Machine vision-based fabric physical property detection method and device

A technology of physical performance and machine vision, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as troublesome operation, troublesome brightness and focal length of cameras, and low detection accuracy, so as to eliminate measurement errors, shorten calculation time, The effect of constant magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

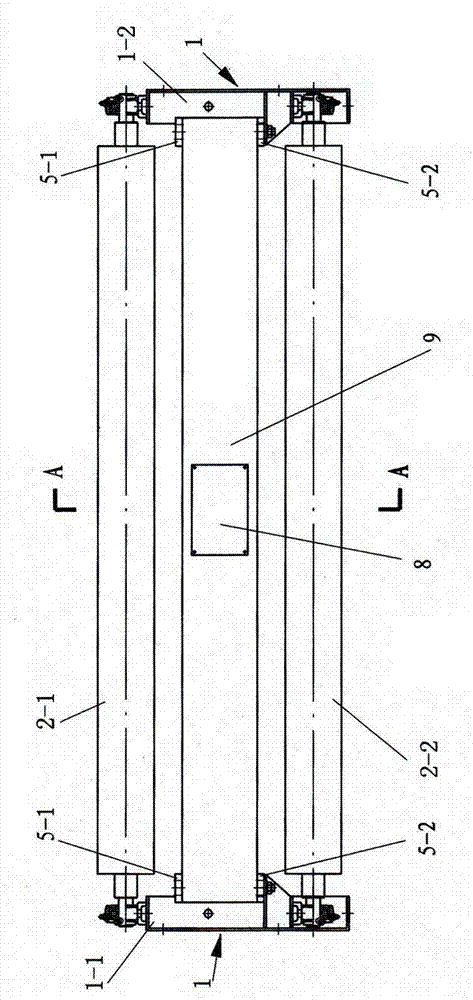

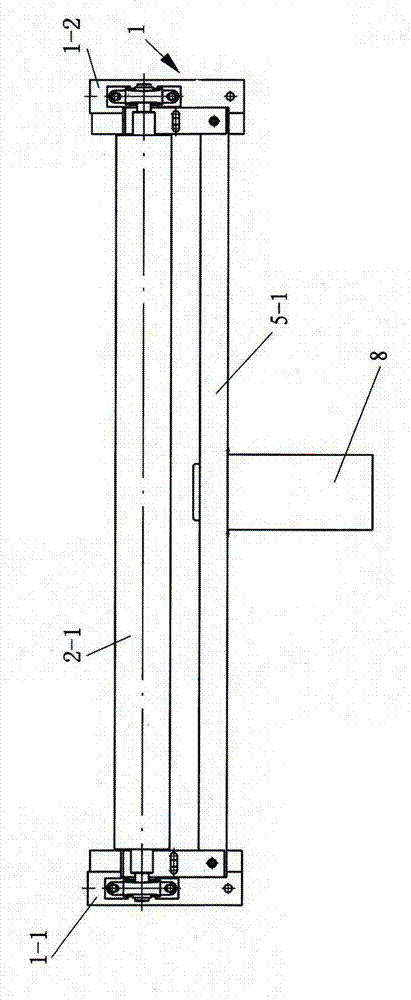

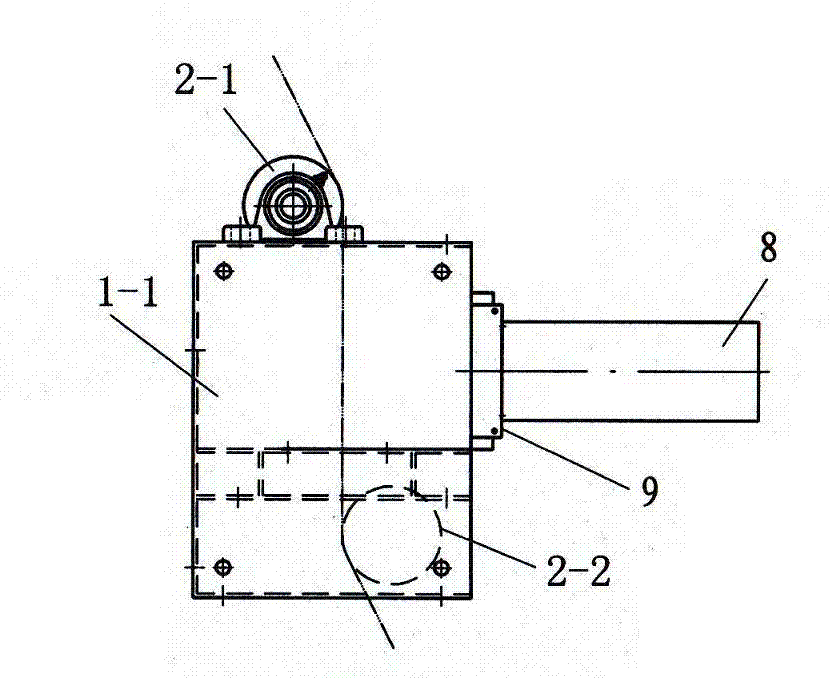

[0039] Such as figure 1 , 2 , 3, 4, 10, 11, 12, 13, 14, 15, a kind of fabric physical performance detection method based on machine vision of the present invention may further comprise the steps:

[0040] a. The area array camera 7 equipped with the telecentric lens 7-1 is arranged face to face with the LED light source 12, and a detection area 16 is formed between the area array camera 7 and the LED light source 12;

[0041] b, the area array camera 7 is controlled by the computer 17,

[0042] c. Pass the tested fabric 3 through the detection area 16, the LED light source 12 shines on the tested fabric 3, and the area array camera 7 takes pictures of the tested fabric 3 (see Figure 10 ),

[0043] d, the image taken by the area array camera 7 is transmitted to the computer 17, and the image of the tested fabric 3 is converted from a time domain image to a frequency domain image by the computer 17 (see Figure 11 ), the frequency domain image contains the density informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com