Patents

Literature

56results about How to "Meet assembly precision requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diffusion welding process for heat exchanger core

ActiveCN106825894AQuality improvementReduce brittle phaseNon-electric welding apparatusRoom temperatureEngineering

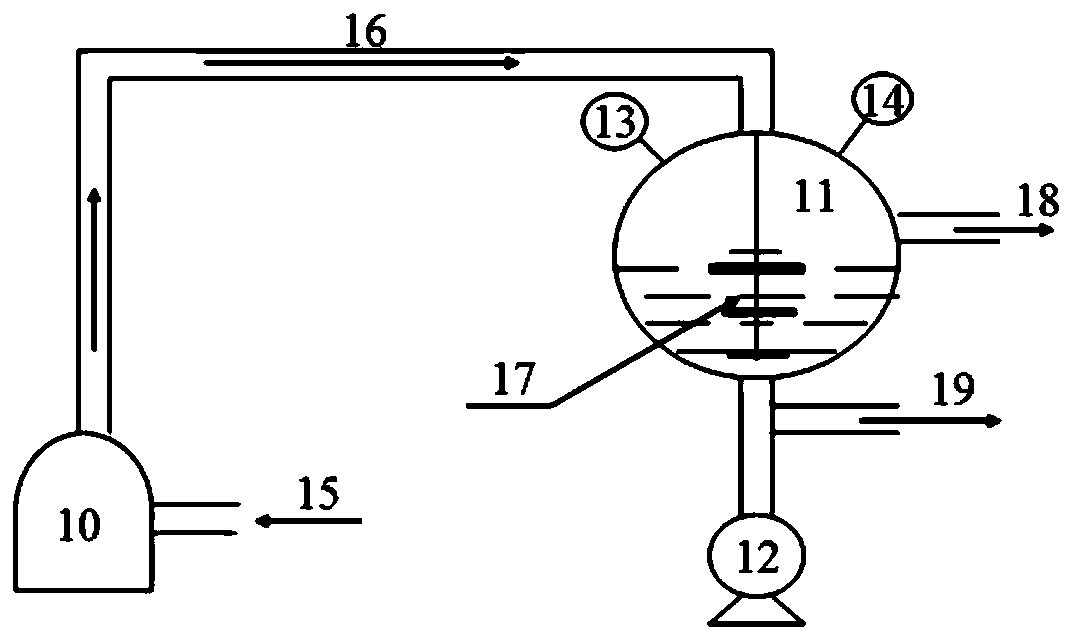

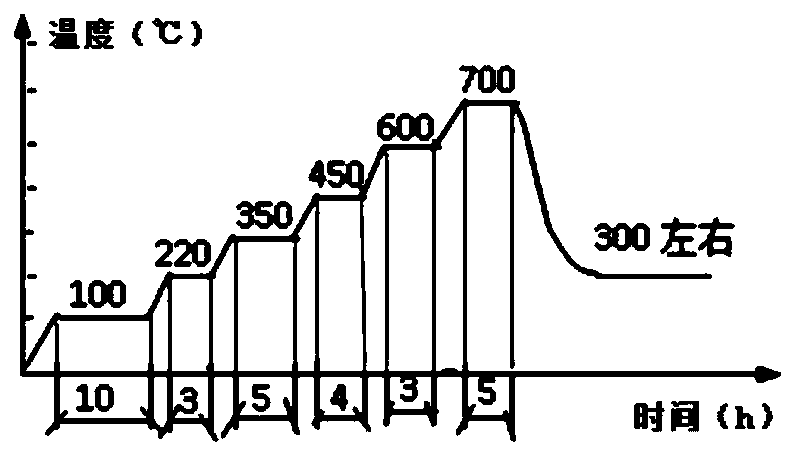

The invention discloses a diffusion welding process for a heat exchanger core. The diffusion welding process comprises the following steps: (1) pre-welding pre-treatment: feeding the well assembled heat exchanger core into a diffusion welding furnace, and vacuumizing the interior of the furnace to be below 0.01 Pa; (2) diffusion welding: raising the temperature to 800-850 DEG C at the speed of 15-20 DEG C / min, keeping the temperature for 30 min, after that, raising the temperature to 1,100-1,150 DEG C at the speed of 10-15 DEG C / min, keeping the temperature for 3 h, and performing vacuum cooling to the room temperature, wherein the pressure (8-9.5 MPa) exerted before is kept in the first 2 h and reduced to 4-6 MPa in the last 1 h; and (3) postweld heat treatment: raising the temperature of the heat exchanger core to 1,150-2,000 DEG C, keeping the temperature for at least 20 h, and after that, reducing the temperature in a water quenching manner. According to the diffusion welding process, such parameters as welding temperature, diffusion time and pressure are controlled, the step of heat treatment after diffusion welding is added, so that brittle phases easily generated during diffusion welding are reduced, and the quality of a welded joint of the heat exchanger core is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

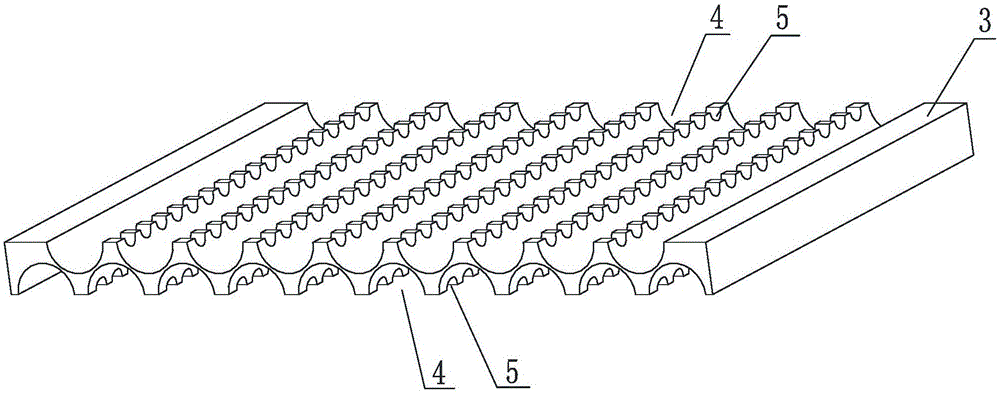

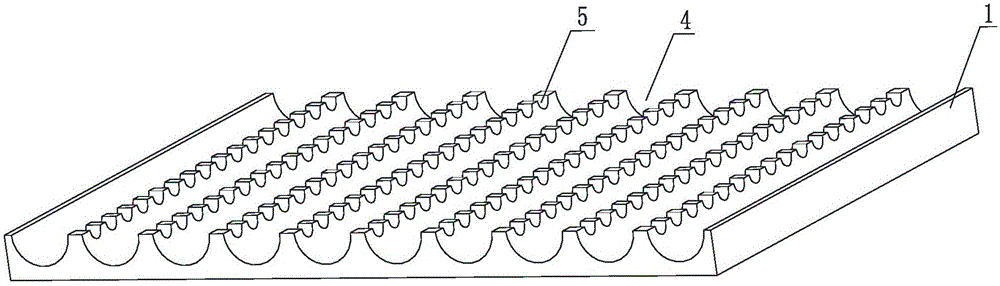

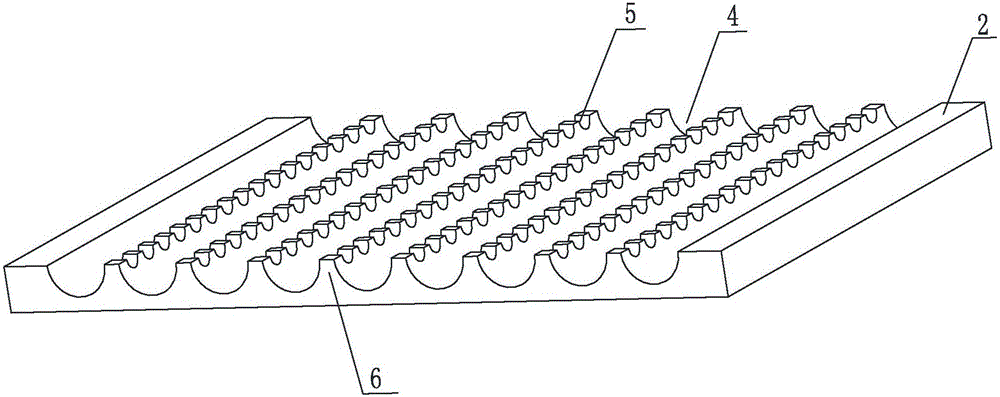

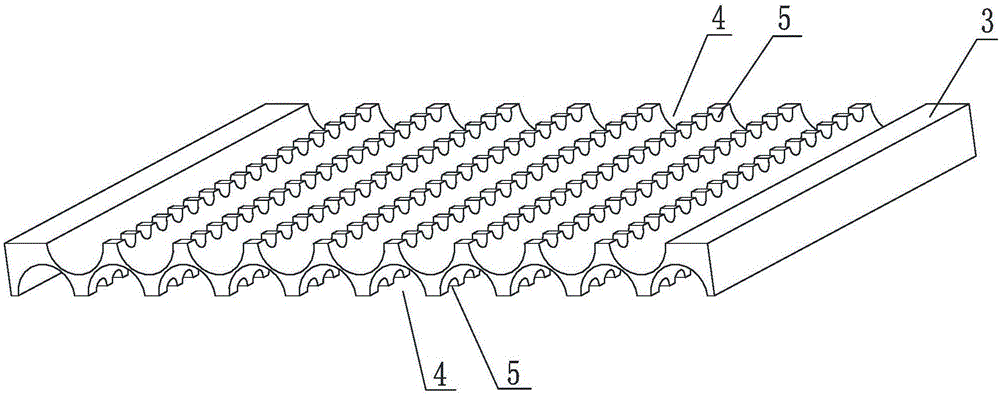

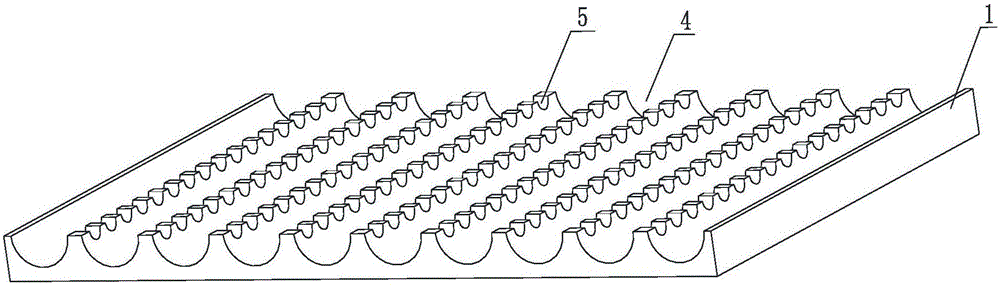

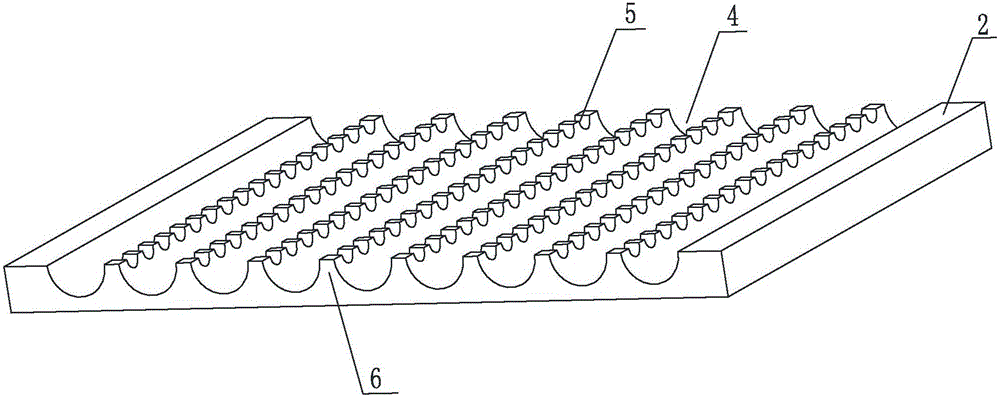

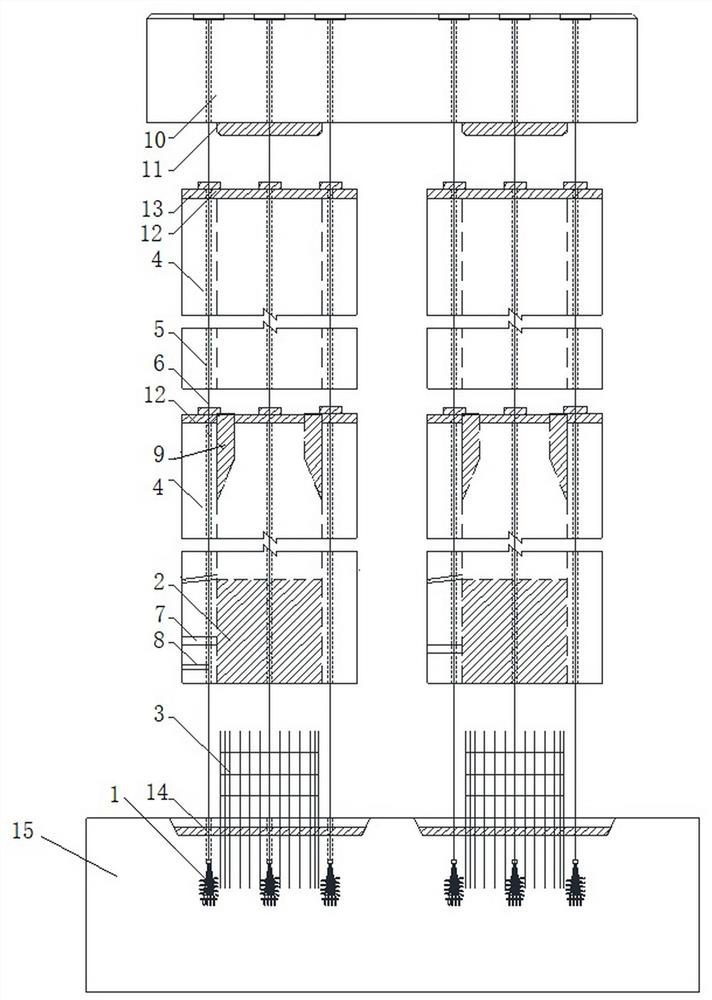

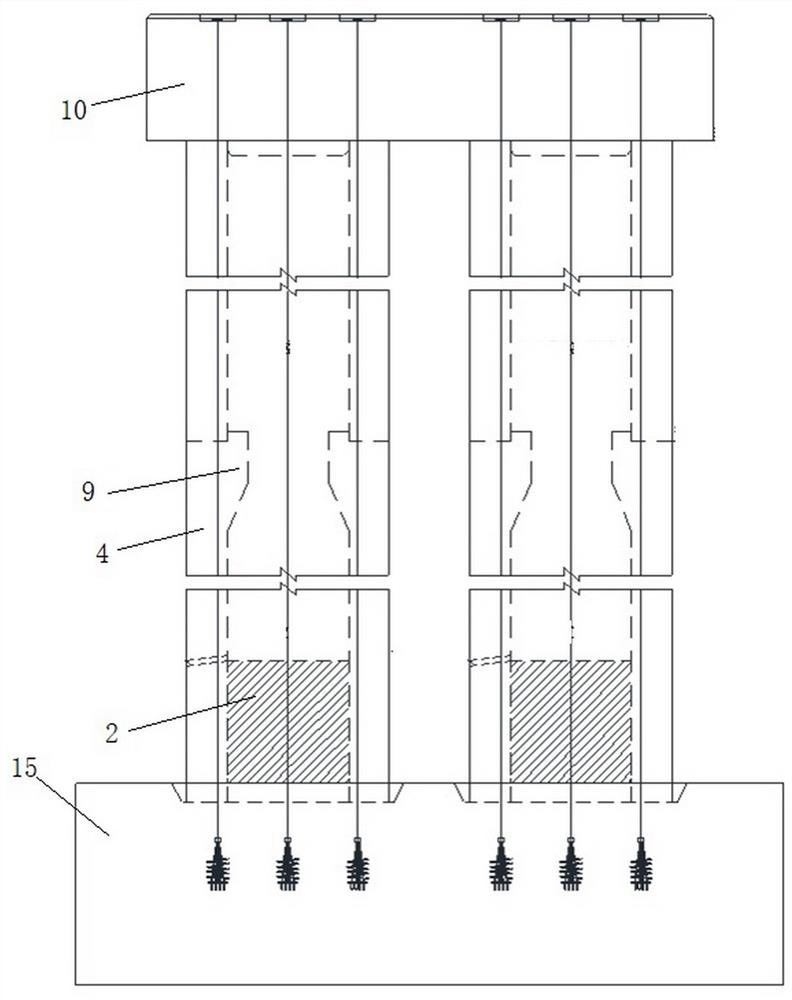

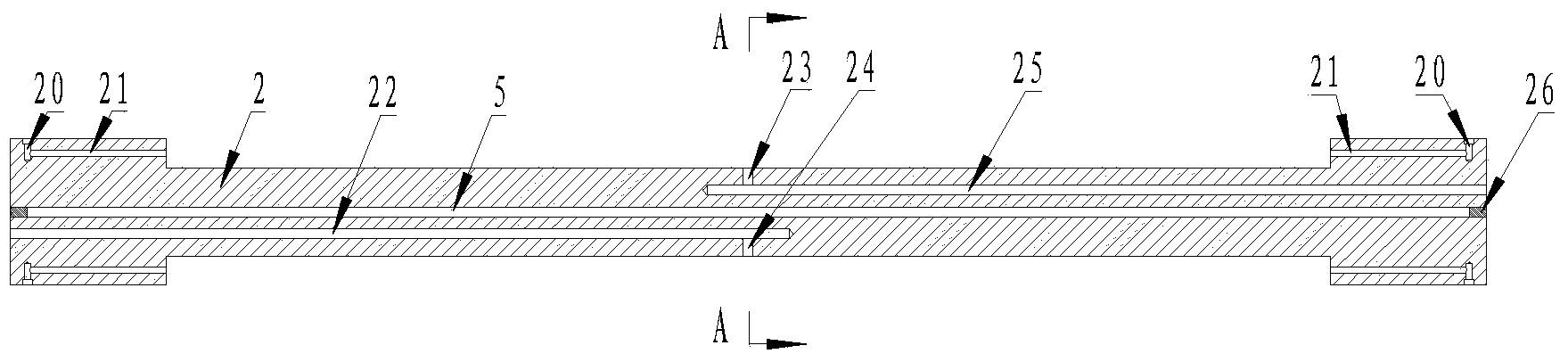

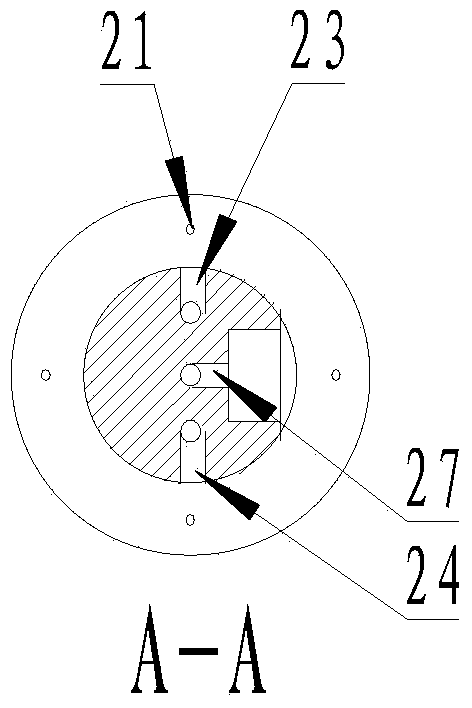

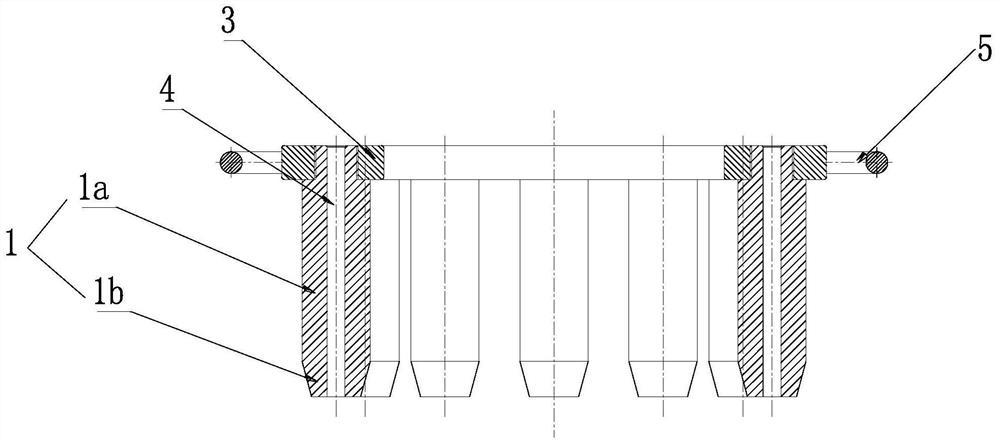

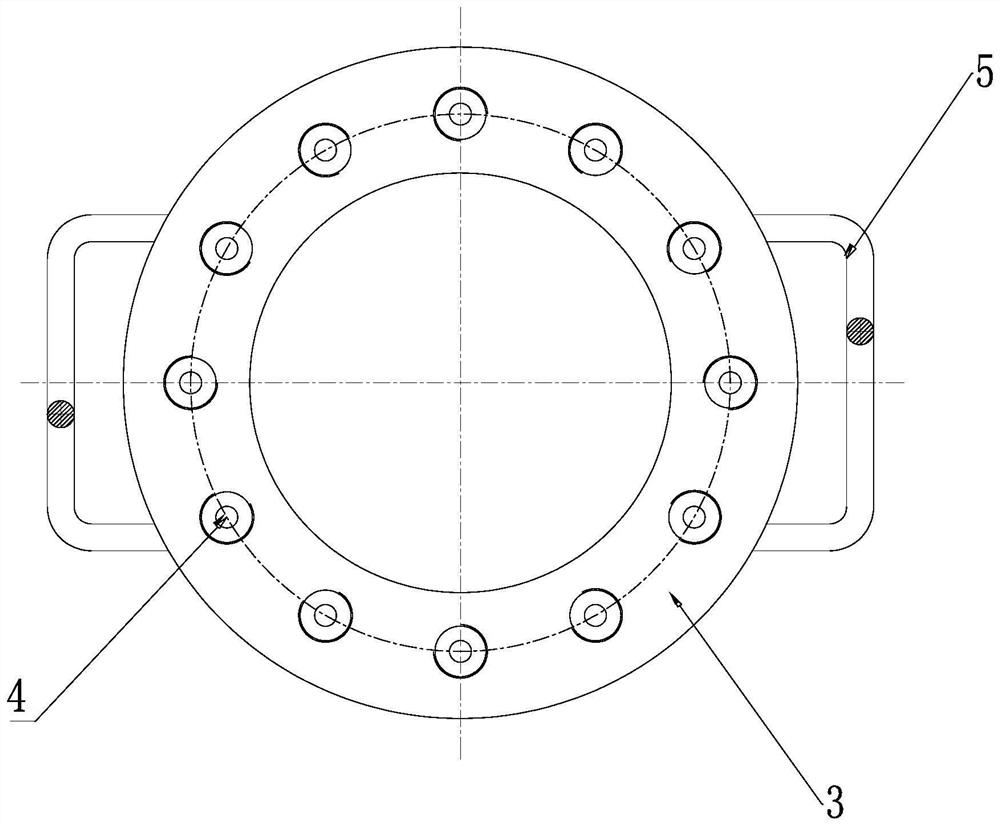

Compact and efficient heat exchanger core and welding fixture thereof

ActiveCN106839831AImprove heat transfer performanceGood high temperature and high pressure resistanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpecial occasion

The invention discloses a compact and efficient heat exchanger core. The compact and efficient heat exchanger core comprises an upper metal cover plate, a lower metal cover plate and a plurality of intermediate metal plates, wherein first semi-circular hole structures are longitudinally and second semi-circular hole structures are transversely etched in the bottom surface of the upper metal cover plate, the top surface of the lower metal cover plate and the top and bottom surfaces of the intermediate metal plates, and the upper metal cover plate, the intermediate metal plates and the lower metal cover plate are sequentially stacked up and down; and the first semi-circular hole structures and the second semi-circular hole structures between the upper and lower adjacent intermediate metal plates, between the uppermost intermediate metal plate and the upper metal cover plate, and between the lowermost intermediate metal plate and the lower metal cover plate are correspondingly combined to form first round holes and second round holes correspondingly. The transversely and longitudinally chemically etched semi-circular hole structures are adopted, so that the boundary layer breakage capability is very strong, the flow disturbance can be enhanced, the heat exchange performance is improved, and the compact and efficient heat exchanger core is suitable for special occasions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Prestress connecting device of railway prefabricated assembly type bridge pier

PendingCN112853947AGuarantee the joint strengthEliminate level deviationBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a prestress connecting device of a railway prefabricated assembly type pier, and particularly relates to a prestress connecting device which is characterized in that a prestress steel bar is anchored to a pier foundation in advance, penetrates through a prestress hole channel of a prefabricated pier and a prestress hole channel of a prefabricated cross beam, is reserved in a tensioning notch of the prefabricated cross beam and applies prestress by tensioning a prestress steel strand; and finally, pressure drop and anchor sealing are conducted on the prestressed pipeline, and connection of the prefabricated assembly type bridge piers is completed. The prestress connecting device of the railway prefabricated pier is a connecting anchoring system, effectively achieves connection of a foundation, a pier body and a cross beam, eliminates cracks at splicing joints by applying prestress, and guarantees durability and normal use of the pier.

Owner:新疆铁道勘察设计院有限公司

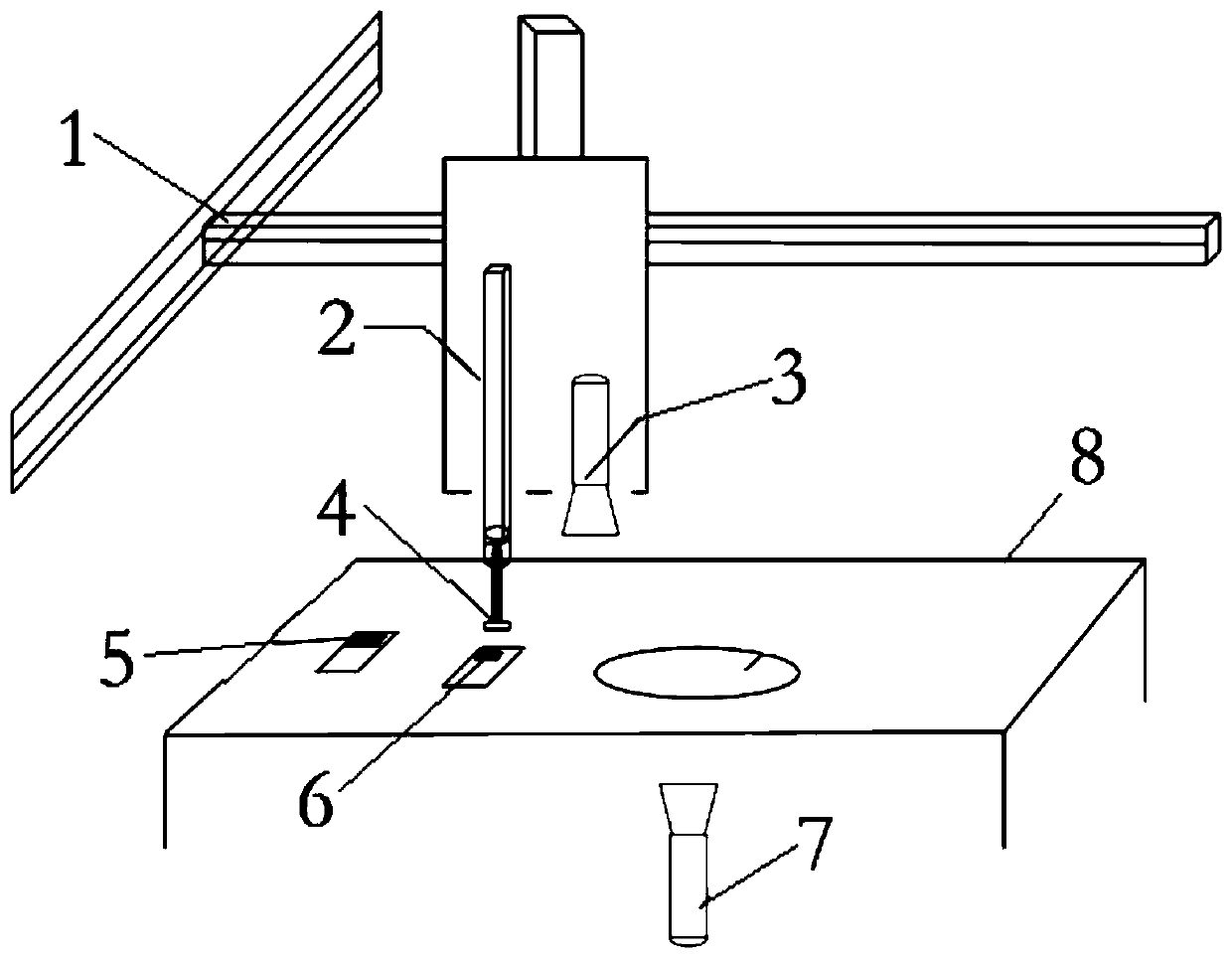

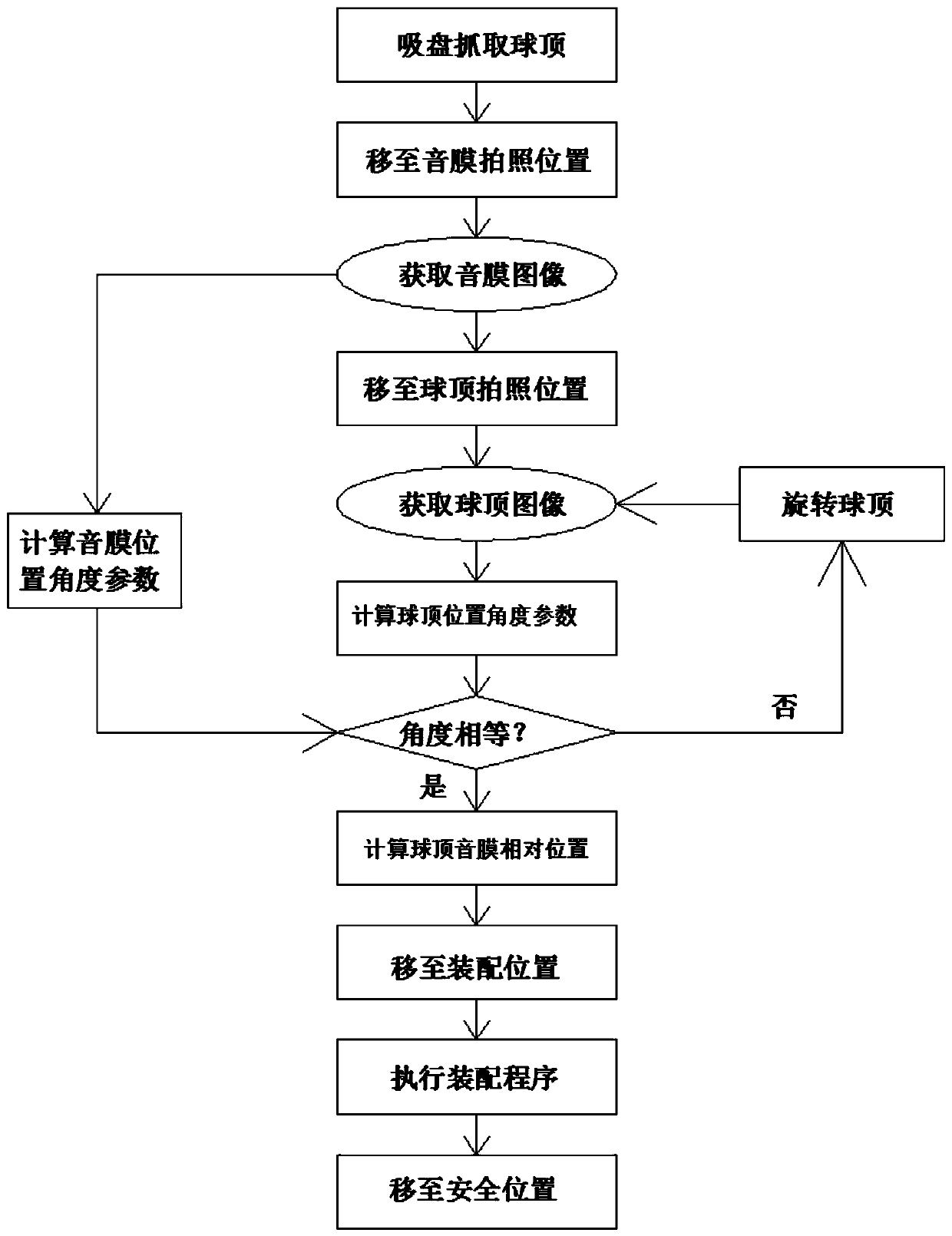

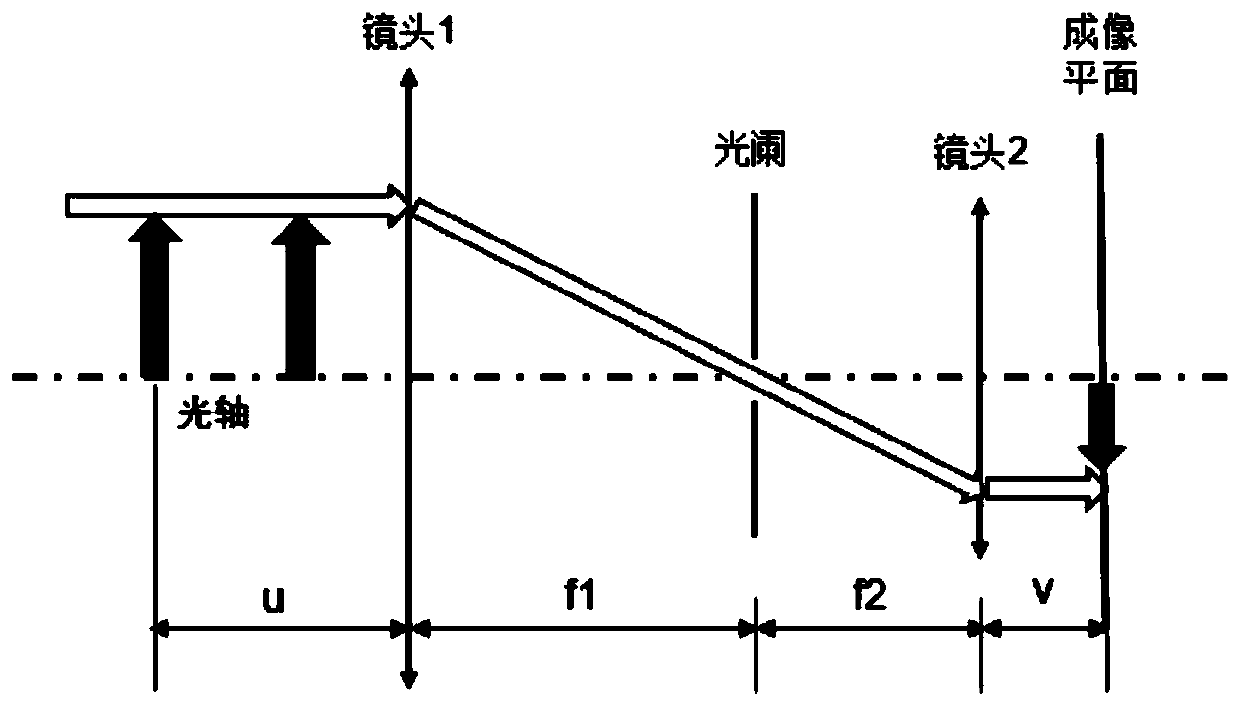

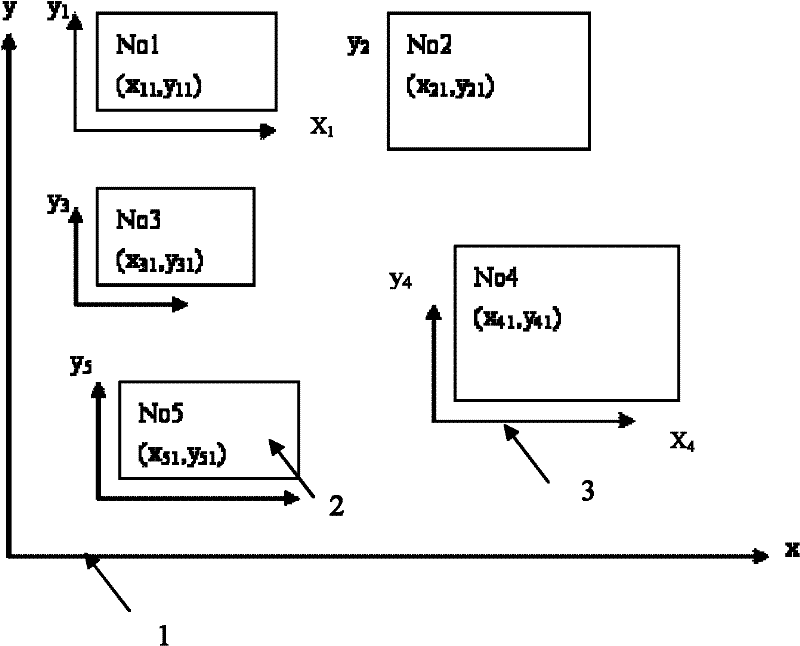

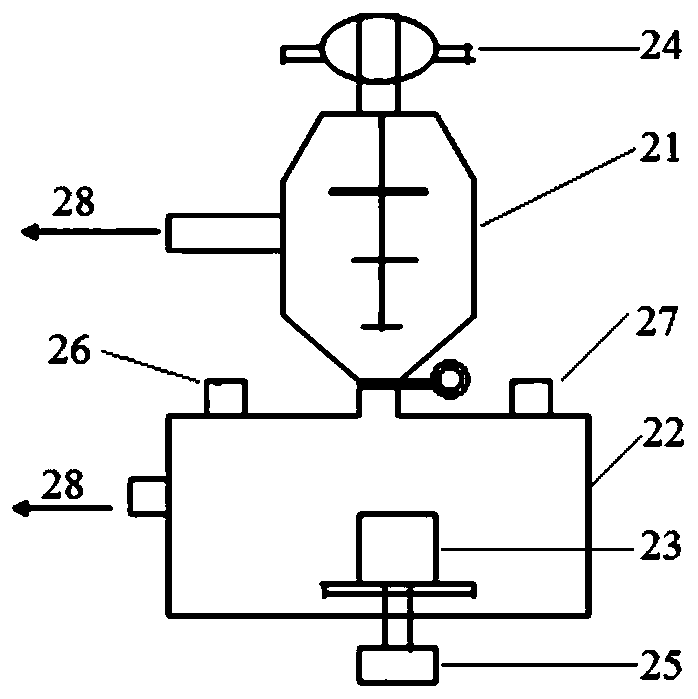

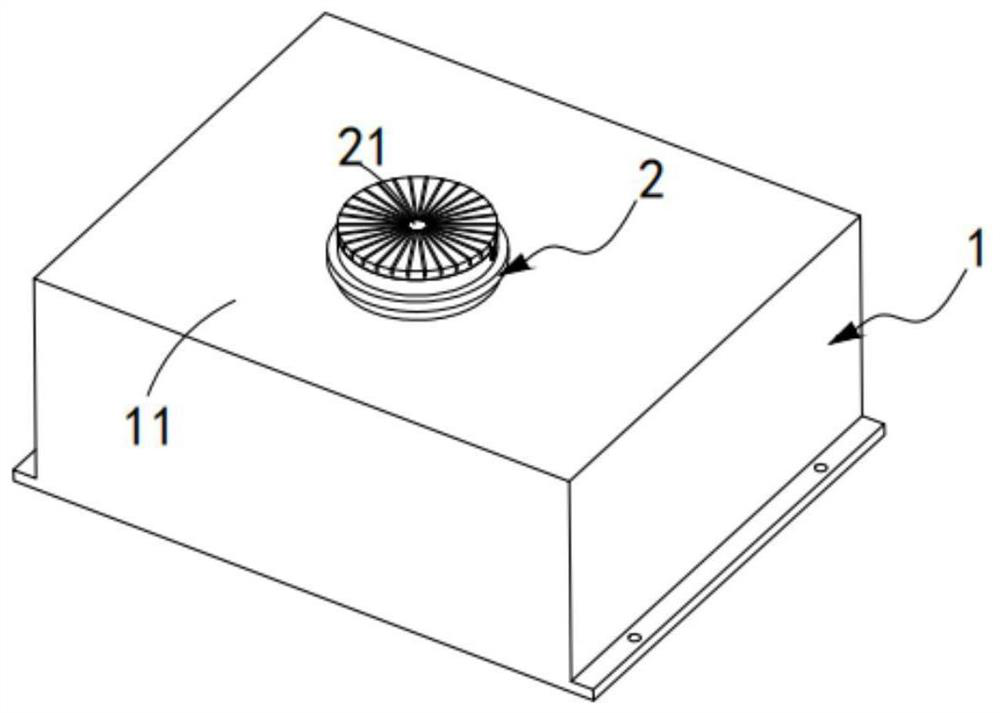

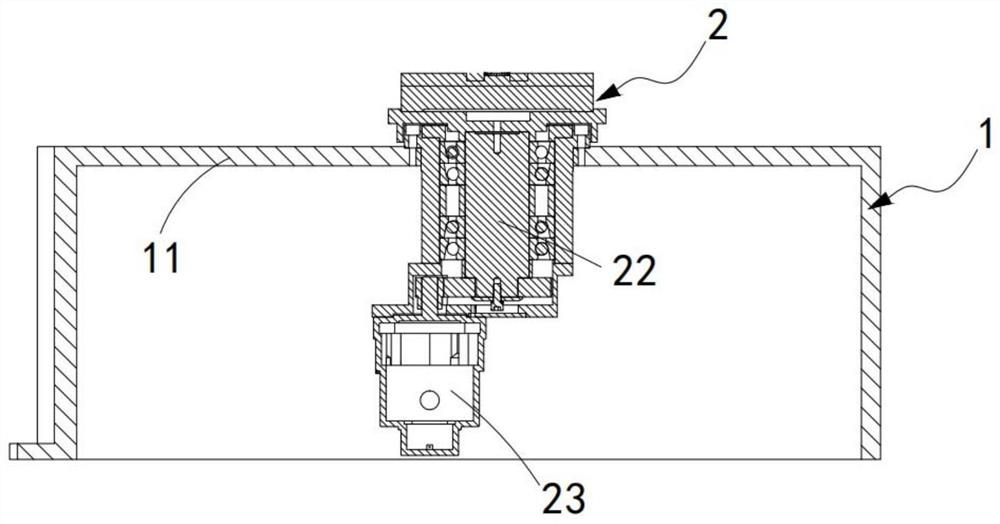

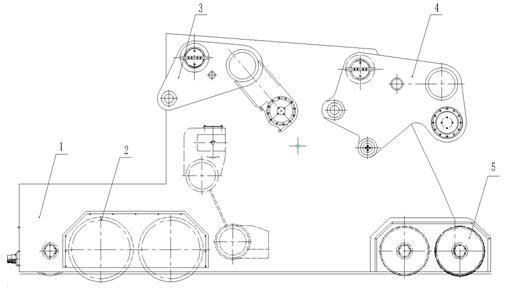

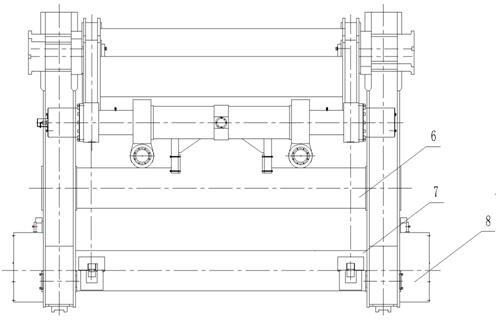

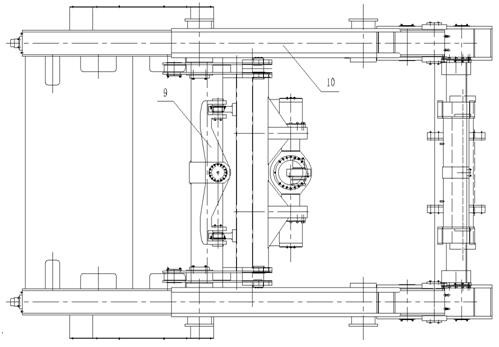

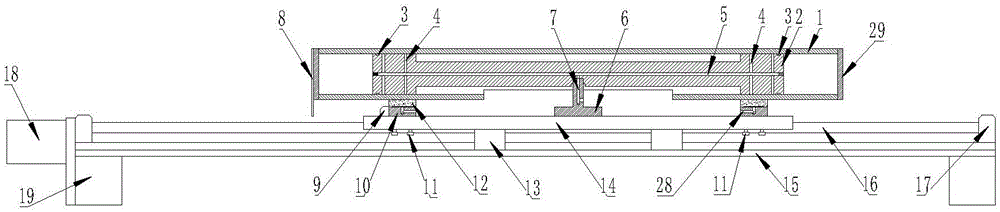

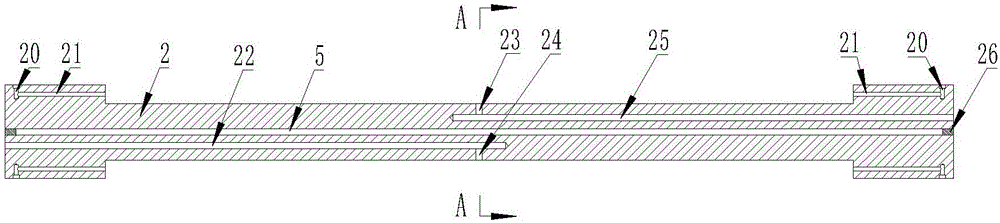

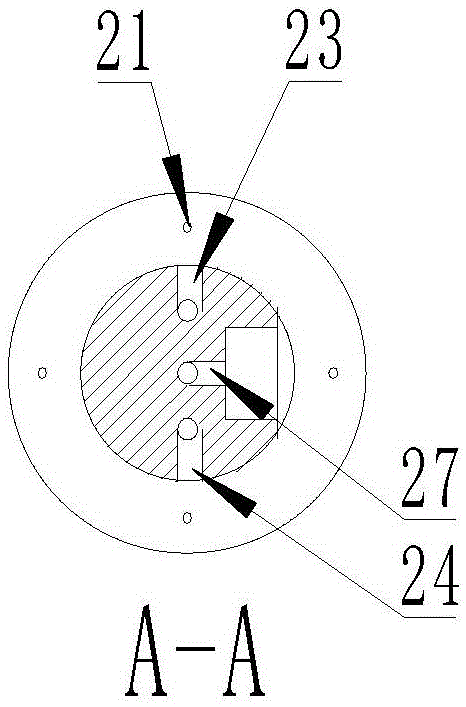

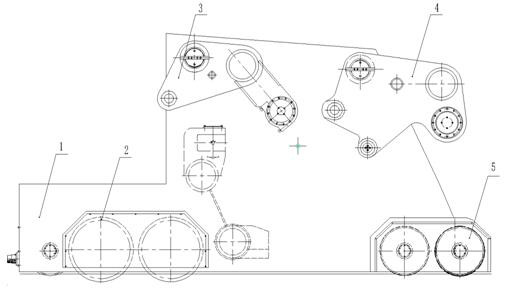

Automatic assembling system for voice diaphragm and globe roof

ActiveCN110125662AImprove image processing capabilitiesReduced precision requirementsMetal working apparatusImaging processingPosition angle

Automatic assembling system for a voice diaphragm and a globe roof comprises a three-axis motion system, the globe roof is grabbed by a vacuum cup on a mechanical arm, the system moves to a voice diaphragm photographing position, and a voice diaphragm image is obtained; the position angle parameter of the voice diaphragm is calculated; then the system moves the globe roof photographing position, aglobe roof image is obtained, and the position angle parameter of the globe roof is calculated; the position angle parameters of the voice diaphragm and the globe roof are judged; if the position angle parameters of the voice diaphragm and the globe roof are not equal, the globe roof is rotated, the globe roof image is acquired again, the position angle parameter of the globe roof is calculated,and whether the angle parameters are equal or not is judged again; if yes, the relative positions of the globe roof and the voice diaphragm are calculated; and an assembly procedure is executed, and finally the system moves to a safe position. According to the automatic assembling system, a voice diaphragm-globe roof rectangular frame is matched based on image processing of a bilateral telecentriclens, errors of the system are overcome, the image processing capacity of a camera is improved, the requirement of the system for the mechanical equipment precision can be greatly reduced, the assembly precision of the system is greatly improved to about 0.03 mm, and therefore the assembly precision requirement of the system is achieved.

Owner:SHANDONG IND TECH RES INST OF ZHEJIANG UNIV

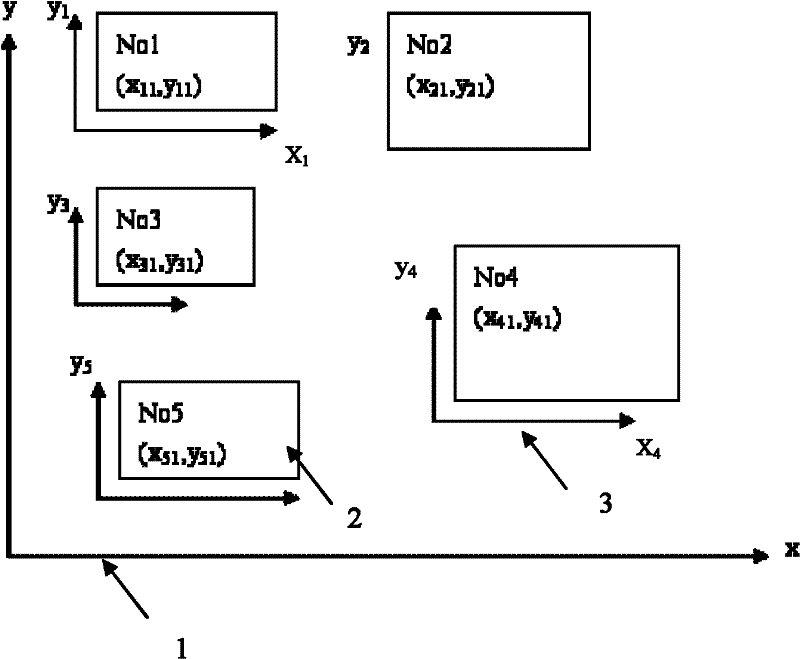

Non-slideway multi-module construction measuring method

InactiveCN102175199AMeet assembly precision requirementsMeasurement devicesComputer moduleEnvironmental geology

The invention discloses a non-slideway multi-module construction measuring method which comprises the steps of: 1, establishing construction site reference coordinates of an integral structure construction module; 2, determining reference coordinates of all submodules; 3, determining relative coordinates in the construction site reference coordinates according to positions of all submodules in reference coordinates of the submodules to obtain coordinate position information of parts in the submodules in the construction site reference coordinates; and 4, determining error requirements on the parts in accordance with the integral structure design size and error requirement according to the information of the part coordinate positions of the submodules. By adopting the method, construction allowance errors of the modules are obtained in the reference coordinates of the submodules, and integral assembly precision requirements are achieved after the submodules are integrally assembled.

Owner:TIANJIN UNIV

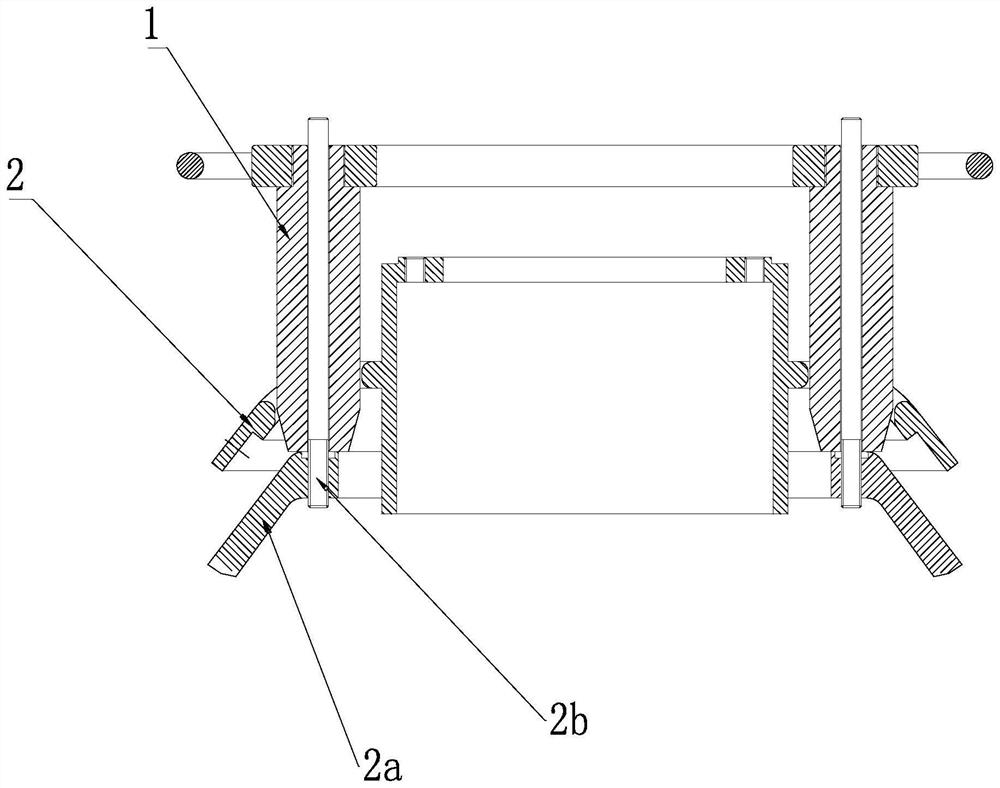

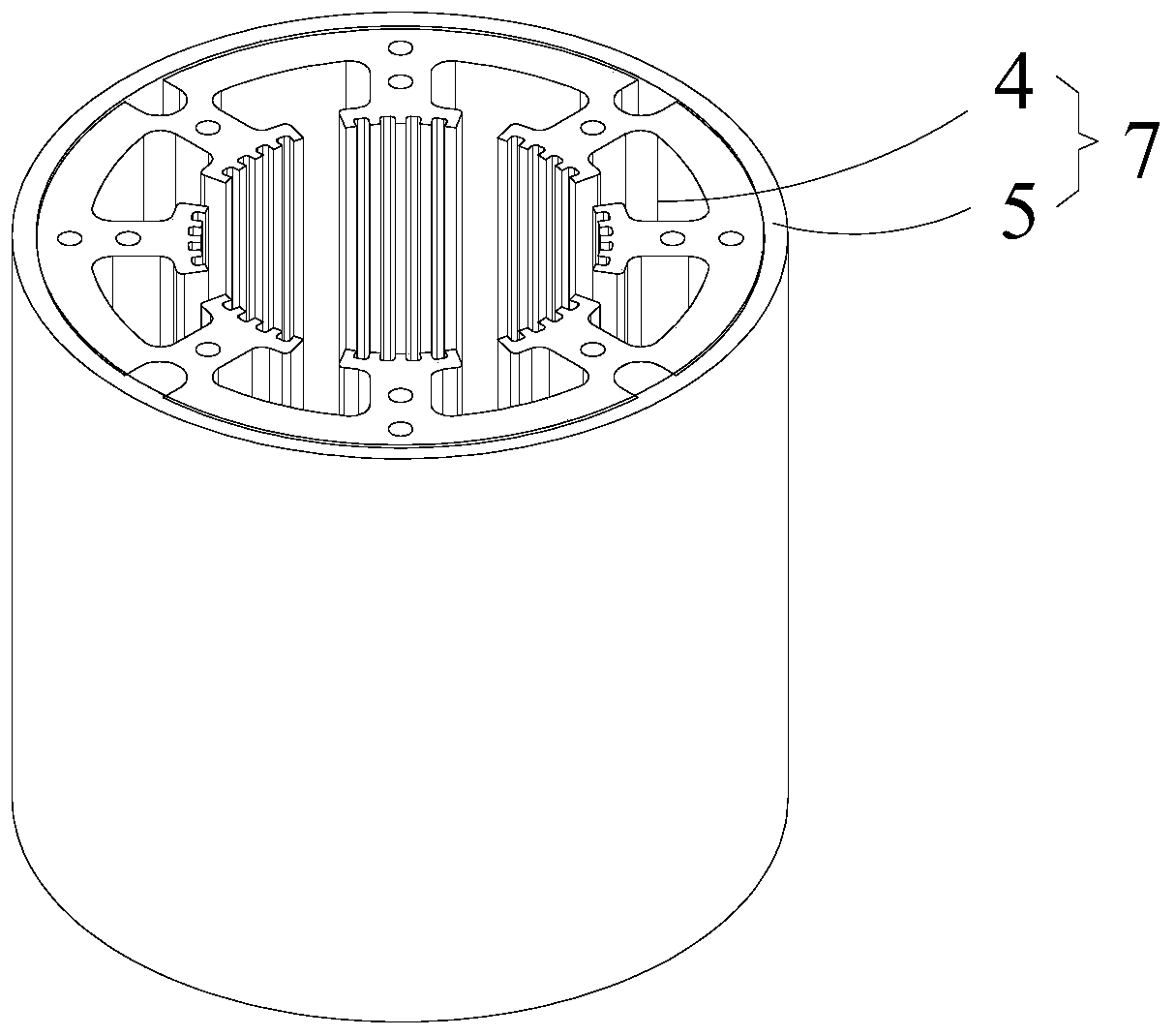

Axial laminated contact/noncontact combined sealing tape type conveyer plastic carrier roller

ActiveCN102363466AAvoid secondary processingGuaranteed concentricityRollersInterference fitClassical mechanics

The invention discloses an axial laminated contact / noncontact combined sealing tape type conveyer plastic carrier roller. The conveyer plastic carrier roller comprises a carrier roller shaft (8), a polyvinyl chloride (PVC) roller body (1) supported and sleeved on a bearing seat (2) through the bearing seat (2) and a bearing (7) arranged at two ends of the shaft, and an axial laminated contact / noncontact combined seal sealed in an annular cavity between the bearing seat (2) and the carrier roller shaft (8) through an end cover (4). The conveyer plastic carrier roller is characterized in that: the axial laminated contact / noncontact combined seal consists of a lamination seat (3) with a hollow columnar structure and an axial combined lamination assembly (6) arranged in a sealed groove machined in the inner wall or the outer wall of the lamination seat; the lamination seat (3) is combined with the carrier roller shaft (8) or the bearing seat (2) in an interference fit mode, and the radialclearance between the lamination seat (3) and the bearing seat (2) or the carrier roller shaft (8) is 0.1 to 1 millimeter; and the clearance between the width of the sealed groove of the lamination seat (3) and the total length of the axial combined lamination assembly (6) is 0.1 to 1 millimeter.

Owner:焦作精创科技有限责任公司

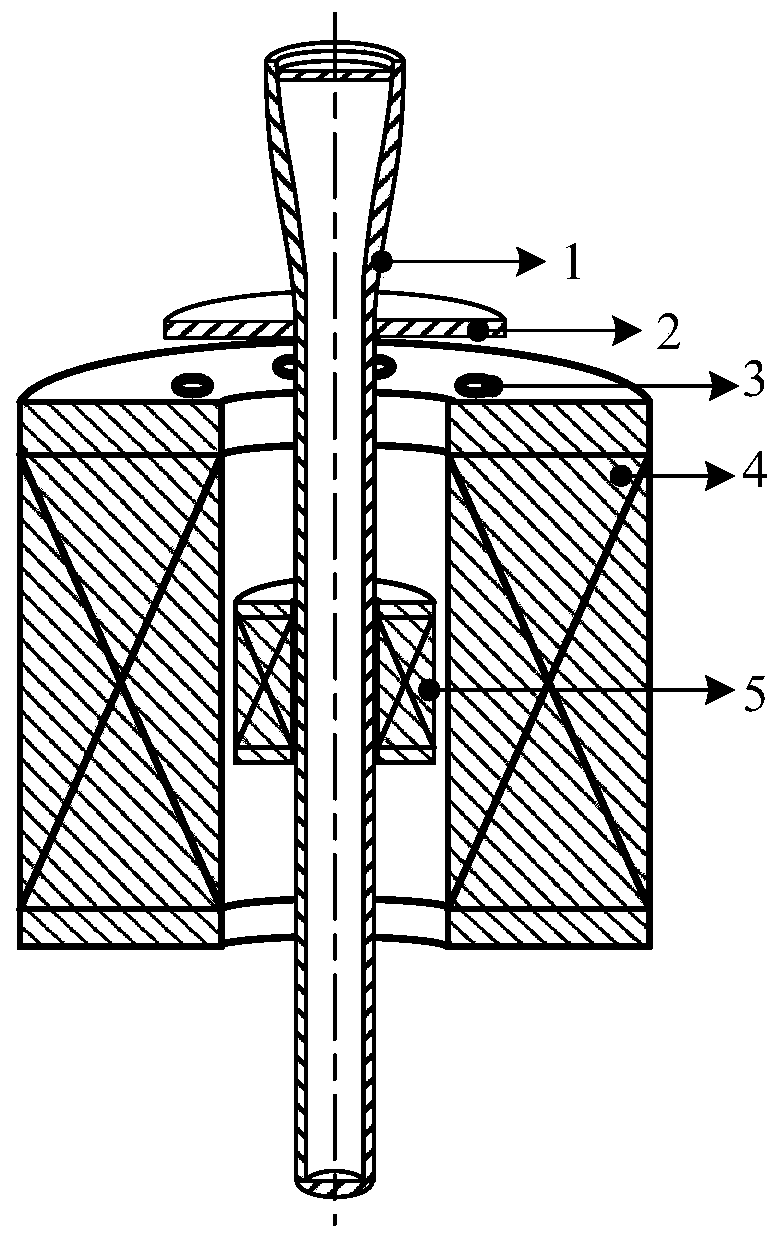

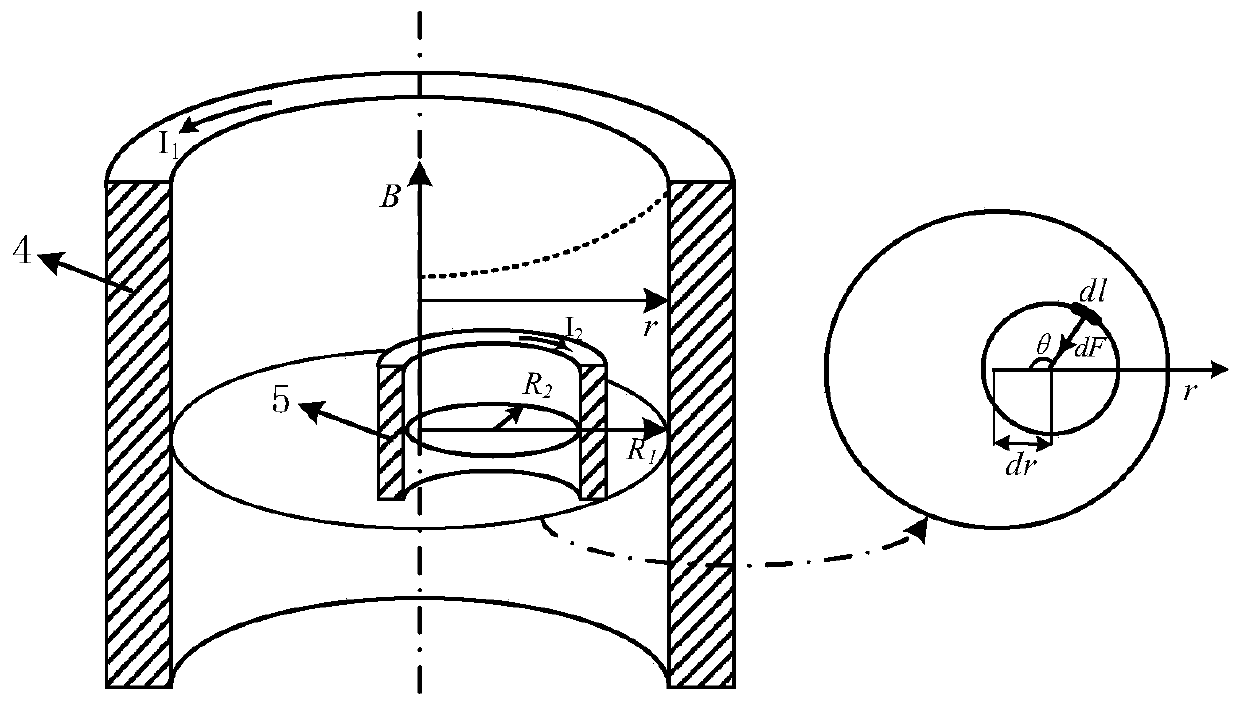

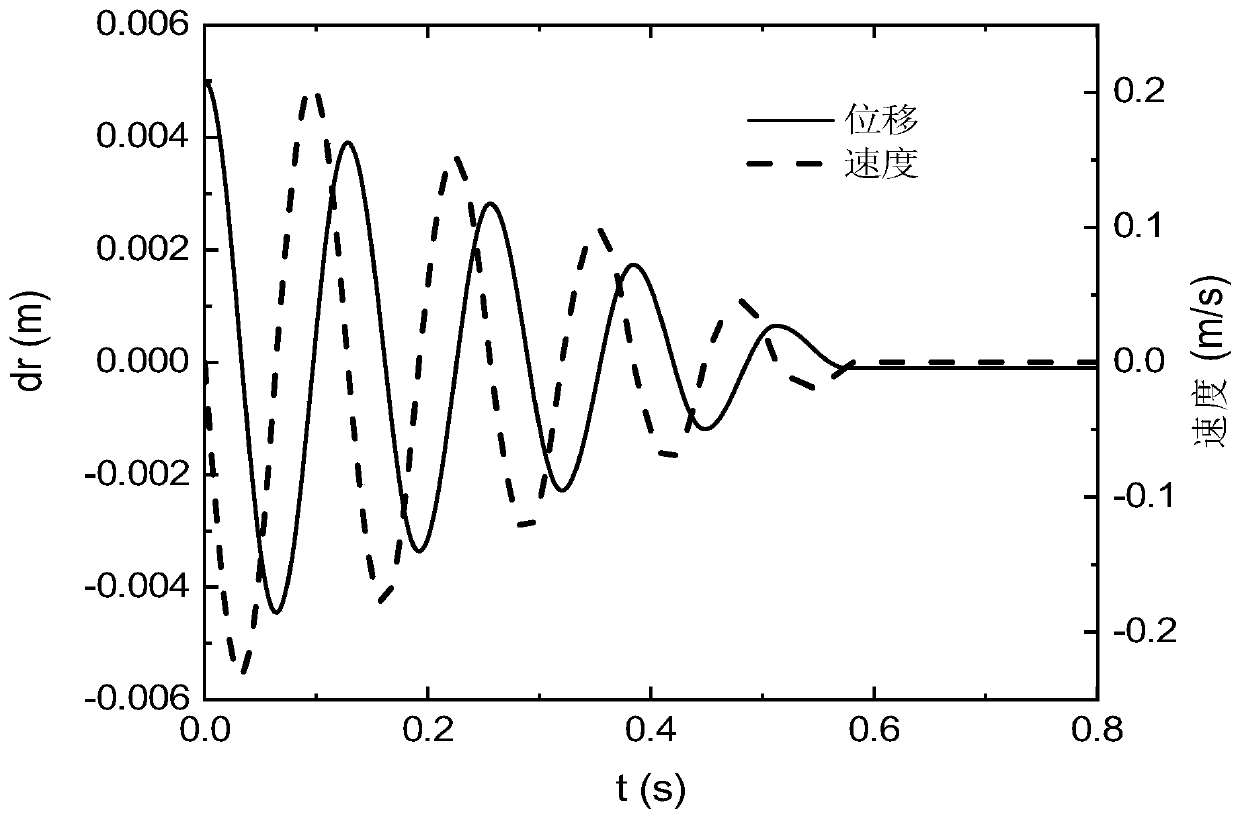

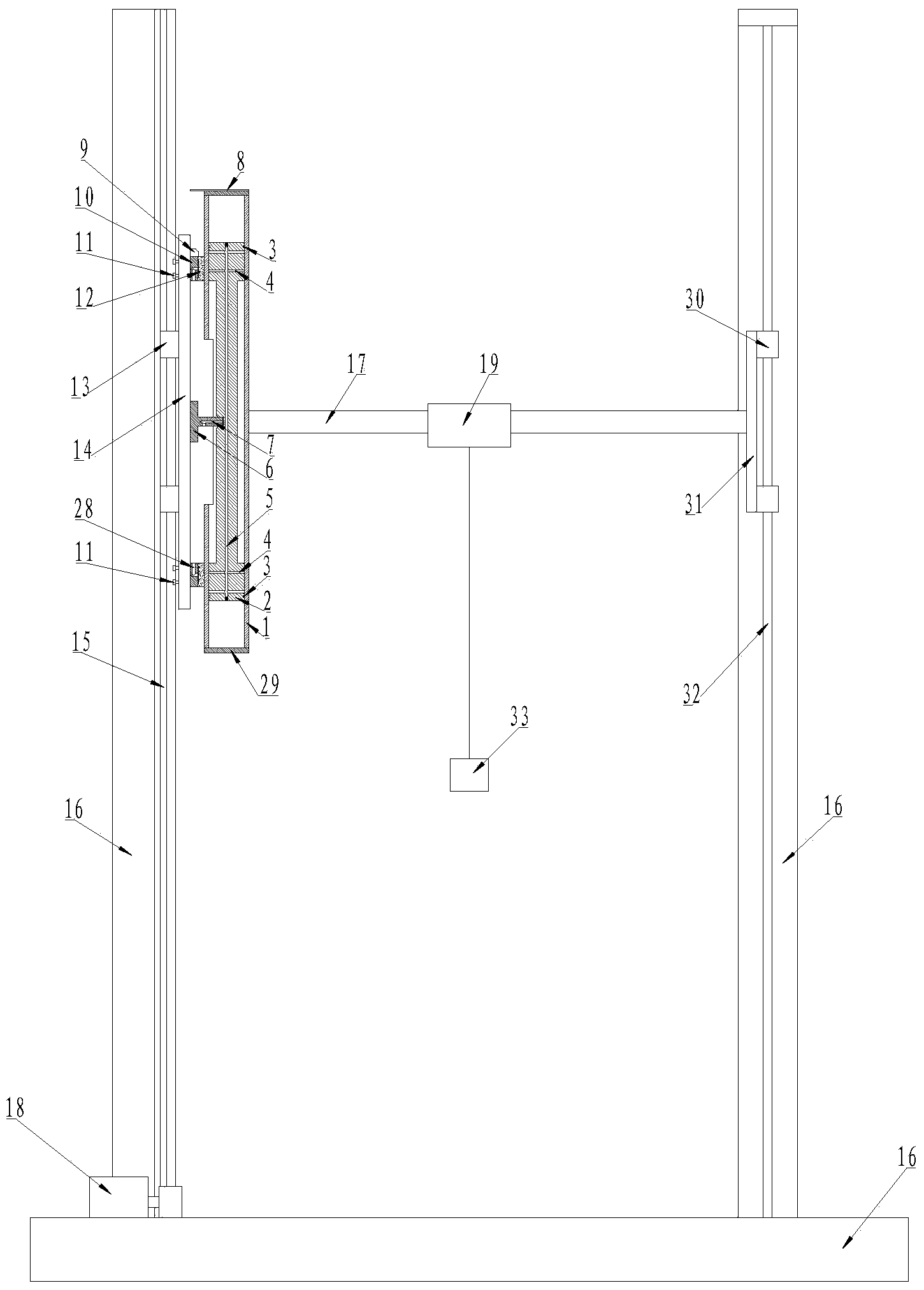

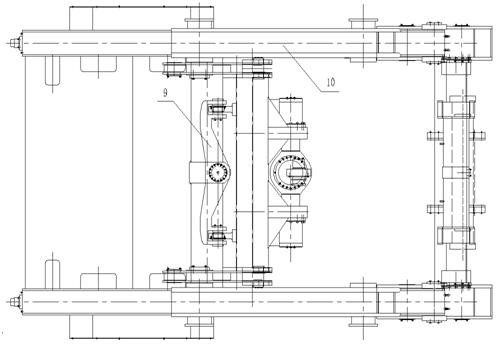

Device and method for coaxially assembling gyrotron body and magnet

PendingCN110808200AControl frictionMeet assembly precision requirementsTubes with helical electron streamInstalling/removing discharge tube/lamp auxillary deviceMagnetMaterials science

The invention discloses a device and method for coaxially assembling a gyrotron body and a magnet. The method comprises: a driving coil is wound around the gyrotron body inside a gyrotron magnet; whenthe driving coil is energized, the electromagnetic force of a magnetic field inside the gyrotron magnet acts on the driving coil, and the current direction of the driving coil is opposite to the current direction of the gyrotron magnet, and the magnetic field distribution inside the gyrotron magnet is configured such that from the magnetic axis of the gyrotron magnet to the inner wall of the magnet, the intensity of the magnetic field gradually increases; according to the left-hand rule of an energized coil in the magnetic field, the resultant force of the electromagnetic force acting on thedriving coil is directed to the magnetic axis direction, so as to drive the gyrotron body to move toward the magnetic axis direction, so that the axis of the gyrotron body coincides with the magneticaxis of the gyrotron magnet. The method enables the gyrotron body to perform a damping motion under the driving of the electromagnetic force acting on the driving coil, and finally makes the axis of the gyrotron body and the magnetic axis of the gyrotron magnet substantially coaxial with each other.

Owner:HUAZHONG UNIV OF SCI & TECH

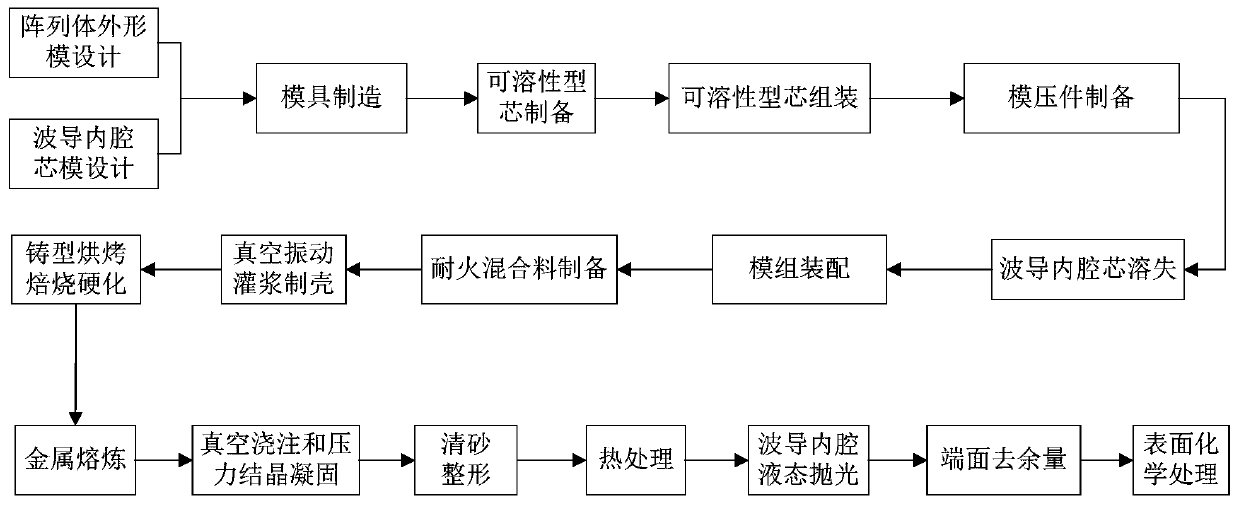

Multi-port millimeter wave bent rectangular waveguide array body integrated whole manufacturing method

ActiveCN110112529AMeet assembly precision requirementsMeet waveguide transmission performanceWaveguide type devicesPhysicsSolubility

The invention relates to the field of millimeter wave bent rectangular waveguides, and discloses a multi-port millimeter wave bent rectangular waveguide array body integrated whole manufacturing method. The method comprises the steps of: manufacturing a shape die of a waveguide array body and a water-solubility core forming die at a waveguide inner cavity; preparing a water-solubility core in thewaveguide inner cavity; obtaining an integrated compressing piece by employing the water-solubility core and the shape die; dissolving the water-solubility core in the waveguide inner cavity; assembling modules; preparing fire-resistant mixture; performing vacuum vibration and grouting to prepare a casted mold; performing calcinations for the casted mold; smelting a molten metal, and performing pressure maintaining, crystallization and solidification; performing sand removal, shaping and thermal treatment; performing liquid state polishing treatment for the waveguide inner cavity; and removingthe excess metal at the flange installation end face of the waveguide array body, and performing chemical treatment for the inner and outer surfaces of the waveguide array body. The products with thesmooth surfaces and the accurate sizes and capable of meeting the assembling precision requirements and the waveguide transmission performances are prepared by employing the method, and has the percent of pass up to 80%.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

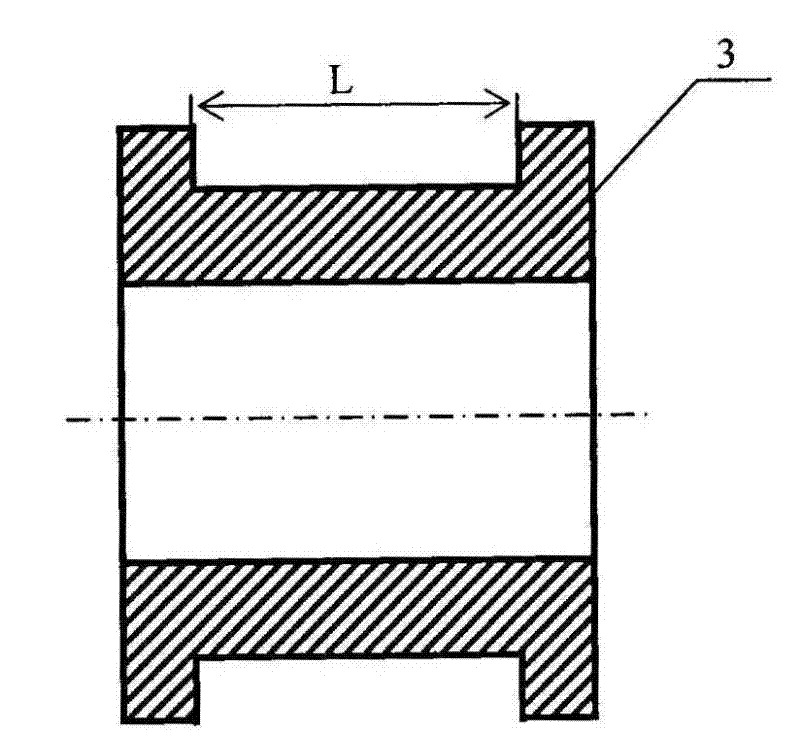

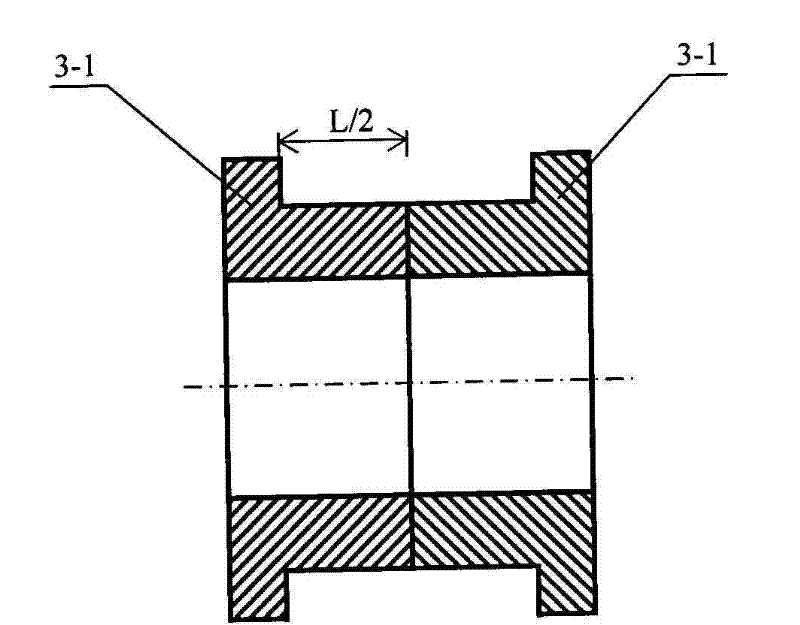

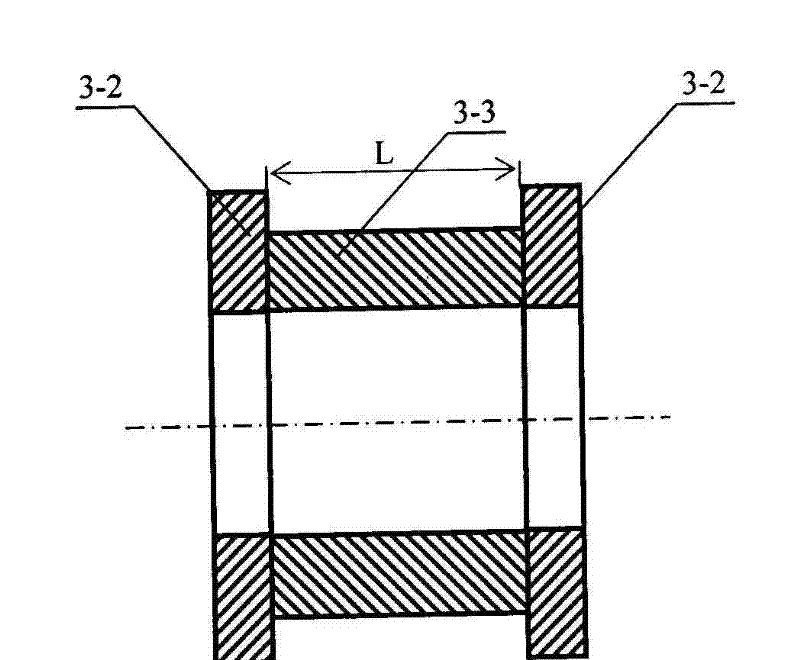

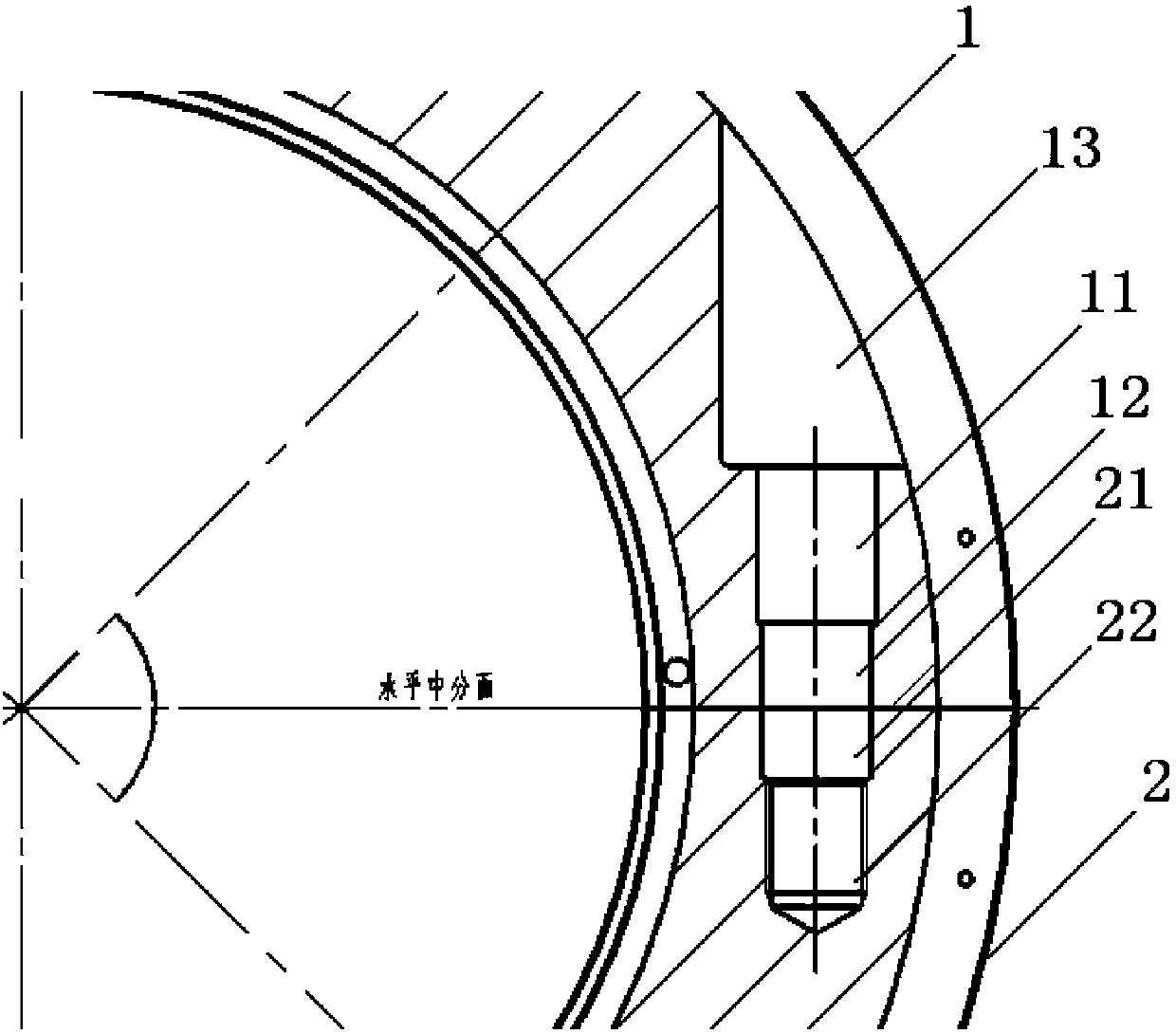

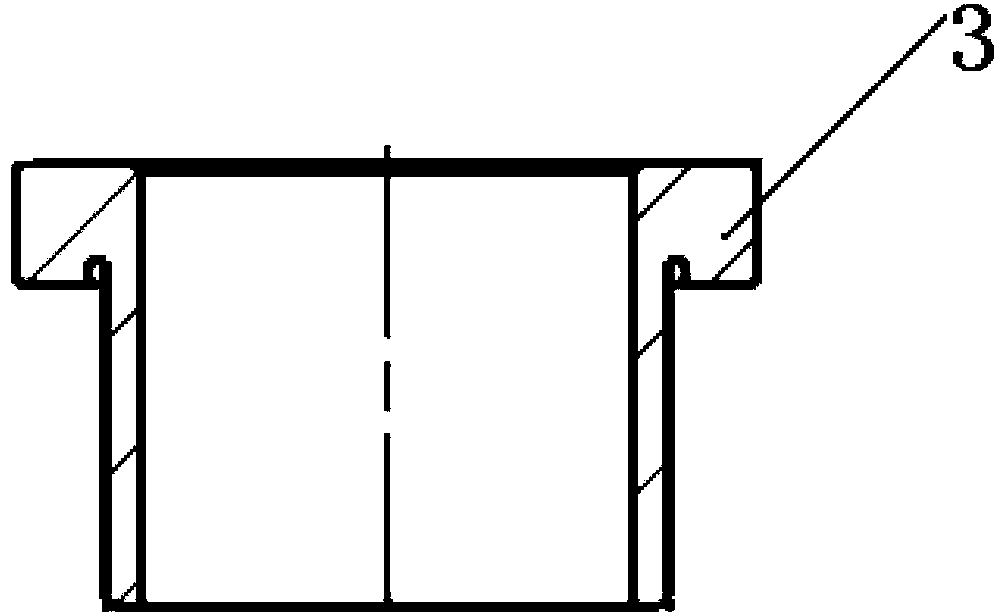

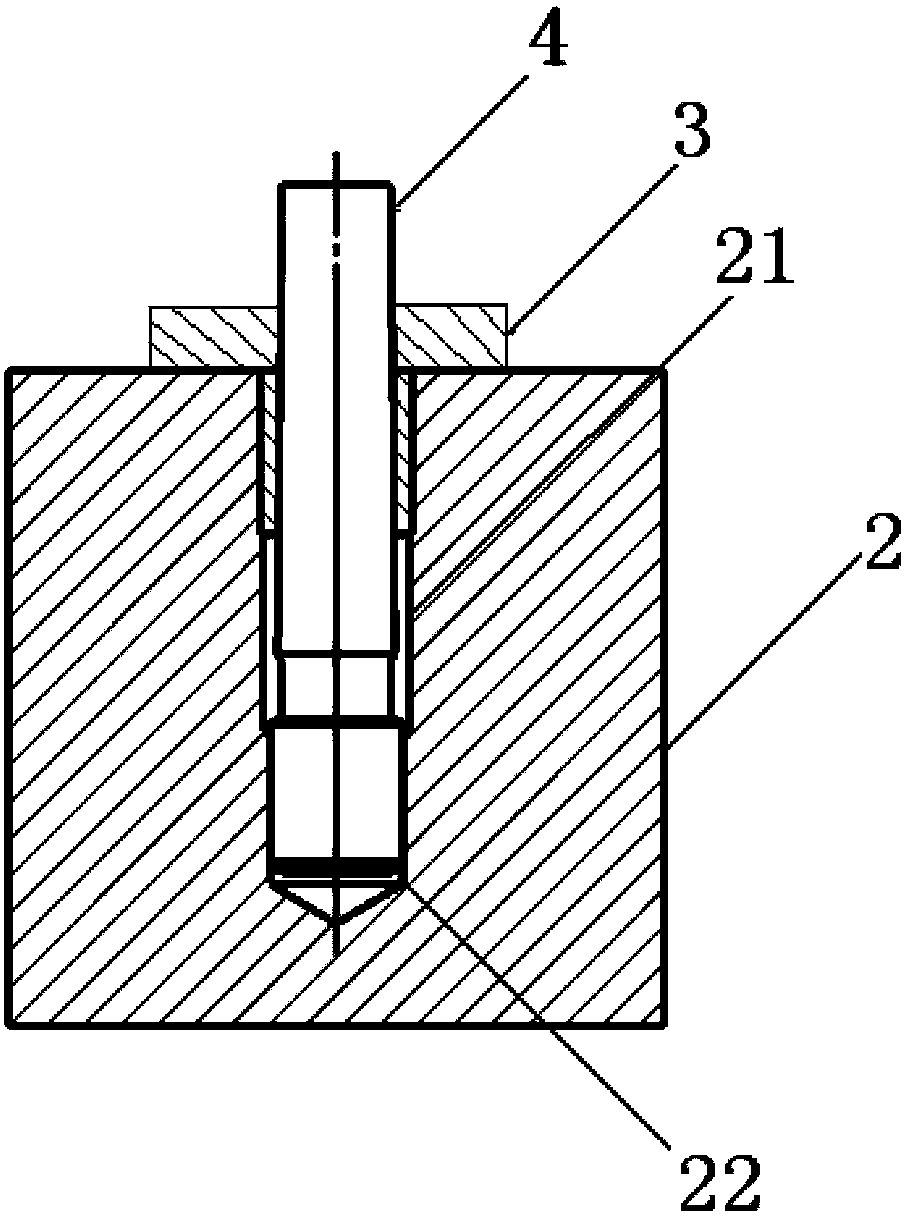

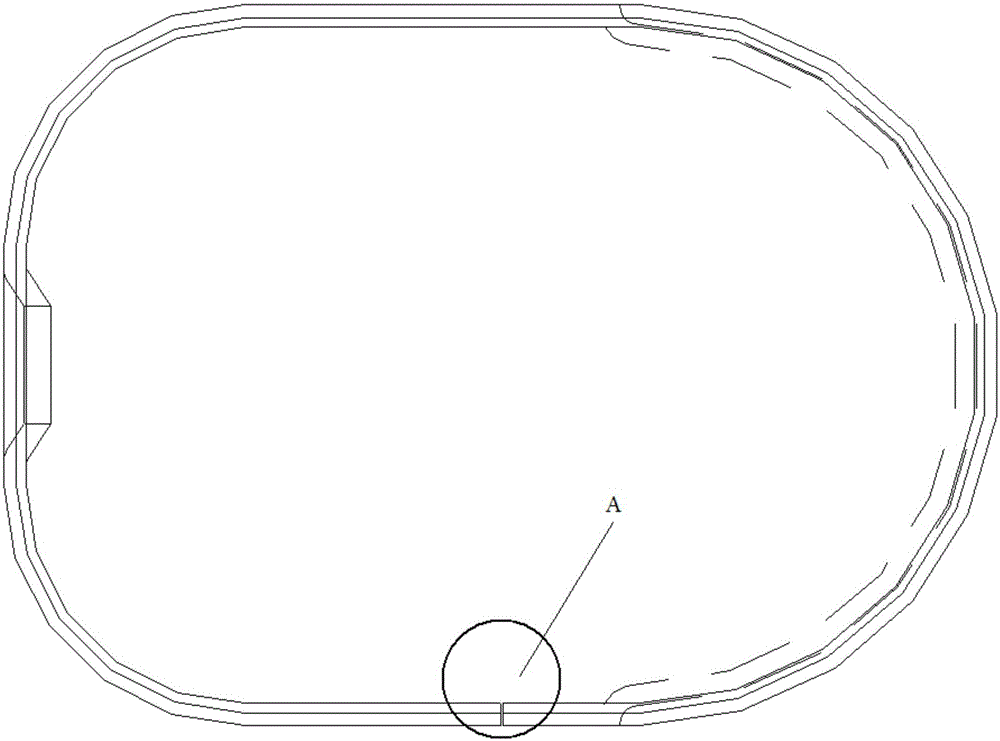

Threaded hole processing method with positioning function

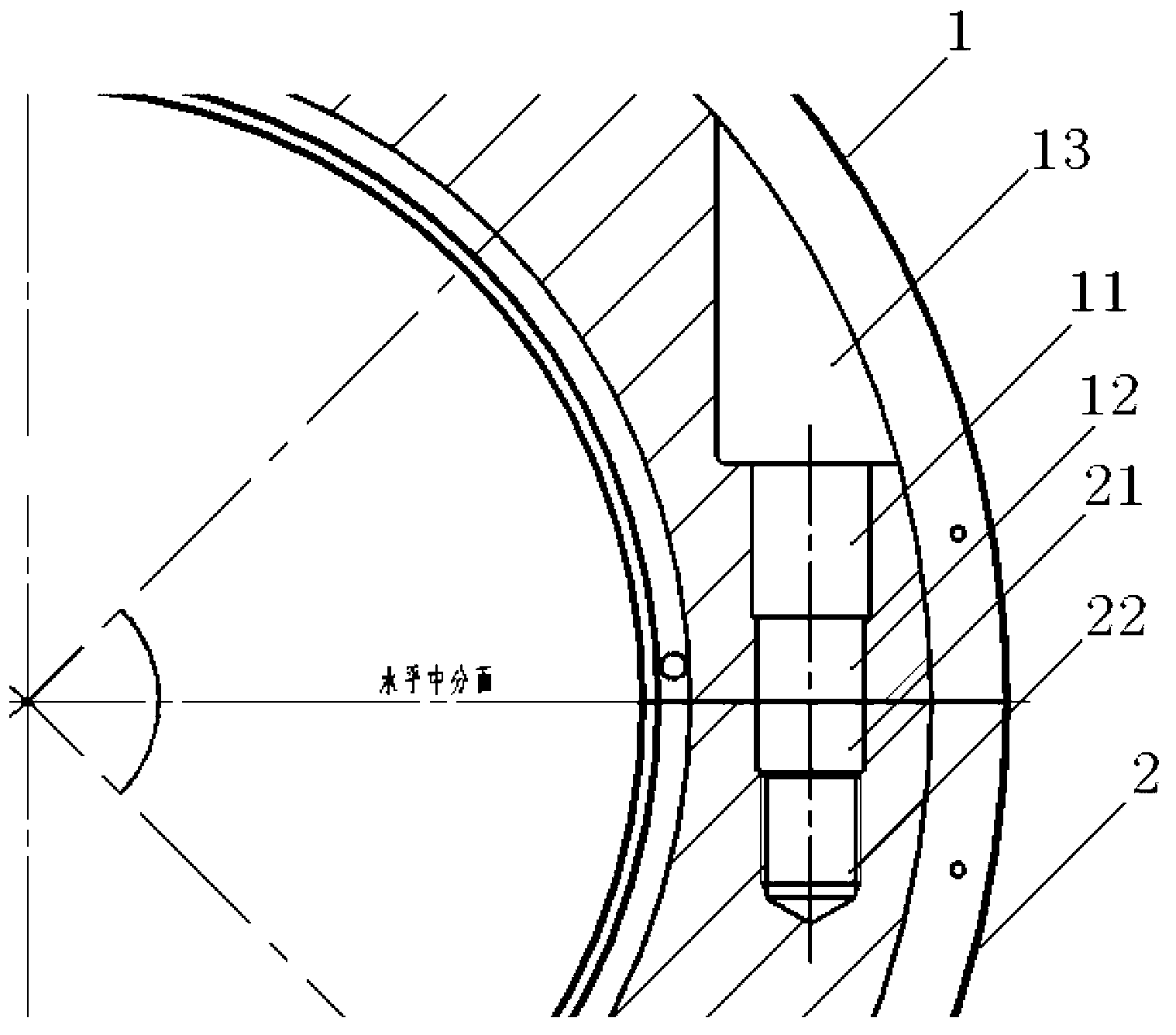

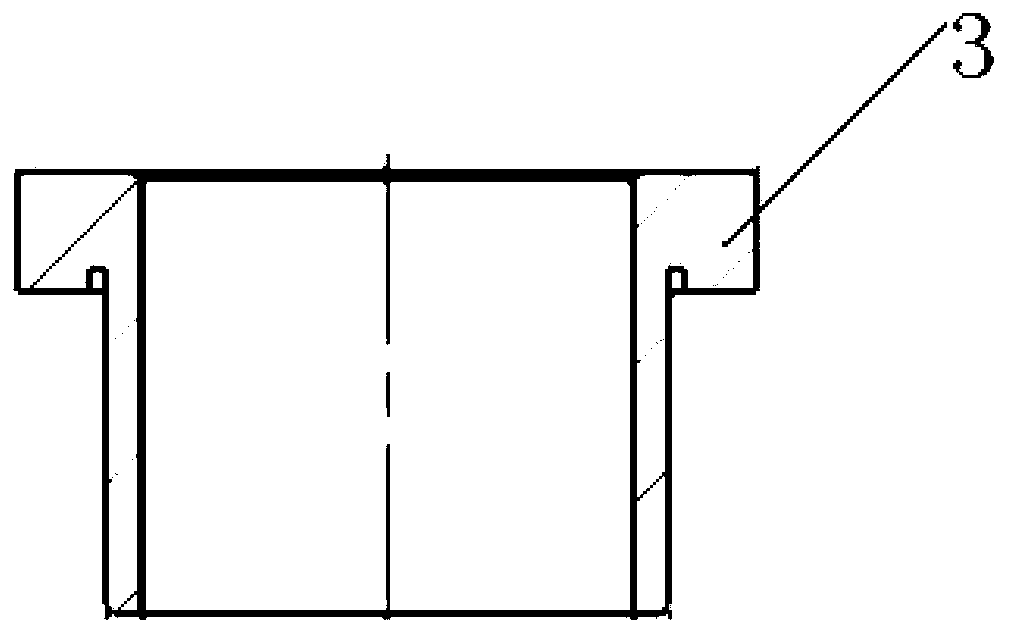

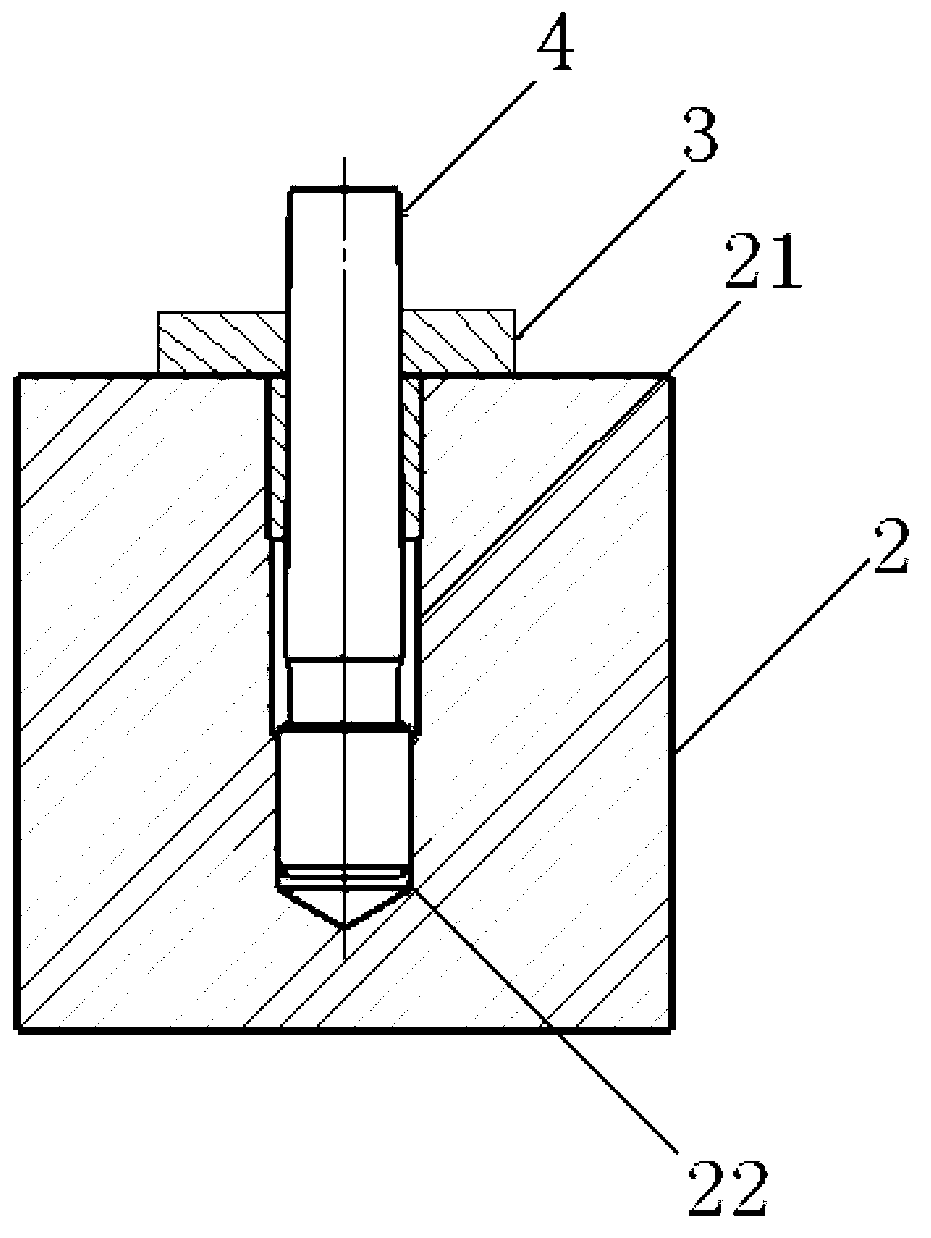

The invention provides a threaded hole processing method with a positioning function; when processing is carried out through the threaded hole processing method with the positioning function, firstly an upper semi-positioning hole is processed; secondly a lower semi-positioning hole is processed with the upper semi-positioning hole as the guidance; thirdly a guide sleeve is arranged in the lower semi-positioning hole as the guidance for processing a lower threaded hole; through the method, the positioned threaded hole can be respectively processed in an upper semi-circular structural piece and a lower semi-circular structural piece; consequently, the processing speed can be effectively improved, and the threaded hole processing difficulty is reduced; meanwhile, the processing method can also effectively ensure the axial positioning and radial spacing requirements of the upper semi-circular structural piece and the lower semi-circular structural piece, so that the assembly precision requirements are met when the upper and lower semi-circular structural pieces are met; and the threaded hole processing method with the positioning function is particularly applicable to a vapor seal or a division sleeve and other work pieces with smaller width of a horizontal split on a steam turbine.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

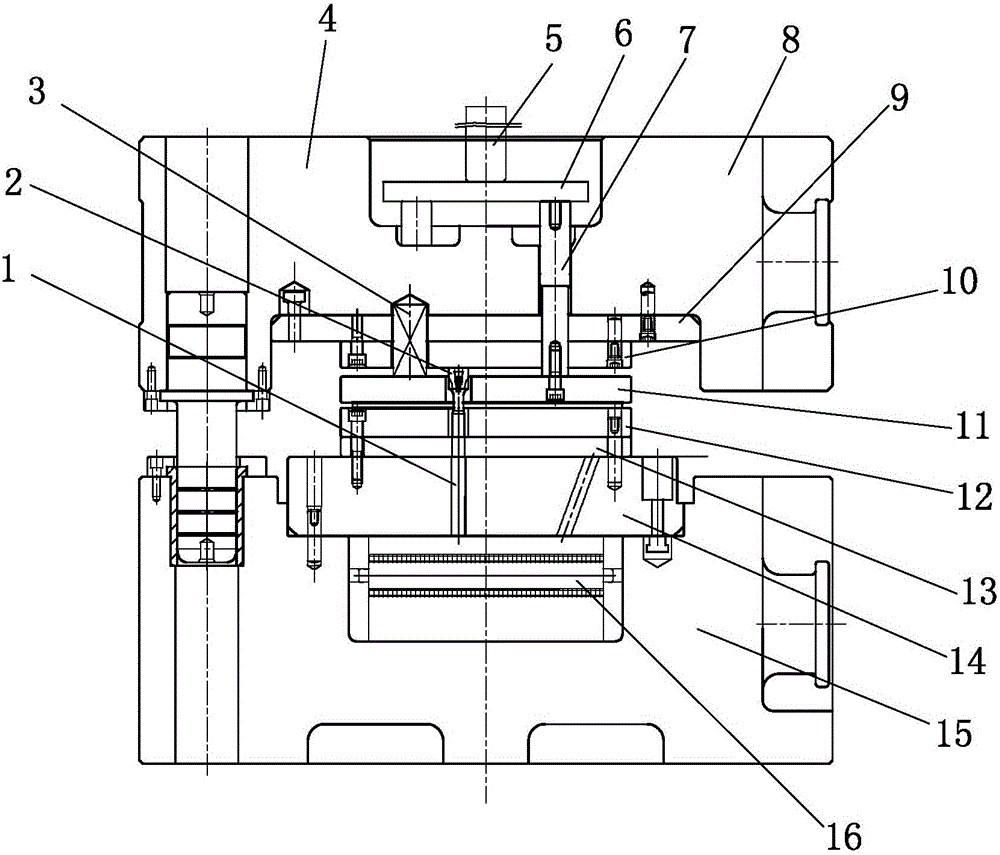

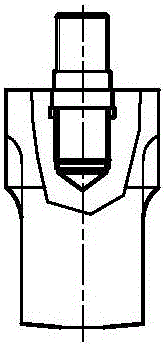

Assembling and adjusting process of automobile frame longitudinal beam punching die

InactiveCN105834285AEasy to debugSave materialShaping toolsPerforating toolsPunchingElectrical and Electronics engineering

The invention discloses an assembling and adjusting process of an automobile frame longitudinal beam punching die. The assembling and adjusting process of the automobile frame longitudinal beam punching die comprises the following steps that (1) the positions of female die fixing plates are adjusted, specifically, cushion blocks of the same height are placed on the female die fixing plates, die adjusting plates are placed on the cushion blocks of the same height, die adjusting pins are arranged in corresponding holes in the die adjusting plates and the female die fixing plates, then the positions of the adjacent female die fixing plates can be determined, and the positions of all the female die fixing plates can be determined through repeated operations; and (2) male die fixing plates are adjusted through the female die fixing plates, specifically, four cylinder pin holes are bored in the four corners of each male die fixing plate, cylinder pin holes of the same diameter are also bored in the same coordinate positions of the corresponding female die fixing plate, cushion blocks of the same height are placed between each male die fixing plate and the corresponding female die fixing plate, process cylinder pins are assembled into the corresponding cylinder pin holes in the male die fixing plates and the female die fixing plates, the male die fixing plates are accurately positioned through the female die fixing plates, then the male die fixing plates are fixed to an upper die through screws, and the positions of the male die fixing plates are determined one by one.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

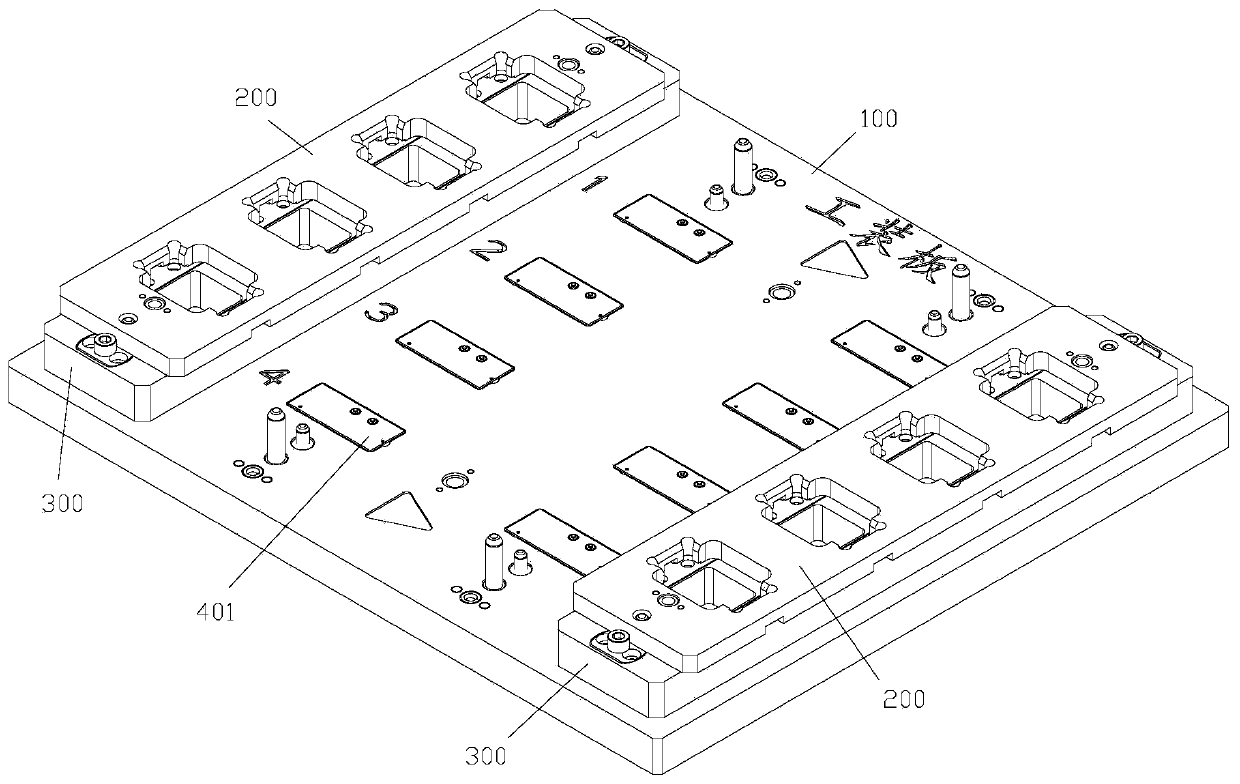

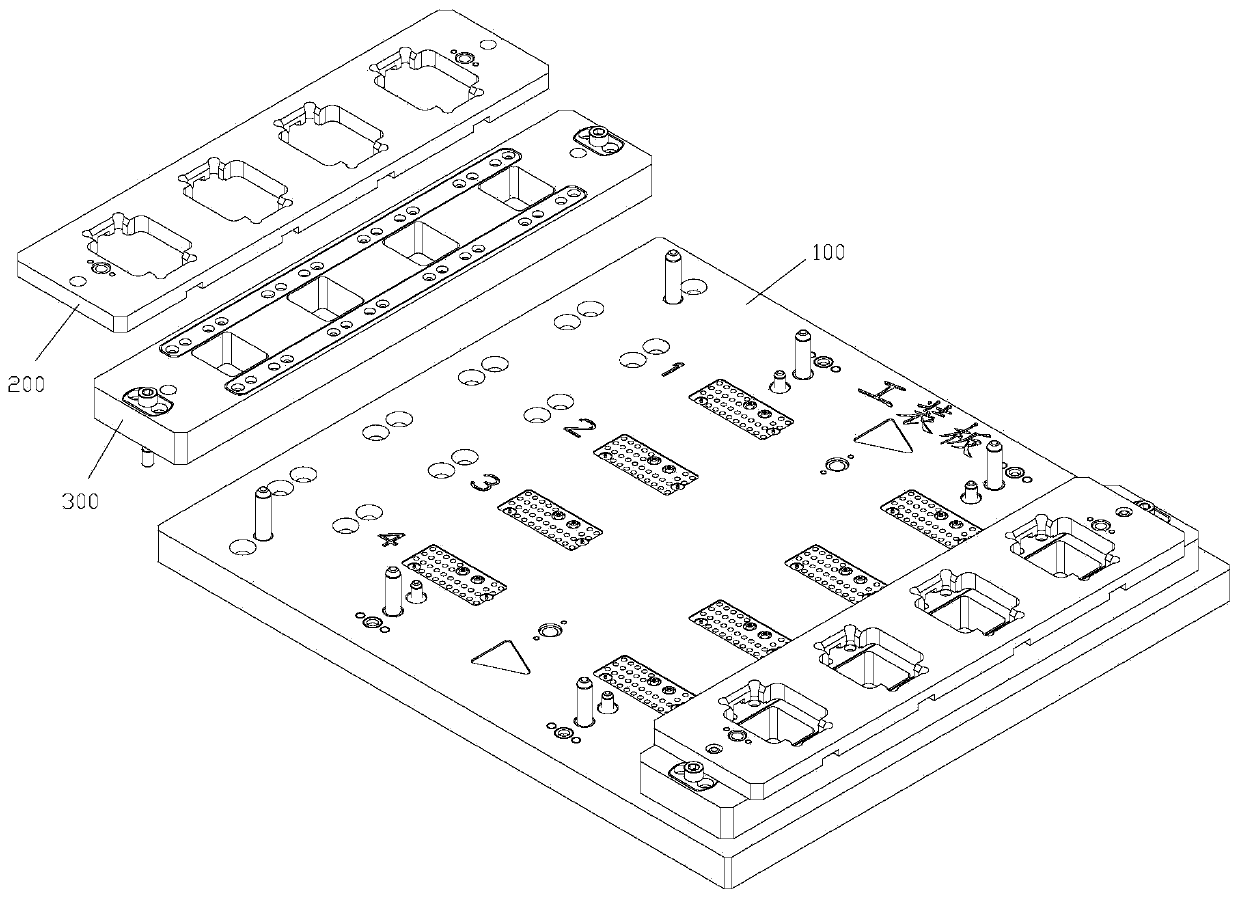

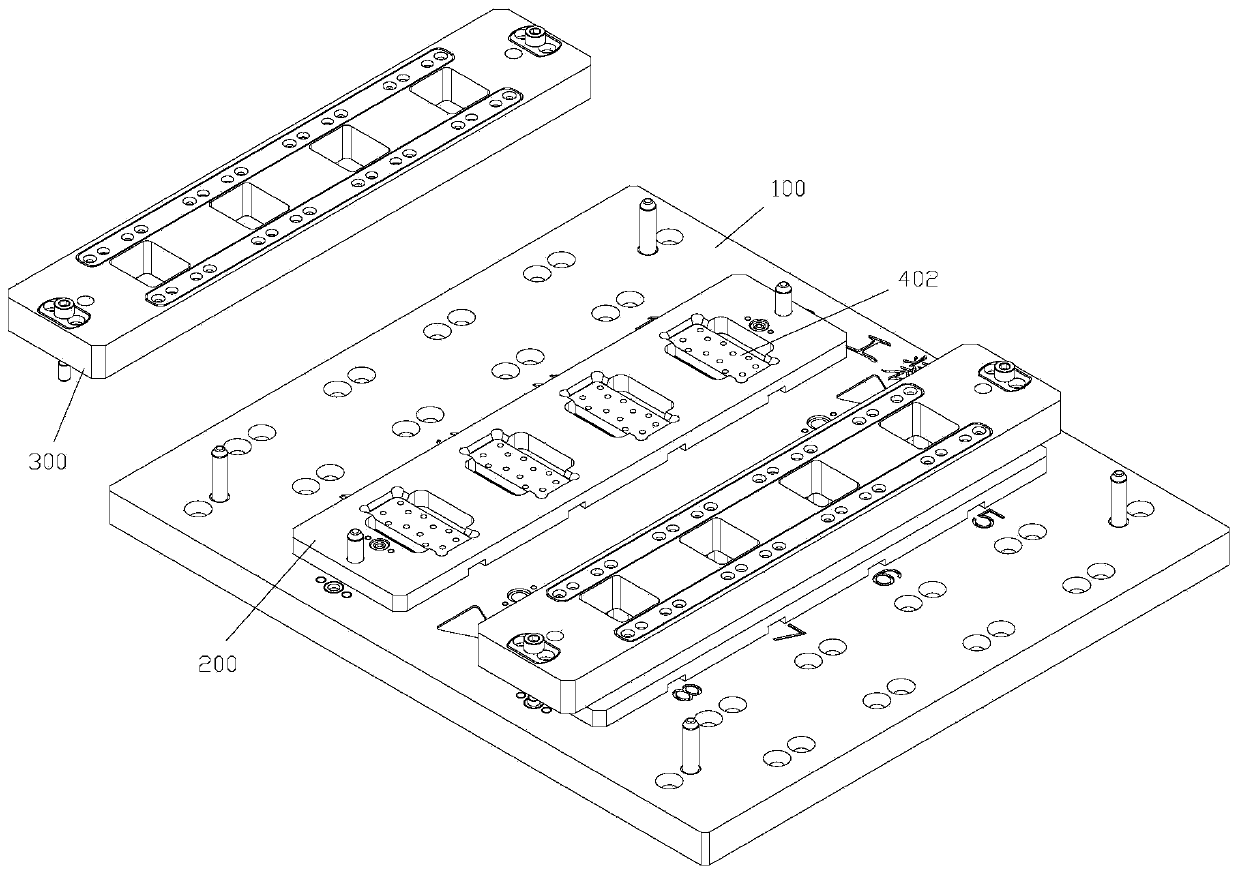

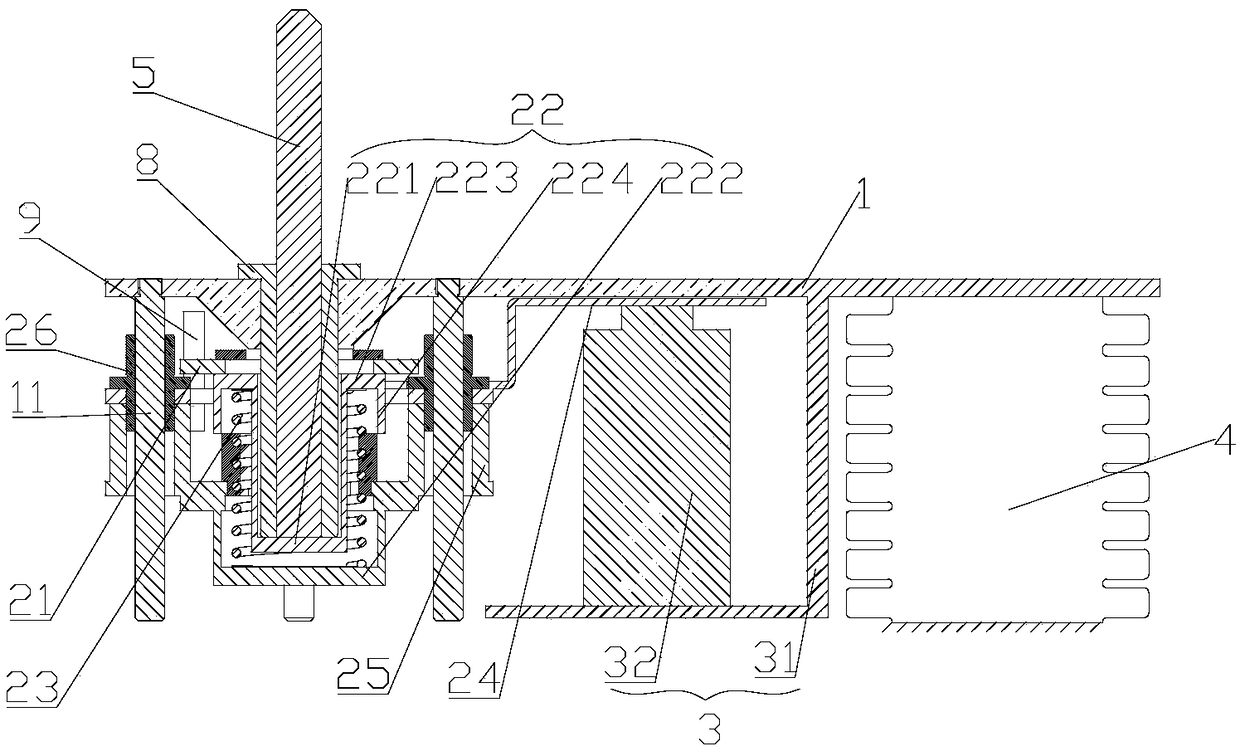

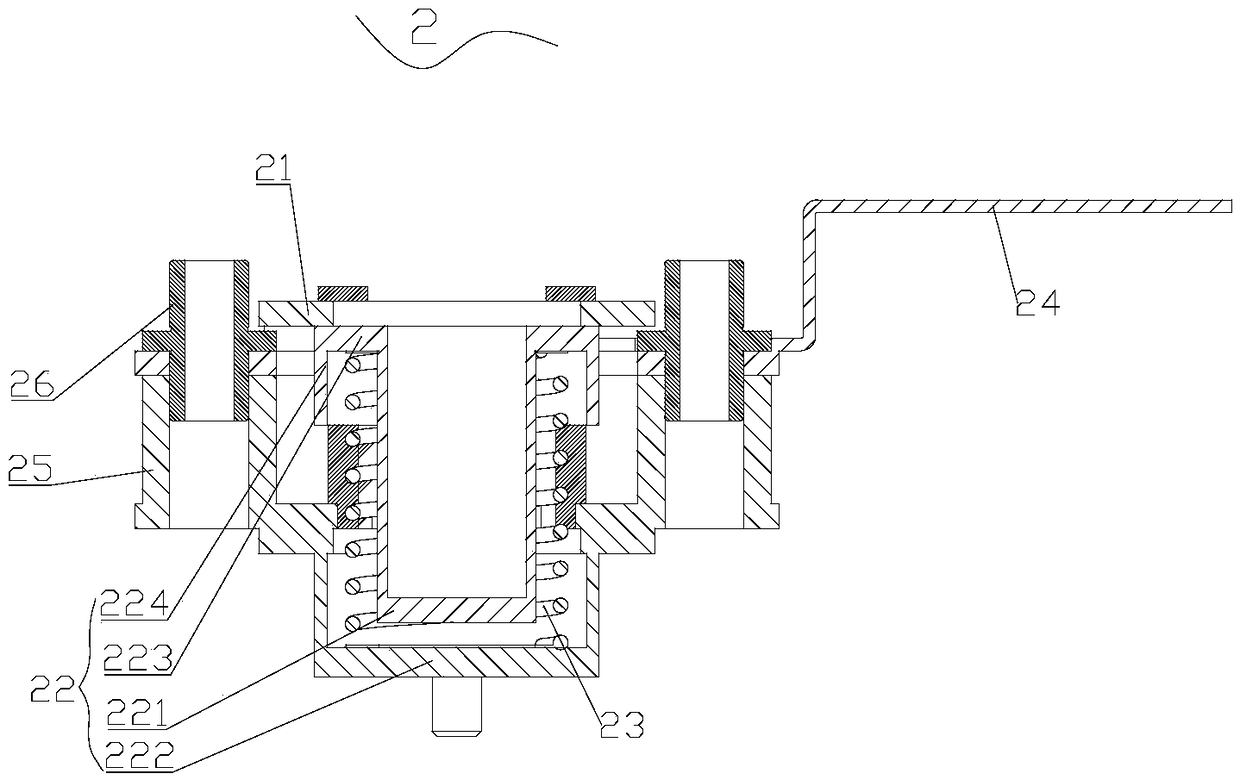

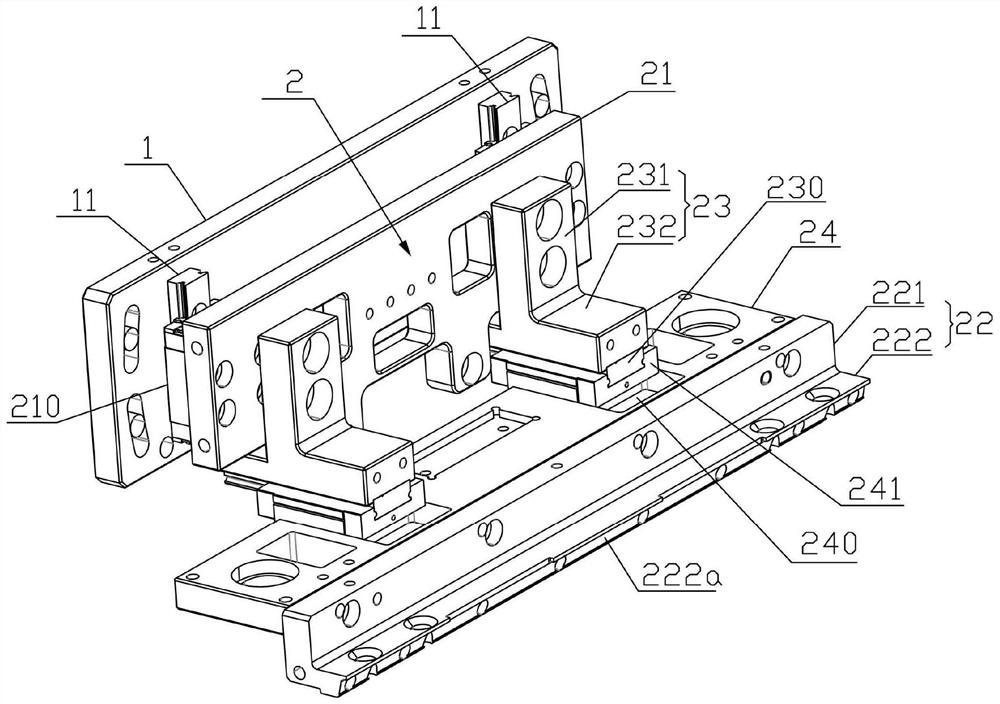

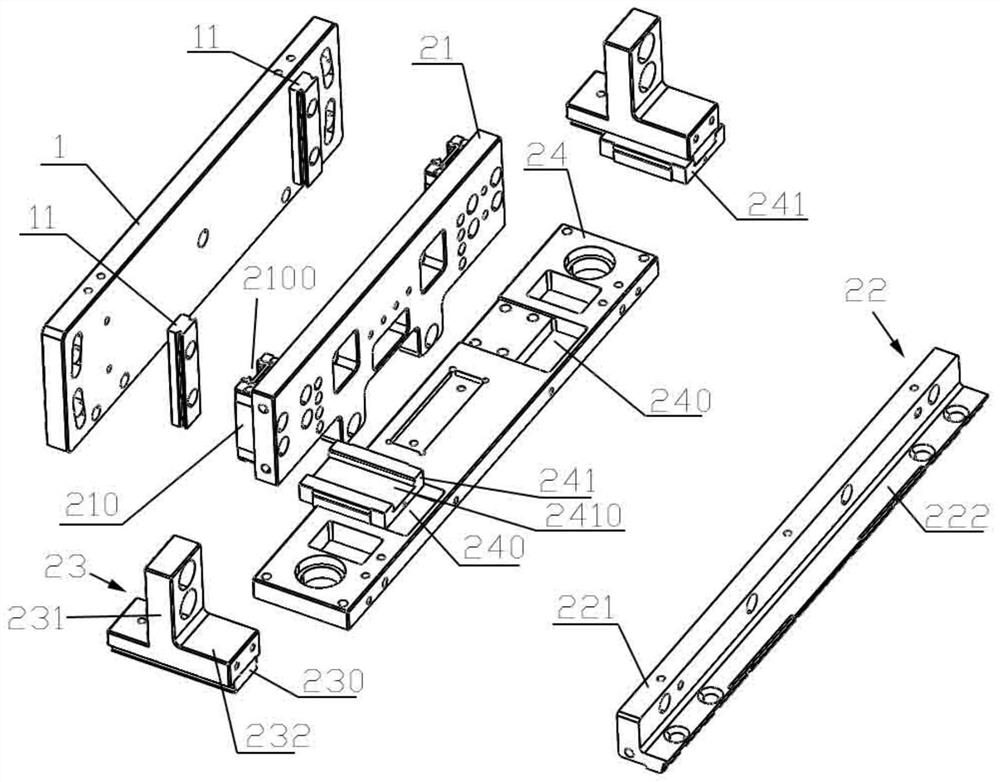

Tool clamp and method for 5G dielectric filter assembly line

InactiveCN110919119APrecise positioningMeet assembly precision requirementsSoldering auxillary devicesDielectricEngineering

The invention relates to a tool clamp for a 5G dielectric filter assembly line. The tool clamp comprises a tool bottom plate, a tool template and a tool pressing plate, wherein an assembly area is arranged on the tool bottom plate, an assembly groove is formed in the assembly area and is used for positioning and placing a PCB, and a PCB positioning pin and a joint positioning sleeve are arranged in the assembly groove; a profiling positioning hole matched with the assembling groove is formed in the tool template, and the profiling positioning hole is matched with a ceramic medium in shape; anelastic floating pressing pin is arranged on the lower surface of the tool pressing plate; and the assembly area is further provided with a template positioning pin and a pressing plate positioning pin, the tool template is provided with a first template positioning hole matched with the template positioning pin, and the tool pressing plate is provided with a pressing plate positioning hole matched with the pressing plate positioning pin. The tool clamp and method are used for assembling and welding of a 5G dielectric filter, and the positioning mode can guarantee the product assembling precision by adopting different positioning modes in combination with different procedures of a product assembling process.

Owner:WUHAN XINHAO INTELLIGENT TECH CO LTD

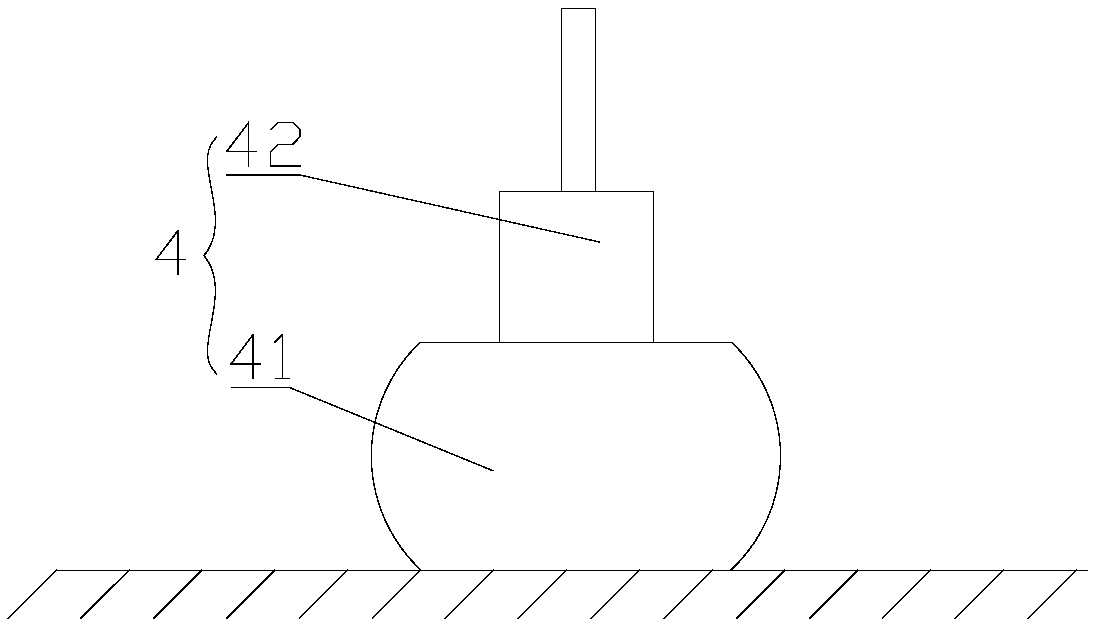

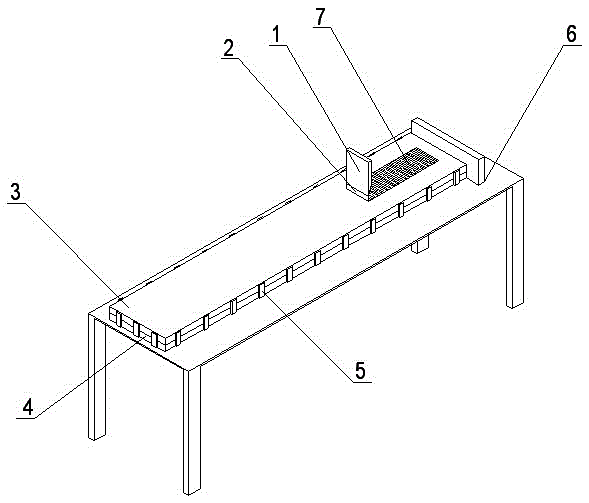

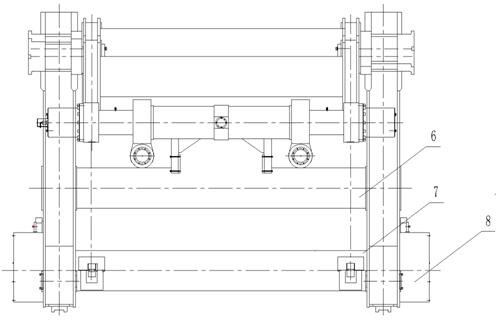

Adaptive flexible guiding-type assembling platform

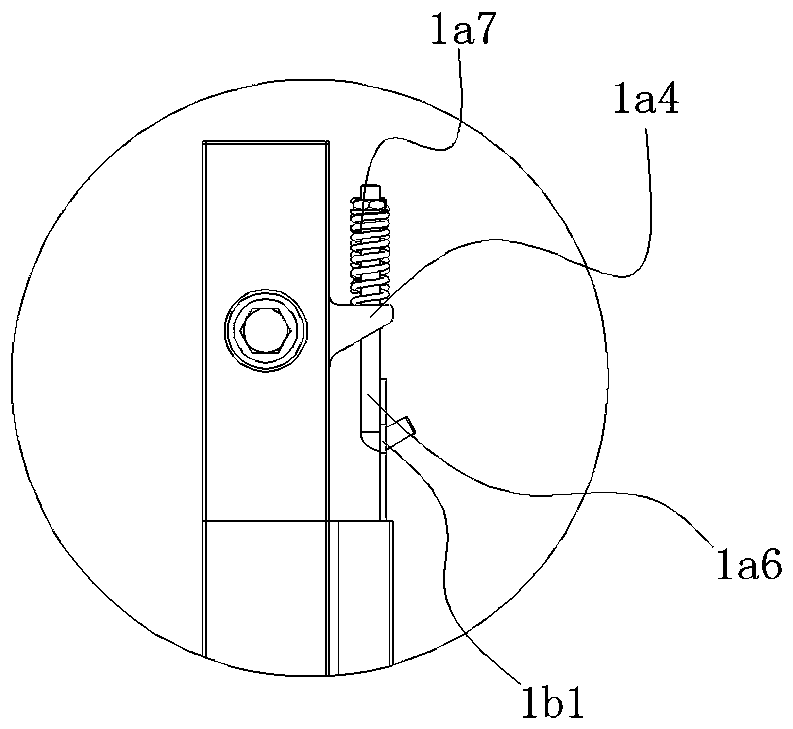

PendingCN109048269AOrientation is accurateMeet assembly precision requirementsMetal working apparatusFixed frameEngineering

The invention discloses an adaptive flexible guiding-type assembling platform. The adaptive flexible guiding-type assembling platform comprises a storage table and a jacking device. A guide hole is formed in the storage table. A guide pin is arranged in the guide hole in a penetrating mode. The adaptive flexible guiding-type assembling platform further comprises a force transmission mechanism anda supporting mechanism. The force transmission mechanism comprises a connecting plate, a force transmission cylinder, an elastic piece and a force transmission plate. The guide pin is sleeved with theconnecting plate. The force transmission cylinder comprises an inner cylinder body and an outer cylinder body. The upper portion of the inner cylinder body and the upper portion of the outer cylinderbody are open, and the lower portion of the inner cylinder body and the lower portion of the outer cylinder body are closed. The lower end of the guide pin is sleeved with the inner sleeve body. A jacking piece which extends outwards is arranged at the upper end of the inner sleeve body. The outer cylinder body is connected with the connecting plate. The elastic piece is arranged between the inner cylinder body and the outer cylinder body. The force transmission plate is arranged at the upper end of the outer cylinder body. The supporting mechanism comprises a fixing frame and a supporting body. The fixing frame is connected with the storage table and corresponds to the force transmission plate. The supporting plate is located on the fixing frame. The jacking device is a flexible jackingdevice. The adaptive flexible guiding-type assembling platform has the advantage that adaptive adjustment can be conducted in the guiding process, and thus, the adaptive flexible guiding-type assembling platform can be widely used for assembling large-load and high-precision products.

Owner:安徽亘鼎智能科技有限公司

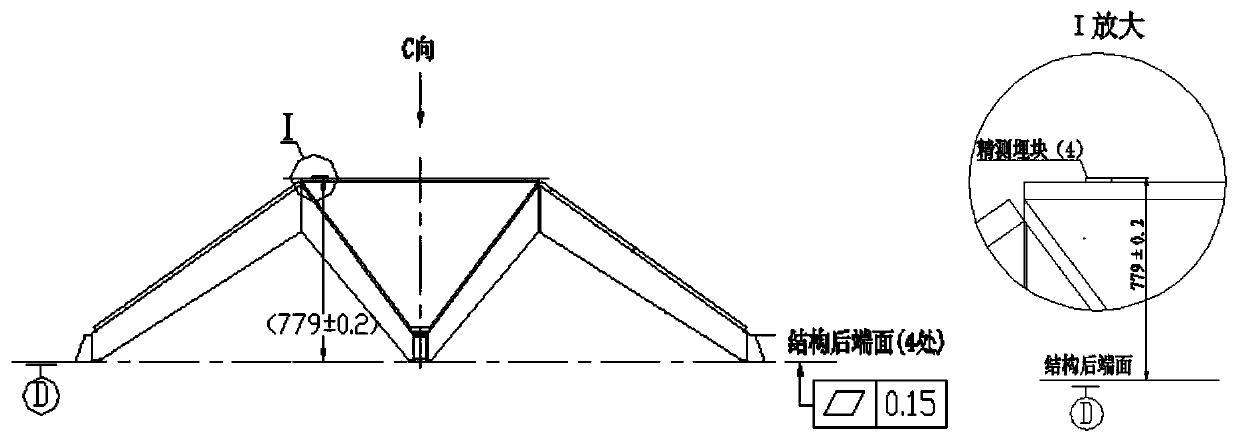

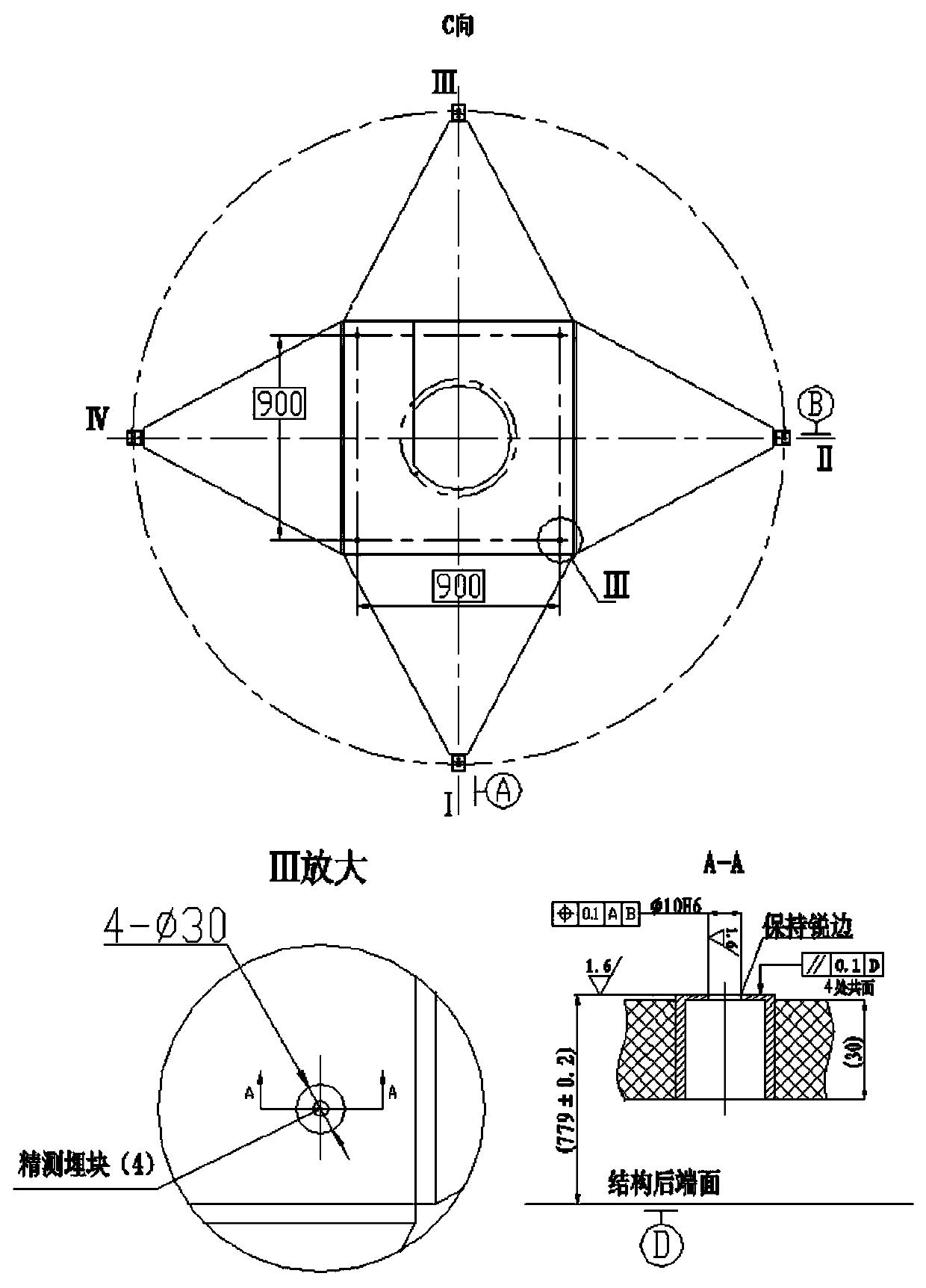

Establishing and measuring method of measuring datum of light honeycomb sandwich box type structure

ActiveCN110836635AImprove efficiencyImprove accuracyUsing optical meansHoneycombStructural engineering

The invention relates to an establishing and measuring method of accuracy datum of a light honeycomb sandwich box type structure. Through the datum conversion, datum plane establishing, process datumand measuring platform establishing and like methods, the assembling accuracy of an electronic instrument on a structure platform is ensured. Through the datum research method, the stable datum establishing, datum prism mounting, and measurement platform researching, the assembling of the precision electronic instrument of an easily-deformed structure platform can be met, and an accuracy demand ofa cabin mechanical coordinate system can be met. The light honeycomb sandwich box type structure can be guaranteed to be located at a no-load condition, a full-load condition, and the process of connecting with other cabins, hoisting and transferring through the datum conversion method, the stable datum establishing, the datum prism mounting, and the measurement platform researching, the measurement datum is stable and free from deformation, and the measurement accuracy under various conditions can be met.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

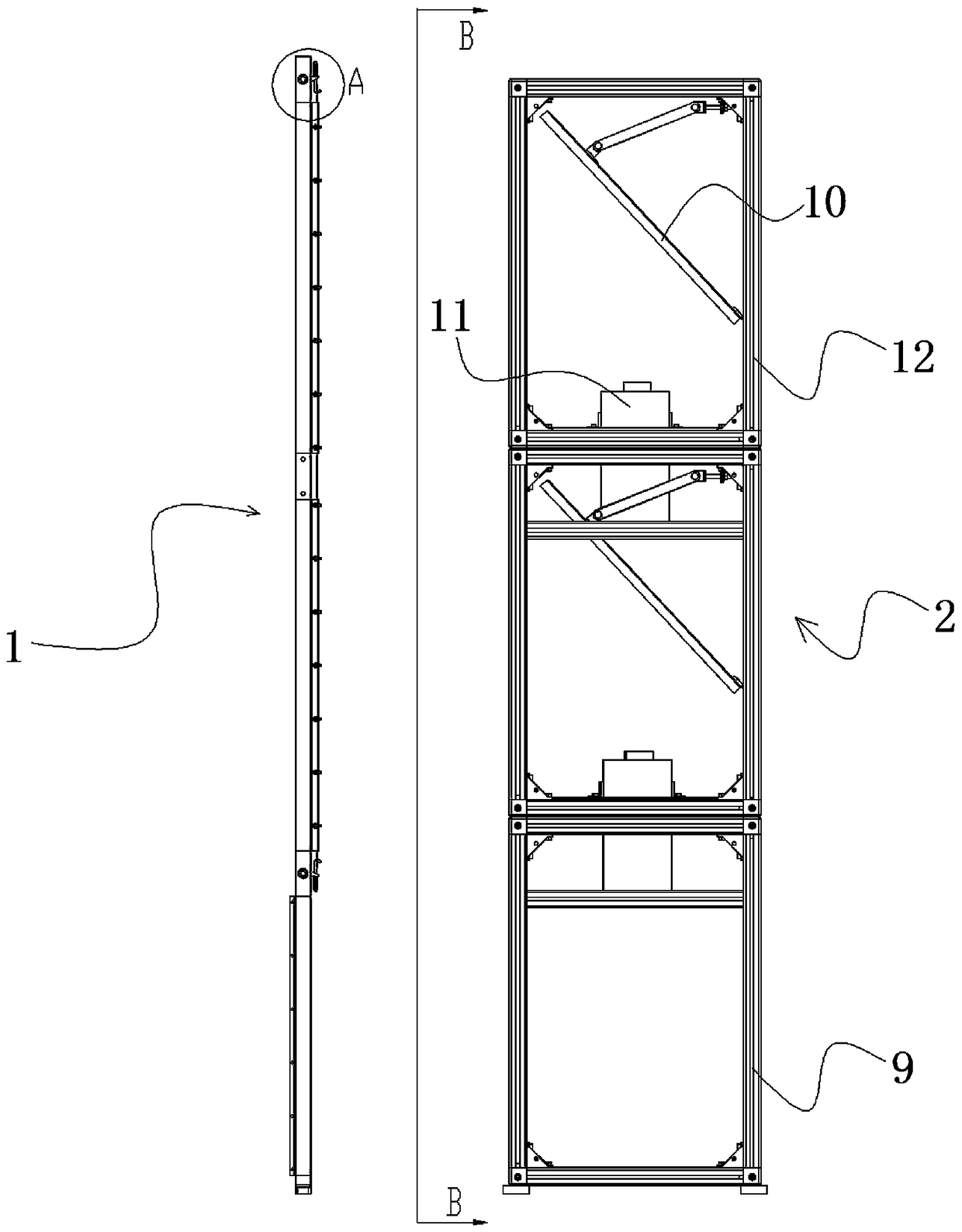

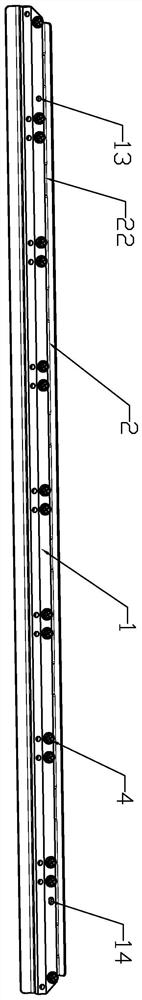

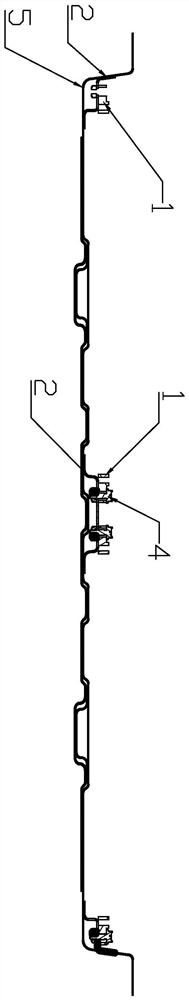

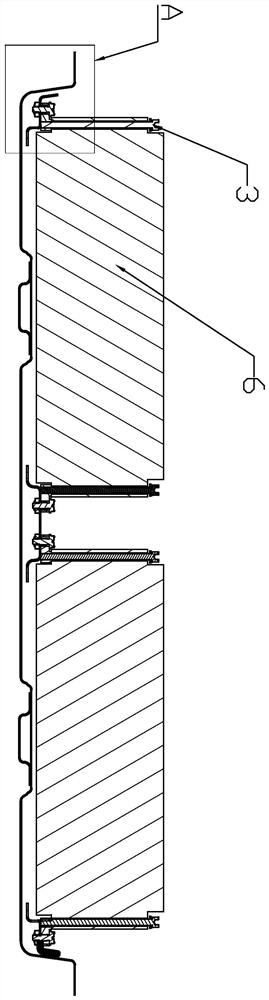

Combined projection device with super large screen

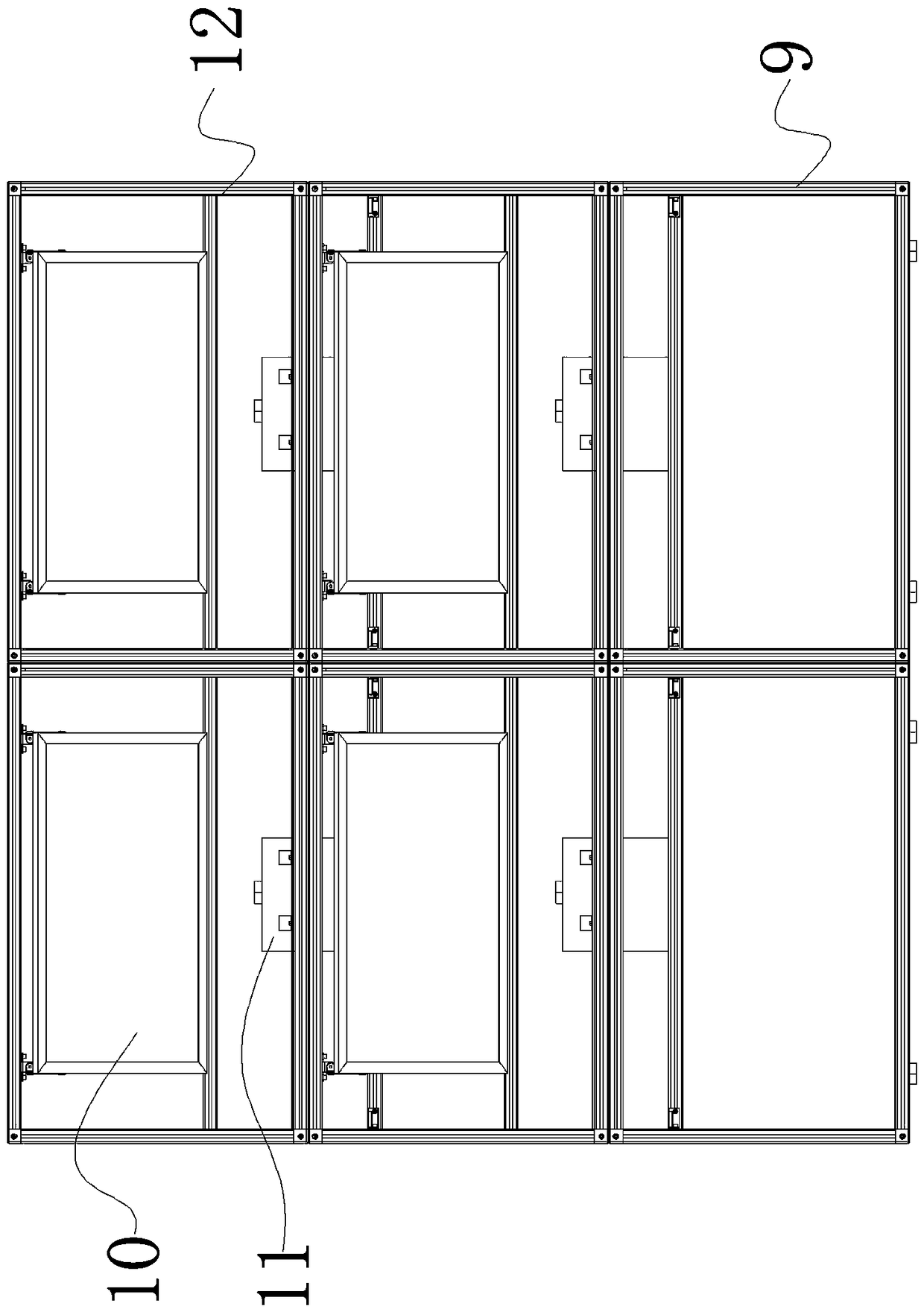

PendingCN108169995AHigh precisionImprove disassembly efficiencyProjectorsPanoramic photographyStructural engineeringLarge screen

A combined projection device with a super large screen comprises a screen. A combined projector frame structure formed by splicing a plurality of cubic frames is arranged in the rear of the screen. Each cubic frame is composed of multiple section bars and multiple connectors combined together. The columns, cross beams and longitudinal beams of the cubic frames are made of section bars of the samestructure. Each section bar is provided with T slots on the four side walls thereof. Threaded holes are formed in the centers of the two end faces of the column section bars, the cross beam section bars and the longitudinal beam section bars. The column section bars, the cross beam section bars and the longitudinal beam section bars intersecting at the same corner of the cubic frames are fixedly connected by 3D corner connectors. Splicing connectors used for splicing and combining are installed at the four corners of the upper and lower end faces and at the four corners of the left and right end faces of each independent cubic frame. The bottom layer of the combined projector frame structure is a control device placement layer, and the cubic frames in the other layers are projector framesequipped with reflectors and projectors.

Owner:重庆融豪太视科技有限公司

Manufacturing process method of special-shaped thin-wall environmental-control cold pipe

ActiveCN109940135AMeet the requirements of three-proof treatmentMeet assembly precision requirementsAdditive manufacturing apparatusFoundry mouldsWaxSelective laser sintering

The invention discloses a manufacturing process method of a special-shaped thin-wall environmental-control cold pipe. According to the method, the rapid, efficient and low-cost manufacturing of the special-shaped thin-wall environmental-control cold pipe can be achieved by rapidly forming a modified wax module through selective laser sintering technology and combining with a manufacturing processof gypsum type precise casting forming under vacuum pressure. The surface roughness of the special-shaped thin-wall environmental-control cold pipe can reach Ra3.2-6.3, the three-prevention treatmentrequirement is completely met, the size precision is high, and the assembly precision requirement can be well met. In addition, the tensile strength of the mechanical property reaches 300 MPa, and theintegral forming completely meets the strength use requirement. Compared with a traditional manufacturing process, the method has the advantages that the cost can be reduced by 40%, the first-batch development production period is only 1 / 5 of the production period of the traditional process method, the development production efficiency is greatly improved, and the product shaping period is shortened.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Two-dimensional constant force following hanging device

A two-dimensional constant force following hanging device comprises a constant force output air cylinder, an air floatation guide rail, air floatation cushions, a linear guide rail, a motor, a laser displacement sensor, a reflector, a support and the like. The air floatation guide rail comprises a first air floatation sleeve, second air floatation sleeves, a first air floatation shaft and a second air floatation shaft. The linear guide rail is parallel to the second air floatation shaft, and the linear guide rail and the second air floatation shaft are vertically installed on the support. The linear guide rail is sleeved with a sliding block which is connected with a fixing plate. The constant force output air cylinder is vertically installed on the fixing plate, the number of the second air floatation sleeves is two, and the second air floatation shaft is sleeved with the second air floatation sleeves which are connected through an installing plate. The first air floatation shaft is sleeved with the first air floatation sleeve. The two ends of the first air floatation shafts are respectively fixedly connected with a cylinder barrel of the constant force output air cylinder and the installing plate on the second air floatation sleeves, and the first air floatation sleeve is connected with a target workpiece through a hanging rope. According to the two-dimensional constant force following hanging device, long-distance constant force hanging is achieved through the constant force output air cylinder, horizontal following is achieved through the air floatation guide rail, two-dimensional constant force hanging accuracy is high, and stability is good.

Owner:SHANDONG BEIDOU REFRIGERATION EQUIP

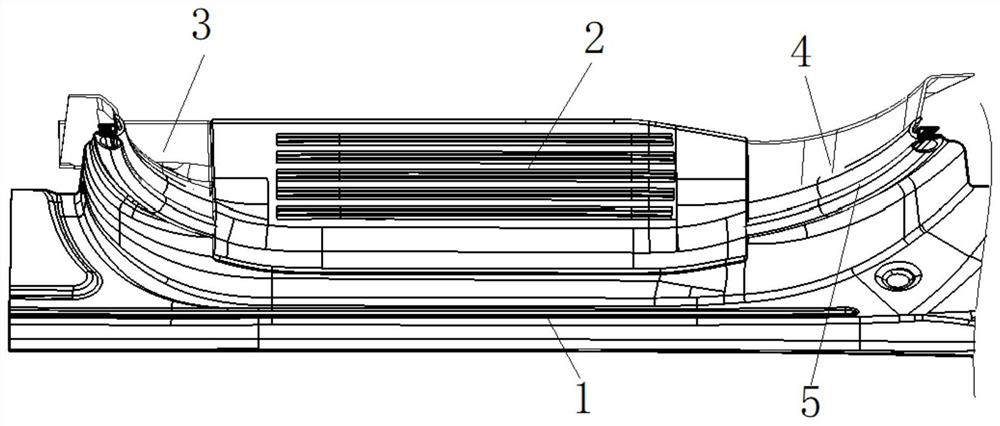

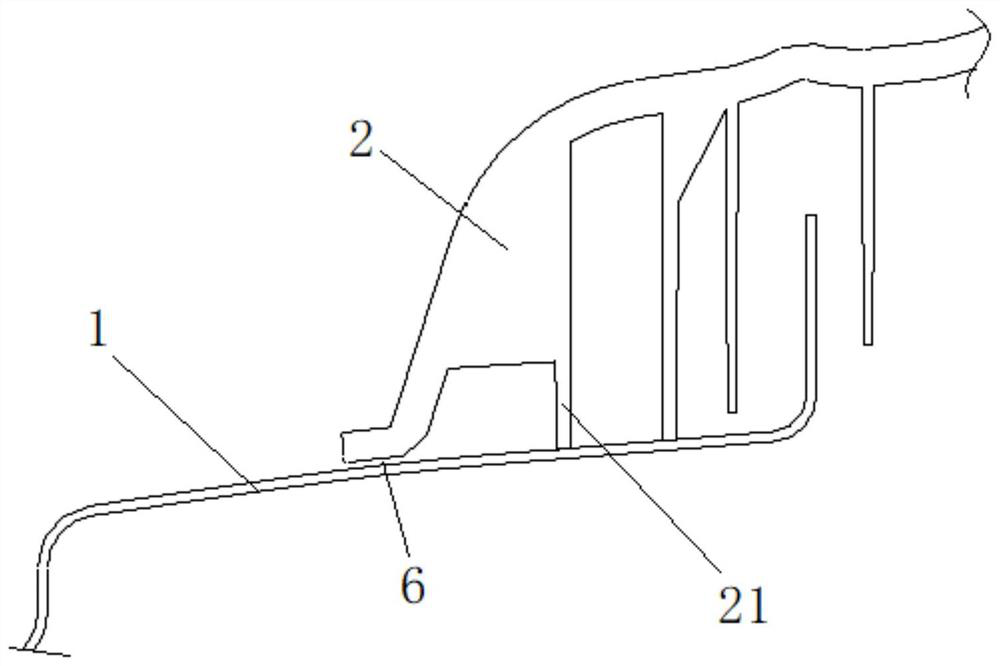

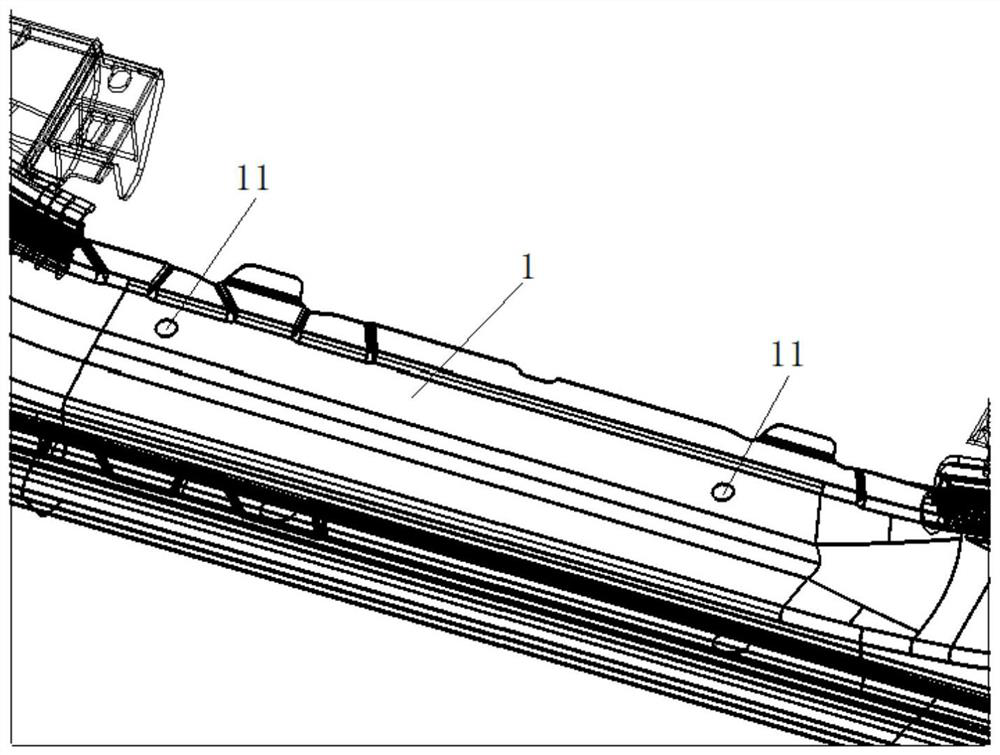

Vehicle welcome pedal structure and vehicle containing same

ActiveCN113428086BAppearance has no effectGuaranteed installation accuracySteps arrangementProduction lineStructural engineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

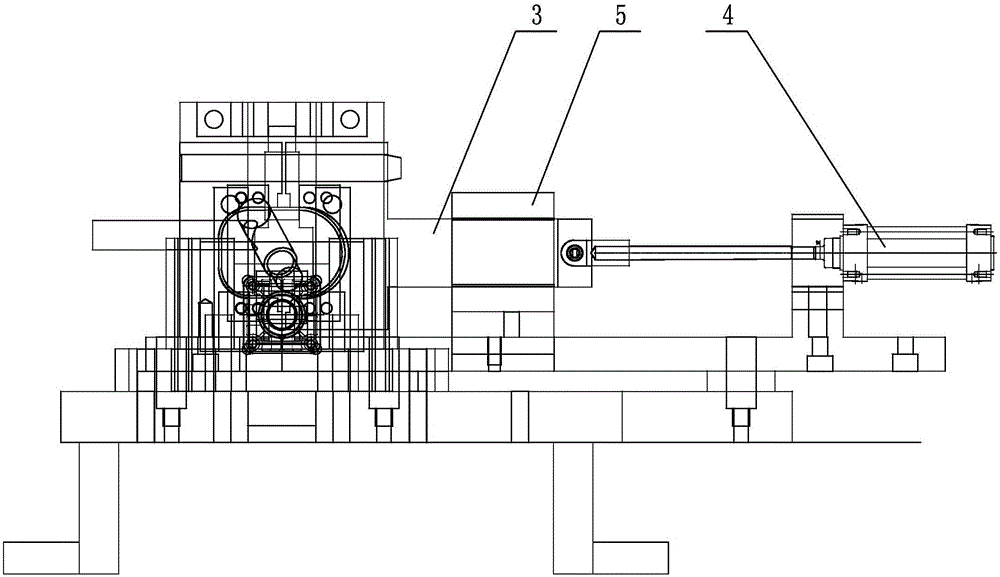

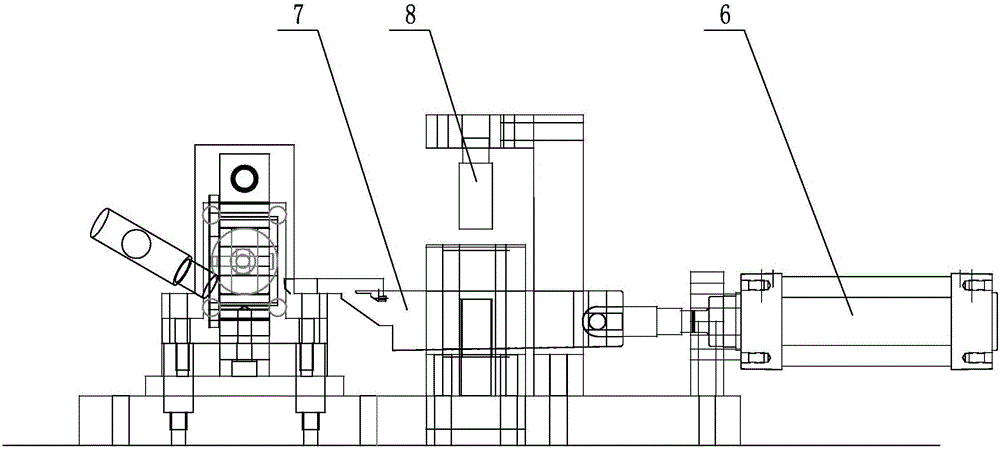

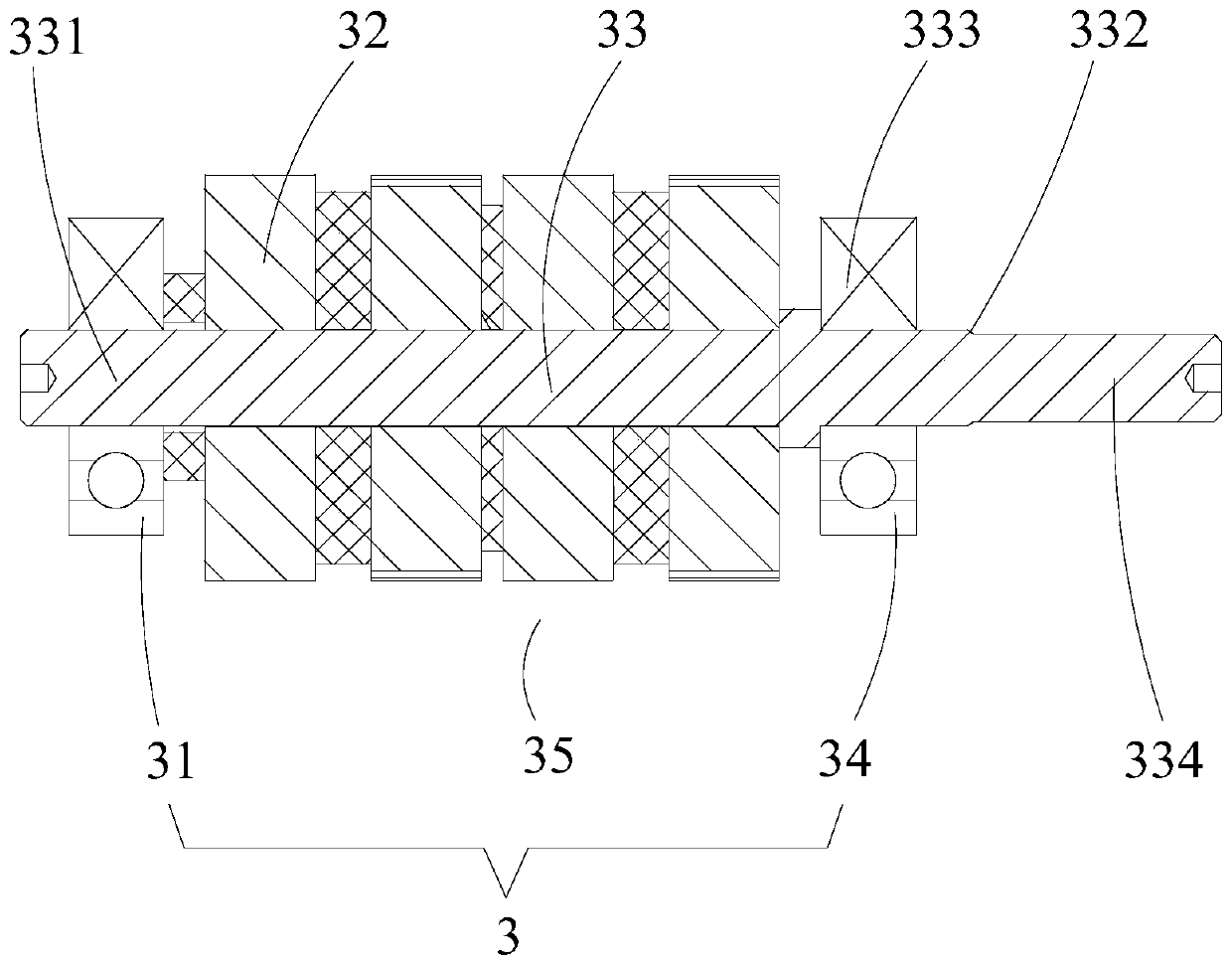

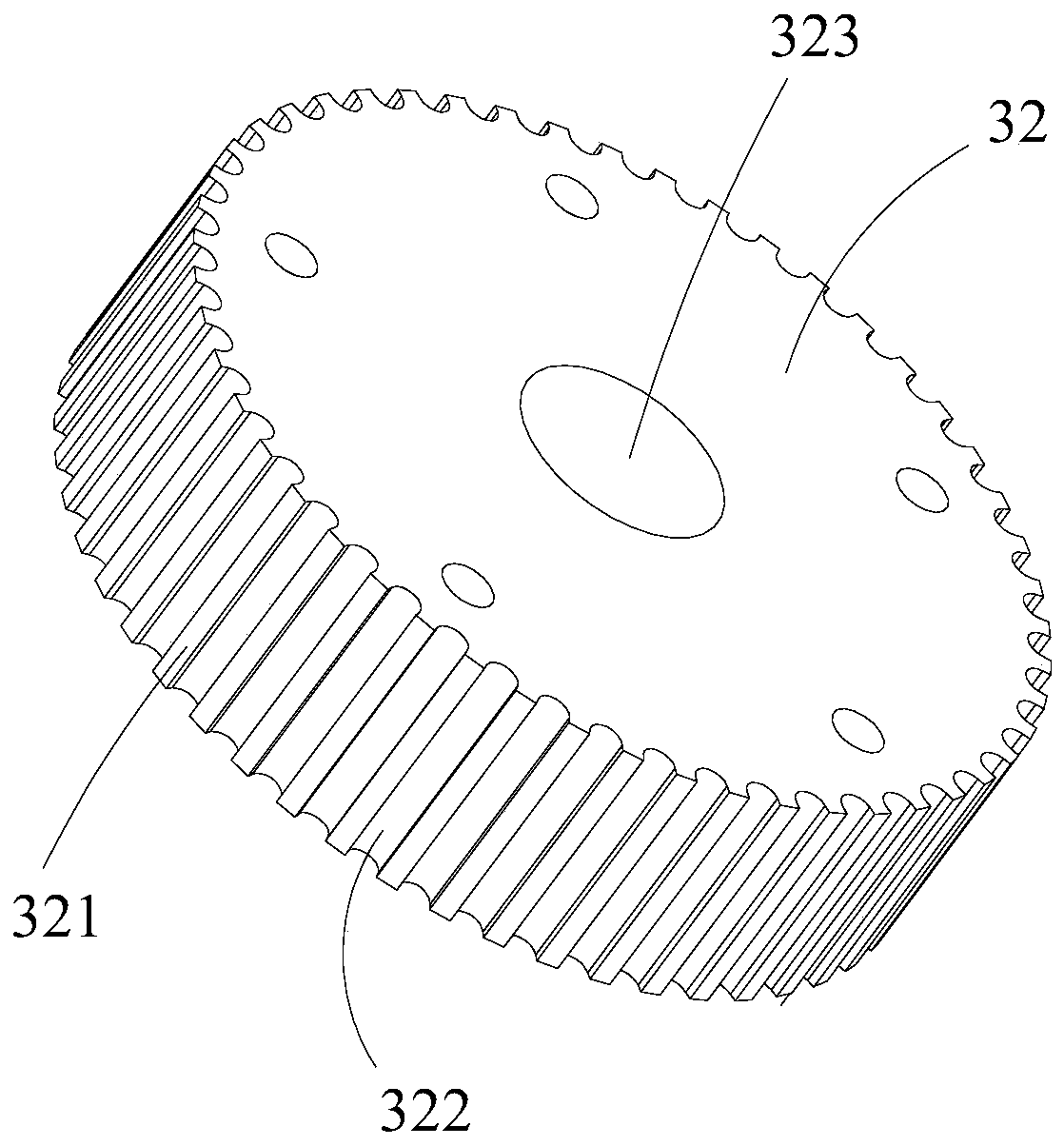

A kind of spindle automatic assembly equipment and spindle assembly method using the same

ActiveCN111347247BGuaranteed coaxialitySolve the technical problem of reduced fit accuracyAssembly machinesMetal working apparatusThermal dilatationEngineering

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD

Welding process method and flow for integrated frame of DDS structure operator rack

ActiveCN112091466AImprove assembly efficiencyReduce total timeWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringIndustrial engineering

The invention discloses a welding process method and flow for an integrated frame of a DDS structure operator rack, wherein the welding process method for the integrated frame of the DDS structure operator rack adopts an integrated frame welding process. In an assembling process, when a left wallboard and a right wallboard are formed, the left wallboard and the right wallboard are positioned by means of a modular integrated assembling technique of an equipment part and front and back rotating racks, and a pipe spacer is post-welded. When the rack is assembled, the method and flow have the characteristics that the assembling effect is good, quick and efficient assembly can be achieved, a process mounting route is reasonable and reliable, the assembling efficiency can be improved greatly, the date of delivery of a product is shortened and the stability of the product is improved, an assembling flow of equipment is optimized and the assembling process is simplified and the like.

Owner:兰州兰石重工有限公司

Long-distance constant force output air flotation device

ActiveCN103511366BReduce the impactHigh precisionServomotorsFluid-pressure actuator componentsConstant forceLight reflection

The invention discloses a long-distance constant force output air floating device which comprises an output air cylinder and a following system. The output air cylinder comprises a cylinder barrel, a connecting rod piston, end covers and air floating mats. The following system comprises a linear guide rail, sliding blocks, a fixing plate, a connecting support, a motor, a laser displacement sensor and a light reflection plate. The connecting rod piston is sleeved with the cylinder barrel, the two ends of the cylinder barrel are sealed through the end covers, an axial groove is formed in the middle of the cylinder barrel, the connecting support penetrates through the axial groove to be connected with the connecting rod piston and the fixing plate, the fixing plate is installed on the linear guide rail through the sliding blocks, the motor can drive the sliding blocks to move, the number of the air floating mats is two, the air floating mats are connected with the fixing plate through air floating mat bases, and the laser displacement sensor is installed on the fixing plate. According to the long-distance constant force output air floating device, the constant force is output through the output air cylinder, the output air cylinder is controlled by the following system to achieve long-distance movement, and the long-distance constant force output air floating device is free of air pipe disturbance influences, good in stability and high in constant force output accuracy.

Owner:湖州兴塘工程建设有限公司

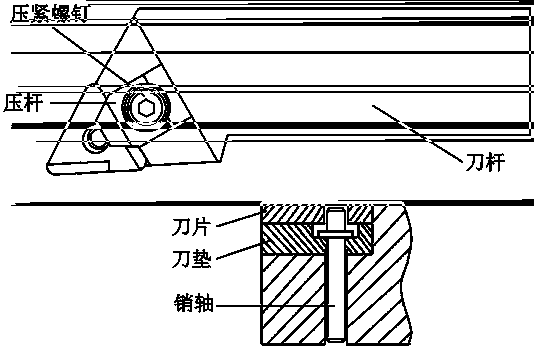

Upward pressing type machine clamp transposition turning tool teaching aid based on 3D printing

PendingCN109158626AMeet assembly precision requirementsFirmly assembledTurning toolsEngineering3D printing

The invention relates to an upward pressing type machine clamp transposition turning tool teaching aid based on 3D printing. The upward pressing type machine clamp transposition turning tool teachingaid comprises a tool rod, a blade, a tool pad, a pin shaft, a pressing screw and a pressing plate. After assembling, an upward pressing type machine clamp transposition turning tool integral structurecan be shown. All components are finished through 3D printing, the components can be assembled on the premise that the printing precision is reasonably controlled, the tool rod, the blade, the tool pad, the pin shaft, the pressing screw and the pressing plate component can be independently shown, and after model assembling is finished, the composition and the structure of an upward pressing typetransposition turning tool can be shown. For the components, different colors of materials are adopted for printing, and the demonstration effect of the teaching aid is enhanced. 3D printing of hollowstructures is adopted in the components large in size, the strength is high, and the mass is small. According to the teaching aid, the advantages of the 3D printing technology in the aspect of modelmanufacturing are sufficiently utilized, the composition and the structure of the upward pressing type machine clamp transposition turning tool are visually shown, the advantages that the strength ishigh, the mass is small, peculiar smells are avoided, cleanliness and environment friendliness are achieved, the price is low, material waste is avoided, and cost is low are achieved, and a good classdemonstration effect can be achieved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Threaded hole processing method with positioning function

The invention provides a threaded hole processing method with a positioning function; when processing is carried out through the threaded hole processing method with the positioning function, firstly an upper semi-positioning hole is processed; secondly a lower semi-positioning hole is processed with the upper semi-positioning hole as the guidance; thirdly a guide sleeve is arranged in the lower semi-positioning hole as the guidance for processing a lower threaded hole; through the method, the positioned threaded hole can be respectively processed in an upper semi-circular structural piece and a lower semi-circular structural piece; consequently, the processing speed can be effectively improved, and the threaded hole processing difficulty is reduced; meanwhile, the processing method can also effectively ensure the axial positioning and radial spacing requirements of the upper semi-circular structural piece and the lower semi-circular structural piece, so that the assembly precision requirements are met when the upper and lower semi-circular structural pieces are met; and the threaded hole processing method with the positioning function is particularly applicable to a vapor seal or a division sleeve and other work pieces with smaller width of a horizontal split on a steam turbine.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

A square battery fixing structure and using method thereof

The invention discloses a square battery fixing structure and a use method thereof, comprising a first fixing piece and a second fixing piece arranged separately, the second fixing piece is a sheet metal piece, the first fixing piece is an aluminum alloy piece, The first fixing part includes a fixing part and a battery fitting part. The shape of the battery fitting part is adapted to the shape of the bottom of the installation structure of the battery module. The battery fitting part is fixedly connected to the battery module through a long fixing part. A via hole is provided on the fixing part, a fixing hole corresponding to the via hole is provided on the side of the second fixing part away from the first fixing part, and a short fixing part is provided on the first fixing part, and the short fixing part Tightly fit through the via hole and the fixing hole. The invention is simple in structure, light in weight, low in cost, easy to generalize, can effectively absorb the tolerance caused by the forming and welding of sheet metal parts, meets the accuracy requirements of battery module installation, and has high assembly flexibility.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

Method for preventing pipe plates from welding deformation through strip surfacing of high-pressure air cooler pipe plates

InactiveCN105945440AReduce straightening processMeet assembly precision requirementsWelding apparatusAlloyEngineering

A method for preventing pipe plates from welding deformation through strip surfacing of high-pressure air cooler pipe plates comprises the following steps that firstly, the periphery of the first pipe plate and the periphery of the second pipe plate are welded together through a plurality of connecting plates and then placed on a surfacing platform and a clamp, a welding machine head conveys a welding belt, a first alloy layer is formed on the surface of the first pipe plate in a surfacing manner, a workpiece is overturned, a first alloy layer is formed on the surface of the second pipe plate in a surfacing manner, and the workpiece is overturned again; and a second alloy layer is formed on the surface of the first pipe plate in a surfacing manner, then the workpiece is overturned, and a second alloy layer is formed on the surface of the second pipe plate in a surfacing manner. The method solves the problem about surfacing deformation of single pipe plates, the requirement for the assembly precision of the air cooler pipe plates and a heat exchange pipe is met, meanwhile, the straightening procedure after surfacing of the pipe plates is reduced, and the production efficiency is improved.

Owner:HARBIN AIR CONDITIONING CO LTD

Compact porous positioning tool

PendingCN114523438AMeet the requirements of concentricity assembly accuracyMeet assembly precision requirementsWork holdersEngineeringMechanical engineering

The invention relates to the field of machinery, and discloses a compact multi-hole positioning tool which comprises a plurality of positioning pin shafts, the outer diameter of each positioning pin shaft is matched with an inner hole of a conical cylinder structure of an upper-layer workpiece, and the plurality of positioning pin shafts are jointly connected to a positioning mounting ring. The axial length of the positioning pin shaft is not less than the stacking height of the upper-layer workpiece and the lower-layer workpiece; the shaft hole penetrates through the positioning pin shaft in the axis direction of the positioning pin shaft, the inner diameter of the shaft hole is matched with the diameter of an anode column arranged on the workpiece on the lowermost layer, and the height of the anode column is not lower than the stacking height of all the workpieces. According to the assembly precision of the large-scale structural member, a proper fit clearance is designed for the positioning tool, and the requirement for the micron-scale or millimeter-scale coaxiality assembly precision of the large-scale structural member can be met.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

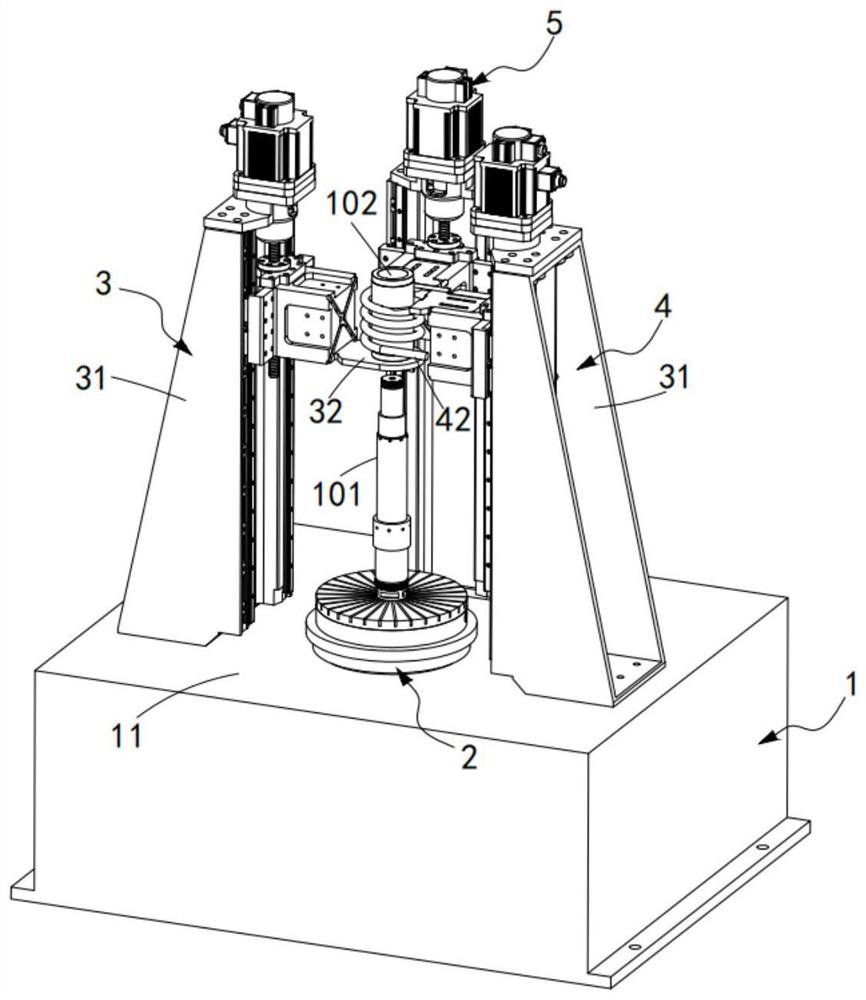

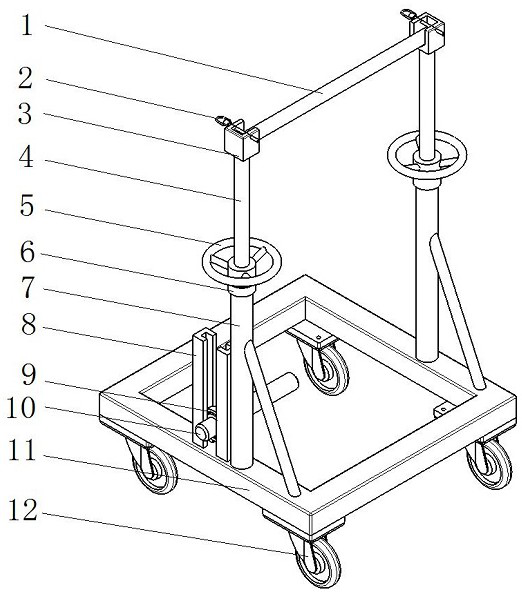

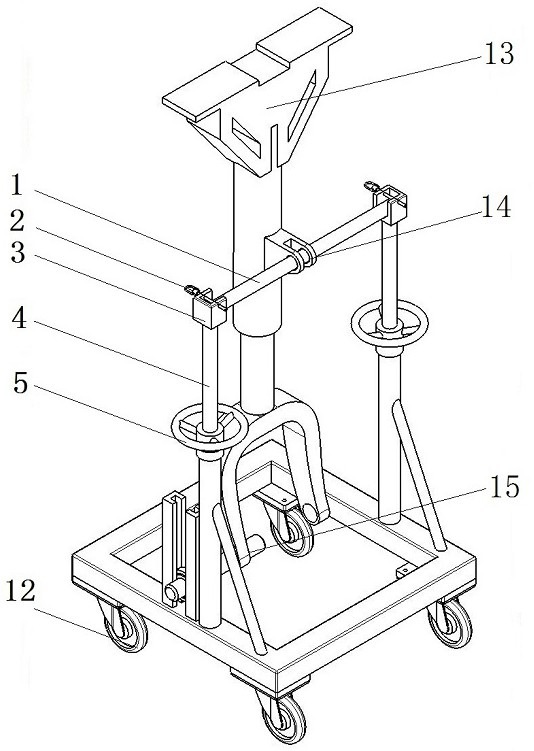

Auxiliary assembly equipment for aircraft nose landing gear strut

InactiveCN111891378ASimple and fast operationEasy maintenanceAircraft assemblyMechanical engineeringAirplane

The invention provides auxiliary assembly equipment for an aircraft nose landing gear strut. The equipment is connected with the nose landing gear strut, used for equipment of the nose landing gear strut and is characterized by comprising a base structure, a lifting structure installed on the base structure and a supporting structure installed on the lifting structure and used for supporting the nose landing gear strut; the supporting structure is connected with a nose landing gear strut; the lifting structure comprises supports installed on the left side and the right side of the base structure; each support comprises a supporting column installed on the base structure, a sleeve assembly installed at the top end of the supporting column and a lead screw penetrating out of the sleeve assembly to be upwards connected with the supporting structure; the sleeve assembly is provided with a rotating disc used for controlling the penetrating degree of the lead screw penetrating out of the sleeve assembly. Through combination of the arrangement and actual production, the safety risk of assembly operation and the damage rate of the nose landing gear strut are reduced, the assembly period ispredicted to be shortened by 25%, and the number of operators is reduced by 1 / 3.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Height self-adaptive assembling component

PendingCN113602809AAchieving a highly adaptive effectMeet assembly precision requirementsConveyor partsSelf adaptiveManufacturing engineering

The invention relates to the technical field of machine manufacturing, in particular to a height self-adaptive assembling component. The height self-adaptive assembling component comprises a first plate and an adsorption assembly, and the adsorption assembly and the first plate are slidably connected in the vertical direction. The height self-adaptive assembling component comprises the first plate and the adsorption assembly, the adsorption assembly is slidably connected with the first plate in the vertical direction, and when a to-be-assembled product makes excessive contact with a target product, the adsorption assembly can slide in the vertical direction relative to the first plate so as to adapt to manufacturing errors of the to-be-assembled product in the height direction, so that the high self-adaption effect is achieved, assembling between the to-be-assembled product and the target product is completed, and the requirement for assembling precision is met.

Owner:BOZHON PRECISION IND TECH CO LTD

Welding fixture for precise stainless steel products

InactiveCN105149753AMeet assembly precision requirementsImprove economyWelding accessoriesEconomic benefitsEngineering

The invention relates to a welding fixture for precise stainless steel products. The welding fixture comprises a bottom plate. The welding fixture is characterized in that a fixed block and a movable block are mounted on the bottom plate; the movable block is connected with a piston rod of a first air cylinder; a second air cylinder which is perpendicular to the first air cylinder is mounted on the bottom plate; a piston rod of the second air cylinder is movably connected with a limit block through a pin shaft; an air cylinder holder is mounted above the limit block; an up-and-down movable air cylinder is mounted on the air cylinder holder; a piston rod of the up-and-down movable air cylinder is positioned right above the limit block; the movable block is arranged on a guiding sliding seat. Aiming at the current using conditions of a conventional fixture in the prior art, the welding fixture disclosed by the invention accurately determines a position in the X direction, a position in the Y direction, and a position in the Z direction, of a joint of a workpiece, and realizes assembling requirements of products. The welding fixture disclosed by the invention has good economy and timeliness. In the long-term production of the welding fixture, the production cost can be greatly reduced, and the economic benefits of products can be improved.

Owner:WUXI ZHONGJIE VIBRATION ISOLATORS

A method for assembling high and low temperature vacuum stepping motors

ActiveCN109995197BPrevent deformation damageMeet assembly precision requirementsManufacturing dynamo-electric machinesElectric machineEngineering

Owner:成都金士力科技有限公司

A dds structure manipulator frame integrated frame welding process method and flow

ActiveCN112091466BSimplify the assembly processImprove assembly efficiencyWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringLeft wall

The invention discloses a DDS structure manipulator frame integrated frame welding process method and process, wherein a DDS structure manipulator frame integrated frame welding process method, the welding process method adopts an integrated frame welding process, and the assembly During the process, when the left and right wall panels are formed, the left and right wall panels are positioned using the modular integrated assembly technology of equipment components and front and rear turrets, and then the spacer pipes are welded. The frame of the present invention has a good assembly effect during assembly, can realize fast and efficient assembly, and can also realize a reasonable and reliable process installation route, which can greatly improve assembly efficiency, shorten the delivery period of the product and increase the stability of the product , optimize the equipment assembly process, simplify the assembly process and other characteristics.

Owner:兰州兰石重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com