Hand punch

A technology of hand beer machine and punching rod, which is applied in the direction of clothing, footwear, sewing tools, etc. It can solve the problems of unsuitable scale factories, low efficiency of buttoning, and high labor intensity, so as to save energy and improve production efficiency. The effect of buckling efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

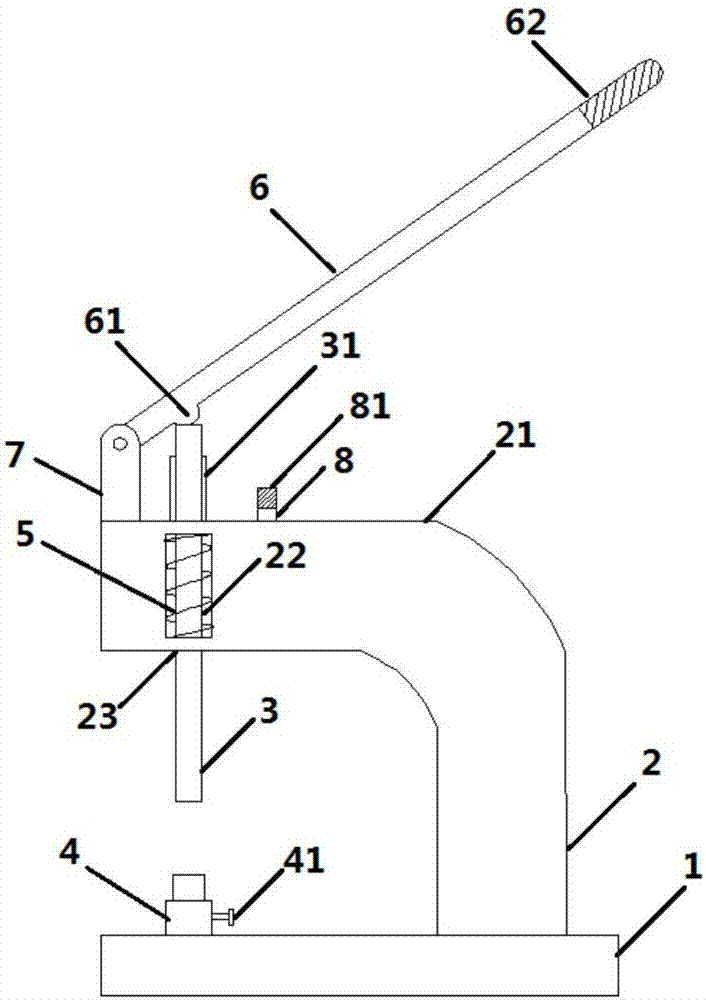

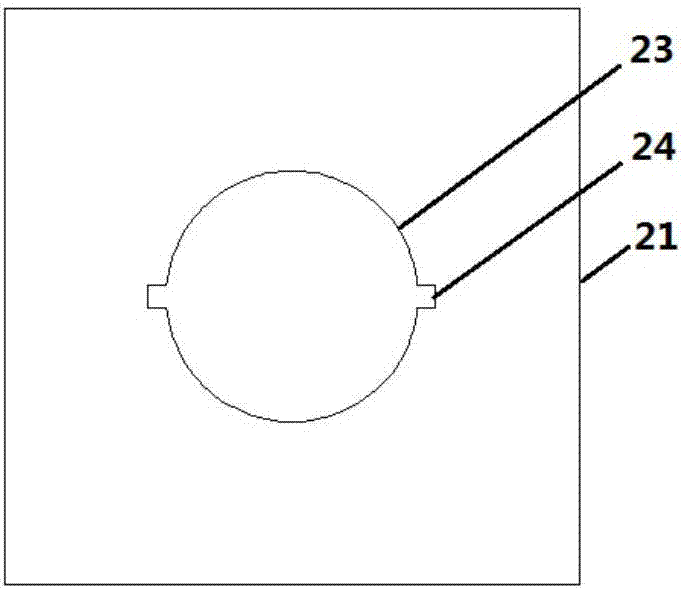

[0018] A hand beer machine, such as figure 1 , 2 As shown, it includes a base 1, a column 2, a punch 3, a lower mold base 4, a spring 5, and a pressure bar 6. The column 2 and the lower mold base 4 are respectively arranged on both sides of the base 1, and the column 2 is provided with The crossbeam 21 extending laterally from the lower mold base 4, the crossbeam 21 just above the lower mold base 4 is provided with a through hole 22 that runs through the cross beam 21 before and after, the shape of the through hole 22 is a vertical rectangle, and the upper part of the through hole 22 The center of wall and lower wall is provided with the circular hole 23 that runs through beam 21, is provided with the spring 5 that vertically places in the through hole 22 between two circular holes 23, is provided with on the sidewall of the circular hole 23 above through hole 22. There is a vertical limiting groove 24, and the punch 3 is inserted into the two round holes 23 and the spring 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com