Edge bonding device of marble slabs

A technology of marble slabs and right-angle steel plates, applied in mechanical equipment, connecting components, etc., can solve the problems of increased difficulty and workload of trimming process, high technical requirements of workers, and many unqualified products, etc., and achieves stable and smooth bonding. The effect of ensuring production quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

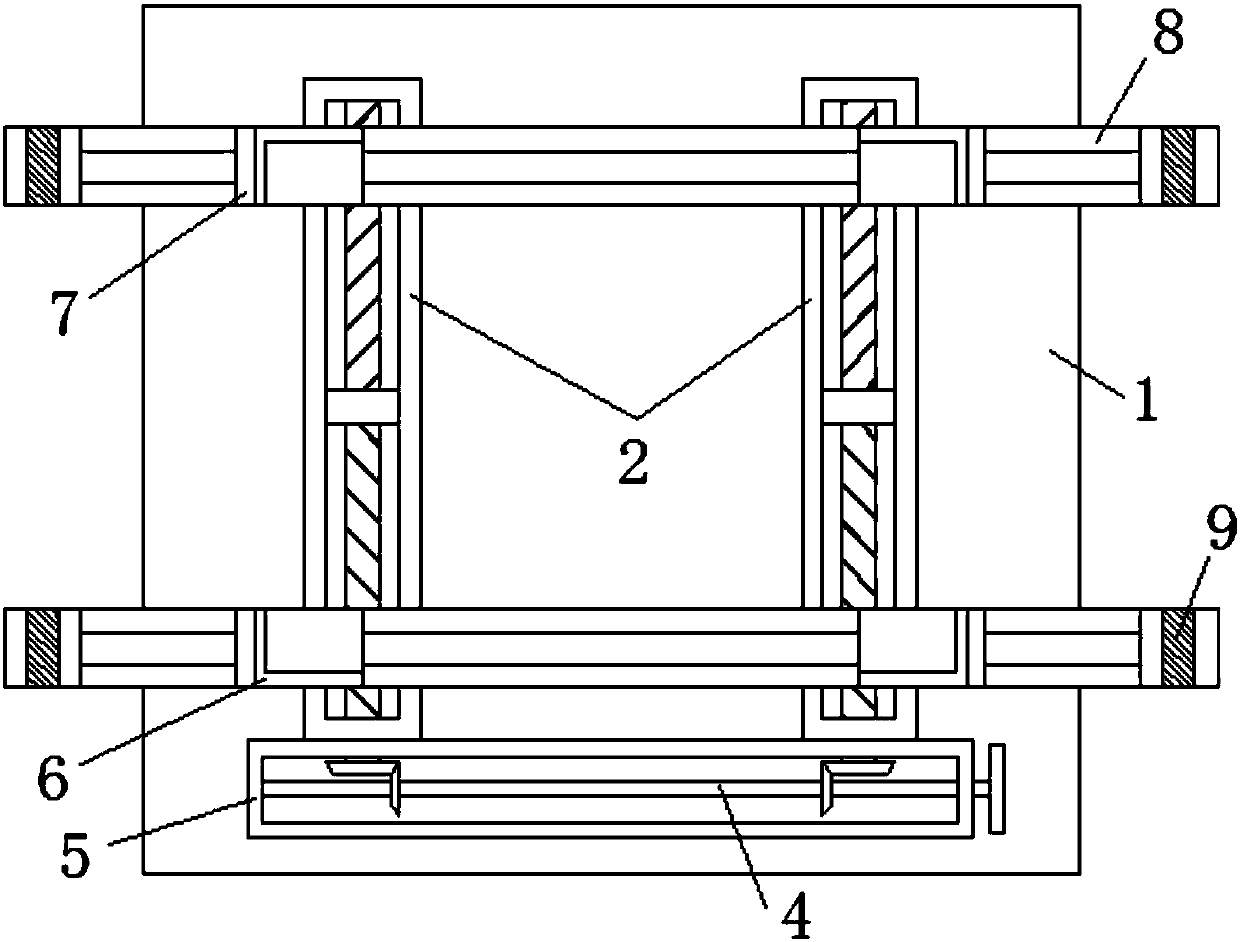

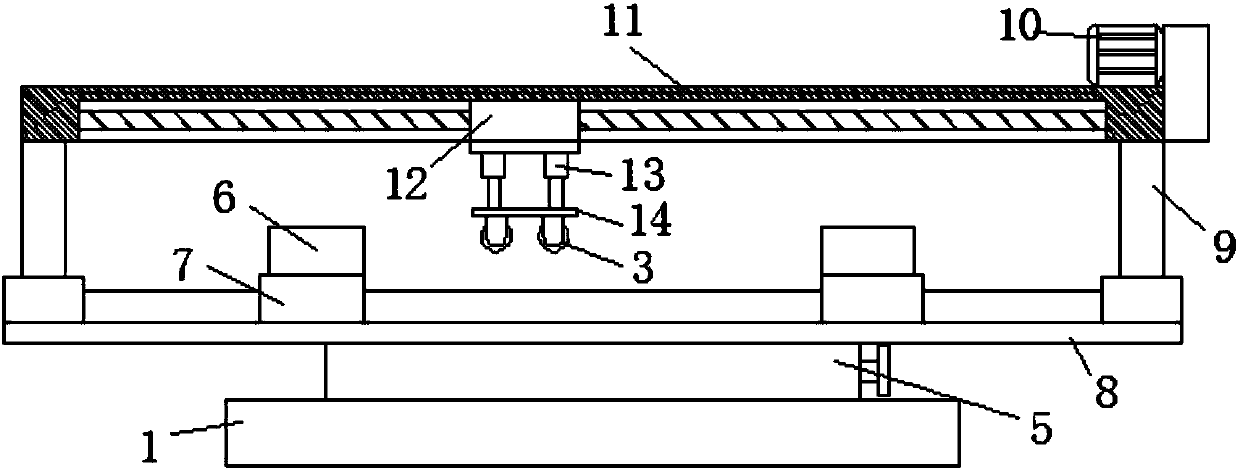

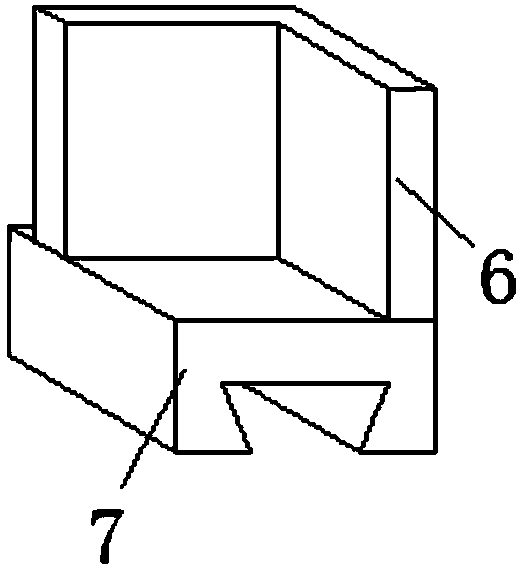

[0021] Such as Figure 1-3 As shown, a marble slab edge bonding device includes a workbench 1, a slide seat 2 is fixedly arranged on the workbench 1, two sets of slide seats 2 are arranged parallel to each other, two sets of slide seats 2 are provided with two sets of Sliders 8 parallel to each other, two sets of sliders 7 are arranged on the sliders 8, right-angled steel plates 6 are arranged on the sliders 7, vertical columns 9 are arranged at both ends of the sliders 8, and beams are arranged on the upper ends of the columns 9 11. The beam 11 is provided with a moving seat 12, and the lower surface of the moving seat 12 is fixedly provided with a vertically downward hydraulic column 13, and the piston shaft end of the hydraulic column 13 is fixedly provided with a plate 14, and the lower surface of the plate 14 is provided with a roller 3 , The rollers 3 are provided with two groups, and are arranged in a single row.

[0022] In this embodiment, a transmission box 5 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com