Additive manufacturing device and method for plasma arc gradient material of bypass hot wire consumable electrode

A plasma arc and gradient material technology, which is applied in the field of additive manufacturing devices and ion arc gradient material additive manufacturing devices, can solve the problems of difficult control of material mechanical properties and molding accuracy, and inability to achieve continuous adjustment of components, so as to improve the The effect of additive deposition efficiency, energy utilization improvement, and stability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

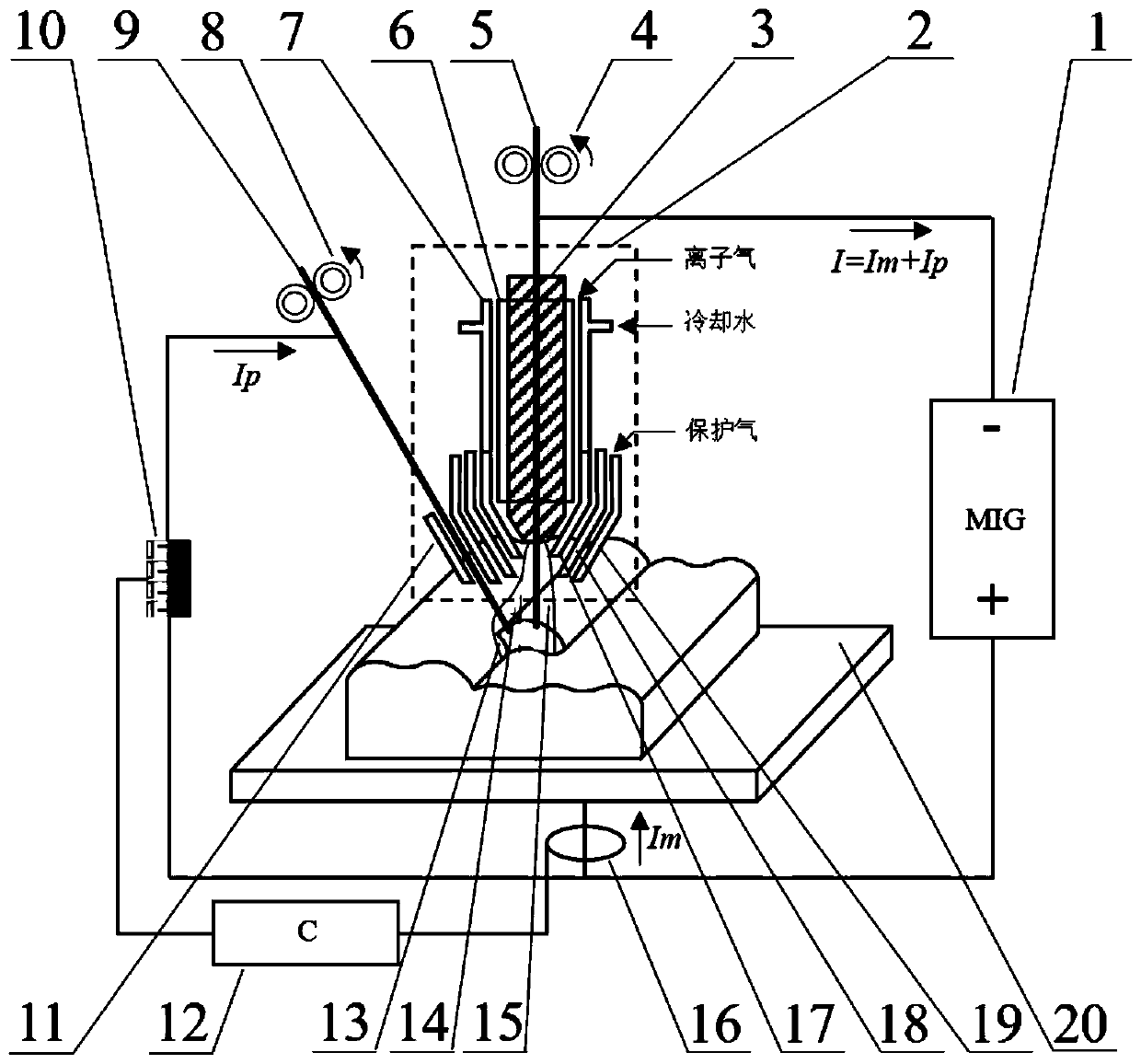

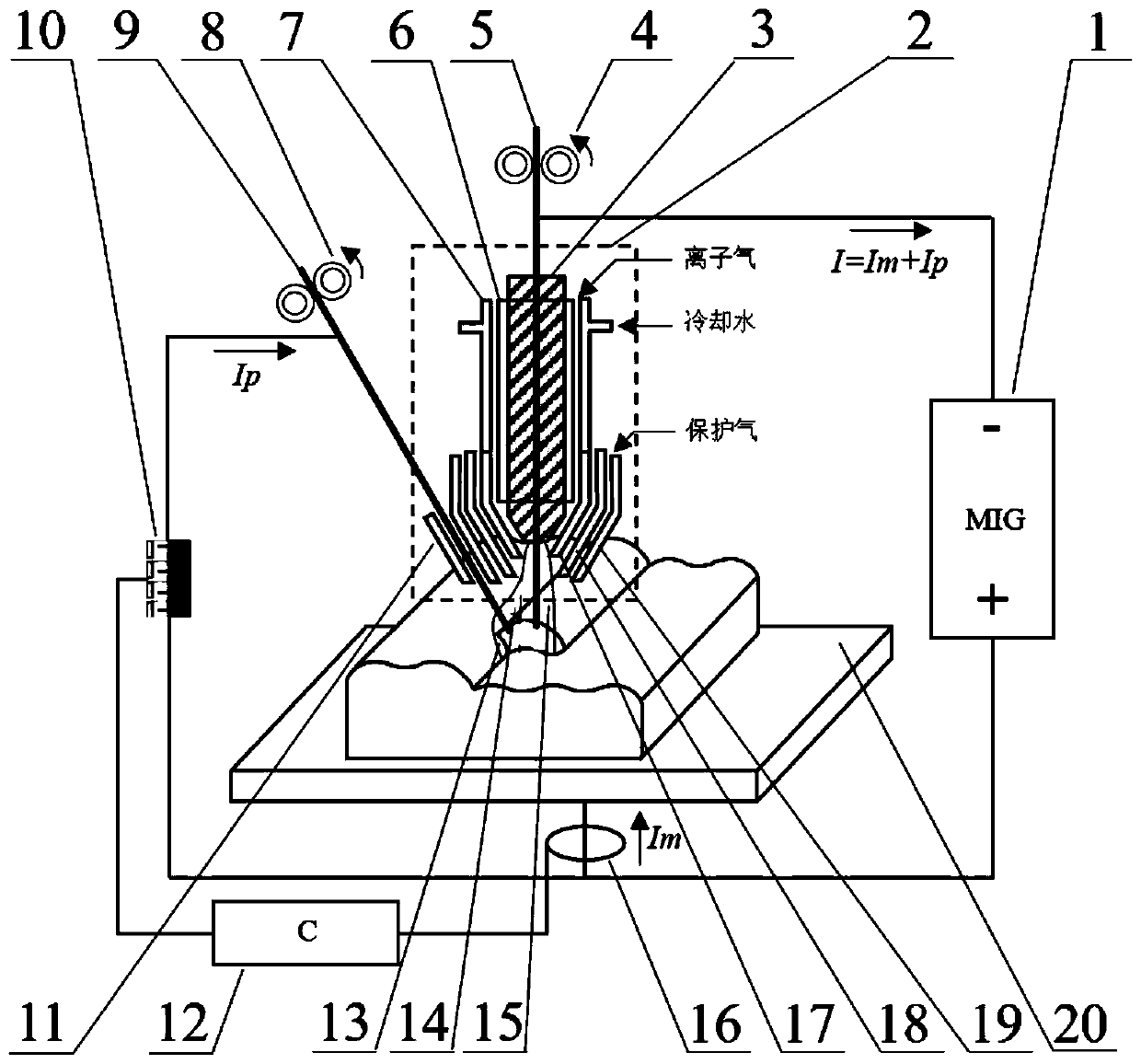

[0030] The invention relates to a device and method for additive manufacturing of a plasma arc gradient material with a bypass hot wire melting electrode, which is mainly composed of MIG welding and wire feeder connected to a power supply, a bypass hot wire melting electrode plasma arc welding torch, an IGBT shunt controller, and a guide Wire nozzle, auxiliary wire feeding machine, current sensor and its control system. The negative pole of the MIG welding power supply is connected to the annular plasma electrode, the positive pole is connected to the workpiece, the IGBT shunt module is connected to the positive pole of the MIG welding power supply through the welding wire, the current sensor is connected to the IGBT shunt module and the workpiece, and the auxiliary wire feeder is used to convey and bypass heat. The heterogeneous fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com