Automatic assembling system for voice diaphragm and globe roof

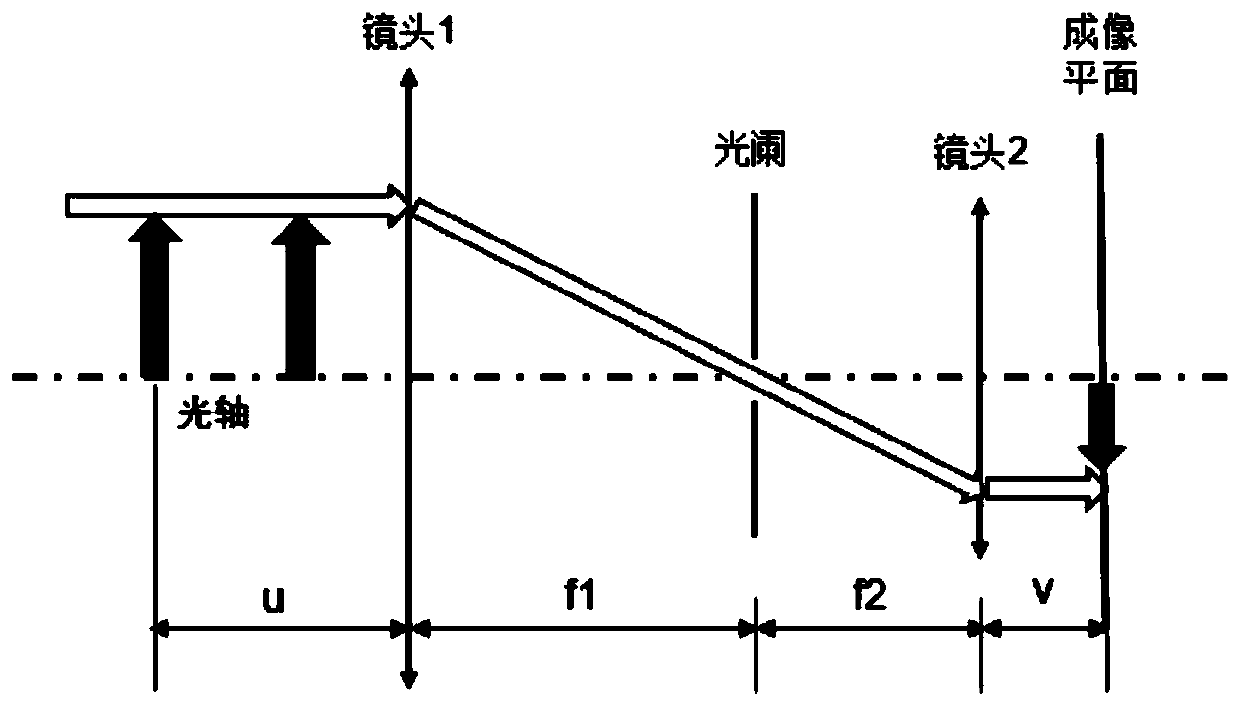

An automatic assembly and dome technology, applied in the field of visual inspection, can solve the problems of image edge position uncertainty, large lens distortion, different magnifications, etc., to improve image processing capability, achieve assembly accuracy requirements, and reduce accuracy requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

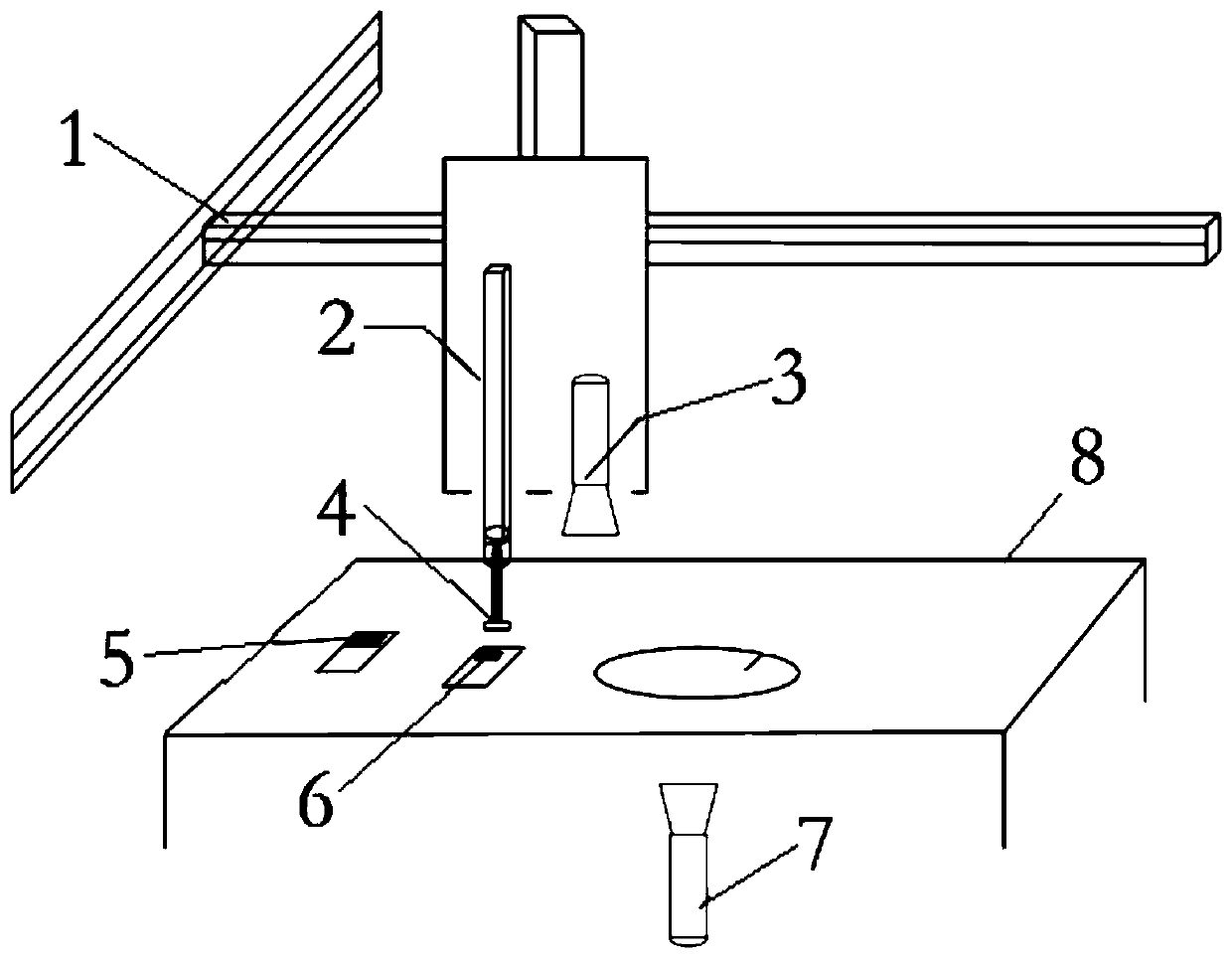

[0144] As an embodiment, the method for calibrating the angle deviation of the machine tool and the camera includes the following steps: installing an automatic assembly system, which includes a three-axis motion system and a platform, the three-axis motion system and the platform constitute the machine tool, and the sound film camera is installed on the three Axis motion system, select the fixed mark point p on the platform, and establish the machine tool coordinate system with the fixed mark point as the origin.

[0145] In the steps of this embodiment, mark the fixed mark point as p1, control the movement of the three-axis motion system, establish a virtual checkerboard, and obtain the machine tool coordinates of the virtual checkerboard with the fixed mark point as the origin; meanwhile, the sound film camera shoots the fixed mark Click to get multiple consecutive pictures.

[0146] In step 2 of this embodiment, the three-axis motion system is controlled to make the camera form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com