System for optical detection on micro-aperture workpiece inner wall

An optical detection and workpiece technology, applied in the direction of optical testing flaws/defects, etc., can solve the problem that small-diameter workpieces cannot be detected, and achieve the effects of low cost, improved detection efficiency, and convenient detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

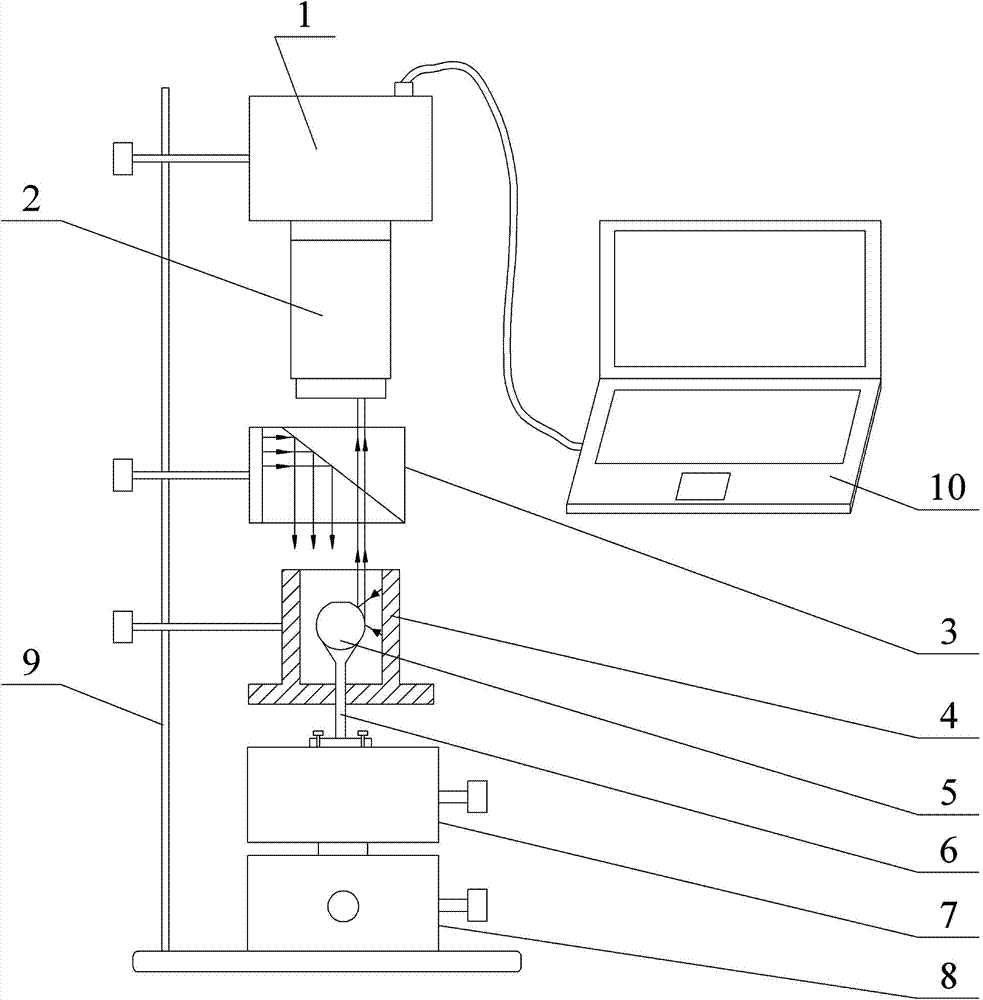

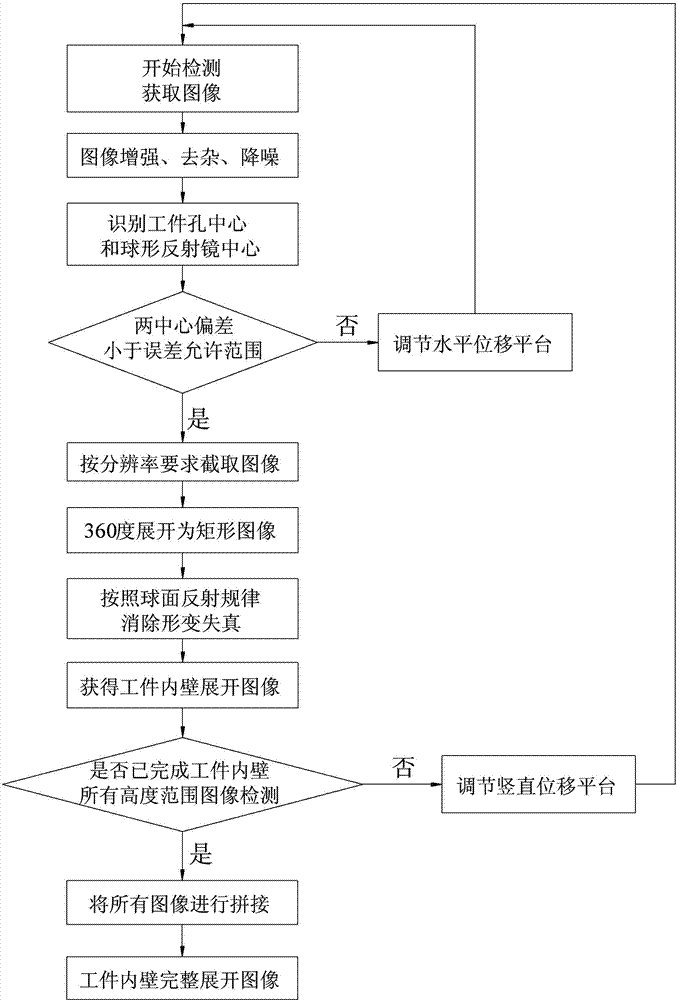

[0015] According to attached figure 1 , the present invention is an optical detection system for the inner wall of a micro-aperture workpiece. The detection system includes an area array CCD camera 1, a telecentric lens 2, a coaxial light source 3, a measured workpiece 4, a spherical mirror 5, a mirror bracket 6, a precision Vertical displacement platform 7, precision horizontal displacement platform 8, optical support 9 and computer 10. First build the detection system according to the structural schematic diagram, assemble the telecentric lens 2 and the front lens of the CCD camera 1, and fix them on the optical bracket 8 with the coaxial light source 3 and the workpiece 4 in order from top to bottom , and adjust the position of the optical bracket so that the axis of the lens and the axis of the workpiece to be measured are on the same vertical axis, the spherical mirror 5 is placed and fixed on the mirror bracket 6, and the mirror bracket 6 is horizontally fixed on the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com