A constant temperature hydrostatic balance and using method thereof

A technology of balance and still water, which is applied in the direction of scientific instruments, instruments, specific gravity measurement, etc. It can solve the problems of experimental data error, water splashing out, affecting the test accuracy, etc., and achieve the effect of high accuracy and no water splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

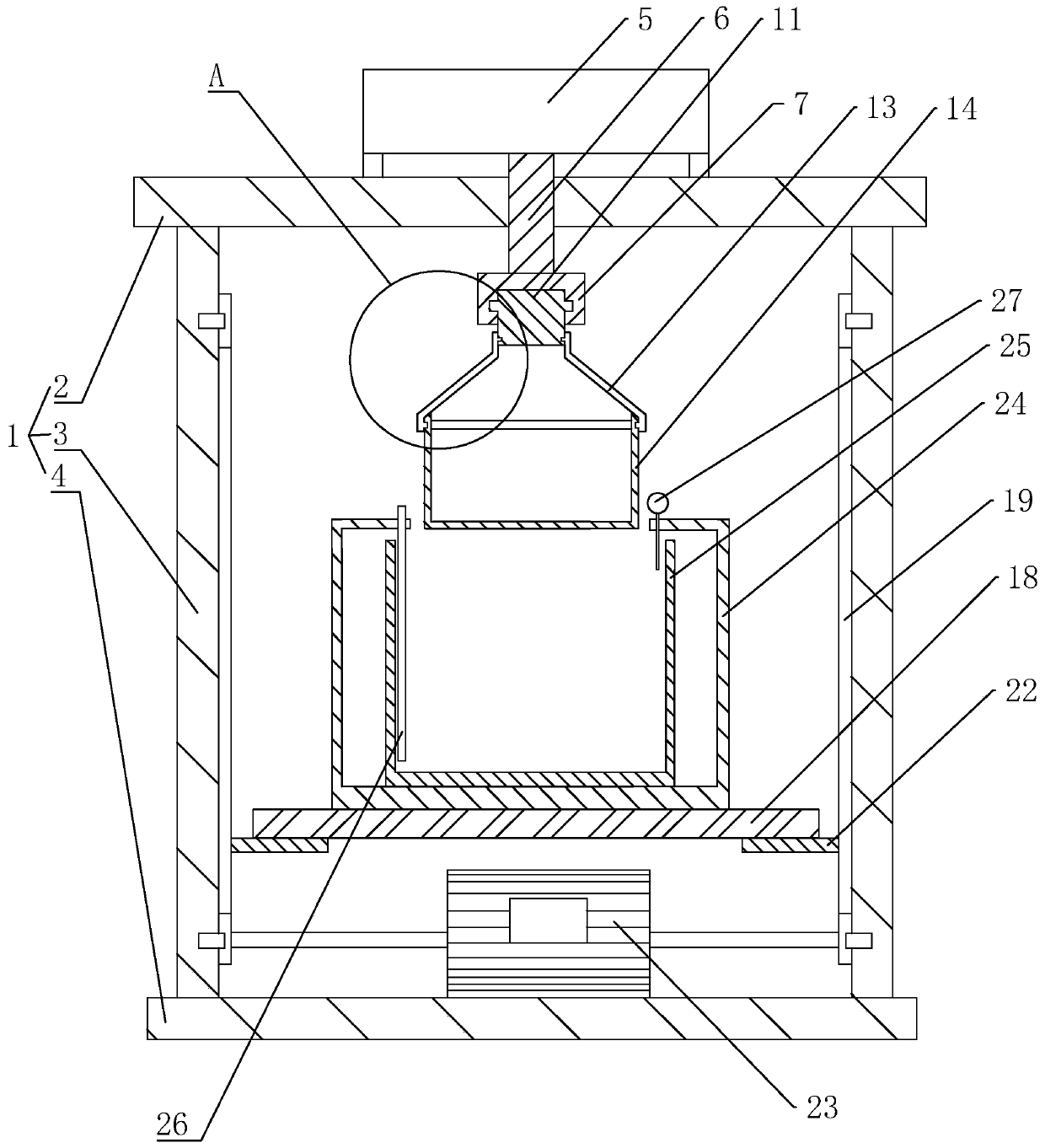

[0045] Such as figure 1 As shown, a constant temperature hydrostatic balance includes a frame 1 , and the frame 1 includes a mounting plate 2 , a supporting plate 3 and a bottom plate 4 . The mounting plate 2 is parallel to the base plate 4 and located above the base plate 4 , and there are two support plates 3 located on both sides of the mounting plate 2 . The supporting plate 3 is perpendicular to the mounting plate 2 and is fixedly connected to the mounting plate 2 and the bottom plate 4 . A balance 5 is arranged on the mounting plate 2, and the balance 5 is a tension balance 5.

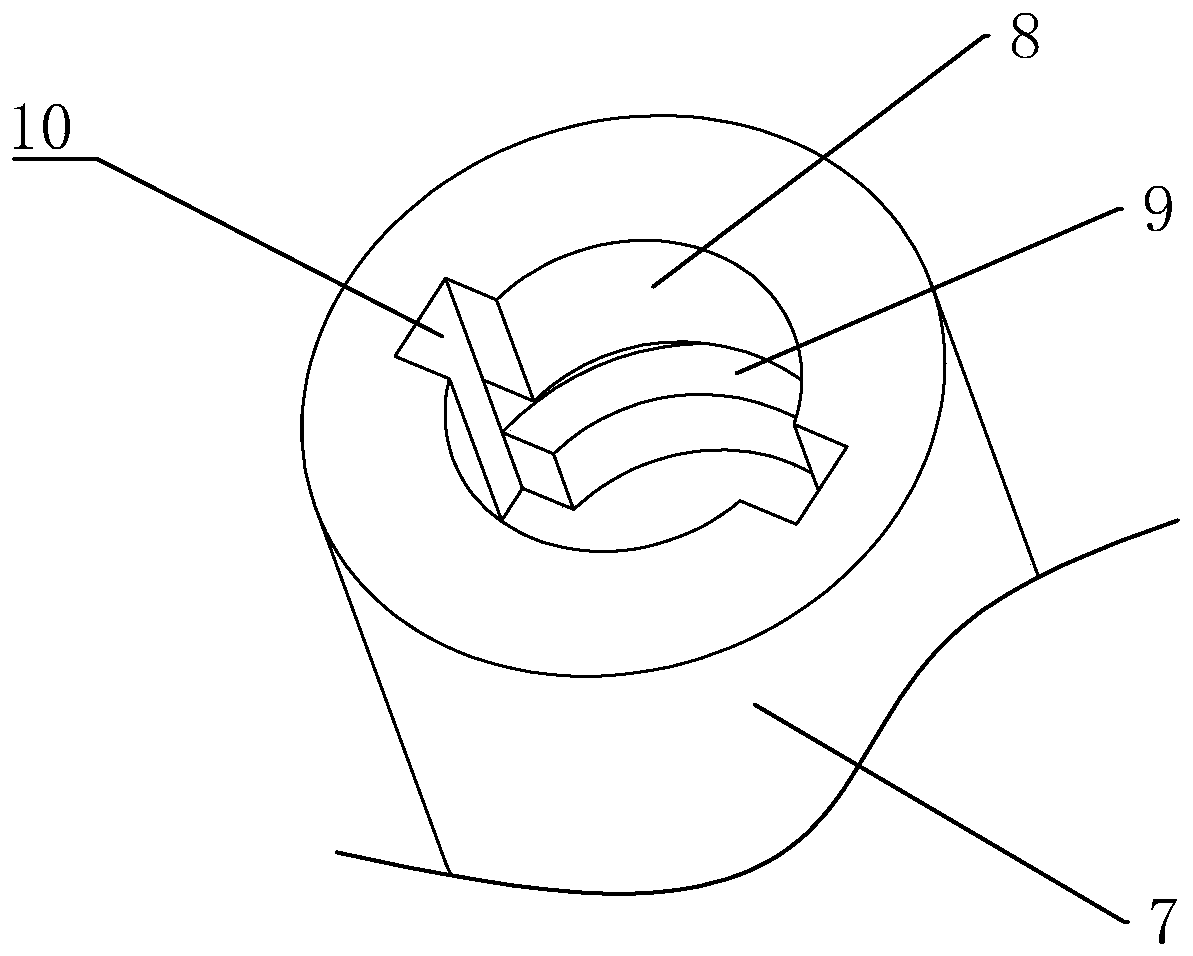

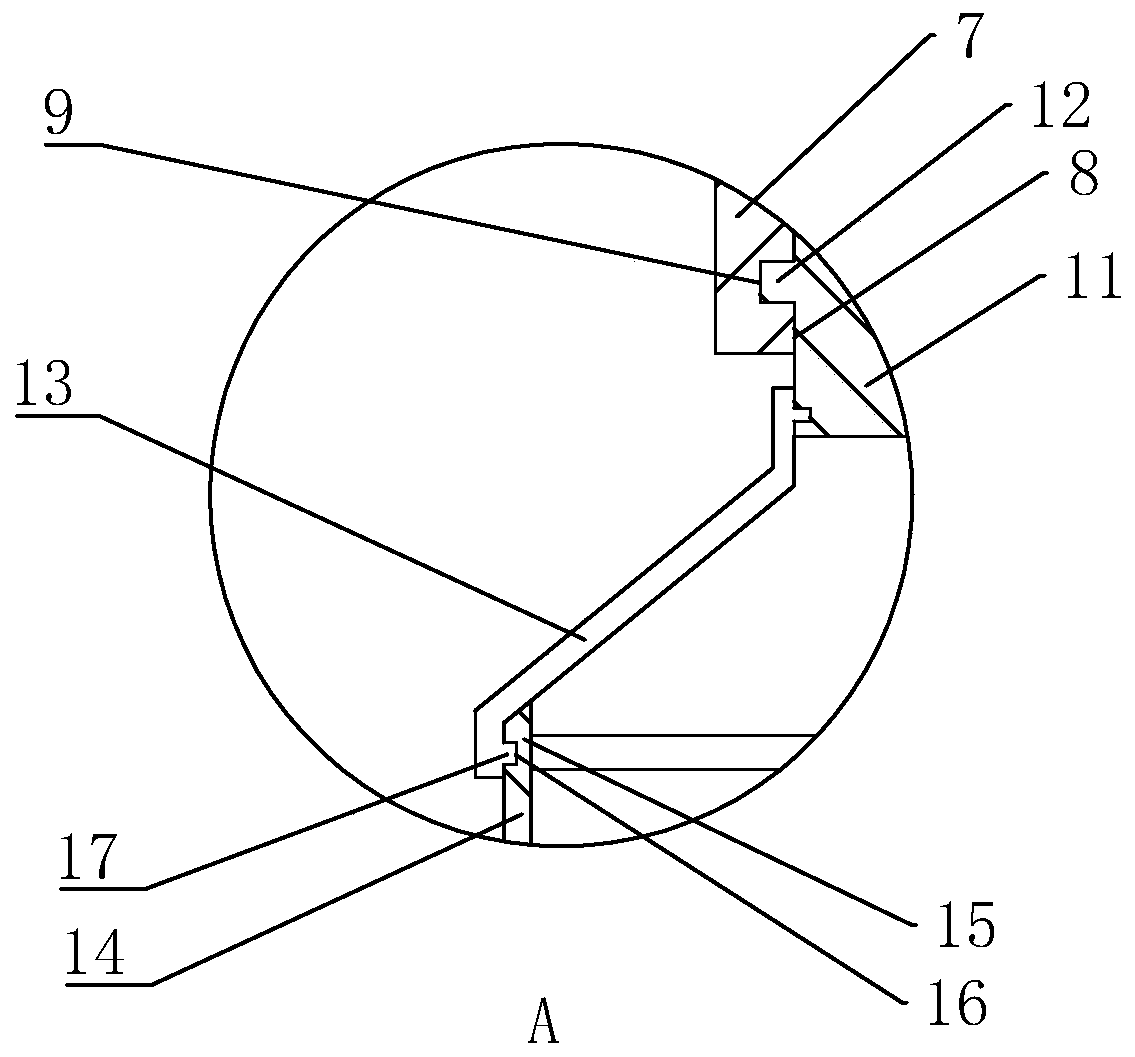

[0046] Such as figure 1 As shown, a mounting block 6 for measuring the weight under force is provided at the force-bearing part of the lower end surface of the balance 5 , and the mounting block 6 is fixedly installed on the balance 5 and passes through the mounting plate 2 . The lower end of the installation block 6 is fixedly provided with a connection block 7 , and the projection of the ins...

Embodiment 2

[0057] A method for using the constant temperature hydrostatic balance described in Embodiment 1:

[0058] S1. It is known that the volume of the connecting block 7 is V 1 , the density of the basket 14, the fixed block 11 and the connecting rod 13 are all ρ 2 ; The volume sum of the basket 14, the fixed block 11 and the connecting rod 13 is V 2 , the mass sum of the basket 14, the fixed block 11 and the connecting rod 13 is M 2 ; Let the volume of the specimen be V 3 , the specimen mass is M 3 , the specimen density is ρ 3 ;

[0059] S2, reset the balance 5 to zero, connect the fixed block 11 to the connecting block 13 by rotation, read, and the weight displayed by the balance 5 is M 2 = a; put in the test piece, read, and the weight displayed by the balance 5 is M 2 +M 3 = b;

[0060] S3. Open the water inlet valve 31 to enter water into the overflow barrel 25, the overflow barrel 25 is filled with water, read the reading, use the heating rod 26 to heat the water te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com