Patents

Literature

560results about How to "No splash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and high-tenacity gas shielded welding wire

ActiveCN101992365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaManganeseMixed gas

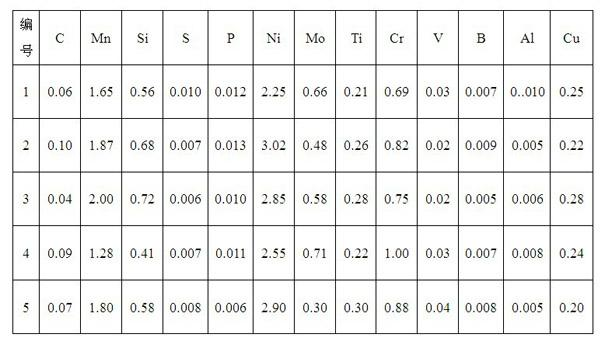

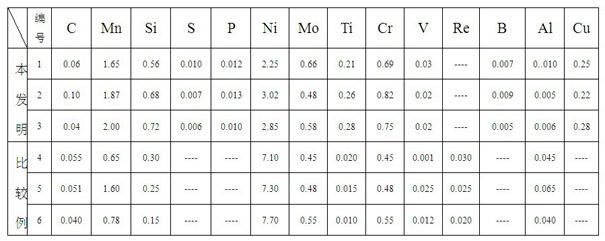

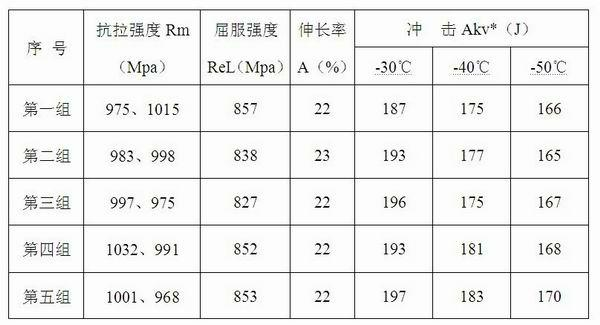

The invention discloses a high-strength and high-tenacity gas shielded welding wire. The welding wire comprises the following chemical composition in percentage by mass: 0.02 to 0.12 percent of carbon (C), 1.20 to 2.10 percent of manganese (Mn), 0.20 to 1.00 percent of silicon (Si), less than or equal to 0.010 percent of sulfur (S), less than or equal to 0.015 percent of phosphorus (P), 2.00 to 3.50 percent of nickel (Ni), 0.20 to 0.80 percent of molybdenum (Mo), 0.20 to 0.30 percent of titanium (Ti), 0.60 to 1.20 percent of chromium (Cr), less than or equal to 0.05 percent of vanadium (V), 0.005 to 0.010 percent of boron (B), less than or equal to 0.015 percent of aluminum (Al), less than or equal to 0.35 percent of copper (Cu) and the balance of iron (Fe). The welding wire is used for welding steels of a strength grade of between 850 and 950MPa; and under the protection of a mixed gas (80 percent of argon (Ar) and 20 percent of carbon dioxide (CO2)), the weld metal tensile strength of the welding wire is more than or equal to 850MPa, the yield strength is more than or equal to 720MPa, the elongation is more than or equal to 22 percent, and the low-temperature impact toughness Akv is more than or equal to 181J at the temperature of -30 DEG C, or more than or equal to 175J at the temperature of -40 DEG C, or more than or equal to 162J at the temperature of -50 DEG C.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel and preparation method thereof

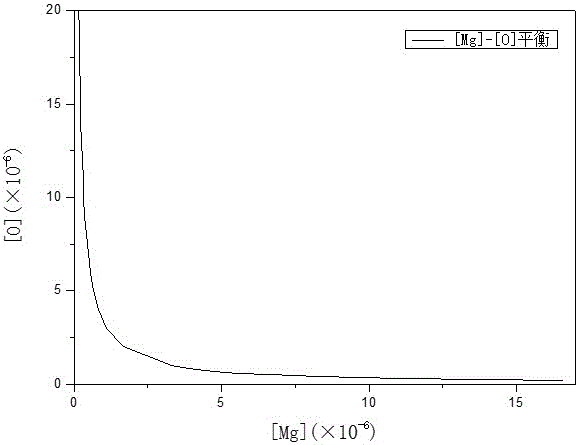

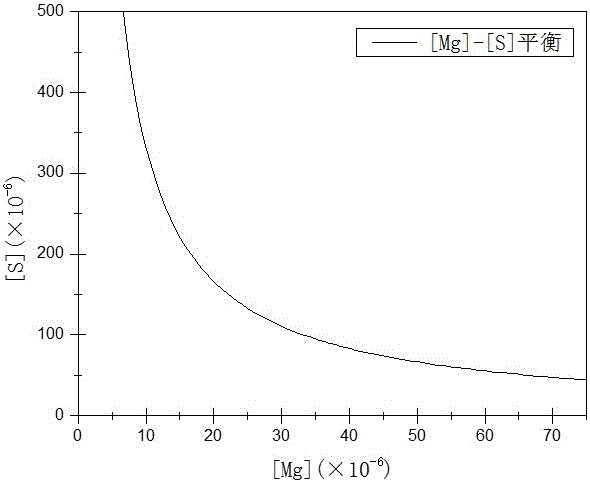

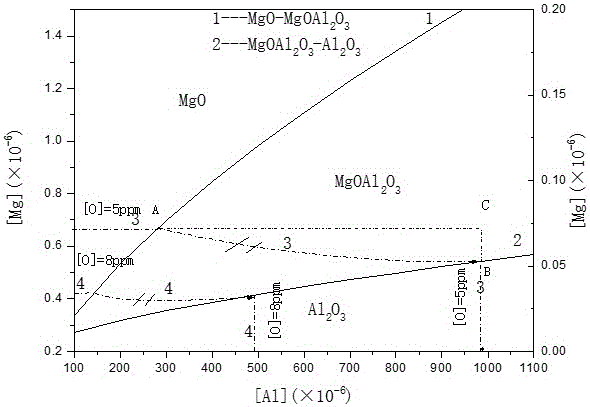

The invention discloses magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel and a preparation method thereof. The steel is prepared from, by weight percent, 0.15%-0.25% of C, not larger than 0.12% of Si, 0.80%-1.50% of Mn, not larger than 0.035% of P, 0.02%-0.055% of S, 0.80%-1.30% of Cr, 0.015%-0.055% of Al, 0.004%-0.015% of N, 0.0006%-0.004% of Mg, 0.0006%-0.005% of Ca, not larger than 0.0025% of [O] and the balance iron and inevitable impurities. Composite modification is carried out on inclusion by adding a small quantity of calcium and magnesium elements in the refining process, and the composite inclusion with oxide (including multiple oxide) as a core is formed, wherein the core of the composite inclusion is wrapped by sulfide; splitting of the oxide to a steel substrate can be relieved, the anti-fatigue performance can be improved, and the transverse mechanical property of the steel can be improved; and the magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel both good in mechanical performance and cutting performance is produced, and has large economic benefits.

Owner:SHANGHAI UNIV

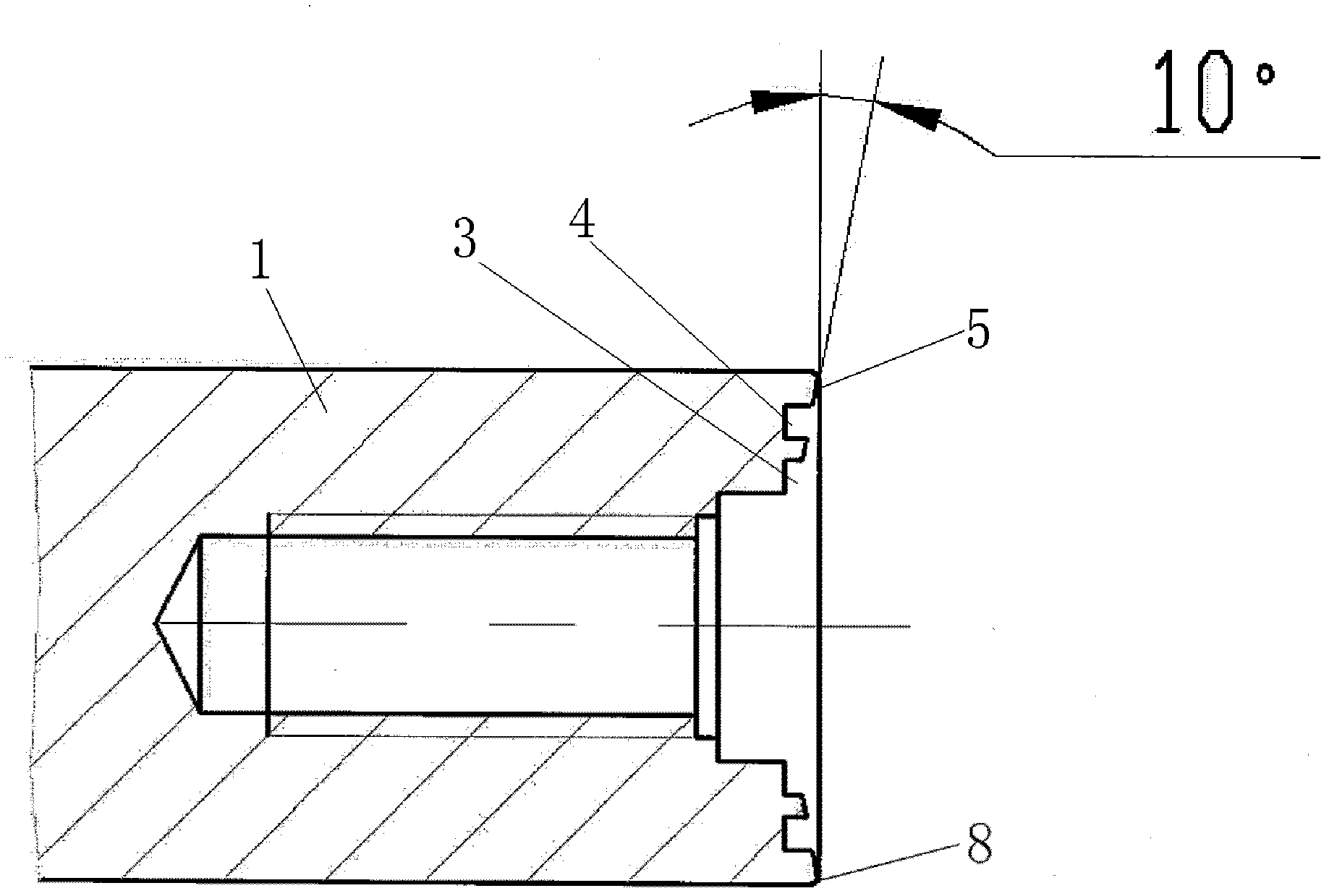

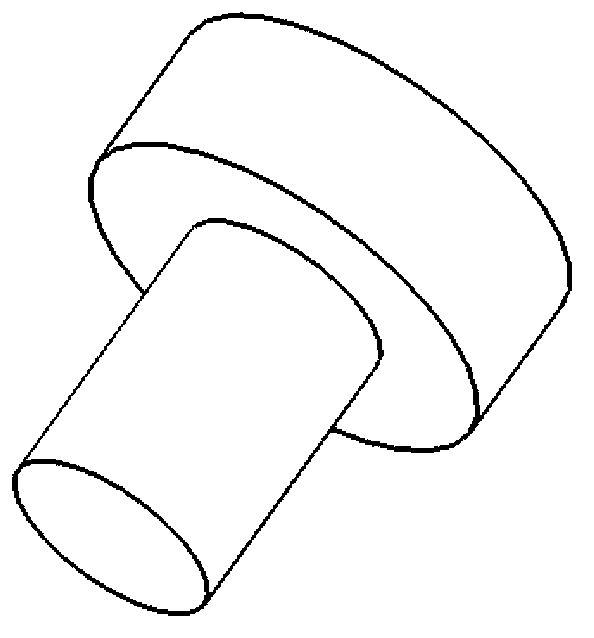

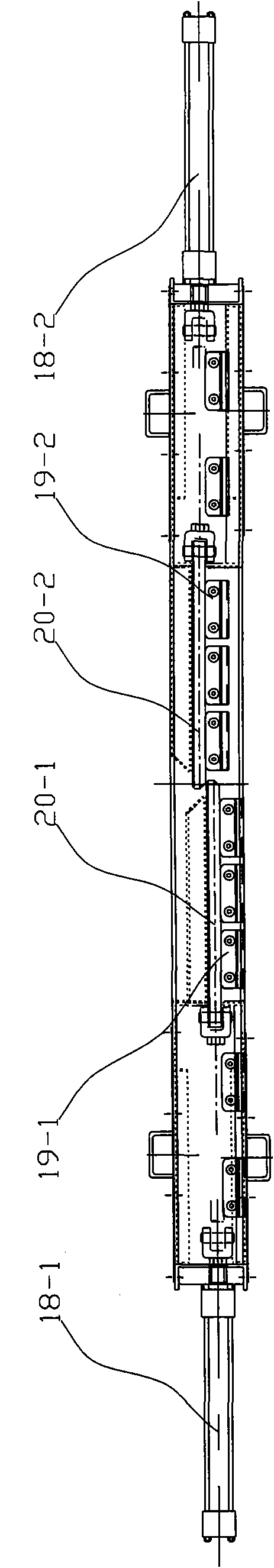

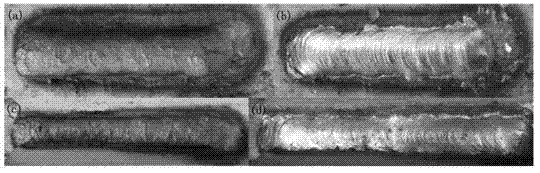

Device and method for repairing friction stir welding weld defect of storage tank for carrier rocket

ActiveCN102581476AGuarantee product qualityReduce scrapNon-electric welding apparatusFilling materialsRocket

The invention provides a device and a method for repairing a friction stir welding weld defect of a storage tank for a carrier rocket. A repair welding pin tool comprises a tool pin clamping structure and a tool pin, the end face of a shaft shoulder portion of the tool pin clamping structure is a recessed slope provided with two concentric-circle annular grooves, the front of the tool pin is of a conical thread structure, and a conical thread is circumferentially provided with three spiral grooves at intervals. The method includes the steps: firstly, manually excavating the tool pin broke at a friction stir welding weld; secondly, performing solid filling for the weld; thirdly, utilizing the repair welding pin tool to start friction stir welding from a center of the broke position of the tool pin filled with welding wires or materials to a set welding end point; and finally, continuing utilizing the repair welding pin tool to perform friction stir welding for the weld again from a welding start point to the welding end point. The method and the device are capable of guaranteeing the quality of the storage tank for the carrier rocket and decreasing scrapping of the storage tank for the carrier rocket due to the key hole type defect.

Owner:CAPITAL AEROSPACE MACHINERY +1

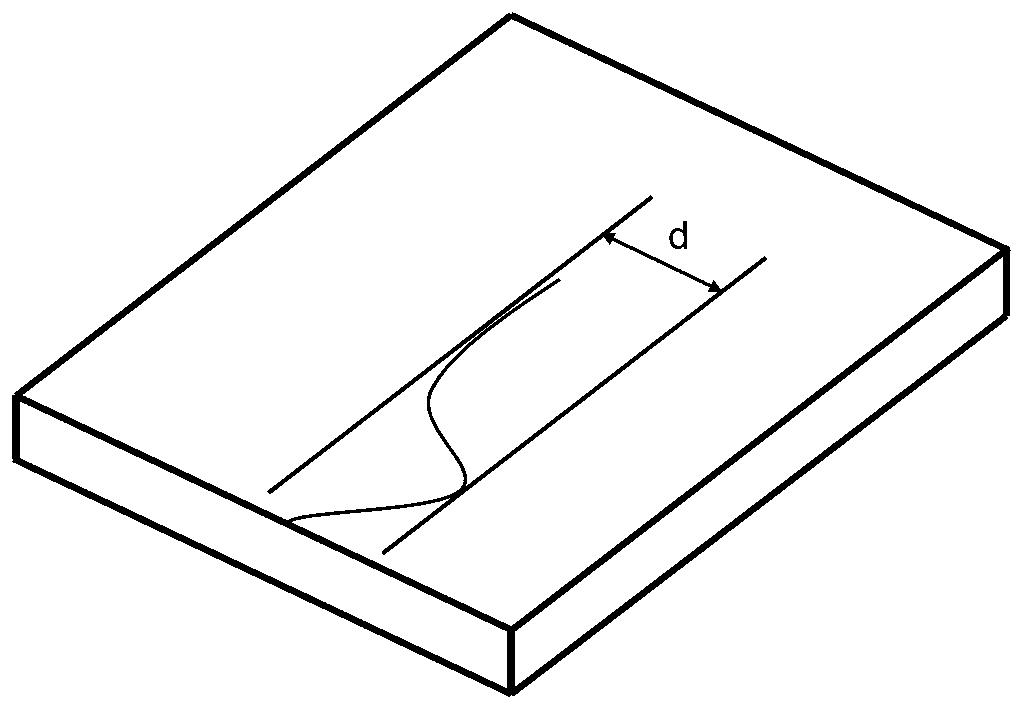

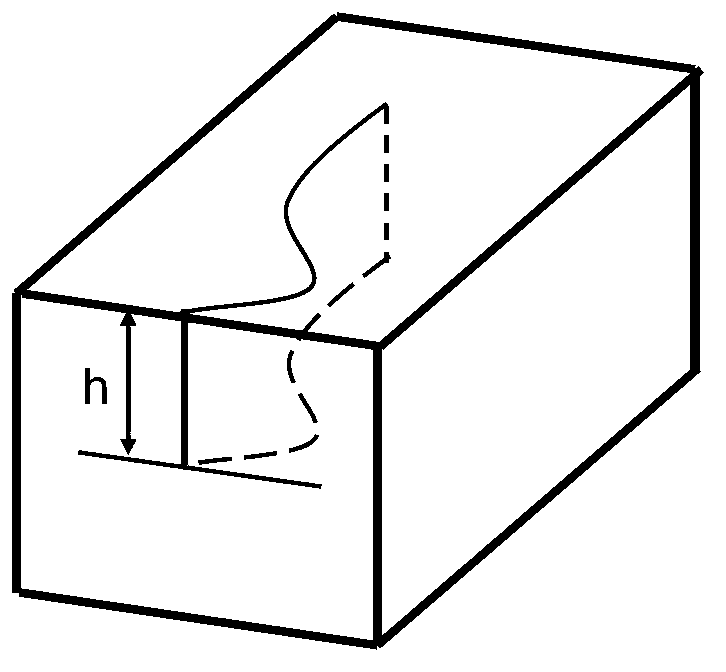

Stirring-friction-based crack repair method

InactiveCN103212778AReduce distortionReduce stressNon-electric welding apparatusUltimate tensile strengthAstronautics

The invention relates to a stirring-friction-based crack repair method which mainly is used for solving the problems in the prior art that the repair cost is high, the repair quality is poor and cracks appear repeatedly. The method is applied to the repair of surface cracks and through cracks of plate-shell metal structures, so as to enable cracked workpieces to meet reuse requirements. The method comprises the following specific steps of designing and manufacturing a friction repair tool according to the position and size of a crack, a material to be repaired, structural characteristics and the like; and realizing the friction between a shaft shoulder and the surface of the material to be repaired through the rotation of the repair tool so as to enable metal of a repair area to reach a thermoplastic state under the action of frictional heat, and realizing the flowing transfer and dynamic recrystallization of thermoplastic metal around the crack by using the rotating and upsetting action of the shaft shoulder of the repair tool, thereby realizing the filling repair of the crack. The method has the advantages that the method is simple, the damage to base metal is little, the quick, equal-strength and in-situ repair of engineering cracks can be realized, and the repair process is economical and environment-friendly. The method can be applied to the crack repair in fields, such as aeronautics and astronautics, shipbuilding, automobiles and rail transportation and has broad application prospects.

Owner:SHENYANG AEROSPACE UNIVERSITY

Acidic coating super two-phase stainless steel electrode

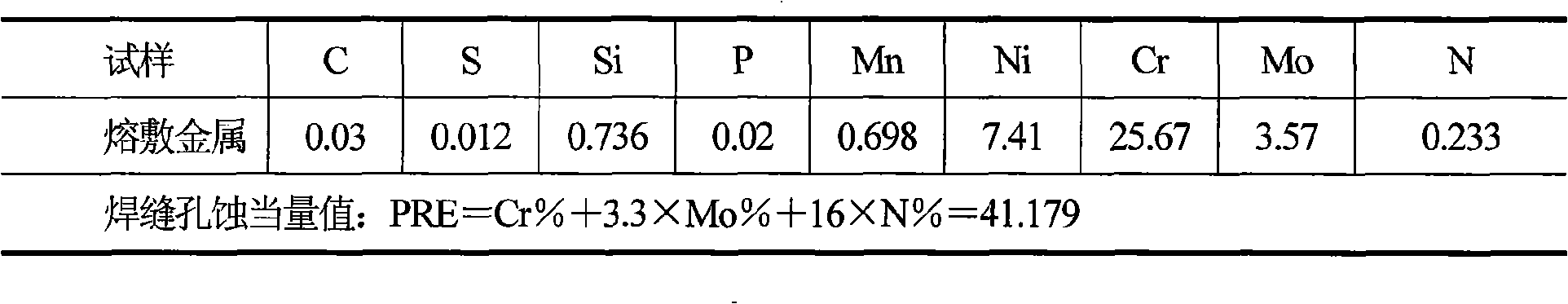

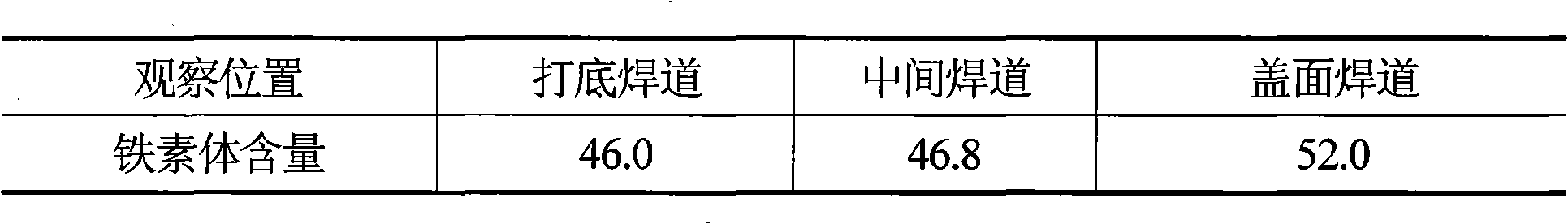

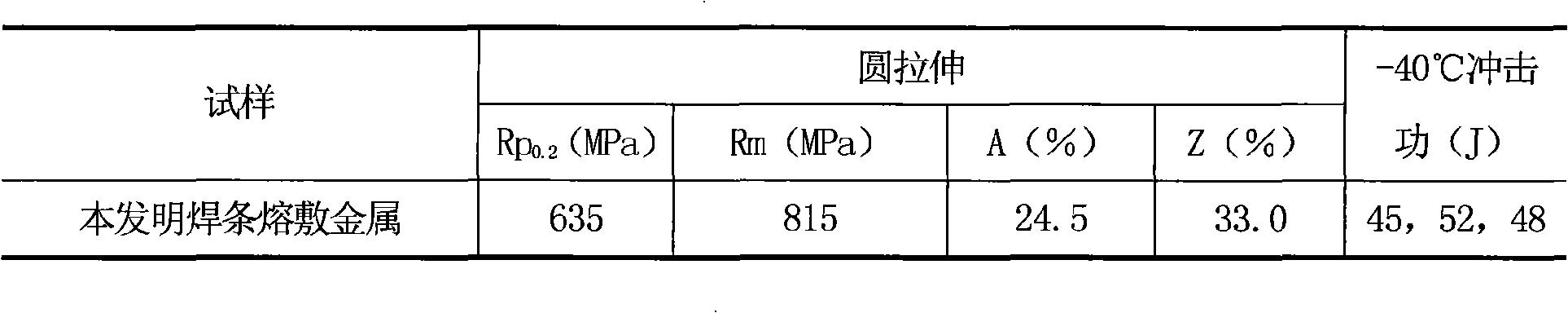

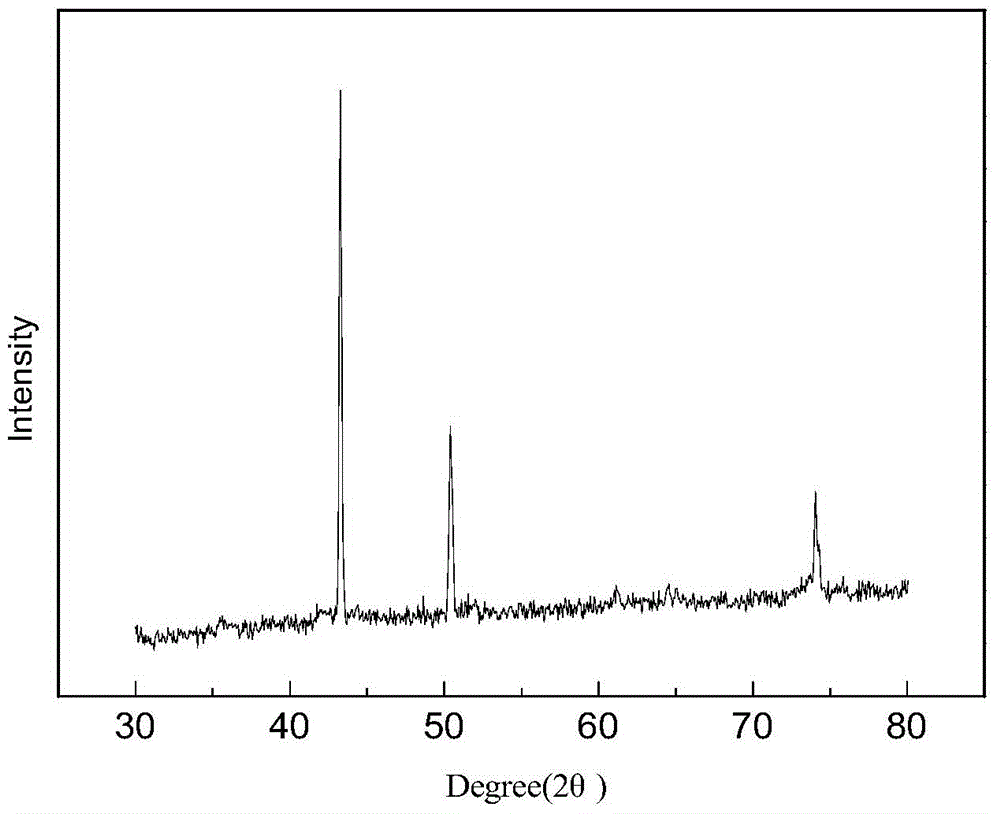

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Method for preparing high-entropy alloy coating

InactiveCN103556146AHigh hardnessImprove wear resistanceArc welding apparatusMetallic material coating processesHigh entropy alloysGas tungsten arc welding

The invention relates to the field of multi-principal element high-entropy alloy materials and in particular relates to a method for preparing a high-entropy alloy coating, belonging to the field of coating preparation. The method for preparing the high-entropy alloy coating comprises the following steps: pretreating a substrate, so that the surface of the substrate is clean and flat; preparing high-entropy alloy powder, uniformly mixing, and adding 3-6wt% of organic solution in the alloy powder; uniformly mixing the organic solution and the high-entropy alloy powder, and preparing into paste; uniformly coating the pasty alloy powder on the treated substrate, wherein the thickness of the coating layer is 0.3-6mm; baking the treated coating layer and substrate in an oven at the temperature of 55-80 DEG C for 20-30 hours; cladding the coating layer on the surface of the substrate through gas tungsten arc welding. According to the method for preparing the high-entropy alloy coating, the high-entropy alloy coating with the thickness of 0.3-6mm can be prepared, a heat affected zone to the substrate in the preparation process is small, and the coating is uniform in distribution and firmly bound to the base material.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Galvanized steel sheet lap-over laser welding method

InactiveCN101508058AReduce manufacturing costImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusAlloyWeld seam

The invention discloses a laser welding method for lapping galvanized steel sheets, which comprises: placing a Al-Sn alloy foil containing 35 to 45 weight percent of Sn between faying surfaces of the steel sheets; and utilizing two laser beams of which the power is respectively from 2 to 3KW and from 3 to 4KW to weld welding seams, wherein the space of the laser beams is between 20 and 50mm and the welding speed is between 4 and 8m / min. The method has low production cost and stable welding quality; and the strength of the obtained welding seams is greater than that of base metal, no welding spatter exists on the surface, and the corrosion resistance of the welding seams is more than three times higher than that of by a sweeping-out method. The method can be used for laser welding of lapped welding seams of DP series, TRIP series and HSLA series hot galvanized steel sheets, and realizes high efficiency, low pollution and low waste material of welding production.

Owner:HUAZHONG UNIV OF SCI & TECH

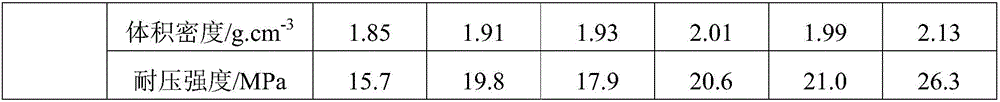

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

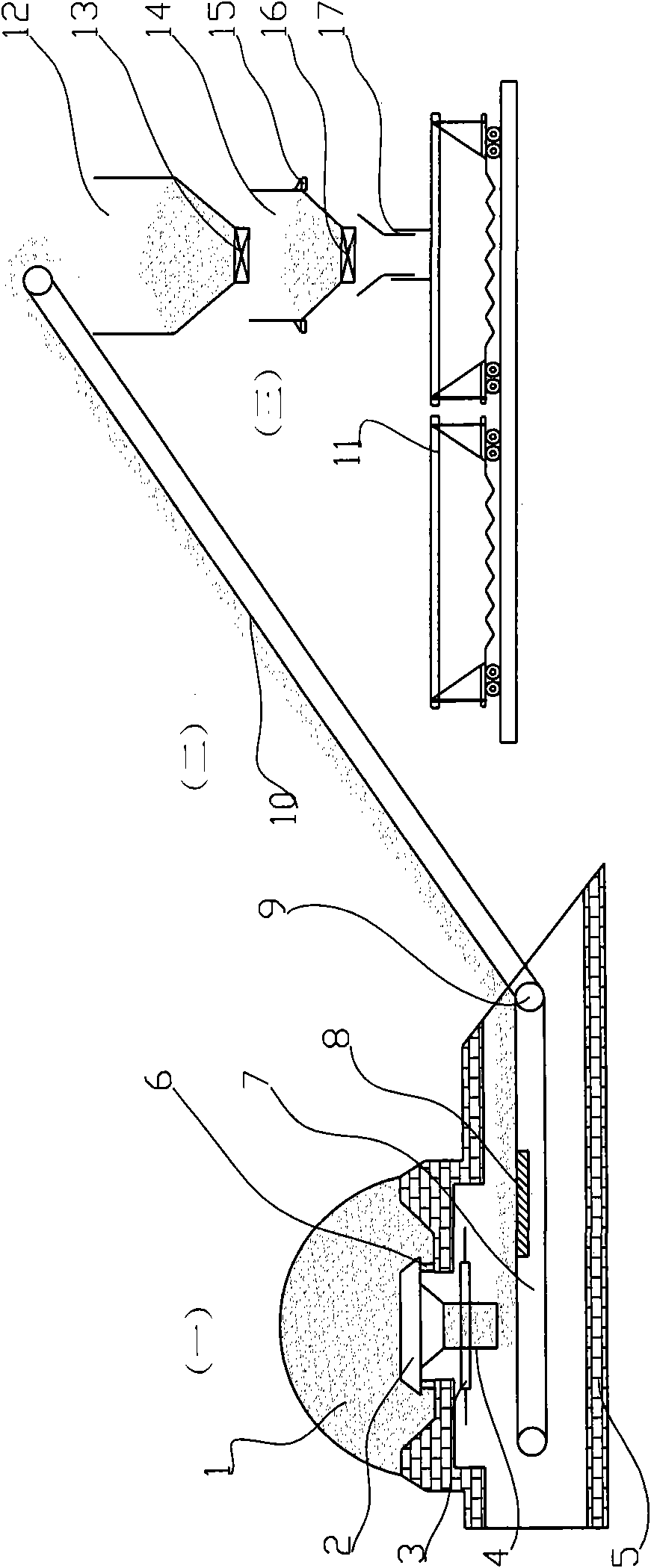

Method and system for transporting and loading bulk materials in storage yard

ActiveCN101786553ANo splashHigh measurement accuracyWeighing apparatus for continuous material flowLoading/unloadingTransport systemUnderground tunnel

The invention particularly relates to a method and a system for transporting and loading bulk materials in a storage yard, which are suitable for bulk material accurate loading of railways, public roads and ships. The invention comprises a storage yard transporting system, a belt transport system and an accurate and rapid quantitative loading system. The invention provides an economical and effective transporting and loading system for bulk materials in a storage yard, which has the following advantages: 1) the storage yard transport system combing a disc vibrating feeder with a low clearance flow control gate is adopted, thus greatly lowering the upper height of an underground tunnel and improving the capability of transporting the materials in the storage yard; 2) the accurate and rapid quantitative loading system is adopted, thus having the characteristics of rapid loading speed, high loading precision and high automation degree; and 3) a four-roller belt weigher is adopted, thus realizing the linkage of the storage yard transport system, the belt transport system and the accurate and rapid quantitative loading system effectively and greatly improving the operation efficiency of the system.

Owner:BIRTLEY TIANJIN IND EQUIP

Austenitic stainless steel gas shield welding wire for vehicle

ActiveCN101100021AExcellent rolling and wire drawing propertiesGood welding performanceWelding/cutting media/materialsSoldering mediaIn vehicleWeld seam

The present invention relates to austenitic stainless steel welding wire for gas protected welding in vehicle. The austenitic stainless steel welding wire has the chemical composition comprising C not more than 0.03 wt%, Si 0.50-0.90 wt%, Mn 1.00-2.50 wt%, P not more than 0.025 wt%, S not more than 0.015 wt%, Ni 9.0-14.0 wt%, Cr 19.5-24.5 wt%, and Fe and inevitable impurity for the rest. The austenitic stainless steel welding wire produced through smelting, rolling, drawing and other steps has excellent performance, including excellent welding performance, is applied for welding steel of 500-700 MPa strength to form weld seam with high strength, high toughness and high corrosion resistance.

Owner:哈焊所华通(常州)焊业股份有限公司

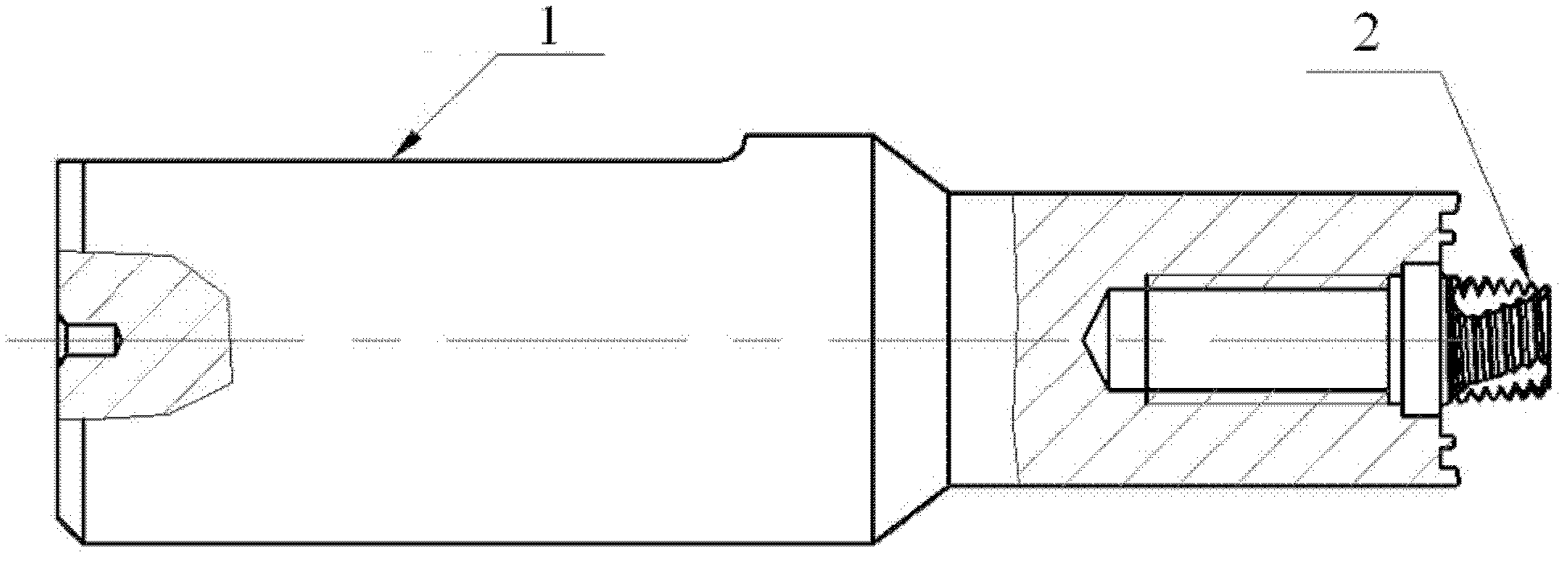

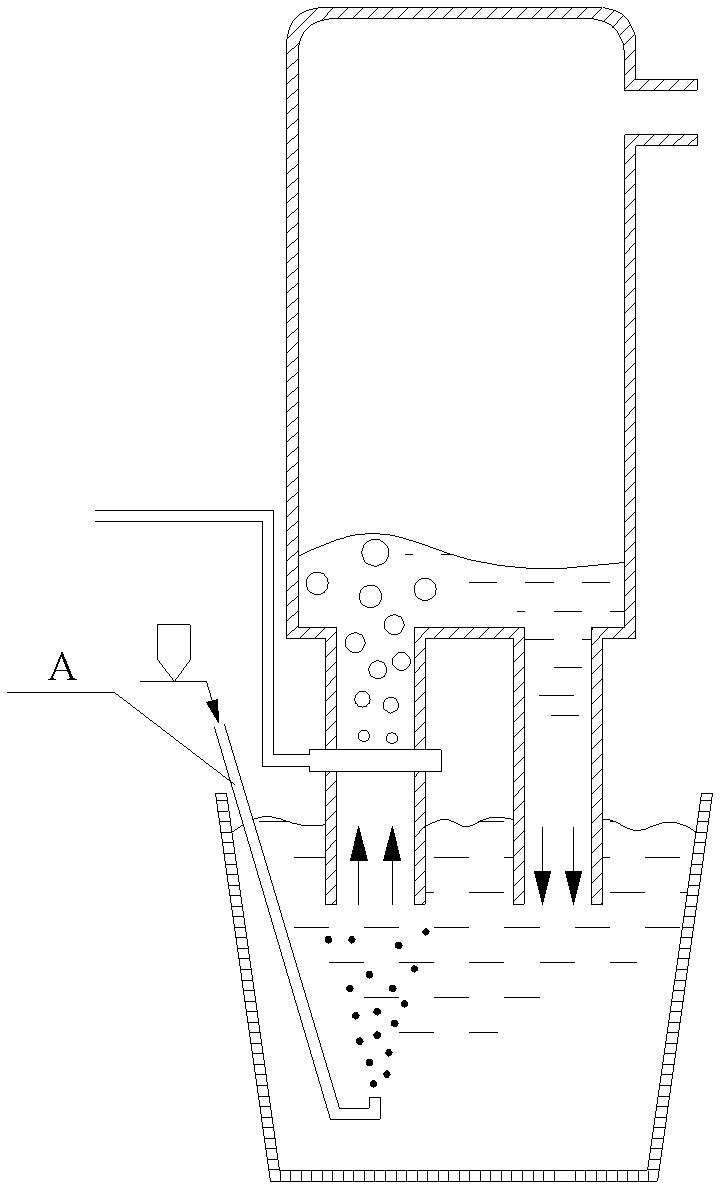

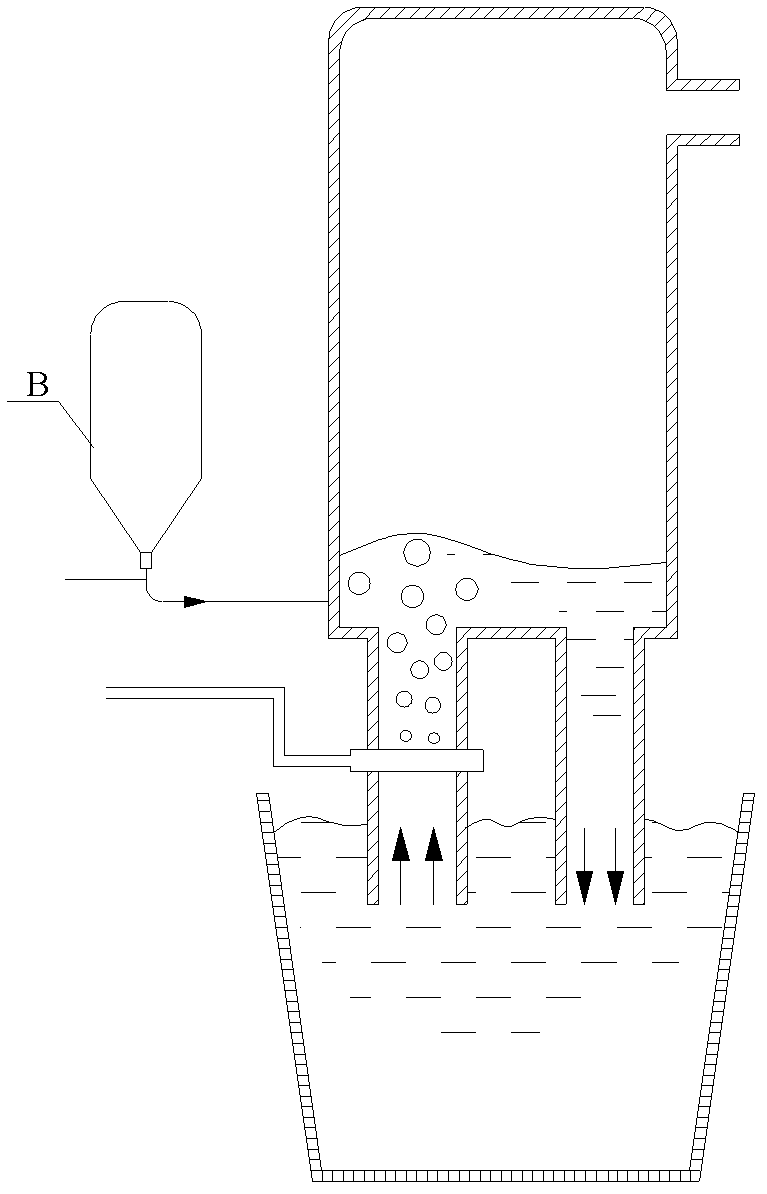

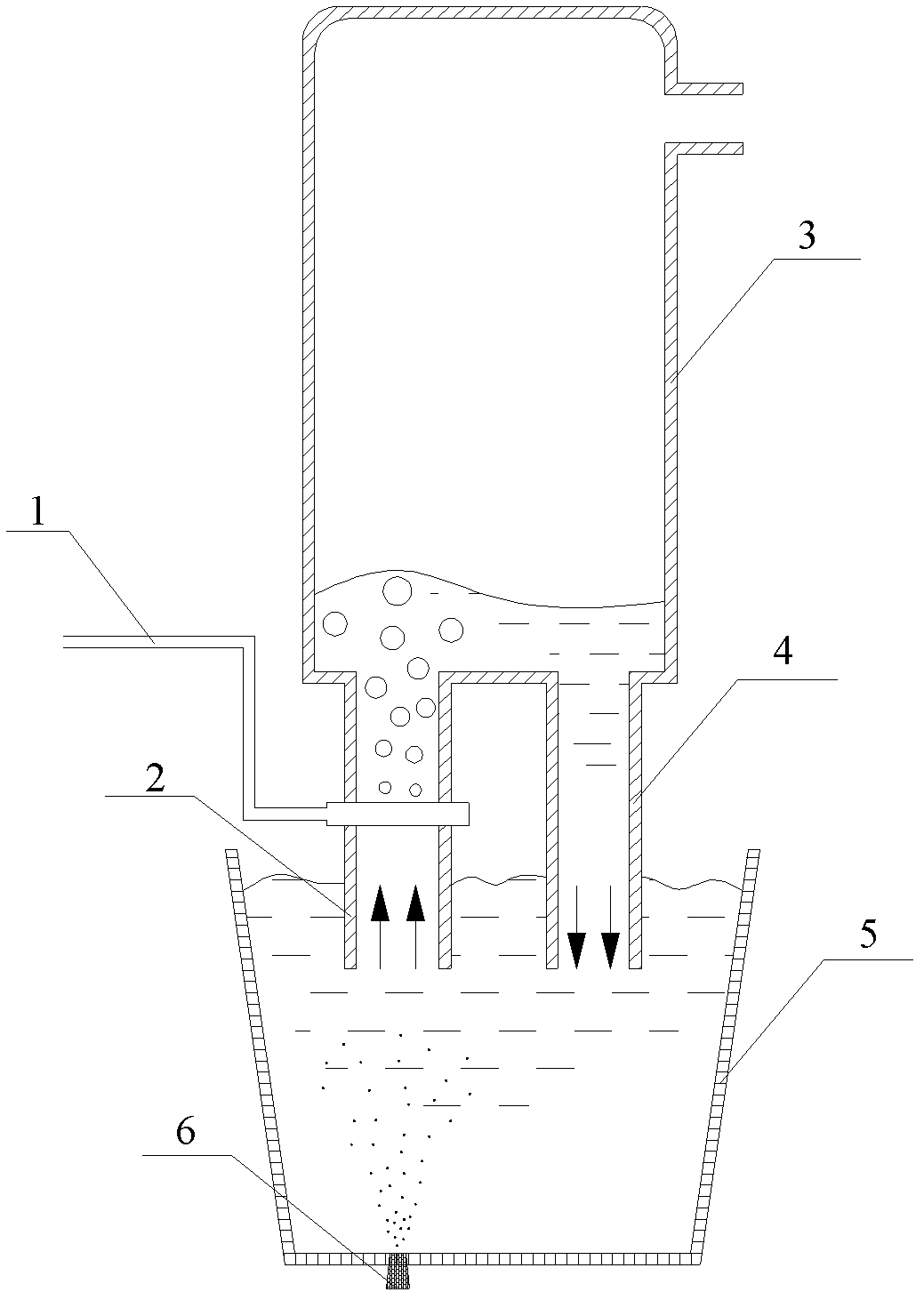

RH vacuum refining bottom blowing powder injection device

ActiveCN102560009ASolve easy blockageImprove product qualityCharge manipulationMetallurgyWater circulation

The invention relates to an RH vacuum refining bottom blowing powder injection device. The device comprises a driving gas system, a vacuum chamber, a steel ladle and a bottom blowing powder injection member, wherein the vacuum chamber is formed above the steel ladle; the driving gas system comprises a driving gas channel and an air compressor connected with the driving gas channel; an ascending pipe and a descending pipe are arranged at the bottom of the vacuum chamber and stretch into molten steel; the driving gas channel is communicated with the ascending pipe; the bottom blowing powder injection member comprises a powder injection element and a gas storage chamber; a steel sleeve is sleeved outside the powder injection element; the gas storage chamber is fixed below the powder injection element; a powder gas flow conveying pipe at the port of the gas storage chamber is connected with a powder injection system; a gap is formed on the powder injection element; one or two bottom blowing powder injection members are arranged at the bottom of the steel ladle; the distance between the bottom blowing powder injection member and the center of the bottom of the steel ladle is 0 to 0.9 time the radius of the bottom of the steel ladle; and the powder injection element penetrates through the bottom of the steel ladle. The device enhances a stirring effect and improves the quality of steel by combining vacuum refining, molten steel circular flow and bottom blowing powder injection refining.

Owner:NORTHEASTERN UNIV

Microtitanium-boron high-toughness gas protective welding stick

InactiveCN1328897AGood workmanshipStable welding arcWelding/cutting media/materialsSoldering mediaAlloyTitanium

The present invention relates to a micro titanium-boron high-toughness gas shielded welding wire, its chemical components (wt.%) are: C 0.03-0.10, Mn 1.00-1.80, Si 0.20-1.00, Ni 0.50-1.40, Ti 0.10-0.20, B 0.002-0.010, S less than or equal to 0.10, P less than or equal to 0.20 and the rest being Fe and other unavoidable impurity. When the welding wire is used to make protective welding by adopting mixed gas (80% Ar+20% CO2), the wield metal tensile strength is greater than or equal to 580 Mpa, -30 deg.C impact work Akv is greater than or equal to 80J, and it adapts to all-position welding. This invented welding wire possesses excellent processing property, and is suitable for gas protective arc welding of large-type structures of 600 MPa level low-alloy high strength steel, engineering machine, railway bridge, marine installation, high-pressure container and oil-gas transmission pipeline, etc.

Owner:武钢集团有限公司

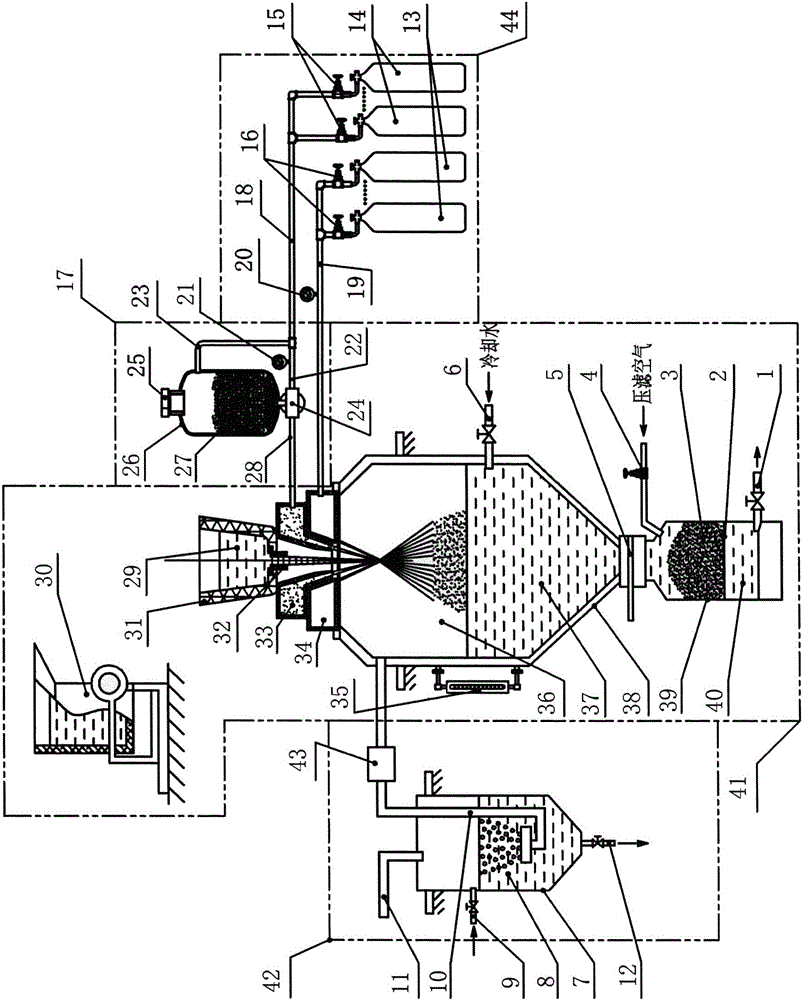

Free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment

The invention provides free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment which comprises a double-nozzle atomizing and water cooling device (41), a spiral mixed powder conveying device (17), a water seal dust removing device (42) and a gas station (44). In the atomizing process, a low-pressure mixed powder jetting nozzle and a high-pressure gas flow nozzle are adopted, and therefore the problem that when a single nozzle is used, erosive wear is caused is solved; a free-falling manner is adopted, and therefore the problems that erosive wear to a molten metal flow guide pipe is caused and molten metal flows back and is sprayed upwards are avoided; a cooling manner of water cooling and fast setting is adopted, the problem that hard abrasive particles drift away from a metal matrix and the problem of control over the depth of distribution are solved, and hard abrasive is controlled to be distributed on a surface shallow layer of the magnetic abrasive; meanwhile, the flight distance of powder mixed molten metal drops is shortened, and the overall height of the free-falling atomizing and condensing chamber and equipment is reduced. The equipment is new equipment provided for realizing a free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method and preparing the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

Holder adhesive for cellulose acetate cigarette tipping paper

InactiveCN105018004APromote wettingLarge wet tackMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEmulsionPlasticizer

The invention discloses a holder adhesive for cellulose acetate cigarette tipping paper. The holder adhesive is prepared from 70-90% of a VAE emulsion and 10-30% of an additive, and the additive comprises polyvinyl alcohol, a plasticizer, a tackifier, an antifoaming agent and a bactericide. The holder adhesive has the characteristics of environmental protection, no boric acid, excellent wet viscosity, excellent in-machine stability, and realization of clean running of a machine.

Owner:CHINA TOBACCO YUNNAN IND

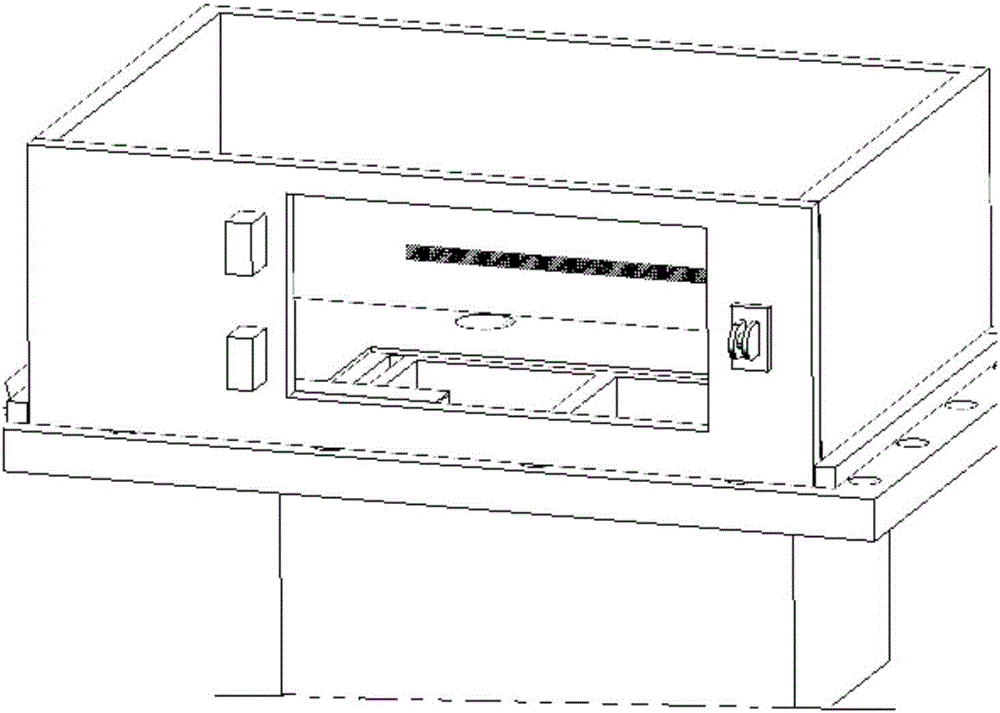

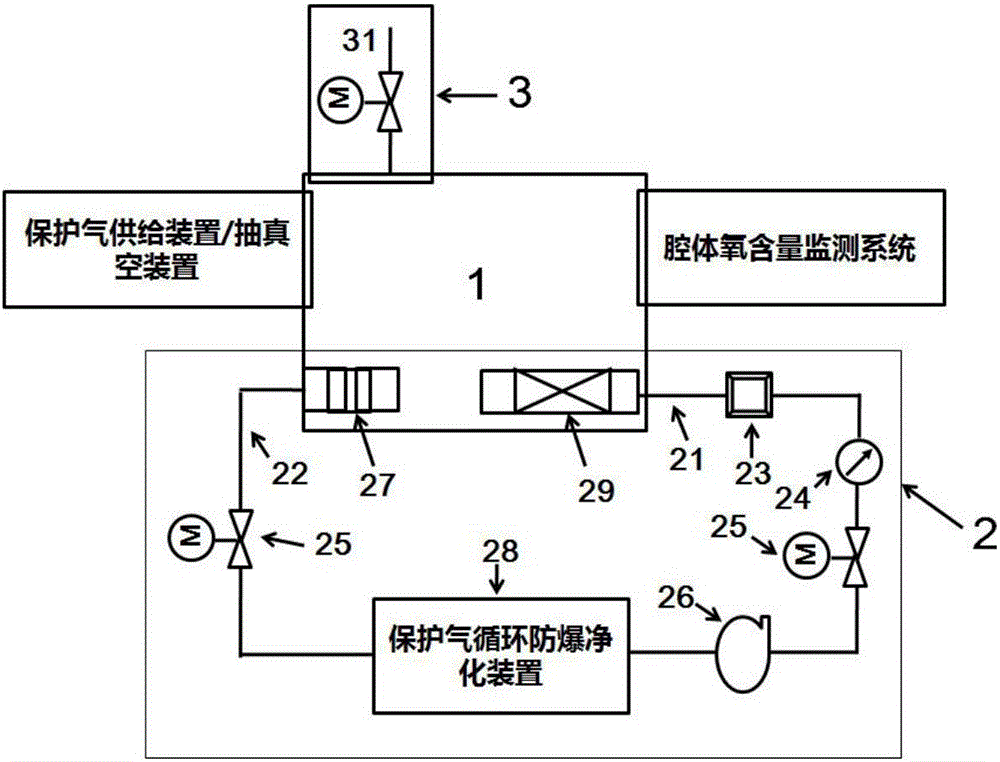

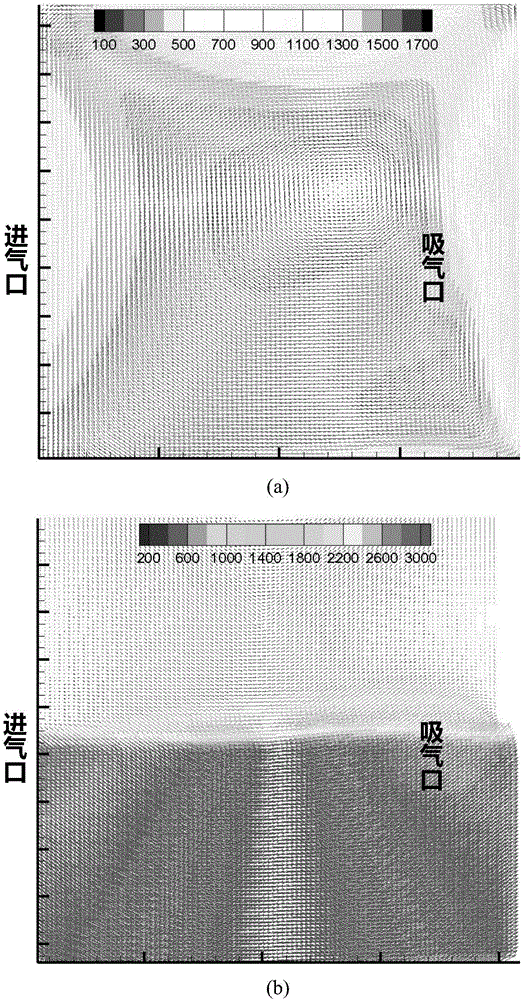

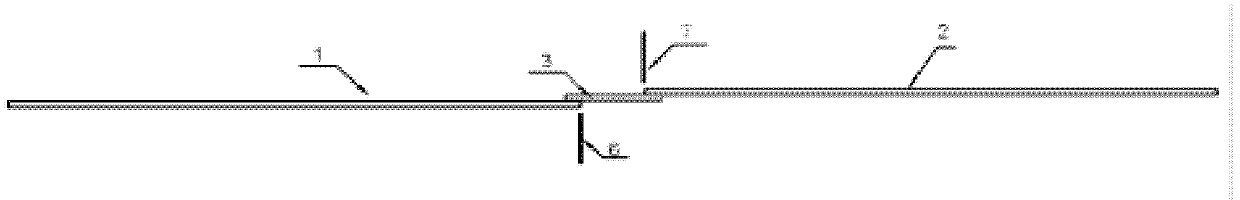

Shielding gas circulating filtration device for 3D printing metal powder bed forming cavity and optimization method of shielding gas circulating filtration device

ActiveCN106513674AEasy accessImprove cleanlinessAdditive manufacturing apparatusIncreasing energy efficiencyFiltrationCarbon Dioxide / Helium

The invention discloses a shielding gas circulating filtration device for a 3D printing metal powder bed forming cavity and an optimization method of the shielding gas circulating filtration device. According to the optimization method, the vertical movement distance z of processed smoke is adjusted and is not larger than the height h of an air suction flow guiding channel, and accordingly the purposes that the processed smoke is completely captured by the air suction flow guiding channel, and the pressure from an air inlet flow dividing port to an air suction flow guiding port in the forming cavity is gradually reduced are achieved; and a machined metal part has the beneficial effects of being good in surface quality, high in density, good in mechanical performance and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal

InactiveCN103372710AContinuous moldingUniform shapeArc welding apparatusWelding/cutting media/materialsShielding gasAluminum metal

Disclosed is a cold metal transition melting-brazing welding connection method for dissimilar magnesium metal and aluminum metal. Cold metal transition welding is adopted, argon is adopted as protecting gas, transition metal is a galvanized steel sheet, two types of welding wires are adopted, an aluminum-silicon welding wire is adopted on the aluminum side, and a magnalium zinc welding wire is adopted on the magnesium side. A welding gun is utilized to align to an aluminum edge and a magnesium edge, high-melting-point transition metal is clamped between magnesium and aluminum to stop mutual contact of liquid magnesium and liquid aluminum, so that melting-brazing welding connections between a magnesium melting welding joint and the transition metal (the galvanized steel sheet) as well as between an aluminum melting welding joint and the transition metal (the galvanized steel sheet) are realized, and connection of dissimilar metal between an aluminum alloy sheet and a magnesium alloy sheet is realized finally.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Low-hydrogen super diphasic stainless steel electrode

InactiveCN101367161AArc stabilizationWell formed weldWelding/cutting media/materialsSoldering mediaPotassium feldsparFerrosilicon

The invention discloses a low-hydrogen type super duplex stainless steel welding rod. The prior duplex stainless steel wire is adopted as a welding core. The coating of the welding rod comprises the compositions in percentage by weight: 35 to 45 percent of marble, 20 to 33 percent of fluorite, 0 to 5 percent of titanium pigment, 2 to 5 percent of potassium feldspar, 0 to 2 percent of sodium carbonate, 5 to 15 percent of iron alloy, 10 to 20 percent of metal powder, and 0 to 2 percent of CrN iron, wherein the iron alloy consists of ferrosilicon and ferromolybdenum under the condition of constant total content, and the metal powder consists of manganese metal, chromium metal, and nickel powder under the condition of the constant total content. After raw materials of the compositions of the coating are mixed evenly, pure sodium water glass with certain Baume concentration is added, and the pressing of the welding rod is performed on welding rod production equipment. The use of the welding rod can satisfy the welding need of super duplex stainless steel in the national engineering construction, the welded welding seam has excellent mechanical property and good corrosion resistance, the tensile strength can reach 800MPa, and the welding rod has good low-temperature toughness.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

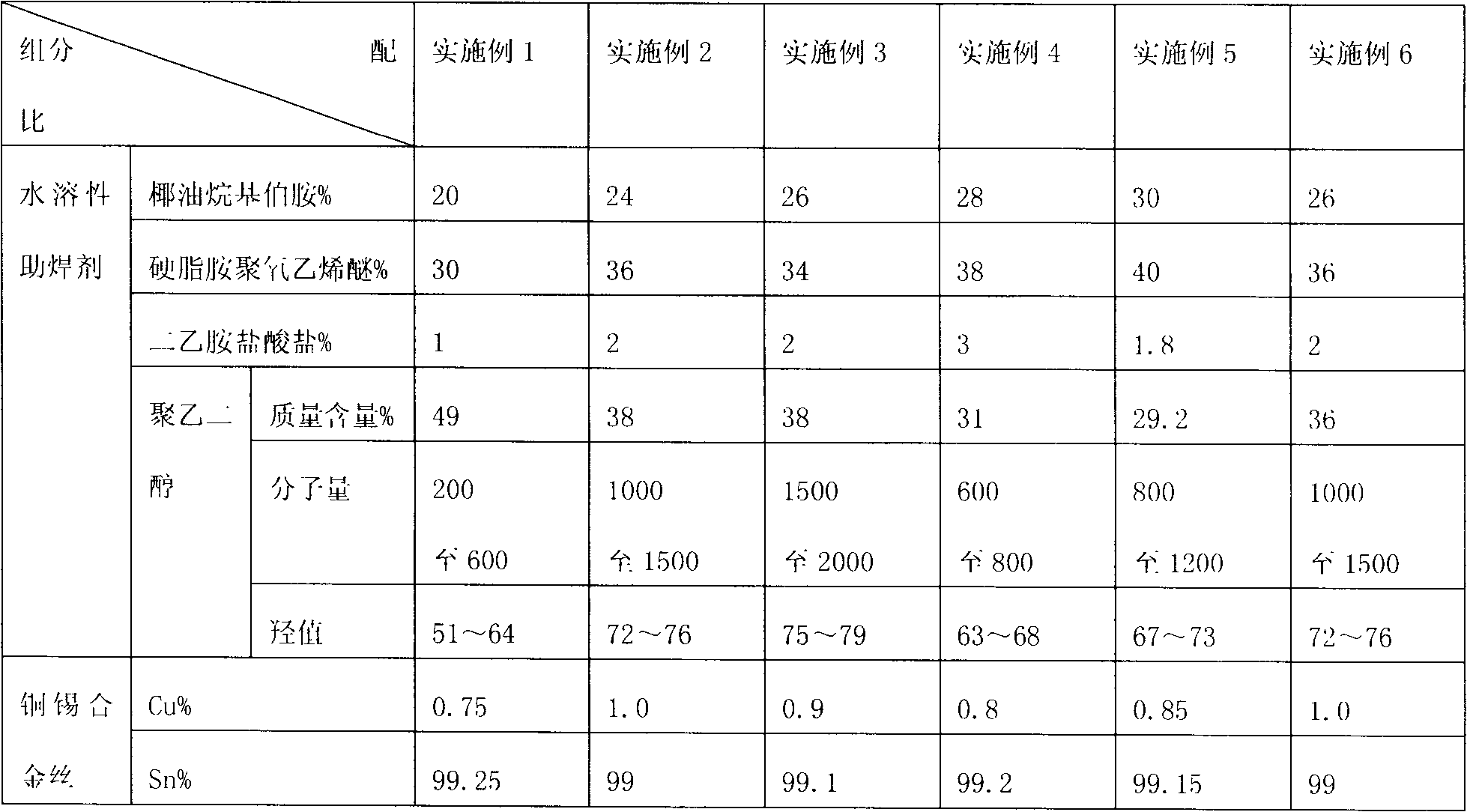

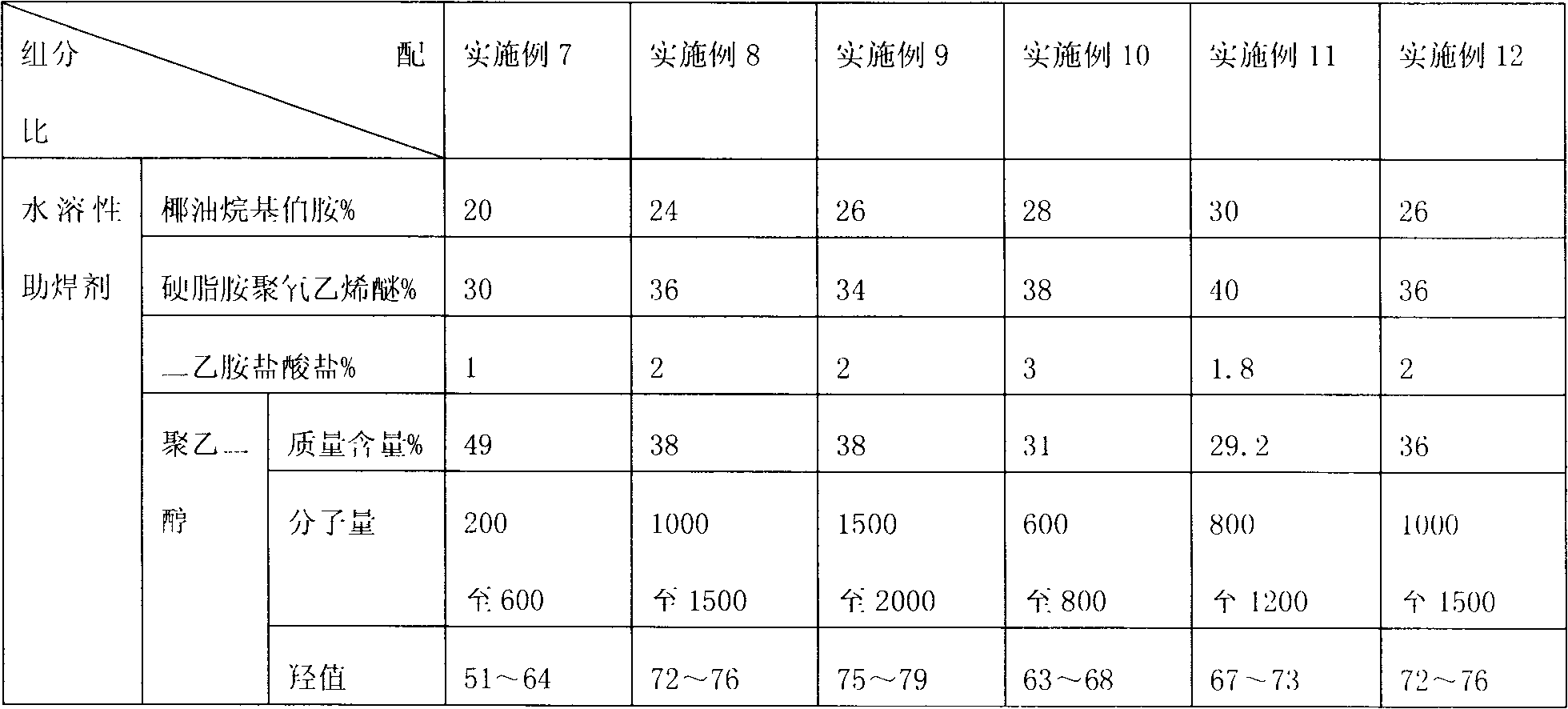

Lead-free welding tin wire and water-soluble welding flux used by same

ActiveCN102161135AReduce pollutionReduce interfacial tensionWelding/cutting media/materialsSoldering mediaPolyethylene glycolAlloy

The invention discloses a lead-free welding tin wire and a water-soluble welding flux used by the same. The lead-free welding tin wire comprises a copper-tin alloy wire provided with a hole cavity and the water-soluble welding flux arranged in the hole cavity; the proportion of the copper-tin alloy wire and the water-soluble welding flux is as follows: 2.0-2.2wt% of the water-soluble welding fluxand the balance of the copper-tin alloy wire, wherein the copper-tin alloy wire comprises the following components: 0.75-1.0wt% of Cu and the balance of Sn; the water-soluble welding flux comprises the following components: 20-30wt% of coconut oil alkyl carbinamine, 30-40wt% of octadecyl amine polyoxyethylene ether, 1-3wt% of diethylammonium chloride and the balance of water-soluble macromoleclarpolymer; the ammonium salt halogenide is diethylammonium chloride; and the water-soluble macromoleclar polymer is polyethylene glycol with the molecular weight of 200-2000. The lead-free welding tin wire provided by the invention has better welding performance and the water-soluble welding flux provided by the invention has better wettability.

Owner:浙江强力控股有限公司

Sleeve-friendly wear-resistant strip flux-cored wire

InactiveCN101524789AImprove the safety of useHigh hardnessWelding/cutting media/materialsSoldering mediaElectrolysisIron powder

A sleeve-friendly wear-resistant strip flux-cored wire belongs to the welding field of material processing project. The aim of the invention is to settle the problem of wearing on the sleeve by the wear-resistant strip. The sleeve-friendly wear-resistant strip flux-cored wire provided by the invention adopts steel strip for packaging the flux core powder which accounts for 22-37% of total weight of flux-cored wire. The flux core powder comprises the following substances by mass percent: 10-30% of high carbon ferro-chrome, 8-17% of ferroboron, 0.5-4% of ferromolybdenum, 5-10% of nickel powder, 1-3% of low carbon ferrosilicium, 2-8% of medium-carbon ferromanganese and the balance of electrolytic iron powder. The preparing method of the invention adopts the prior art. The sleeve-friendly wear-resistant strip flux-cored wire provided by the invention can effectively increase the using safety of wear-resistant strip, reduce the wearing on the sleeve and prolong the lifetime of drill pipe.

Owner:BEIJING GABBARD ENG & TECH

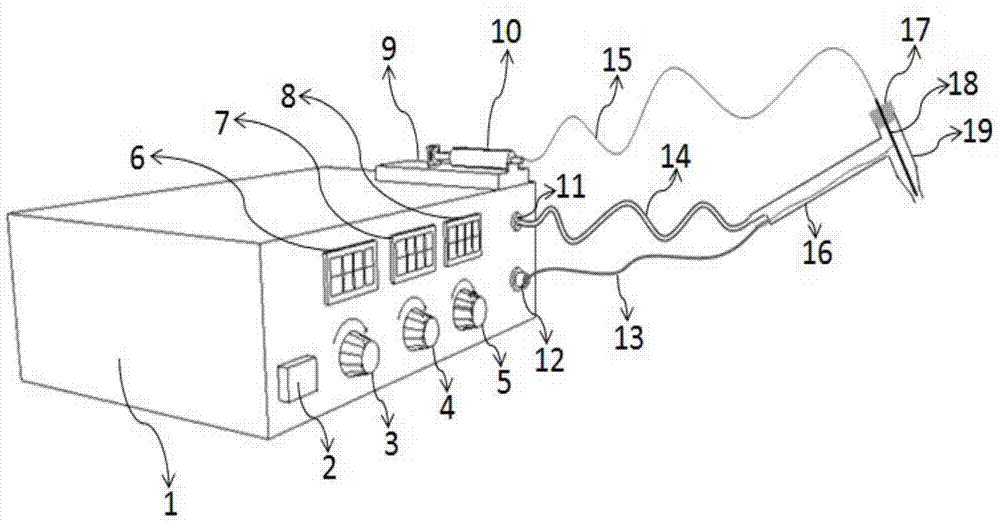

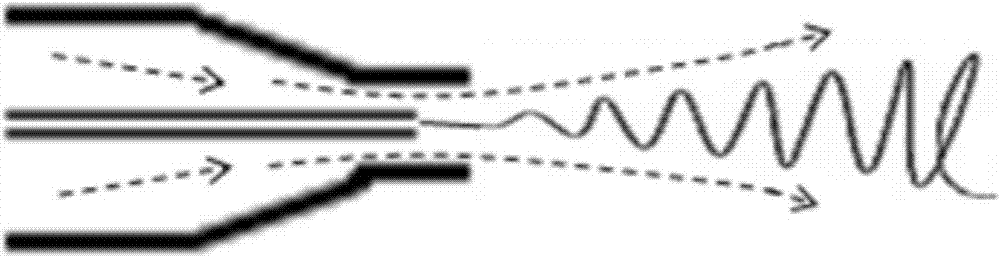

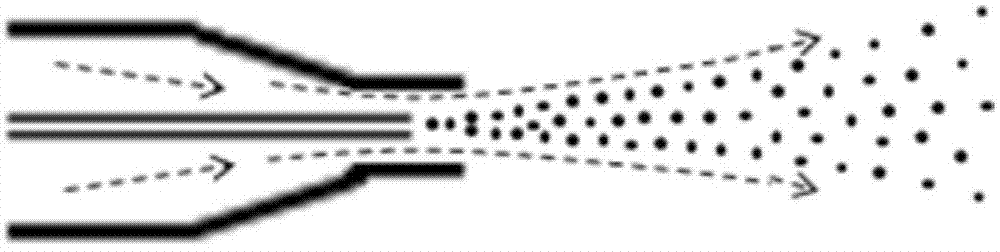

Airflow-guide-type directional in-situ electrostatic spraying device

InactiveCN103611206AAchieve orientationDirectional in-situ electrostatic spraying realizationMedical applicatorsMedical atomisersDrugs solutionSprayer

The invention discloses an airflow-guide-type directional in-situ electrostatic spraying device which comprises a spray gun, an injector and a high-voltage electrostatic generator. The spray gun comprises a spray gun handle and a spray gun pipe, a hollow metal capillary pipe coaxial with a spray gun sprayer is arranged in the spray gun pipe and communicated with the injector through a liquid incoming pipe, an annular passage formed between the spray gun pipe and the metal capillary pipe is an airflow passage, communicated with the spray gun handle and communicated with an airflow guide pipe through the spray gun handle, and a pipe cavity of the metal capillary pipe is connected with the high-voltage electrostatic generator through a guide line. Airflow of the airflow passage plays a role in orientation and constraining, ring wrapping effect and faraday cage effect are weakened, a spraying area is limited within a very small range, orientation and fixed-point spraying, of a drug solution, in a specific area are realized, and the drug solution is almost free of splashing, thereby being high in utilization rate and having better treatment effect.

Owner:QINGDAO XINZHIYUAN HEALTH TECH

Concurrent measuring method for multiple metallic elements in transformer oil

ActiveCN101221127AAccelerate oil deteriorationImprove safe operationPreparing sample for investigationAnalysis by material excitationDirect readingEnvironmental geology

The invention relates to a method for simultaneously determining various metal elements in transformer oil. An analyzing sample of the transformer oil of the invention is weighed quantificationally after a collected oil sample is heated and stirred uniformly; an infrared heating method is adopted for carrying out vaporizing and carbonizing at constant temperature on the analyzing sample of the quantificational transformer oil, a box type high temperature furnace is adopted for carrying out high temperature cineration on the carbonized sample, acid liquid is adopted for carrying out dissolving on the incinerated sample under the lower temperature heating condition, a soluzione leggermente acida is adopted for carrying out diluting and volume fixing on the dissolved sample to be prepared into analyzing liquid. The analyzing liquid accurately determines the content of various metal elements by using a complete spectrum direct reading plasma emission spectrum apparatus. The method of the invention can determine a plurality of elements and has high accuracy, can determine oil mediums with different varieties and content ranges, being capable of accurately showing the change current of the metals in the oil mediums and being convenient for accurately analyzing and finding out hidden troubles in time.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

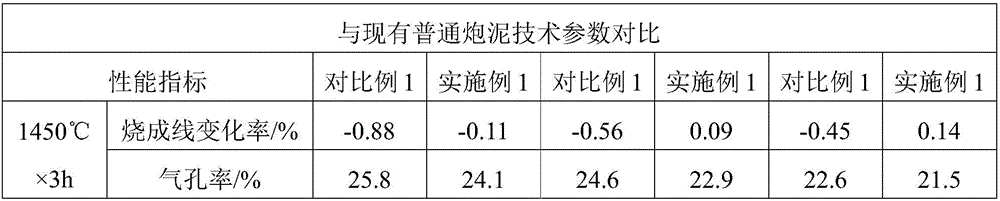

Anhydrous stemming for large and medium sized blast furnace and preparation method of anhydrous stemming

The invention relates to an anhydrous stemming for a large and medium sized blast furnace and a preparation method of the anhydrous stemming. The stemming comprises the raw materials of bauxites aggregate and fine powder, silicon carbide aggregate and fine powder, coke, plastic clay powder, asphalt powder and a micro powder additive, the micro powder additive comprises metallic silicon powder, metallic aluminum powder, high-carbon resin powder, alumina micro powder, silica fume, sodium carboxymethyl cellulose and sodium hexametaphosphate in parts by weight, and tar is taken as a binding agent in the producing and stirring processes. The anhydrous stemming realizes high-temperature rapid sintering of the stemming, the binding degree of new and old stemming is strengthened, the capability of resisting scouring of an iron slag of a mud drum of an iron notch is improved, the porosity of the stemming material is low, the compactness of the stemming material is good, the property of resisting corrosion and permeation of an iron slag liquid of the stemming is strengthened, the stemming is favorable for keeping the depth of the iron notch and the stability of the pore size of the iron notch, and can well adapt to the performance requirement of enlargement of the blast furnace on the stemming of the iron notch.

Owner:CHINA JINGYE ENG +1

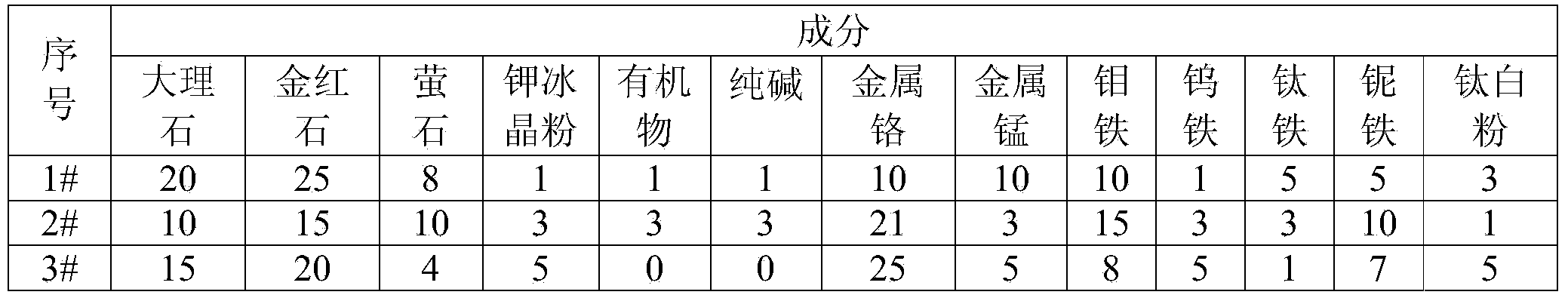

Lime-titania type nuclear power nickel base covered electrode coating and preparation method thereof

ActiveCN102773635ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaSolid componentNuclear power

The invention relates to a lime-titania type covered electrode coating in the welding technical field, in particular to a covered electrode coating used for a nickel base material Inconel 690 in nuclear power equipment. The covered electrode coating comprises solid components of, by mass, 12-20% of marble, 6-10% of fluorite, 35-42% of artificial rutile, 2-4% of titanium dioxide, 2-5% of feldspar, 8-15% of manganese metal, 3-6% of ferrotitanium, 0-1% of soda, 0-1% of CMC, 1-3% of nickel powder, 5-8% of chromium metal and 5-8% of ferroniobium, and the powder of the components are evenly mixed to produce the covered electrode coating. By aid of the technical scheme, the problem of poor welding technology of the covered electrode caused by low melting point, large metal viscosity and the like of the nuclear power nickel base material is solved completely, and deposited metal of the covered electrode is provided with good mechanical properties.

Owner:POWERCHINA SPEM CO LTD +1

Low-alloy steel covered arc welding electrode with Cr control capacity and FAC resisting capacity of weld metal of basic slag system

InactiveCN102658442AEasy to operateSimple welding processWelding/cutting media/materialsSoldering mediaSlagUltimate tensile strength

The invention relates to a low-alloy steel covered arc welding electrode with Cr control capacity and FAC resisting capacity of a weld metal of a basic slag system. The low-alloy steel covered arc welding electrode comprises a core wire and a coating, wherein the core wire comprises the following components in percent by mass: 0-0.10 percent of C, 1.00-1.60 percent of Mn, 0-0.50 percent of Si, 0.15-0.35 percent of Cr, 0.60-1.20 percent of Ni, 0.15-0.35 percent of Mo, 0-0.007 percent of Ti, 0-0.010 percent of S and 0-0.015 percent of P. The low-alloy steel covered arc welding electrode has better welding process property in a welding process; and a weld has properties such as better strength, impact flexibility and FAC resistance.

Owner:POWERCHINA SPEM CO LTD +1

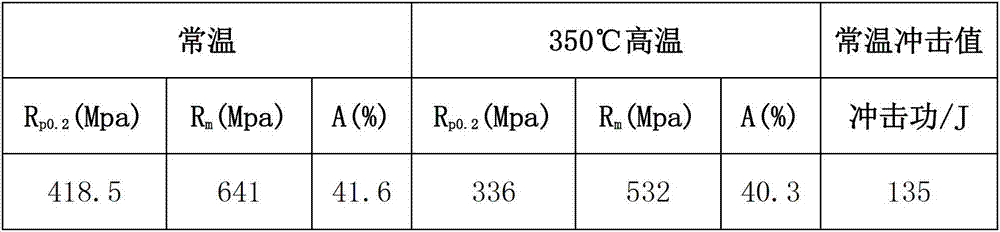

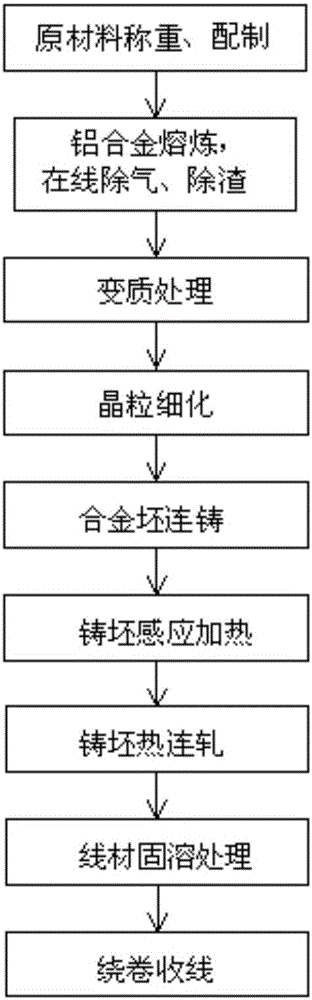

Continuous casting and rolling method for ZL114A welding wire rods

InactiveCN106244861AEasy to detectFor precise controlMetal rolling arrangementsWire rodSolution treatment

The invention belongs to the field of technical processes for cast aluminium alloys, and specifically relates to a continuous casting and rolling method for ZL114A welding wire rods. The method comprises the following steps: raw material weighing and preparation; aluminium alloy smelting, and online degassing and deslagging; modification treatment; grain refinement, alloy blank continuous casting; casting blank induction heating; casting blank hot-continuous rolling; wire solution treatment; and wire winding. The method disclosed by the invention overcomes the shortages of the prior art; online detection and accurate control can be realized for the chemical components of the produced aluminium alloy wire blanks; the alloy has a low hydrogen content inside and less inclusion, and is almost free from segregation; welding wires are good in welding manufacturability, and free from splashing and chip falling during a use process; welding arcs are stable; and welded joints have high interior quality and mechanical property.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Electric welding rod with novel slag system for welding 9Ni steel for storage tanks of LNG (liquefied natural gas) ships

ActiveCN103753051AGood mechanical propertiesMeet welding requirementsWelding/cutting media/materialsWelding/soldering/cutting articlesLiquefied natural gasElectric arc

The invention discloses an electric welding rod with a novel slag system for welding 9Ni steel for storage tanks of LNG (liquefied natural gas) ships. The electric welding rod comprises a core wire and a coating. The coating is coated on the surface of the core wire, the core wire comprises, (in wt%), lower than or equal to 0.02% of C, lower than or equal to 0.01% of S, lower than or equal to 0.01% of P, higher than or equal to 99.0% of Ni and lower than or equal to 0.50% of other elements, and the total quantity of various compositions of the core wire is 100%; the coating comprises, by weight, 10-20% of marble, 15-25% of rutile, 4-10% of fluorite, 1-5% of titanium dioxide powder, 1-5% of potassium cryolite powder, 10-25% of chromium metal, 3-10% of manganese metal, 8-15% of ferro-molybdenum, 1-5% of ferrotungsten, 1-5% of ferrotitanium, 5-10% of ferroniobium, 0-3% of organic matters and 0-3% of soda ash, and the total quantity of various powder compositions of the coating is 100%; the various powder compositions are proportionally uniformly mixed with water glass to obtain a mixture, the mass of the water glass accounts for 22%-30% of the total mass of the coating, the mixture is fed into an extrusion press and is coated on the core wire, and the mixture and the core wire are baked at a low temperature and then are baked at a high temperature to obtain the electric welding rod. The electric welding rod has the advantages that electric arcs are stable during welding, the electric welding rod is low in splashing and good in slag removing property, formed weld joints are attractive, and an all-position welding effect can be realized.

Owner:上海焊接器材有限公司

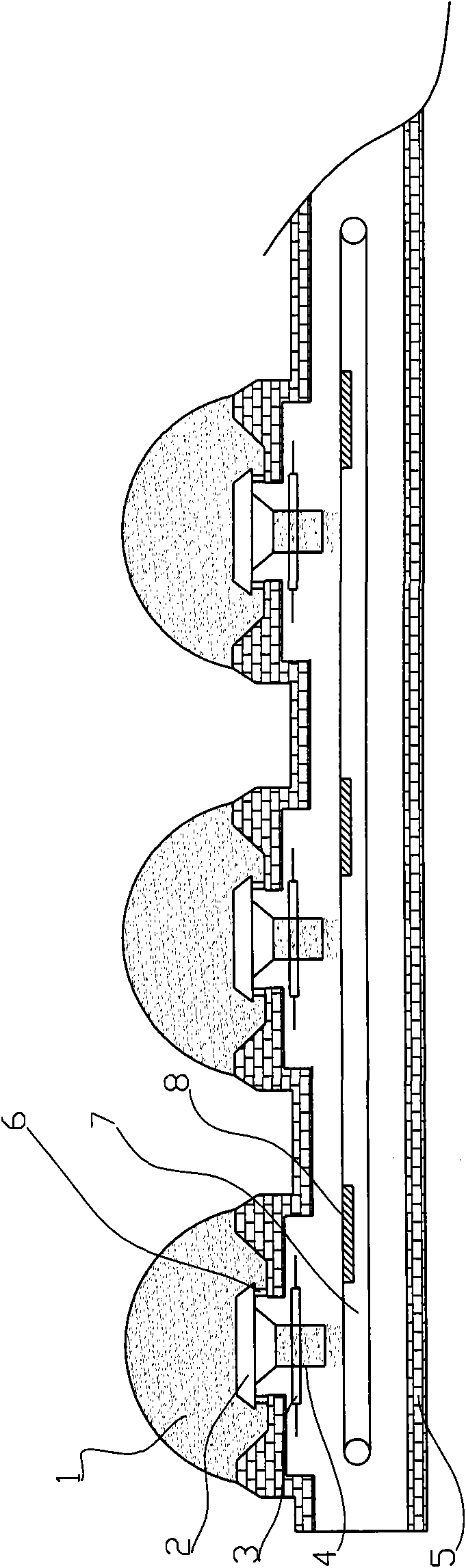

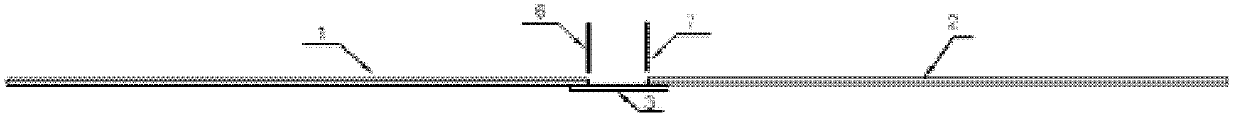

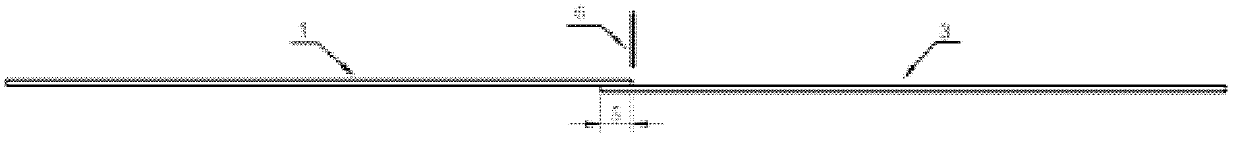

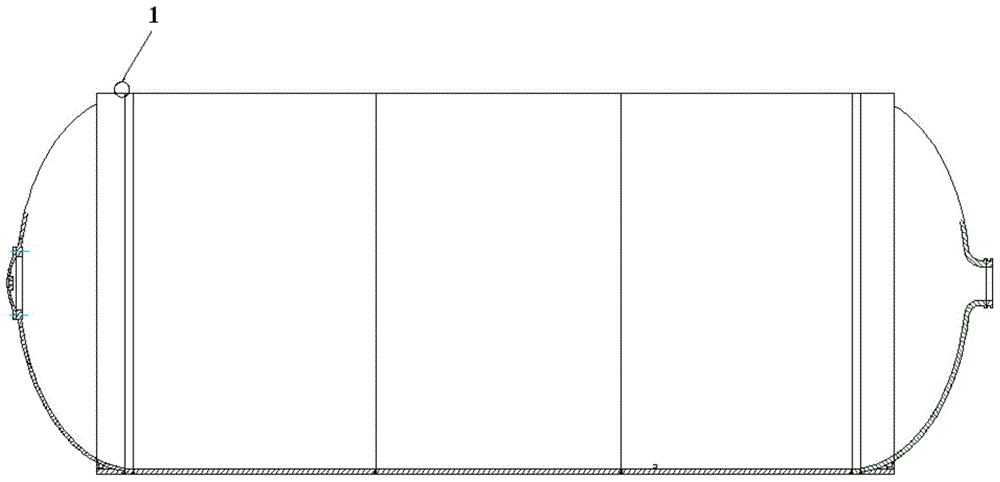

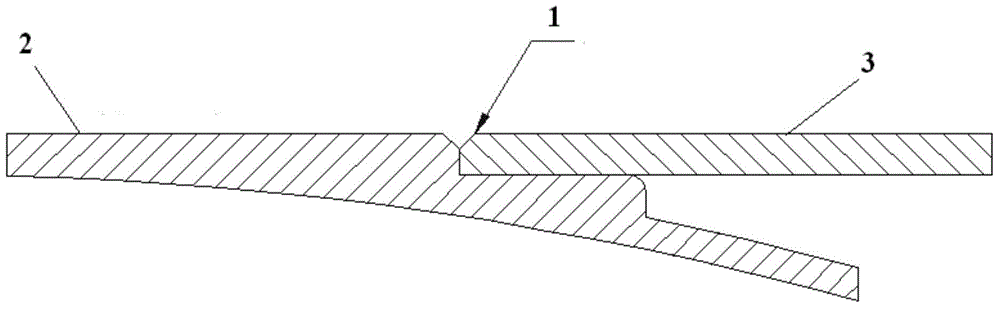

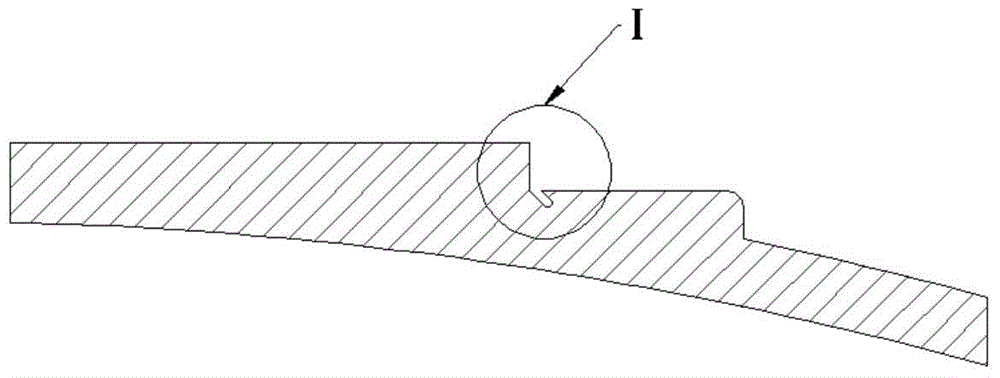

Friction stir welding method for lock bottom circular seam of carrier rocket storage tank

ActiveCN104439686AImproved consistency and stability of mechanical propertiesImprove performanceDomestic vesselsMetal working apparatusLap jointFusion welding

The invention belongs to welding methods, and particularly relates to a friction stir welding method for a lock bottom circular seam of a carrier rocket storage tank. The method comprises the following steps that firstly, welded parts are transformed, welding leakage grooves are formed in a tank bottom fork-shaped ring, and the welding leakage grooves are formed in the bottommost portion of a tank bottom fork-shaped circular welding seam; secondly, the welded parts are in lap joint, and the welded tank bottom fork-shaped ring is in lap joint with a short shell to form the welding joint; thirdly, welding is carried out, and welding is carried out along the welding joint through the friction stir welding manner. The method has the obvious advantages that nearly defect-free welding can be achieved, the consistency and stability of the mechanical property of the joint are obviously improved, and compared with a fusion welding lock bottom joint, the performance of the lock bottom circular seam is improved by about 20 percent to 30 percent.

Owner:CAPITAL AEROSPACE MACHINERY +1

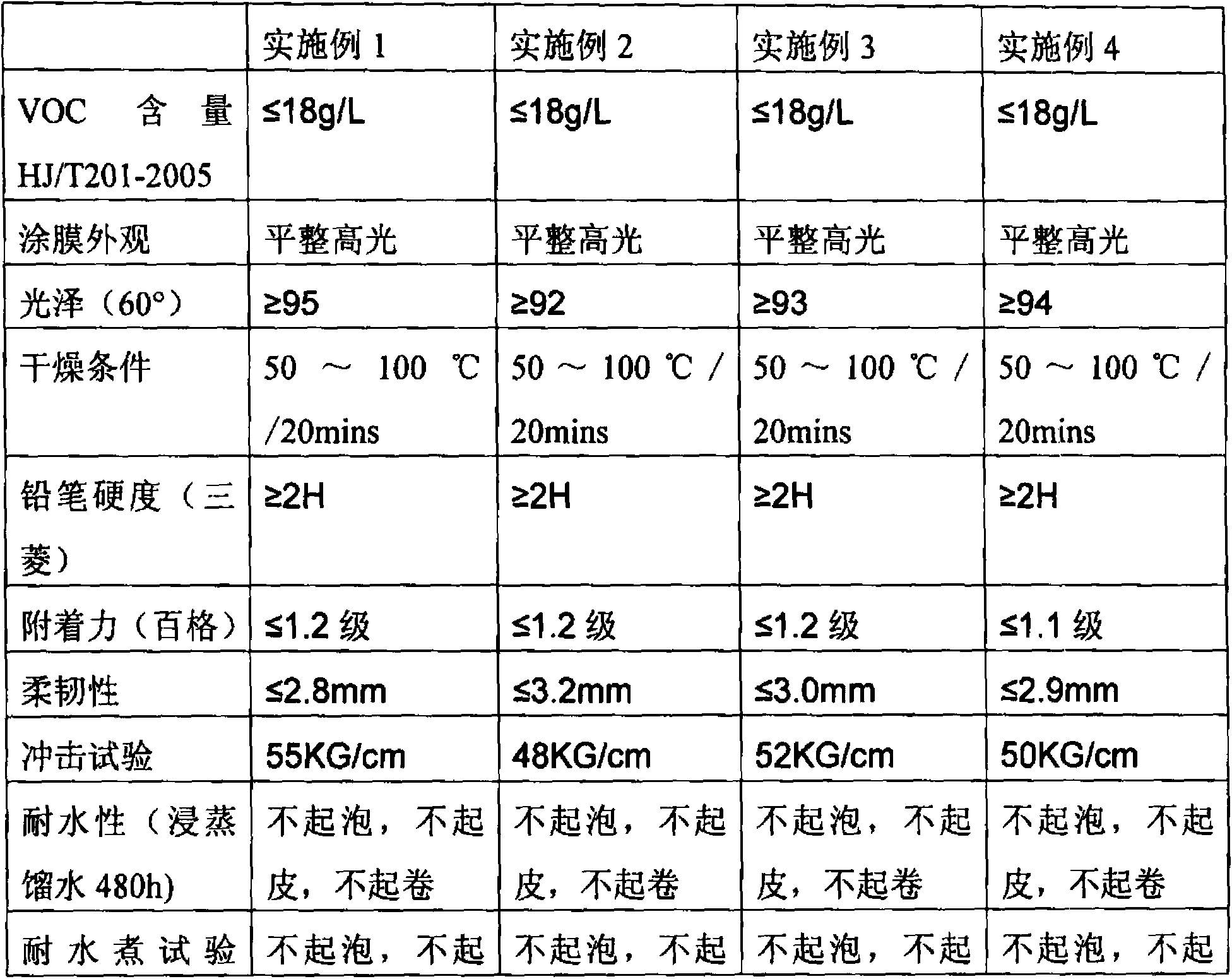

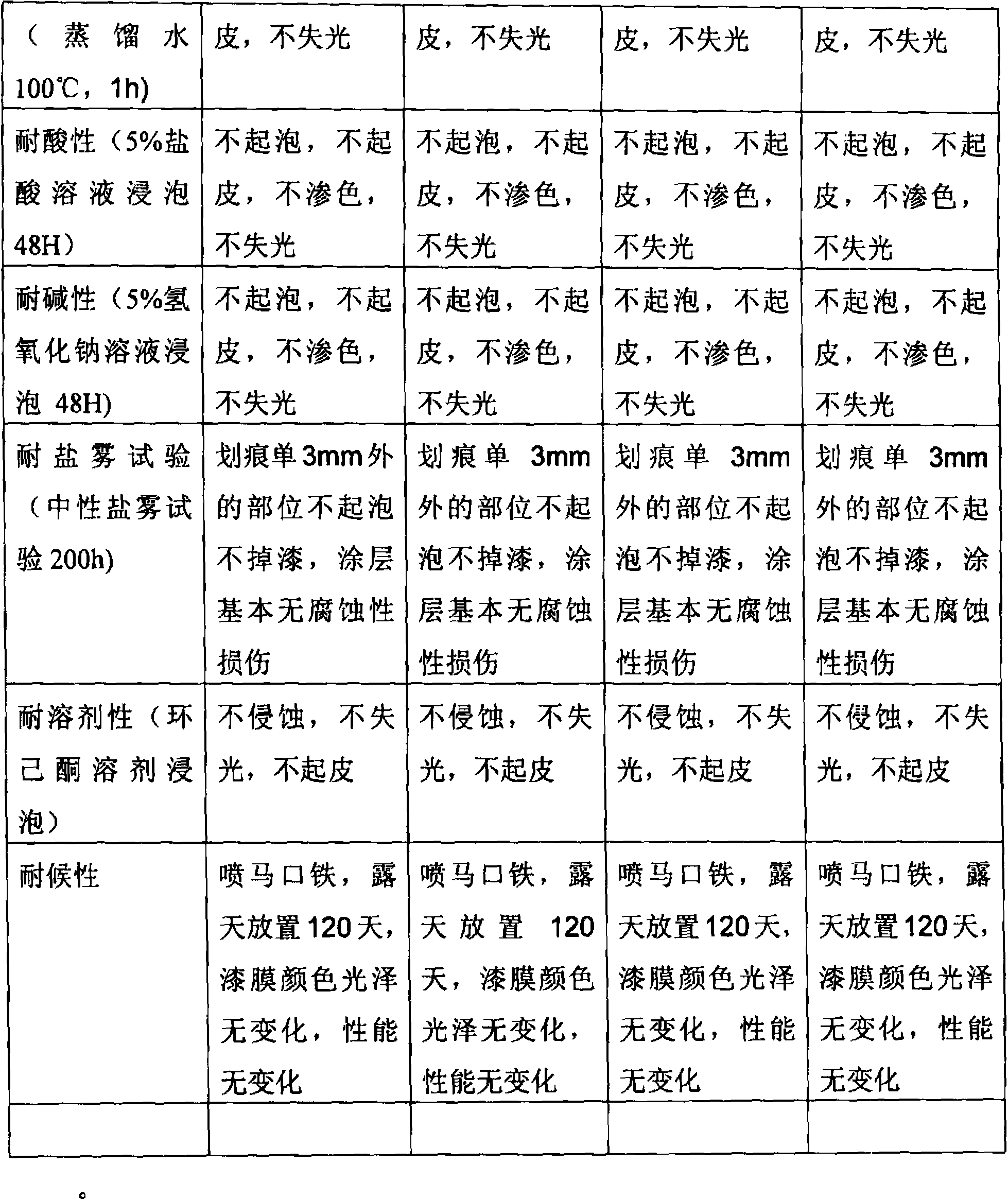

Environment-friendly water-based nano varnish and preparation method

InactiveCN104178013AGood weather resistanceGood compatibilityPolyurea/polyurethane coatingsWater basedState of art

The invention relates to environment-friendly water-based nano varnish and a preparation method thereof. The preparation method comprises the following steps: putting 10-30 parts by weight of water-based nano activation base material in a reaction kettle, slowly adding 1-5 parts by weight of coupling agents and 1-5 parts by weight of aids in sequence, standing for 8-48 hours for curing, and putting the obtained cured material, 50-70 parts by weight of emulsion and 10-30 parts by weight of water in an activation kettle to undergo group activating, crosslinking and grafting, thus obtaining a product under the conditions of nitrogen or argon protection, pressure of 0.1-3Mpa and activation time of 8-48 hours, wherein the temperature range of the activation kettle is controlled to be 30-80 DEG C. Compared with the prior art, the environment-friendly water-based nano varnish has the advantages of complete water-based environment-friendly system, no environmental pollution, complete water-based low-temperature self-drying system, no safety hazards such as burning and explosion, high adhesion to metal materials, good hardness, strong scratch resistance and the like.

Owner:JIANGSU MEIYICHEN NEW MATERIAL TECH

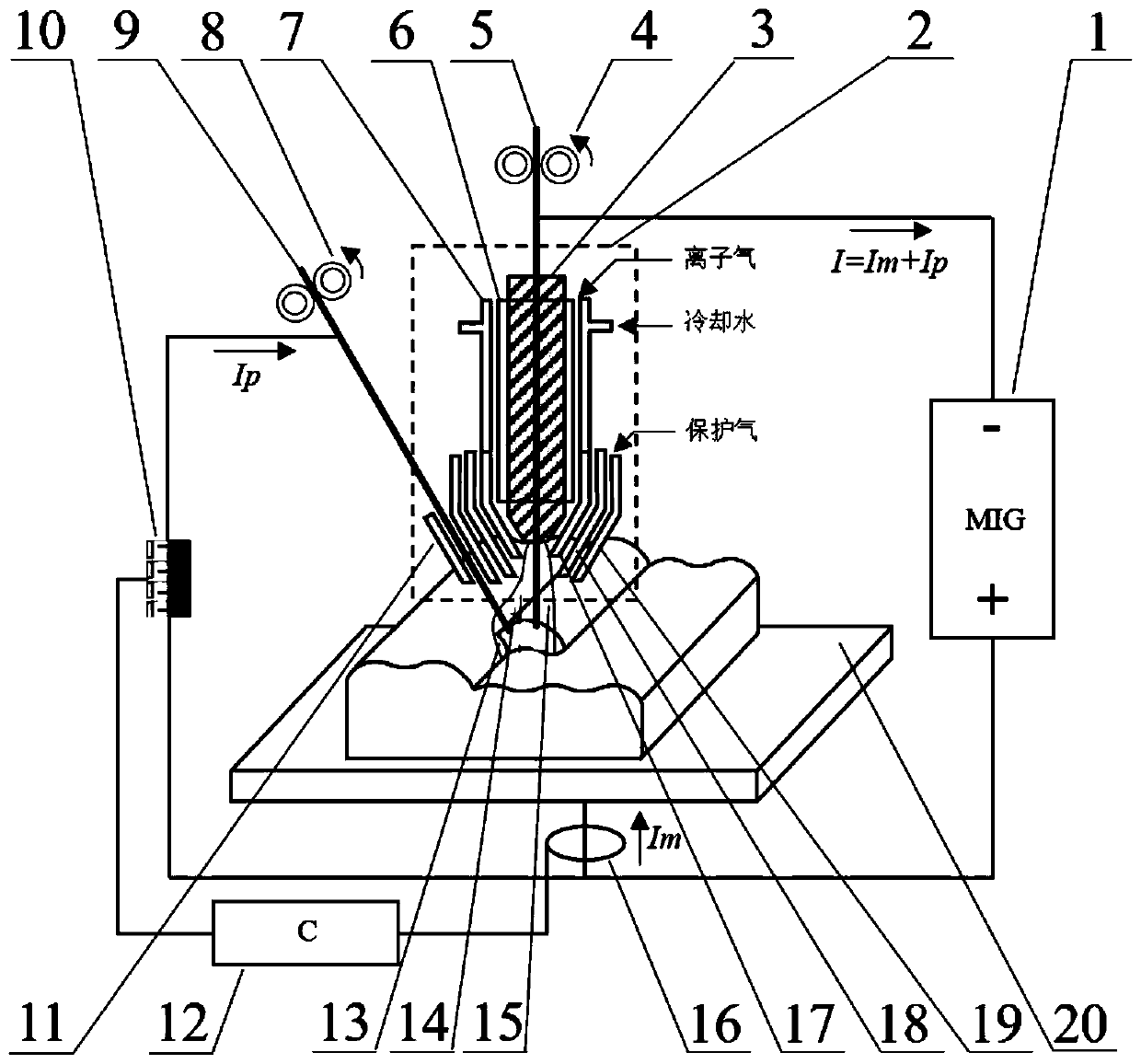

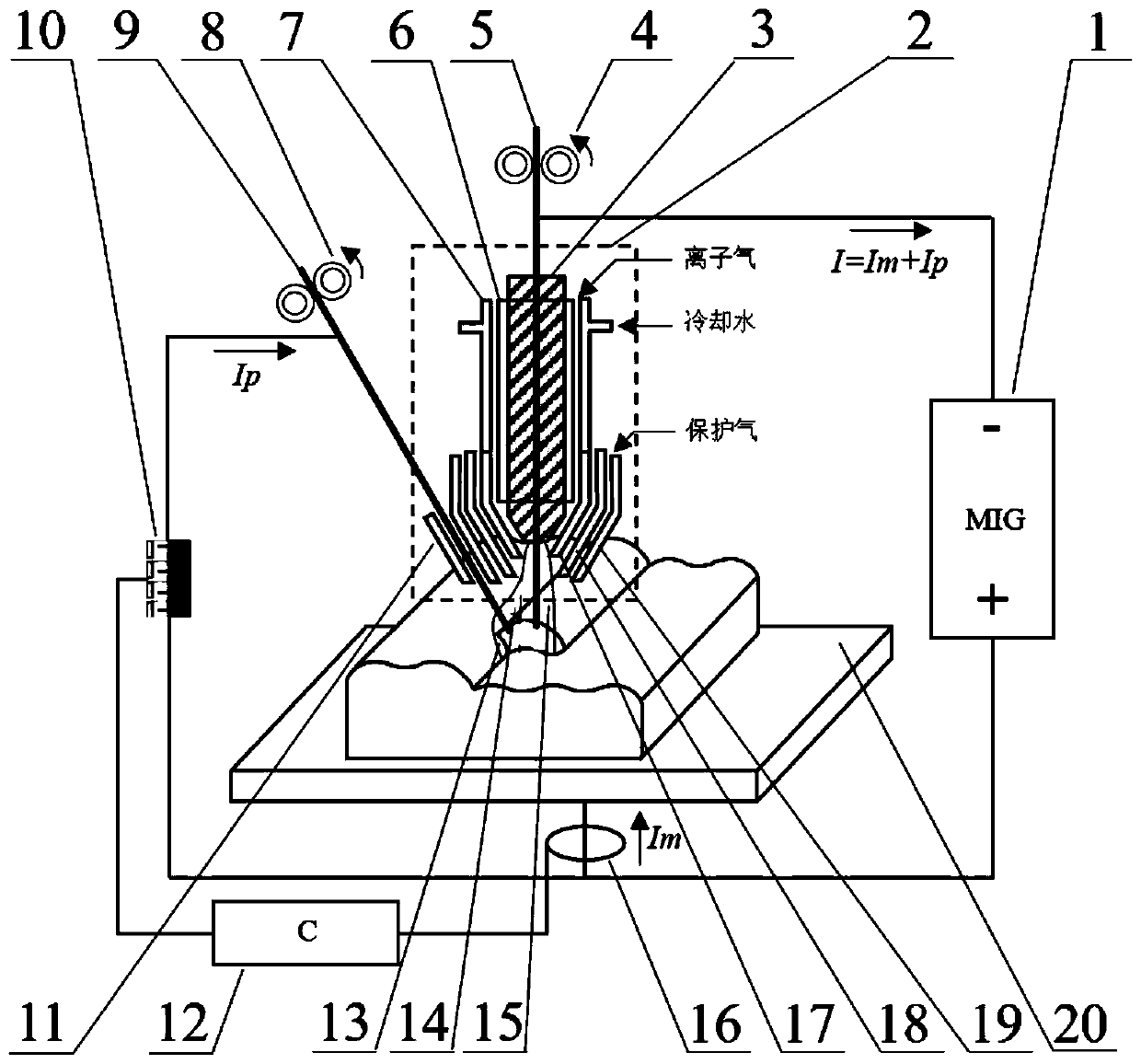

Additive manufacturing device and method for plasma arc gradient material of bypass hot wire consumable electrode

ActiveCN111168263AImprove Additive Deposition EfficiencyReduce welding heat inputAdditive manufacturing apparatusWelding apparatusElectric arcWelding power supply

The invention provides an additive manufacturing device and method for a plasma arc gradient material of a bypass hot wire consumable electrode. The device consists of an MIG welding power supply, a bypass hot wire consumable electrode plasma arc welding gun, an IGBT shunt controller, a workpiece, a current sensor and a current controller, wherein the MIG welding power supply, the bypass hot wireconsumable electrode plasma arc welding gun, the workpiece and the current sensor define a closed circuit; the MIG welding power supply, the bypass hot wire consumable electrode plasma arc welding gun, the workpiece, the IGBT shunt controller and the current controller define a closed circuit. The additive manufacturing device efficiently improves conventional electric arc welding basically, is controllable in heat input, is high in welding electric arc restraint intensity, and has the characteristics of low cost, high efficiency, high stability and the like of electric arc additive manufacturing.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com