Patents

Literature

511 results about "Telecentric lens" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

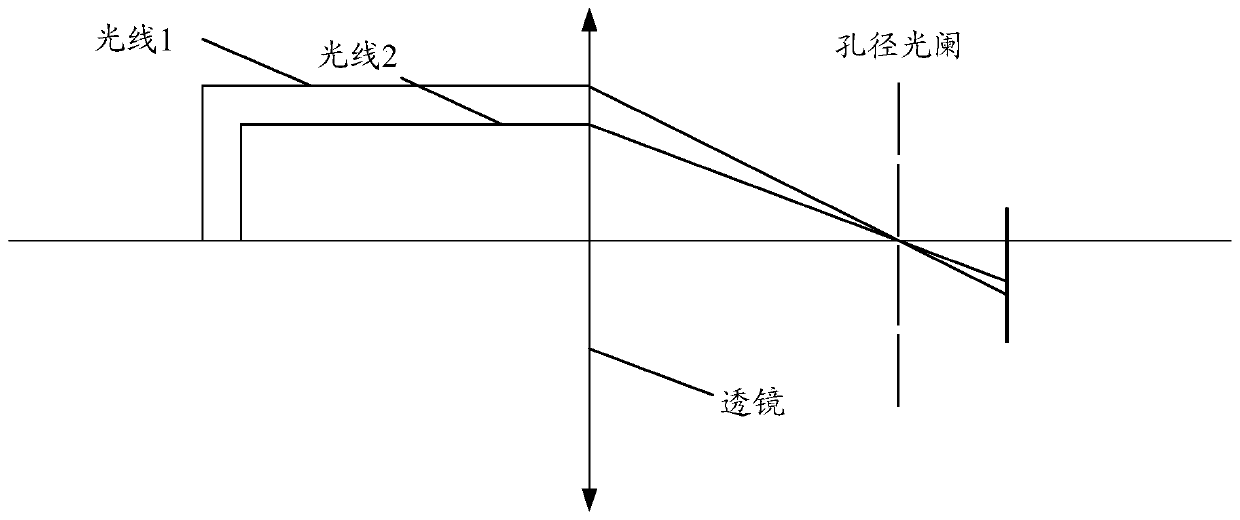

A telecentric lens is a compound lens that has its entrance or exit pupil at infinity; in the prior case, this produces an orthographic view of the subject. This means that the chief rays (oblique rays that pass through the center of the aperture stop) are parallel to the optical axis in front of or behind the system, respectively. The simplest way to make a lens telecentric is to put the aperture stop at one of the lens's focal points.

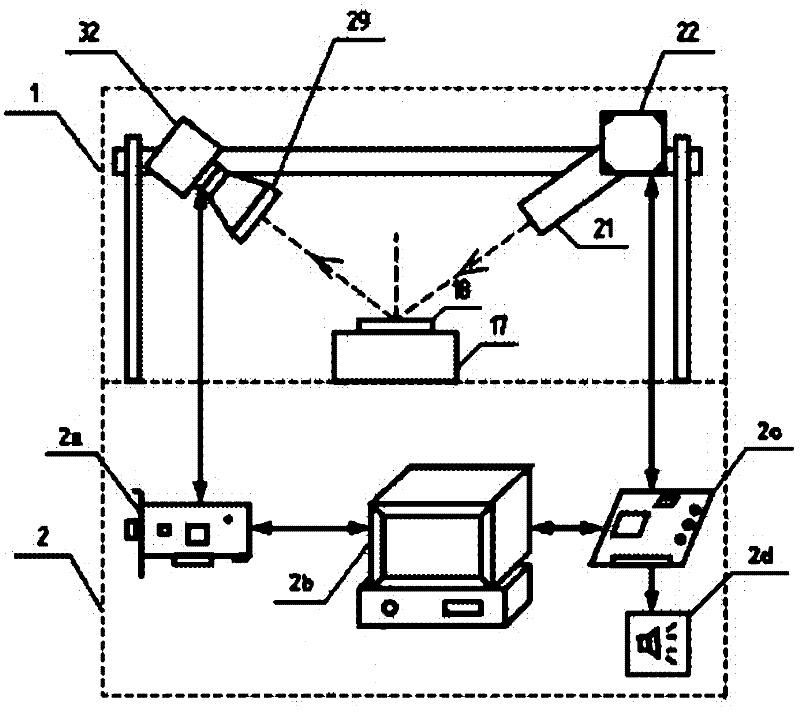

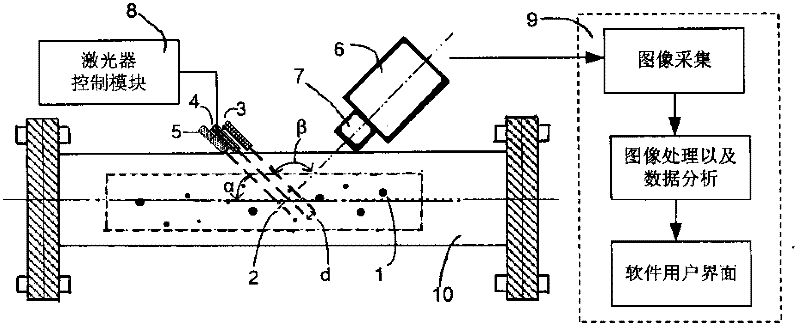

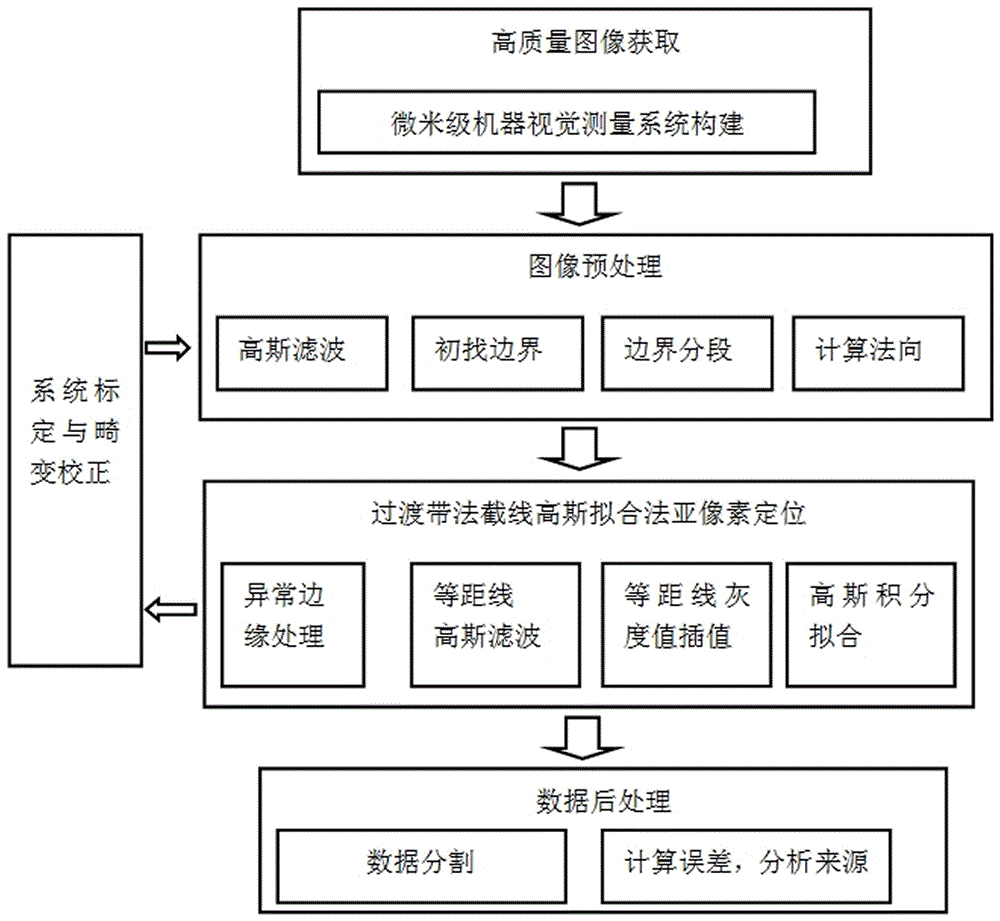

Device and method for detecting micro defects on bright and clean surface of metal part based on machine vision

ActiveCN102590218ARealize installation positioningEasy to operateOptically investigating flaws/contaminationEffect lightCcd camera

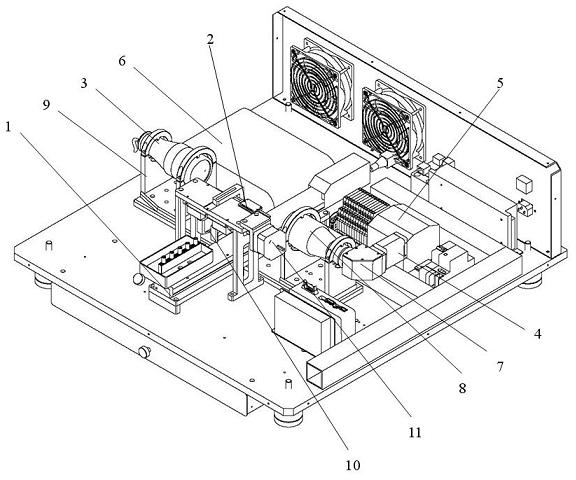

The invention relates to a device and method for detecting micro defects on the bright and clean surface of a metal part based on machine vision. The device comprises an imaging, positioning and adjusting mechanism and a processing unit, wherein the imaging, positioning and adjusting mechanism comprises a base plate, a guide rod, a fixed support, a sliding support, a stepping motor, a CCD (Charge Coupled Device) camera, a telecentric lens and parallel light sources, wherein the imaging and coaxial lighting of the CCD camera are primarily adjusted; an image collection card, an industrial personal computer, an equipment control card and an alarm are electrically connected in the processing unit and are used for collecting, transmitting, storing, processing, displaying and alarming image. The method comprises coaxial lighting adjustment and image processing, wherein coaxial lighting adjustment comprises the steps of triggering the equipment control card via software of the industrial personal computer to drive the stepping motor, and adjusting the rotating angles of the parallel light sources until the coaxial lighting condition is satisfied; and image processing comprises the steps of detecting defects on the internal surface of the detected part, respectively detecting large and small defects on the outer edge on the surface of the detected part, displaying the processing images in real time and judging the results.

Owner:安徽中科智能高技术有限责任公司

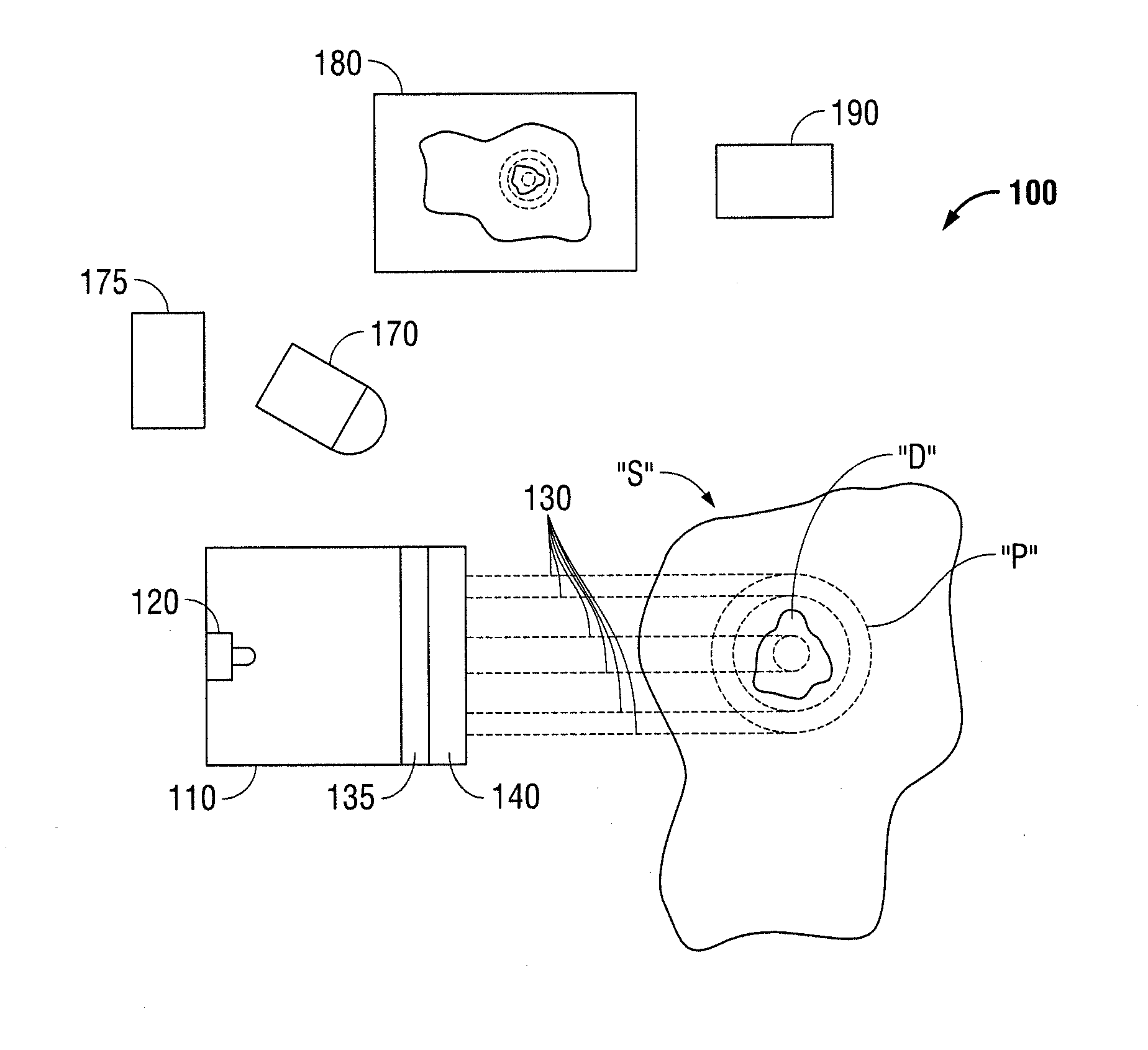

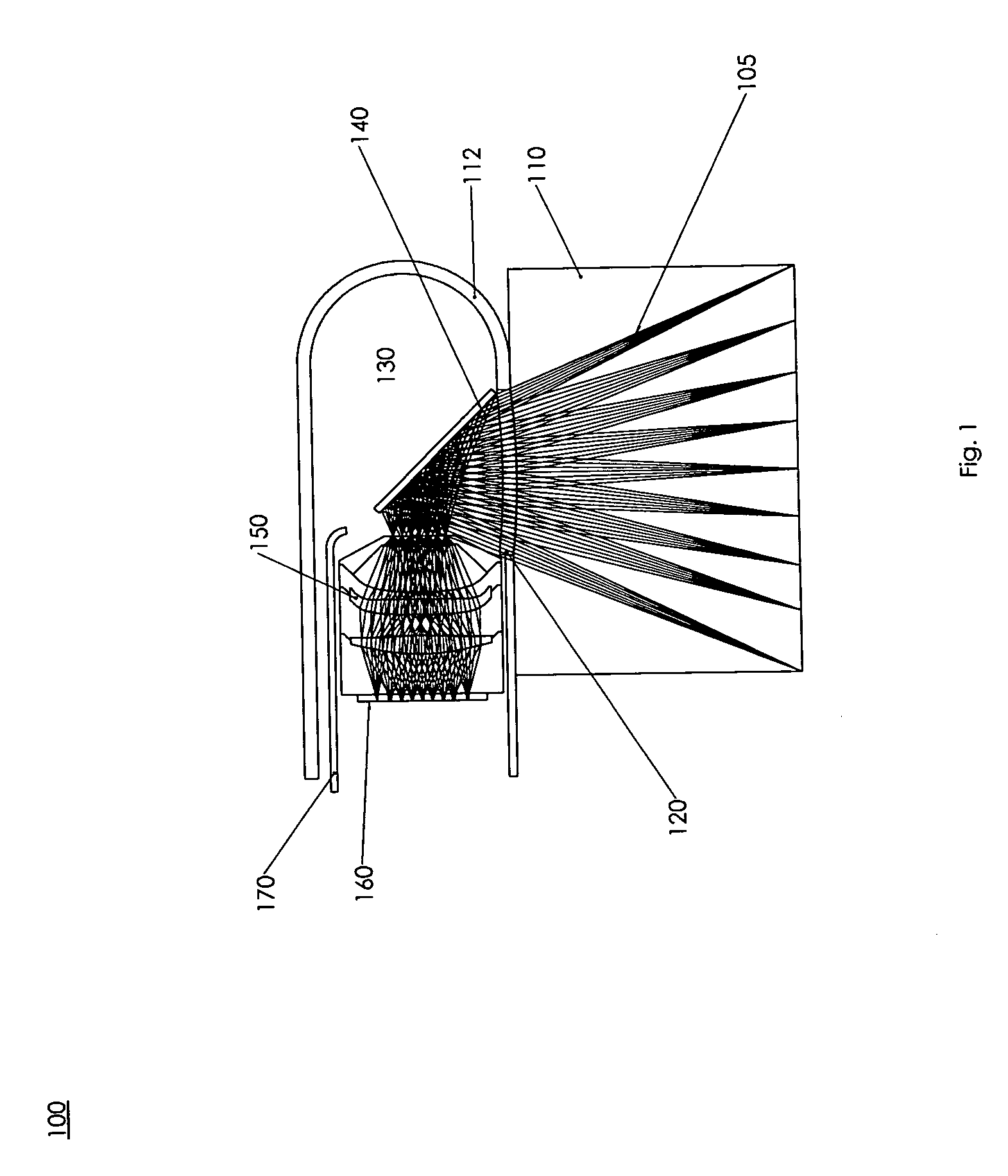

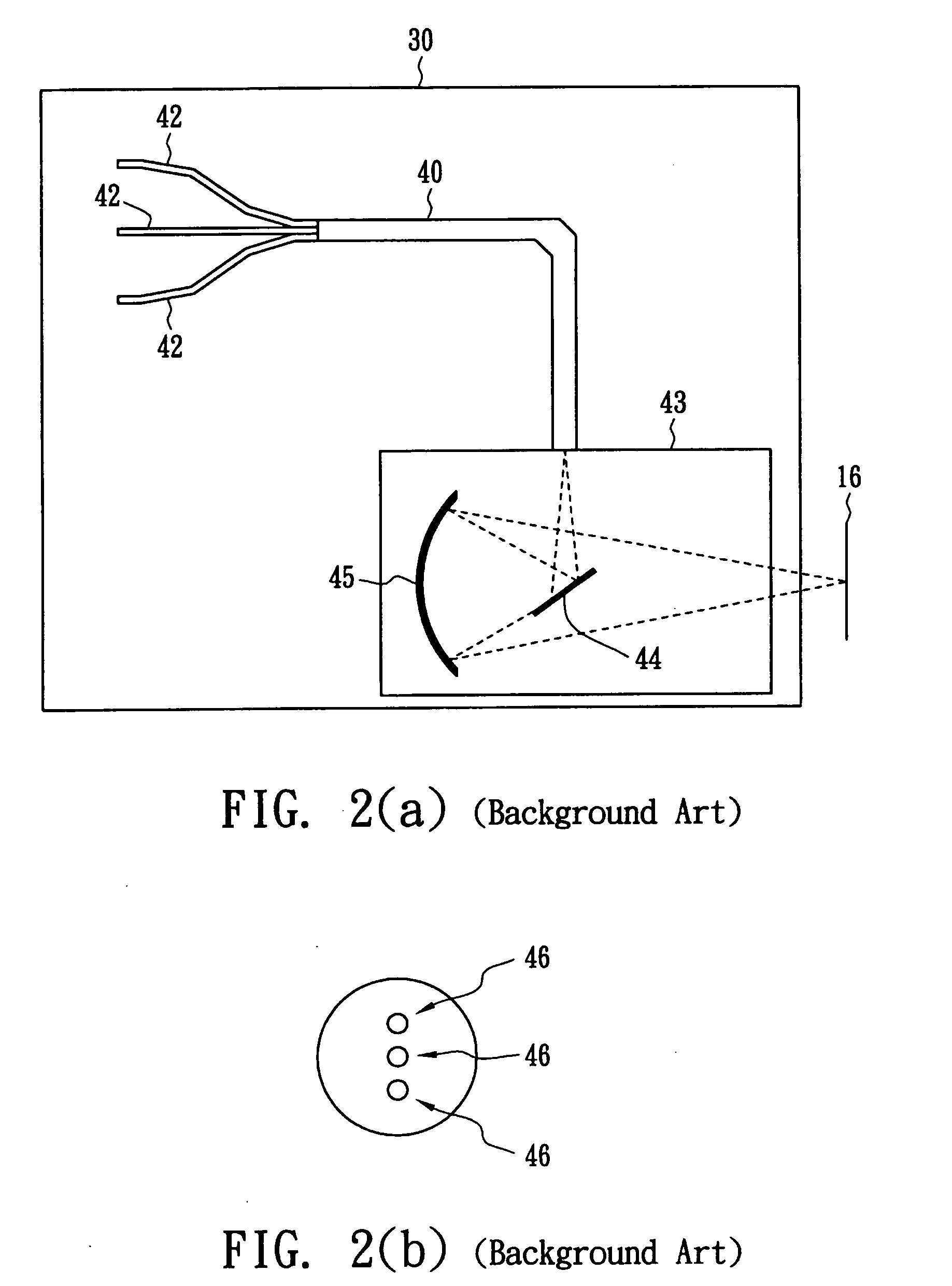

Telecentric Scale Projection System for Real-Time In-Situ Surgical Metrology

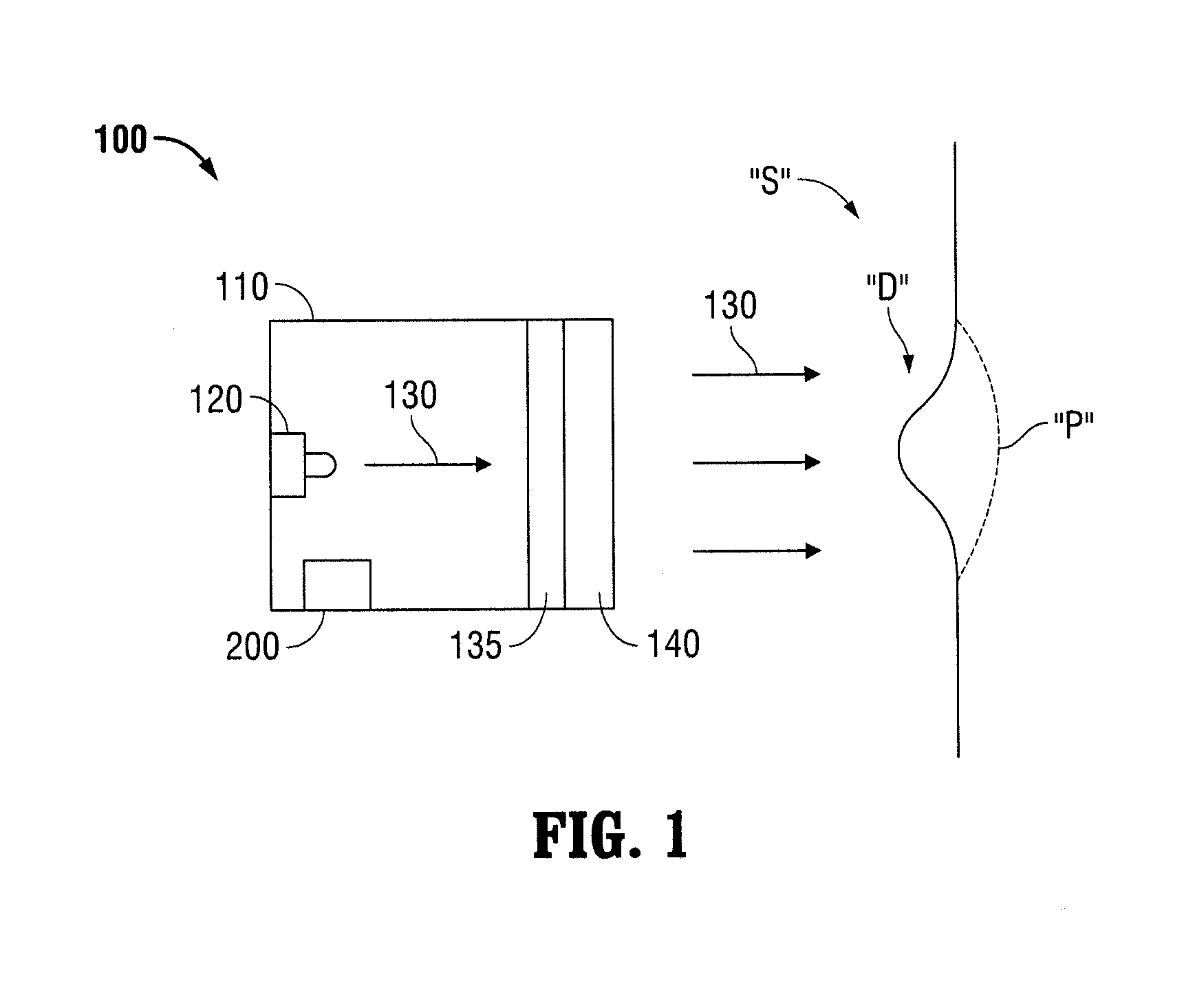

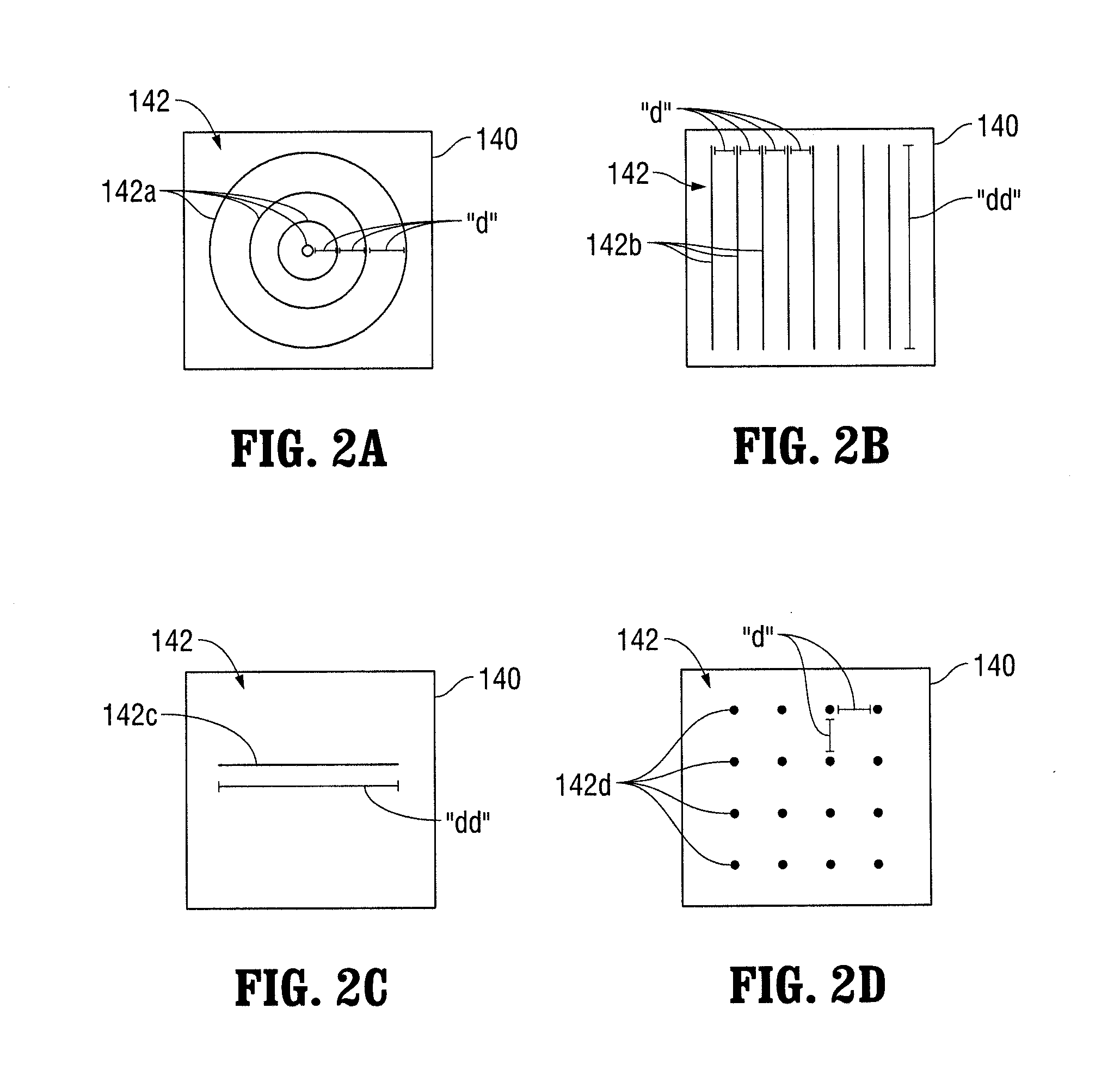

InactiveUS20140031665A1Superior in pointAdditive manufacturing apparatusSurgeryMetrologySurgical site

A system and method for determining endoscopic dimensional measurements including a projector assembly comprising a light source for projecting light through a telecentric lens and into a surgical site, and a mask coupled to the projector assembly. Light projected from the light source projects through the mask. The projected light through the mask may be a collimated pattern which does not significantly change in size as a function of the distance to a projected plane. The projected light patterns may include multiple wavelengths of light for measurements of different features of tissue and may be produced using a laser in conjunction with a light shaping optical diffuser, or using a light emitting diode in conjunction with a light shaping optical diffuser, or using a spatial filter. The projected light patterns may take the form of concentric rings with each ring representing a radius of a given dimension.

Owner:TYCO HEALTHCARE GRP LP

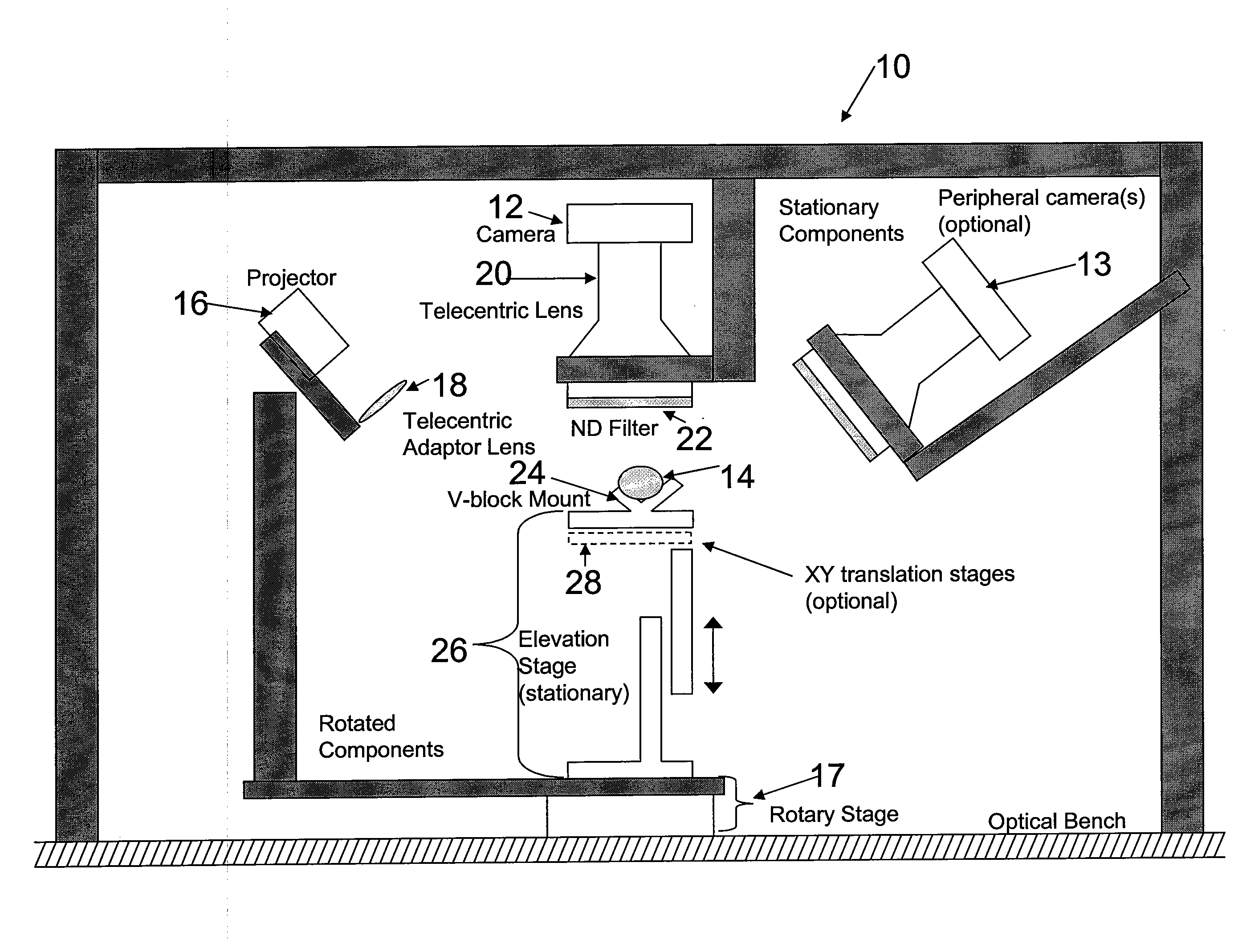

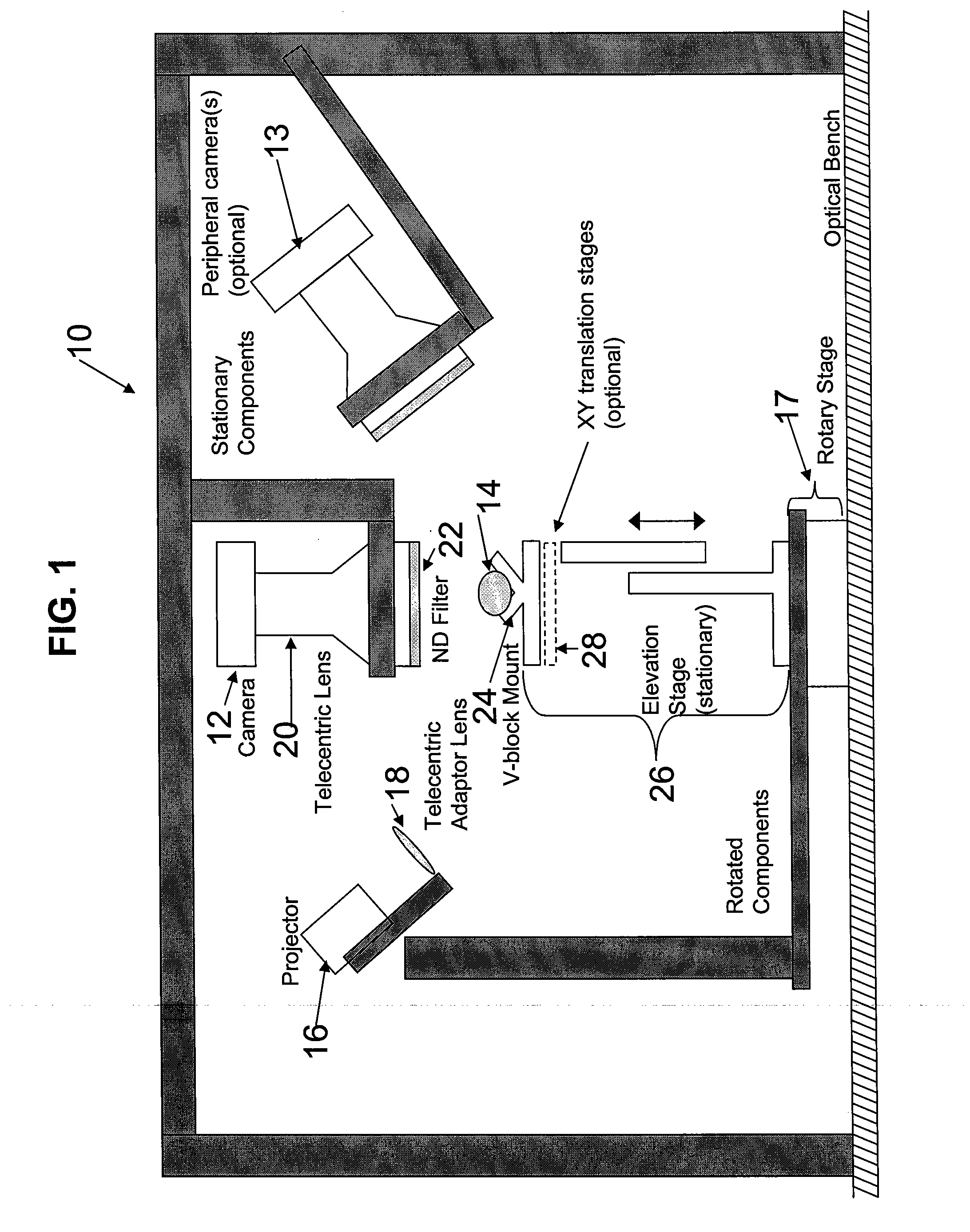

Apparatus and Method for 3-Dimensional Scanning of an Object

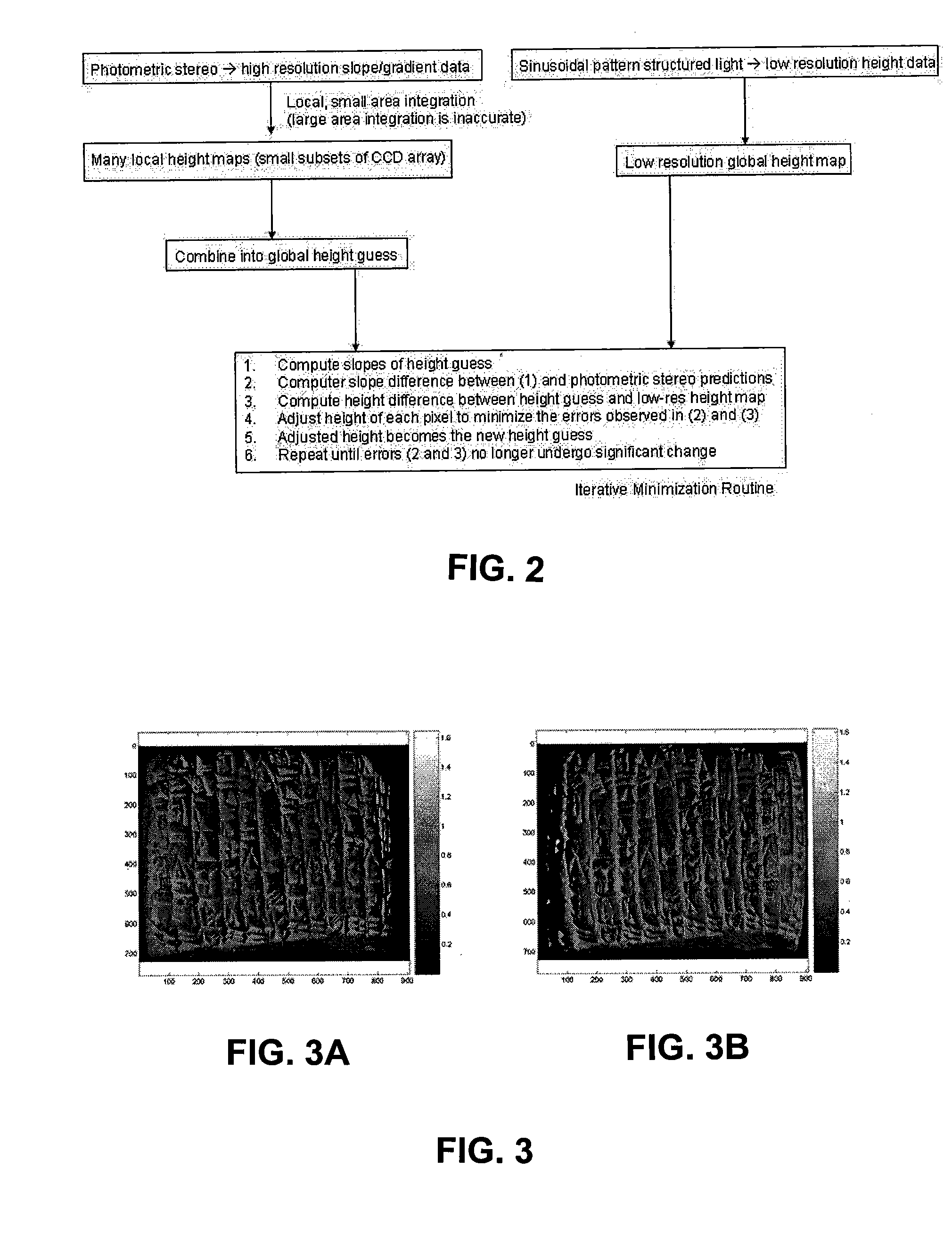

InactiveUS20080232679A1High resolution scanningSmall amount of timeCharacter and pattern recognitionMinimization algorithmLuminosity

A 3-dimensional scanner capable of acquiring the shape, color, and reflectance of an object as a complete 3-dimensional object. The scanner utilizes a fixed camera, telecentric lens, and a light source rotatable around an object to acquire images of the object under varying controlled illumination conditions. Image data are processed using photometric stereo and structured light analysis methods to determine the object shape and the data combined using a minimization algorithm. Scans of adjacent object sides are registered together to construct a 3-dimensional surface model.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

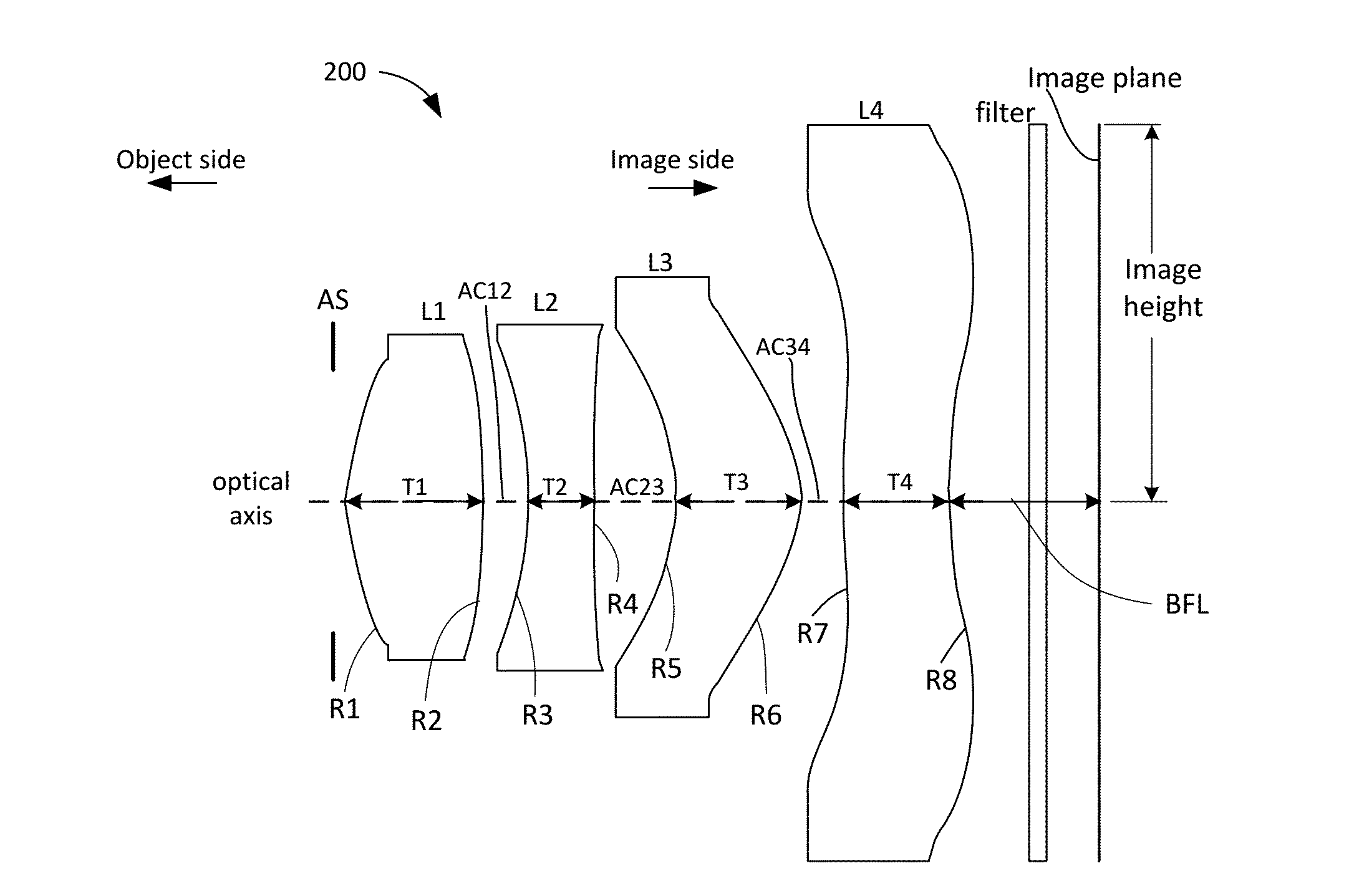

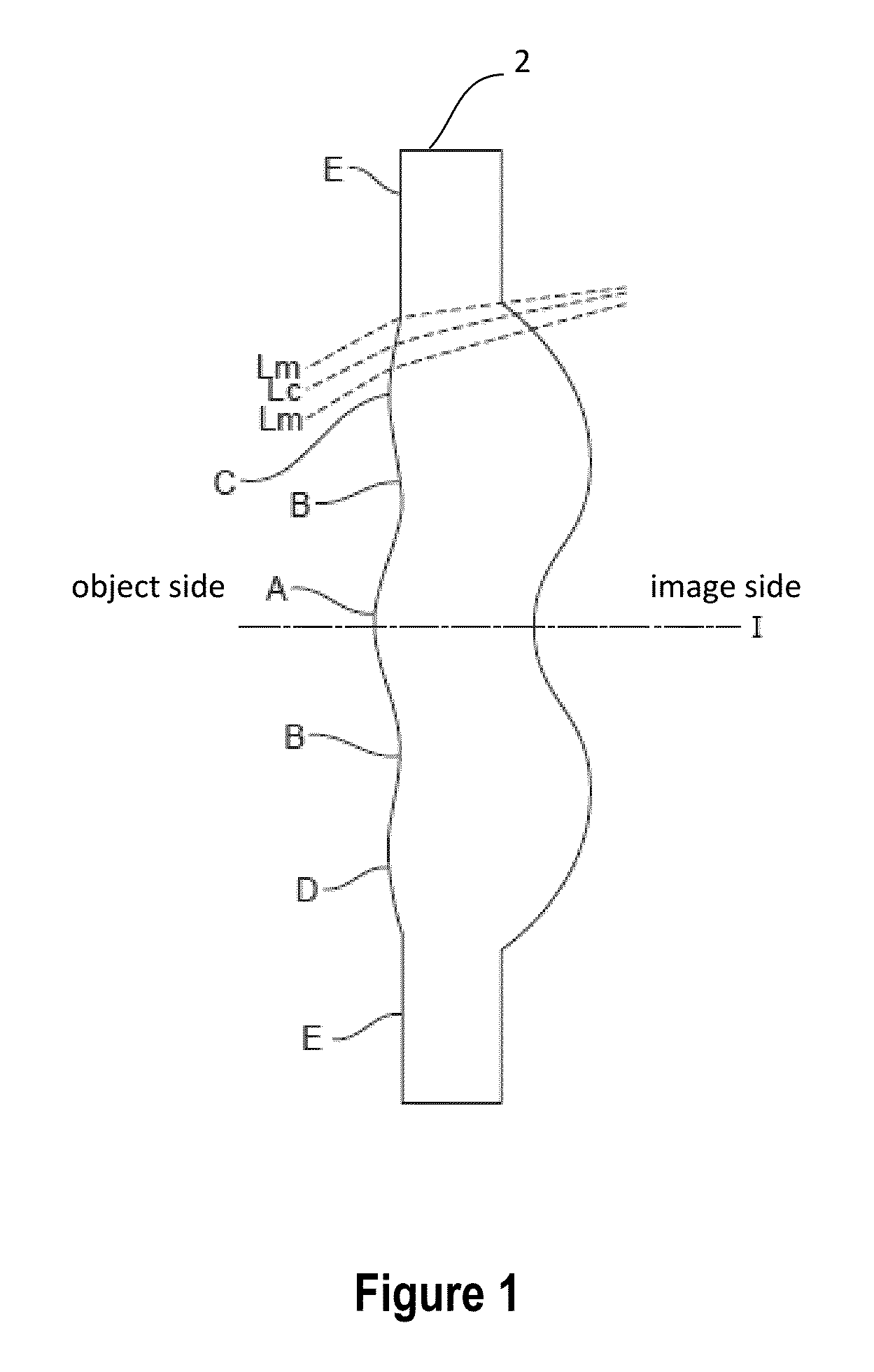

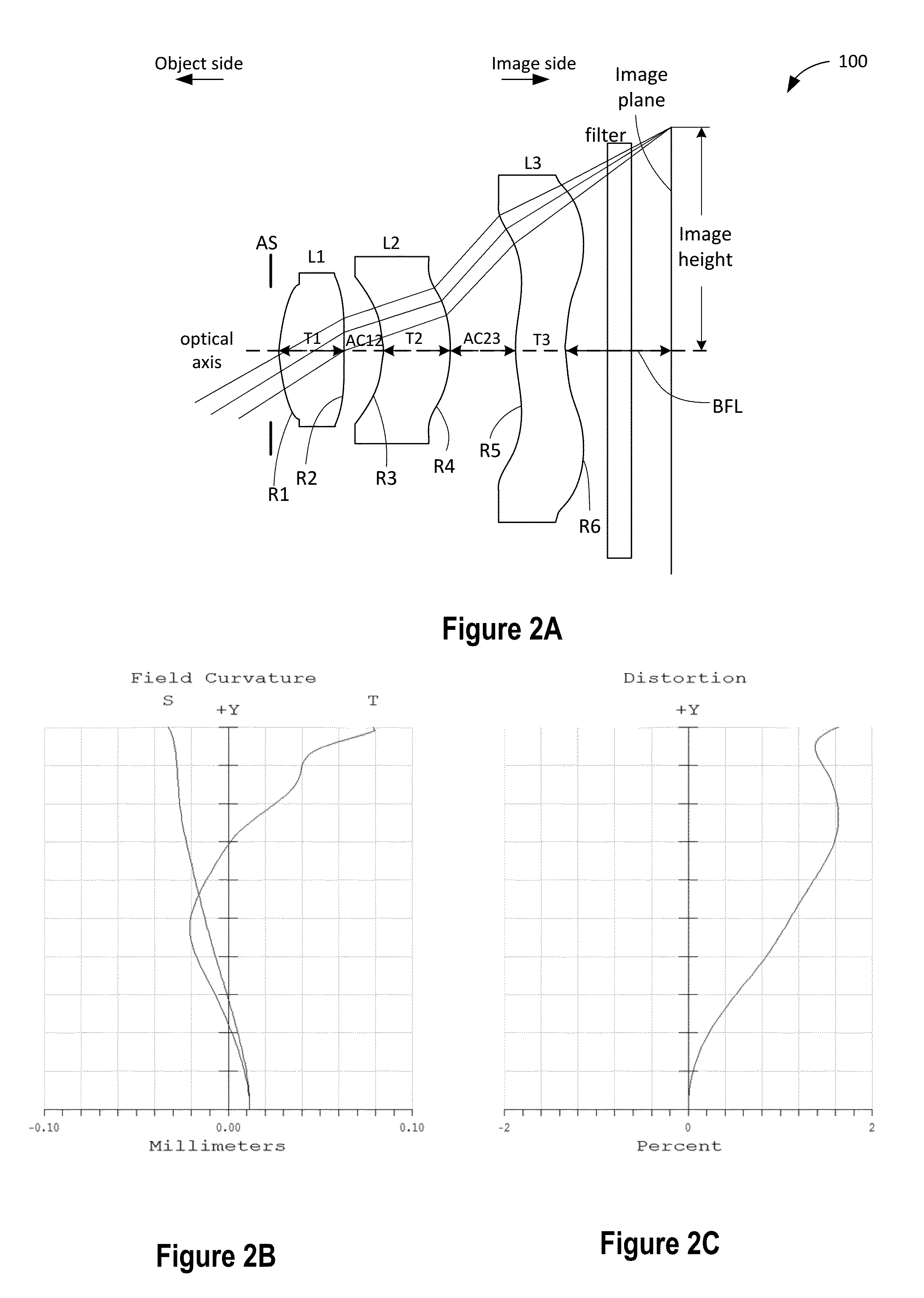

Near-infrared lens for cameras in mobile devices

A first optical imaging system includes, in order from the object side to the image side, a first lens element, a second lens element, and a third lens element, arranged along an optical axis. A second optical imaging system includes, in order from the object side to the image side, a first lens element, a second lens element, a third lens element, and a fourth lens element, arranged along an optical axis. A third optical imaging system is a telecentric lens system having only lens elements having a refractive power and a chief ray angle smaller than 1 degree. The lens elements of the optical imaging systems may be made of the same material having absorption in visible wavelengths and high transmission in near infrared radiation. The lens elements may be coated with an antireflective coating that is optimized for near infrared radiation.

Owner:GENIUS ELECTRONICS OPTICAL CO LTD

Coaxial narrow angle dark field lighting

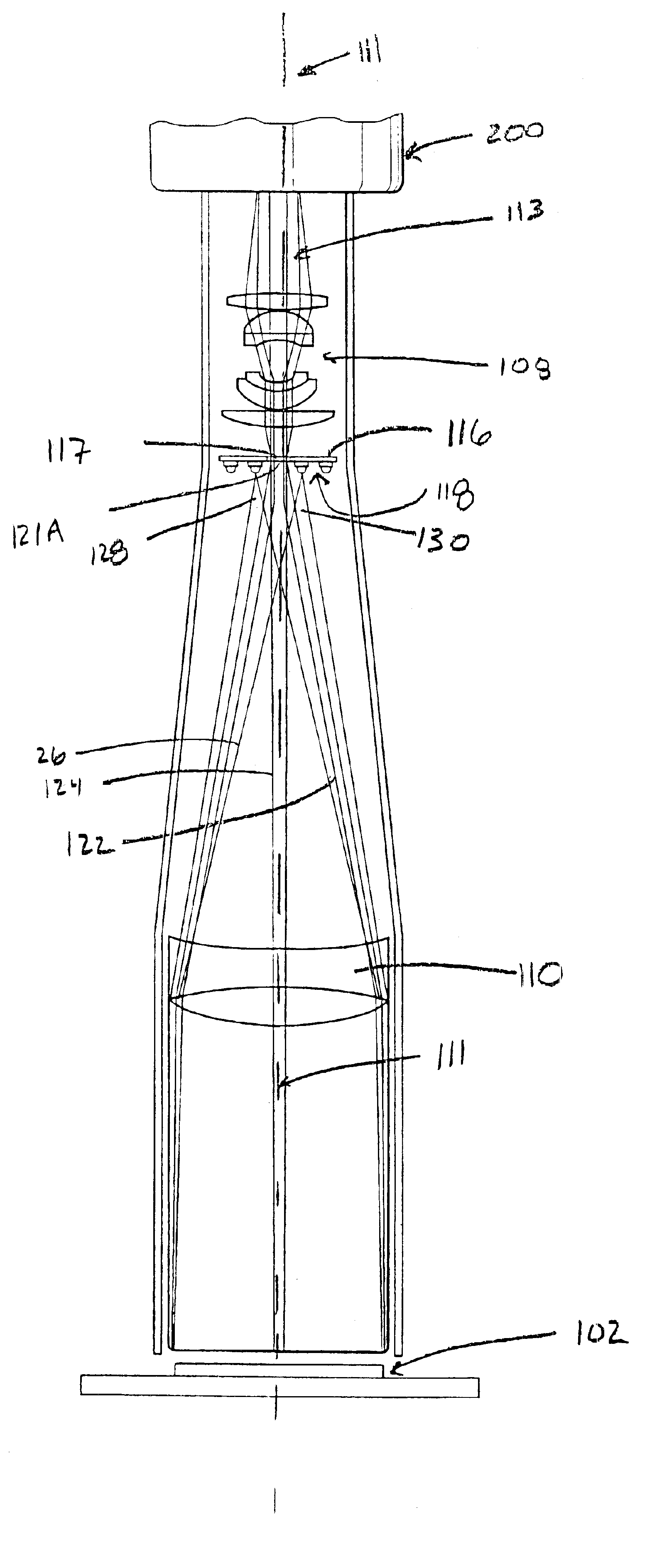

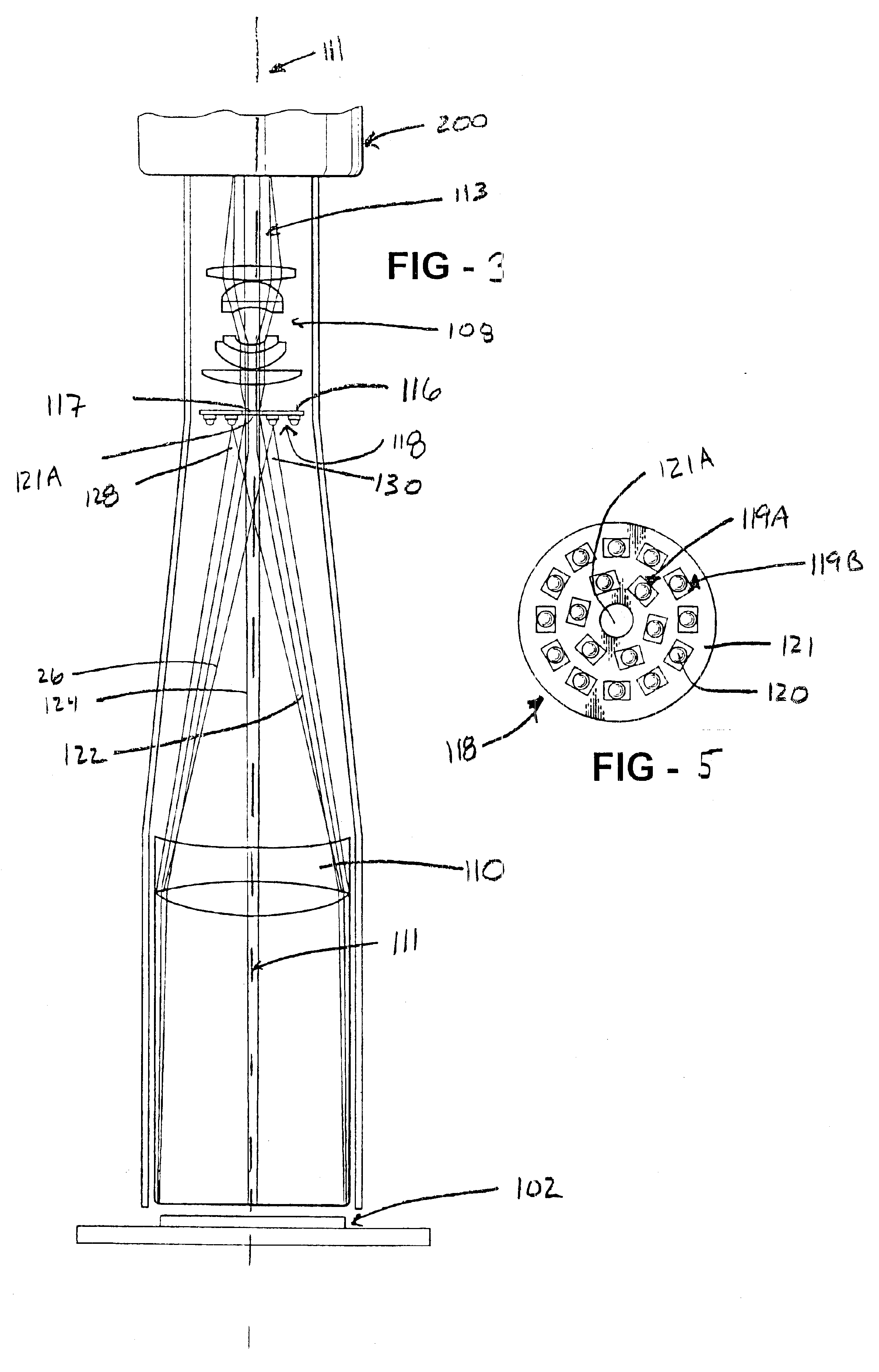

InactiveUS6870949B2Scattering properties measurementsCharacter and pattern recognitionCamera lensEffect light

A coaxial narrow angle dark field imaging system is provided. The system utilizes a telecentric lens to illuminate objects with symmetric coaxial narrow angle dark field illumination. The illumination technique is particularly suited to highlight minor features or defects on planar specular objects. In particular, the coaxial light source directs light rays towards a telecentric lens which redirects the light rays towards the substantially planar specular object. The light rays are reflected back through the telecentric lens towards a camera. To the extent that the light rays are reflected from a planar specular portion of the object the light rays are blocked by a telecentric stop. Light rays reflected from a defect or feature in the planar specular object will pass through an aperture in the stop to a camera.

Owner:ELECTRO SCI IND INC

Method and apparatus for manufacturing microstructure and device manufactured thereby

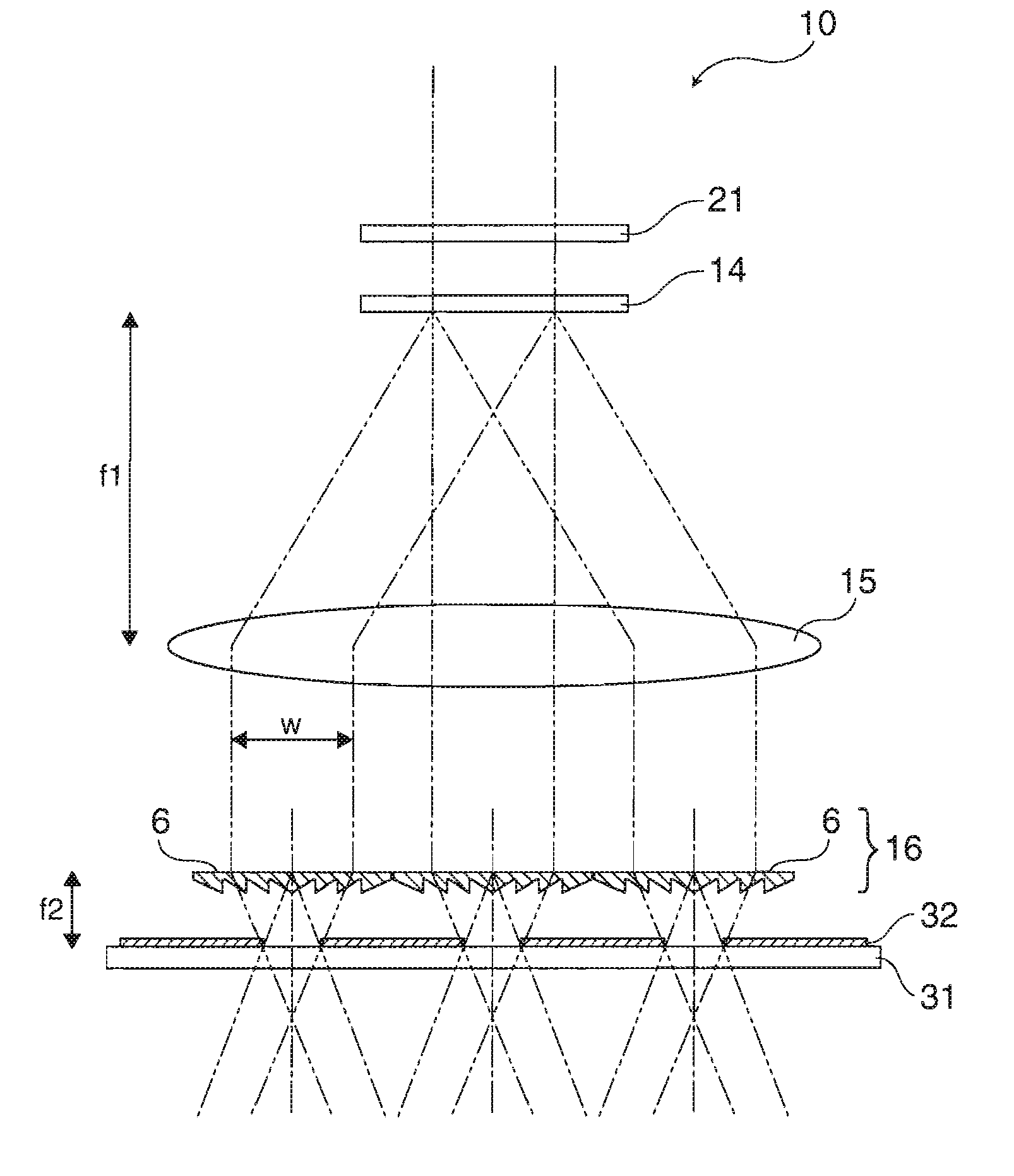

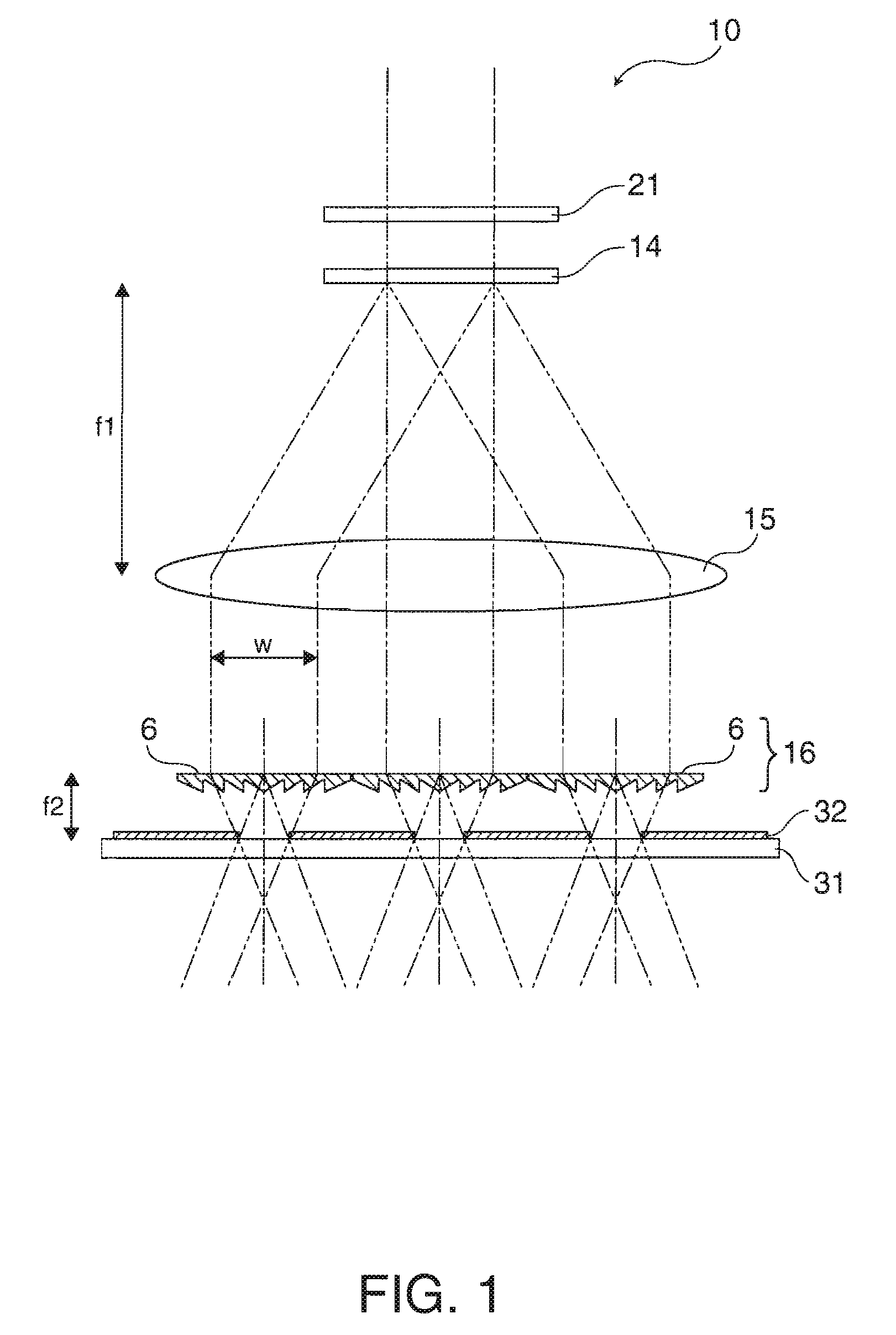

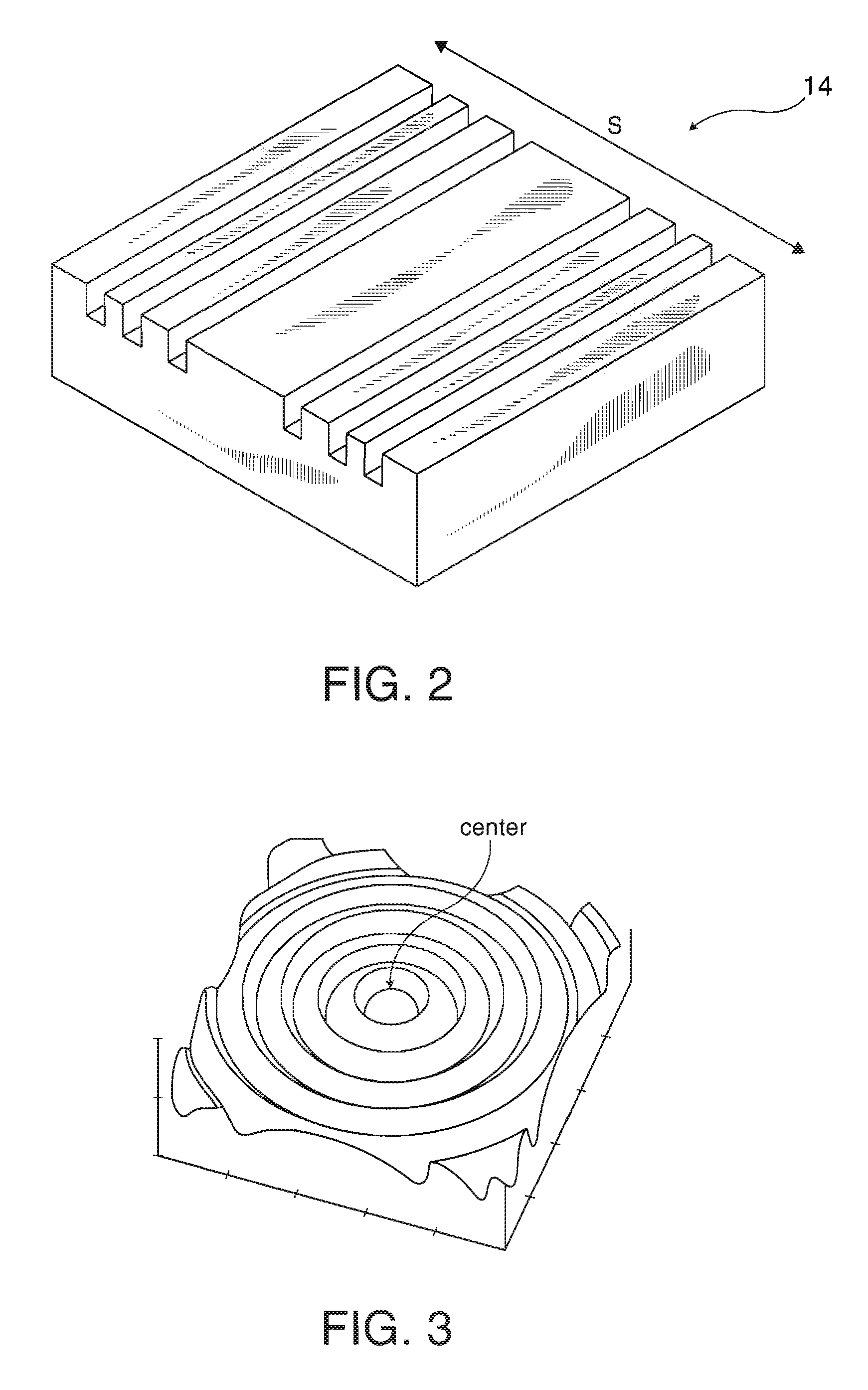

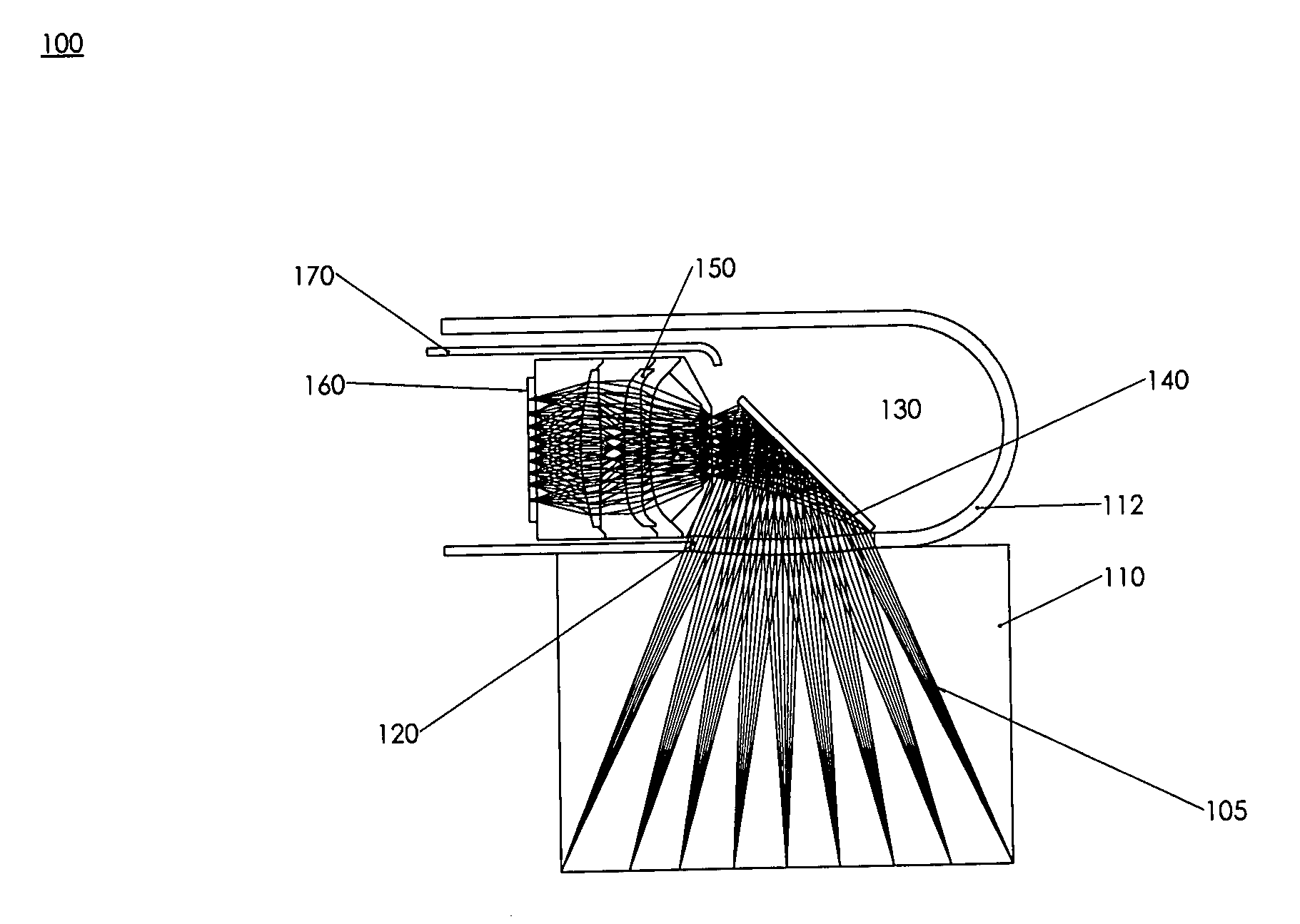

InactiveUS20070177116A1Improve throughputGood reproducibilityProjectorsPhotomechanical apparatusLight beamTelecentric lens

A method for manufacturing a microstructure, includes: dividing an incident laser beam into a plurality of diffracted beams by means of a diffractive optical element; concentrating said divided plurality of diffracted beams into mutually parallel diffracted beams by means of a telecentric lens; causing each of said mutually parallel diffracted beams to enter perpendicularly to the plane into a collection of axicons comprised of a plurality of axicons arranged into an array in such a manner that the center of each diffracted beam and the center of each axicon coincide, thereby forming a plurality of arrayed Bessel beams; and irradiating said plurality of arrayed Bessel beams onto a machined body.

Owner:SEIKO EPSON CORP

Acoustic imaging probe incorporating photoacoustic excitation

Various embodiments of the present invention provide for a photoacoustic imaging probe for use in a photoacoustic imaging system, whereby the probe is comprised of a cohesive composite, acoustic lens incorporating aspheric geometry and exhibiting low or practically no measurable dispersion of acoustic waves constructed of at least one material with a low acoustic impedance and attenuation and a relatively low acoustic velocity and at least one other material with a low acoustic impedance and attenuation and a relatively high acoustic velocity. The probe is housed in a conduit filled with a low acoustic velocity and low acoustic impedance fluid such as water or mineral oil. The lens may be designed as a telecentric lens, an acoustic zoom lens, a catadioptric lens, or a reflective lens. The lens focuses acoustic waves on an acoustic imager which detects the image. The acoustic imager may be designed as a 2 dimensional array of transducers. Research to date indicates that within the range of acoustic frequencies of interest, 1 MHz-50 MHz and preferable 2 MHz-10 MHz, there exists little velocity variation within the materials of interest, and the lens design approach may currently be considered to be essentially monochromatic. The acoustic waves can be generated when an emitting light source illuminates a test subject comprising materials that generate acoustic waves at differing intensities and / or frequencies when illuminated with light, for example tissue containing blood vessels, wherein the blood vessels excite and generate an acoustic pulse. The probe has an acoustic window made of a material with low acoustic impedance which allows the acoustic pulse to enter the probe without distortion and then may be reflected by a mirror onto the acoustic lens. The probe may include the emitting light source and an optical window to allow light emitting from said light source to illuminate the test subject.

Owner:ARNOLD STEPHEN C

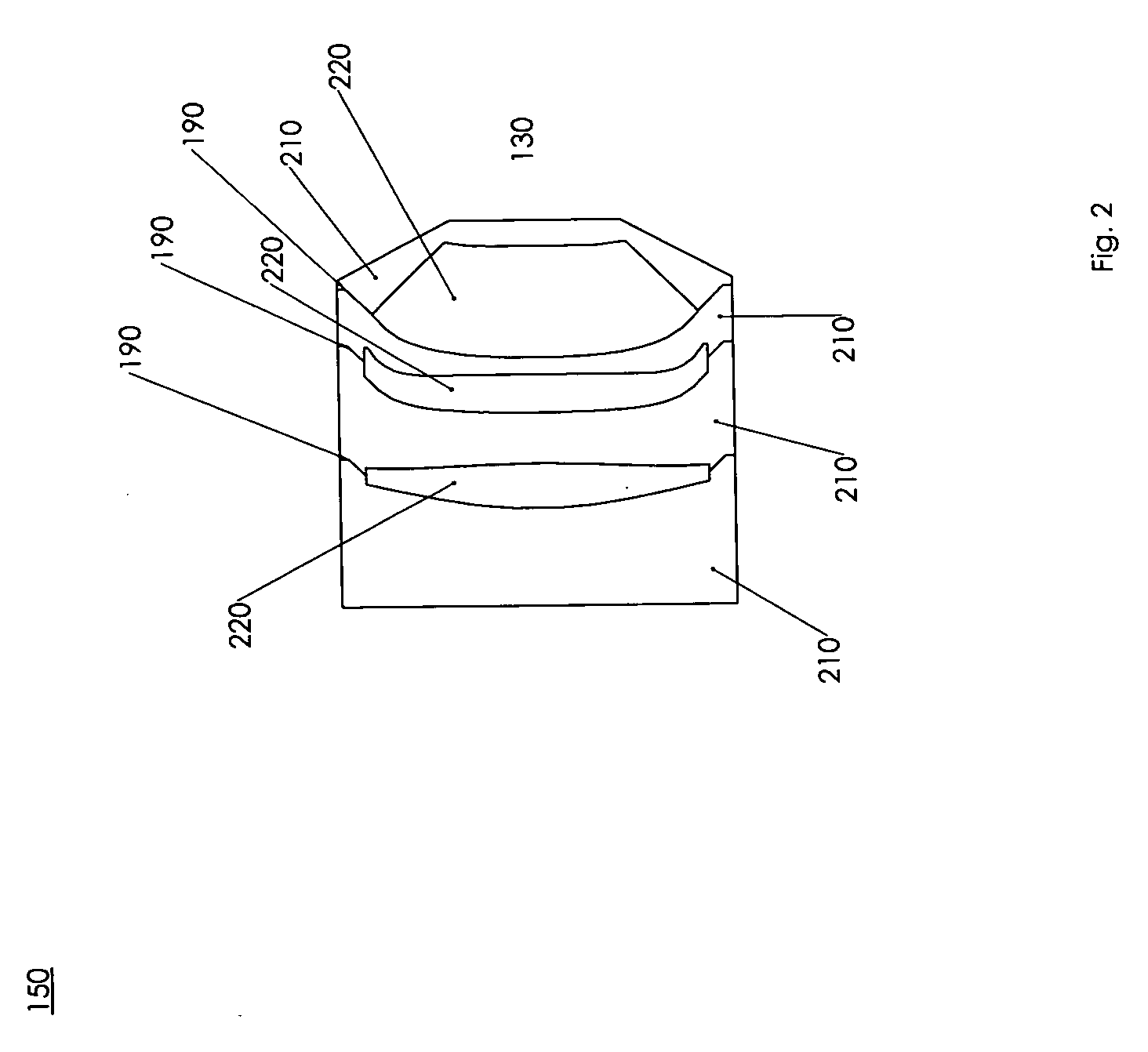

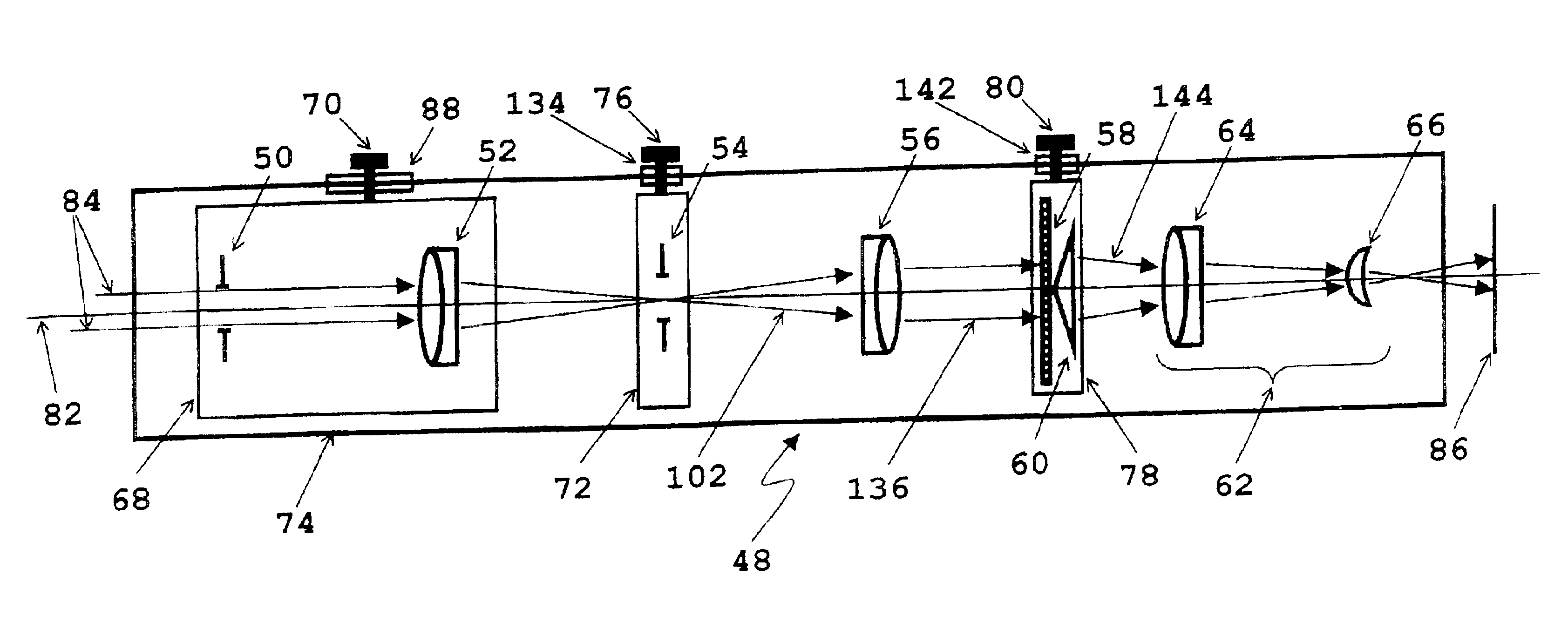

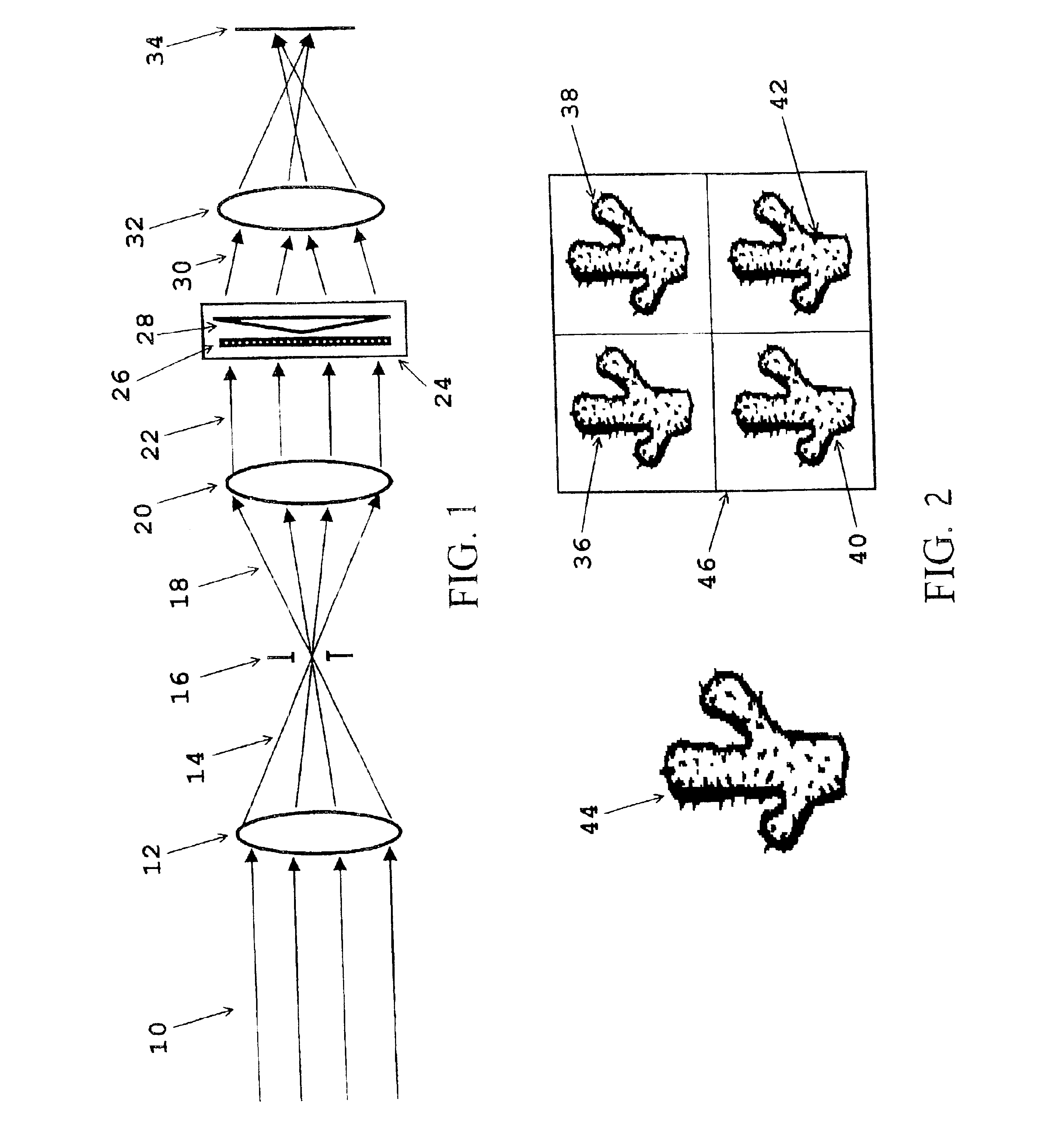

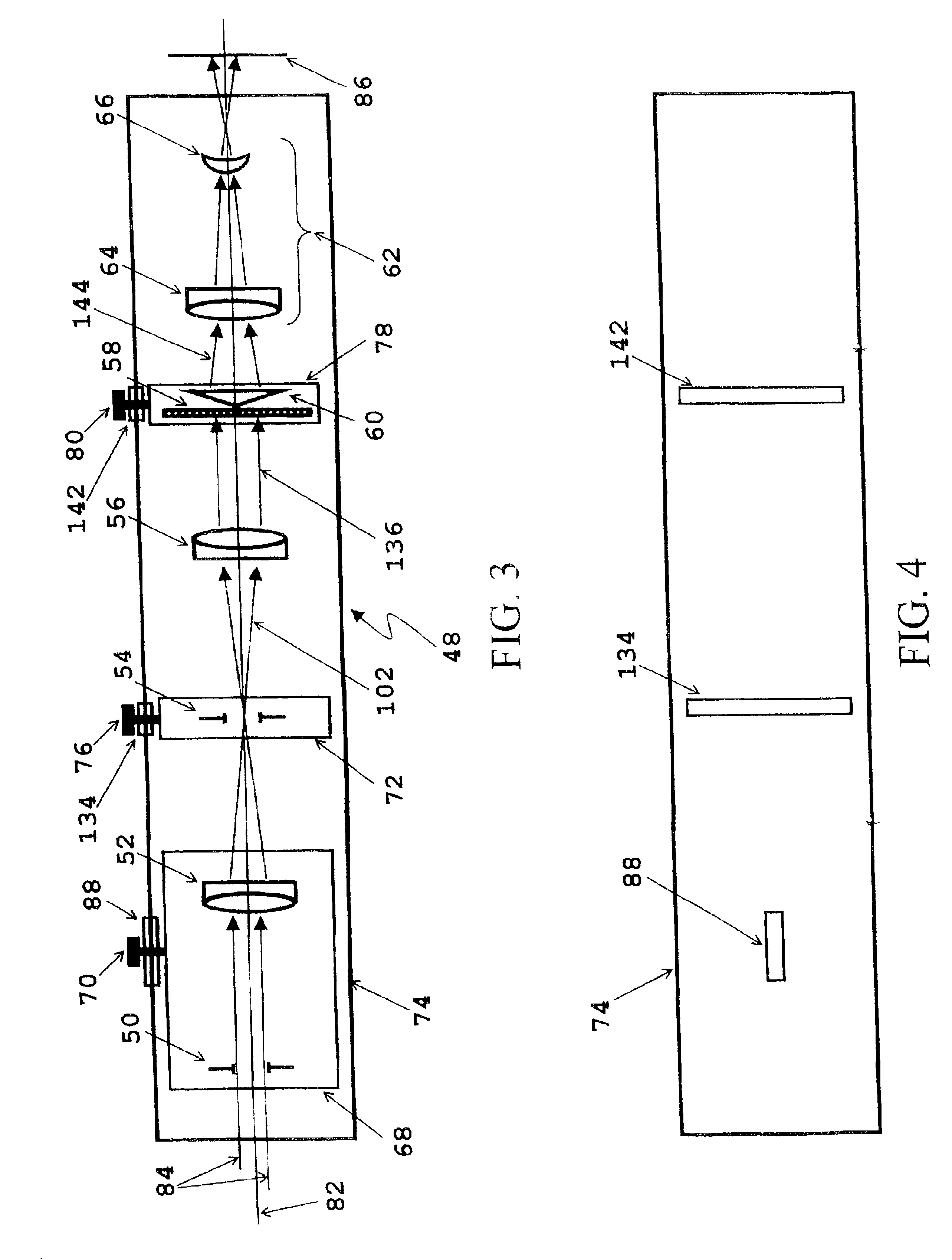

Multiple imaging system

A series of optical elements is used to produce multiple simultaneous adjoining images on a single image plane. A first, intermediate, image is produced using the first telecentric imaging lens. This intermediate image is produced at a plane coincident with an adjustable-size rectangular field stop. The rectangular field stop is mounted in a sub-housing that allows its free rotation. A second telecentric lens collimates the light from the intermediate image. This collimated light is next passed through an optical splitting means, which uses the principal of refraction to separate the light into multiple components. The optical splitting means is mounted in a sub-housing that allows its free rotation. From here, the light next passes through a third and final lens, which produces a second, final, image on a single, planar detection device. The final image consists of a plurality of identical copies of the intermediate image.

Owner:FOSTER-MILLER

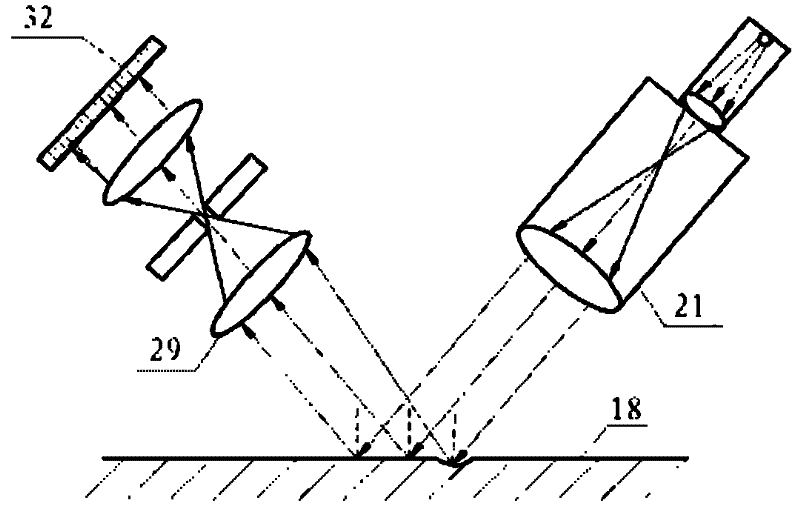

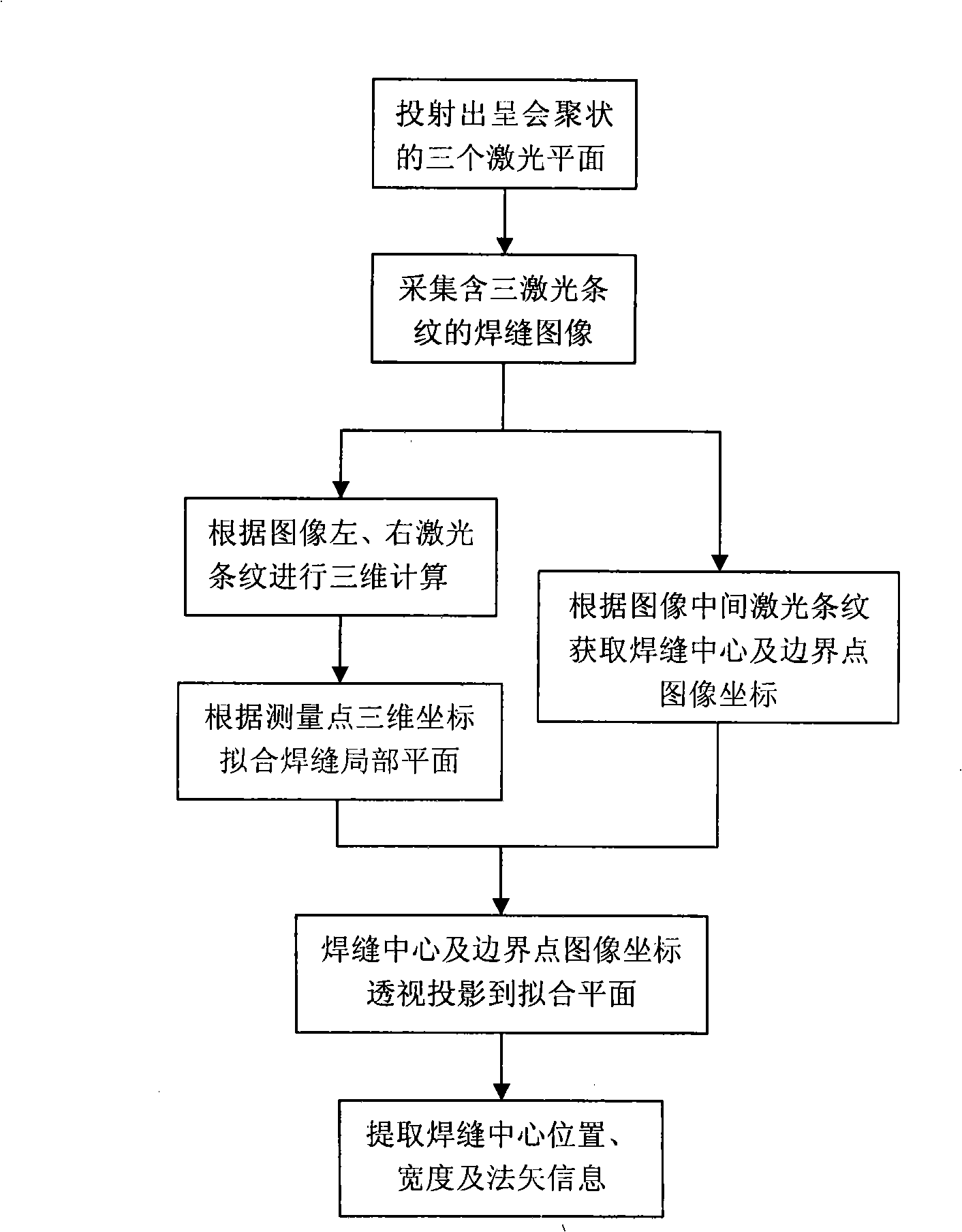

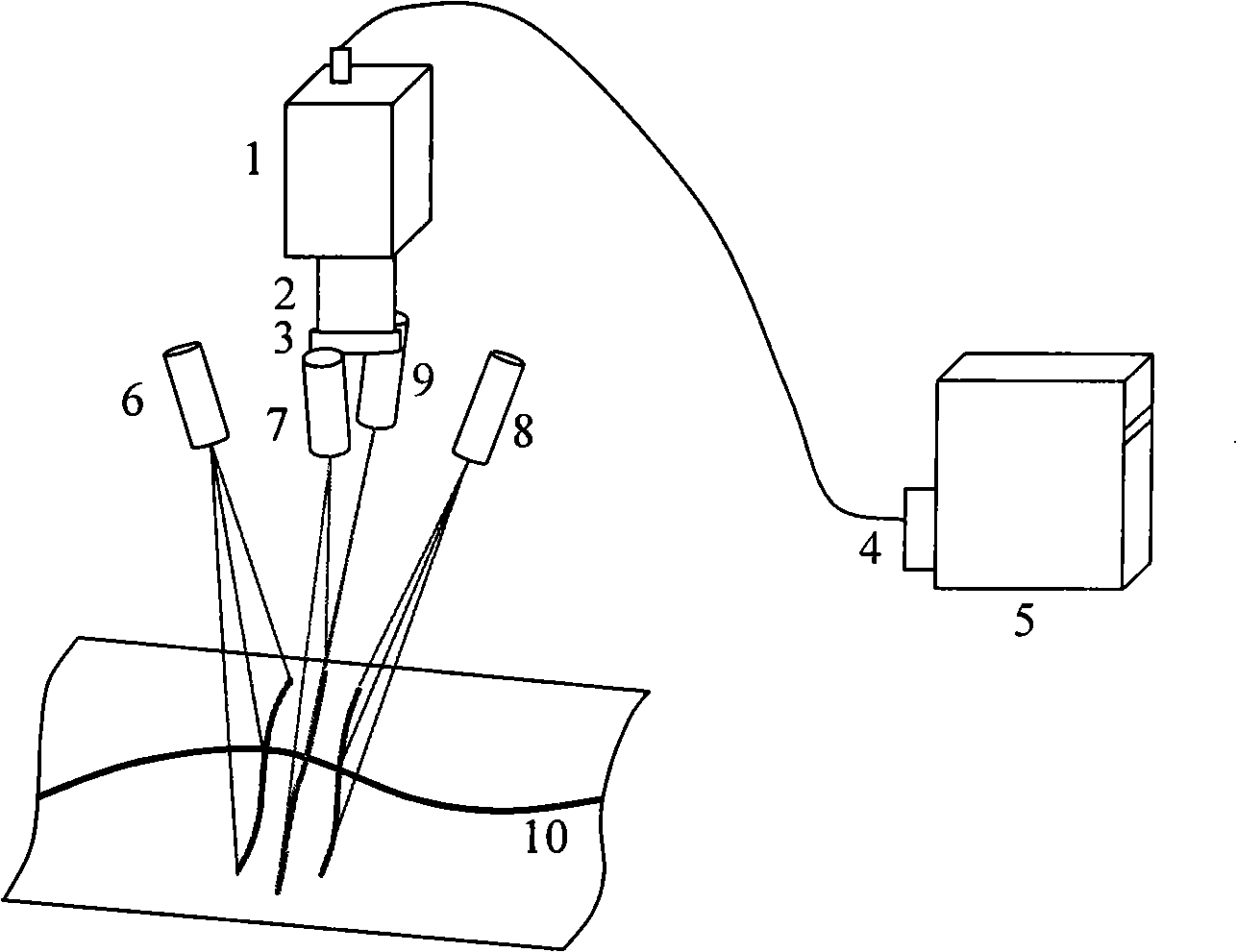

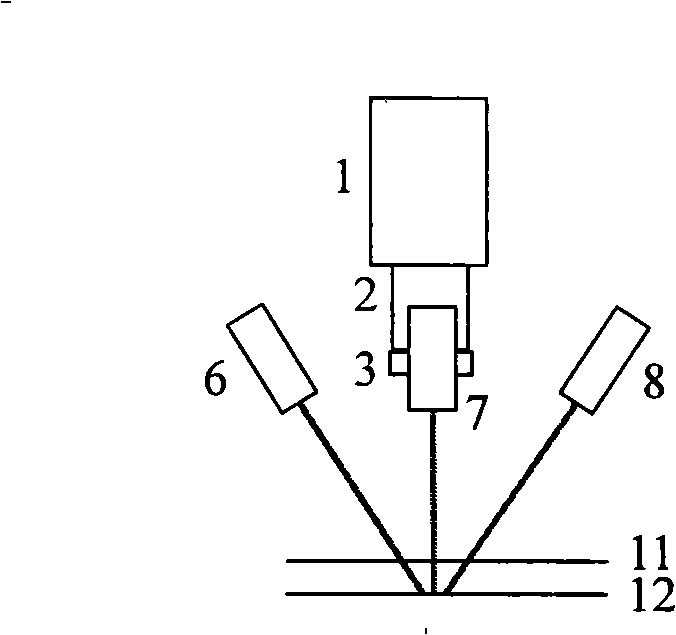

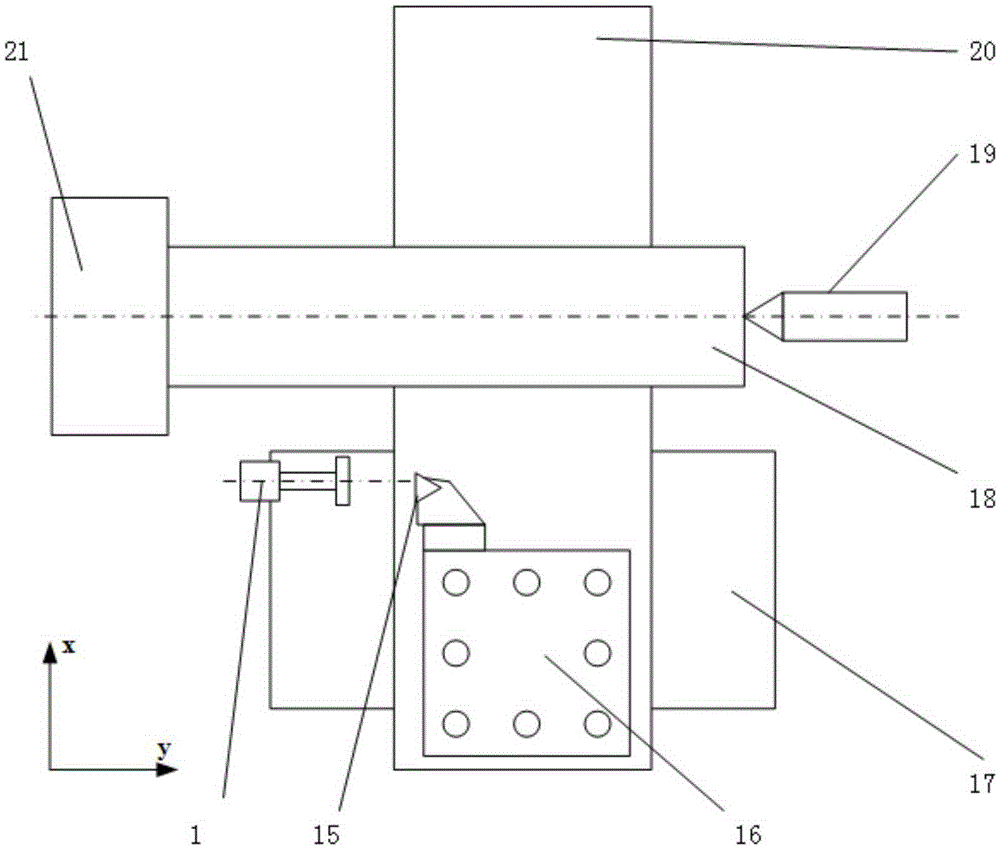

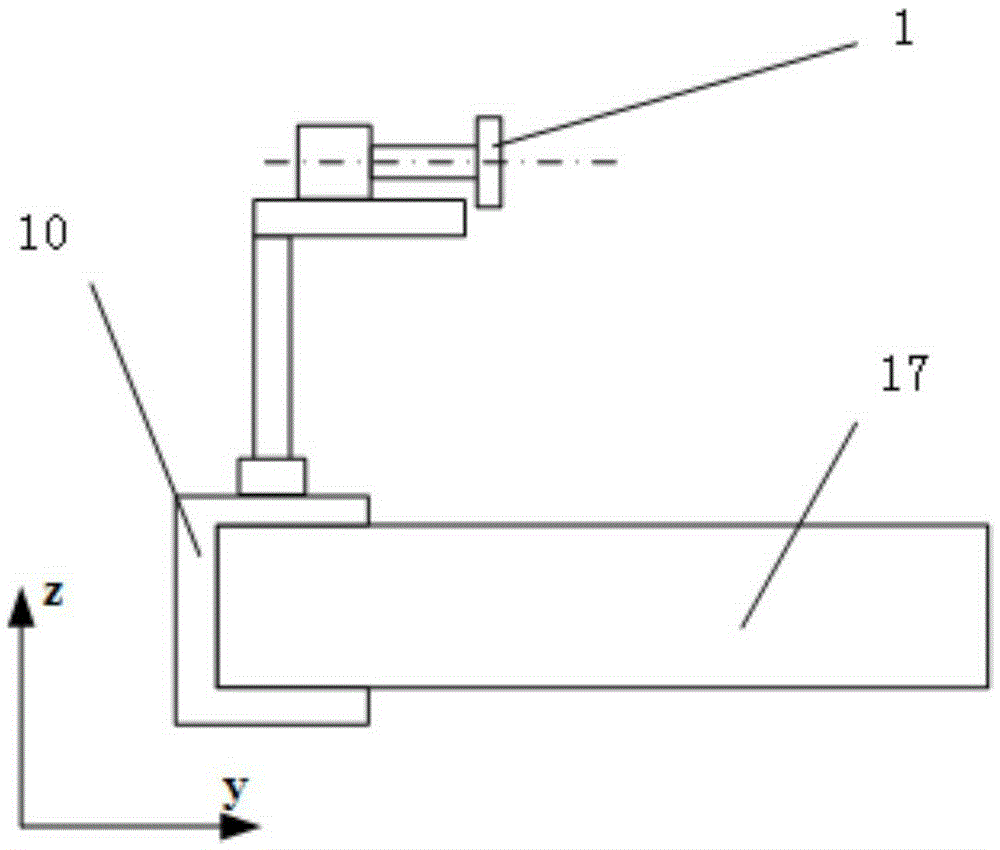

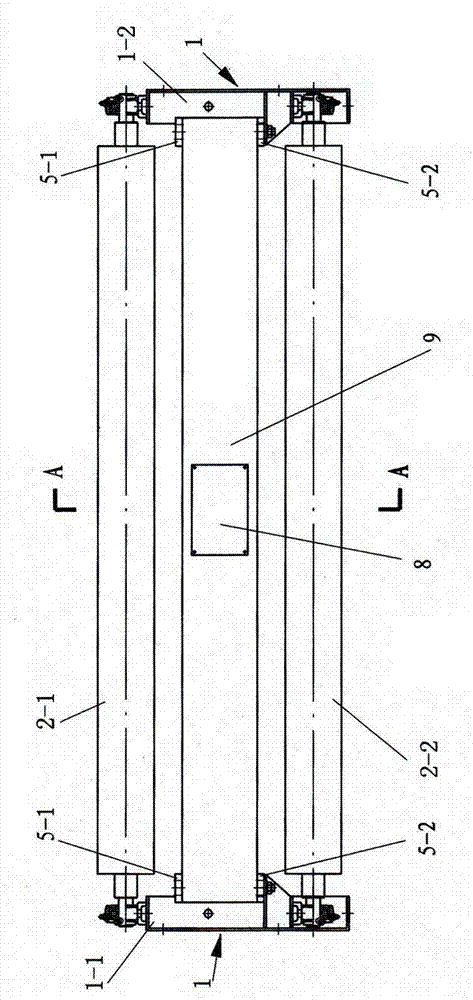

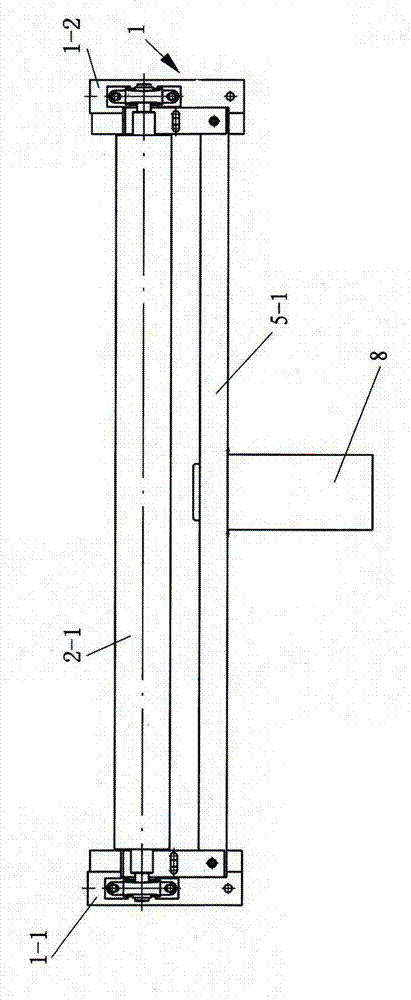

Laser welding narrow butt-jointed seam measurement method and device

The invention relates to a measuring method of a strictured butt-jointed seam in laser welding, and a device; two-dimension and three-dimension visual information is combined together organically, the information of three-dimension position, normal vector and weld width of a seam center is obtained at a same measurement position by carrying out calibration to a CCD camera and two laser planes and utilizing a seam image containing three laser stripes. The device comprises a telecentric lens, the CCD camera, an image grabbing card, a band-pass filter and a computer. Each linear light source laser projects three converged laser planes, the laser stripes formed by the intersection of all the laser planes and the plane which is vertical to the principal optic axis of the CCD camera are approximately parallel. The first and third linear light source lasers are symmetrically installed on the left and the right sides of the CCD camera and form the angles of 15 degrees to 60 degrees with the principal optic axis of the CCD camera; the second linear light source laser is symmetrically installed at the front side or the back side of the CCD camera and forms the angles of 10 degrees to 30 degrees with the principal optic axis of the CCD camera. The device has simple structure, with rich measurement information.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Surround sensing system with telecentric optics

ActiveUS10183541B2Reduce the amount requiredAccurate detectionUsing optical meansResilient suspensionsBandpass filteringAngle of incidence

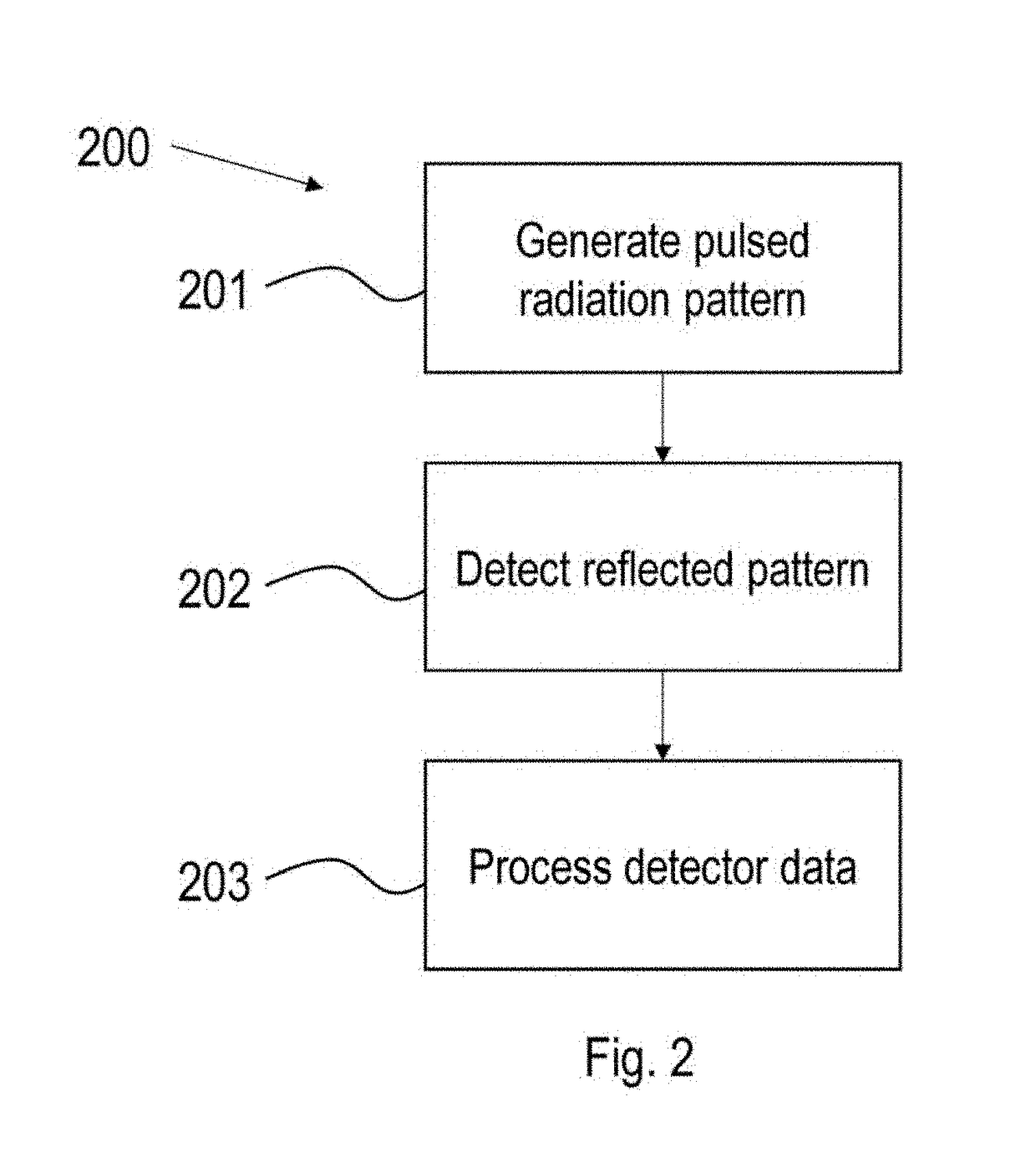

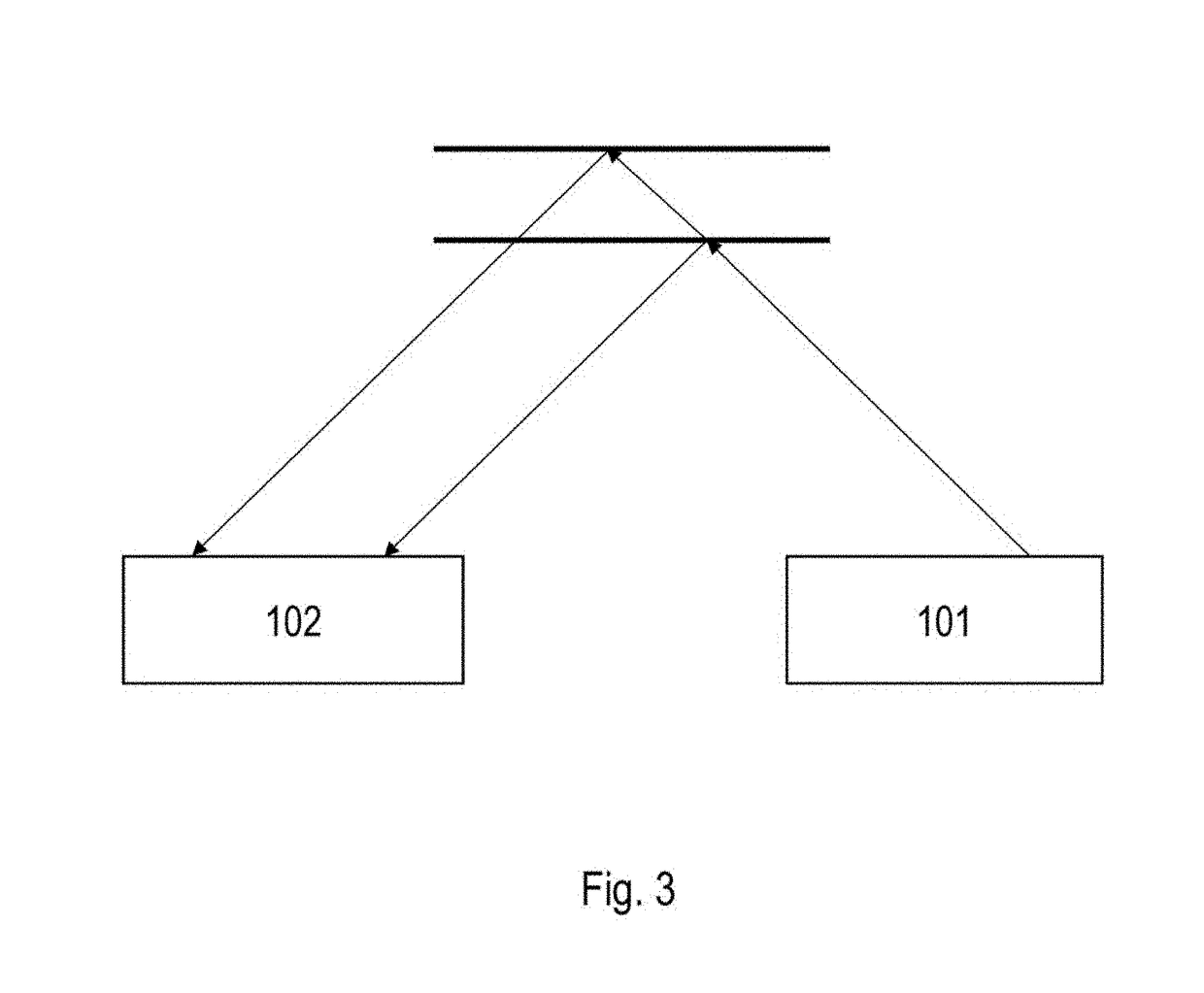

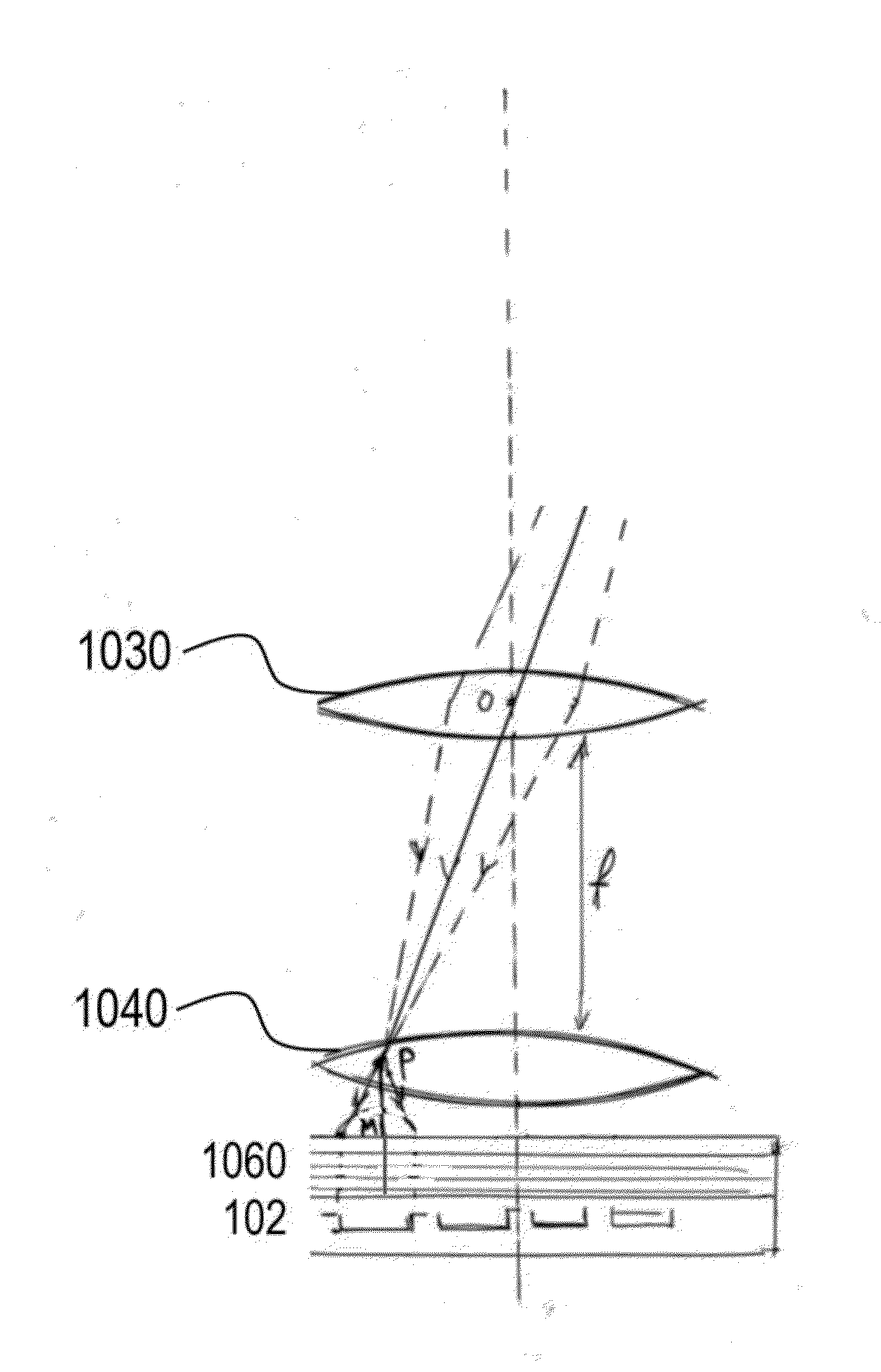

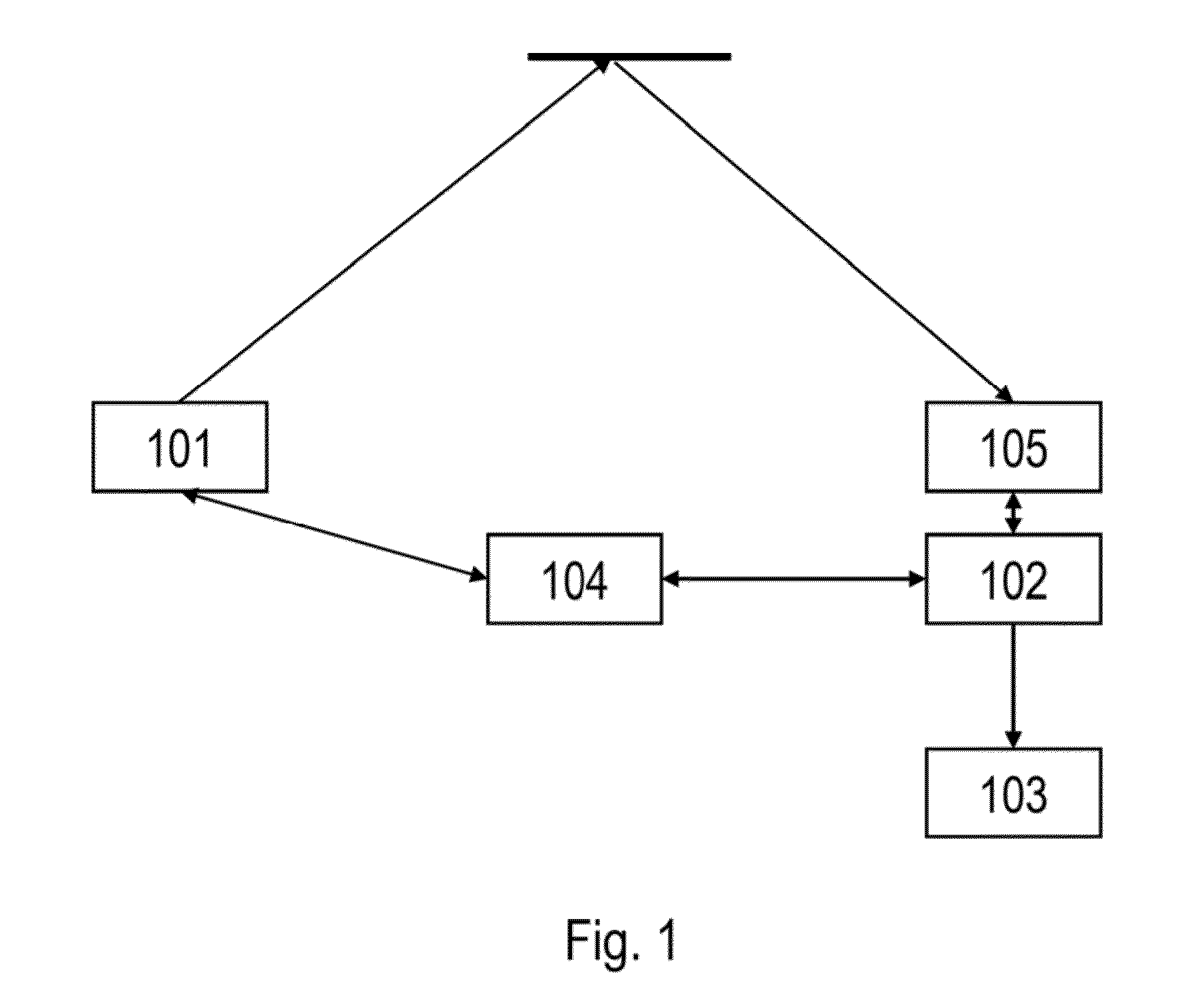

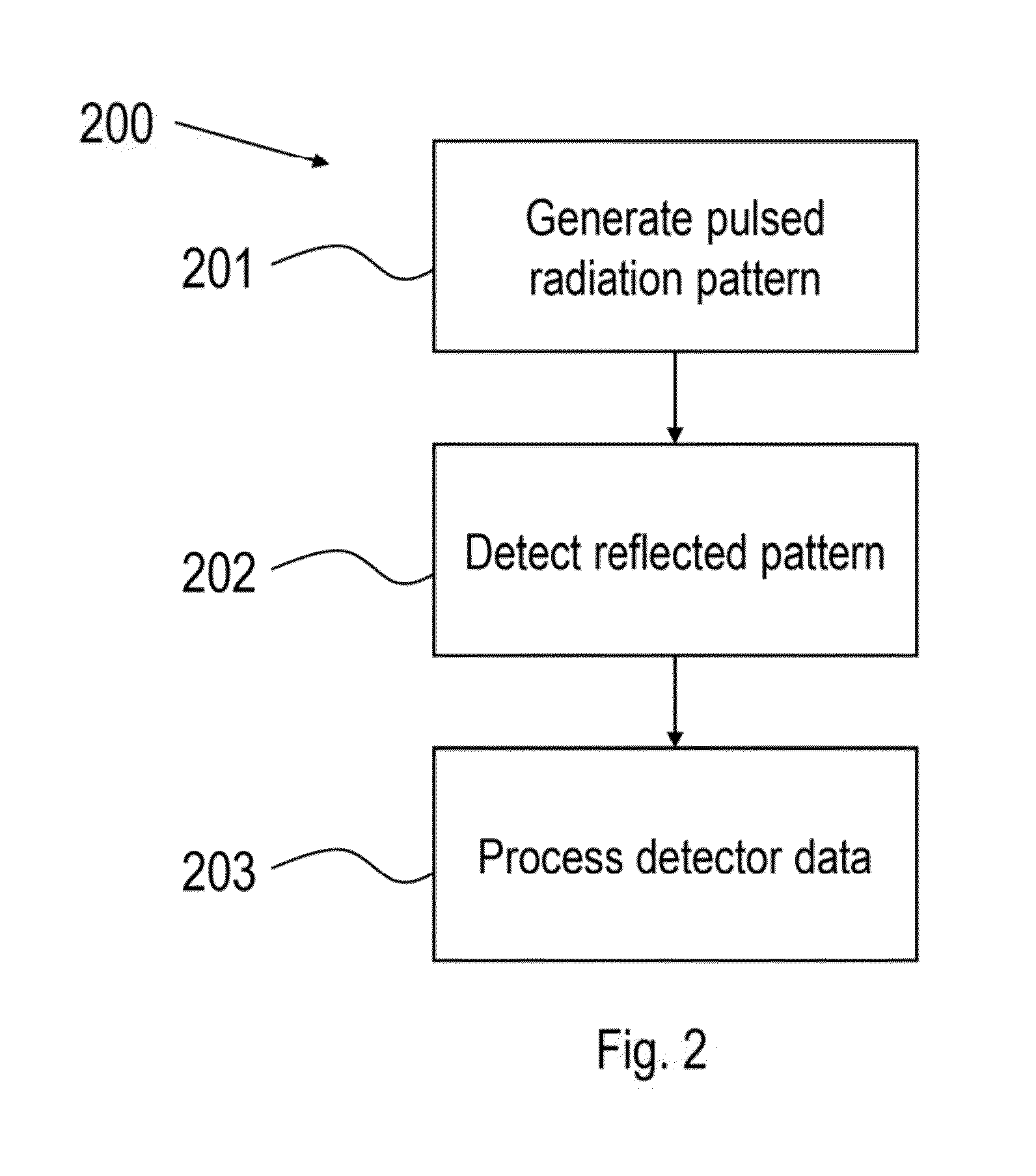

The invention pertains to a system comprising: a source to generate a pulsed radiation pattern; a detector; a processor to process data from the detector when radiation is reflected by an object; a synchronization means interfacing between the detector and the source; wherein: the detector is synchronized with the source so that radiation to be processed is detected only during the pulses, the processor determines a characteristic of the object by determining displacement of detected spots with reference to predetermined positions, the source emits monochromatic light and the detector is equipped with a bandpass filter and optics arranged so as to modify an angle of incidence onto said filter to confine light to a predetermined range around a normal of said filter, said optics comprising an image-space telecentric lens.

Owner:XENOMATIX NV

Surround sensing system with telecentric optics

ActiveUS20160200161A1Decrease the filling factorReduce lossesDigital data processing detailsAnimal undercarriagesBandpass filteringAngle of incidence

The invention pertains to a system comprising: a source to generate a pulsed radiation pattern; a detector; a processor to process data from the detector when radiation is reflected by an object; a synchronization means interfacing between the detector and the source; wherein: the detector is synchronized with the source so that radiation to be processed is detected only during the pulses, the processor determines a characteristic of the object by determining displacement of detected spots with reference to predetermined positions, the source emits monochromatic light and the detector is equipped with a bandpass filter and optics arranged so as to modify an angle of incidence onto said filter to confine light to a predetermined range around a normal of said filter, said optics comprising an image-space telecentric lens.

Owner:XENOMATIX NV

Systems and Methods for Use of Optical Odometry Sensors In a Mobile Robot

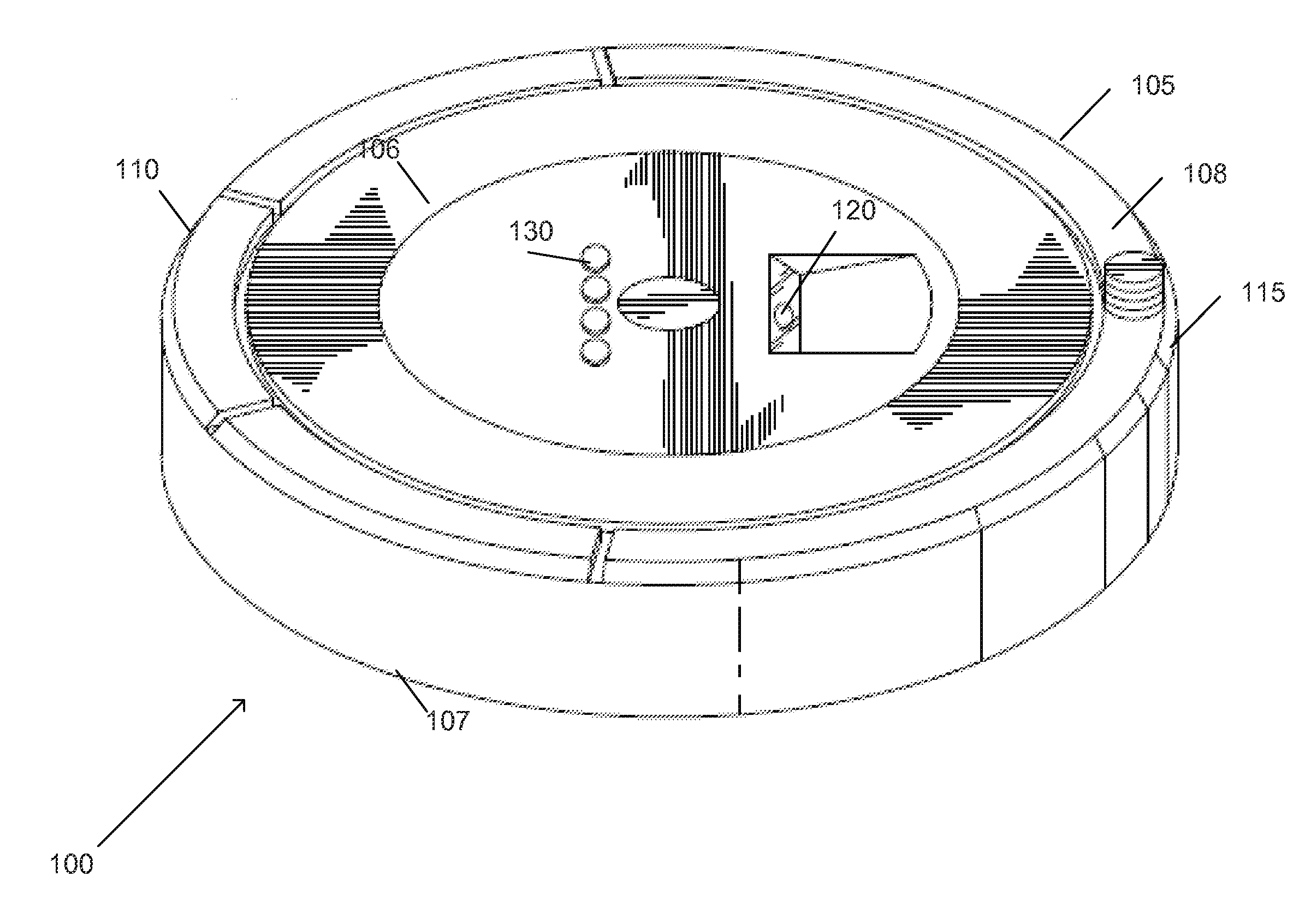

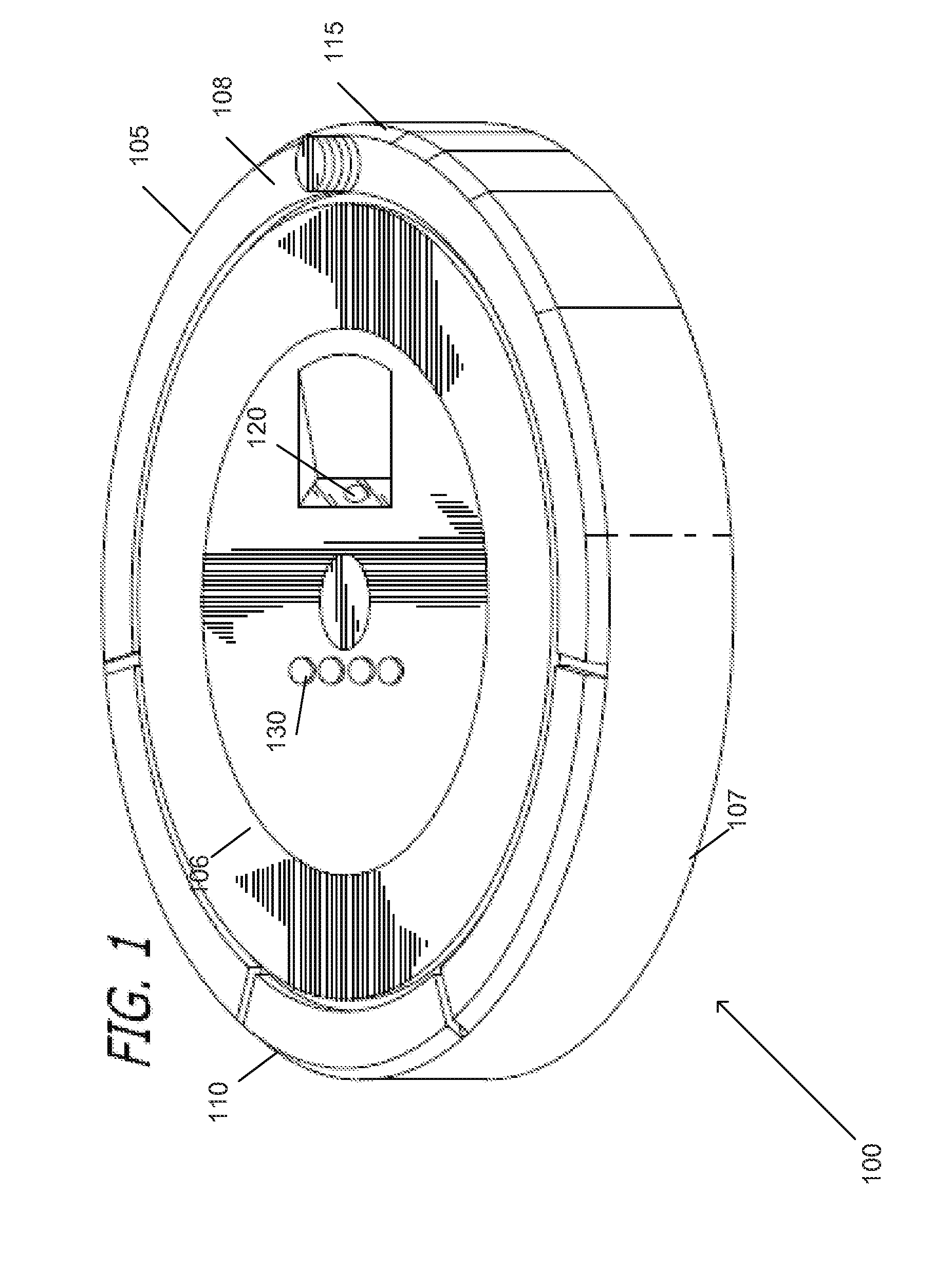

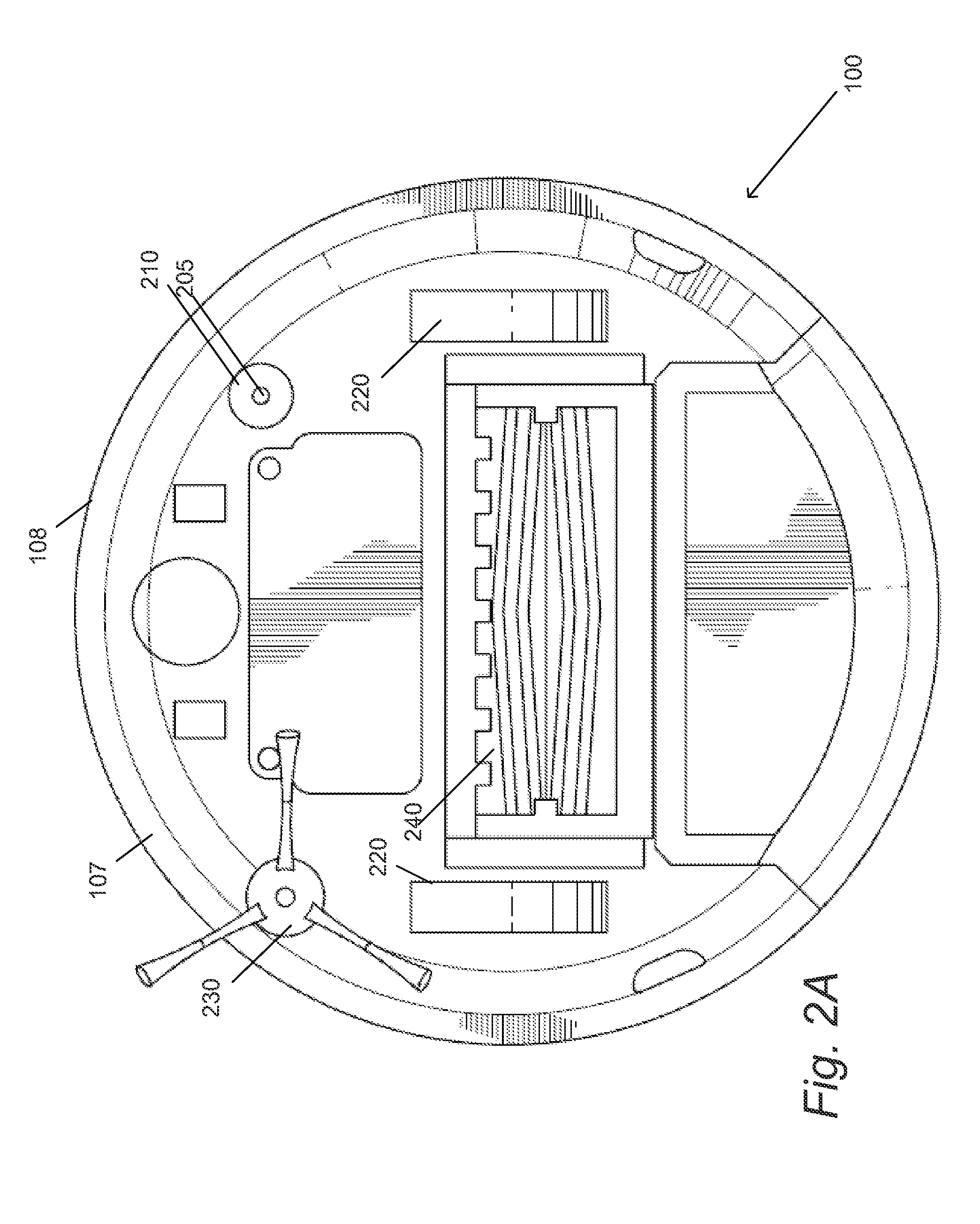

Systems and methods for use of optical odometry sensor systems in a mobile robot. The optical odometry sensor system is positioned within a recessed structure on an underside of the mobile robot body and configured to output optical odometry data. The optical odometry sensor system includes an optical odometry camera that includes a telecentric lens configured to capture images of a tracking surface beneath the body and having a depth of field that provides a range of viewing distances at which a tracking surface is captured in focus from a first distance within the recessed structure to a second distance below the underside of the mobile robot body.

Owner:IROBOT CORP

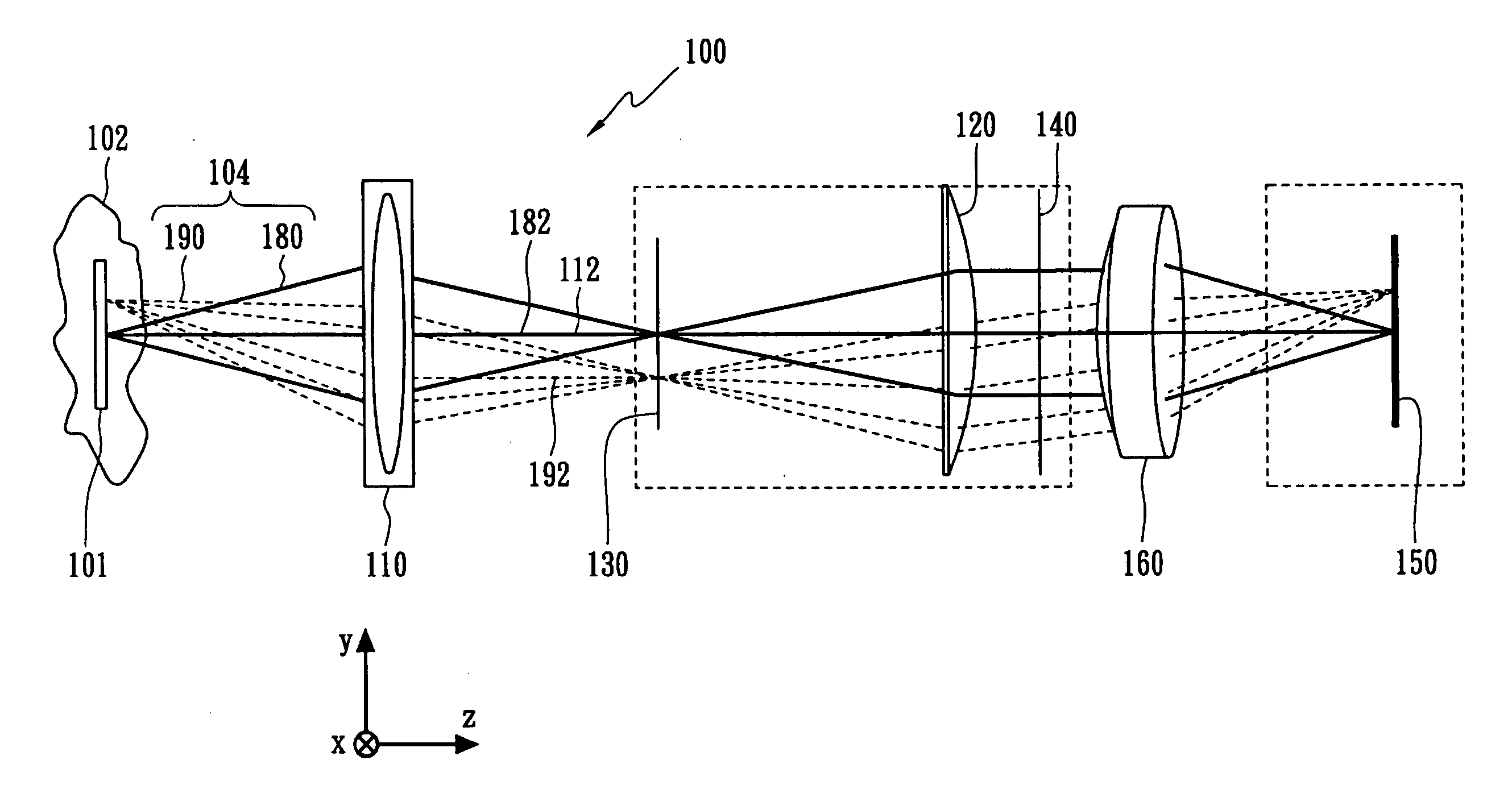

On-line measurement method for particle size distribution and shape distribution of granules in airflow conveying pipe

InactiveCN102410974ALower requirementLow costParticle size analysisUsing optical meansMeasurement deviceRgb image

The invention discloses an on-line measurement method for particle size distribution and shape distribution of granules in an airflow conveying pipe, and belongs to the technical field of on-line measurement of gas-solid phase flow. The on-line measurement method comprises the following steps: in the gas-solid phase fluid pipe, irradiating three sections in a granular flow field at the same time by three pulse laser sheet sources with different spectrums, and capturing RGB (red, green and blue) images of the flowing granules on the three illuminated sections of the flow field at the same time by adopting an RGB digital camera; and decomposing the RGB image of each frame and respectively processing three sub-images by an image processing method so as to obtain particle size distribution and shape distribution of the measured granules. The on-line measurement method has the beneficial effects that the images of the granules on three different sections of the flow field can be acquired at the same time by adopting three lasers with different spectrums, the RGB camera and a telecentric lens; imaging on a plurality of focusing surfaces can be realized simultaneously; and the exposure time of the camera can be controlled by means of pulse feedback of the lasers so as to realize imaging of the flowing granules, thus greatly lowering the complexity of a measuring device and improving the measurement efficiency.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

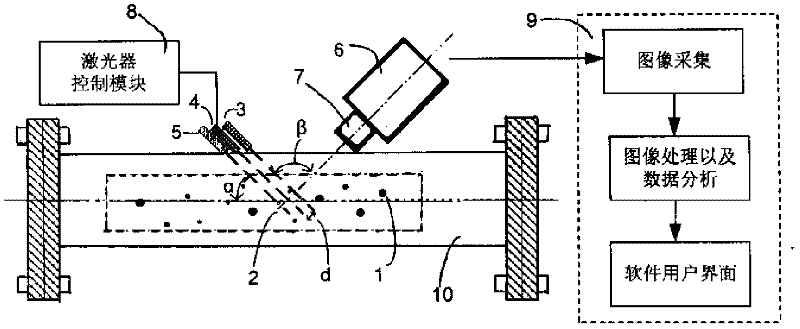

Apparatus for measuring imaging spectrograph

ActiveUS20060077385A1Reduce positional differencesHigh resolutionRadiation pyrometrySpectrum investigationEntrance angleSpectrograph

The present invention discloses an apparatus for measuring spectrum and image with high spatial resolution and spectral resolution. The apparatus comprises an imaging side telecentric lens for collecting light from an object, an optical slit positioned behind the imaging side telecentric lens, an aspheric lens for collimating lights from the optical slits, a dispersing device for separating the lights of different wavelengths into a plurality of sub-rays of different entrance angle, an achromatic lens for focusing the sub-rays, and an optical sensor for detecting the optical intensity of the sub-rays. The dispersing device can be a transmission or reflection diffraction grating, and the optical sensor may consist of a plurality of photo-detectors positioned in a two dimensional array.

Owner:IND TECH RES INST

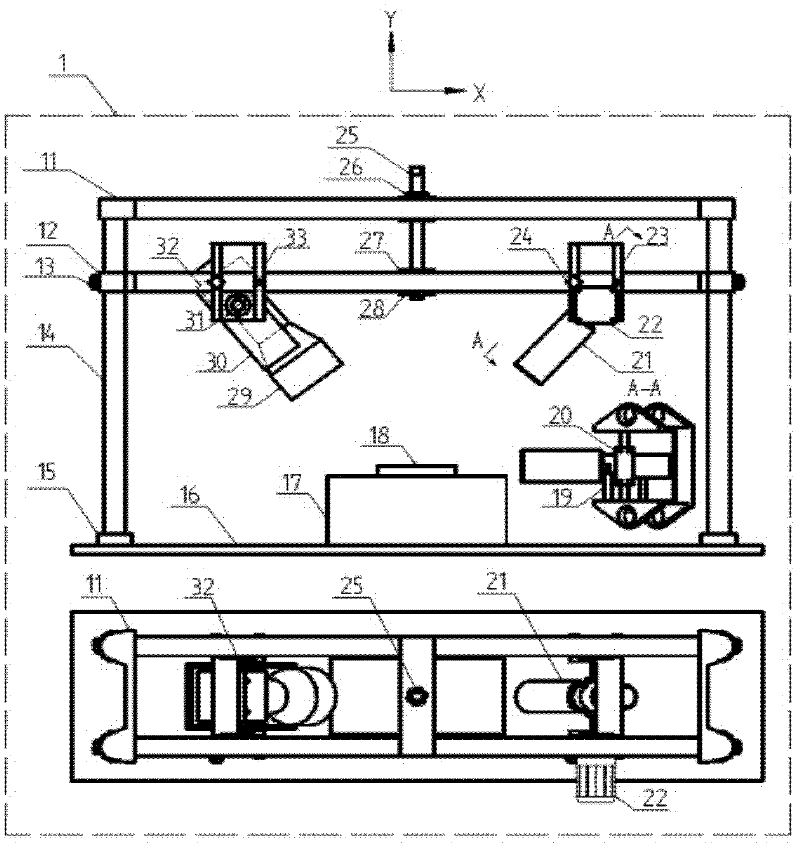

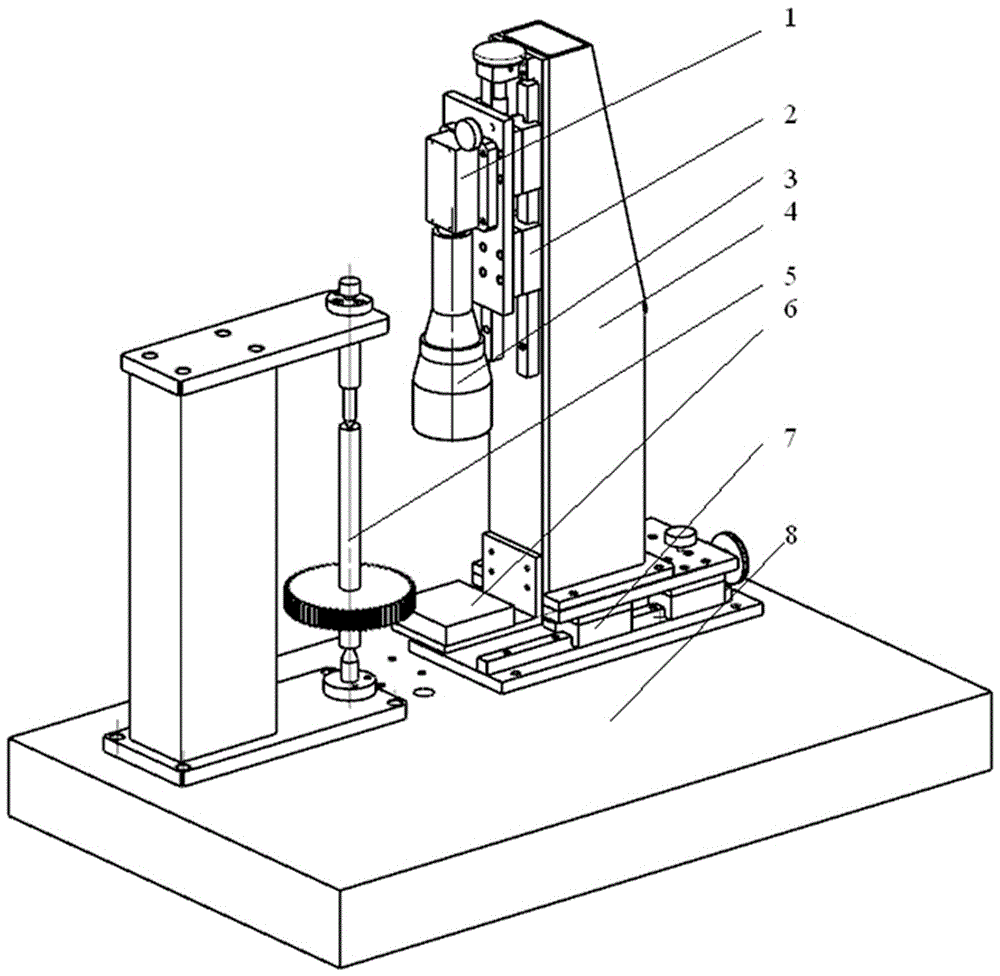

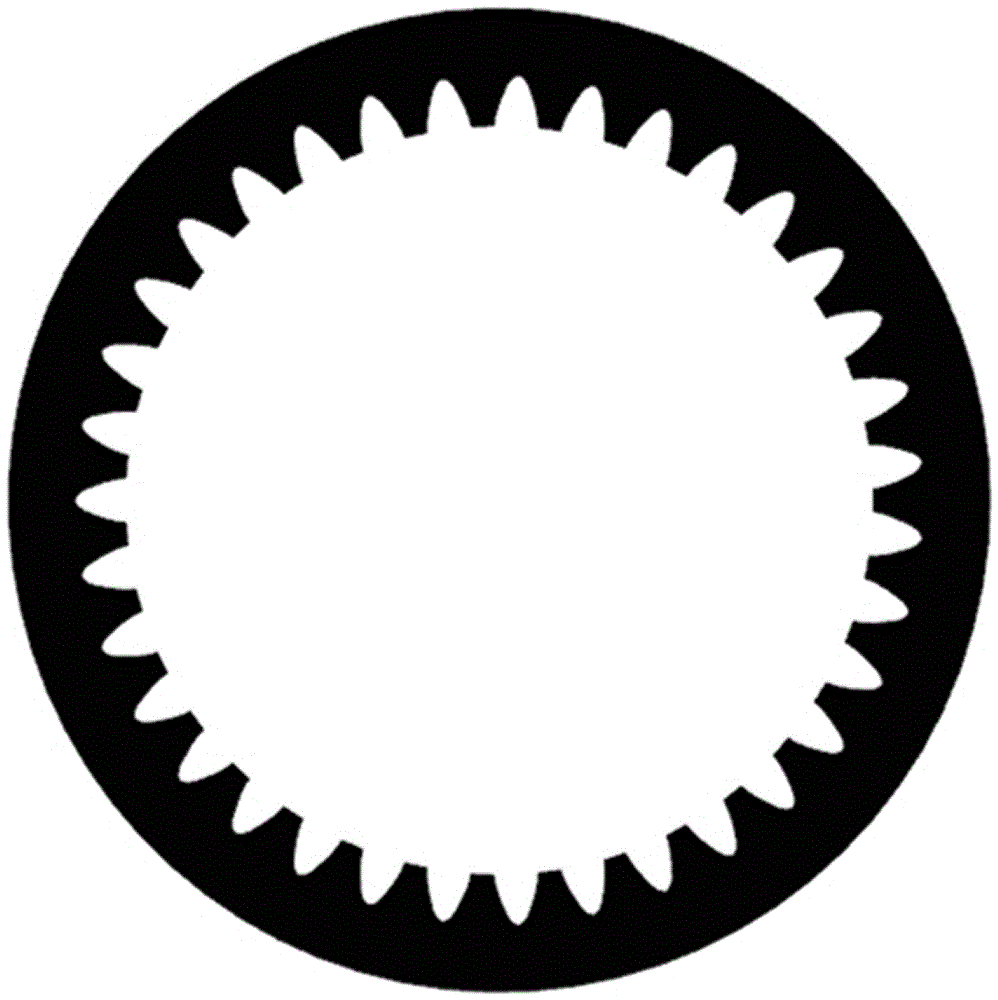

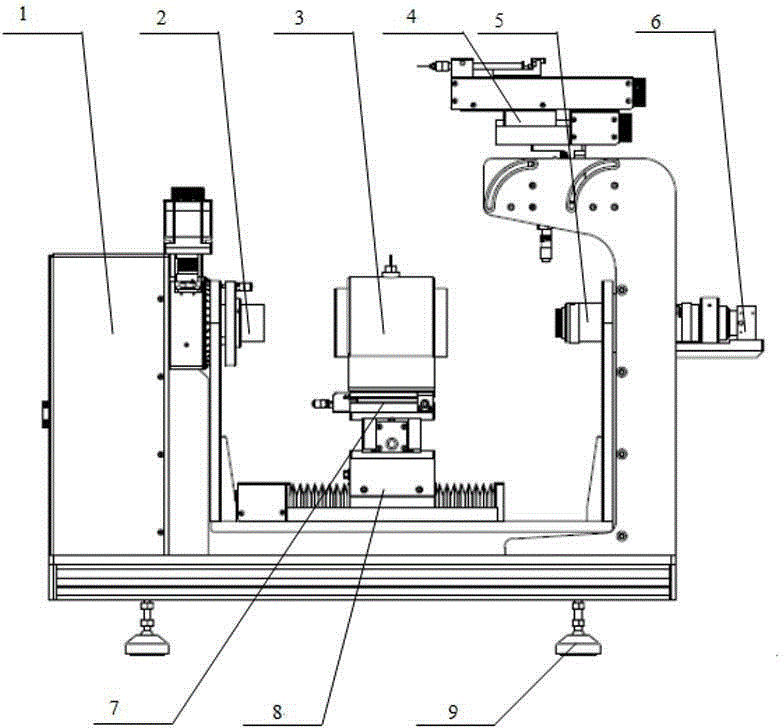

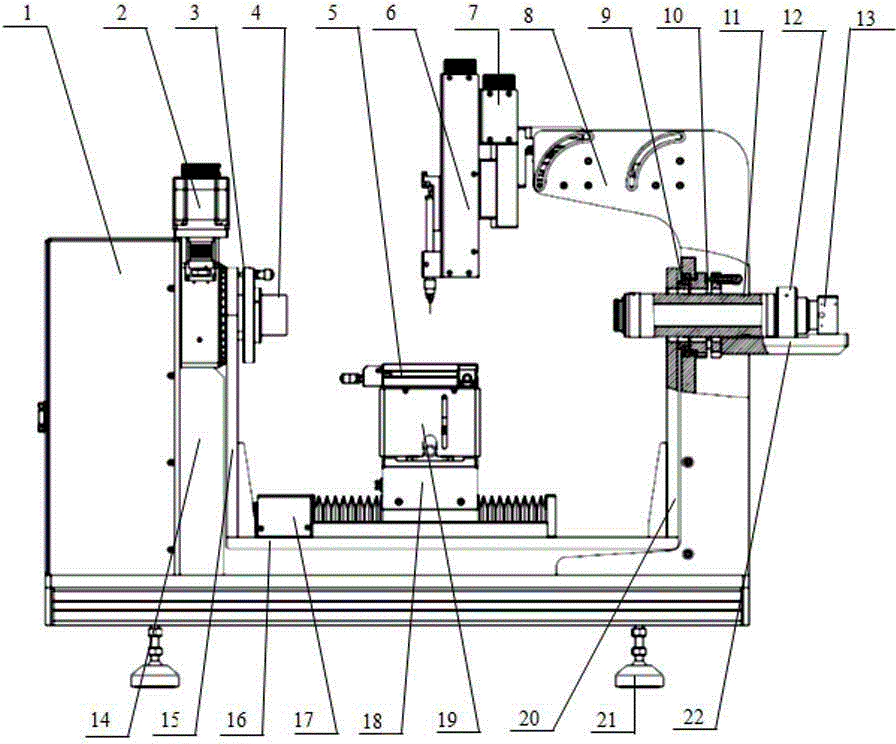

Machine-vision-based rapid detection device and detection method for medium and small module gears

InactiveCN106017350AEasy to operateFriendly interfaceImage enhancementImage analysisMachine visionTelecentric lens

The invention provides a machine-vision-based rapid detection device and a detection method for medium and small module gears, and belongs to the technical field of high-precision detection. The device and the method are capable of rapidly detecting the errors of high-precision medium and small module gears in the non-contact manner. The device comprises a marble platform, and a vision measuring system is arranged on the marble platform. The vision measuring system comprises an industrial camera, a telecentric lens and a parallel light source. The industrial camera is connected with the telecentric lens. An object distance adjustment mechanism, a vertical column, a horizontal adjustment mechanism and a dual-tip gear positioning mechanism are also arranged on the marble platform. The vertical column is vertically arranged on the horizontal adjustment mechanism. The object distance adjustment mechanism is arranged on one side of the vertical column. The industrial camera is arranged on the object distance adjustment mechanism. The parallel light source is arranged on the horizontal adjustment mechanism and is opposite to the telecentric lens. The dual-tip gear positioning mechanism is arranged on one side of the parallel light source on the horizontal adjustment mechanism. The dual-tip gear positioning mechanism and the horizontal adjustment mechanism are in the same straight line and are aligned with each other. The output end of the industrial camera is connected with a computer.

Owner:SHENYANG POLYTECHNIC UNIV

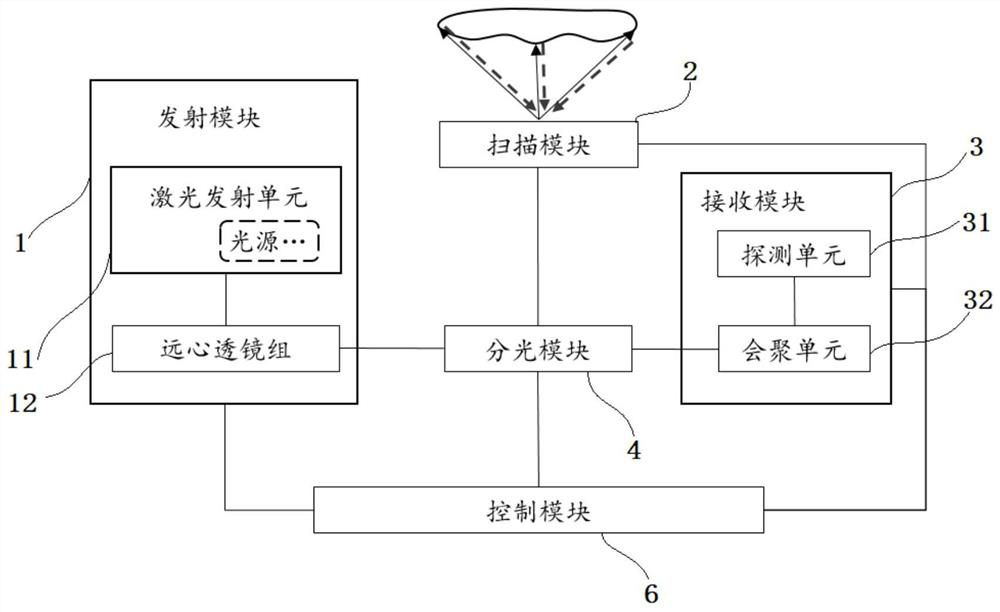

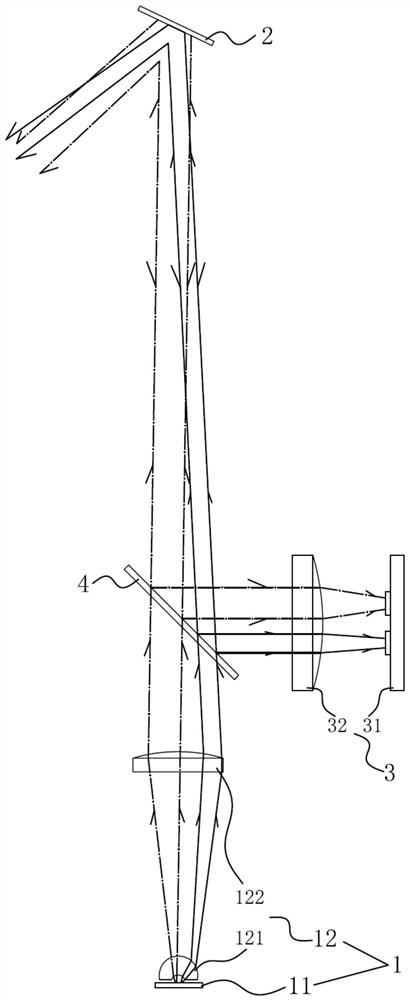

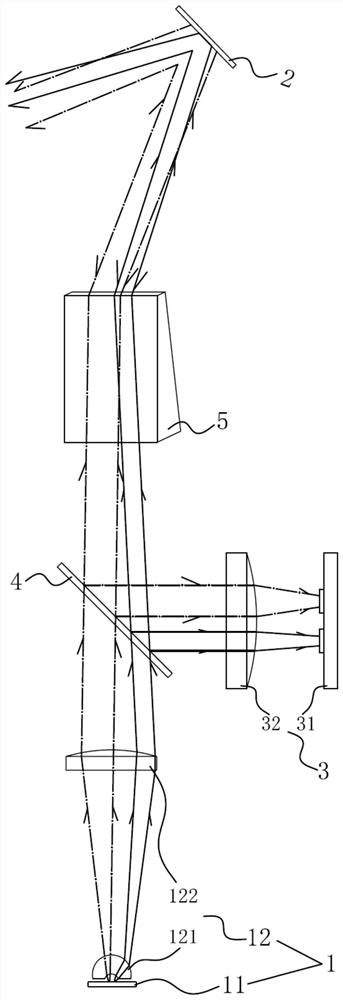

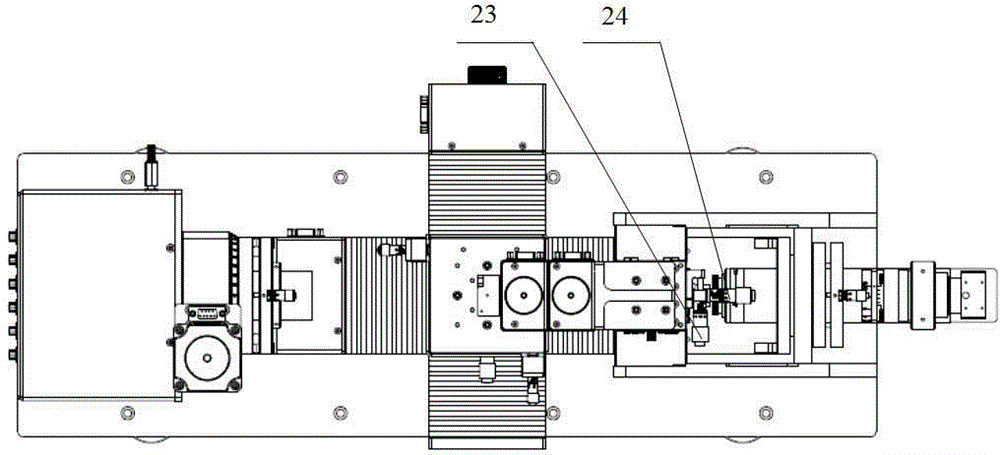

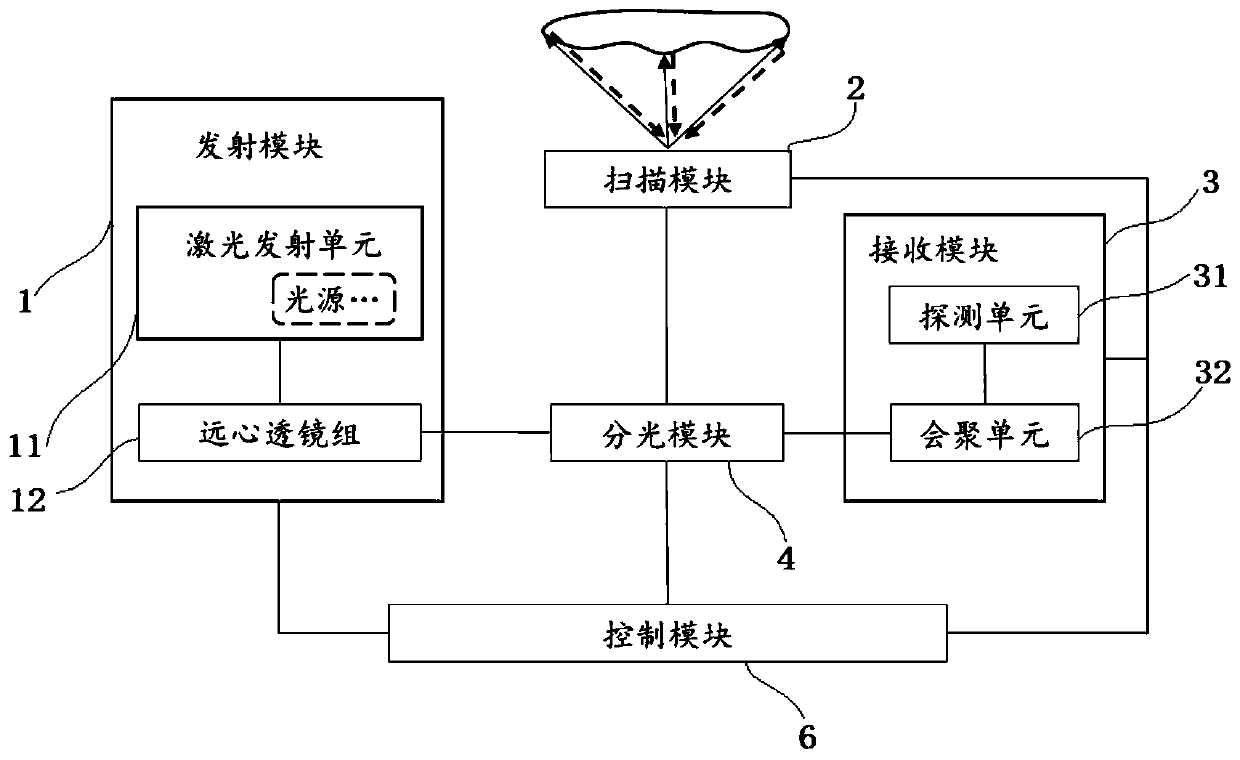

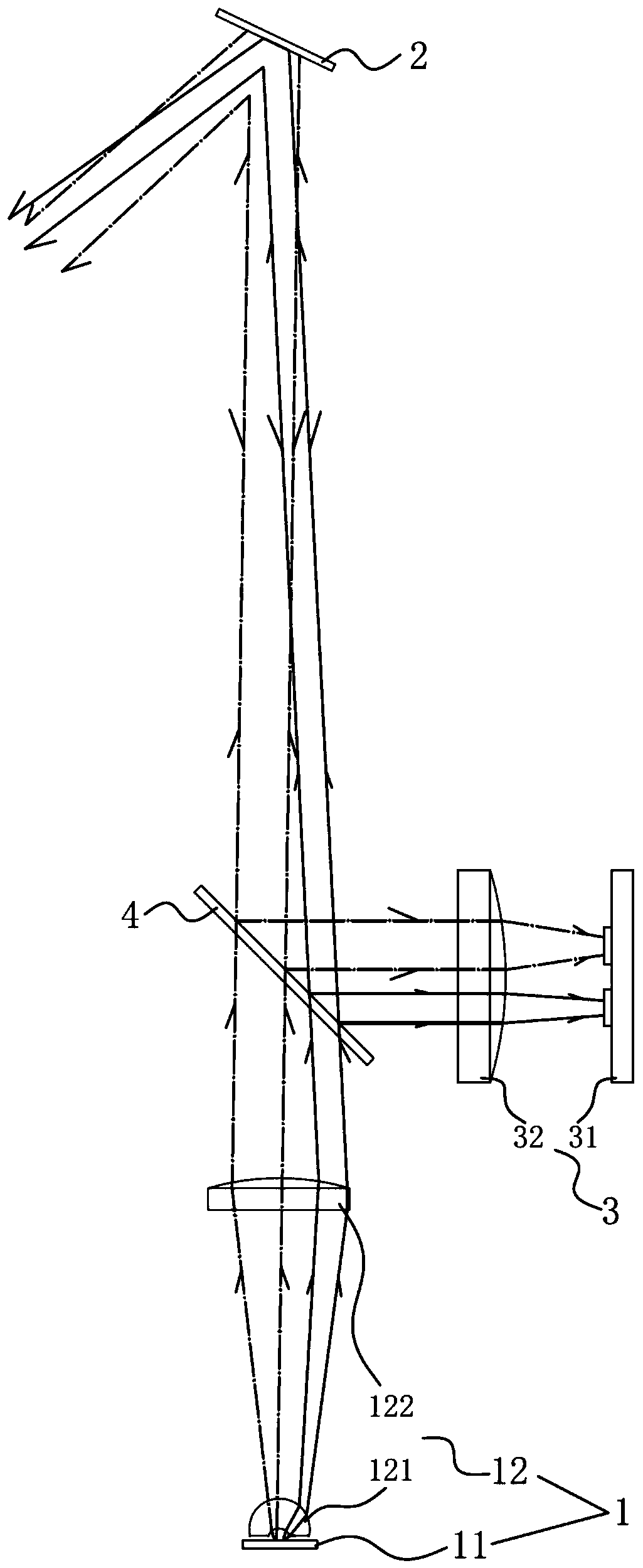

A laser radar system

ActiveCN109917348BGuaranteed exit efficiencyCollimation is effectiveWave based measurement systemsRadar systemsLight beam

The present invention provides a laser radar system, comprising a transmitting module and a scanning module sequentially arranged along a first optical path. The transmitting module comprises a laser transmitting unit and a telecentric lens assembly. The laser transmitting unit comprises a plurality of light sources for transmitting a plurality of laser beams. The telecentric lens assembly is used for respectively collimating each of the plurality of laser beams into parallel beams, and enabling the plurality of parallel beams to be converged along the first optical path and to be incident to the scanning module. The scanning module is used for reflecting the converged parallel beams to a three-dimensional space, and receiving and reflecting an echo beam reflected by a target to be detected. According to the laser radar system of the present invention, laser beams emitted at different angles can be guaranteed to be efficiently collimated and emitted, the emergence efficiency of laser is guaranteed to the maximum extent, and some of laser beams transmitted by the plurality of light sources are protected from being scattered outside the scanning module to form the stray light in the operation process of the laser radar system.

Owner:HESAI TECH CO LTD

Image method measuring device and method for gas-liquid two-phase flow in pipelines

ActiveCN103424406AIncrease exposure timeMeet the simultaneous measurement of particle sizeMaterial analysis by optical meansCamera lensLaser light

The invention discloses an image method measuring device and method for gas-liquid two-phase flow in pipelines. The image method measuring method is characterized by comprising the steps of using a light source to light liquid drop to be tested through a transparent pipeline or a window, using a laser light source to light the liquid film level, using a telecentric lens and a CCD or CMOS image sensor to image liquid drop or liquid film in an area to be tested, comparing the out-of-focus blur radius of one single liquid drop image with the allowed confusion circle size of a measuring system to remove liquid drop images out of a camera lens focus depth range, processing an image of movable liquid drop in the focus depth range to extract the particle size, the speed and the direction, carrying out statistics on a lot of liquid drop to obtain the particle size distribution in the area to be tested, the speed distribution in the area to be tested, the average volume concentration in a statistic period in the area to be tested and the average volume flow rate in the statistic period in the area to be tested, and determining the thickness of the liquid film according to the distance between the liquid level of the liquid film image and the pipe wall. The image method measuring method has the advantages of only using one set of system to achieve the purpose of simultaneously measuring multiple parameters of the gas-liquid two-phase flow in the pipelines, simplifying the measuring system and reducing measuring cost.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

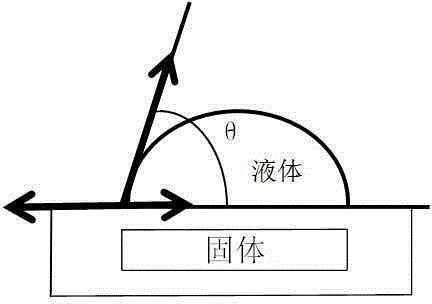

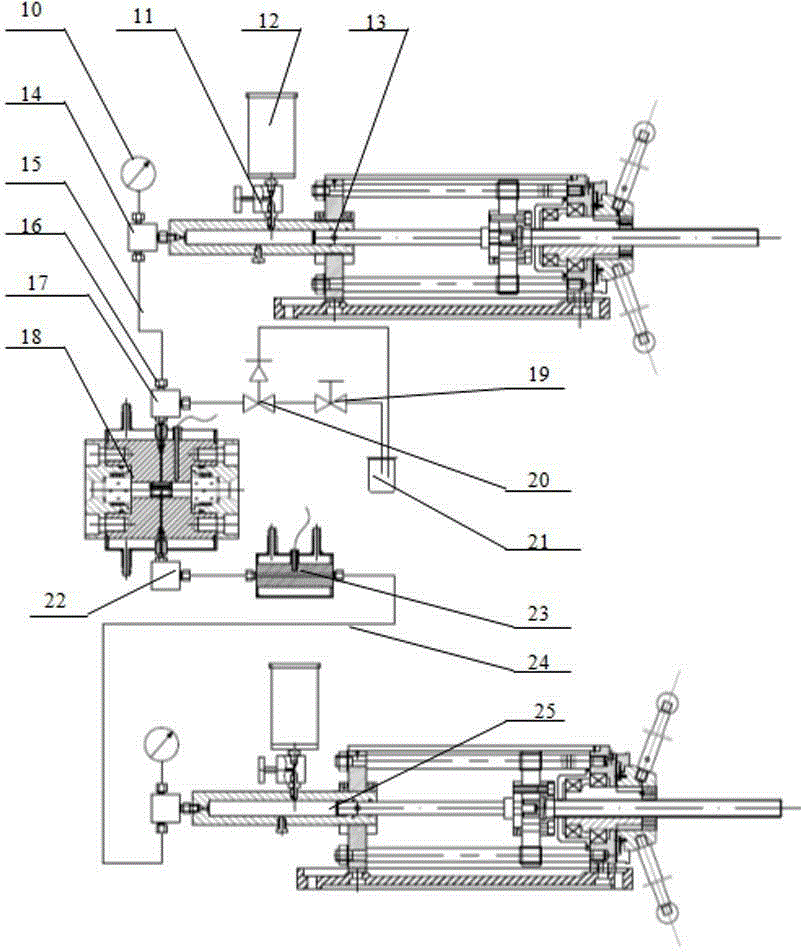

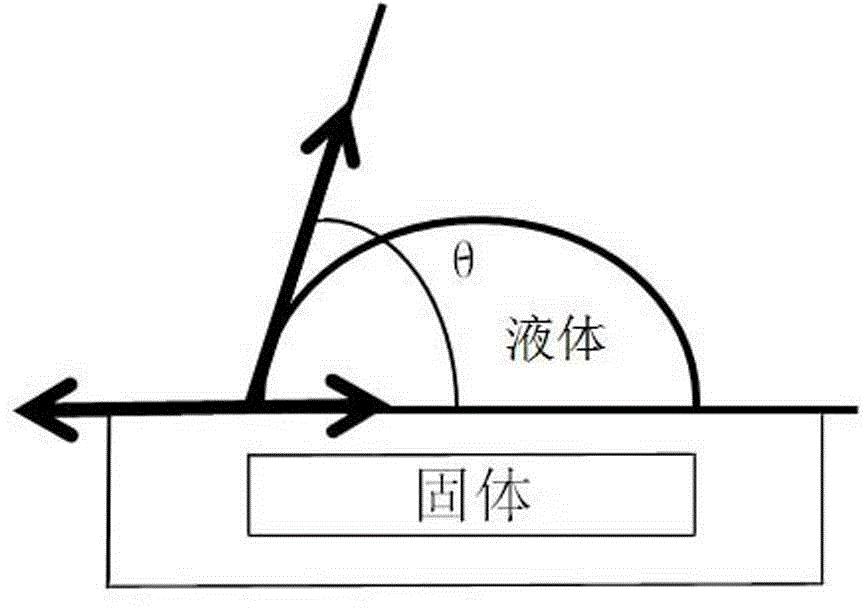

Device and method for testing contact angle and interfacial tension at ultrahigh pressure and high temperature

InactiveCN105203432AImage analysisSpecial data processing applicationsUltra high pressureEngineering

The invention discloses a device and method for testing a contact angle and interfacial tension at ultrahigh pressure and high temperature, and relates to a testing method for testing a contact angle and interfacial tension by the adoption of a vacuum liquid drop method or image fitting method for fitting a Young-Laplace equation, and a testing device for testing a contact angle and surface / interfacial tension at ultrahigh pressure and high temperature. The device is composed of two booster pumps, an ultrahigh-pressure and high-temperature cavity of a two-side observation window made of sapphire glass, a high-viscosity sample heating pool, a high-pressure connection accessory, a camera with a telecentric lens, a collimated light source and the like. After a liquid drop outline image is shot, the fitting Young-Laplace equation is used for testing the contact angle and the interfacial tension value, and the testing device and method can analyze the contact angles and interfacial tension values under different pressure conditions, have the extremely high popularization value in the fields of oil field, petrochemical engineering, new material research and the like, particularly can test the interfacial tension value and the contact angle by simulating recovery environment actual pressure and temperature conditions in tertiary oil recovery simulation experiments, and are quite effective.

Owner:上海梭伦信息科技有限公司

Method and device for detecting tiny bearing surface defect by computer vision technology

InactiveCN101221134AHigh degree of automationImprove efficiencyOptically investigating flaws/contaminationSortingProduction lineVisual technology

The invention relates to a computer visual detecting field and provides a method and a device for detecting defects on the surfaces of a tiny bearing by adopting computer visual technology. The technical proposal is that: the system for detecting the defects on the surface of the tiny bearing works on line in a production line; arranging the tiny bearing (4) needed to be detected on an automatic line (5) and leading a digital camera to shoot the surface image of the bearing through the control of a sensor when the tiny bearing moves to the lower side of the digital camera; a cold light source (2) changes the beams into parallel beams through a telecentric lens (3) to lead the beams to vertically illume the surface of the bearing; using a dark box (6) to insulate the bearing from the outside optical source; transmitting collected gray images to the computer through an image collecting card and analyzing automatically whether the bearing has defects by using special software according to the gray changes of the images; a removing mechanism automatically removes the bearings with defects. The device can be conveniently connected with a bearing production line, has a simple structure, is easy to be maintained and has low device investment.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

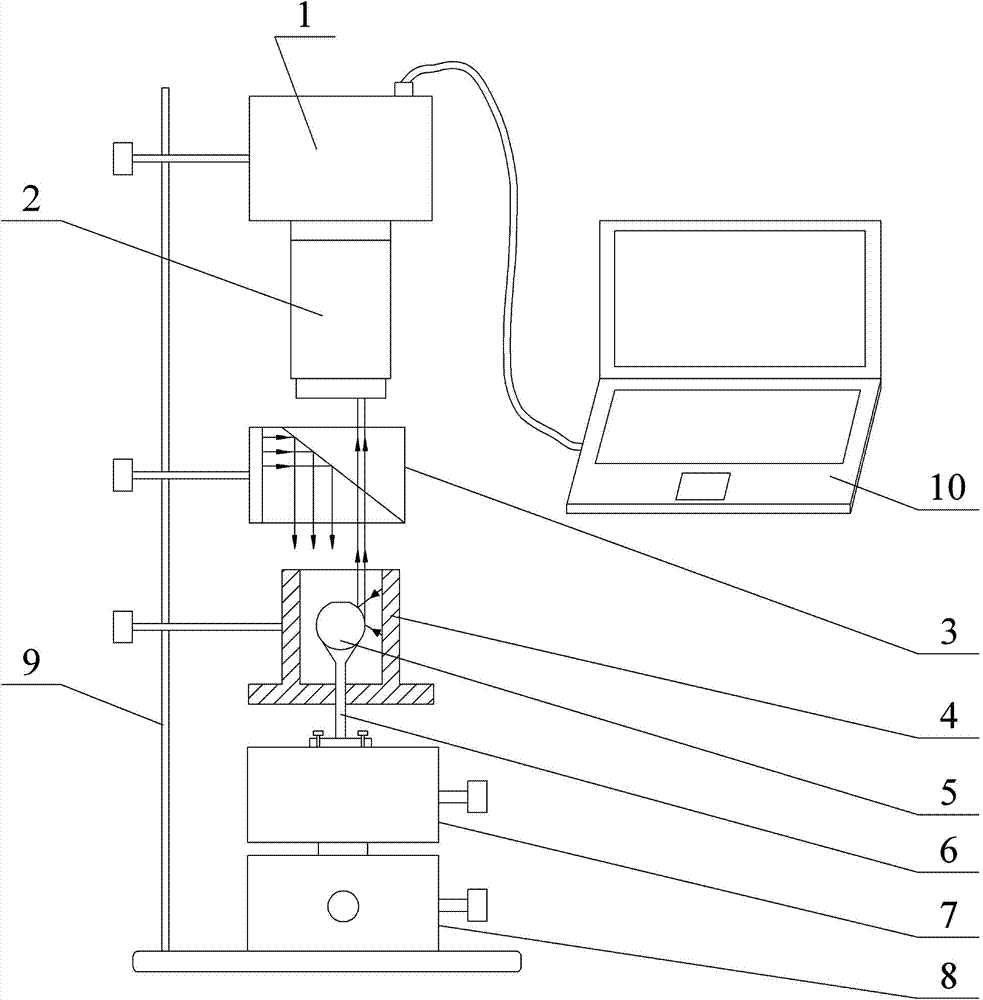

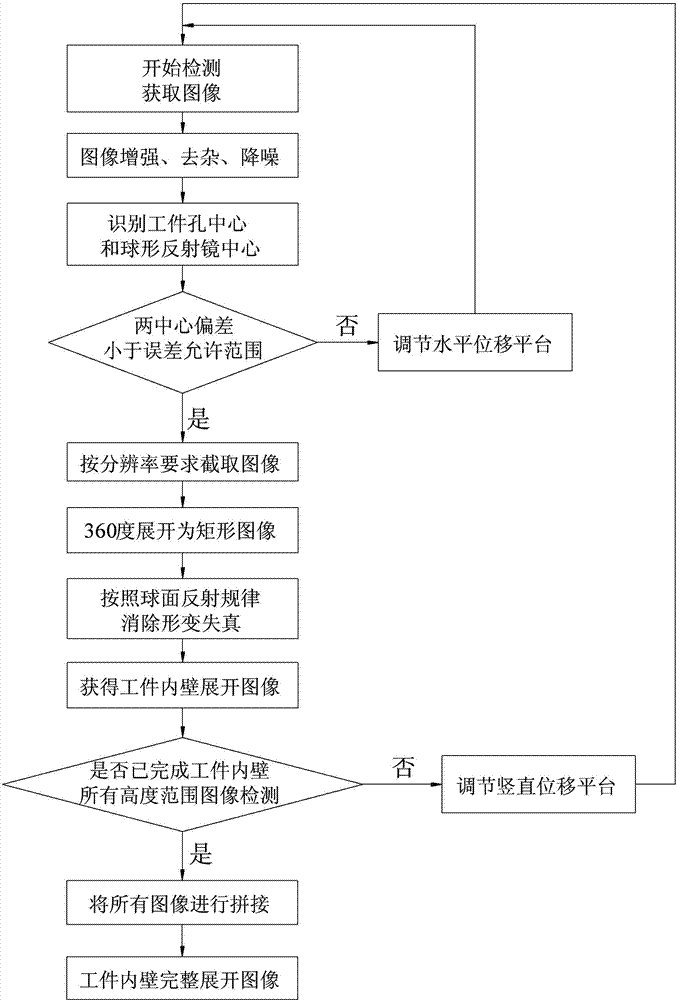

System for optical detection on micro-aperture workpiece inner wall

InactiveCN103575748ALow costEasy to detectOptically investigating flaws/contaminationEngineeringTelecentric lens

The invention discloses a system for optical detection on a micro-aperture workpiece inner wall. Through the system, reflection images of the whole inner wall can be obtained by one step, the acquired images can be stored in a computer, and the acquired images can be processed to form a 360-degree developed view of the workpiece inner wall by a digital image-processing technology. The principle of the system comprises that parallel lights emitted by coaxial light sources vertically and downward enter into workpiece apertures and then the lights are reflected by a spherical reflector to illuminate the workpiece inner wall; the reflected lights illuminating the workpiece inner wall are reflected upward by the spherical reflector, then go through illuminating surfaces of the coaxial light sources and enter into a telecentric lens so that reflection images are formed in CCD; a circular ring image of a part of the workpiece inner wall at a certain height is reflected so that a corresponding circular ring image is formed in the CCD; and the reflection images obtained by the CCD is processed by the digital image processing technology to form the 360-degree developed view of the workpiece inner wall. The system solves the problem that the image of the micro-aperture workpiece inner wall can be obtained difficultly, and reduces an equipment detection cost.

Owner:SHANGHAI JIAO TONG UNIV

Vision detection system and detection method

InactiveCN102636494ASolve the positioning problemSave spaceOptically investigating flaws/contaminationUsing optical meansCamera lensProgrammable logic controller

The invention relates to a vision detection system. The vision detection system comprises a rack, a digital camera, a light source, a PLC (Programmable Logic Controller), an industrial personal computer, a steering device and a lens, as well as a support, a stepping motor, an ejecting device and an optical fiber sensor, wherein the steering device comprises a device body and a prism, and the light source and the lens are arranged on the support. The light source is a bilateral telecentric light source, and the lens is a bilateral telecentric lens. The ejecting device is arranged on a guide rail and controlled by the stepping motor, and the optical fiber sensor is arranged above the guiderail and controlled by the PLC. In addition, the invention further discloses a detection method of the vision detection system. Compared with the prior art, the vision detection system has high detection efficiency, is accurate, does not need manual intervention, effectively solves the positioning problem of products to be detected through the arrangement of the ejecting device, leads the camera to be horizontally arranged by the arrangement of the steering device, thus greatly saving the space of the device and enabling the design to be more compact.

Owner:SUZHOU QIANZHAO AUTOMATION TECH

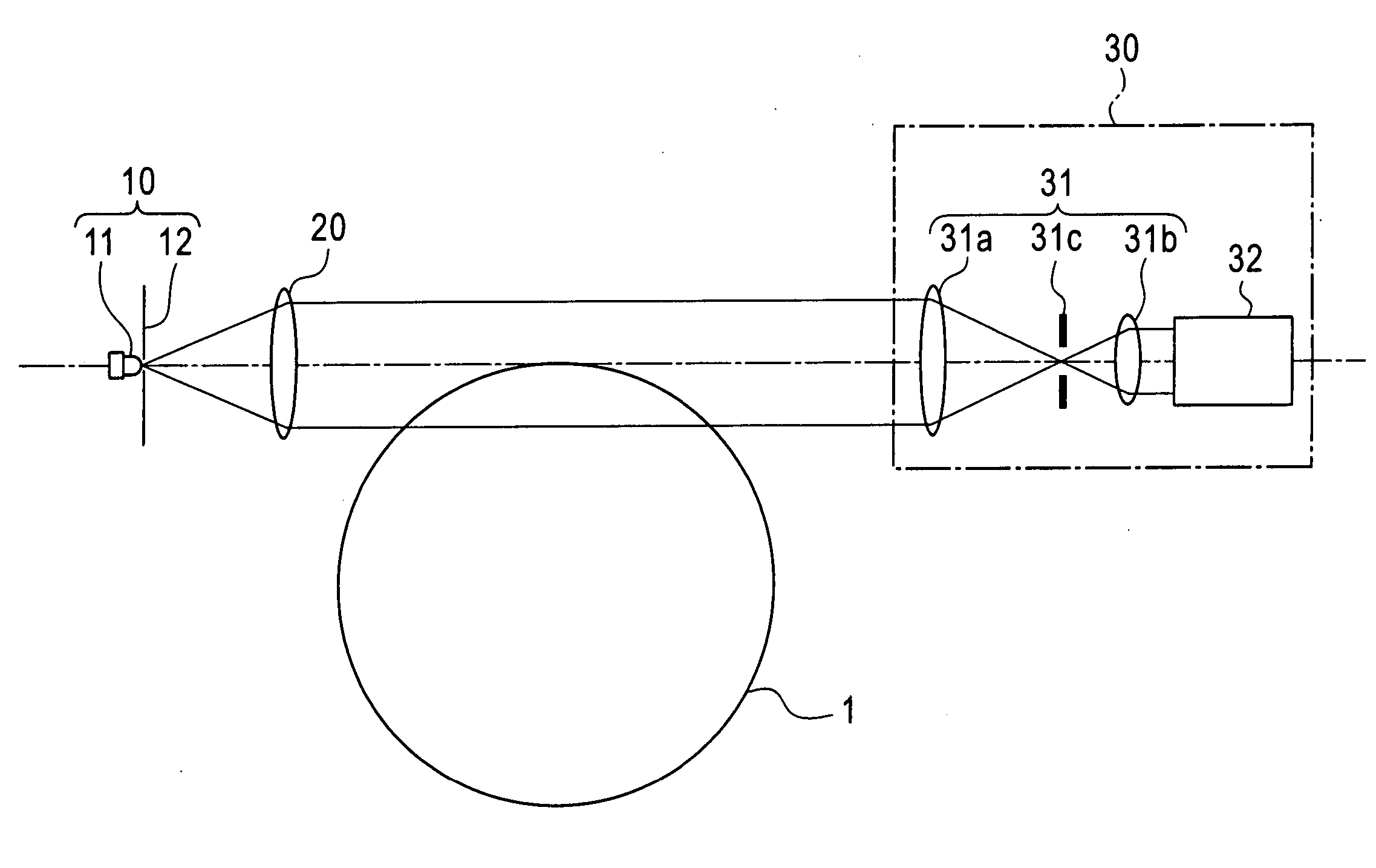

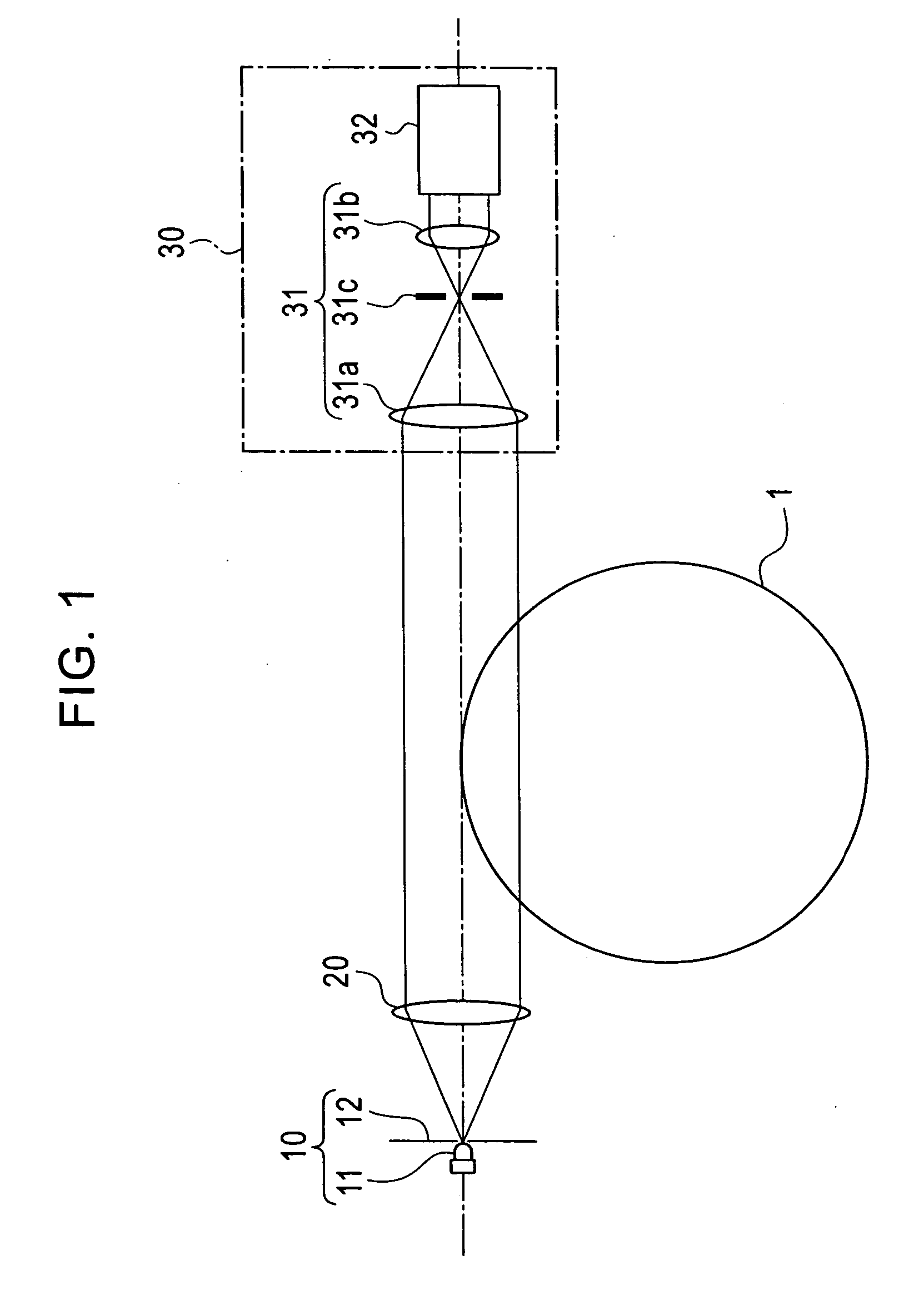

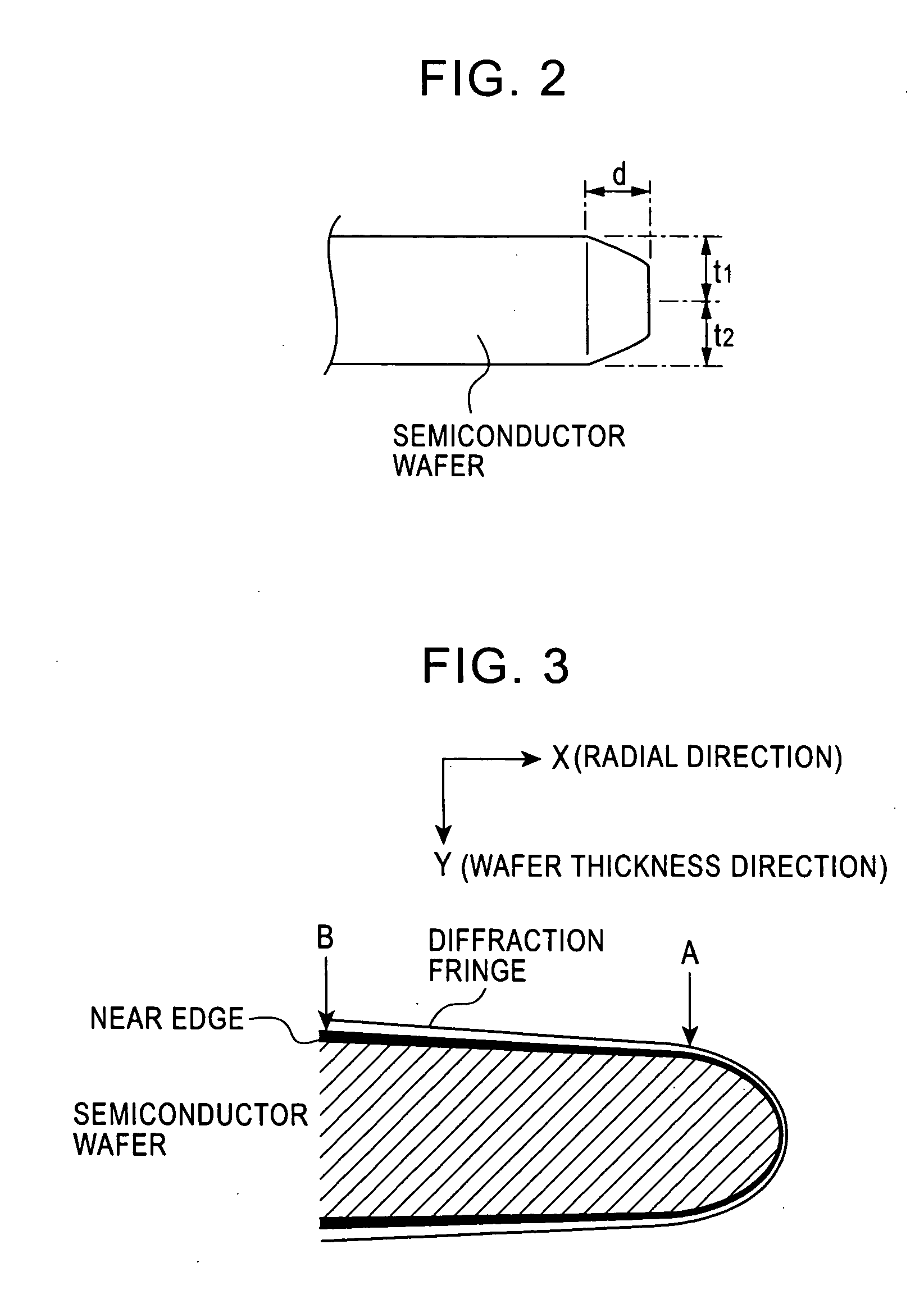

Shape measuring apparatus

A shape measuring apparatus includes a point light source including a white light-emitting diode, a collimator lens for forming a parallel beam as a result of causing light emitted from the point light source to be incident upon the collimator lens, a telecentric lens device, including two-side telecentric optics or object-side telecentric optics, for being irradiated with the light that has passed an object to be measured from the collimator lens, and an image sensor for projecting thereon an image of the object produced by the light that has passed through the telecentric lens device.

Owner:KOBE STEEL LTD

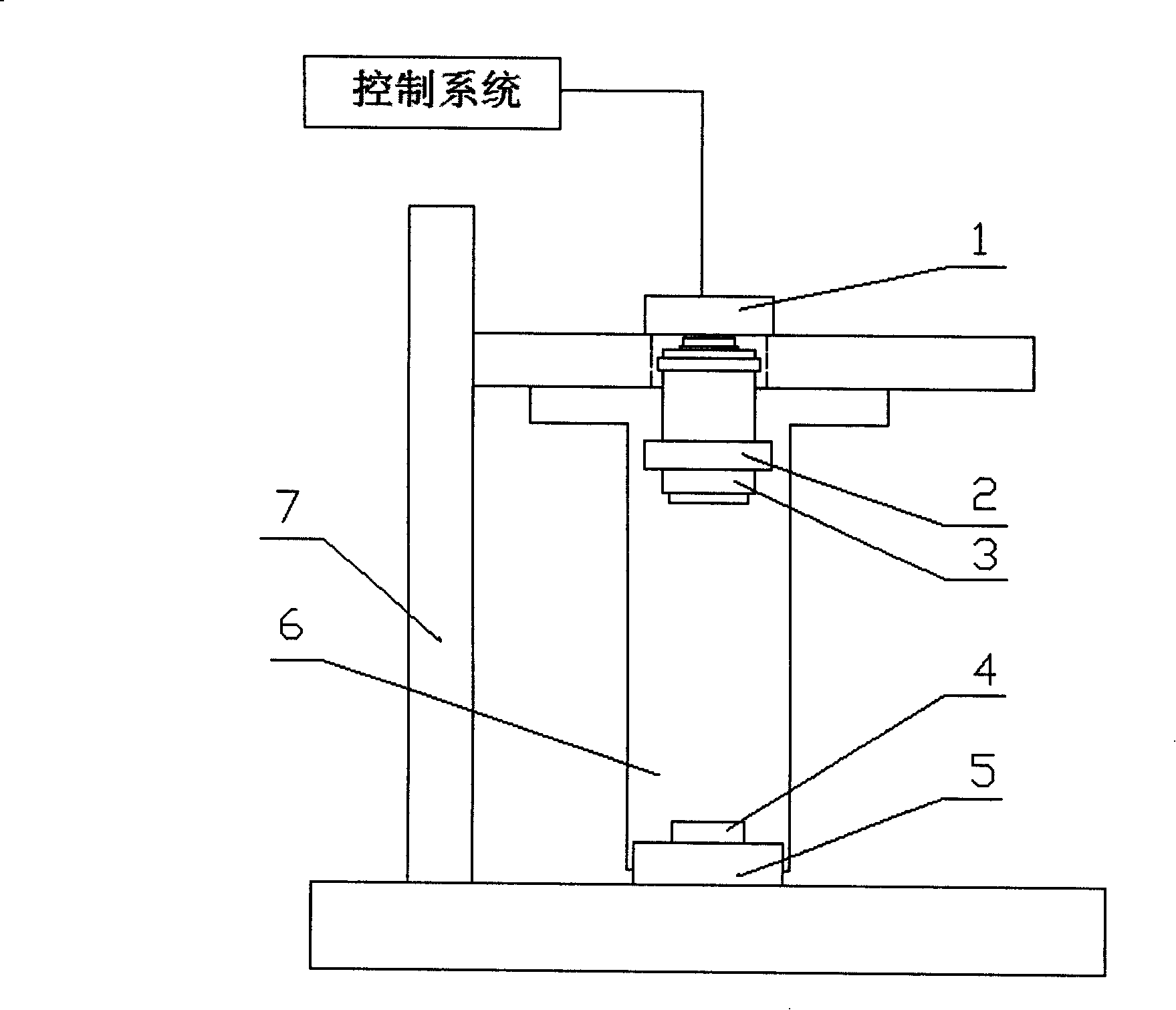

Intrinsic contact angle test and test method thereof

The invention discloses an intrinsic contact angle test apparatus and a test method thereof. A true drop technology or an image fitting technology is adopted to fit the test dynamic contact angle of a Young-Laplace equation, and Wenzel-Casie-Baster stimulation is used to derive an intrinsic contact angle calculating equation. The invention also provides the intrinsic contact angle test apparatus. The apparatus comprises a combination boy controlled by the rotating mechanism of a worm and gear structure and having a lens and a sample bench which rotate together, a XYZ and horizontally-adjustable sample bench combination body, a sample clamp, an injection pump and an XYZ control mechanism combination body thereof, a camera with a telecentric lens, and a parallel light source. The contact angle is obtained by shooting the profile image of a liquid drop and adopting the Young-Laplace equation fitting test. The apparatus and the test method can be used to analyze the chemical anisotropy of a material and the intrinsic contact angle under contact angle hysteresis condition due to surface roughness, and has extremely broad popularization values in fields of new materials and bionic materials.

Owner:上海梭伦信息科技有限公司

Laser radar system

ActiveCN109917348AGuaranteed exit efficiencyCollimation is effectiveWave based measurement systemsRadar systemsThree-dimensional space

The invention provides a laser radar system which comprises a transmitting module and a scanning module which are sequentially arranged along a first optical path. The transmitting module comprises alaser transmitting unit and a telecentric lens group; wherein the laser transmitting unit is provided with a plurality of light sources and is used for emitting a plurality of laser beams; the telecentric lens group is used for respectively collimating the laser beams into parallel light beams and enabling the plurality of parallel light beams to be converged along a first light path and transmitted to the scanning module; and the scanning module is used for reflecting the converged parallel light beams to a three-dimensional space and receiving and reflecting echo light beams reflected by a to-be-detected target. The laser radar system can ensure that laser beams emitted at different angles are effectively collimated and emitted, the laser emitting efficiency is ensured to the maximum extent, and the situation that in the working process of the laser radar system, laser beams emitted by a plurality of light sources are partially scattered outside a scanning module to form stray lightcan be avoided.

Owner:HESAI TECH CO LTD

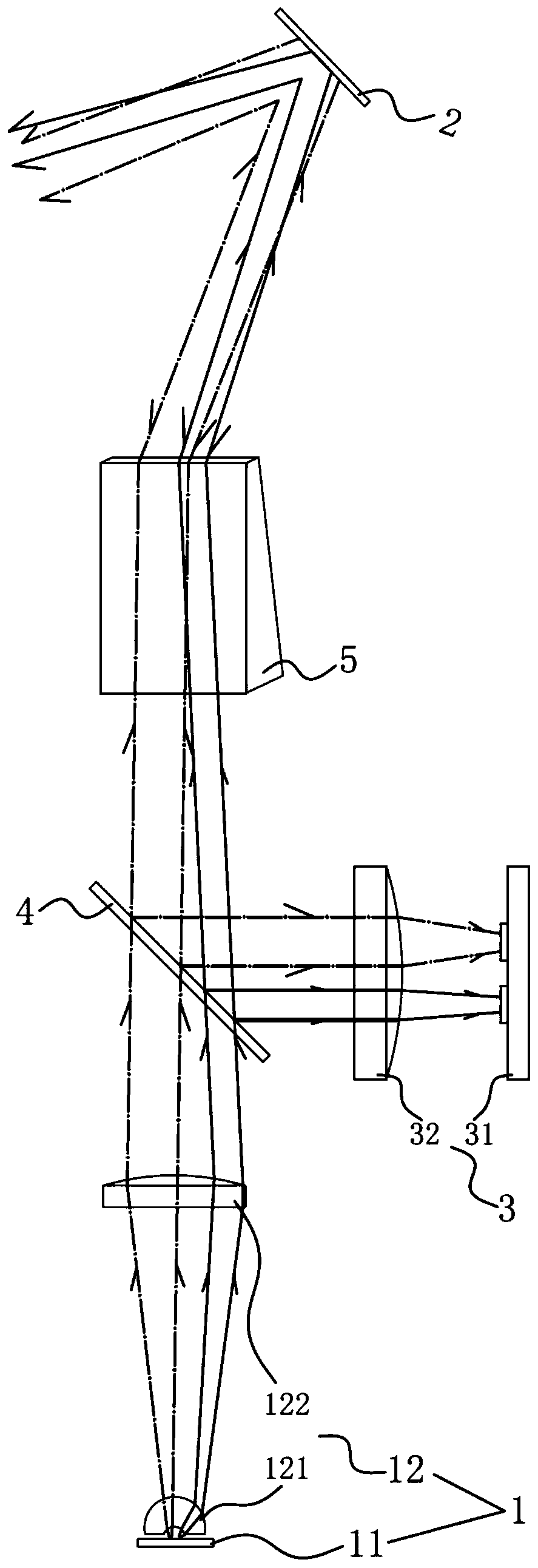

Fingerprint identification device and electronic device

ActiveCN109791612AReduce exposure timeImprove image qualityPrint image acquisitionOptical elementsImaging qualityTelecentric lens

The embodiment of the present application provides a fingerprint identification device and an electronic device. The fingerprint identification device includes: a micro telecentric lens array group for receiving an optical signal formed by reflection of a human finger; and a fingerprint sensor disposed below the micro telecentric lens array set and used for imaging based on the optical signal passing through the micro telecentric lens array set. The fingerprint identification device and the electronic device of the embodiment of the present invention can avoid the light loss in the vertical direction with respect to the scheme of the periodic through-hole array, thereby reducing the exposure time of the fingerprint sensor. The fingerprint recognition device also reduces the imaging distortion of the entire system relative to the microlens scheme. The fingerprint recognition device is capable of improving the image quality and contrast.

Owner:SHENZHEN GOODIX TECH CO LTD

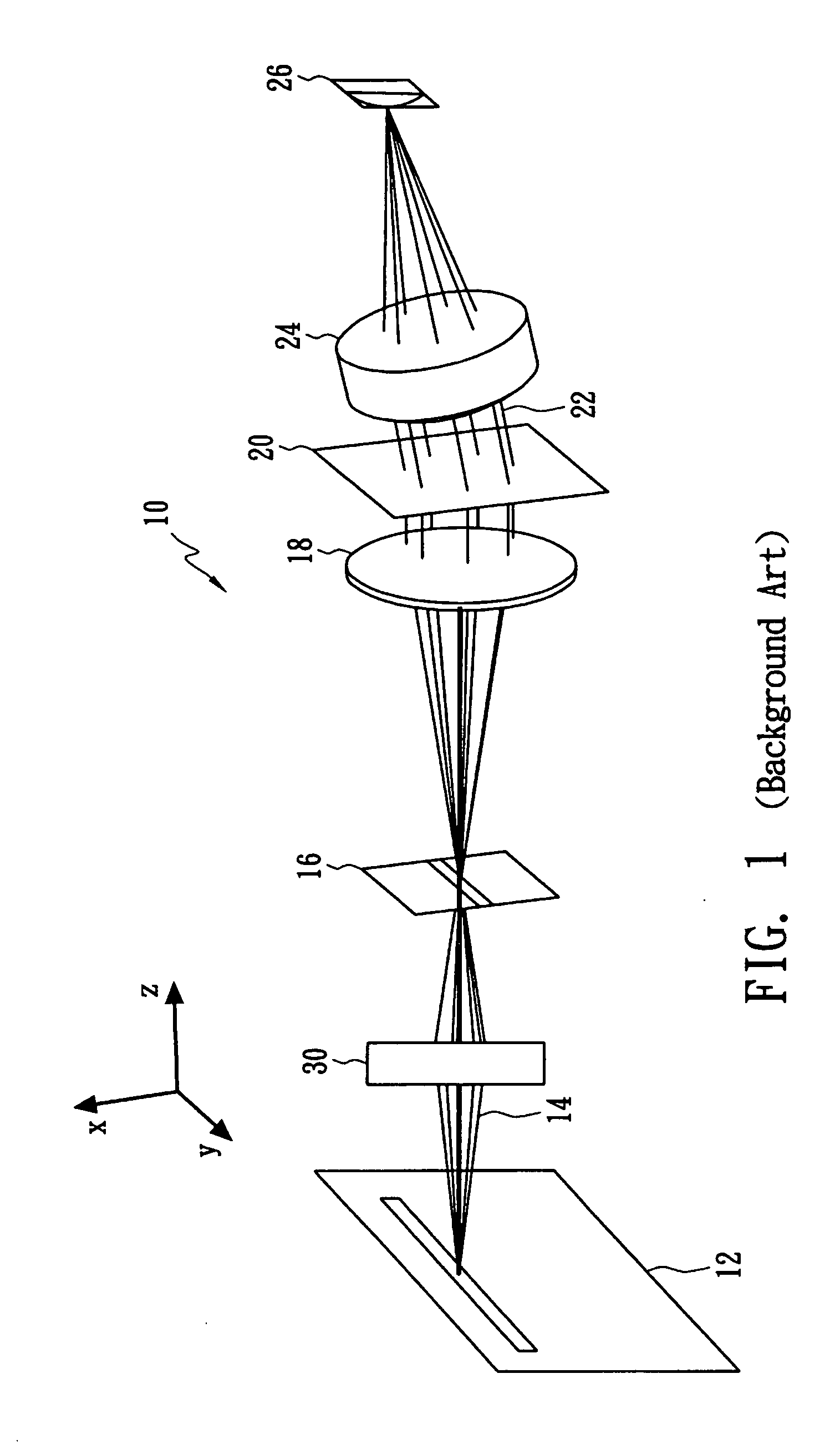

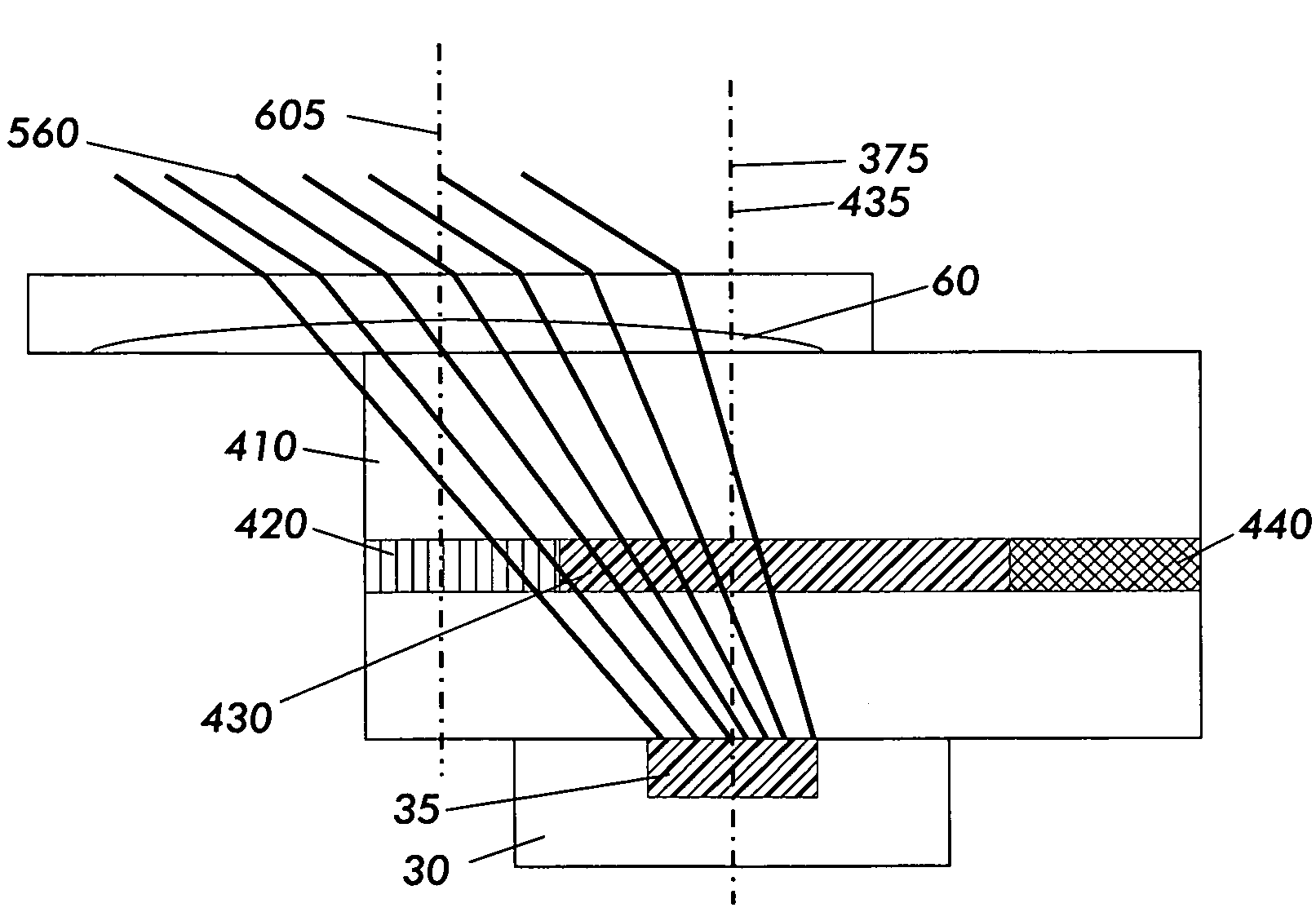

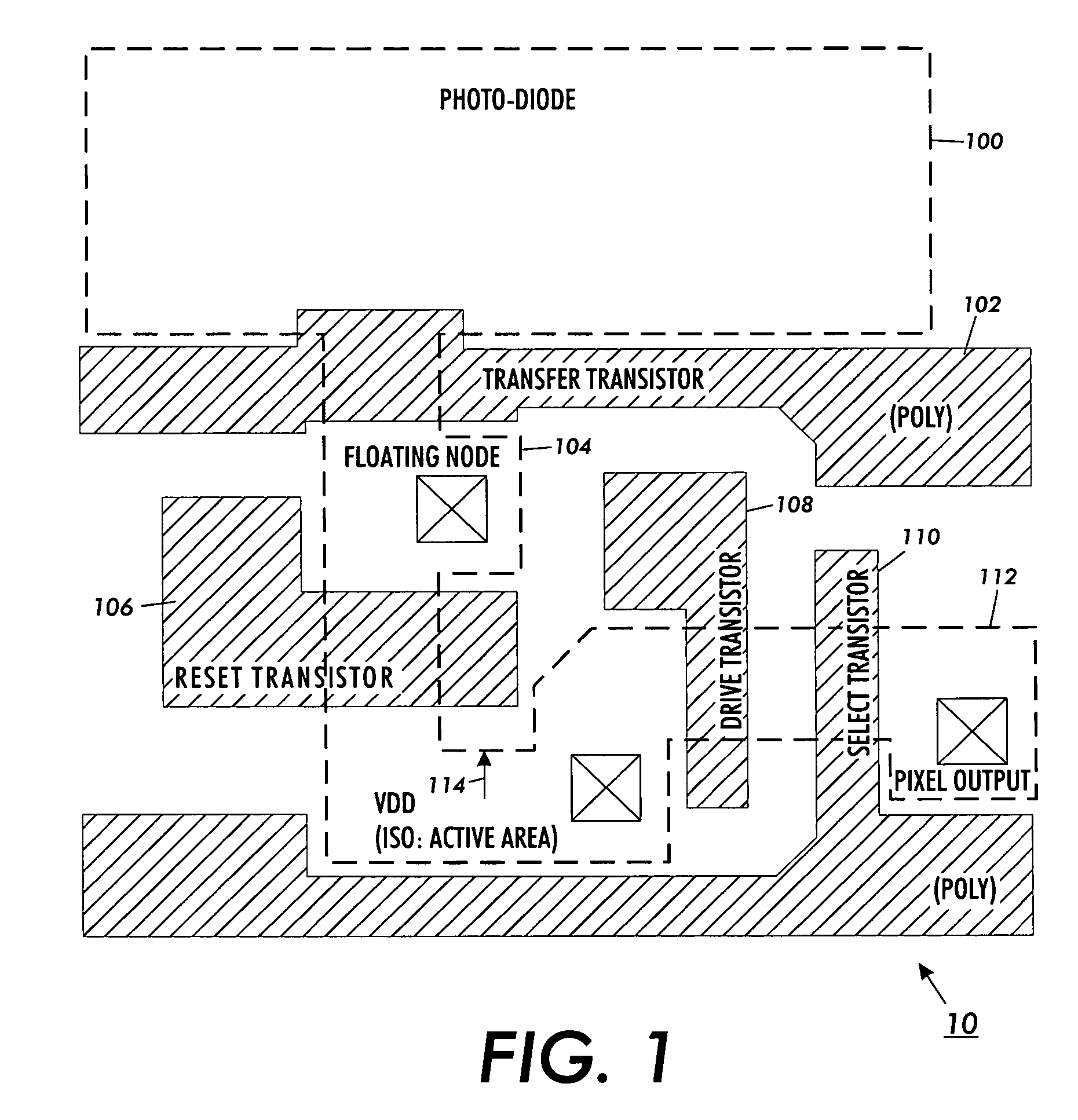

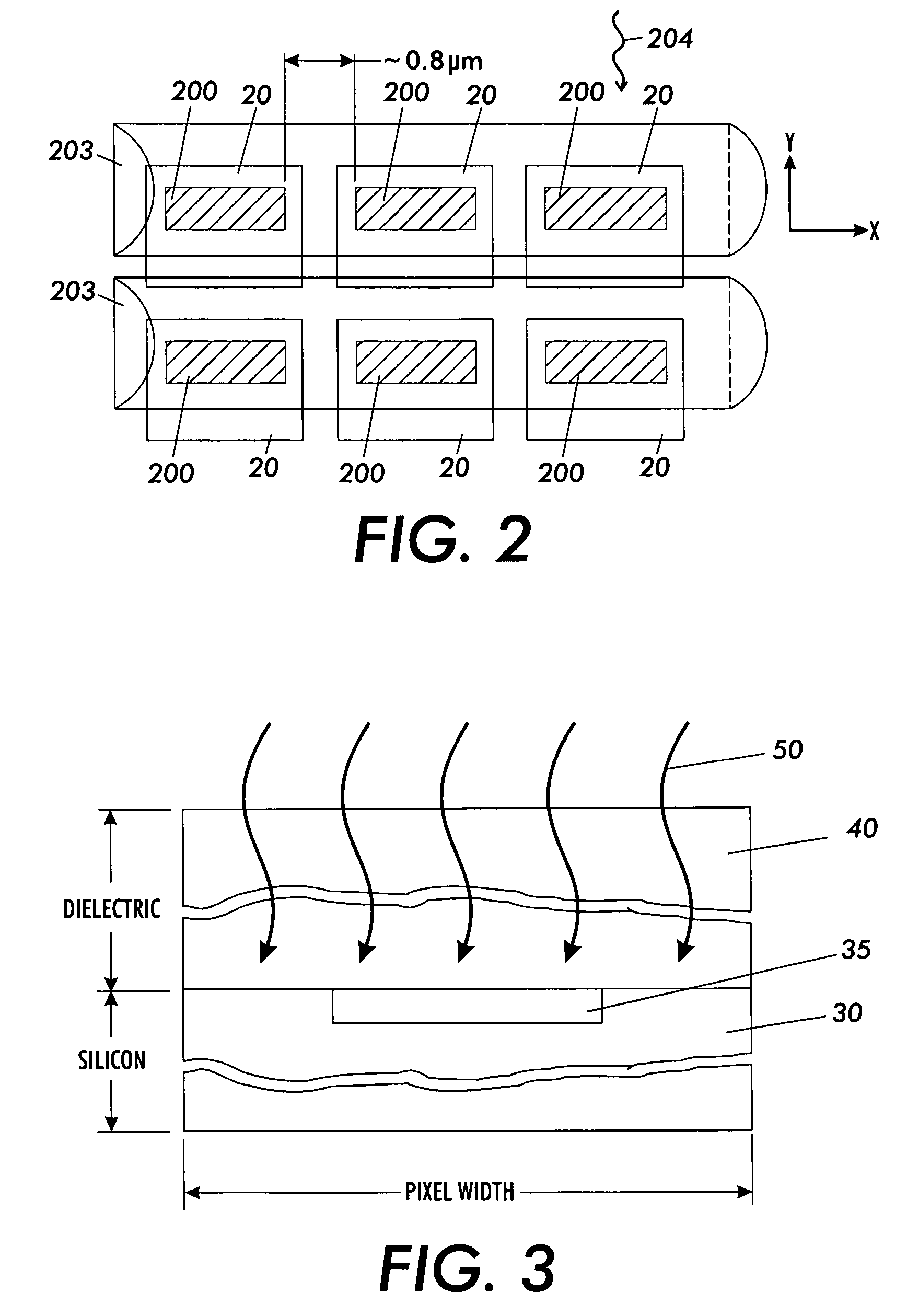

Microlens for use with a solid-state image sensor and a non-telecentric taking lens

ActiveUS7427742B2Light sensitivity can be maximizedTelevision system detailsBeam/ray focussing/reflecting arrangementsCamera lensTelecentric lens

An imager includes a two-dimensional array of photosensors, each photosensor having a center point. A non-telecentric lens is positioned over the two-dimensional array of photosensors, and a two-dimensional array of microlenses is positioned over the two-dimensional array of photosensors. Each microlens is associated with a corresponding photosensor, and each microlens has a center point. A color filter array is positioned over the two-dimensional array of photosensors. The color filter array includes a plurality of color filter areas. Each color filter area is associated with a corresponding photosensor and has a center point. A layer of transmissive apertures is further positioned over the two-dimensional array of photosensors. Each aperture is associated with a corresponding photosensor and having a center point. The microlens is positioned over the corresponding photosensor such that the center point of the microlens is offset from the center point of the corresponding photosensor. The color filter area is positioned over the corresponding photosensor such that the center point of the color filter area is offset from the center point of the corresponding photosensor. Finally, the aperture is positioned over the corresponding photosensor such that the center point of the aperture is offset from the center point of the corresponding photosensor.

Owner:SK HYNIX INC

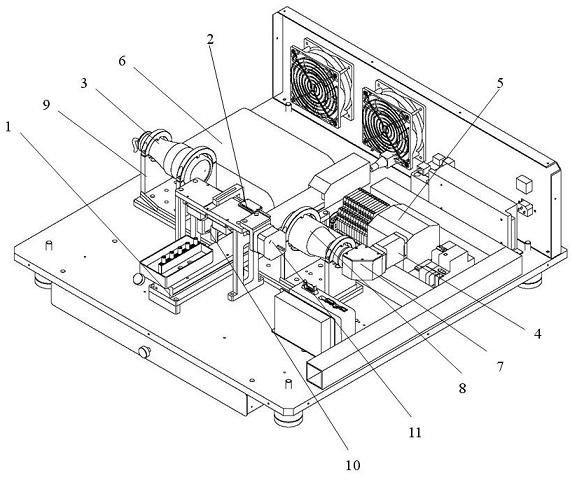

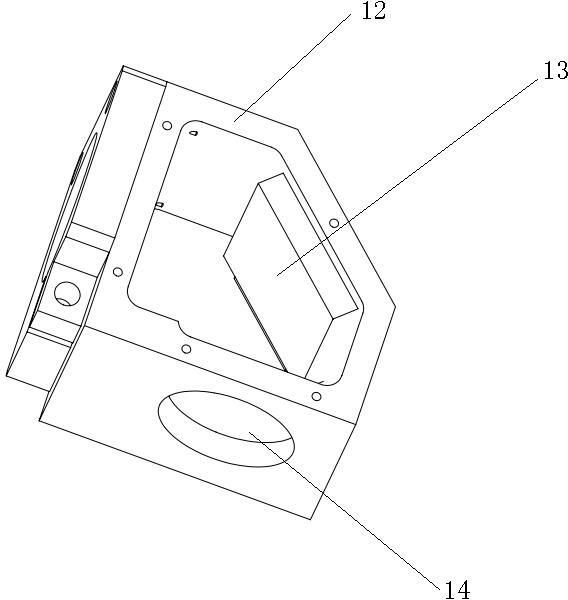

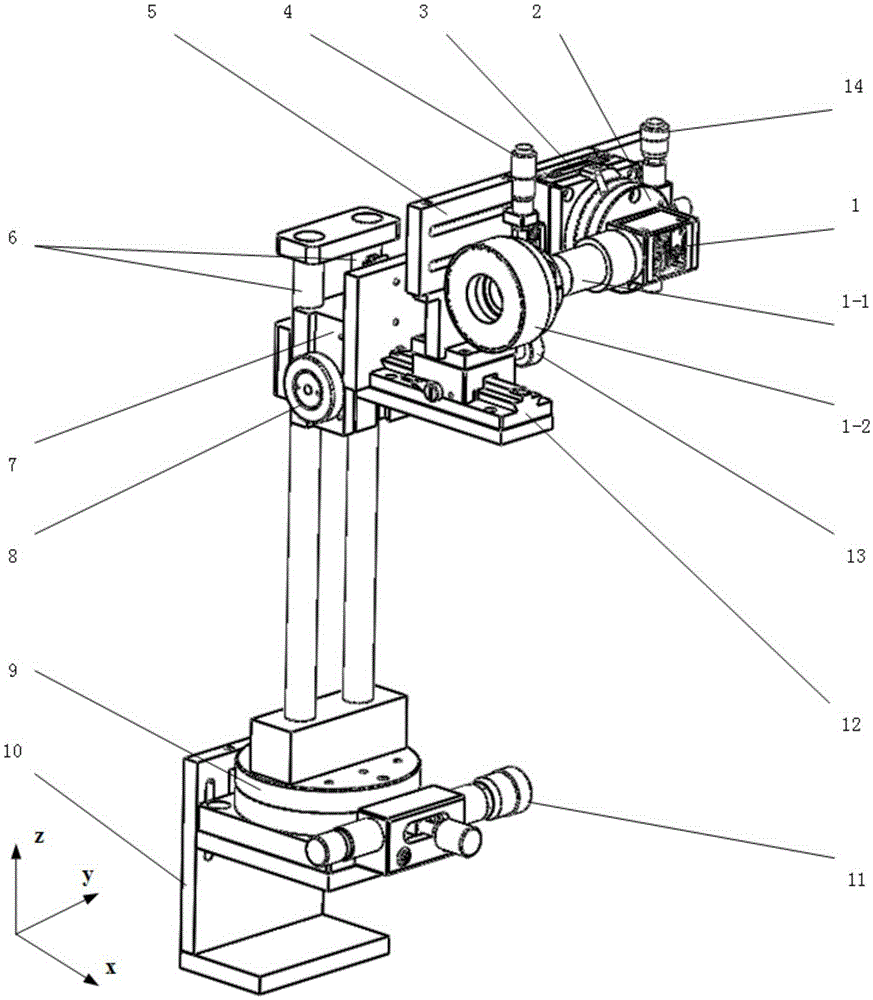

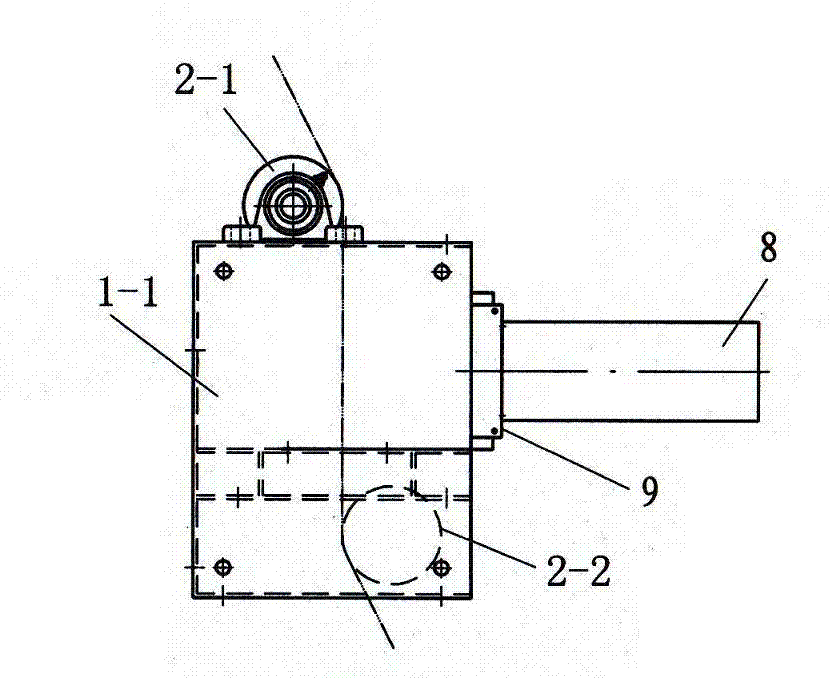

In-situ detecting equipment for abrasion on rear face of turning tool

ActiveCN105345599ASolving Distortion Correction IssuesHigh measurement accuracyMeasurement/indication equipmentsCamera lensImage resolution

The invention discloses in-situ detecting equipment for abrasion on the rear face of a turning tool. The in-situ detecting equipment comprises an imaging device and a pose and position adjusting device, wherein the imaging device comprises a camera, a telecentric lens and coaxial light sources, the telecentric lens is mounted on the camera, and the coaxial light sources are fixed at the tail end of the telecentric lens; the pixel of the camera is not lower than 200w, and the chip of the camera is not smaller than 1 / 1.8 inch in size; the distortion factor of the telecentric lens is not higher than 0.02 percent; the image resolution of the combination of the camera and the telecentric lens is not lower than 400 pixel / mm, and the entire length is not longer than 150 mm; and the pose and position adjusting device is used for achieving multi-degree-of-freedom precision adjustment of the imaging device. During the work, the imaging device is fixed on one side, positioned on the outer normal of the rear face of the turning tool, of a lathe lateral displacement planker through the pose and position adjusting device. The in-situ detecting equipment provided by the invention has the advantages of high measuring accuracy, convenience in measurement and the like, and is applicable to abrasion on the rear face of the turning tool.

Owner:HUAZHONG UNIV OF SCI & TECH

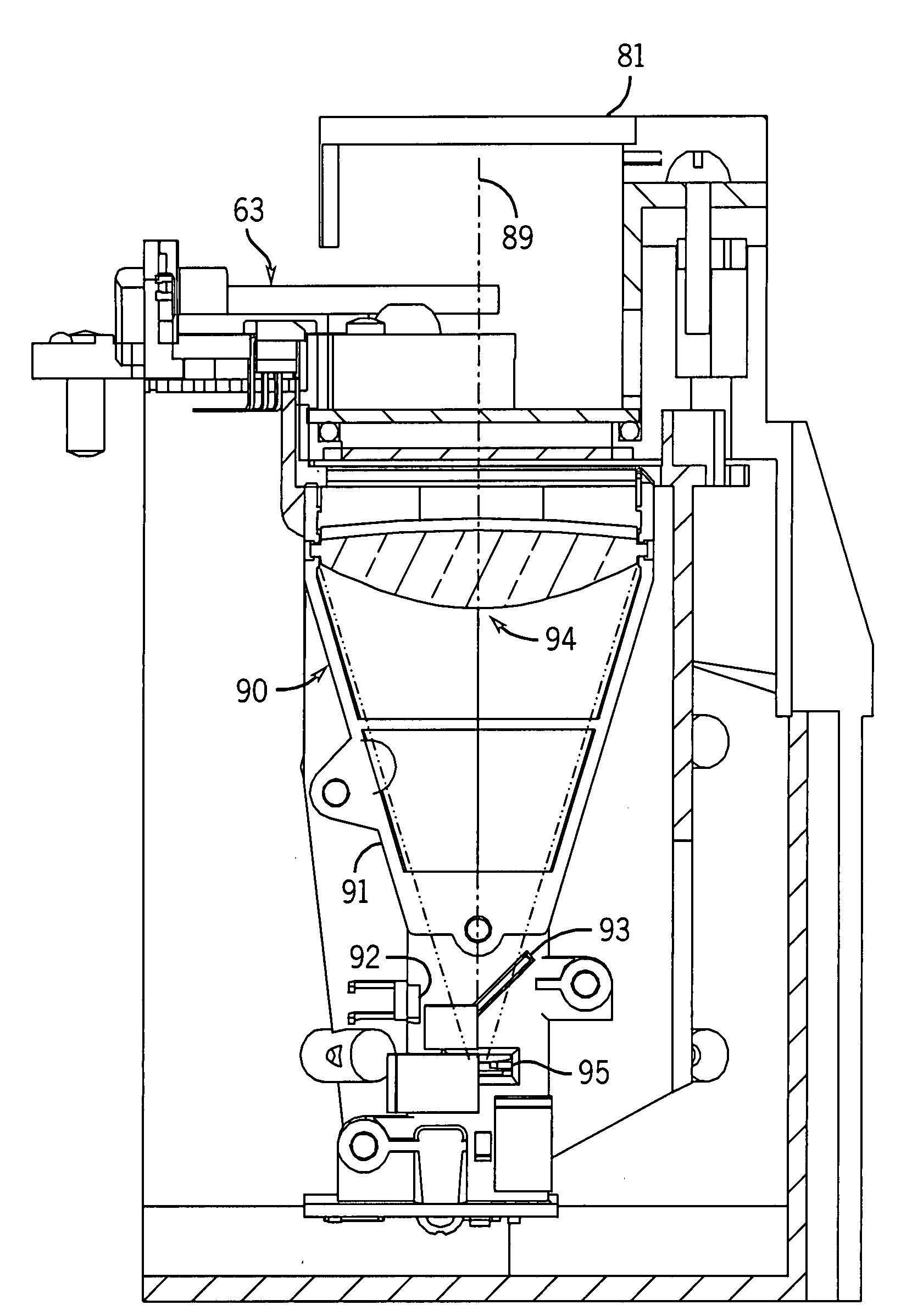

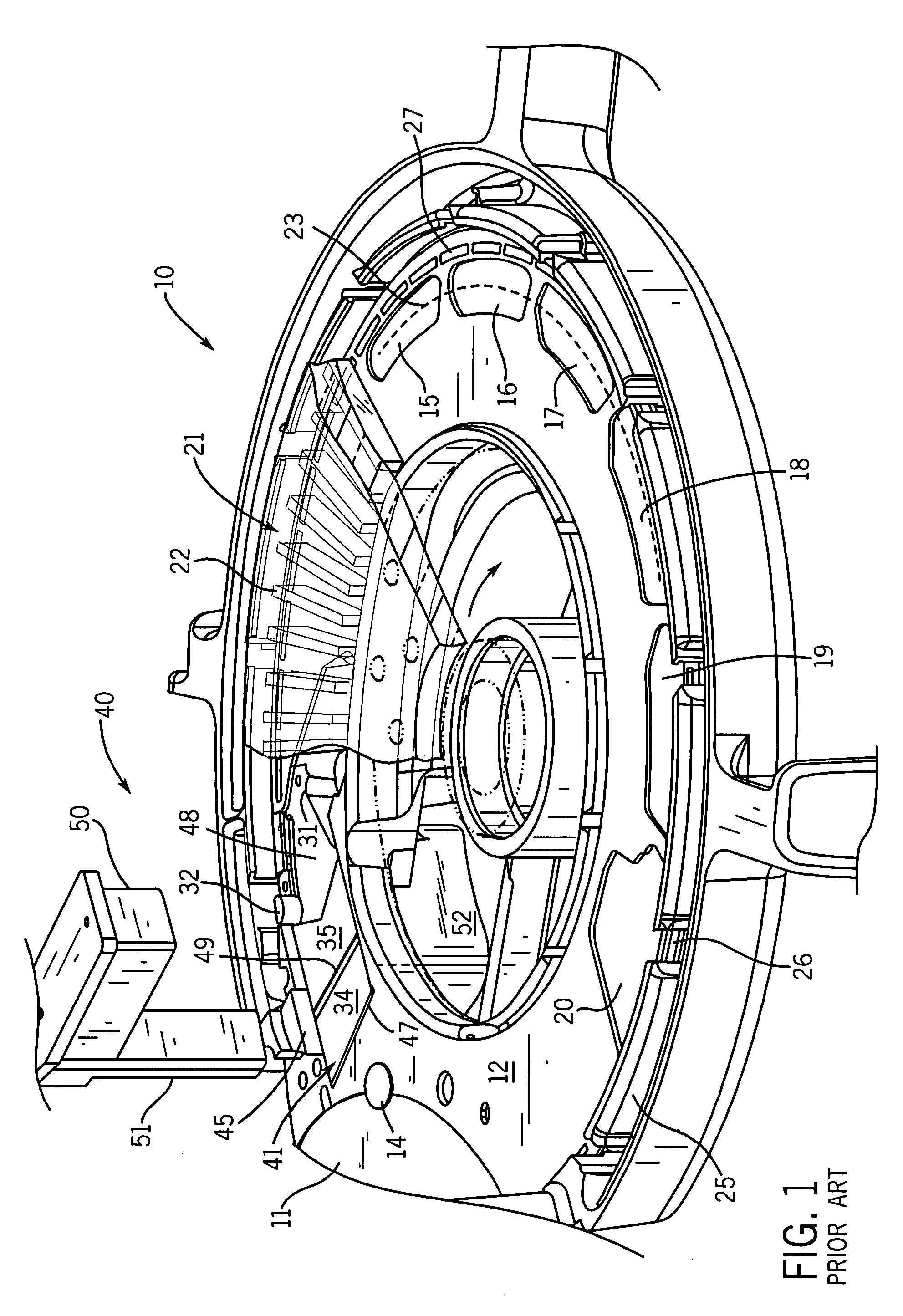

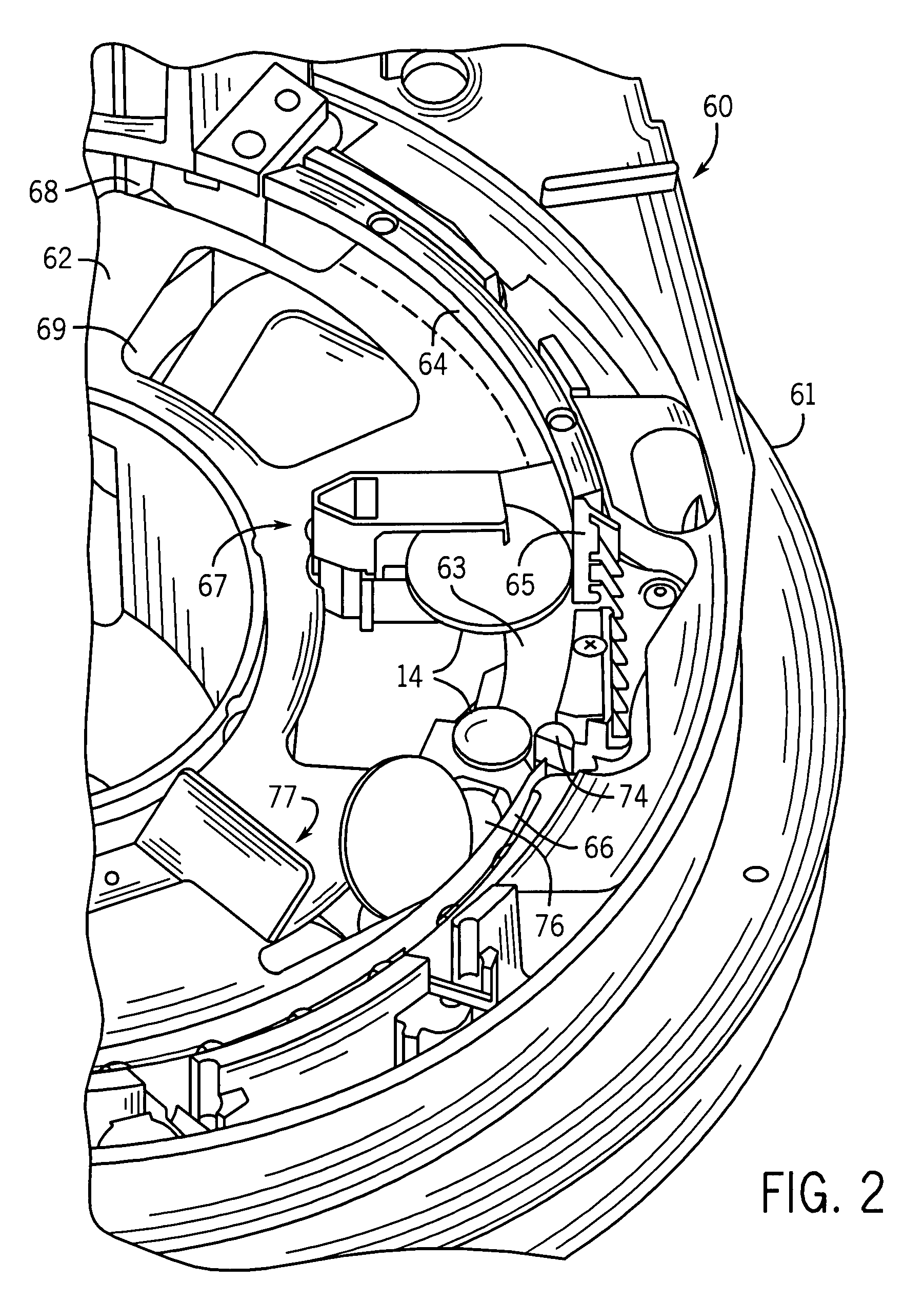

Method and sensor for sensing coins for valuation

ActiveUS20090048803A1Rapidly and accurately identifyingAccurate imagingCoin testingPaper-money testing devicesApparent SizeTelecentric lens

A coin sensor and method of identifying coins by size and also discriminating invalid coins includes a portion of a coin track (63) over which coins (14) pass in a single file, an illumination source (92) for illuminating at least portions of the coins (14) as the coins move along the coin track (63), an optical detector (95) spaced from the coin track (63) for detecting a size of at least a portion of each coin passing the coin sensor along the coin track, and a telecentric lens (94) positioned between the optical detector (95) and the coin track (63), such that the portion of each coin passing the optical detector (95) is seen to have an apparent size and configuration independent of a variation in distance of the coin from the telecentric lens (94) as each coin moves along the coin track (63). The optical sensor and detector (90) can be angled to assist in preventing stray light from the bottom of the coins from being transmitted to the detector (95). The sensor assembly (67) also includes inductive sensors (98, 99) and a Hall effect sensor (97) for discriminating invalid coins.

Owner:TALARIS INC

Machine vision-based fabric physical property detection method and device

ActiveCN102778414AHigh density accuracyGuaranteed stabilityUsing optical meansSpecific gravity measurementProduction lineTime domain

The invention discloses a machine vision-based fabric physical property detection method and device. The machine vision-based fabric physical property detection method comprises the following steps: a, arranging an area-array camera with a telecentric lens and an LED (light-emitting diode) light source in a face-to-face manner, and forming a detection area between the area-array camera and the LED light source; b, controlling the area-array camera by a computer; c, enabling a fabric to be detected to pass through the detection area and the LED light source to irradiate the fabric to be detected, and photographing the fabric to be detected by the area-array camera; and d, transmitting images photographed by the area-array camera to the computer, converting the images of the fabric to be detected from time domain images to frequency domain images by the computer, extracting peak position coordinates of the horizontal direction and / or vertical direction of center position coordinates from the frequency domain images, calculating the distance between the peak position coordinates and the center position coordinates, and then calculating the density value of the fabric to be detected and / or the weft bevel angle of the fabric to be detected. The machine vision-based fabric physical property detection device comprises a framework, an LED light source and an area-array camera, wherein a telecentric lens is mounted on the area-array camera. According to the machine vision-based fabric physical property detection method and device, the images of a fabric flowing on the production line can be acquired, and high detection accuracy is achieved.

Owner:顾金华

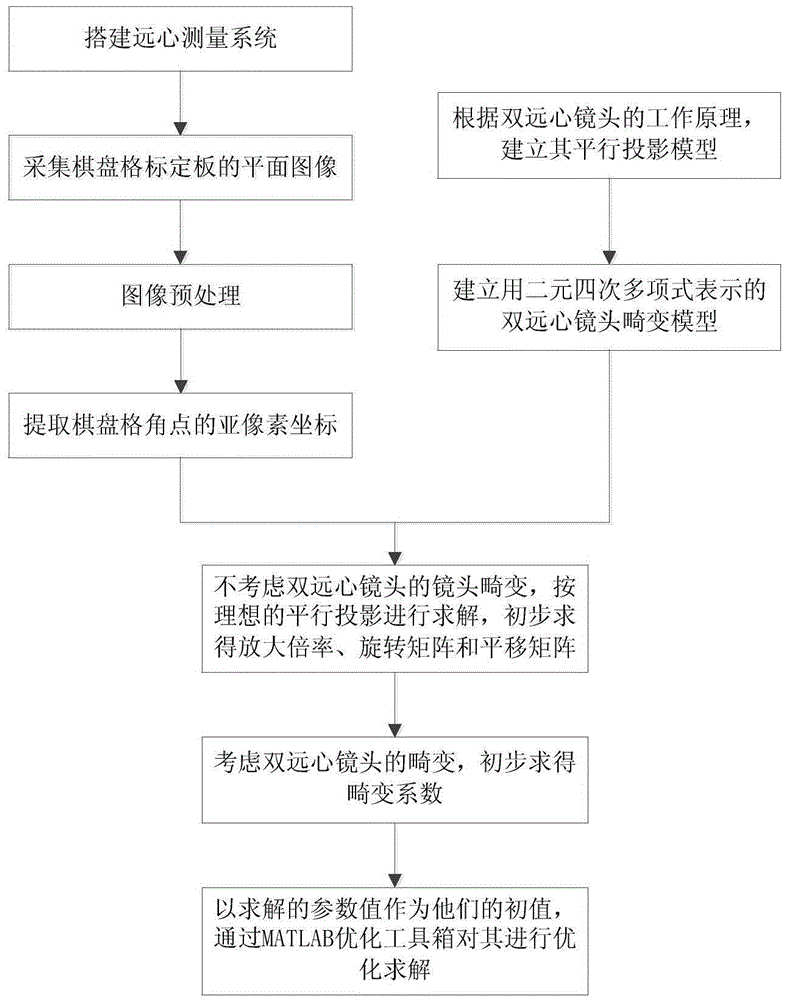

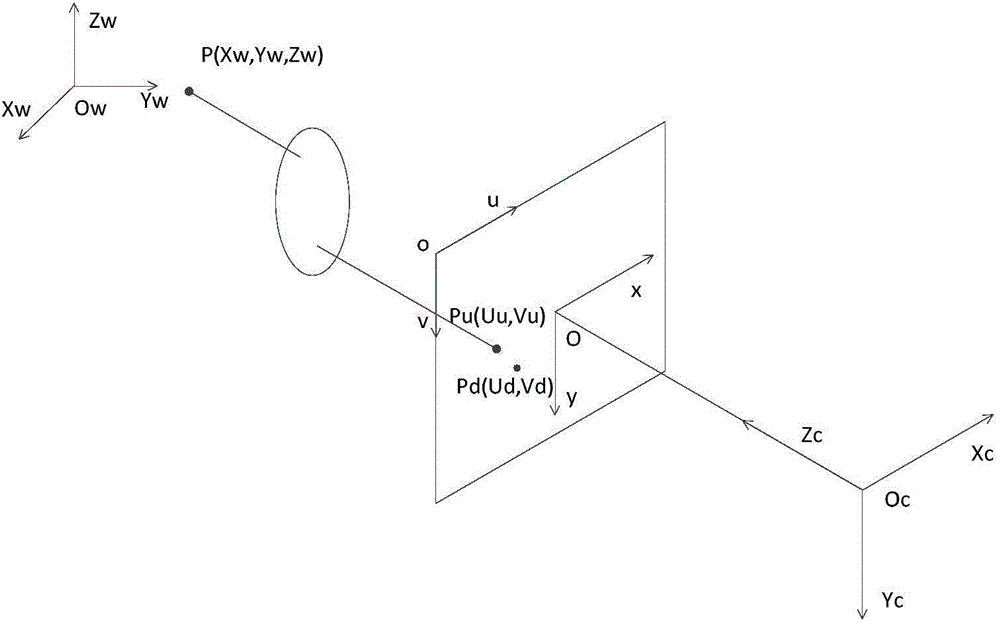

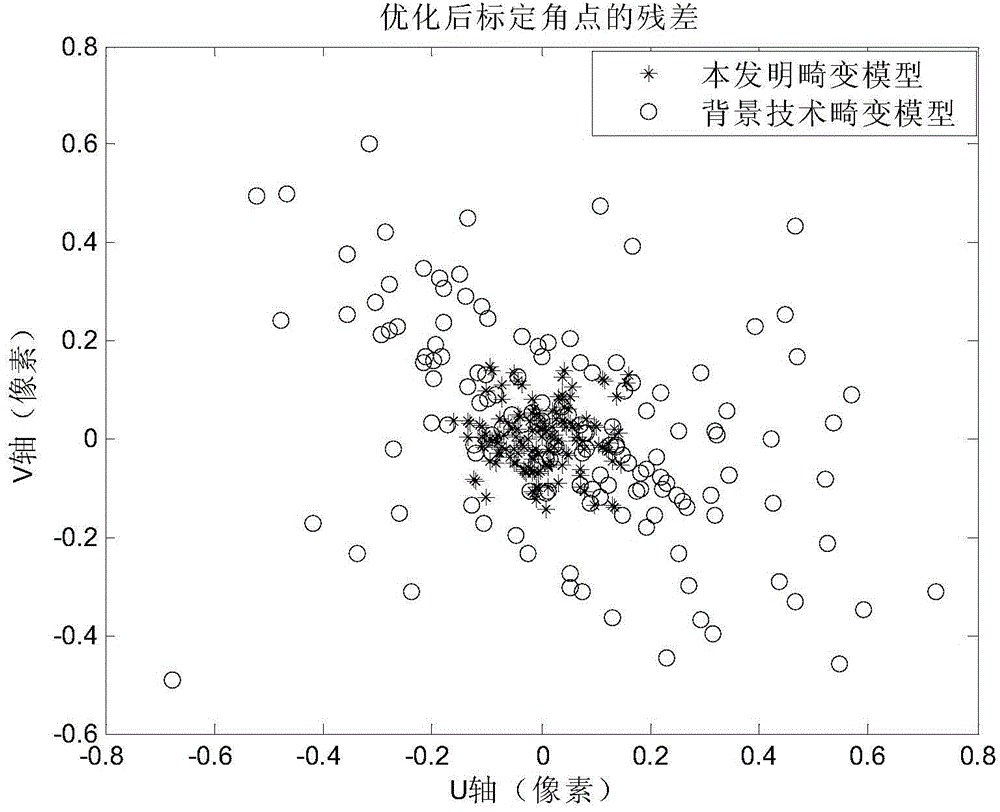

Double-telecentric lens calibration method based on binary quartic polynomial distortion error compensation

InactiveCN104881874AImprove calibration accuracyImprove optimization efficiencyImage analysisCamera lensAlgorithm

The invention discloses a double-telecentric lens calibration method based on binary quartic polynomial distortion error compensation, and the method is used to solve a technical problem that an existing double-telecentric lens calibration method is low in precision. The technical scheme is that a double-telecentric lens and a CCD camera are used to set up a telecentric measuring system, a checker calibration board is adjusted to obtain clear calibration board images, a Harris algorithm is applied to obtain sub pixel angle point coordinates of a checker image; considering that a distortion center would influence the calibration precision, a u0 and a v0 are introduced when a parallel projection model of a double-telecentric lens is established; according to an existing distortion model, a binary quartic polynomial is used to perform distortion error compensation; according to characteristics of the established model, in a calibration solving process, a three-step method is used, and a calibration parameter linear resolution result is used as an initial value of a nonlinear optimization input parameter, so as to improve optimization efficiency. The method is simple in calibration process, other special experiment equipment is not needed, and calibration precision of the double-telecentric lens is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com