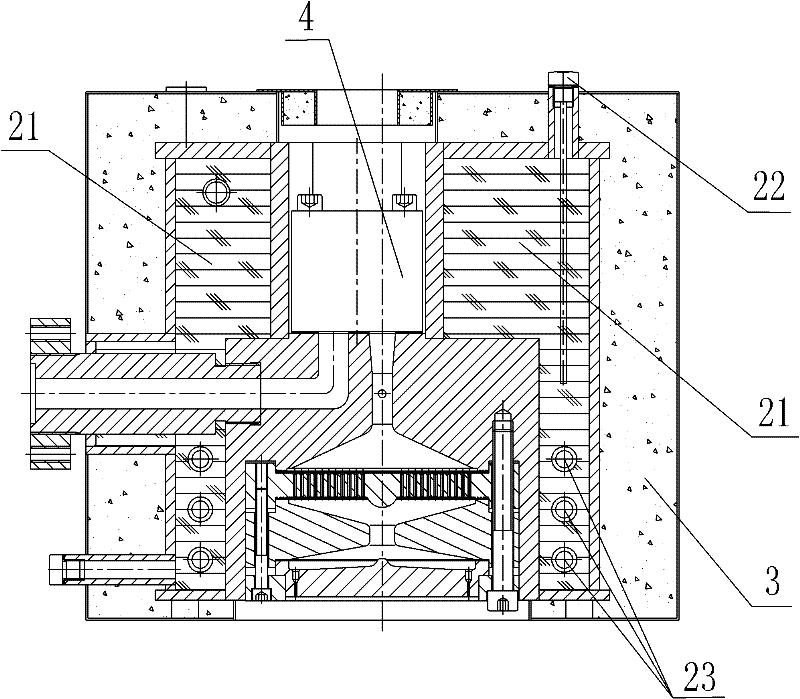

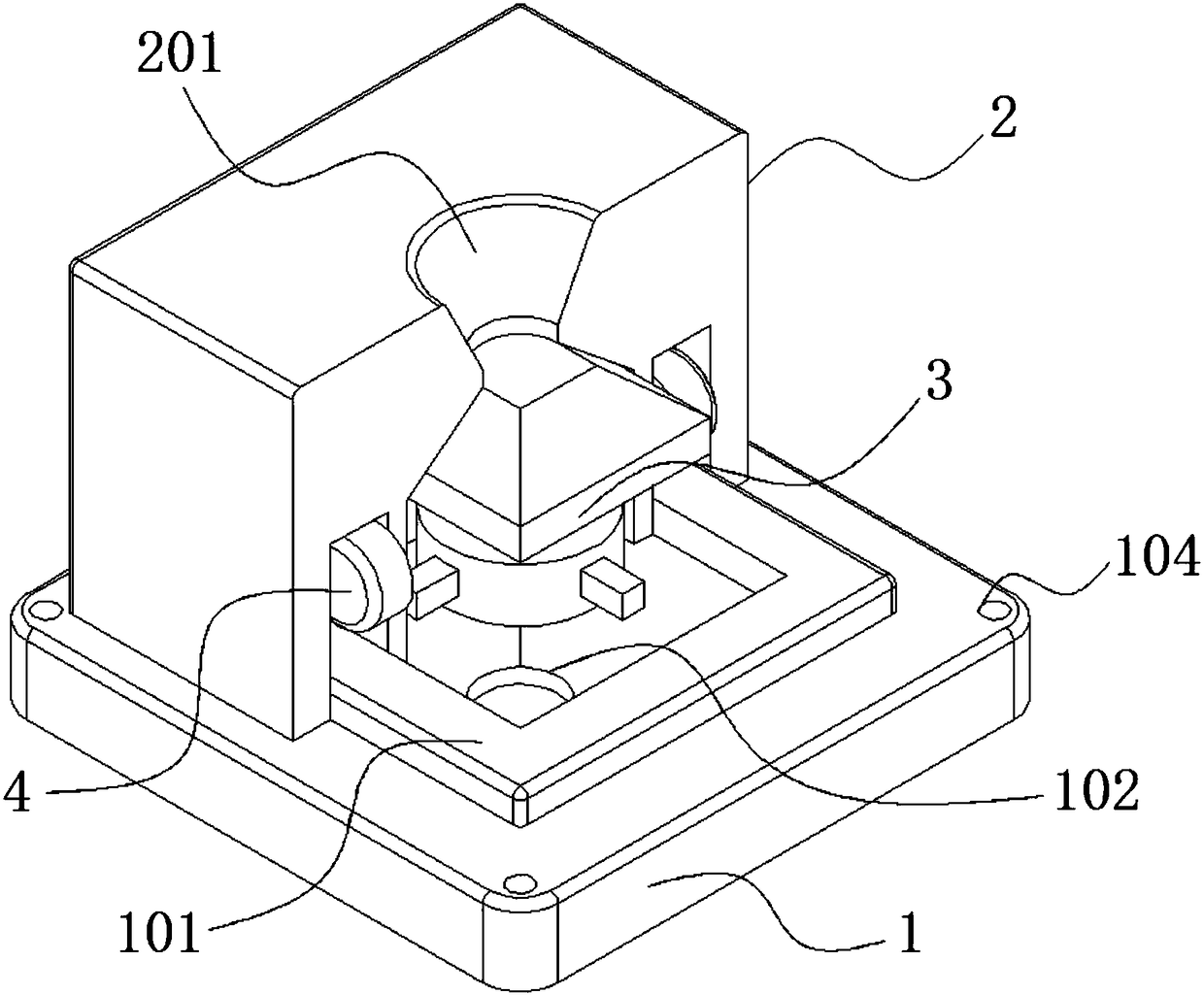

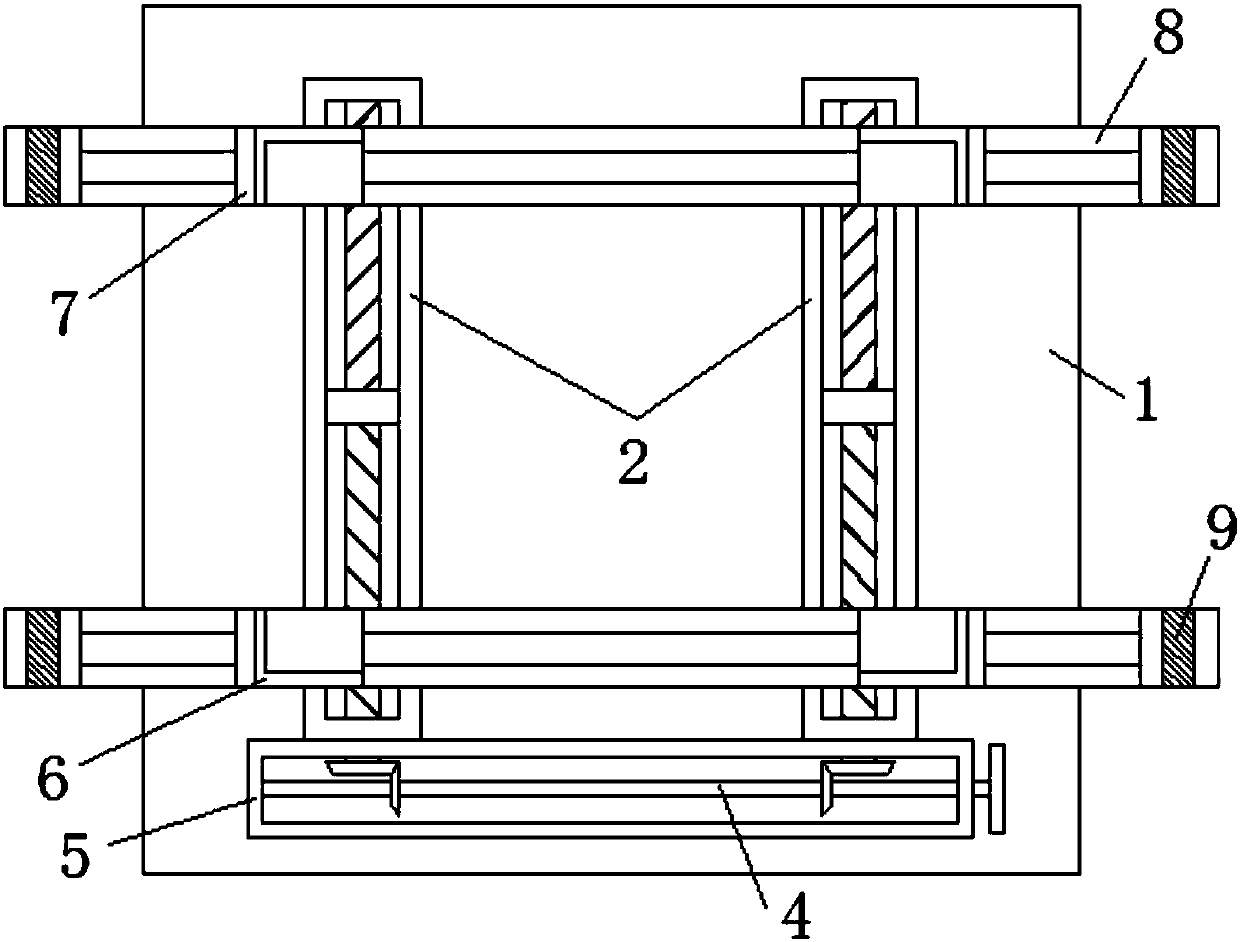

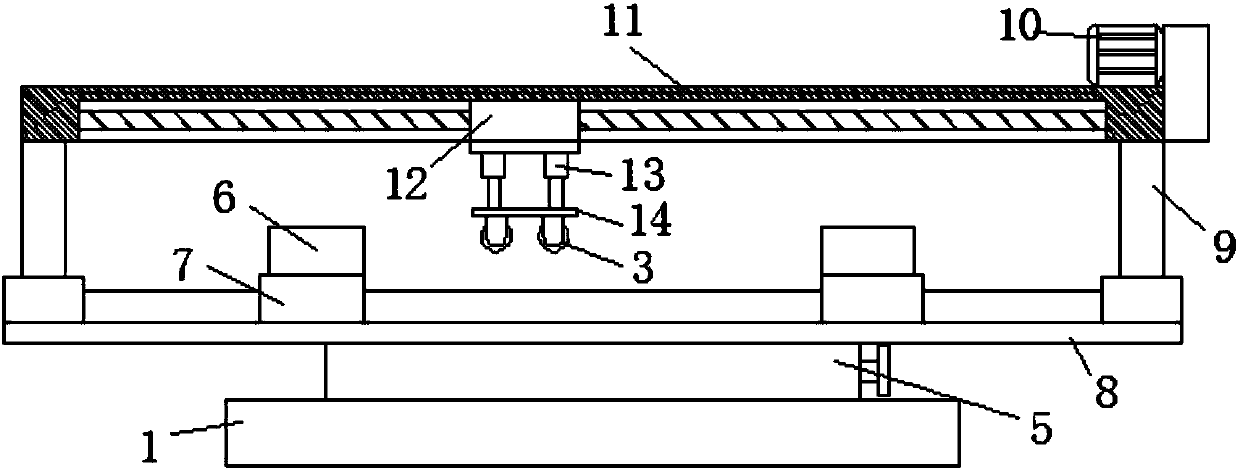

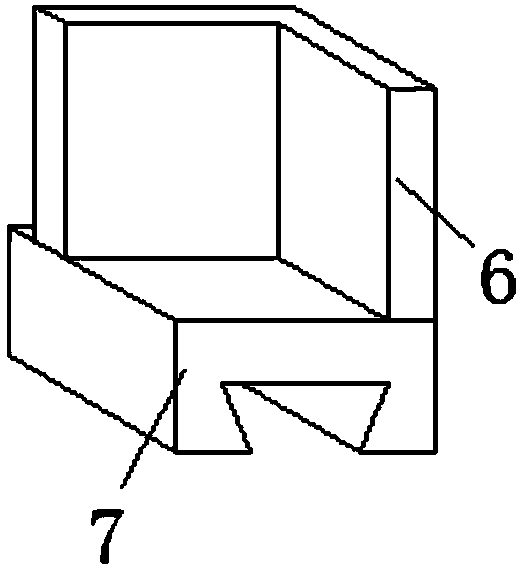

Clamping mechanism for automobile inspection tool

InactiveCN107953283AGuarantee the quality of productionSimple structureWork holdersMechanical engineeringEngineering

The invention discloses a clamping mechanism for an automobile inspection tool. The mechanism comprises a clamping platform, wherein the top of the clamping platform is fixedly provided with a fixingframe; a movable frame movably installed at the top of the clamping platform is arranged on one side of the fixing frame; one side, close to the movable frame, of the fixed frame is fixedly provided with a first connecting rod; one end, close to the movable frame, of the first connecting rod is fixedly provided with a first clamp; one side, close to the first clamp, of the movable frame is fixedlyprovided with a second connecting rod; one end, far away from the movable frame, of the second connecting rod is movably connected with a buffer block; and a second clamp is fixedly arranged on one side, close to the first clamp, of the buffer block, and the first clamp and the second clamp are arranged oppositely. The mechanism is simple in structure and convenient to operate, the clamping mechanism can be prevented from being damaged to the automobile inspection tool due to too large clamping force in the process of clamping the automobile inspection tool, appearance integrity of the automobile inspection tool is guaranteed, clamping is firm, and use requirements of people are met.

Owner:柳州市钜嘉机械有限公司

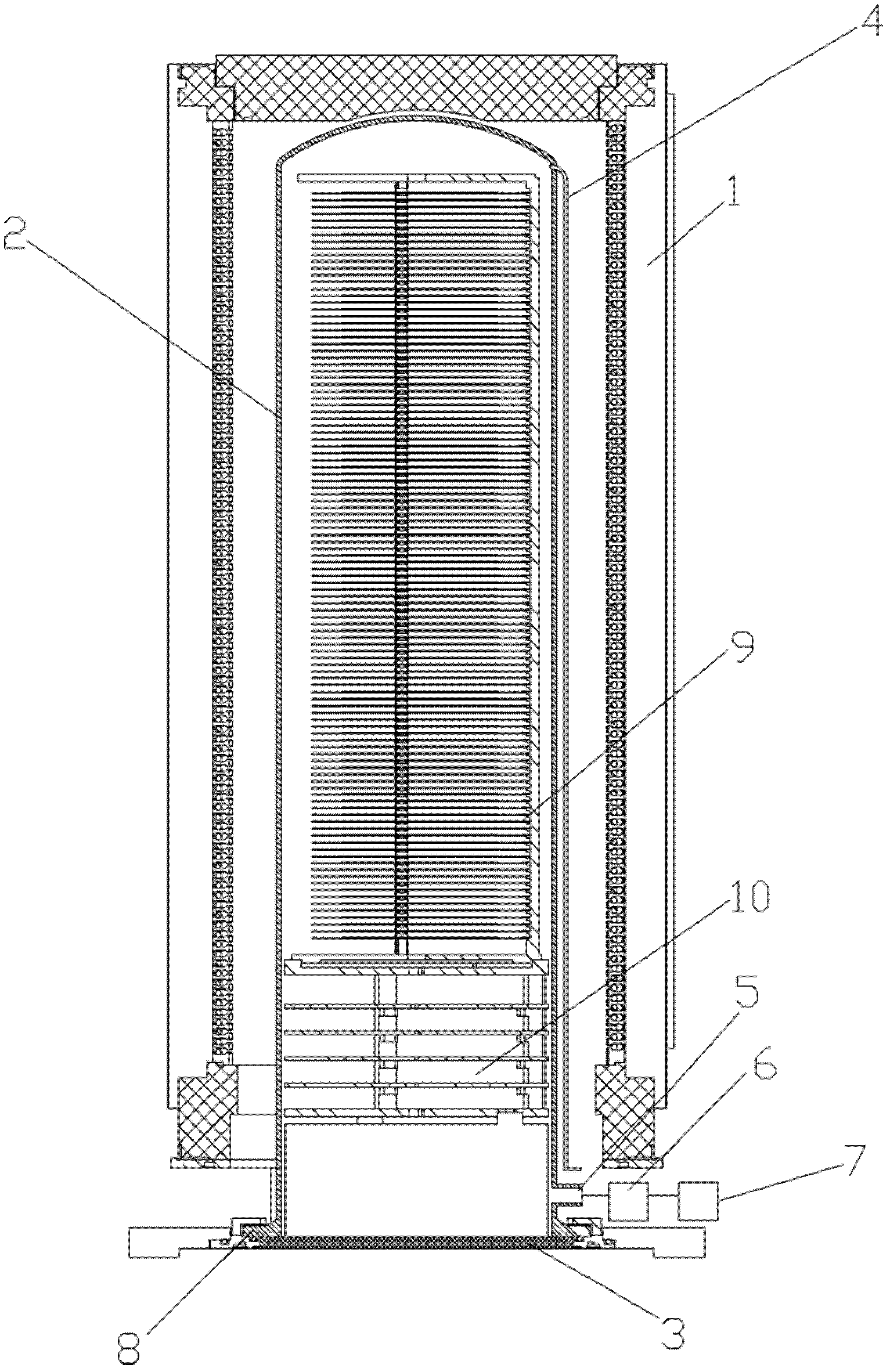

Heat treating equipment and method for semiconductor chip

ActiveCN102881615AGuarantee the quality of productionGuarantee product qualitySemiconductor/solid-state device manufacturingSilicon chipProcess engineering

The invention discloses heat-treating equipment and method for a semiconductor chip, which relate to the technical field of a semiconductor chip process, the heat-treating equipment comprises a heater, a process pipe, a seal plate, a gas inlet pipe, a gas outlet pipe, a gas collection unit and an oxygen content measuring unit, wherein an orifice of the process pipe is perpendicularly downward, a part of the process pipe is positioned in the heater, a flange is arranged at the outer edge of the orifice of the process pipe, the seal plate is connected with the process pipe by the flange, an inlet of the gas outlet pipe is formed on a side wall of the process pipe, close to the orifice, an outlet of the gas inlet pipe is formed at the end of the process pipe, opposite to the orifice, the gas collection unit is connected with an outlet of the gas outlet pipe, and the oxygen content measuring unit is connected with the gas collection unit. With the adoption of the gas collection unit and the oxygen content measuring unit, the oxygen content in a reaction cavity of the heat-treating equipment can be accurately measured, after the oxygen content in the reaction cavity is below a certain threshold, the heat-treating process is performed to ensure the production quality of the silicon chip.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

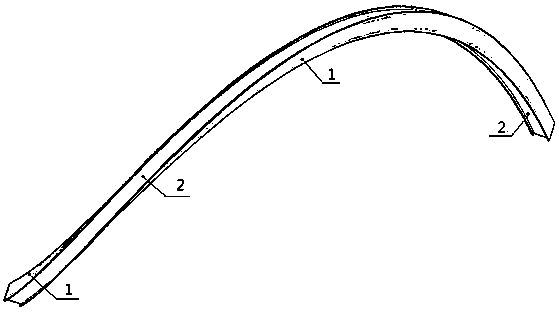

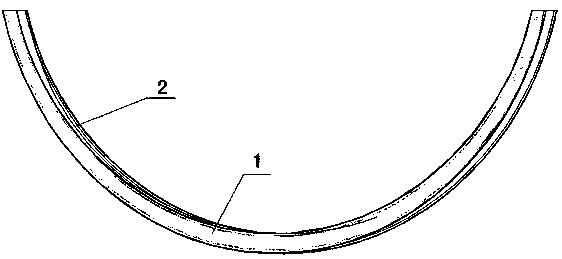

Manufacturing method for spiral twisted box type

ActiveCN108723630AIncrease productivityGuarantee the quality of productionWelding/cutting auxillary devicesAuxillary welding devicesHot pressingHelix

The invention relates to a manufacturing method for a spiral twisted box type. The method comprises that the entire engineering model diagram is drawn, the same components are classified, flange plates and web plates of the different members are respectively extended and sampled, the extended flange plates and web plates are discharged in a segmented mode, the upper and lower flange plates are hot-pressed and molded by using a die made according to the box-type member twisted shape size, the web plates are rolled by using a plate rolling machine, an shape-imitation assembly tread is made according to the different members, the segmented pressed-molded flange plates are placed on the special assembly tread for splicing, welding, repairing so as to be tightly attach to the tread, and then the web plates and internal partition plates are assembled; and the internal partition plates are welded, the assembly accuracy is controlled by the assembly tread and the fit gap of the tread, the boxflange plates and the web plates, finally, the additional flange plates are assembled, and by combining with the trimming, the assembly detecting, welding of the box type main seam, post-welding detecting, member rust removal, and member coating are conducted. By means of the manufacturing method, the production efficiency can be improved, the production quality is ensured, and the requirements ofthe assembly accuracy are met.

Owner:二十二冶集团装备制造有限公司

Coating mechanism for processing composite cloth

PendingCN108582952AGuarantee the quality of productionImprove feeding efficiencyLiquid surface applicatorsLamination ancillary operationsElectric machineryAgricultural engineering

The invention provides a coating mechanism for processing composite cloth, belongs to the technical field of textile machinery and solves the problem of poor coating effect in the prior art. The coating mechanism for processing the composite cloth comprises a rack, a coating table, a PET transfer membrane, a conveying belt, a plurality of driving rollers and a low temperature pressure roller, wherein a coating is contained on the coating table; a liquid level sensor is arranged in the coating table; the PET transfer membrane is jointed with the conveying belt; the conveying belt sleeves the plurality of driving rollers; the driving rollers are rotationally arranged on the rack and are connected with a working motor I capable of enabling the driving rollers to rotate; the low temperature pressure roller is rotationally arranged above the coating table; one end of the low temperature pressure roller is connected with a working motor II capable of enabling the low temperature pressure roller to rotate; the coating table is connected with a coating supplementing mechanism capable of supplementing the coating for the coating table; the coating supplementing mechanism comprises a coatingsupplementing pipe, an electromagnetic valve, a driving pump and a coating supplementing tube; and one end of the coating supplementing pipe is connected with the coating table. The coating mechanismprovided by the invention has the advantage of improving the coating effect.

Owner:陈琴华

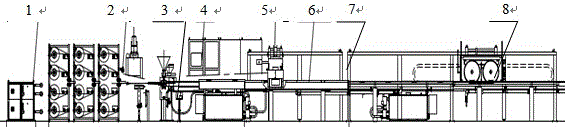

Optical cable casing pipe forming processing device

InactiveCN105904698AGuarantee the quality of productionIncrease production speedFibre mechanical structuresForm processingWater tanks

The invention relates to an optical cable casing pipe forming processing device including an optical fiber releasing frame, an extruder and casing pipe forming mold, a cooling water tank and a traction device. The optical cable casing pipe forming processing device is characterized in that an auxiliary traction device is arranged in the cooling water tank or between the cooling water tank and the traction device along the traction direction of an optical cable casing pipe; the auxiliary traction linear velocity of the auxiliary traction device is higher than the traction linear velocity of the traction device to draw the optical cable casing pipe. The optical cable casing pipe forming processing device has the beneficial effects: 1, residual length of the casing pipe is controlled by arrangement of the auxiliary traction device and is used for compensating the shrinkage amount of the casing pipe after cooling, relatively large after-shrinkage of common casing pipes in production is avoided, the production quality of the optical fiber casing pipe is ensured, the casing pipe production speed and follow-up process control are facilitated to be improved, and the production of complete-dry type casing pipes and PP casing pipes are facilitated; and 2, a longitudinal moving device can adjust the length of a casing pipe lengthened stretched section, and moves the casing pipe to an optimum traction position according to the detected temperature of the casing pipe, so as to ensure the traction effect and the processing quality of the casing pipe.

Owner:YANGTZE OPTICAL FIBRE AND CABLE JOINT STOCK LIMITED COMPANY

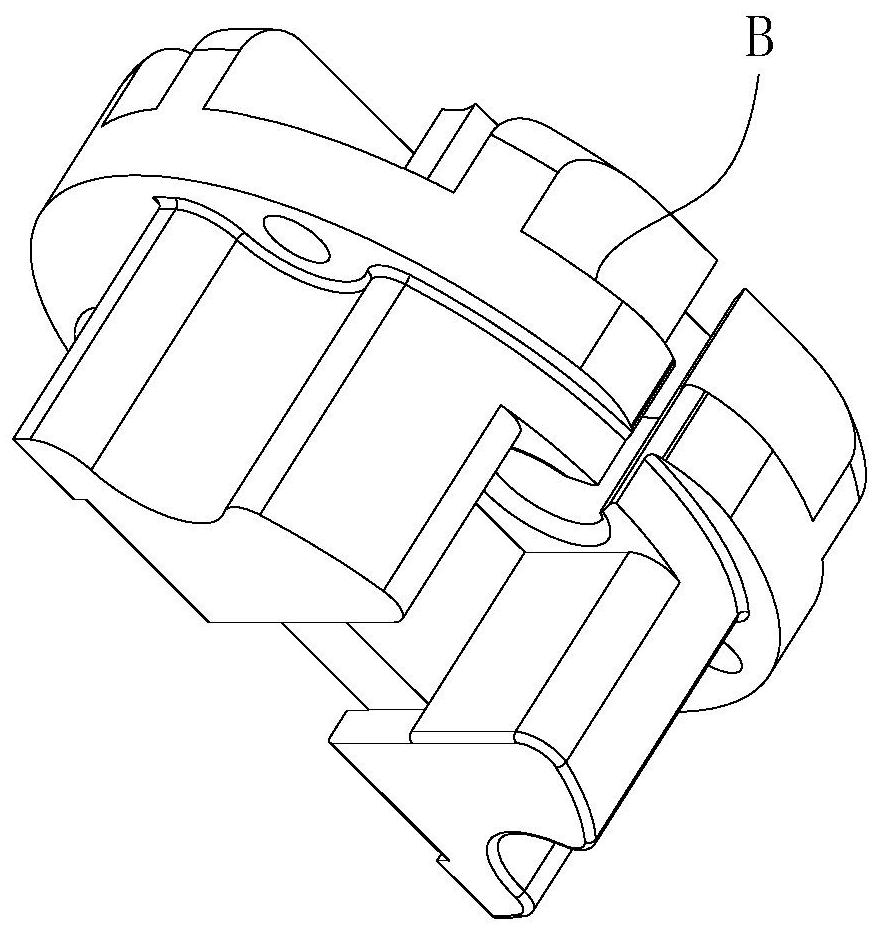

Intelligent lamp holder rear cover mounting device

ActiveCN112355628AIncrease productivityGuarantee the quality of productionLighting heating/cooling arrangementsAssembly machinesPhysicsMechanical engineering

The invention relates to an intelligent lamp holder rear cover mounting device. The intelligent lamp holder rear cover mounting device comprises a heat dissipation base feeding device and an LED lampbead feeding device, wherein the heat dissipation base feeding device is used for guiding out a heat dissipation base; the LED lamp bead feeding device is used for guiding LED lamp beads to the outletposition of the heat dissipation base feeding device and mounting the LED lamp beads on the heat dissipation base; a wire penetrating and sleeving device is arranged beside a positioning and mountingmechanism and used for enabling LED lamp bead wires to penetrate through mounting holes of the heat dissipation base; and a bottom cover feeding device is further arranged beside the outlet of the heat dissipation base feeding device and used for mounting a bottom cover on the heat dissipation base. By adoption of the intelligent lamp holder rear cover mounting device, the production efficiency of LED lamp holders can be improved, meanwhile, LED lamp wicks are protected, and the production quality of the lamp holders is guaranteed.

Owner:HEFEI WISDOM BRIDGE INFORMATION TECH CO LTD

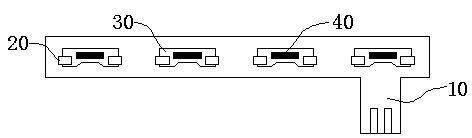

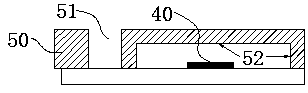

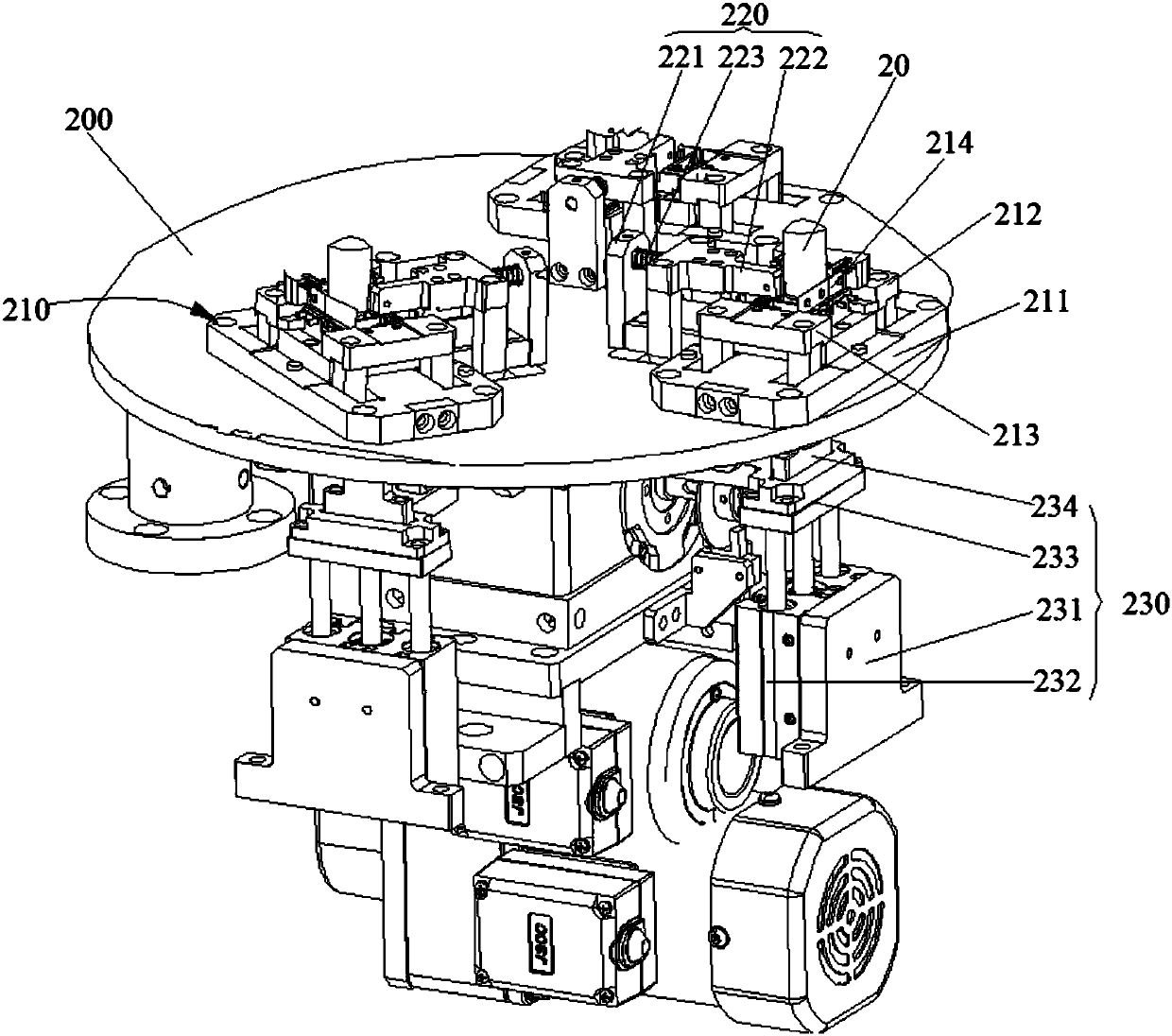

Automatic production system for LED lamp holder

PendingCN112361237AIncrease productivityGuarantee the quality of productionAssembly machinesMetal working apparatusMechanical engineeringLight tube

The invention relates to an automatic production system for an LED lamp holder, which comprises a heat dissipation base feeding device, a reflection bowl feeding device and an LED lamp bead feeding device, wherein the heat dissipation base feeding device is used for guiding out a heat dissipation base, the reflection bowl feeding device guides a reflection bowl out to the outlet position of the heat dissipation base feeding device and installs the heat dissipation base and the reflection bowl, the LED lamp bead feeding device is used for guiding LED lamp beads to the outlet position of the heat dissipation base feeding device and installs the LED lamp beads and the heat dissipation base, a lamp tube feeding device is further arranged beside the heat dissipation base feeding device, a positioning installation mechanism is arranged beside the lamp tube feeding device, and the positioning installation mechanism is used for achieving installation of the heat dissipation base and the lamp tube. The system can improve the production efficiency of the LED lamp holder, achieves protection for an LED lamp wick, and guarantees the production quality of the lamp holder.

Owner:HEFEI WISDOM BRIDGE INFORMATION TECH CO LTD

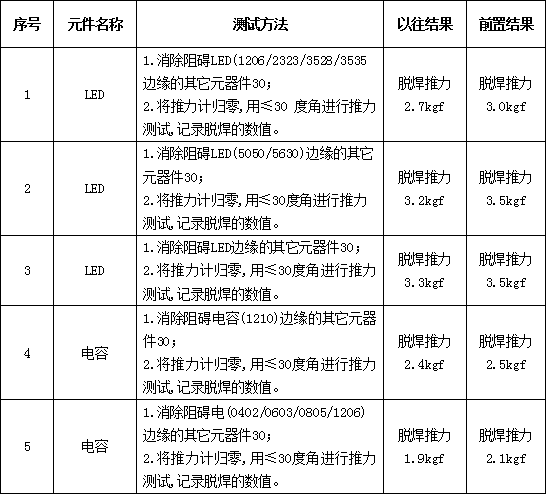

FPC component mounting process

InactiveCN109548313AIncrease thrustGuarantee the quality of productionPrinted circuit assemblingReflow solderingManufacturing quality

The invention relates to an FPC component mounting process, which comprises the following steps: S1, FPC board fixing; S2, glue printing; S3, solder paste printing; S4, mounting; S5, solidifying; S6,intermediate inspection; S7, reflow soldering; and S8, product detection, and process completion. A double-steel-mesh design is adopted in the process. Glue and solder paste are skip-printed at presetpositions of an FPC board in turn. The solder paste steel mesh plate adopts a clearance design, so that the dispensing position and the solder paste steel mesh do not interfere with each other. The component mounting thrust is strengthened. The manufacture quality of the circuit board is ensured. The technical problem that the current LED or capacitor mounting thrust is not up to the standard issolved. The FPC component mounting process is applicable to large-scale efficient production.

Owner:SHENZHEN TECHASER TECH

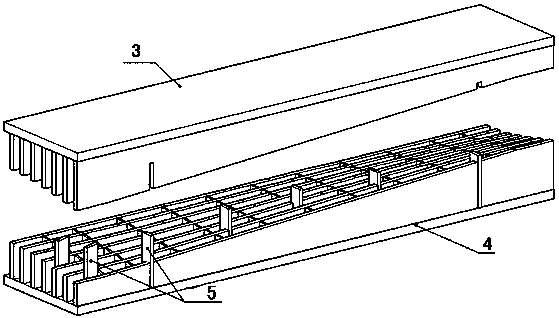

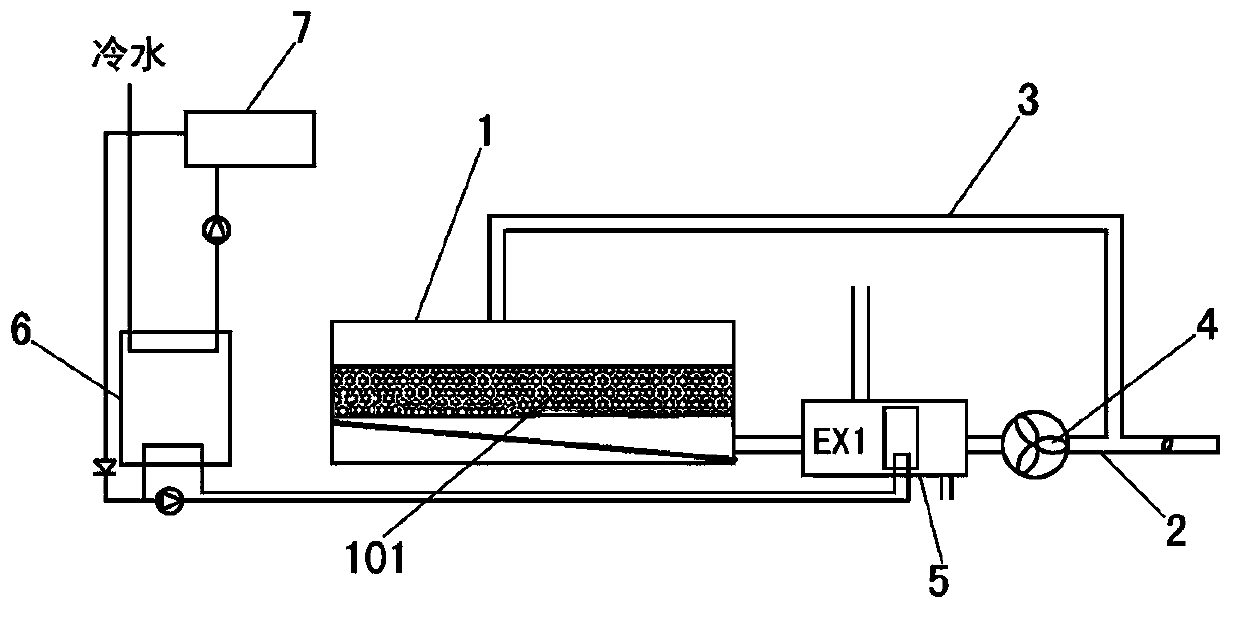

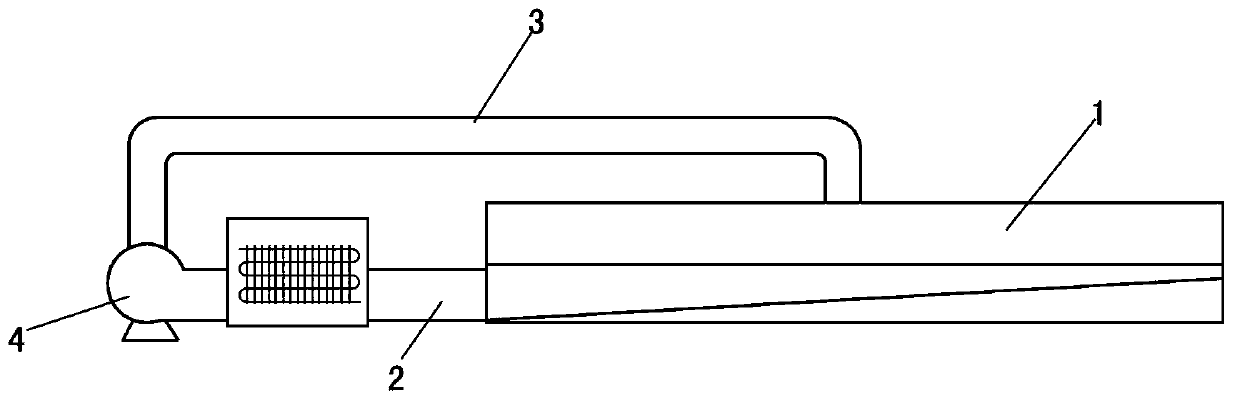

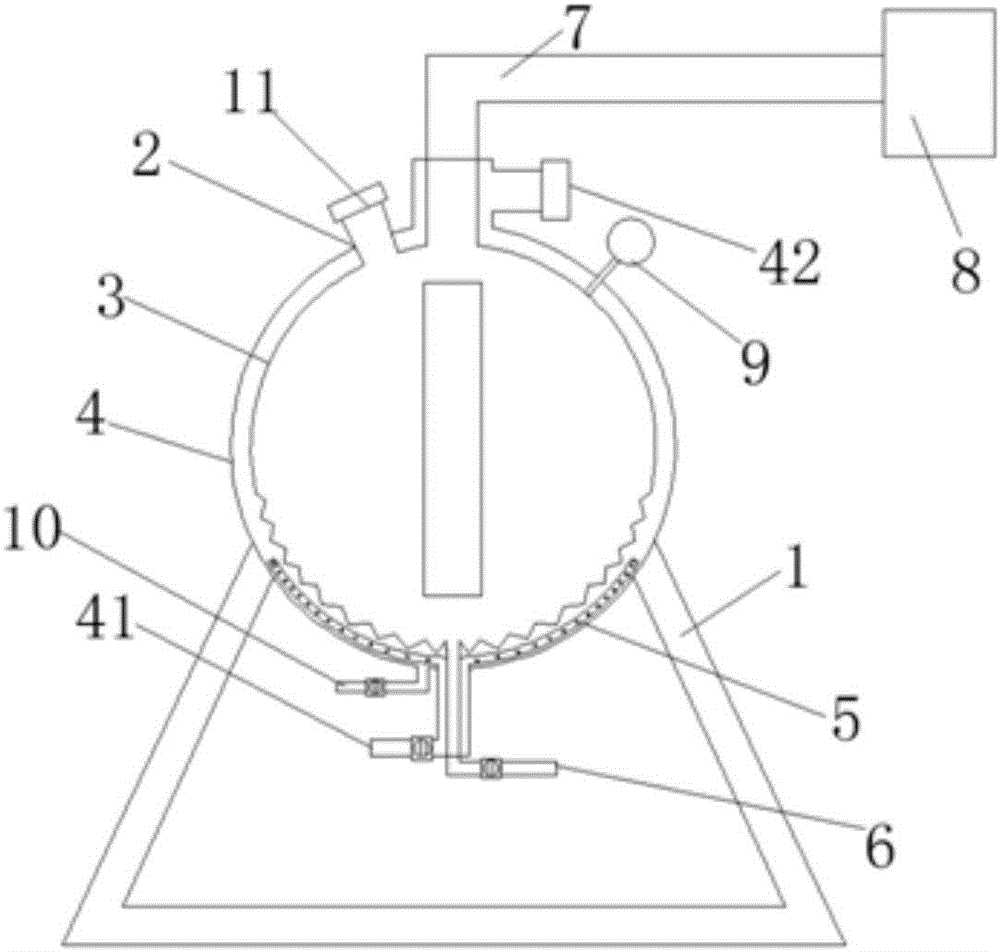

Soybean sauce starter propagation device capable of recycling respiratory heat

ActiveCN103652806AGuarantee the quality of productionGuaranteed growth environmentHeat pumpsClimate change adaptationWater circulationEngineering

The invention discloses a soybean sauce starter propagation device capable of recycling respiratory heat. The soybean sauce starter propagation device comprises a starter tank as well as a thermotank, an air energy heat pump and a hot water storage tank, wherein an air inlet tube and an exhaust tube are arranged on the starter tank; a fan for accelerating air flowing is arranged on the air inlet tube; the thermotank is used for raising the temperature of hot or cold air flowing through the thermotank or used for subsequently conveying the heated air into the starter tank through the air inlet tube through a heat exchanger arranged inside the thermotank; the air energy heat pump is connected with the heat exchanger arranged inside the thermotank; the hot water storage tank is used for receiving hot water produced through the air energy heat pump; the thermotank is arranged at the middle section of the air inlet tube and is positioned between the starter tank and the fan; the hot water storage tank is connected with the air energy heat pump through a communication pipeline; water circulation is formed between the air energy heat pump and the heat exchanger through the communication pipeline. The soybean sauce starter propagation device is used for recycling and utilizing biologic respiratory heat generated in the starter propagation process, the temperature of a starter material can be adjusted, and the purposes of energy conservation and consumption reduction are achieved. The soybean sauce starter propagation device is a precedent for recycling and utilizing the biologic respiratory heat generated from soybean sauce starter propagation by using the air energy heat pump at home and abroad.

Owner:LEE KUM KEE XIN HUI FOOD

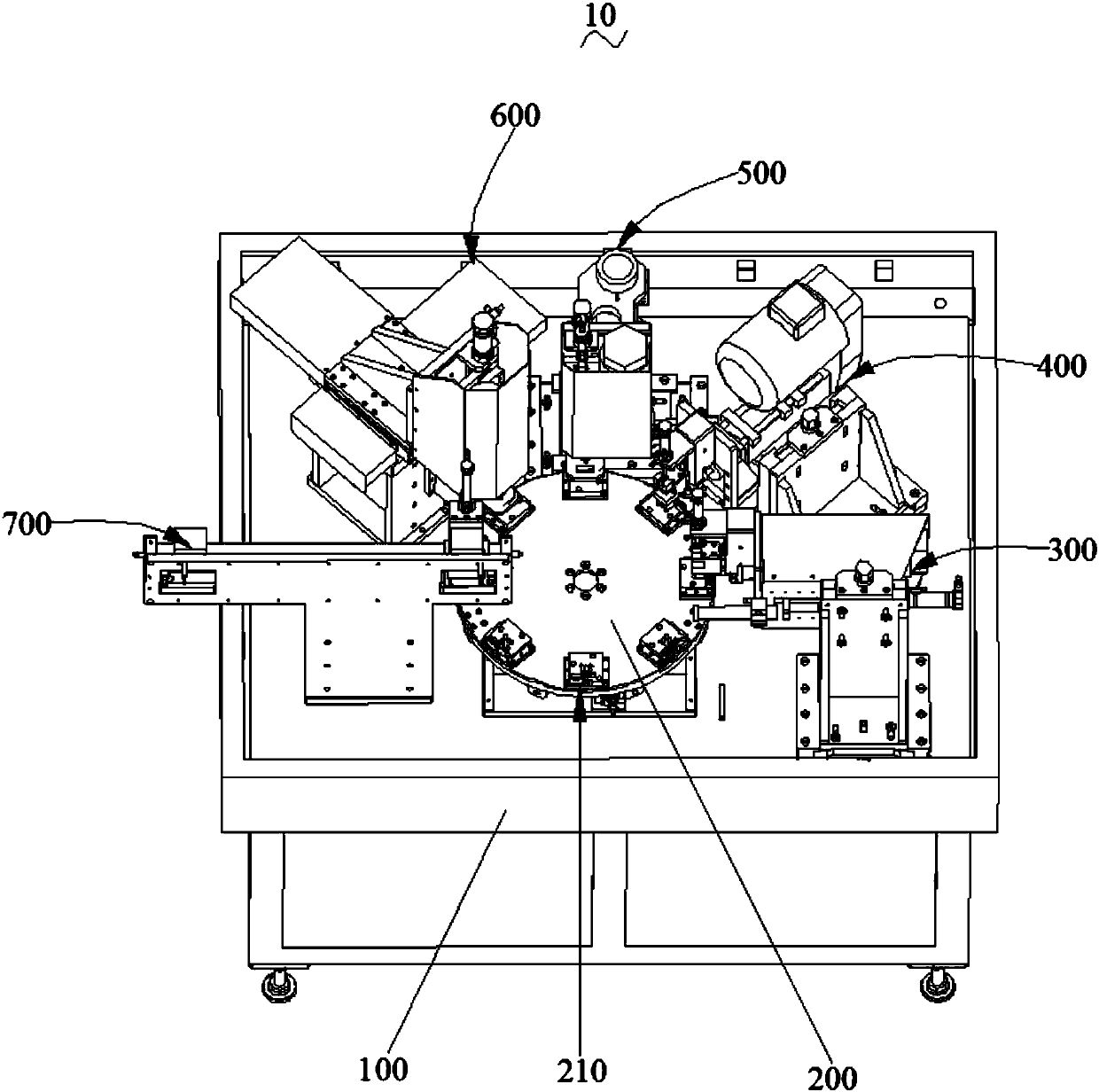

Battery discharge mechanism and battery assembly equipment

InactiveCN108054401AIncrease productivityGuarantee the quality of productionPrimary cell manufactureAssembling battery machinesElectrical and Electronics engineeringCoating

The invention discloses a battery discharge mechanism, which comprises a discharge support frame, a discharge movement sliding plate, a discharge sliding plate driving part, a discharge lifting plate,a discharge lifting part and a discharge clamping device. The invention further discloses battery assembly equipment, which comprises the battery discharge mechanism, a work base table, a battery transmission rotation disk, a battery powder feeding mechanism, a battery carbon rod feeding mechanism, a battery sealing glue coating mechanism and a battery sealing cover feeding mechanism. According to the present invention, the battery powder feeding mechanism, the battery carbon rod feeding mechanism, the battery sealing glue coating mechanism, the battery sealing cover feeding mechanism and thebattery discharge mechanism are sequentially arranged around the battery transmission rotation disk so as to complete the processing of the battery powder feeding, the battery carbon rod feeding, thebattery sealing glue coating, the battery sealing cover feeding, the battery discharge and other production processes of the cylindrical battery, such that the production efficiency is substantiallyimproved, the production quality is ensured, and the production cost is effectively reduced.

Owner:惠州联合诚创企业管理咨询有限公司

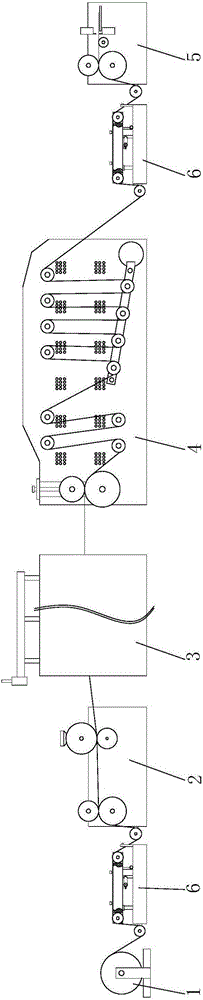

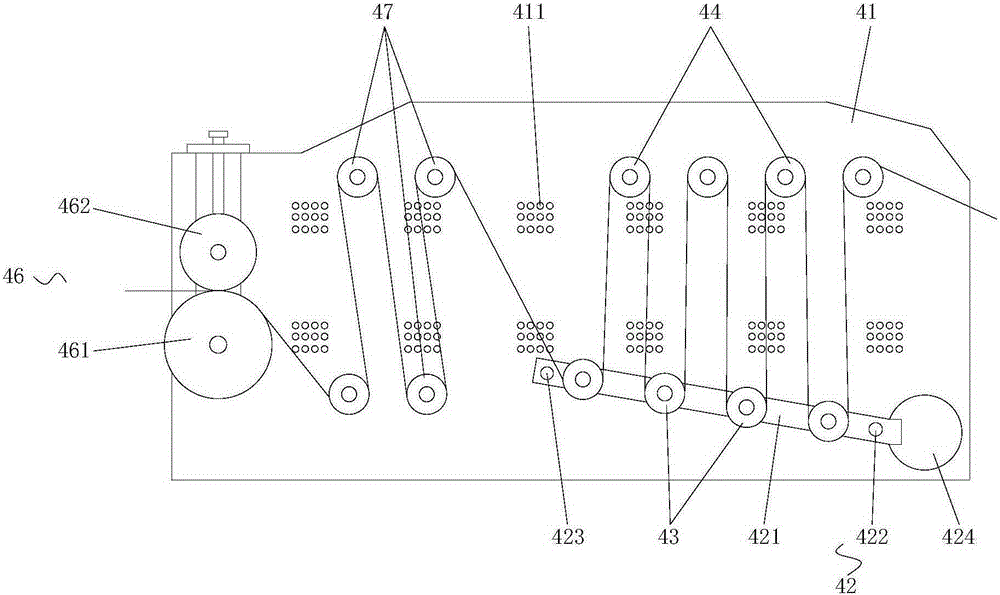

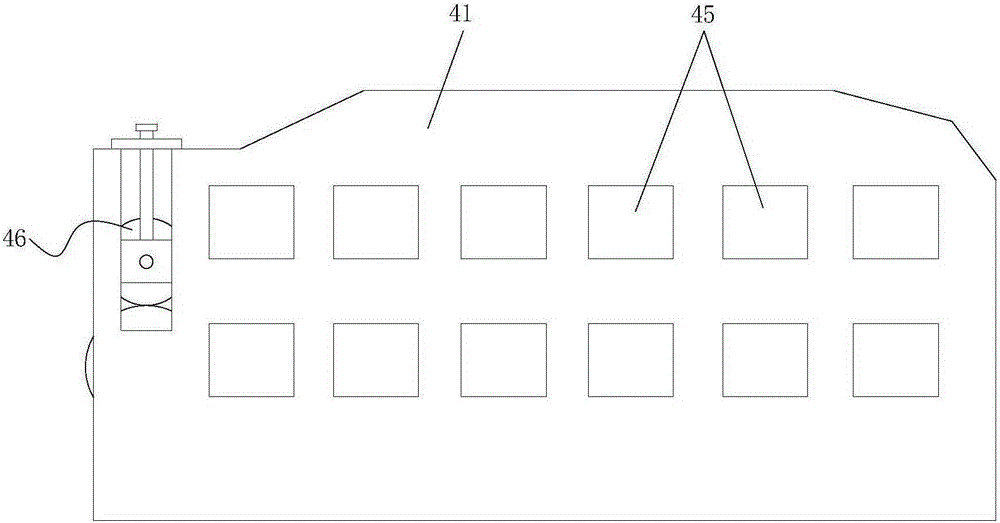

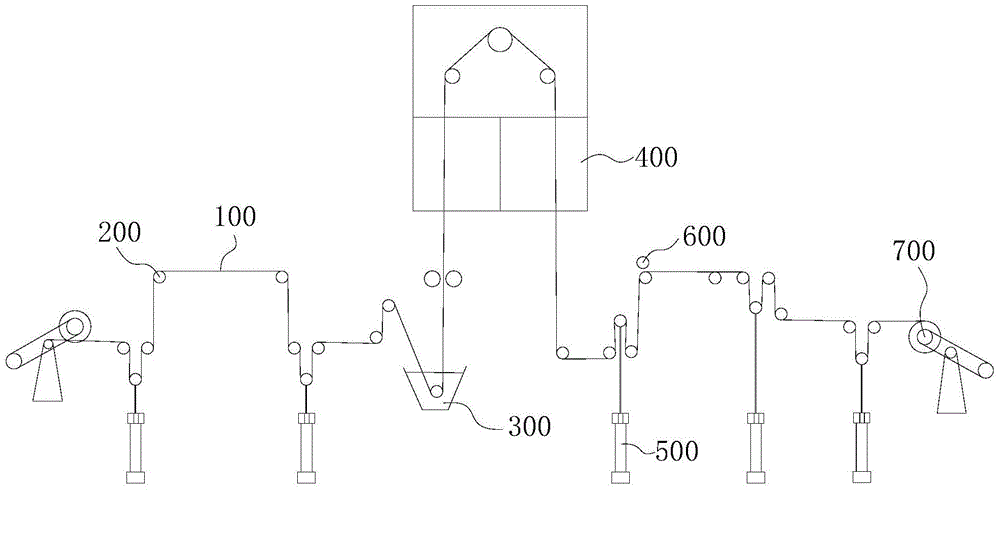

Automatic control color card coating and printing machine

PendingCN105196696AGuarantee the quality of productionGuaranteed production efficiencyRotary pressesPrinting press partsAutomatic controlColor code

The invention relates to an automatic control color card coating and printing machine, which sequentially comprises a hair rolling mechanism, a coating and printing mechanism, a drying box, a cooling buffer mechanism, a slitting mechanism and a PLC control system along the flow direction of a color card paper base. By the technical scheme, the color card paper base is send out by the hair rolling mechanism; a color code layer is printed on the color card paper base by the coating and printing mechanism; the color card paper base enters the drying box; the drying box dries the color code layer on the color card paper base; the color card paper base enters the cooling buffer mechanism for cooling; and finally the color card paper base enters the slitting mechanism for slitting to form a color card with preset size. The color card paper base is inconsistent in front and back speeds when entering the slitting mechanism, so that the inconsistent front and back speeds can be buffered through the cooling buffer mechanism; the color card paper base can stably carry out pipeline flowing; and the production quality and the production efficiency of the color card are ensured.

Owner:RAINBOW PUTIAN PAINT COLOR CARD

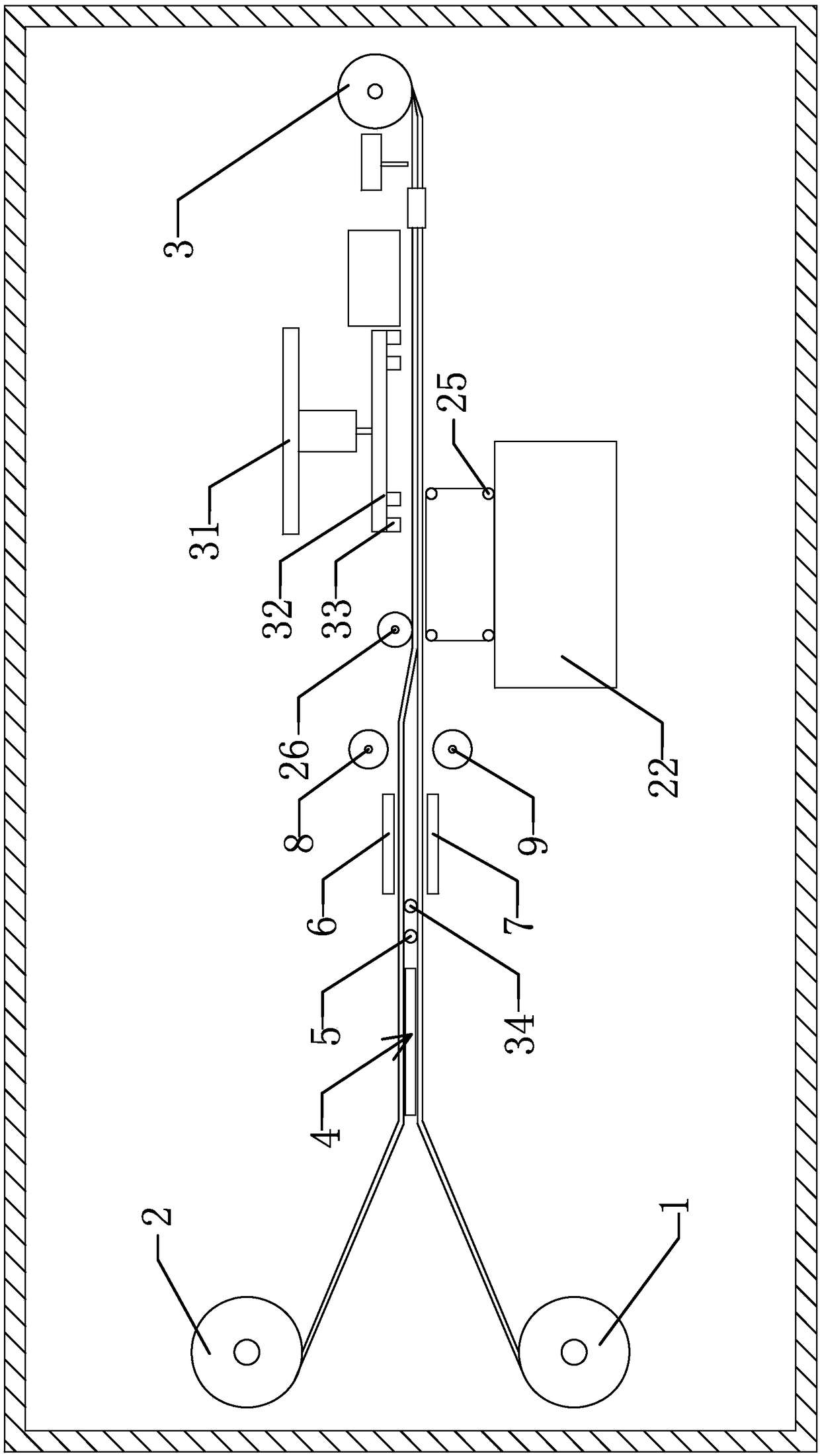

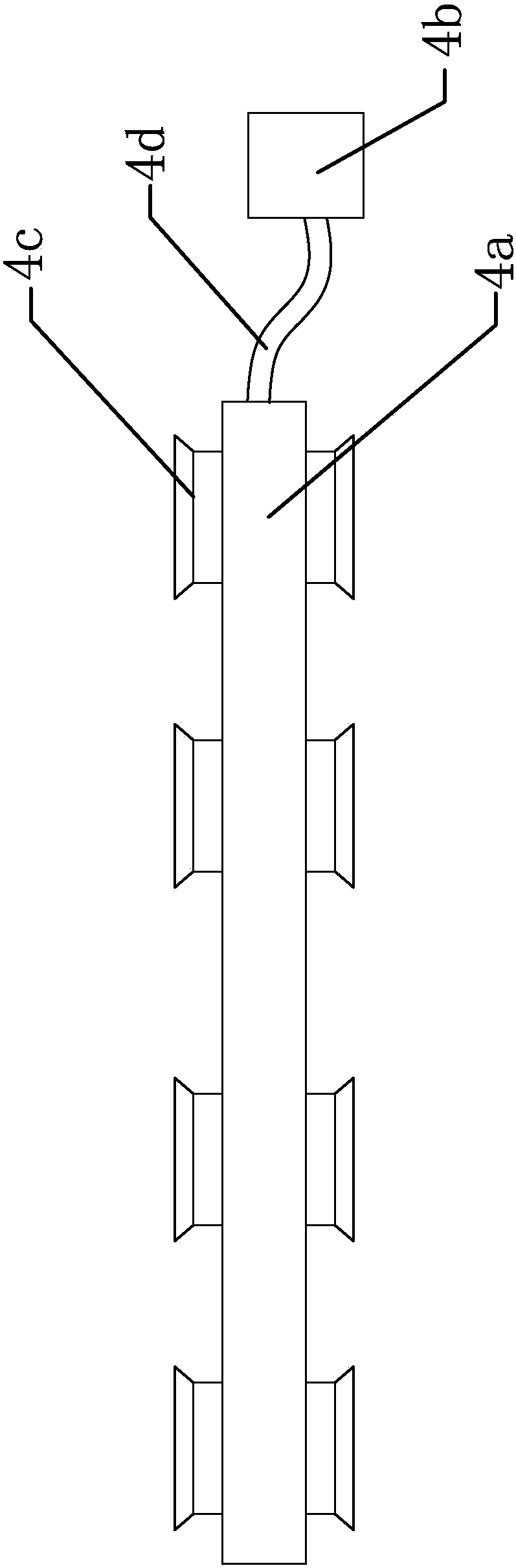

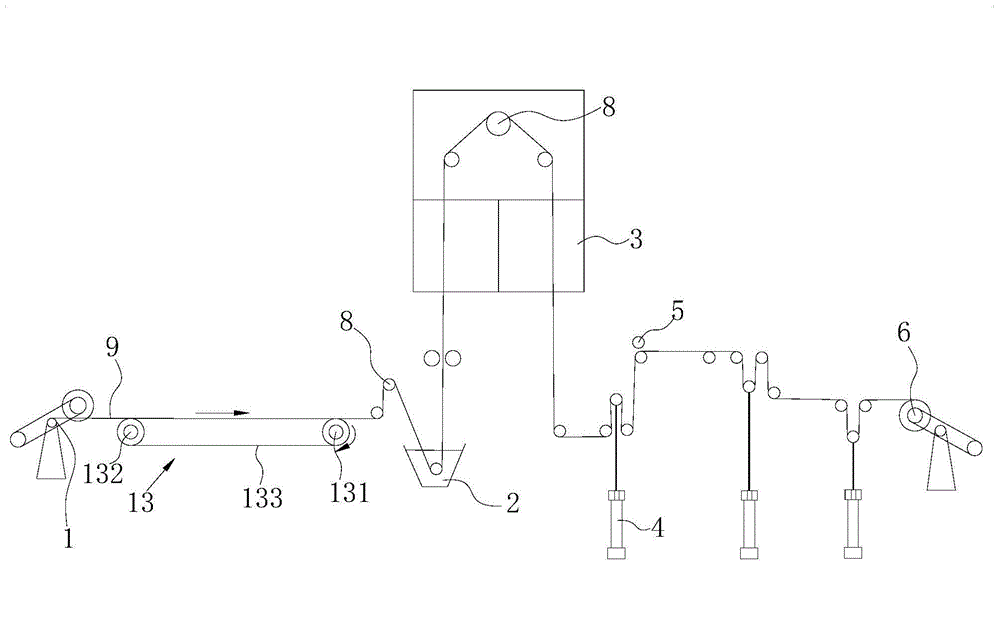

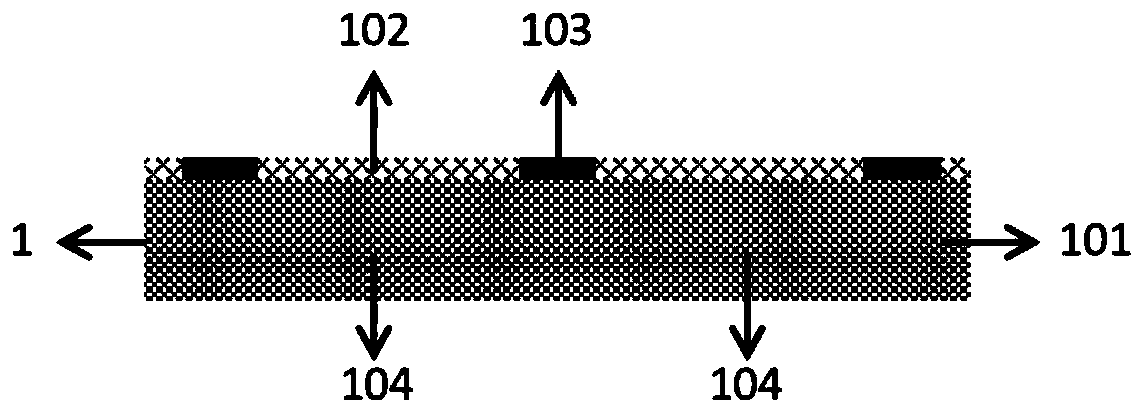

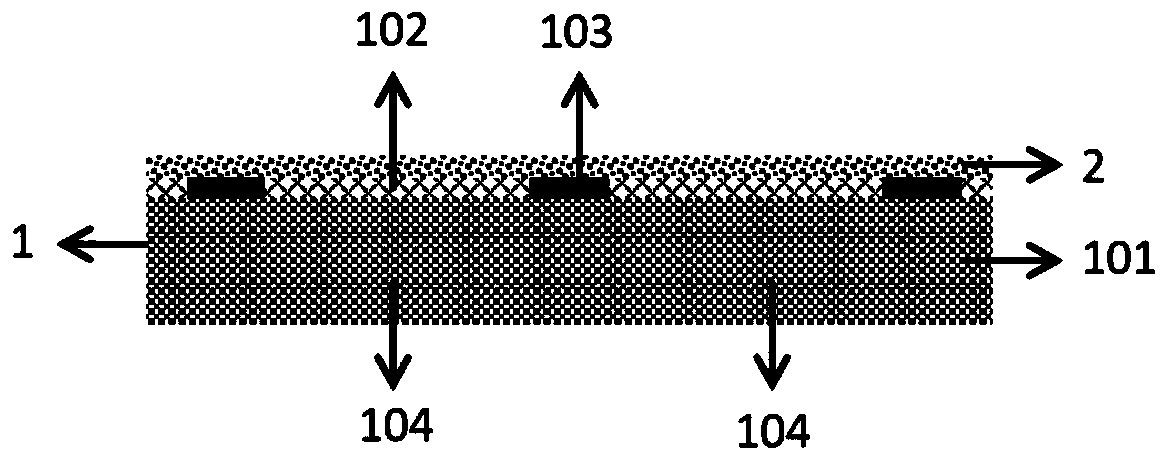

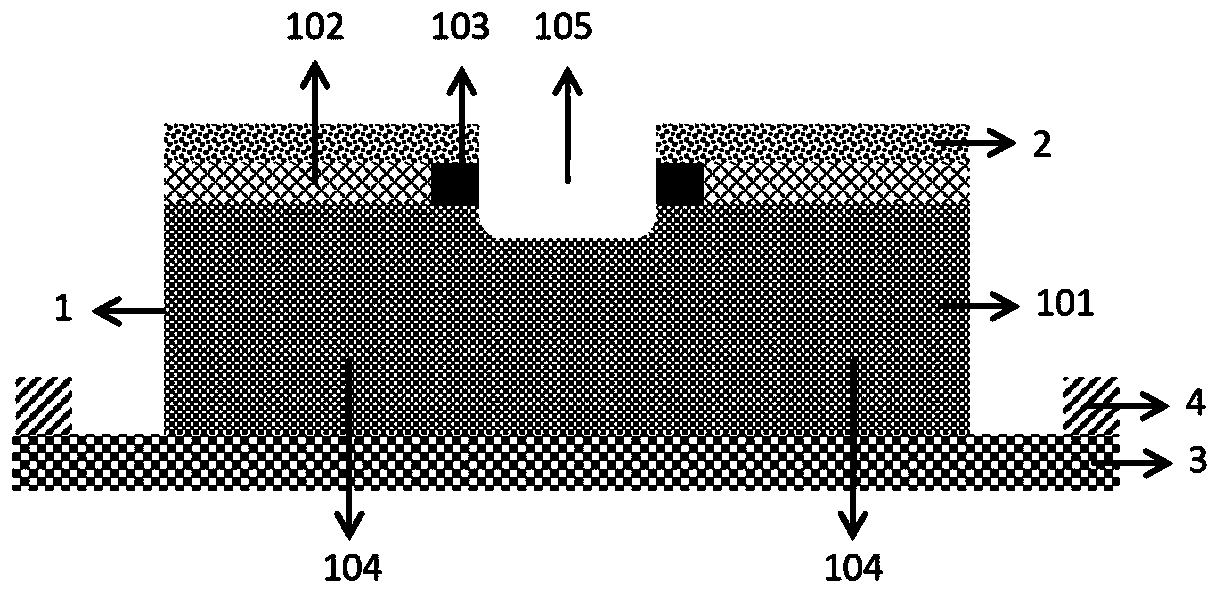

Process and device for producing thin prepreg

The invention discloses a process and a device for producing a thin prepreg. The process comprises the impregnation process; and before the impregnation process, a reinforcing material is arranged on a carrier so that the carrier directly acts on a roll shaft to share the acting force applied by the roll shaft on the reinforcing material. By arranging the reinforcing material on the carrier before the impregnation, the roll shaft can be prevented from being directly contacted with the reinforcing material, the pulling force directly applied from a device to the reinforcing material is effectively reduced, the condition that the reinforcing material is partially stressed unevenly is reduced, the thin reinforcing material is protected particularly, such phenomena as dislocation, shape change and tearing of the thin reinforcing material and the ultrathin prepreg are reduced, and the production efficiency and product percent of pass are improved.

Owner:GUANGDONG SHENGYI SCI TECH

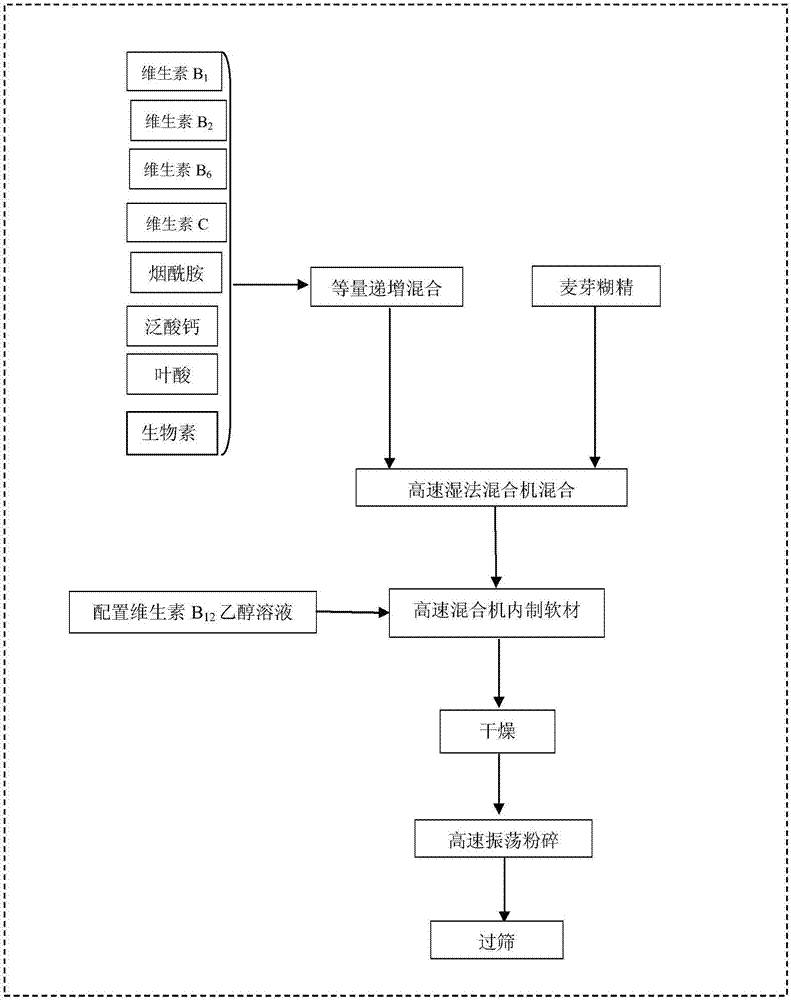

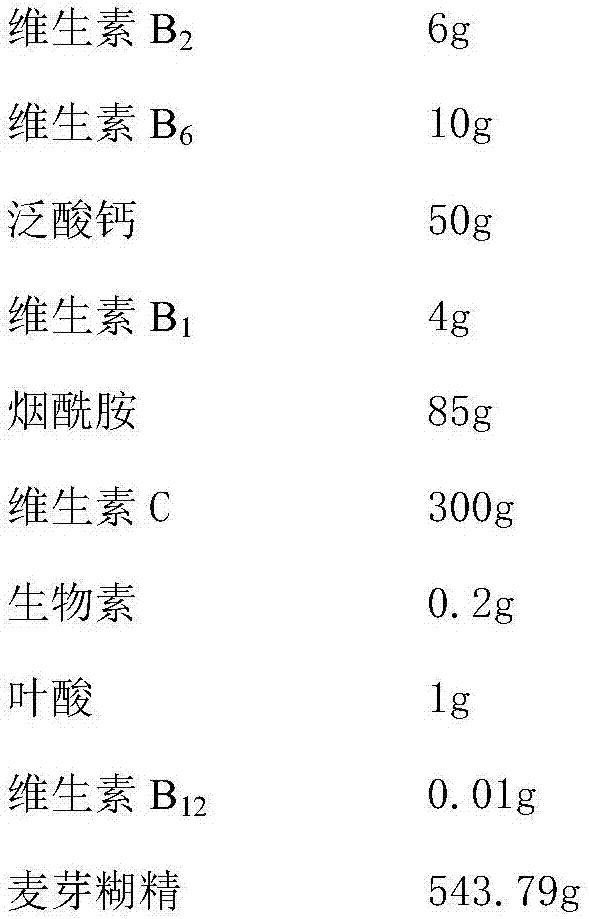

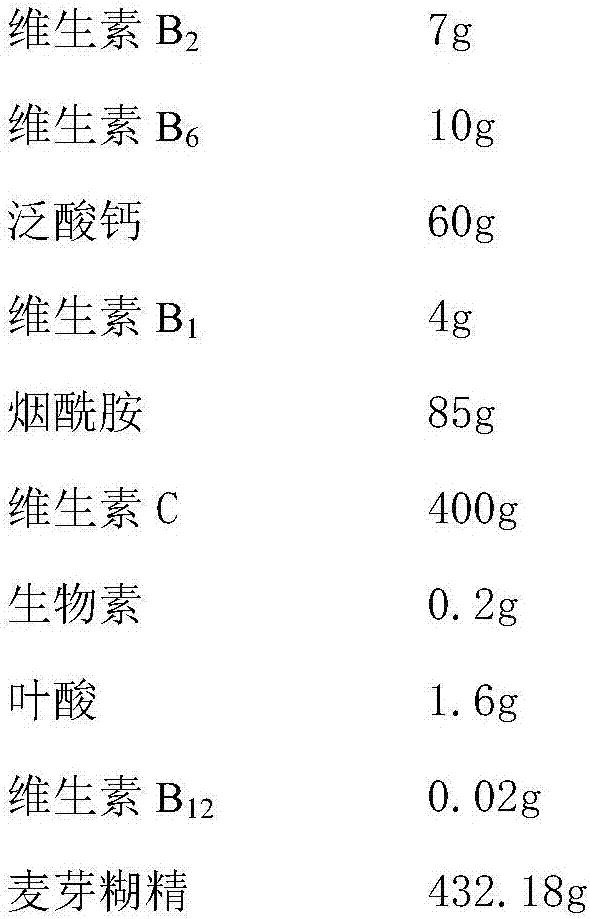

Vitamin premix suitable for soft capsule preparation and preparation method of vitamin premix

InactiveCN107969704AGuarantee the quality of productionEnhance physical fitnessMetabolism disorderCapsule deliveryChemistryFolic acid

The invention relates to a vitamin premix suitable for soft capsules and a preparation method of the vitamin premix. The vitamin premix comprises the following raw materials of vitamin B1, vitamin B2,vitamin C, nicotinamide, vitamin B6, calcium pantothenate, vitamin B12, biotin, folic acid and maltodextrin. The preparation method comprises the following steps of making the raw materials into softmaterials, performing drying, performing crushing, and performing screening so as to make uniform fine powder of which the fineness is greater than or equal to 100 meshes. According to the vitamin premix and the preparation method thereof, a technology for making the soft materials by a wet method material mixing manner is firstly used, so that the condition of component changes caused by spray drying and high temperature generally used in the preparation of the premix is avoided. The fineness of granules of the prepared vitamin premix can achieve 200 meshes, the materials are uniformly distributed, the classifying phenomenon in the production and transportation process cannot occur, and the stability is good.

Owner:山东禹王制药有限公司

Online detection method for leakage of W-shaped radiant tube of annealing furnace

InactiveCN110672789AGuarantee the quality of productionSave manpower and timeDetection of fluid at leakage pointMaterial analysisGalvanizationGas analyzer

The invention discloses an online detection method for the leakage of a W-shaped radiant tube of an annealing furnace and belongs to the technical field of annealing furnace equipment detection methods, and the method is used for detecting whether a W-shaped radiant tube of a cold-rolled galvanized vertical annealing furnace leaks or not. According to the technical scheme, the leakage detection isconducted on the W-shaped radiant tube through an online isolation detection method, according to the detection method, when a burner is in a closed state, for a normal radiant tube, a gas analyzer displays that O is larger than or equal to 20.9% and smaller than or equal to 21%, CO is equal to 0 ppm, and draft is larger than or equal to 8 mbar and smaller than or equal to 15 mbar. If the burneris in a closed state, the gas analyzer displays that a detection result that O is less than or equal to 20.9%, the radiant tube is damaged, and the change of a numerical value reflects the leakage degree of the radiant tube. The method is simple and convenient to operate, the production stop is not needed, radiant tubes can be detected one by one, the detection result is accurate, the atmosphere change in the furnace caused by the leakage of the radiant tubes is fundamentally eradicated, and the product quality is guaranteed.

Owner:TANGSHAN IRON & STEEL GROUP +1

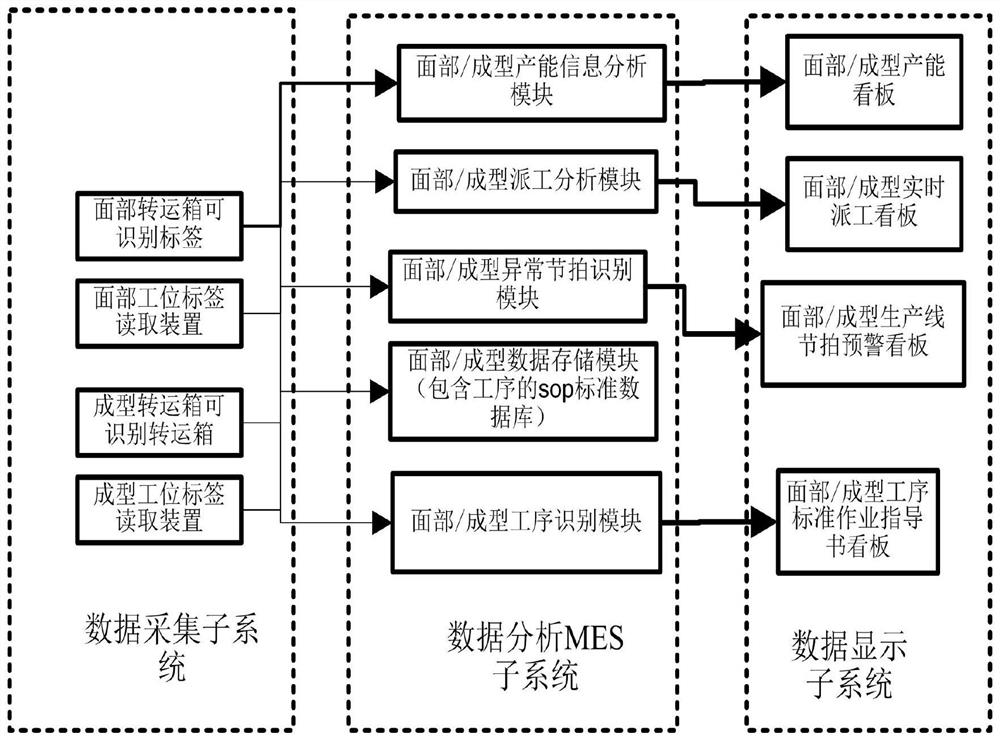

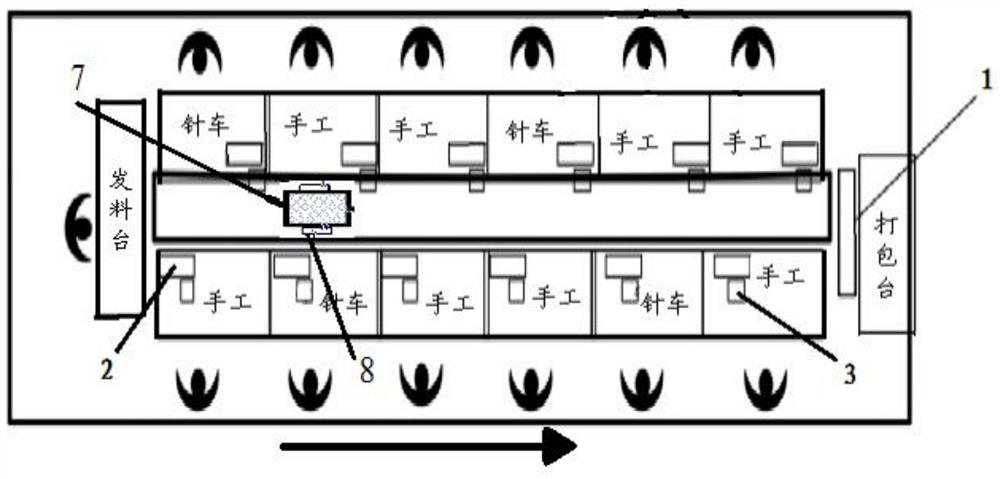

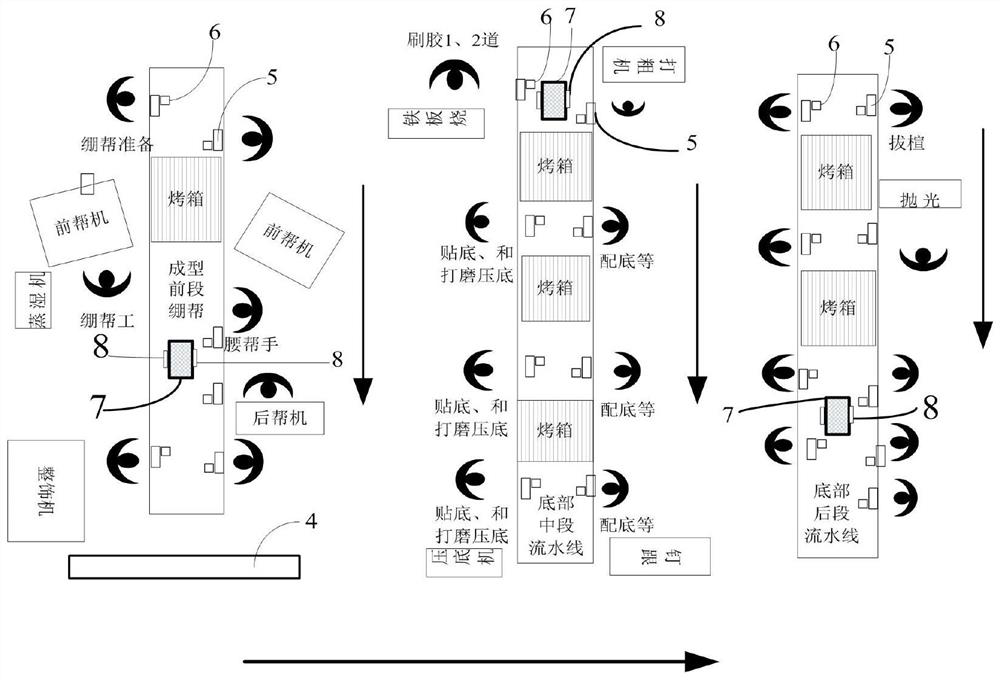

Intelligent management system and method for shoe production line

ActiveCN112415967AIncrease productivityGuarantee the quality of productionShoemaking devicesTotal factory controlCollections dataManagement system

The invention relates to an intelligent management system and method for a shoe industry production line, and the system comprises a data collection subsystem, a data analysis subsystem and a data display subsystem, and collects productivity information and worker information of the production line through the data collection subsystem, and transmits the productivity information and worker information to the data analysis subsystem, and the data analysis subsystem processes the information and displays and publishes the production line capacity condition required by a manager. Meanwhile, a capacity distribution scheme can be automatically generated, and intelligent management of the production line is realized, so that the production efficiency of the shoe production line is improved, leanproduction is realized, and shoe making enterprises are enabled.

Owner:SICHUAN UNIV +1

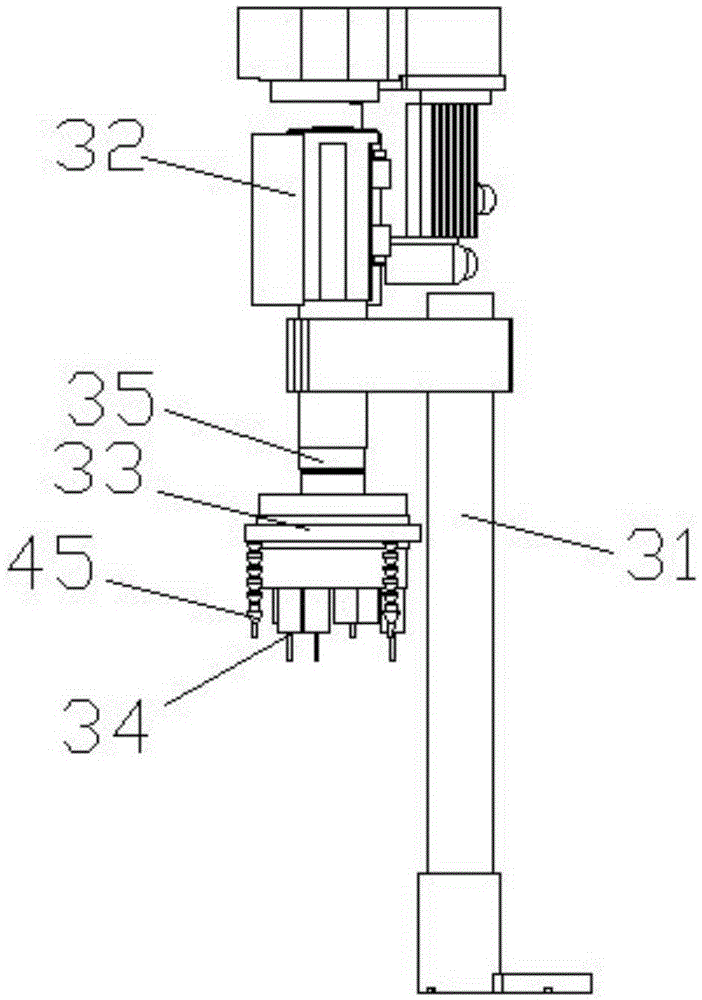

Porous tapping mechanism used for sliding table type porous tapping and drilling all-in-one machine

InactiveCN105382353AIncrease productivityGuarantee the quality of productionThread cutting machinesOther manufacturing equipments/toolsProduction qualityEngineering

The invention discloses a porous tapping mechanism used for a sliding table type porous tapping and drilling all-in-one machine, comprising a tapping fixing column, a tapping driver, a tapping multi-spindle tool and a screw tap; the tapping driver is fixed on the tapping fixing column; a tapping multi-spindle tool grip is arranged on the tapping driver; the tapping multi-spindle tool is arranged below the tapping multi-spindle tool grip; and the screw tap is arranged on the tapping multi-spindle tool. The porous tapping mechanism can complete drilling simultaneously in multiple hole sites, improve production efficiency and ensure production quality.

Owner:SUZHOU JINYIKANG AUTOMATION EQUIP

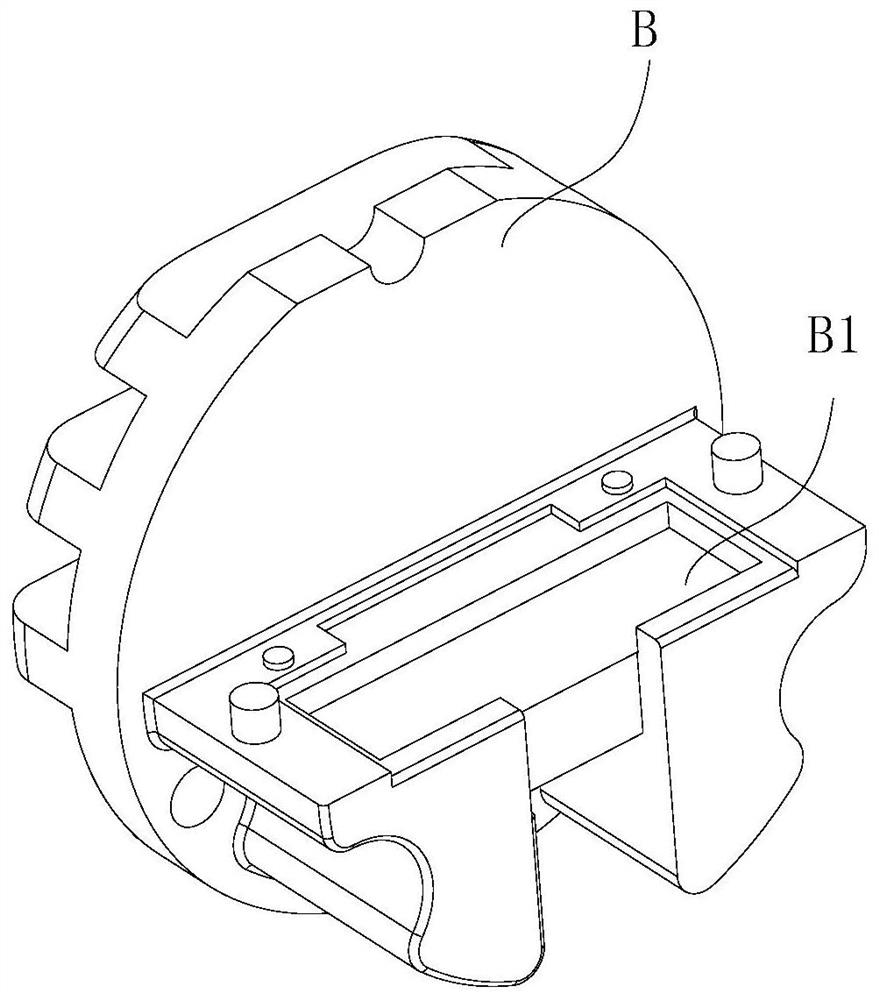

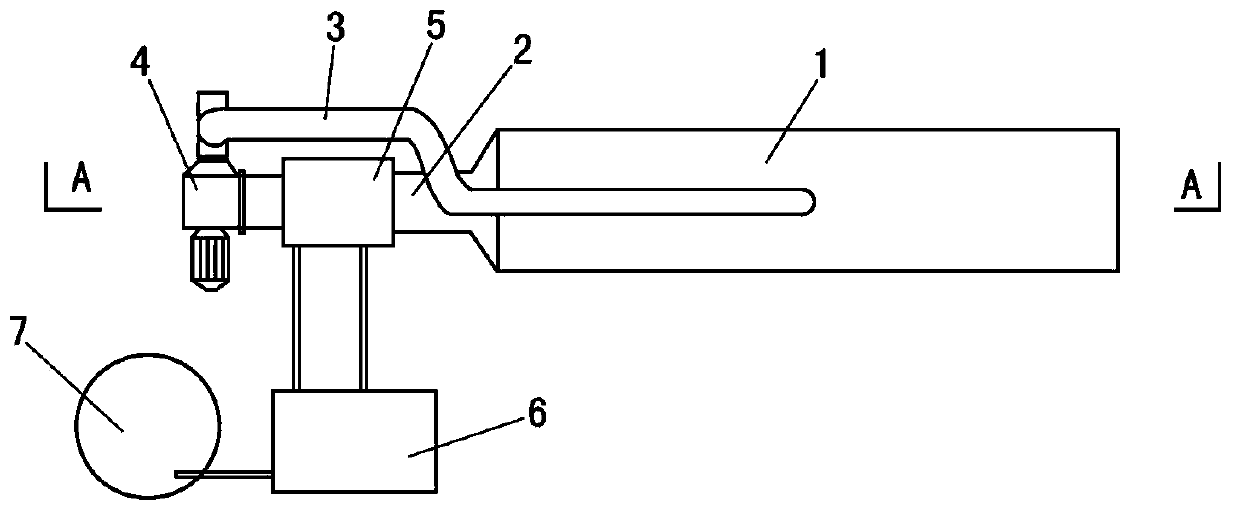

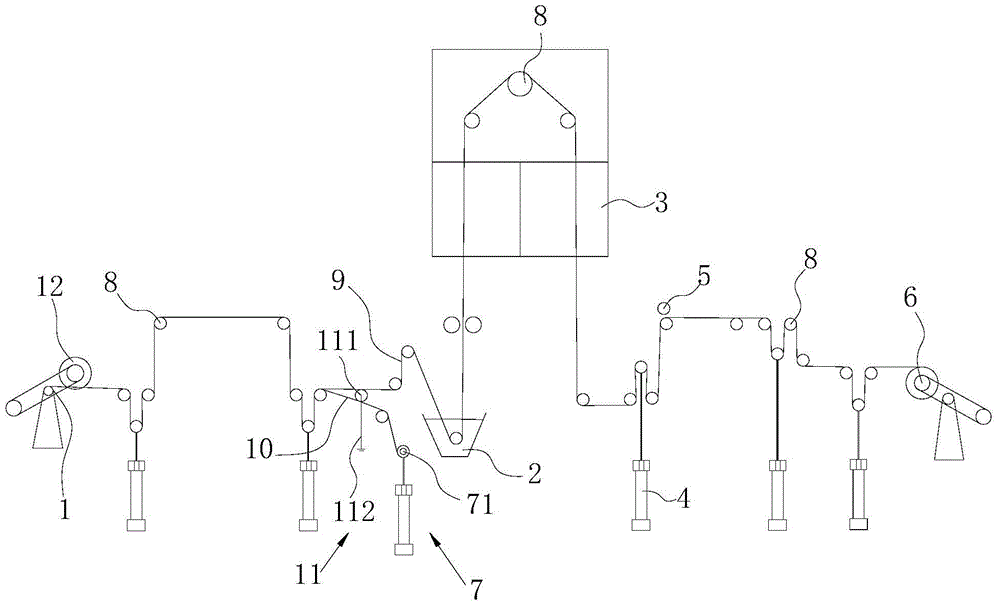

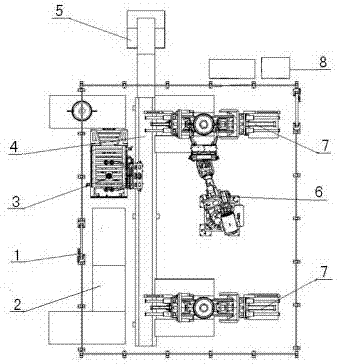

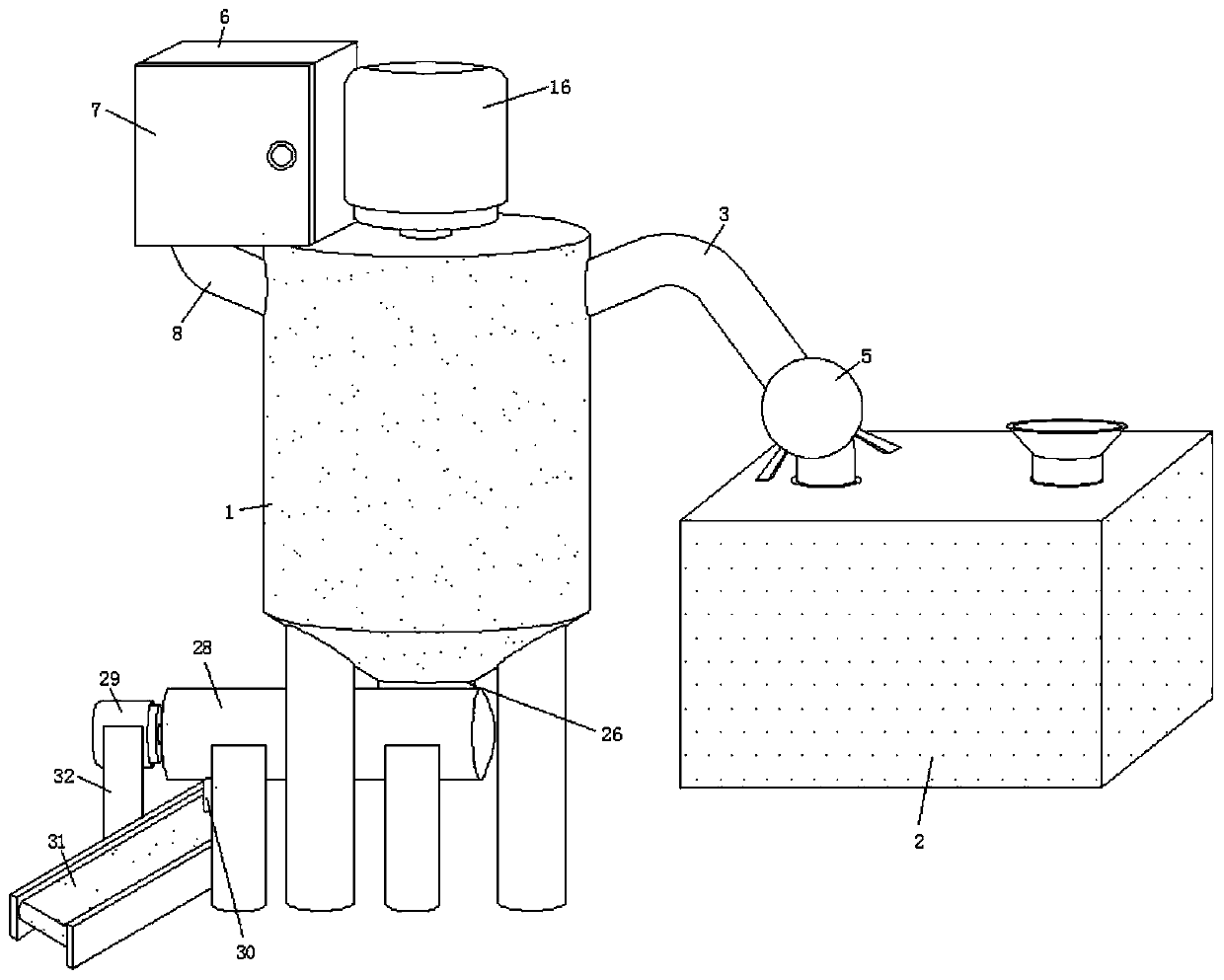

Production unit automatically breaking off hub casting lug

PendingCN107377951AIncrease productivityGuarantee the quality of productionRobotic systemsProcess engineering

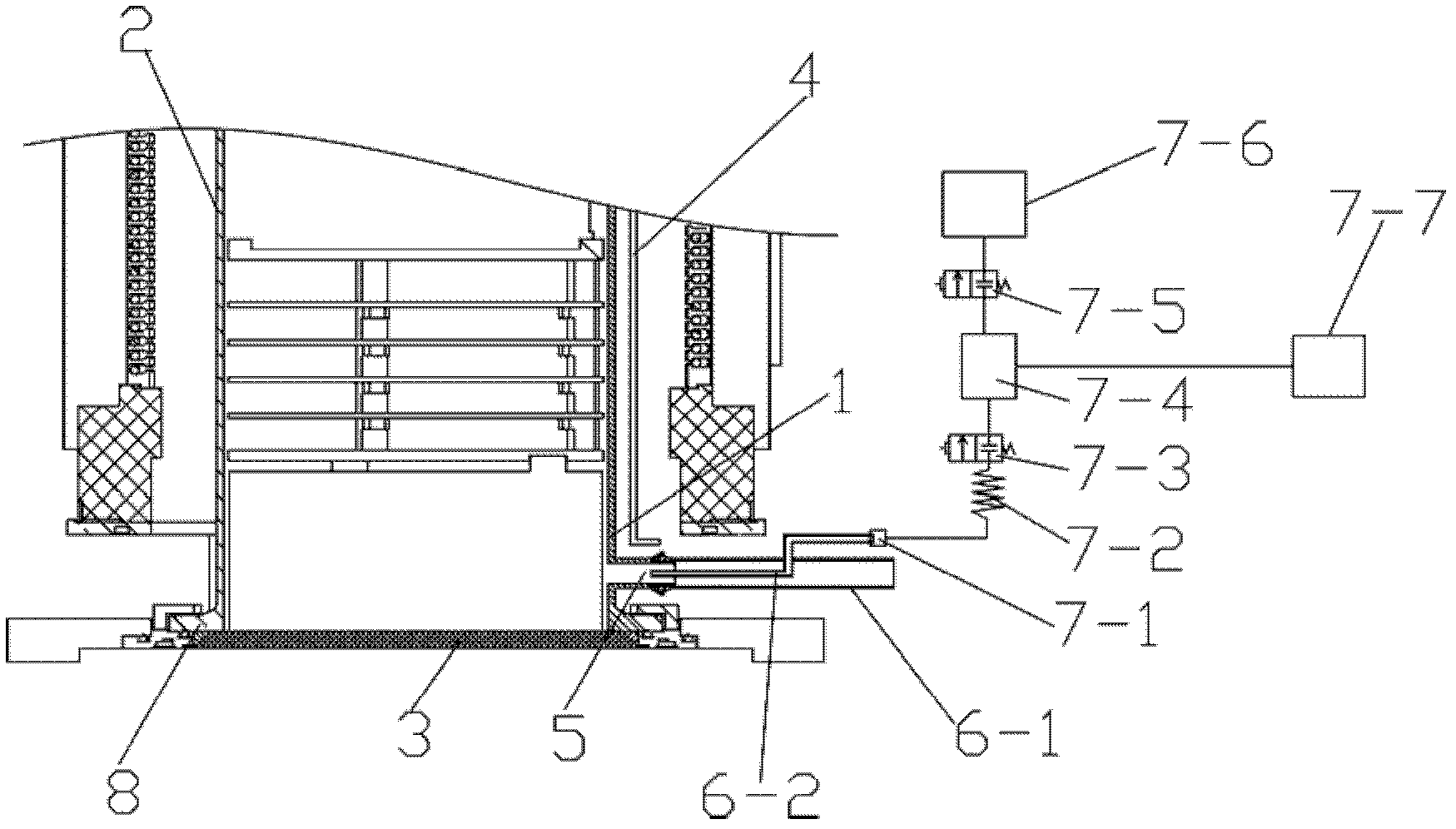

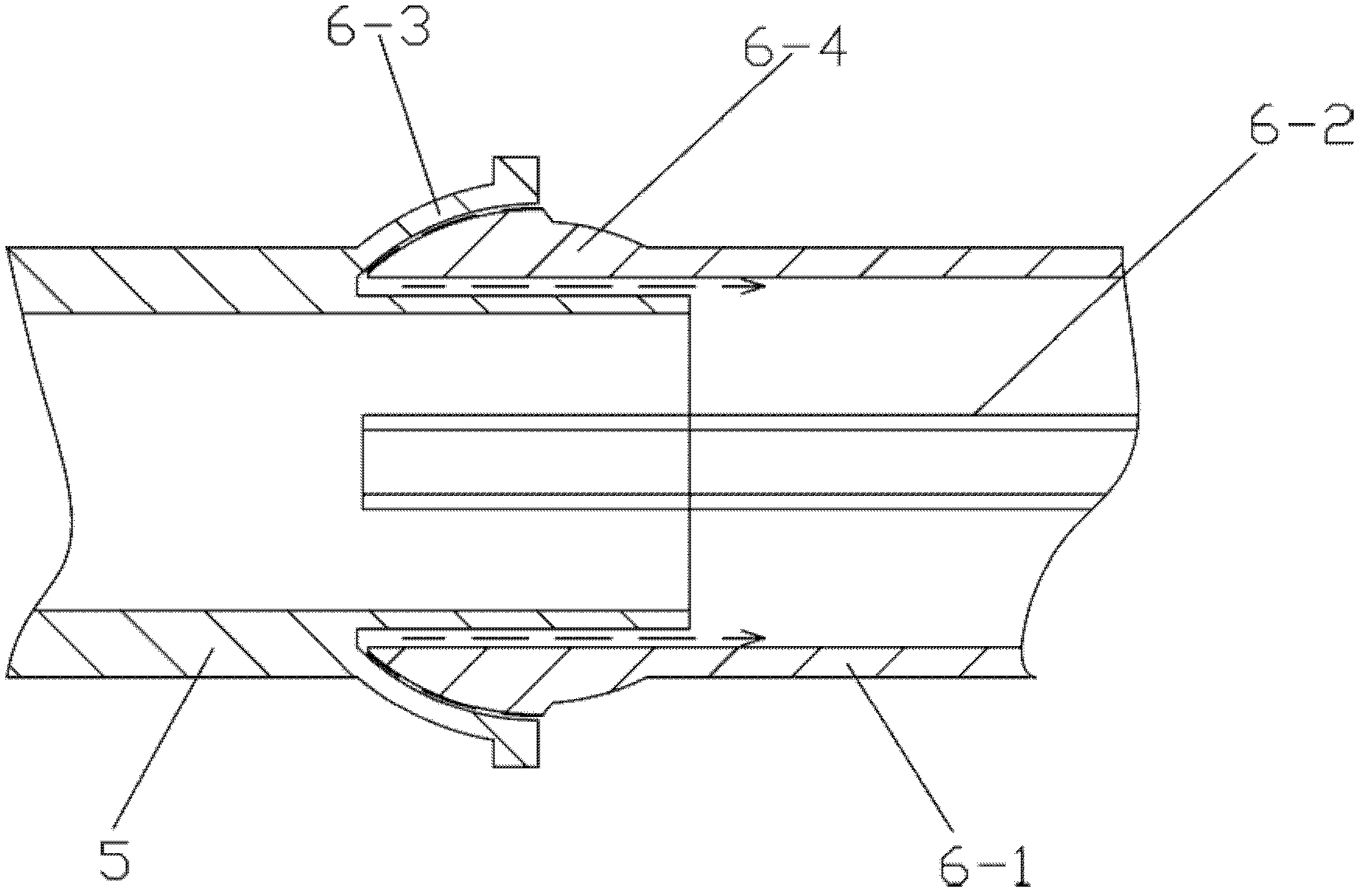

A production unit automatically breaking off a hub casting lug consists of a protective fence (1), a feeding-discharging logistic line (2), a casting lug servo identifying-positioning machine (3), an automatic waste material discharging device (4), a waste material box (5), a robot (6), casting lug breaking machines (7) and a control case (8) and is surrounded by the periphery of the protective fence (1), wherein the feeding-discharging logistic line (2) is provided with a feeding port and a discharging port, the casting lug servo identifying-positioning machine (3) is arranged in the middle of the feeding-discharging logistic line (2), the waste material box (5) is connected to the automatic waste material discharging device (4), the automatic waste material discharging device (4) is arranged on one side of two casting lug breaking machines (7), the robot system (6) operates in the production unit, and the control case (8) is arranged on one side of the production unit. One robot can be simultaneously matched with two breaking machines, the production tact is effectively mastered, the production efficiency is greatly improved, and the heavy production work of workers is thoroughly liberated.

Owner:江苏天宏智能装备有限公司

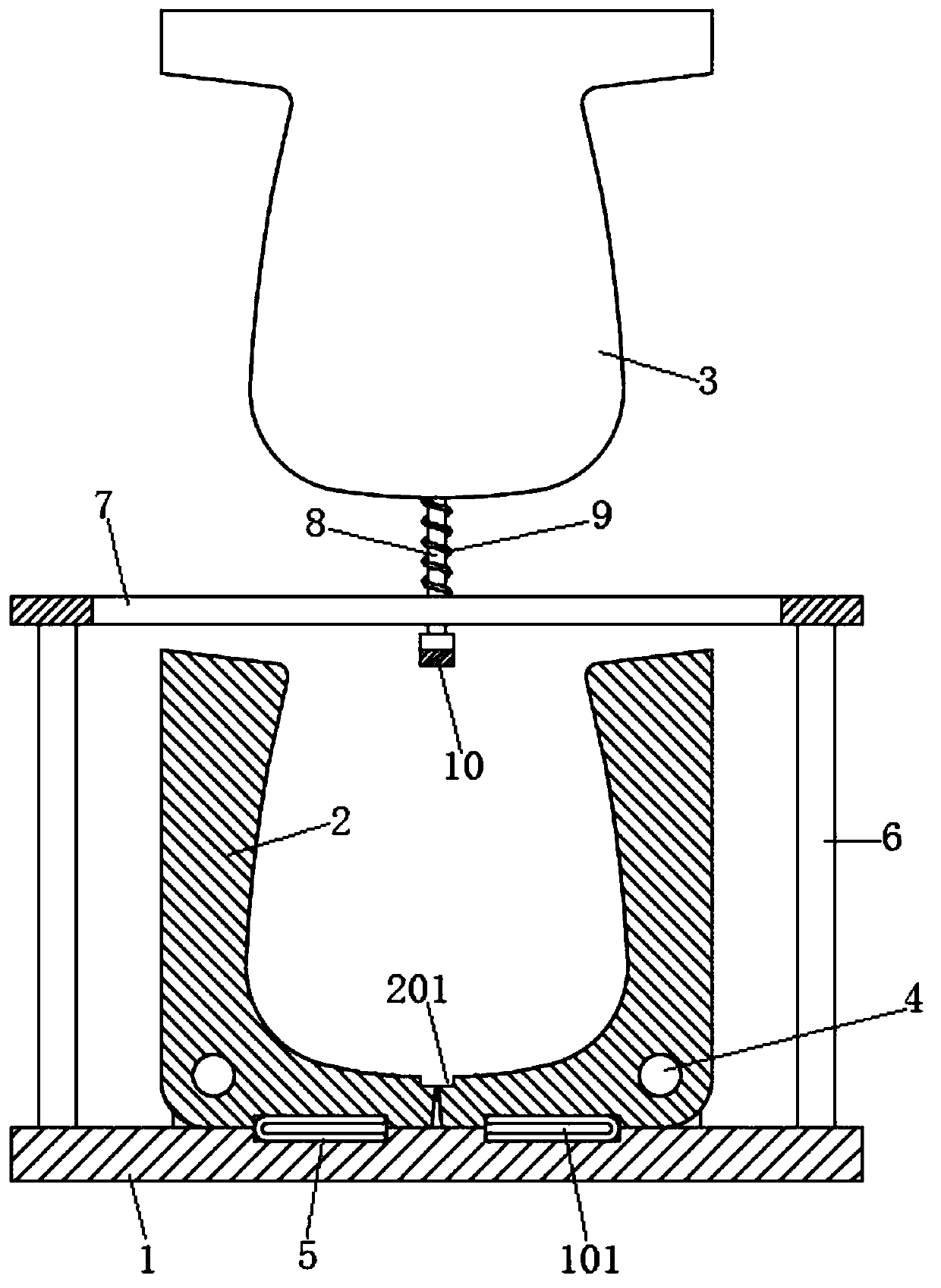

Stamping die for hoop forming

InactiveCN111360160AImprove forming effect and stamping efficiencyGuarantee the quality of productionShaping toolsStructural engineeringMechanical engineering

The invention discloses a stamping die for hoop forming, and relates to the technical field of mechanical forming. The stamping die comprises a base plate, a female die and a male die, wherein the female die comprises a pair of half-shaped dies which are oppositely arranged, and the lower parts of the half-shaped dies are rotatably connected to the upper surface of the base plate through rotatingshafts; the male die is arranged right above the female die; a pair of mounting grooves are symmetrically formed in the upper surface of the base plate, the two mounting grooves are in a one-to-one correspondence to the two half-shaped dies, elastic sheets are arranged in the mounting grooves, and the elastic sheets are connected with the lower parts of the half-shaped dies; and supporting columnsare vertically arranged on the opposite sides of the female die, the upper ends of the two supporting columns are connected through an undertaking frame, and the undertaking frame is provided with apositioning component used for limiting the position of a piece to be pressed. The stamping die not only has simple and reasonable structural design and convenient use, but also effectively improves the forming effect and stamping efficiency of the piece to be pressed, and has higher market application value.

Owner:HEFEI ZHENGTE MACHINERY CO LTD

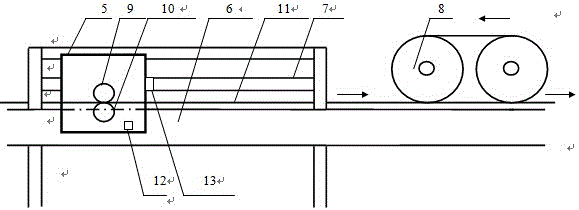

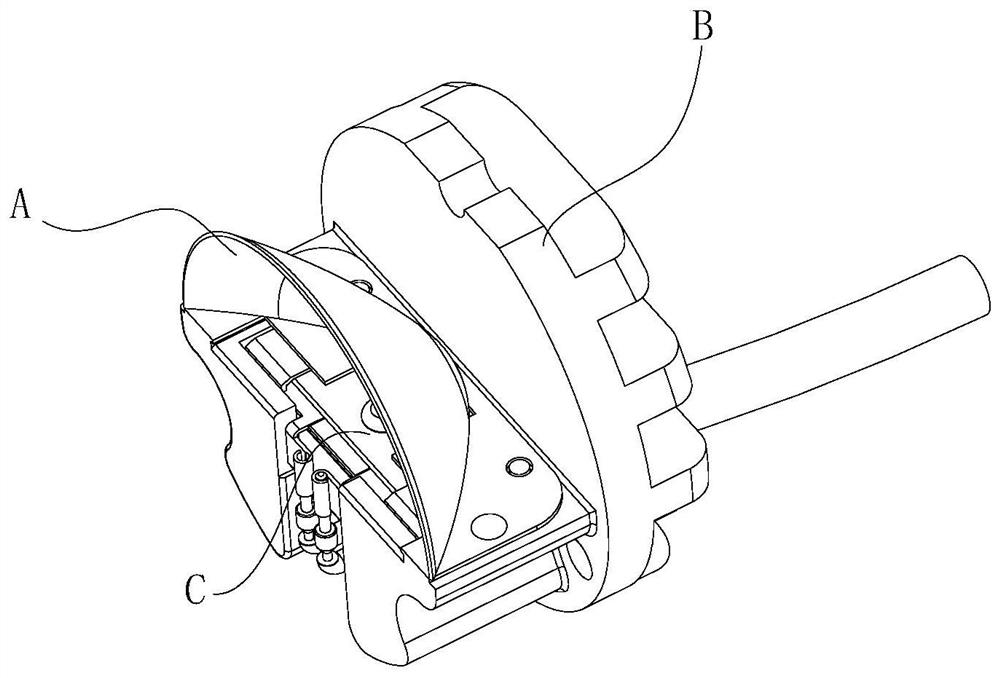

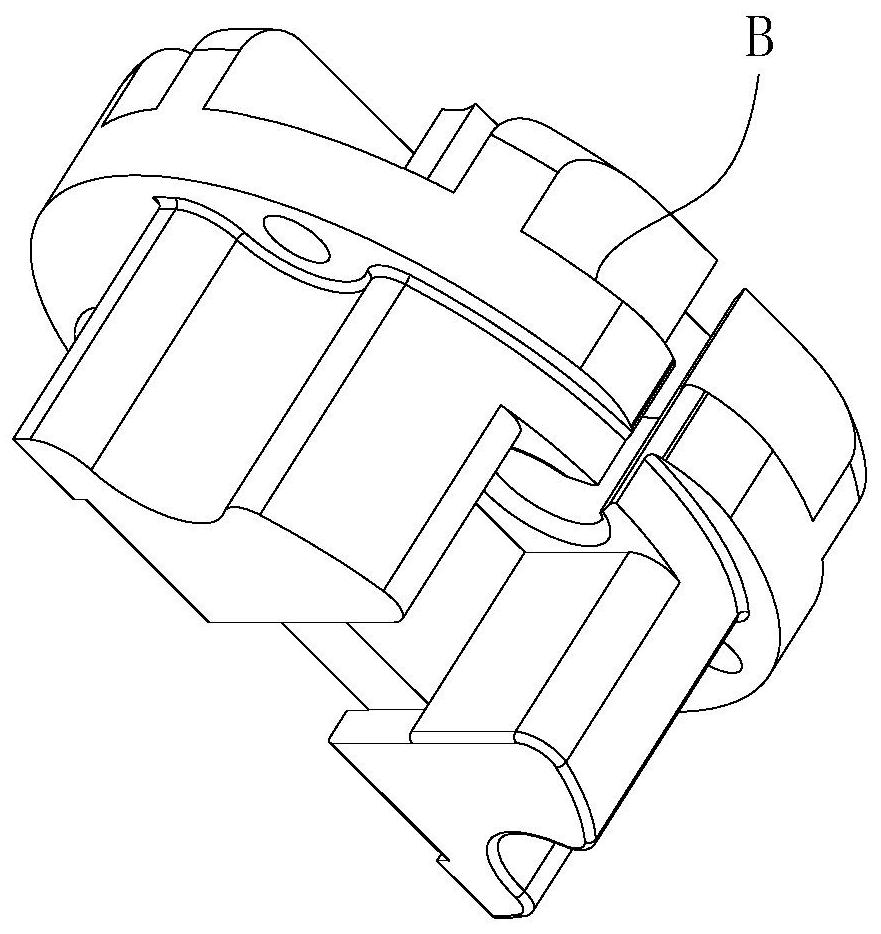

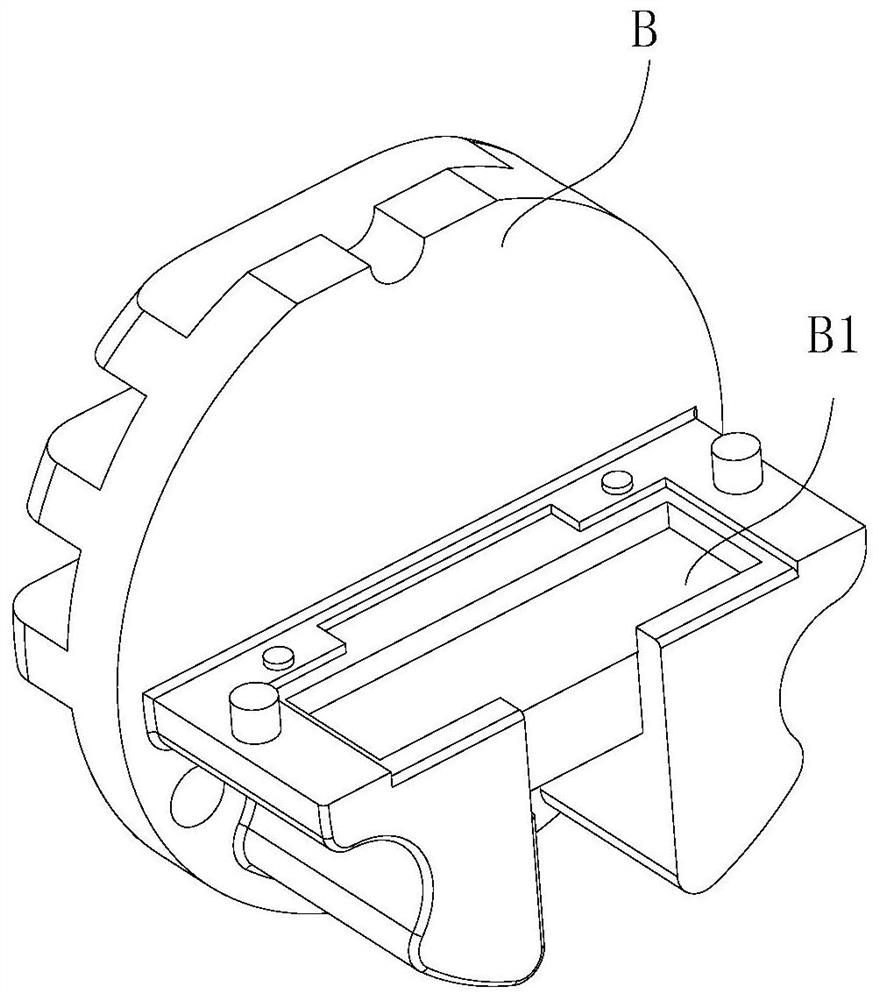

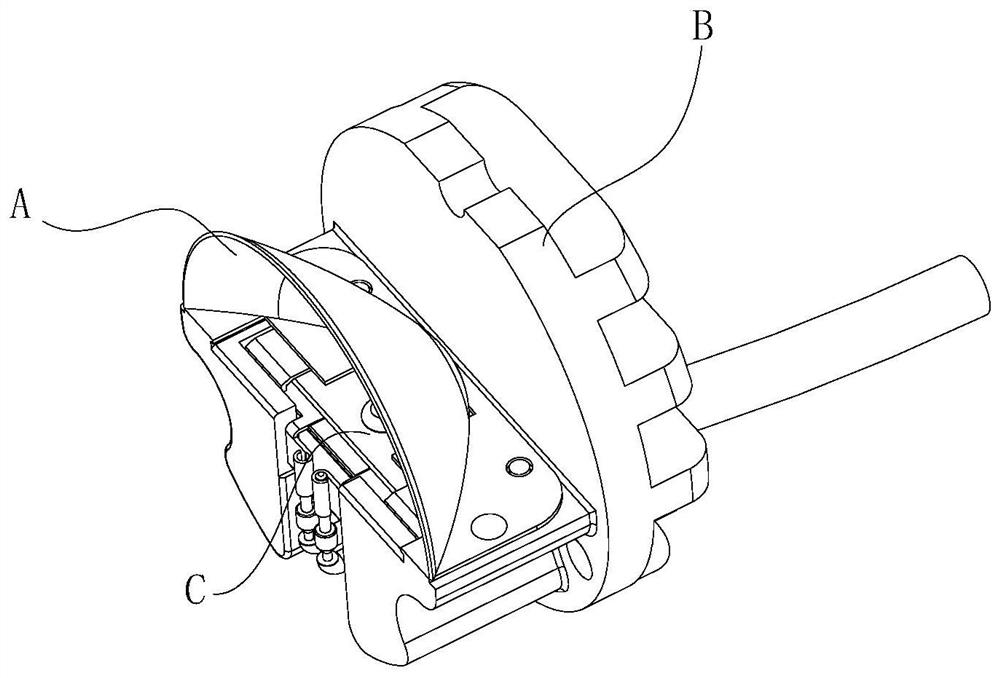

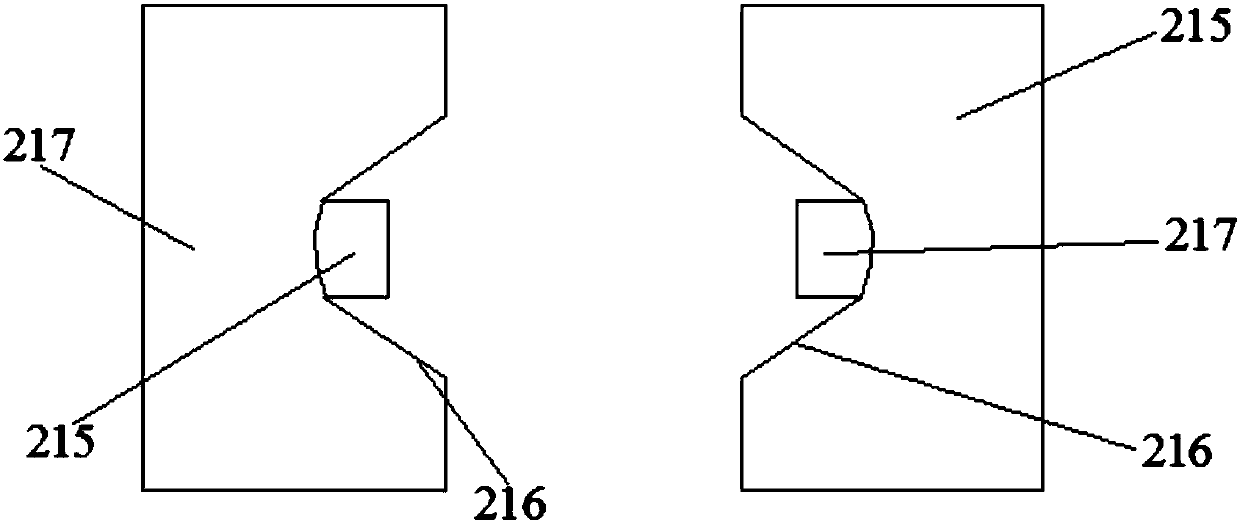

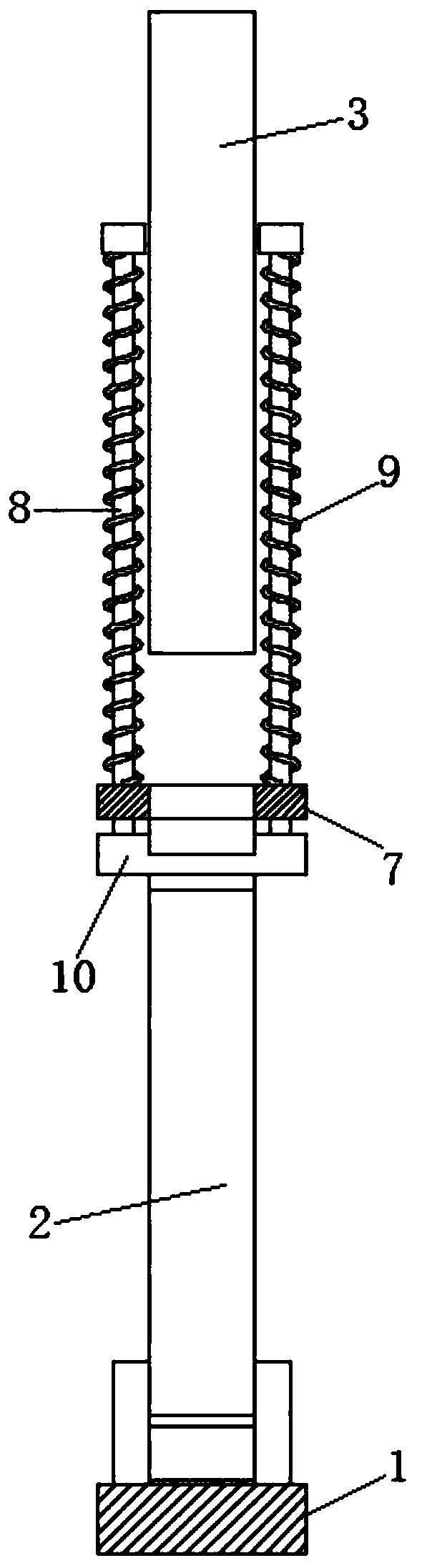

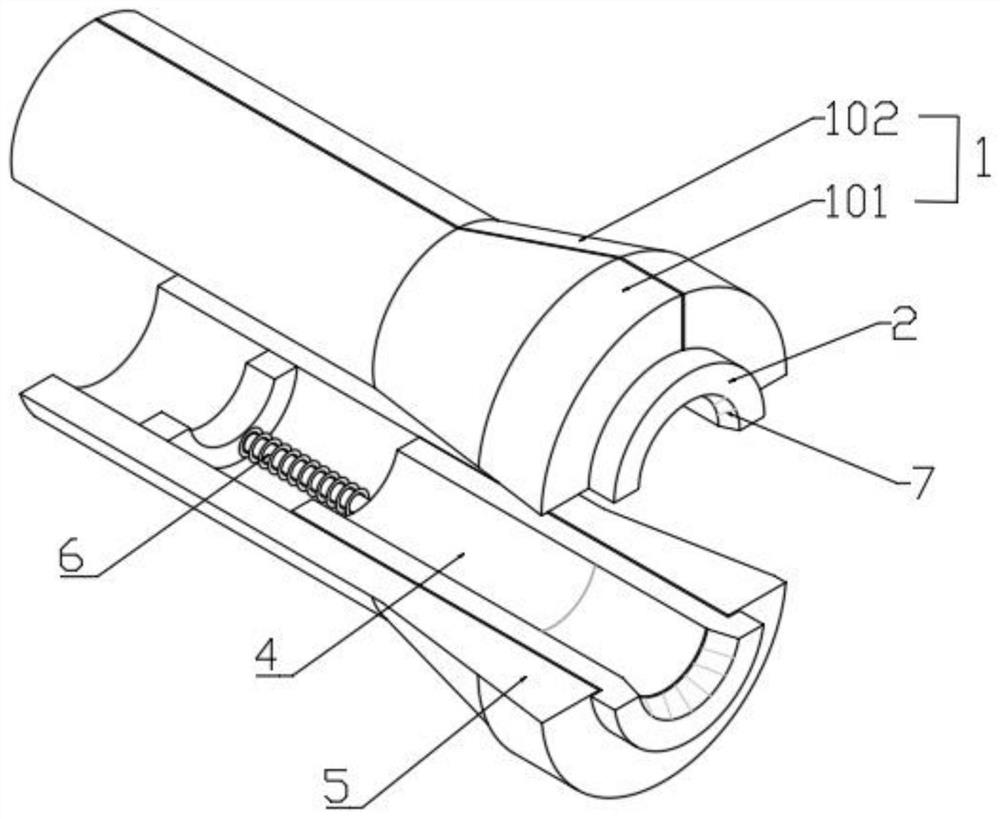

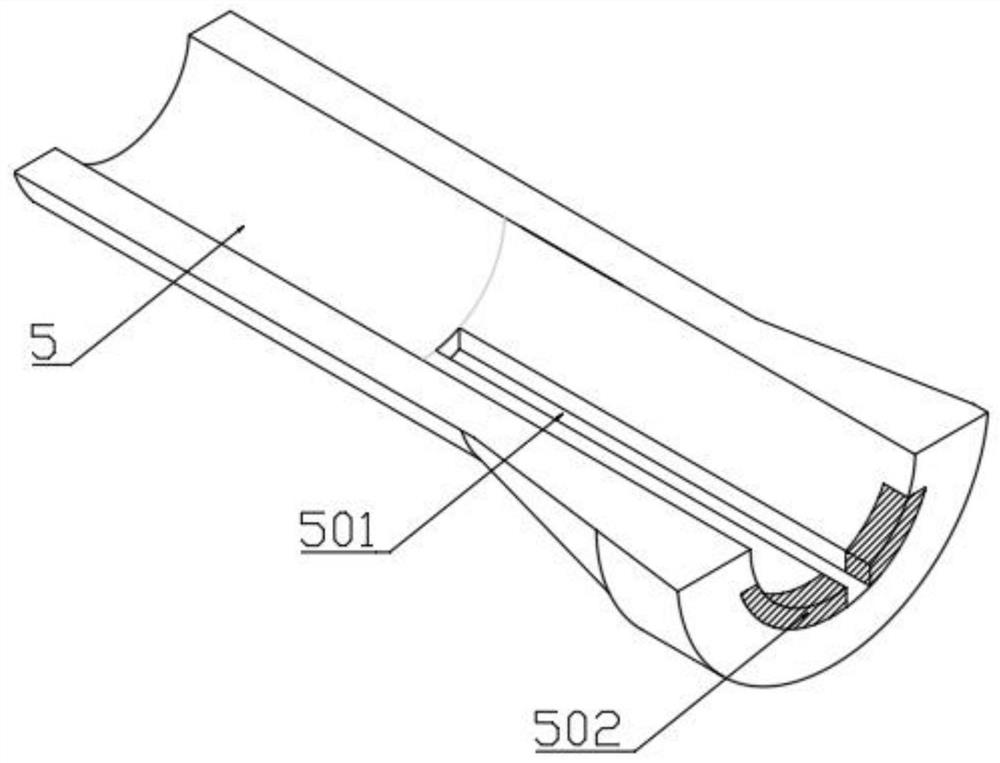

Specially-shaped part clamping equipment of numerically-controlled lathe

InactiveCN111673492AClamping is firmGuarantee the quality of productionWork clamping meansPositioning apparatusBell mouthStructural engineering

The invention provides specially-shaped part clamping equipment of a numerically-controlled lathe, belongs to the technical field of tool fixtures, and aims to solve the problems that existing tool fixtures of numerically-controlled lathes are single in function, specially-shaped parts cannot be clamped directly, the production precision is difficult to guarantee and the production quality is reduced. The equipment comprises an upper clamping plate; each of the upper clamping plate and a lower clamping plate adopts the half-cylindrical-pipe-shaped structure; the front end of the upper clampingplate and the front end of the lower clamping plate are distributed in the half-horn shapes. According to the equipment, an upper cushion block and a lower cushion block are added to the outside of aspecially-shaped casing pipe part, a first arc-shaped surface is formed at the front end of the upper cushion block, a second arc-shaped surface is formed at the front end of the lower cushion block,the arc-shaped surfaces are matched with the horn mouth part of the specially-shaped casing pipe part in diameter, the specially-shaped casing pipe part is clamped between the cushion blocks during clamping, the middle section of the part can be thickened, the horn mouth can be avoided, the specially-shaped casing pipe part can be clamped firmly, the specially-shaped part can be clamped easily and quickly, the influence of the specially-shaped part on production and machining can be eliminated, and the production quality is guaranteed.

Owner:湖北豪凯汽车零部件有限公司

Wafer separation method

InactiveCN110379771APrevent metal layer from liftingGuarantee the quality of productionSolid-state devicesSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringMetal

The invention discloses a wafer separation method, which is used for separating a wafer into a plurality of independent chips according to cutting channels arranged on a wafer circuit layer, wherein the cutting channel includes a metal layer and / or a low-k layer. The wafer separation method includes the steps of firstly attaching layer of transparent protective film to the surface of the wafer circuit layer; and then separating the wafer into a plurality of independent chips according to the cutting channels by using a mechanical cutting method. According to the invention, the problems of tilting and corner collapse of the metal layer and / or stripping and cracking of the low-k layer and the like in the cutting channels during the mechanical cutting process are effectively prevented throughsimply attaching a layer of transparent protective film to the surface of the wafer circuit layer, so that the wafer separation scheme of full mechanical cutting can be realized, and the production cost is effectively reduced while the production quality is ensured.

Owner:苏州长瑞光电有限公司

Easy-to-clean material mixing device used for production of bagged mini breads

ActiveCN111357784AEnsure thorough mixingGuarantee the quality of productionMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsChemistryEngineering

The invention discloses an easy-to-clean material mixing device used for production of bagged mini breads. The material mixing device comprises a material mixing barrel; one side of the material mixing barrel is provided with a wheat flour storage assembly; the wheat flour storage assembly includes a wheat flour storage vessel; the inner wall of the wheat flour storage vessel is glidingly connected with a partition plate; the side, away from the mixing barrel, of the inner bottom face of the wheat flour storage vessel is fixedly connected with a servo motor I by a screw; an output end of the servo motor I is fixedly connected with a screw rod through a coupling; a rolling groove is further formed in the bottom face of the partition plate; a feeding tube is further connected with the side,away from the mixing barrel, of the upper end of the wheat flour storage vessel in a penetrating manner; and a flour suction tube is further connected in a penetrating manner between the other side ofthe upper end of the wheat flour storage vessel and the side wall of the top part of the material mixing barrel. The invention has a good mixing effect on raw materials of the mini breads, and a negative pressure sucking way is employed during feeding of wheat flour, which very well avoids the phenomenon that flour in the center of a dough obtained after material mixing is unmixed due to accumulation of the wheat flour, and accordingly, a certain quality guarantee is provided for high-quality production of the mini breads.

Owner:ANHUI PANPAN FOOD CO LTD

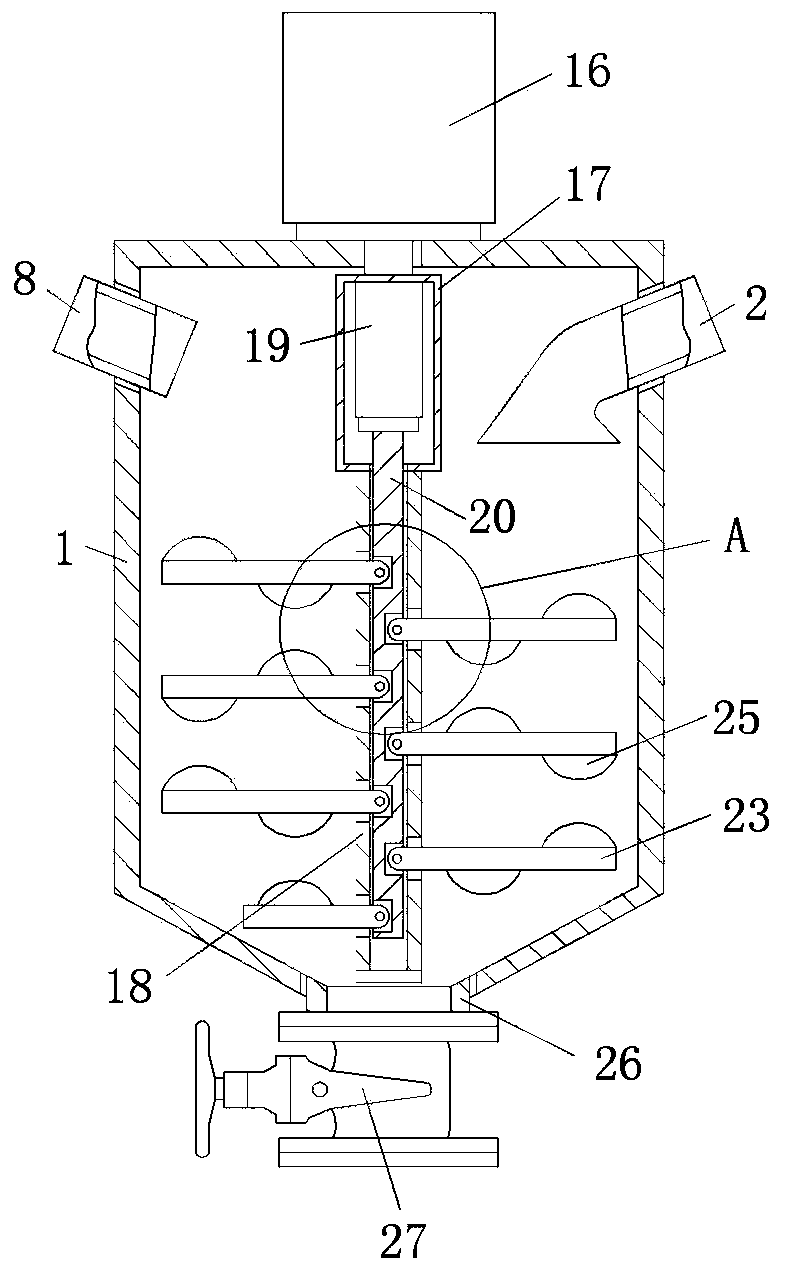

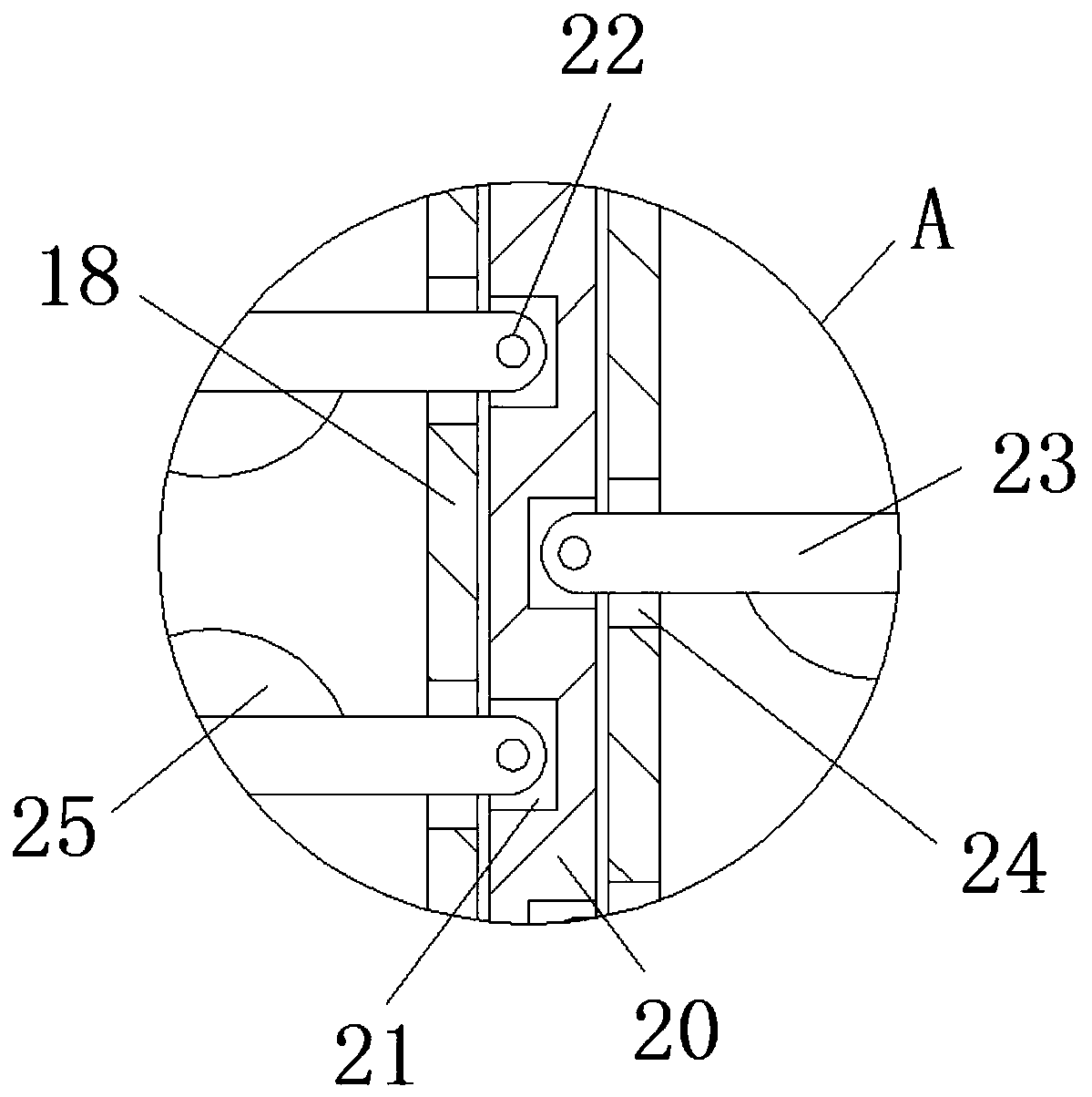

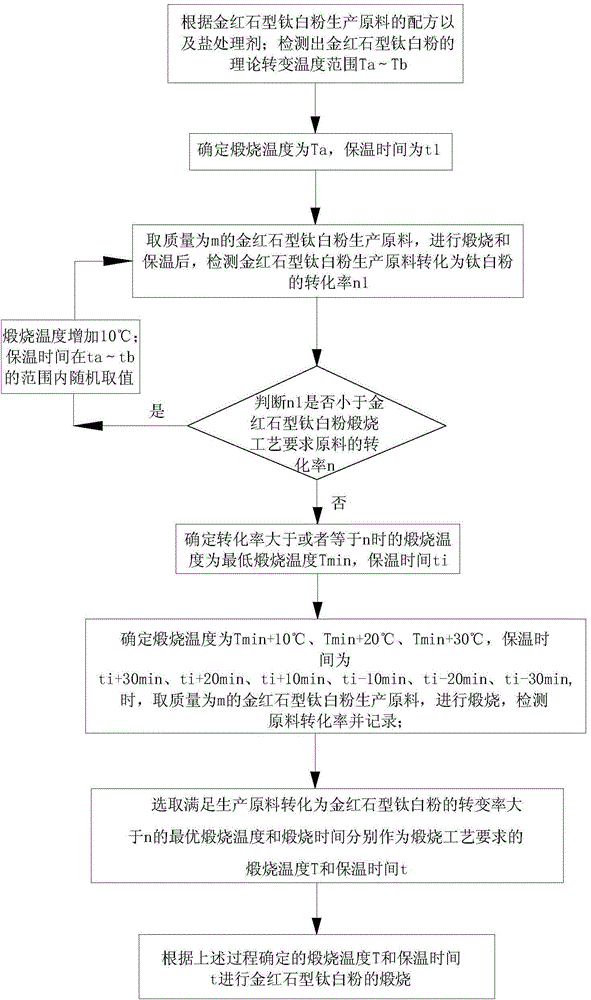

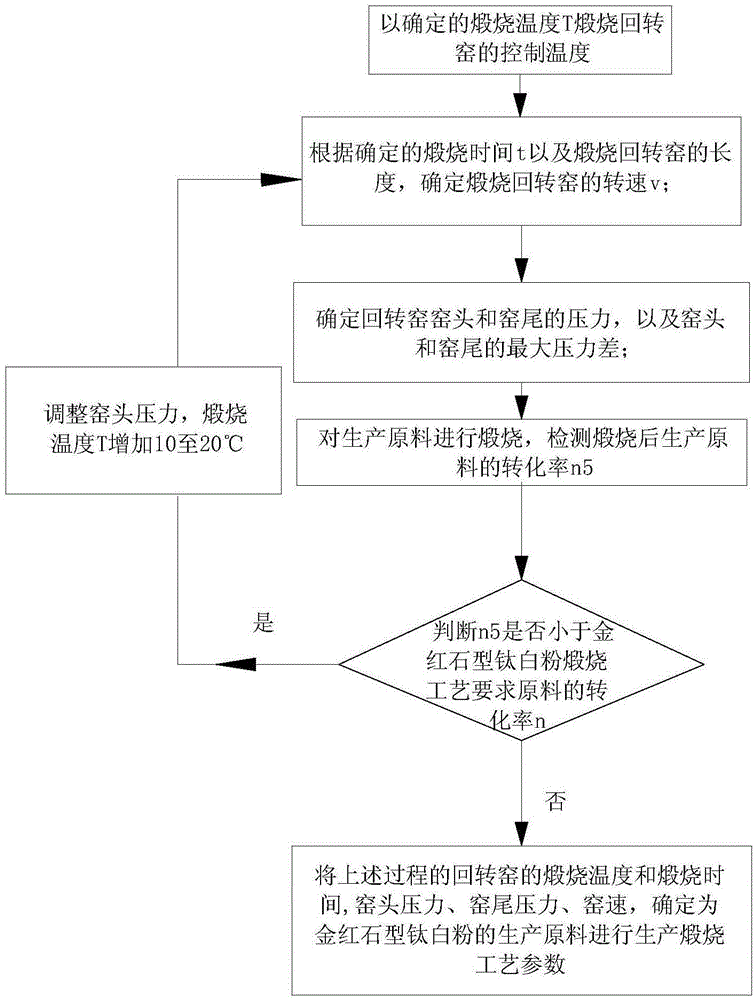

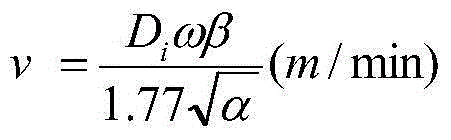

Calcining method for preparing rutile-type titanium dioxide powder

InactiveCN104591274AShort holding timeGuarantee the quality of productionTitanium dioxideHolding timeDioxide titanium

The invention discloses a calcining method for preparing rutile-type titanium dioxide powder and capable of reducing the energy consumption in the production process of rutile-type titanium dioxide powder. The calcining temperature and holding time in the calcining process of the method are determined by the following manner: determining a theoretical conversion temperature range and the holding time range of raw materials for the production; determining specific calcining temperature and the holding time and calcining a sample of the raw materials, if the conversion rate is not in line with production process requirements, adjusting the calcining temperature and the holding time again and calcining a sample of the raw materials until the conversion rate is in line with production process requirements; and based on the calcining temperature T and the holding time t, respectively calcining the sample of the raw materials at the calcining temperatures of T+10, T+20, T+30 (DEG C) and holding times of t-30, t-20, t-20, t+10, t+20 and t+30 (minutes) and detecting to obtain the optimal calcining temperature and the holding time. By the method, the energy consumption in the production is reduced and the production cost is decreased.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Chemical fiber isothermal die

InactiveCN102493005ASame wire diameterGuarantee the quality of productionArtificial thread manufacturing machinesFilament/thread formingHeating systemFiber

The invention relates to a chemical fiber isothermal die, which is provided with a fiber spraying device, a metering pump and a medium heat-conductive heating system, wherein the fiber spraying device is arranged at the center of the bottom of the die, and the metering pump is arranged on the upper portion of the fiber spraying device. The medium heat-conductive heating system comprises a storage box used for containing heating media and covered outside the periphery of fiber spraying device and the metering pump, heating tubes are arranged in the storage box, and a heat insulation layer is wrapped outside the medium heat-conductive heating system. The heating system outside the die heats in a conducting manner by means of external media, the temperature of the heating media in the storage box rises after the heating media is heated by the heating tubes, and the temperature in each portion of the storage box is uniform due to heat transmission, so that uniform heating is realized. Further, by the aid of the additional heat insulation layer, the values of temperature of different portions of the die are equal, and accordingly, the diameters of fibers sprayed by the fiber spraying device are equal and production quality is guaranteed.

Owner:曾华良

Processing device and method for product capable of tonifyig qi and blood, delaying ageing and improving facial appearance

InactiveCN109805392AIncrease productivityGuarantee the quality of productionRotary stirring mixersFood scienceProduct processingFacial appearance

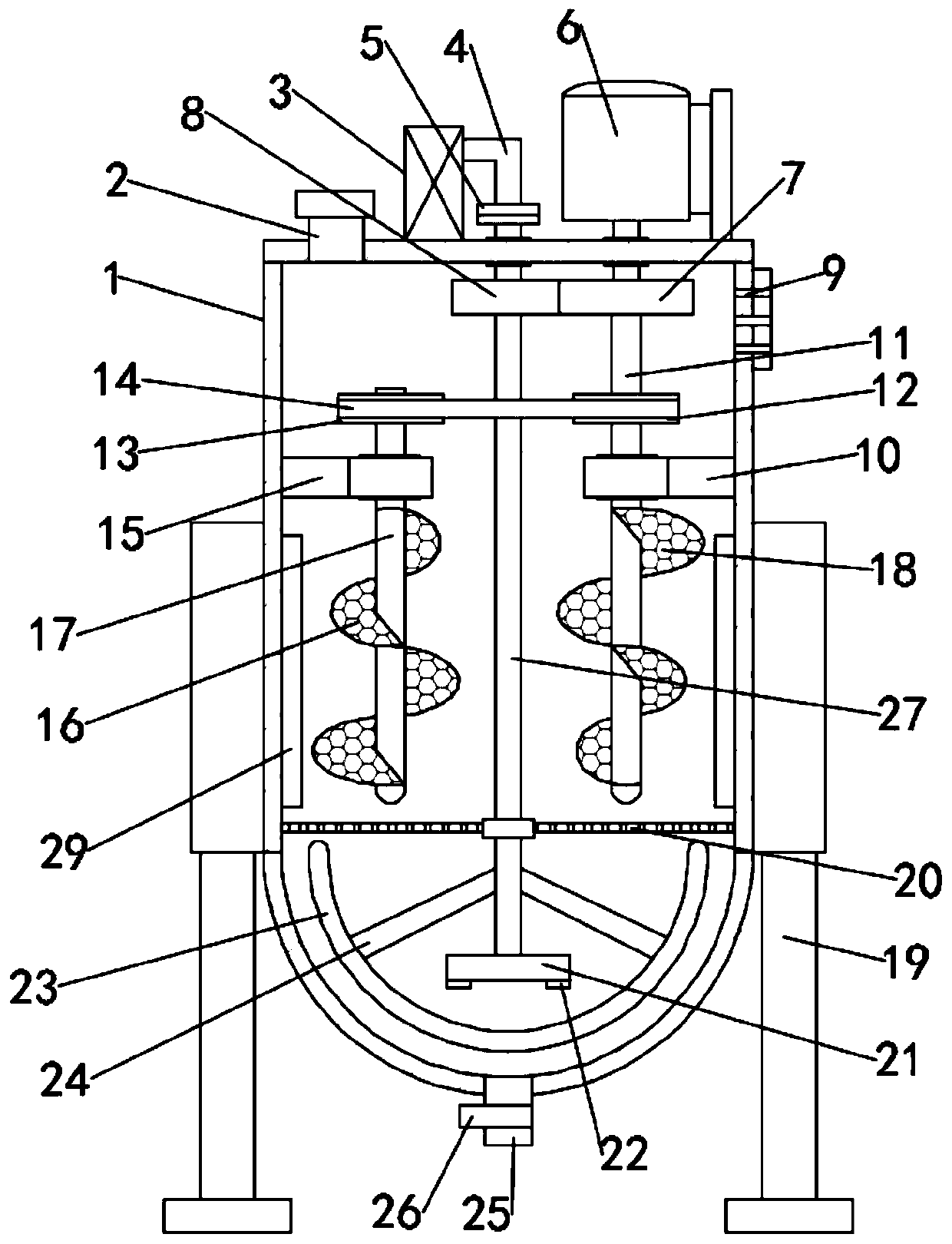

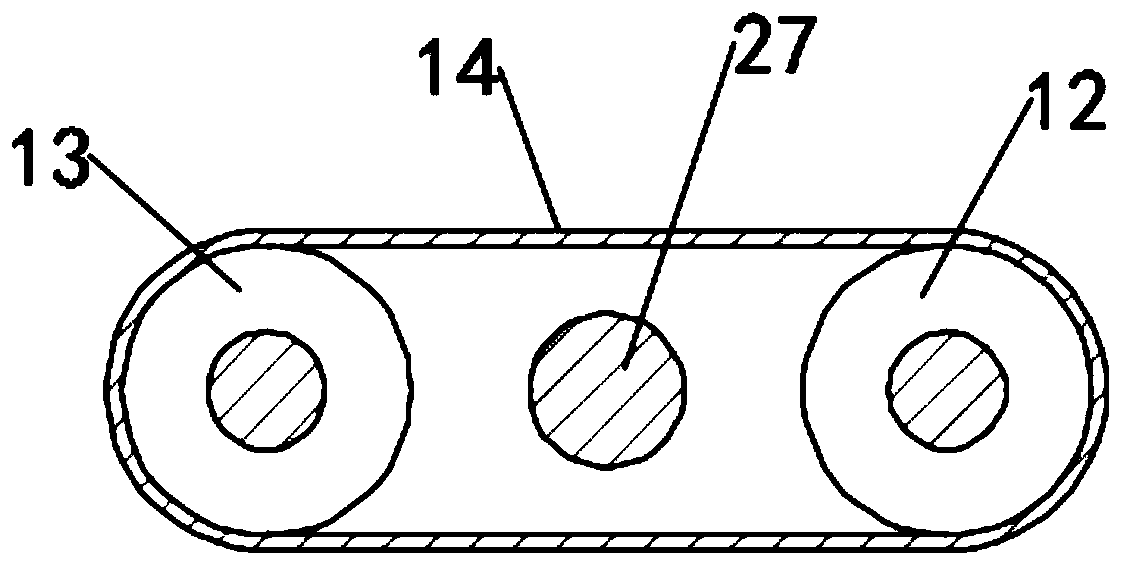

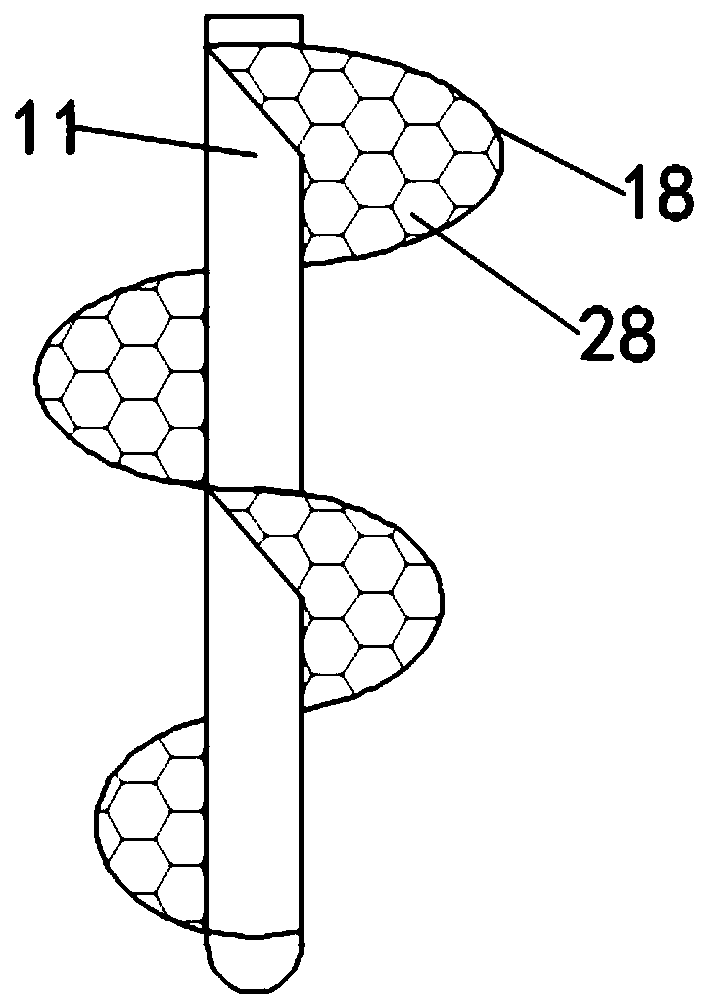

The invention relates to the field of processing of health-care products and in particular discloses a processing device for a product capable of tonifyig qi and blood, delaying ageing and improving facial appearance. The processing device comprises a kettle body, wherein the kettle body is internally provided with a hollow rotary shaft along the middle axis in a rotary manner; an air distributionnet plate is fixedly arranged in a lower inner cavity of the kettle body; an arc-shaped stirring rod, which is matched with an inner wall of a bottom inner cavity of the kettle body, is arranged on the hollow rotary shaft located below the air distribution net plate through an inclined supporting rod; an air distribution disc is connected and mounted at the bottom end of the hollow rotary shaft located below the air distribution net plate; two spiral stirring mechanisms are symmetrically arranged in an upper inner cavity of the kettle body. The invention further provides a processing method for the product capable of tonifyig the qi and blood, delaying the ageing and improving the facial appearance. The product processing device provided by the invention can be used for sufficiently mixing raw materials of the product to react and the production efficiency of the product is accelerated; the product obtained by the product processing method provided by the invention has excellent effects of tonifyig the qi and blood, delaying the ageing and improving the facial appearance.

Owner:樟树市益康药业有限公司

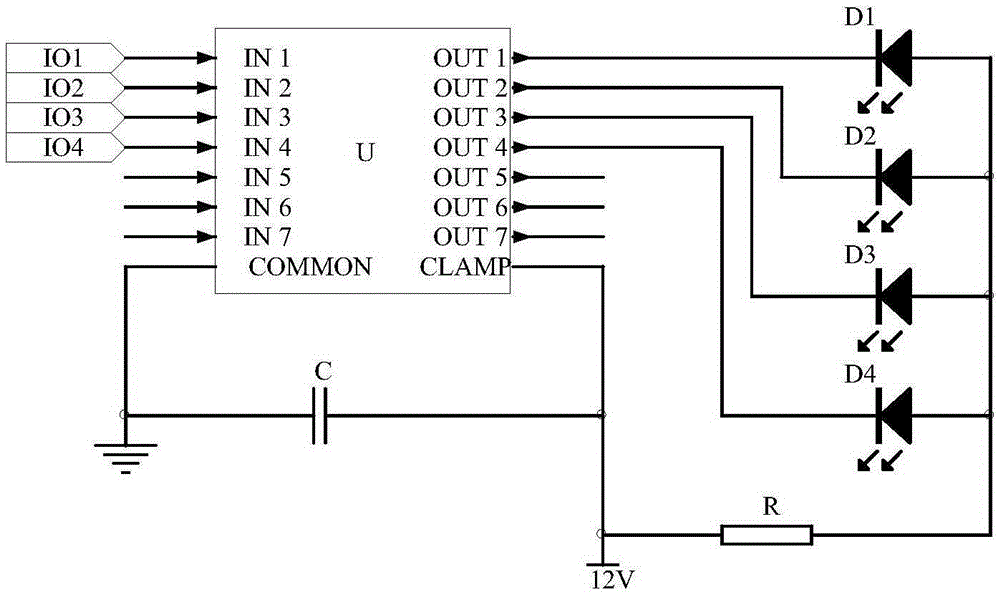

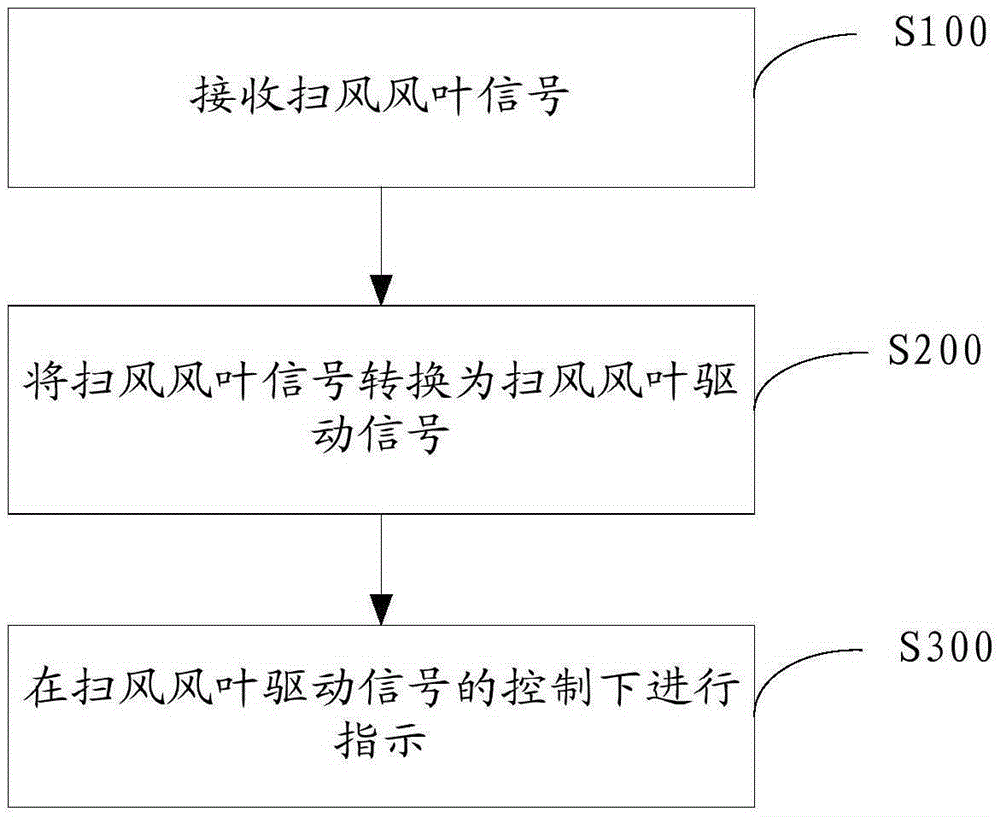

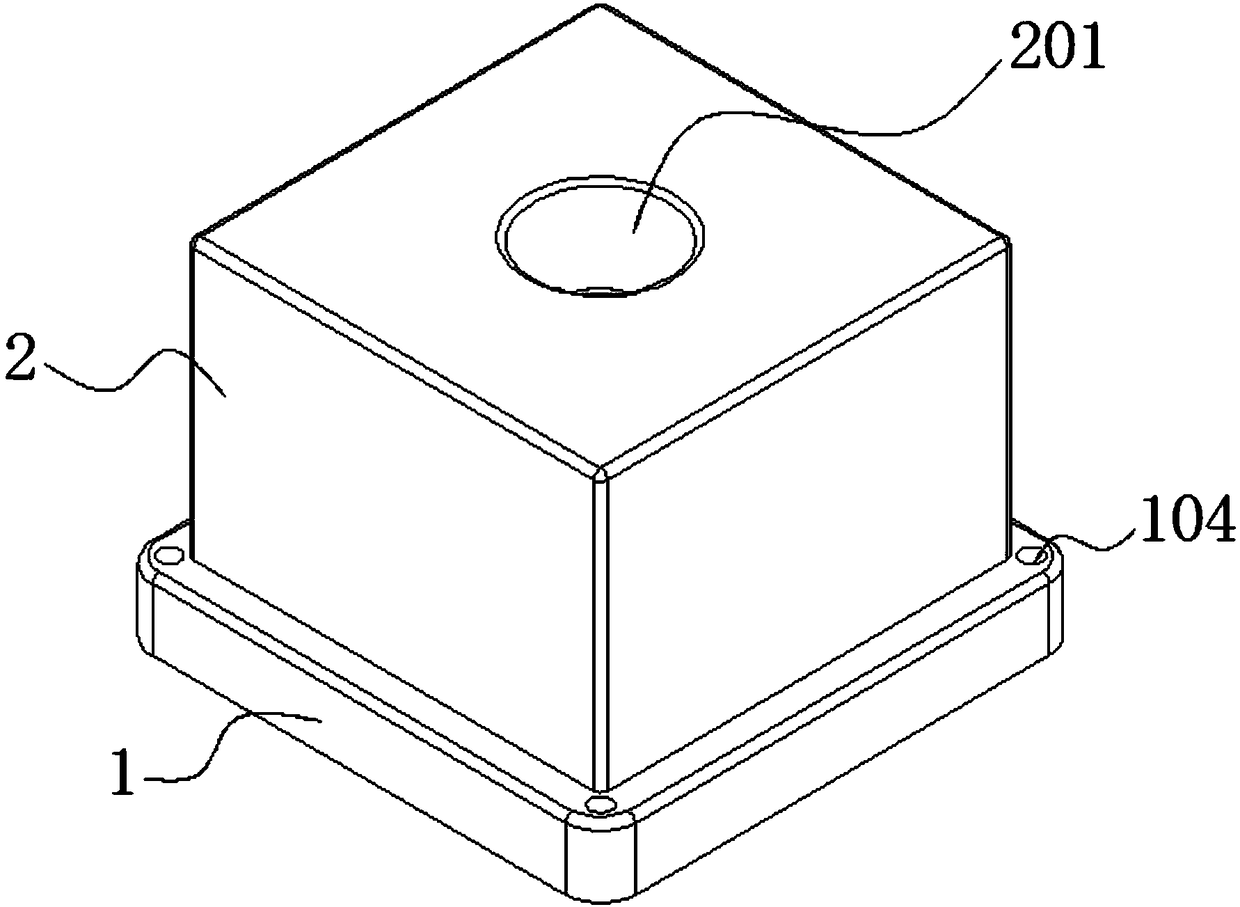

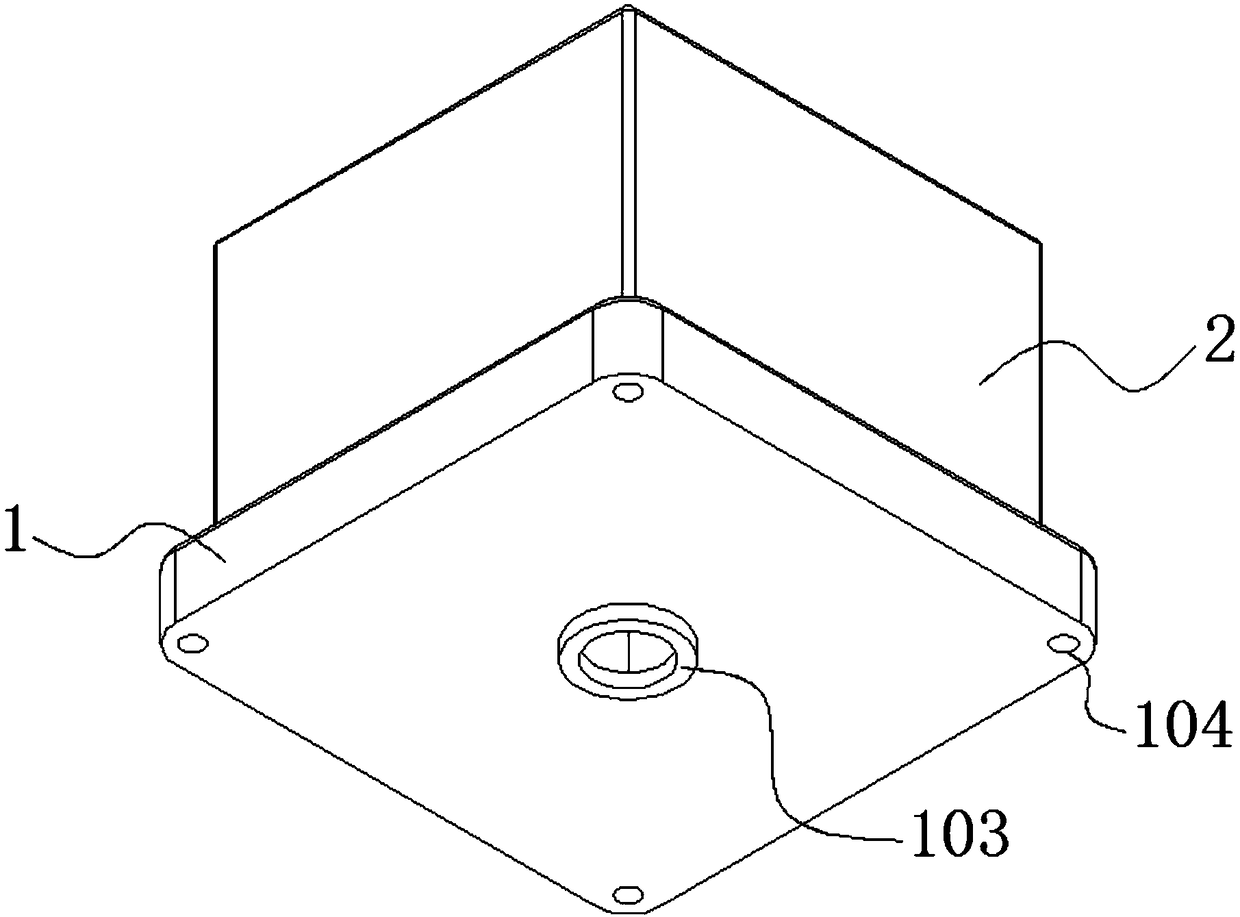

Detecting device for air conditioner wind-sweeping fan blade drive signal, test method for detecting device and air conditioner

InactiveCN105333573AAvoid time cost and labor cost wasteGuarantee the quality of productionMechanical apparatusSpace heating and ventilation safety systemsFan bladeSignal transition

The invention provides a detecting device for an air conditioner wind-sweeping fan blade drive signal, a test method for the detecting device and an air conditioner. The detecting device comprises a drive circuit which is respectively connected with a master control circuit and an indicator circuit, and is used for receiving a wind-sweeping fan blade signal conveyed by the master control circuit, and converting the wind-sweeping fan blade signal into a wind-sweeping fan blade drive signal; and the indicator circuit is used for receiving the wind-sweeping fan blade drive signal and carrying out indication under the control of the wind-sweeping fan blade drive signal. The detecting device is used for detecting whether the wind-sweeping fan blade drive signal is normal or not before the whole air conditioner is assembled, and is quick and effective, so that the problem that time cost and labor cost are wasted due to the fact that a conventional whole machine test is required to return to repair and re-assemble when a wind-sweeping fan blade is found to be abnormal is avoided, product production quality is guaranteed, and generalizability is high.

Owner:GREE ELECTRICHEFEI +1

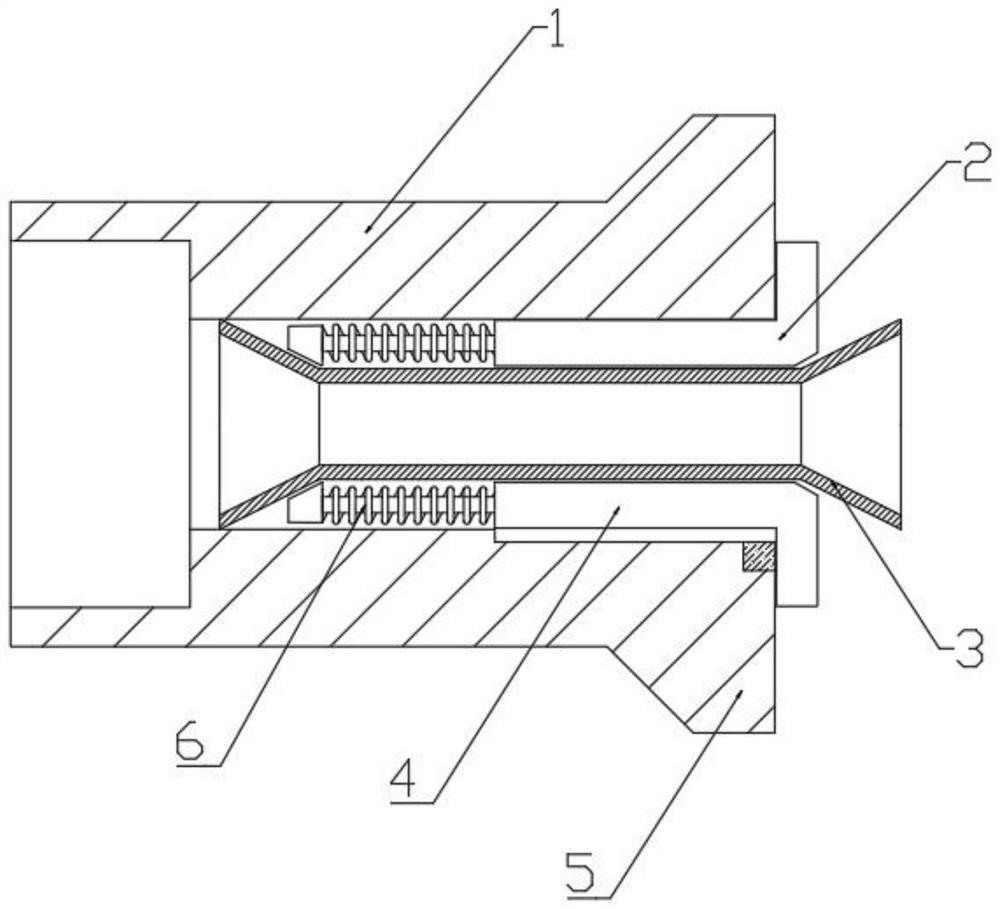

Anti-backflow device for injection mold

The invention discloses an anti-backflow device for an injection mold, and relates to the technical field of molds. The device comprises a base, wherein a shell is fixed on one surface of the base, and a flow limiting device is fixed on the inner surface of the shell through a fixing rod; a heating device is fixed on the inner surface of the shell, and a conical hole is formed in one surface of the shell; an injection cavity is formed in one surface of the shell, one end of the conical hole communicates with the injection cavity, and the flow limiting device comprises a hollow rod; a telescopic rod is arranged on the inner surface of the hollow rod in a sliding fit mode, and a spring is fixed between the inner surface of the hollow rod and one end of the telescopic rod; and one end of thetelescopic rod is fixedly provided with a flow limiting block coordinated with the injection cavity. According to the anti-backflow device, the shell, the base and the flow limiting device are used ina cooperating mode, the functions that injection molding materials pass through the device by one-way pressure and an injection molding opening of the mold is reversely and automatically limited to prevent the backflow are achieved, the use is simple and convenient, the production quality of the mold is ensured, and the production efficiency is improved.

Owner:WENZHOU POLYTECHNIC

Method for characterizing mixture reinforced thermo plastics (RTP) particle hardness

ActiveCN102980820AGuarantee the quality of productionSimple methodInvestigating material hardnessHardnessAlloy

The invention discloses a method for characterizing mixture reinforced thermo plastics (RTP) particle hardness. The method includes that a way of low pressure compression and sieving is used, low pressure compression is used to damage a particle structure, a brush is used to disperse sampling blocks, a sieving way is used to judge a proportion that the particles is crushed, and therefore hardness of hard alloy mixture particles is characterized in ration, real-time monitor to the hardness of the particles in the mixture RTP particle manufacturing process can be achieved, and the production quality of products is guaranteed. The method has the advantages of being simple, easy to operate, good in reproducibility of data and the like. The hardness of the hard alloy mixture consisting of materials with different constituents or mixture ratios all can be characterized through the method.

Owner:XIAMEN TUNGSTEN

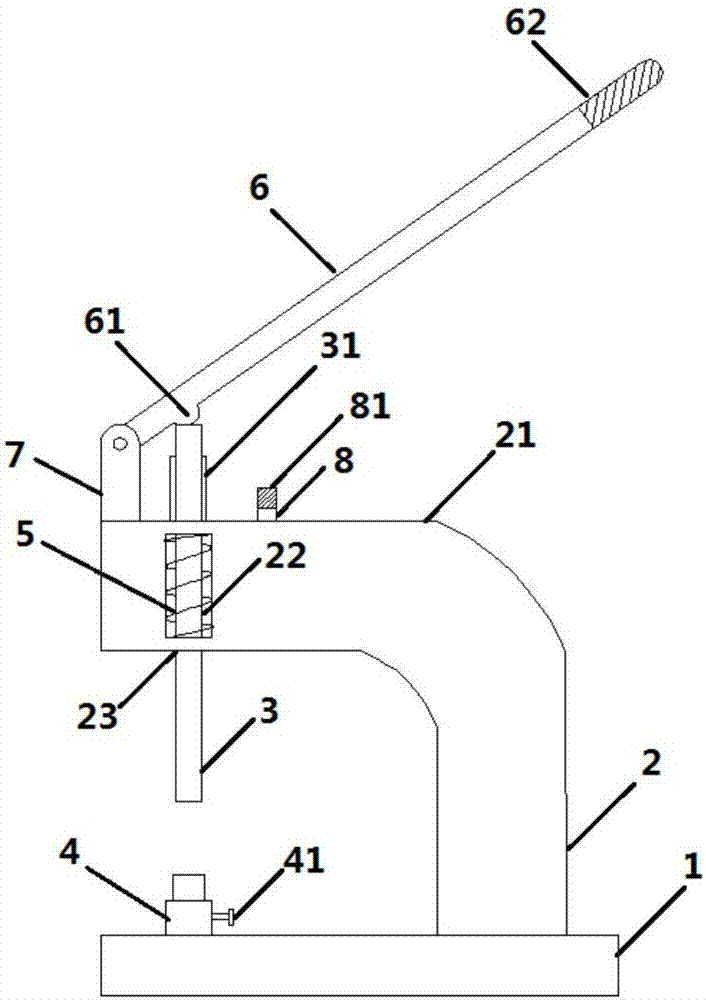

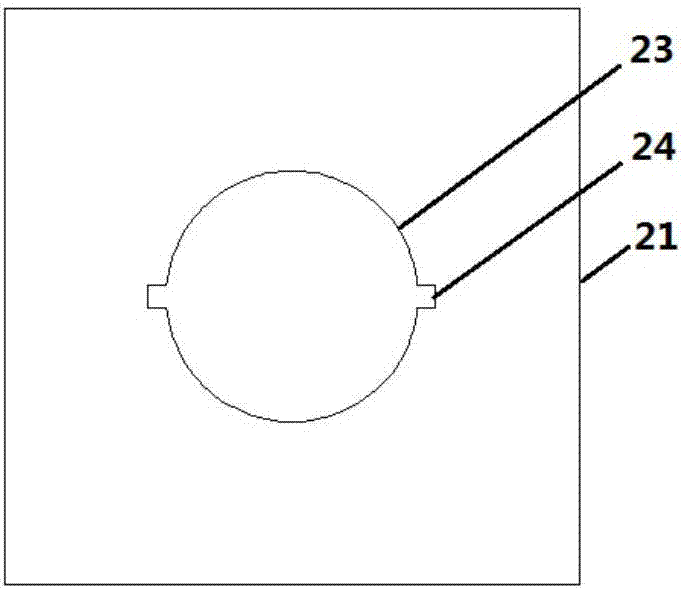

Hand punch

InactiveCN107114870AGuarantee the quality of productionSimple structureFasteningsClothes making applicancesEngineeringMinor axis

The invention discloses a hand beer machine, which comprises a base, a column, a punch, a lower mold seat, a spring, and a pressing bar. The crossbeam extending laterally from the base, the crossbeam directly above the lower mold base is provided with a through hole passing through the crossbeam front and back, the center of the upper wall and the lower wall of the through hole is provided with a round hole penetrating through the crossbeam, and the through hole between the two round holes There is a vertically placed spring inside, and a vertical limit groove is provided on the side wall of the round hole above the through hole. The punch is inserted into the two round holes and the spring from top to bottom, and the upper part of the punch is provided with a The limit protrusion corresponding to the limit groove, the short shaft is arranged on the beam around the upper end of the punch rod, the pressure rod is hinged with the top of the short shaft, the pressure rod rotates around the short axis, and the side of the pressure rod is against the punch rod the top of. The invention has the advantages of simple structure, convenient use, low purchase and use cost, improved buckling efficiency, improved use safety and energy saving.

Owner:ANHUI NUOHAO SHOES

Edge bonding device of marble slabs

InactiveCN107859679AIncrease productivityGuarantee the quality of productionFastening meansPistonPlate column

The invention discloses a marble plate edge sticking device, which comprises a workbench, on which a sliding seat is fixedly arranged, two sets of sliding seats are arranged parallel to each other, and two sets of sliding seats parallel to each other are arranged on the two sets of sliding seats. There are two groups of slide blocks on the slide table, right-angle steel plates are set on the slide block, vertical upright columns are set on both ends of the slide table, beams are set on the upper end of the upright columns, a moving seat is set on the beam, and a moving seat is set on the bottom of the moving seat. The surface is fixed with a vertically downward hydraulic column, the piston shaft end of the hydraulic column is fixed with a flat plate, the lower surface of the flat plate is provided with rollers, and there are two groups of rollers arranged in a single row. This kind of marble slab edge bonding device improves production efficiency while ensuring production quality, reducing process difficulty requirements and reducing post-trimming process difficulty and labor intensity. After bonding, rollers are used for rolling to ensure that the bonding is stable and smooth, and the pass rate is improved. .

Owner:惠州市梦芭迪工业产品设计中心(普通合伙)

Spherical concentrator capable of being uniformly heated

InactiveCN106377913AImprove the uniformity of heatingGuarantee the quality of productionEvaporator accessoriesCondensed waterEngineering

The invention discloses a spherical concentrator capable of being uniformly heated. The spherical concentrator comprises a support, a spherical concentrator body, an inner tank, an outer tank, a steam inlet, a steam outlet, a steam dispersion pipe, a discharging pipe, a circulation channel, a condenser, a compression gauge, a condensed water outlet, and a feed inlet. The arrangement of the steam dispersion pipe has a guiding effect for heating steam, the spherical concentrator is capable of being uniformly heated, the inner tank is completely coated by the outer tank, so that the upper part of the spherical concentrator can be heated, so that heating uniformity on the spherical concentrator can be enhanced. the materials in the spherical concentrator can be uniformly heated, and the production quality of the materials can be guaranteed. The spherical concentrator body selects a spherical shape which can increase the capacity of the spherical concentrator, production efficiency is increased, the wall of the inner tank is in an unevenness waveform structure, absorptivity of the steam heat by the tank wall can be increased, and the energy is saved.

Owner:弘毅天承知识产权股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com