Vitamin premix suitable for soft capsule preparation and preparation method of vitamin premix

A vitamin premix and vitamin technology, which is applied in capsule delivery, pharmaceutical formula, food forming, etc., can solve the problem of no grading phenomenon, and achieve the effects of avoiding component changes, simple preparation process, and enhancing physical fitness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

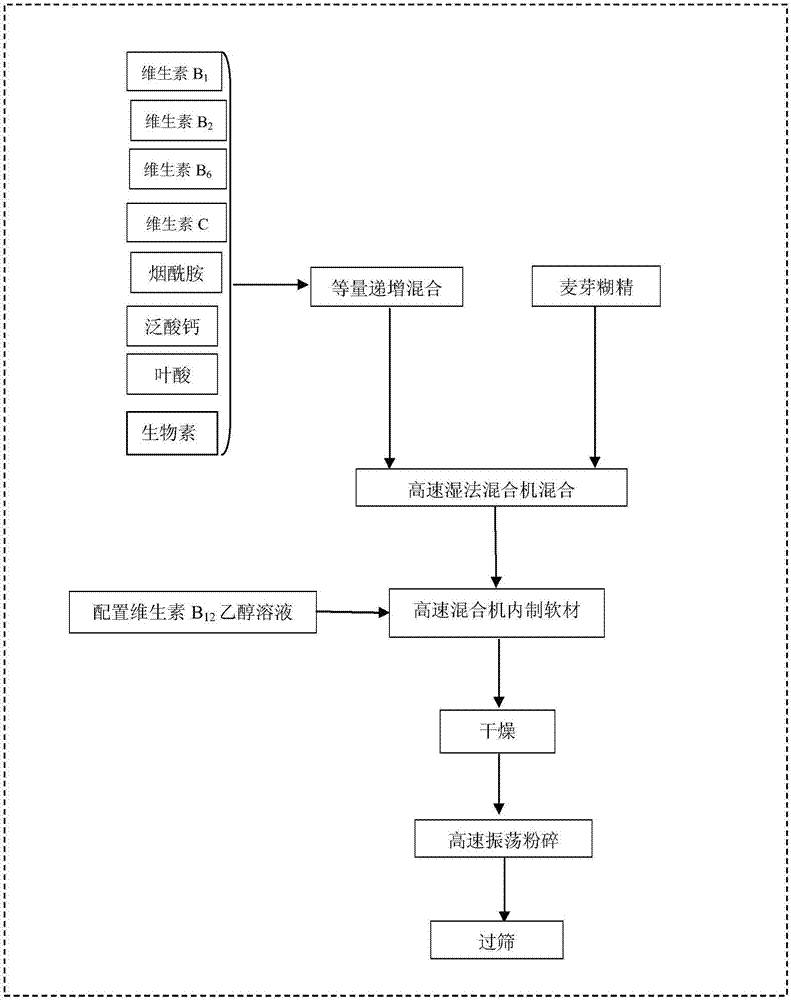

[0032] Embodiment 1: A kind of vitamin premix material suitable for soft capsule dosage form, consists of vitamin B 1 , Vitamin B 2 , vitamin C, niacinamide, vitamin B 6 , calcium pantothenate, vitamin B 12 , biotin, folic acid, maltodextrin, the process is as follows figure 1 shown.

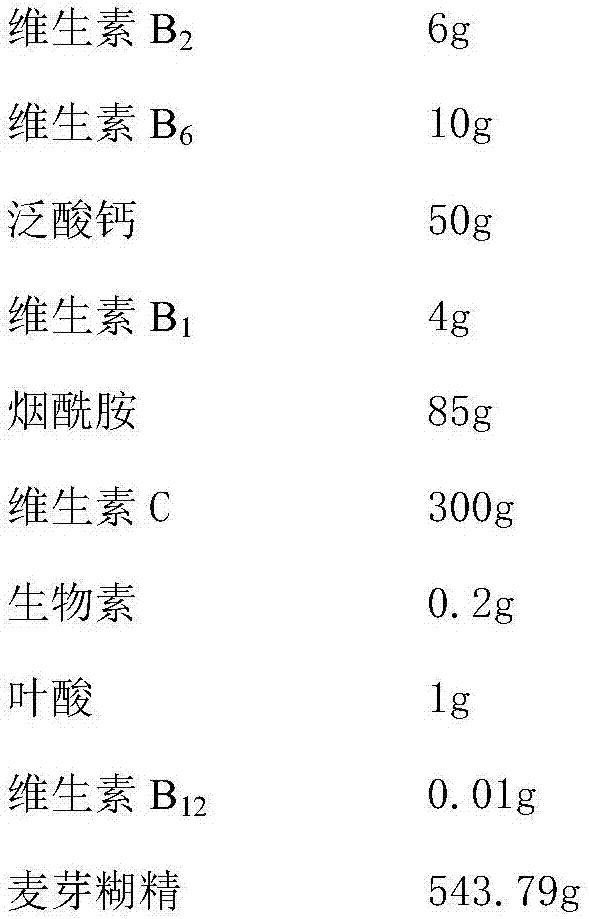

[0033] The composition of raw materials is as follows:

[0034]

[0035] The preparation steps are as follows:

[0036] (1) Put vitamin B in a clean bag 1 , Vitamin B 2 , vitamin C, niacinamide, vitamin B 6 , calcium pantothenate, biotin, and folic acid are increased by the same amount. First, mix 0.2g of biotin with an equal amount of folic acid (0.2g) to obtain a 0.4g mixture; then add the same amount of folic acid (0.4g) as the mixture and mix , to get 0.8g mixture; then add the same amount of folic acid (0.6g) and vitamin B 1 (0.2g), to get 1.6g of the mixture; and so on, until the maximum amount of vitamin C is added, the mixture and maltodextrin are placed in a high-speed wet m...

Embodiment 2

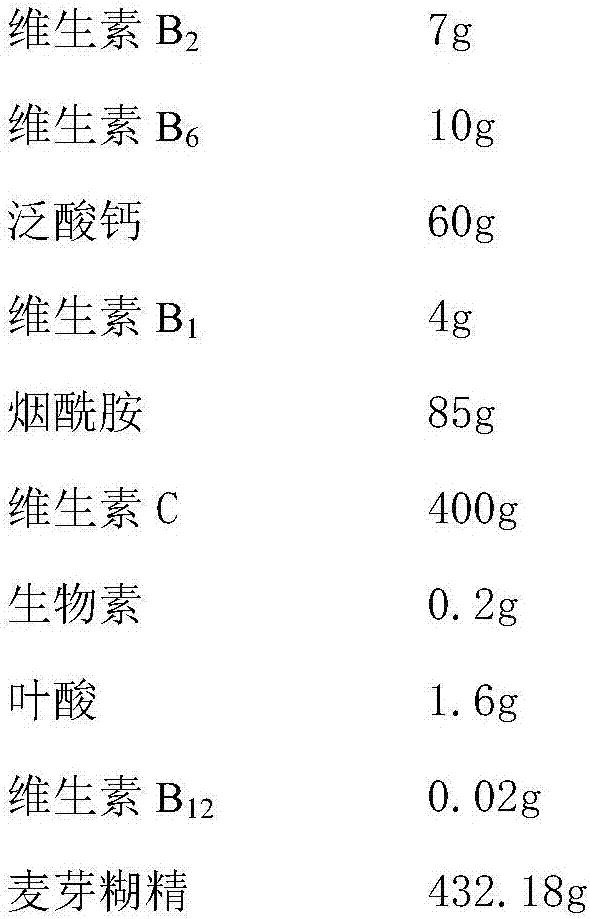

[0039] Embodiment 2: As described in Embodiment 1, the difference is that the raw material weight composition is changed into:

[0040]

[0041] According to the method described in Example 1, the vitamin premix B suitable for soft capsule preparations was prepared.

Embodiment 3

[0042] Embodiment 3: as described in embodiment 1, difference is, raw material weight composition changes into:

[0043]

[0044] According to the method described in Example 1, the vitamin premix C suitable for soft capsule preparations was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com