Patents

Literature

374results about How to "No smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

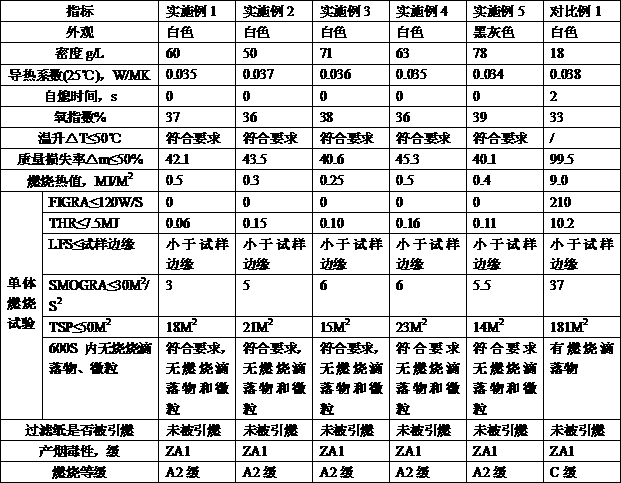

High-flame-retardance composite heat-insulating foam material and preparation method thereof

The invention relates to the technical field of polystyrene foam materials, in particular to a high-flame-retardance composite heat-insulating foam material and a preparation method thereof. The high-flame-retardance composite heat-insulating foam material comprises polystyrene foaming particles with the density of 18 to 20 g / L and a flame-retardant composite layer wrapped on the surface of the polystyrene foaming particles, wherein the flame-retardant composite layer consists of a flame-retardant binder of 5 to 50 g / L and an inorganic flame retardant of 5 to 75 g / L. Compared with the prior art, the invention optimizes the formula of the flame retardant and adopts environment-friendly, non-toxic and low-price organic and inorganic flame retardants. The prepared composite heat-insulating material has low production cost. After the product is combusted, the product has the advantages of alveolate skeleton structure, no melted drop, low smoke output quantity, no combustion dripping substance and no particle, so the flame-retardant performance and the flame-retardant grade of the product are obviously improved and the product has wide development prospect in the heat insulation field of buildings such as roofs and walls.

Owner:宁波龙利钜能新材料有限公司 +1

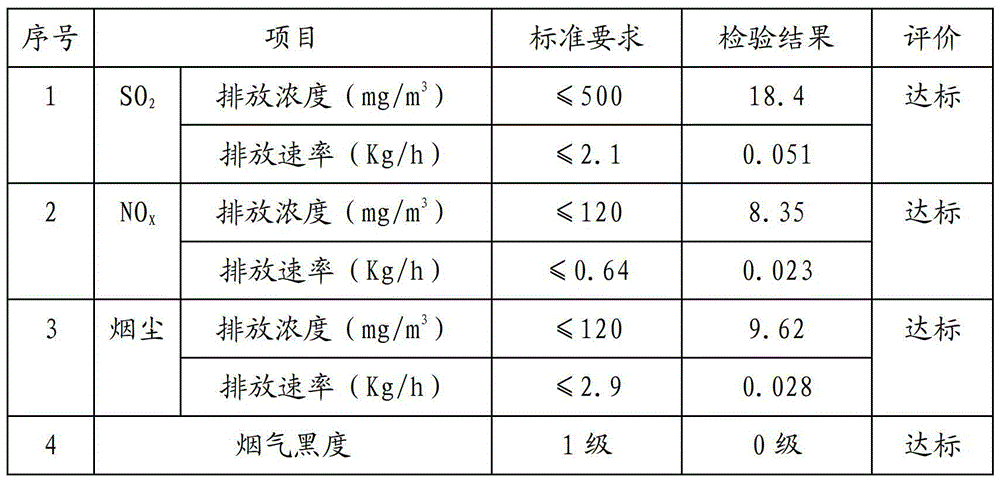

Alcohol-based fuel oil

ActiveCN103184081AProduct performance is stableClean and environmentally friendly oxygen contentLiquid carbonaceous fuelsSolventGlycerol

The invention discloses alcohol-based fuel oil which consists of the following components in part by weight: 70 to 75 parts of methanol, 4 to 6 parts of dimethylbenzene, 4 to 6 parts of No.200 solvent oil, 4 to 6 parts of paraffin oil, 4 to 6 parts of glycerol and 5 to 10 parts of water. Flame generated in the burning process of the alcohol-based fuel oil disclosed by the invention is stronger than that generated in the burning process of diesel oil and liquefied petroleum gas; the alcohol-based fuel oil is more completely and more sufficiently burnt; tail gas generated in the burning process of the alcohol-based fuel oil is cleaner and has no odor; and the alcohol-based fuel oil has the advantages of stable performance, high thermal efficiency, economy, safety and no pollution.

Owner:DONGGUAN CITY QUAN RAN TRADING

Multi-element nitralloy material and preparation method and application thereof

The invention discloses a multi-element nitralloy material and a preparation method and application thereof and belongs to the technical field of alloy material development. The multi-element nitralloy material comprises 9-48% of V, 13-45% of Si, 0.05-9% of Mn, 3.3-14% of Fe, 15-30.5% of N, 0.01-5.0% of Cr, 0.06-2.0% of Al, 0-7.0% of Ti, 0-6.5% of B, 0-4.5% of Nb, 0-1.8% of C, 0-0.1% of P, and 0-0.1% of S. According to the multi-element nitralloy material and the preparation method and application thereof, the content of nitrogen in the alloy can be effectively controlled to be within a reasonable range according to different combining capacities of various elements and the nitrogen; meanwhile, the content of the nitrogen can be adjusted within a wider range according to requirements of practical purposes, and great convenience is provided for a molten steel microalloying reinforcing technique; safety and environmental friendliness are achieved in the preparation and using process, and no smoke or dust or odor is generated.

Owner:马鞍山中科冶金材料科技有限公司

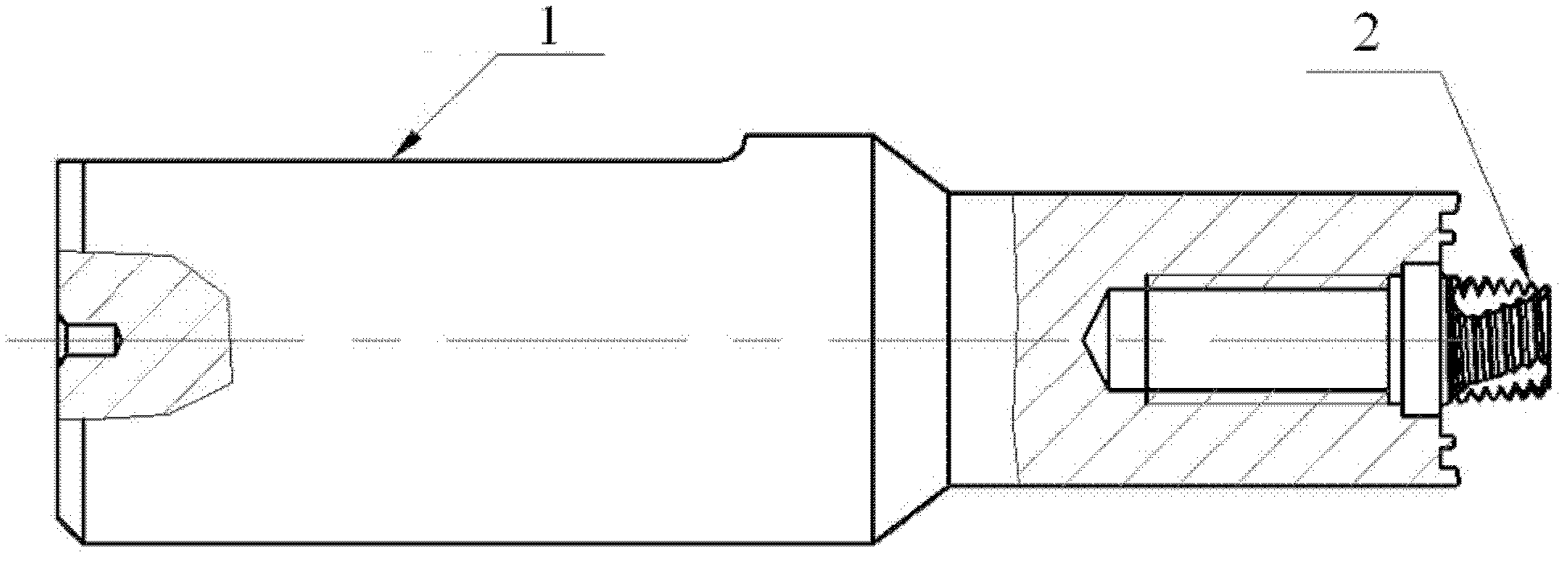

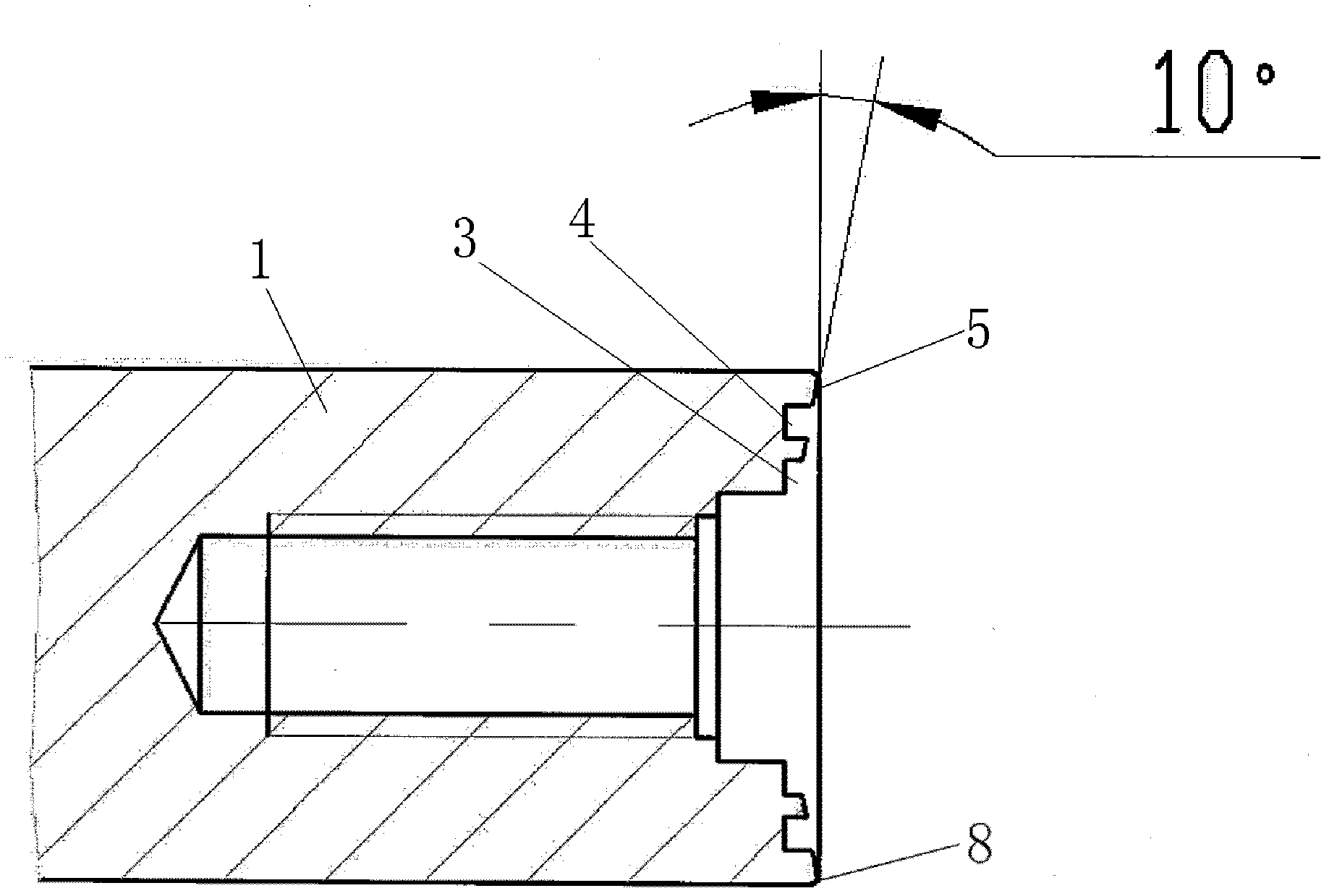

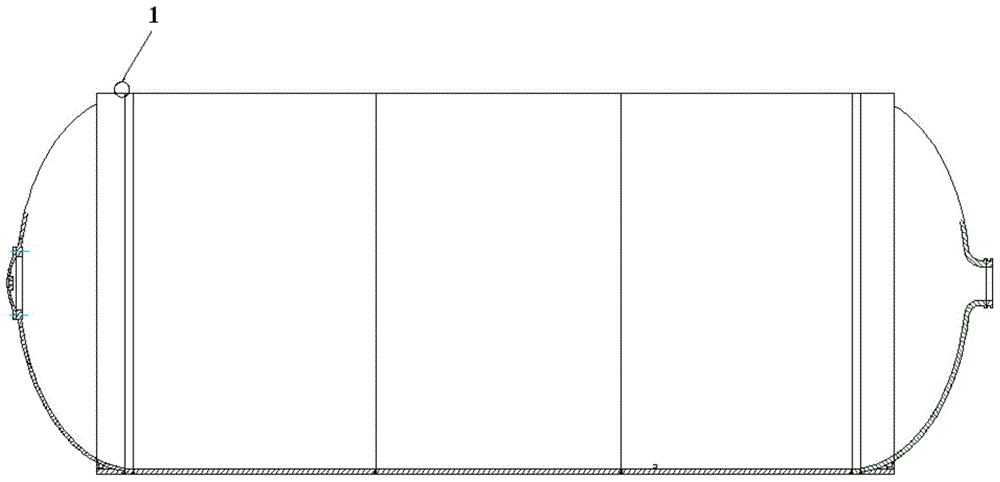

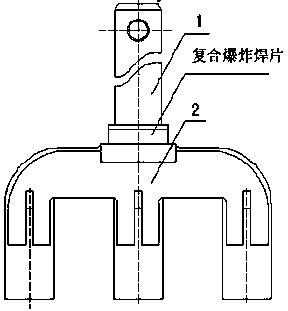

Device and method for repairing friction stir welding weld defect of storage tank for carrier rocket

ActiveCN102581476AGuarantee product qualityReduce scrapNon-electric welding apparatusFilling materialsRocket

The invention provides a device and a method for repairing a friction stir welding weld defect of a storage tank for a carrier rocket. A repair welding pin tool comprises a tool pin clamping structure and a tool pin, the end face of a shaft shoulder portion of the tool pin clamping structure is a recessed slope provided with two concentric-circle annular grooves, the front of the tool pin is of a conical thread structure, and a conical thread is circumferentially provided with three spiral grooves at intervals. The method includes the steps: firstly, manually excavating the tool pin broke at a friction stir welding weld; secondly, performing solid filling for the weld; thirdly, utilizing the repair welding pin tool to start friction stir welding from a center of the broke position of the tool pin filled with welding wires or materials to a set welding end point; and finally, continuing utilizing the repair welding pin tool to perform friction stir welding for the weld again from a welding start point to the welding end point. The method and the device are capable of guaranteeing the quality of the storage tank for the carrier rocket and decreasing scrapping of the storage tank for the carrier rocket due to the key hole type defect.

Owner:CAPITAL AEROSPACE MACHINERY +1

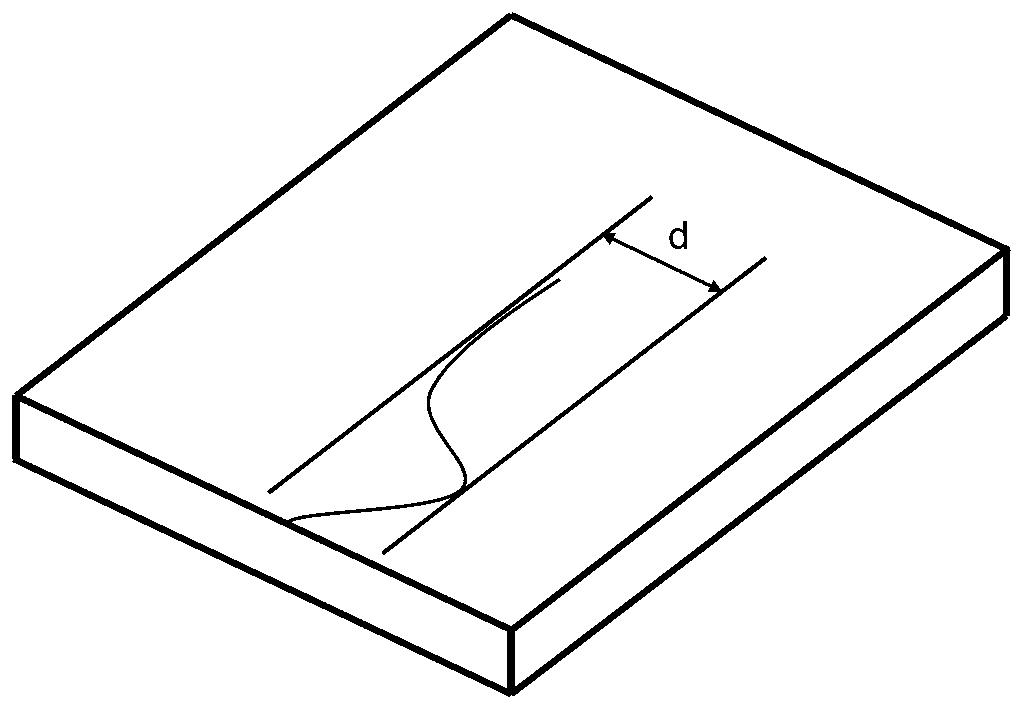

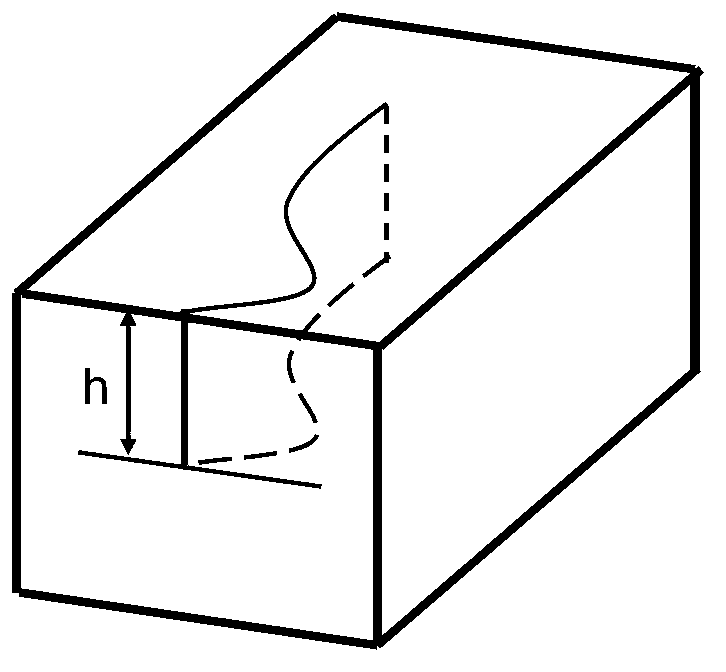

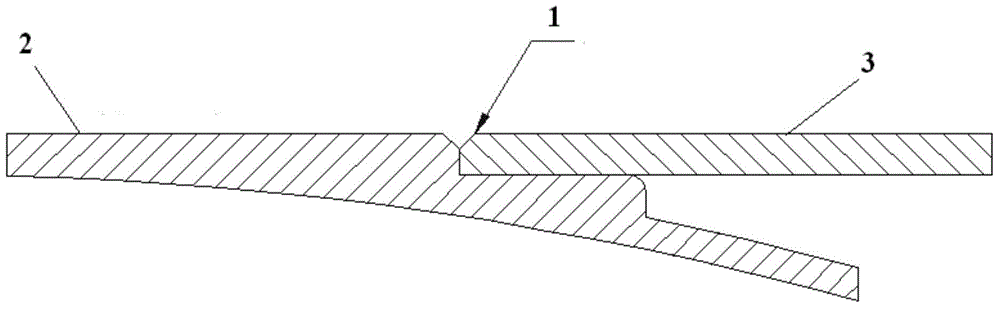

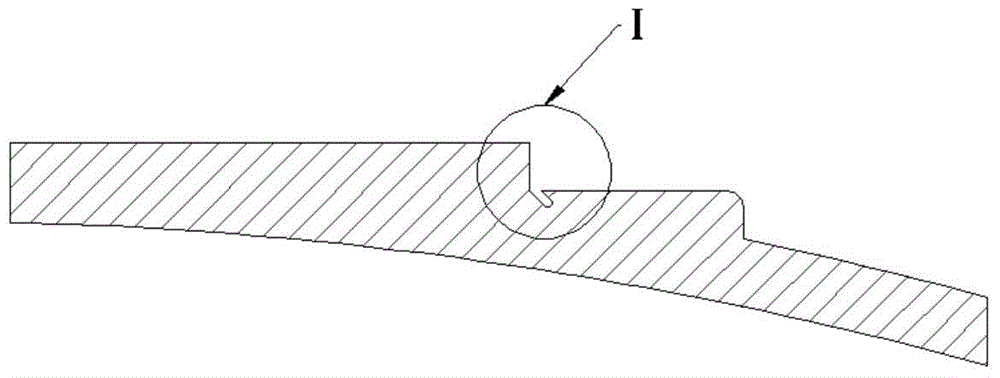

Stirring-friction-based crack repair method

InactiveCN103212778AReduce distortionReduce stressNon-electric welding apparatusUltimate tensile strengthAstronautics

The invention relates to a stirring-friction-based crack repair method which mainly is used for solving the problems in the prior art that the repair cost is high, the repair quality is poor and cracks appear repeatedly. The method is applied to the repair of surface cracks and through cracks of plate-shell metal structures, so as to enable cracked workpieces to meet reuse requirements. The method comprises the following specific steps of designing and manufacturing a friction repair tool according to the position and size of a crack, a material to be repaired, structural characteristics and the like; and realizing the friction between a shaft shoulder and the surface of the material to be repaired through the rotation of the repair tool so as to enable metal of a repair area to reach a thermoplastic state under the action of frictional heat, and realizing the flowing transfer and dynamic recrystallization of thermoplastic metal around the crack by using the rotating and upsetting action of the shaft shoulder of the repair tool, thereby realizing the filling repair of the crack. The method has the advantages that the method is simple, the damage to base metal is little, the quick, equal-strength and in-situ repair of engineering cracks can be realized, and the repair process is economical and environment-friendly. The method can be applied to the crack repair in fields, such as aeronautics and astronautics, shipbuilding, automobiles and rail transportation and has broad application prospects.

Owner:SHENYANG AEROSPACE UNIVERSITY

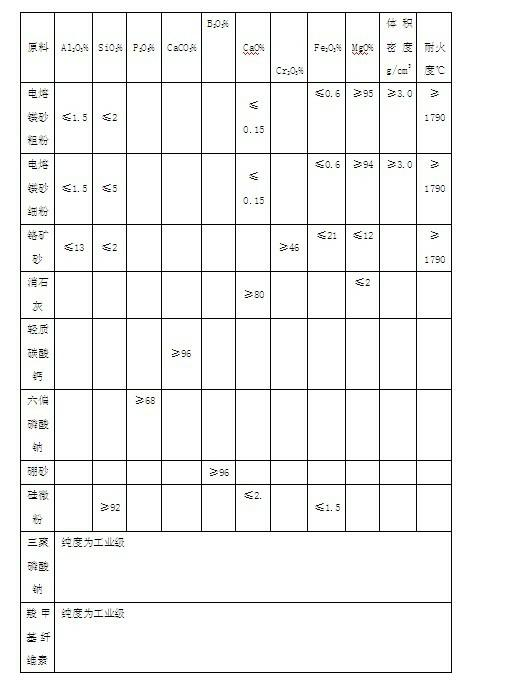

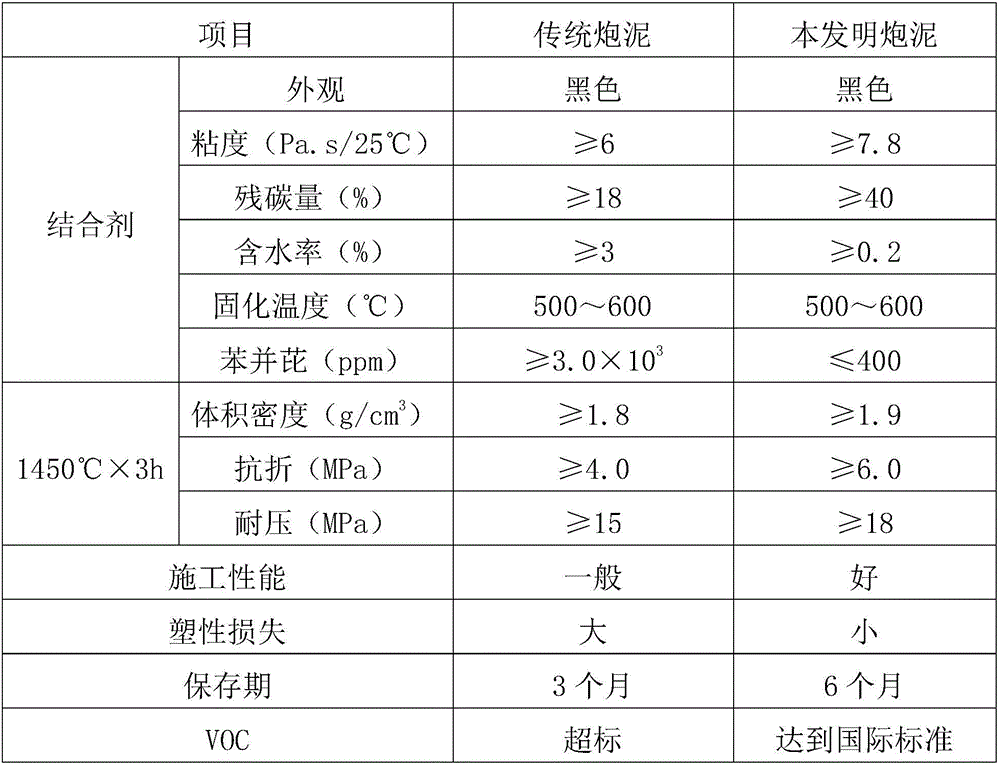

Novel RH gunning refractory

ActiveCN102659432AHigh bonding strengthGood high temperature performanceEnvironmental indexRefractory

The invention relates to a novel RH gunning refractory belonging to the refractory material field. The gunning refractory comprises the following raw materials in weight percent: 50-60% of fused magnesite crude powder, 15-30% of fused magnesite fine powder, 10-255% of chrome ore, 0.5-2% of slaked lime, 1-5% of light calcium carbonate, 1-4% of sodium hexametaphosphate, 2-55% of borax, 2-4% of silica powder, 0.5-4% of sodium tripolyphosphate and 0.005-0.1% of carboxymethylcellulose; and the raw materials are evenly mixed in a stirring device to obtain a finished product. The RH gunning refractory prepared from the raw materials provided by the invention is low in production cost, resistant to erosion and good in impermeability; an RH insert tube after being subjected to gunning maintainmentcan be used more than 85 times and the RH insert tube can be used for 5-6 furnaces after every time of gunning maintainment; the service life of the RH insert tube is obviously prolonged and the production efficiency is greatly improved; and in the use process, no harmless gas gives out, no peculiar smell is produced and no thick smoke is generated; and therefore the novel RH gunning refractory completely meets specified environmental indexes and utilization requirements..

Owner:攀枝花市银江金勇工贸有限责任公司

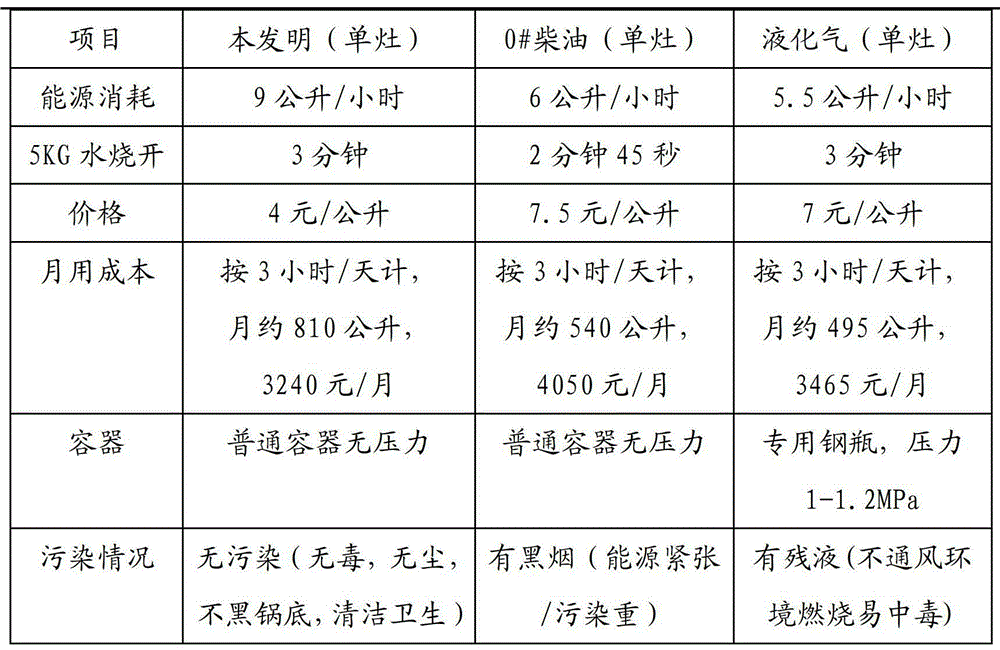

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

Preparation method for sausage

The invention discloses a preparation method for a sausage, comprising the steps of selecting materials, wringing, mixing materials, pickling, filling, baking, cooling, inspecting and packaging, wherein the baking process is as follows: circularly heating a heating pipe in the heating pipe by steams in a bakery built by brick structures; heating the bakery to 40 degrees centigrade; and then putting the filled sausages in the bakery; controlling the steam flow so that the sausages are baked for 4 hours when the bakery temperature is 45-50 degrees centigrade; preliminarily removing the moisturein the sausages; after 4 hours, heating the bakery to 60-63 degrees centigrade so as to bake the sausages for 7-10 hours continuously ; finally, stopping steam supply; and cooling to room temperature. The preparation method for the sausage has the following advantages: the food preparing link is safer by using the process; and the benzopyrene is avoided.

Owner:NANTONG YUTU GROUP

Friction stir welding method for lock bottom circular seam of carrier rocket storage tank

ActiveCN104439686AImproved consistency and stability of mechanical propertiesImprove performanceDomestic vesselsMetal working apparatusLap jointFusion welding

The invention belongs to welding methods, and particularly relates to a friction stir welding method for a lock bottom circular seam of a carrier rocket storage tank. The method comprises the following steps that firstly, welded parts are transformed, welding leakage grooves are formed in a tank bottom fork-shaped ring, and the welding leakage grooves are formed in the bottommost portion of a tank bottom fork-shaped circular welding seam; secondly, the welded parts are in lap joint, and the welded tank bottom fork-shaped ring is in lap joint with a short shell to form the welding joint; thirdly, welding is carried out, and welding is carried out along the welding joint through the friction stir welding manner. The method has the obvious advantages that nearly defect-free welding can be achieved, the consistency and stability of the mechanical property of the joint are obviously improved, and compared with a fusion welding lock bottom joint, the performance of the lock bottom circular seam is improved by about 20 percent to 30 percent.

Owner:CAPITAL AEROSPACE MACHINERY +1

Method for preparing light, thin, heat-insulating flame-retardant plush fabric

InactiveCN106192176AComfortable to wearGood warmth retentionFabric breaking/softeningWeft knittingYarnPolyester

The invention relates to a method for preparing a light, thin, heat-insulating and flame-retardant plush fabric. The method comprises the steps of weaving a fabric, wherein terry yarn is 98% of 32S / 1 aramid fiber 1313 / 2% of conductive filament, and connecting yarn is 100D / 36F polyester flame-retardant double-sided plush; causing the fabric to undergo dyeing, drying, soft forming, galling, intermediate shaping, combing, shearing and final shaping, and obtaining the light, thin, heat-insulating and flame-retardant plush fabric. The method is short in process and good in stability, the obtained plush fabric insulates heat, is light and thin, has an outstanding flame-retardant effect, does not melt, has no melting drip and does not generate smoke, the afterflame time is 0 s, the smoldering time is 0 s, the plush fabric is permanently resistant to flame and is comfortable to wear and soft in touch, the final finished knitted fabric gram weight is 271 g / m2, the heat-insulating value CLO is 0.5-1.0, and the plush fabric has good application prospects.

Owner:SHANGHAI CHALLENGE TEXTILE

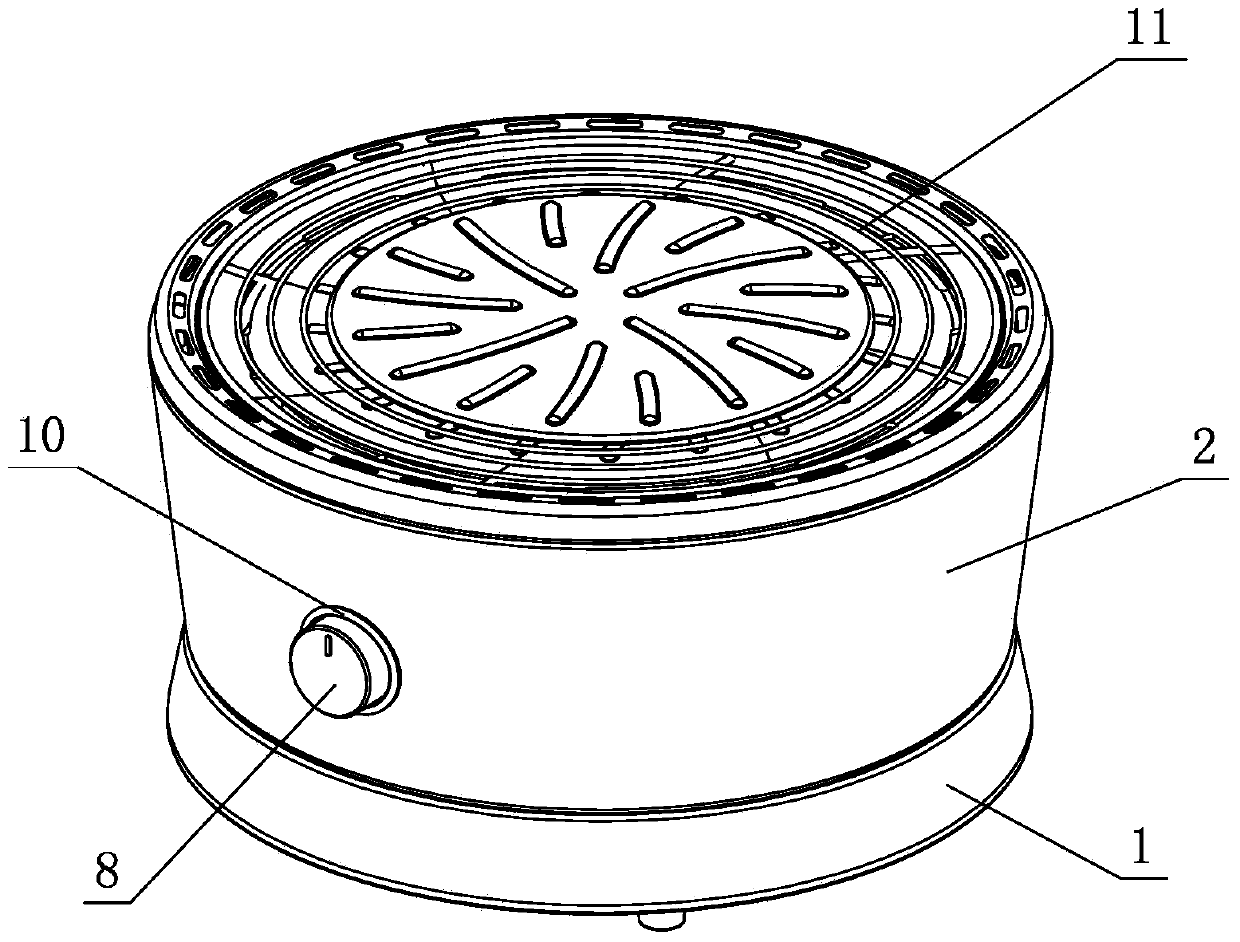

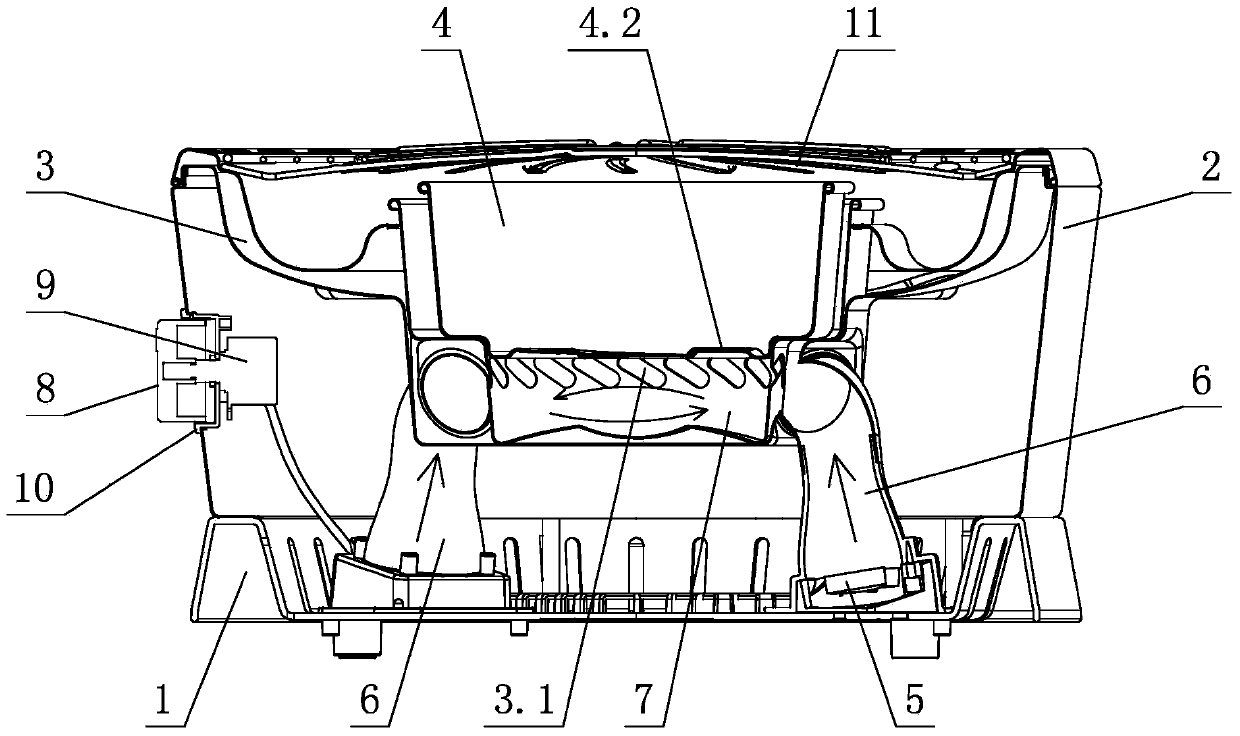

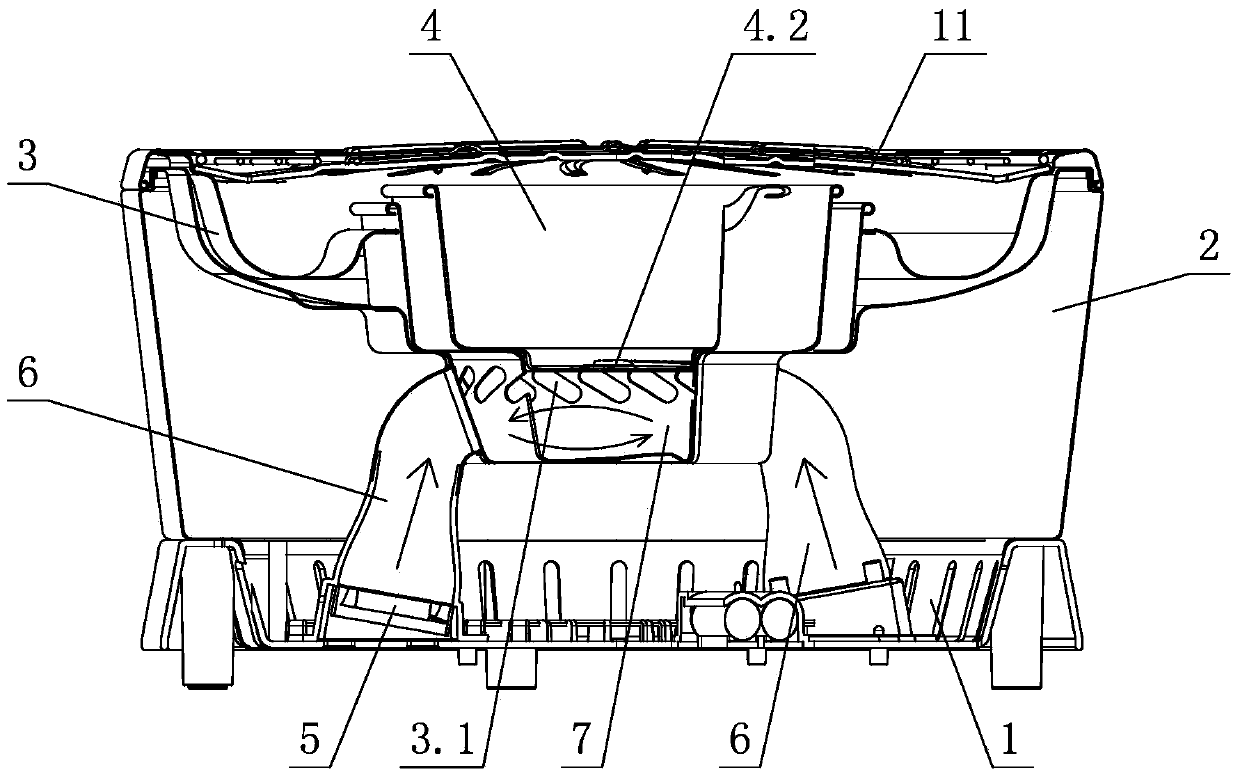

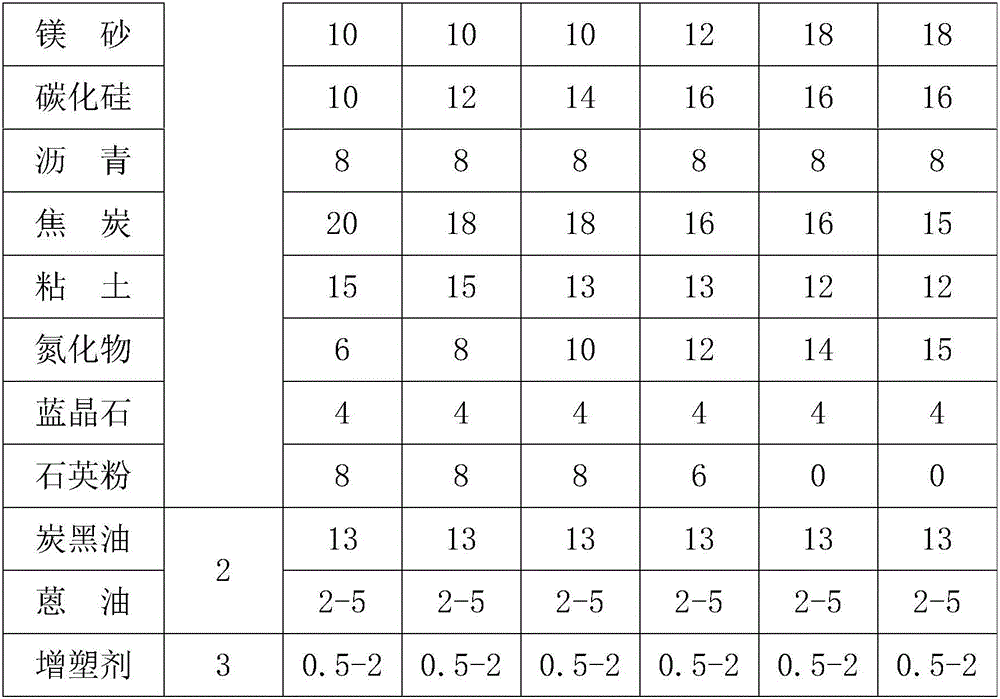

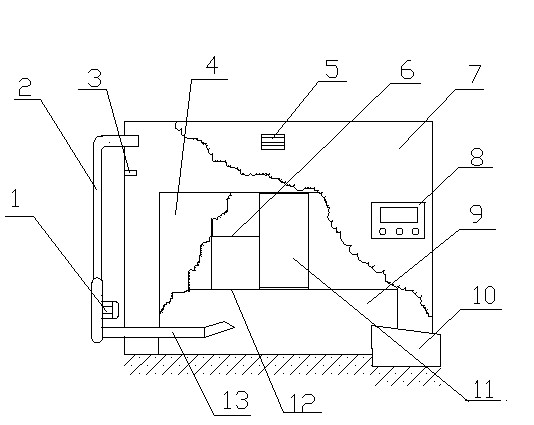

Smokeless barbecue oven

ActiveCN104172942AEasy to useGreat tasteDomestic stoves or rangesLighting and heating apparatusEngineeringThermal efficiency

A smokeless barbecue oven comprises a base and a casing placed at the upper part of the base; the casing adopts a hollow structure; a bracket is placed at the upper part of the casing; a charcoal tray is place in the bracket; one or more fans are arranged on the base; one or more air passages corresponding to the fans are formed in the barbecue oven; the air passages are obliquely formed in a curved manner to form certain included angles with the barbecue oven in the vertical direction. Through the structural improvement, the problems in the prior art that the temperature of the barbecue oven in the working state is not even, the firepower is not adjustable and the heavy smoke is generated when the wood char is not burnt fully are solved effectively. The smokeless barbecue oven has the characteristics that the structure is simple and reasonable, the performance is reliable, the manufacturing cost is low, the firepower is even and adjustable, the operation is simple and convenient, the energy conservation and environmental protection are realized, the smokeless barbecue oven is clean and hygienic, the wood char is burnt fully and no smoke is generated and the heat efficiency is high and the like; the smokeless barbecue cuisine is realized for a user; as the major parts are made of stainless steel material, the durability is achieved and the practicability is high.

Owner:FOSHAN SIXVECTOR DESIGN & CONSULTANT CO LTD

Buccal type smoke-free tobacco product

ActiveCN102920014AKeep healthyGood for healthTobacco preparationFlexible coversDietary fiberAdhesive

The invention discloses a buccal type smoke-free tobacco product. The buccal type smoke-free tobacco product comprises an edible packaging film, a tobacco extractive microcapsule, a dietary fiber, an adhesive and condiment, wherein the tobacco extractive microcapsule is the microcapsule formed by packaging the tobacco extractive by a microcapsule coating raw material; and the dietary fiber is obtained by being extracted from a tobacco stalk or a tobacco leaf. The buccal type smoke-free tobacco product solves a problem that body of an involuntary smoker in the environment where is full of smoke of a conventional tobacco product; and the buccal type smoke-free tobacco product increases intake of the dietary fiber of a human body, is durable in mouthfeel, and reduces the environment to an ambient environment.

Owner:CHINA TOBACCO HUNAN INDAL CORP

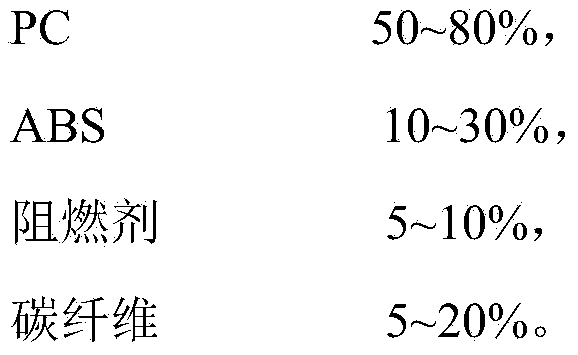

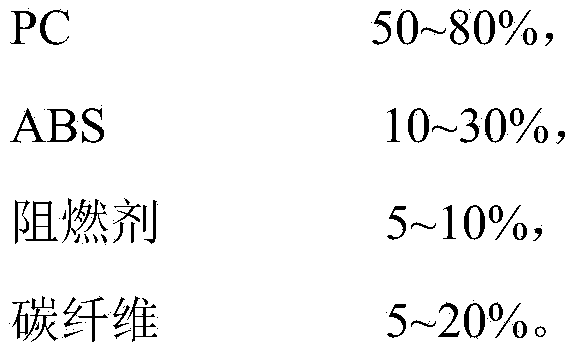

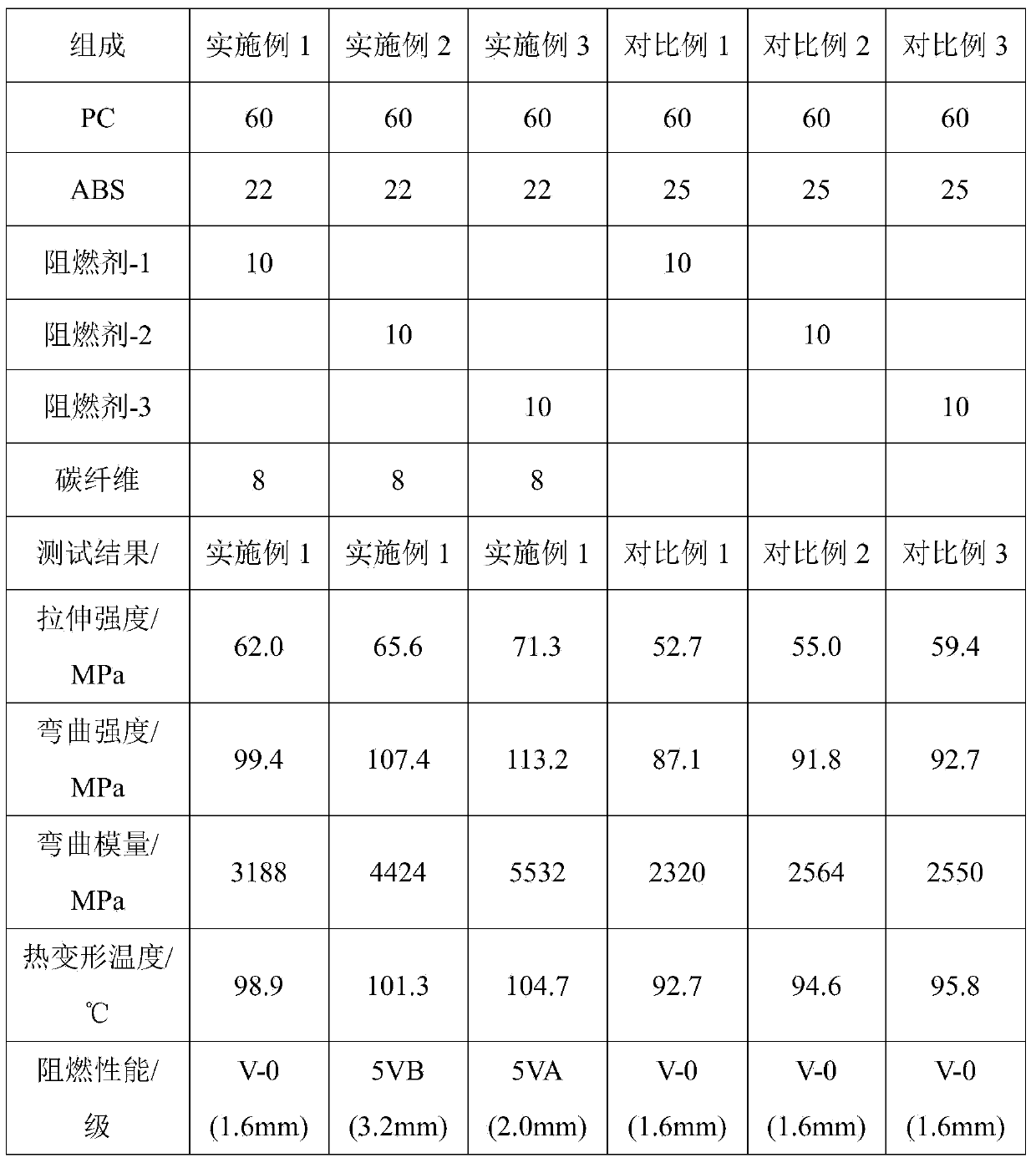

UL94-5VA-grade high-performance flame-retardant reinforced PC (polycarbonate)/ABS (acrylonitrile butadiene styrene) blend and preparation method thereof

The invention discloses a UL94-5VA-grade high-performance flame-retardant reinforced PC (polycarbonate) / ABS (acrylonitrile butadiene styrene) blend and a preparation method thereof. The UL94-5VA-grade high-performance flame-retardant reinforced PC / ABS blend comprises the following raw materials in percentage by weight: 50-80% of PC, 10-30% of ABS, 5-10% of flame retardant and 5-20% of carbon fiber. The blend has multiple properties of high strength, high heat resistance, high flame retardance, low combustion smoking amount and the like. The obtained flame-retardant reinforced PC / ABS blend can not only meet the basic UL94V-0 requirements, but also achieve various indexes of UL94-5VA under the relatively low thickness of 2.0mm of a sample piece, the sample piece has no distortion and no perforation under multiple actions of flame and keeps the relatively complete appearance and shape, and the property has an important role for preventing fire and reducing loss against key electronic parts of automobiles, engineering machines and household electrical products.

Owner:CHONGQNG PRET NEW MATERIAL +2

Friction welding method of aluminum guide rod and steel claw

InactiveCN103586577ALower resistanceImprove the effect of electrolysisWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingStructural engineering

The invention discloses a friction welding method of an aluminum guide rod and a steel claw. The method for directly welding the aluminum guide rod and the steel claw in a friction mode is adopted, four stages of frictional heating are adopted, and the rotation speed, the friction pressure and the friction time of a main shaft in the friction process of each stage are set; according to upsetting, when rotation of the main shaft is not stopped completely, rapid feeding is started, the upsetting process is started, and the phase error of the aluminum guide rod and the steel jaw is smaller than +1 degree or -1 degree when braking is over by utilizing closed-loop control. The friction welding joint of the aluminum guide rod and the steel claw is beautiful, a whole static stretching contrast test of the joint is performed on the performance of the joint, the mechanical property of an anode guide rod assembly utilizing friction welding is larger than the mechanical property of an anode rod guide rod assembly utilizing explosion soldering flakes, and therefore the mechanical strength of the joint can meet the requirement of practical application.

Owner:兰州连城铝业有限责任公司 +1

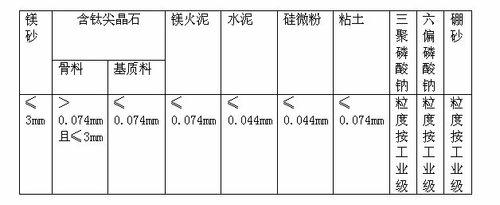

Titaniferous-spinel-added gunning mix for steel converter

ActiveCN102633514AReduce manufacturing costImprove erosion resistance and erosion resistanceSodium triphosphateMagnesium

The invention relates to a titaniferous-spinel-added gunning mix for a steel converter, belonging to the field of refractory materials. The gunning mix comprises the following raw materials in percentage by weight: 50-60% of magnesia, 4-8% of titaniferous spinel as aggregate, 6-15% of titaniferous spinel as substrate, 20-30% of magnesium fireclay, 1-5% of cement, 2-4% of silicon micropowder, 1-3% of clay, 0.1-1% of sodium tripolyphosphate, 1-4% of sodium hexametaphosphate and 2-4% of borax. The raw materials are evenly mixed in a mixing plant to obtain the finished product. The byproduct titaniferous spinel of the ferrotitanium ferroalloy smelting product is used instead of part of magnesia and magnesium fireclay as the aggregate and substrate, thereby lowering the production cost, solving the problem of comprehensive utilization of the byproduct in the ferrotitanium production as well as the problem of environmental protection, and greatly prolonging the service life of the gunning mix. Every time the spray repair is carried out, the titaniferous-spinel-added gunning mix can be used by 8-12 furnaces, so the production efficiency of the steel converter is greatly enhanced.

Owner:攀枝花市银江金勇工贸有限责任公司

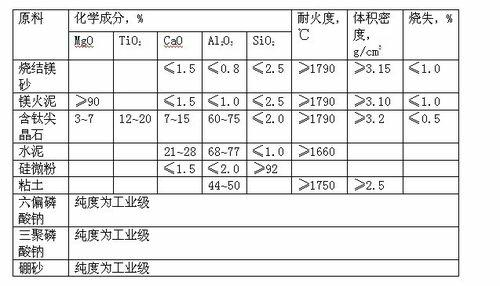

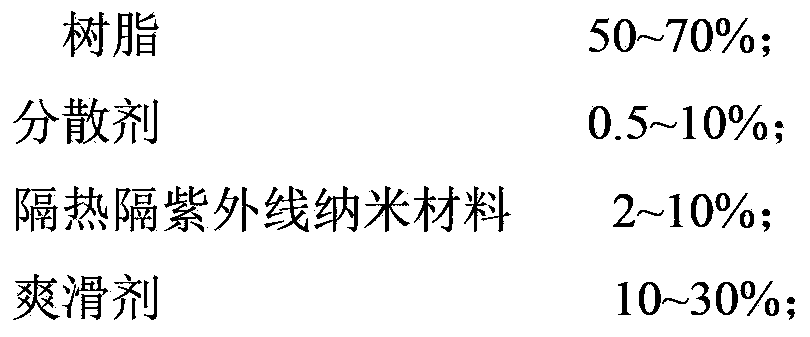

High-heat-insulation, ultraviolet-isolation and transparent colored master batch and preparation method thereof

The invention discloses a high-heat-insulation, ultraviolet-isolation and transparent colored master batch which comprises the following components in percentage by weight: 50-70% of resin, 0.5-10% of dispersing agent, 2-10% of heat-insulation ultraviolet-isolation nano material, 10-30% of slipping agent and 0-10% of coloring agent. The invention further discloses a preparation method of the high-heat-insulation, ultraviolet-isolation and transparent colored master batch. According to the master batch and the preparation method, the master batch and a transparent polyester chip are matched at a ratio, and subjected to extrusion and two-way stretch to produce a high-heat-insulation, ultraviolet-isolation and transparent colored film; the high-heat-insulation, ultraviolet-isolation and transparent colored film has excellent heat-insulation and ultraviolet-isolation functions; the heat-insulation and ultraviolet-isolation capacity can be adjusted as required; the color is uniform and consistent; and when the master batch is applied to PET (polyethylene glycol terephthalate) film extrusion or sheet extrusion, the master batch is smog-free, high in transparency and good in smooth effect.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

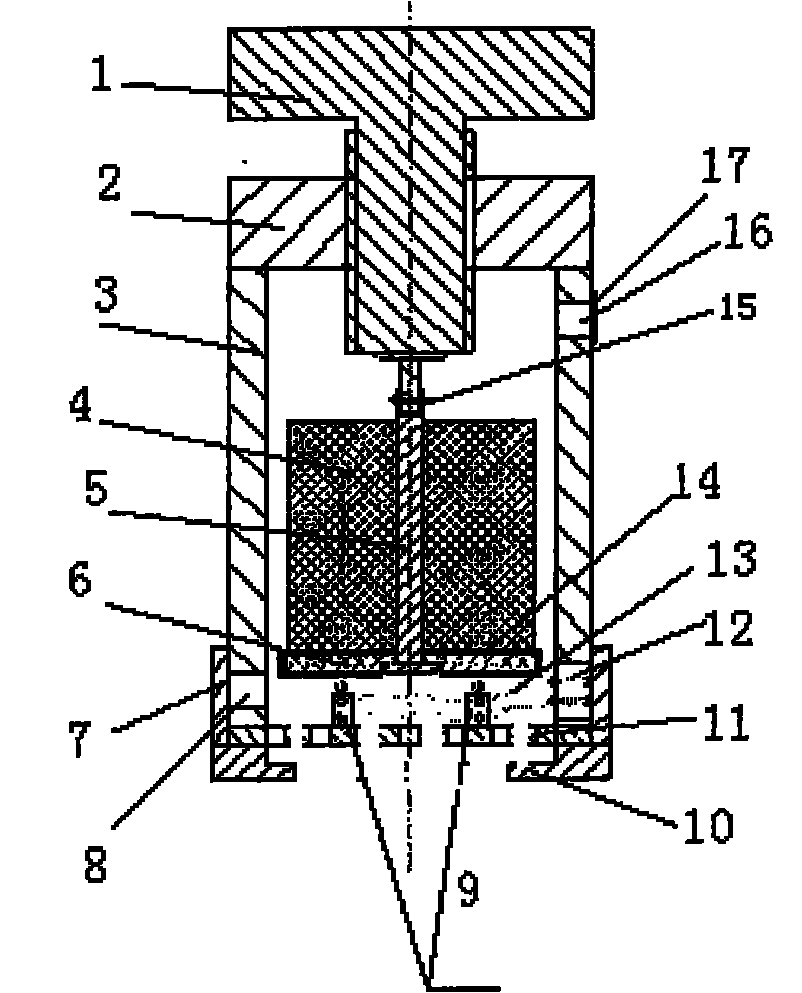

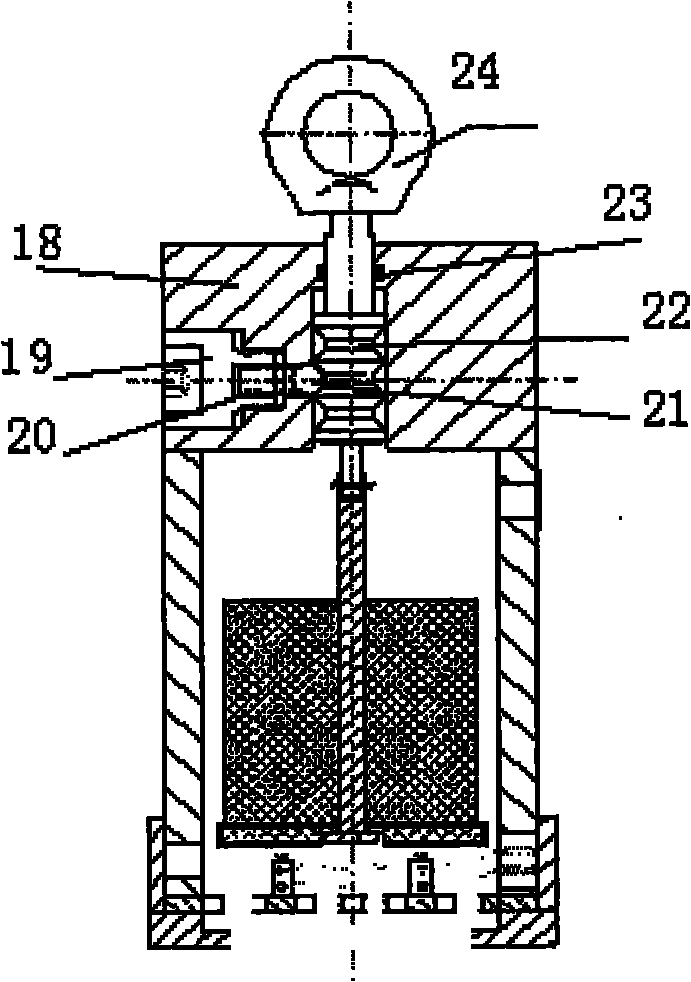

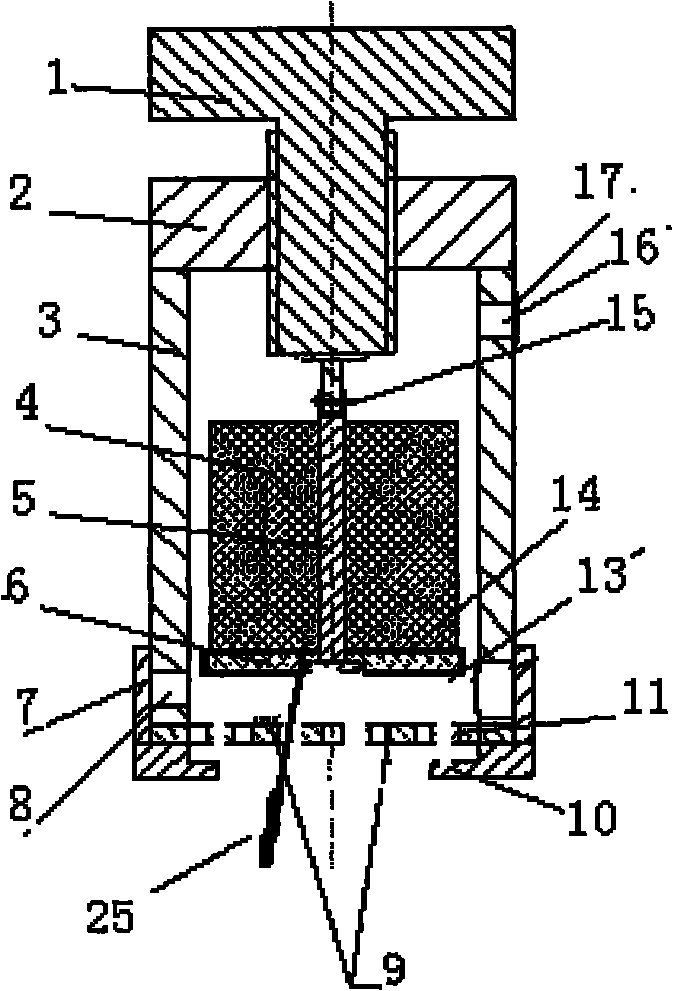

Moxibustion device

ActiveCN102247281AExtend moxibustion timeAdjustable temperatureDevices for heating/cooling reflex pointsEngineeringMoxibustion

The invention relates to a moxibustion device. The moxibustion device is characterized by comprising a moxibustion drum, a moxa granule, a moxa granule rack and a temperature adjusting device, wherein the top of the moxibustion drum is provided with a moxibustion cap; the moxa granule is vertically positioned on the moxa granule rack; the moxa granule rack is connected to the lower part of the temperature adjusting device and placed in the moxibustion drum; the temperature adjusting device is exposed out of the upper end of the moxibustion drum after penetrating through the middle part of the moxibustion cap; the distance from the moxa granule rack to the bottom of the moxibustion drum is adjusted by adjusting the length of the temperature adjusting device exposed out of the upper end of the moxibustion drum; the lower part of a drum wall is provided with an air inlet, and the upper part of the drum wall is provided with an air outlet, and the ratio of the total area of the air inlet to the area of the moxibustion drum is (1-10):100. The moxibustion device disclosed by the invention has the advantages of no smoke, environment friendliness, long moxibustion time, adjustable temperature, good effect as well as safety and convenience for use.

Owner:赵百孝

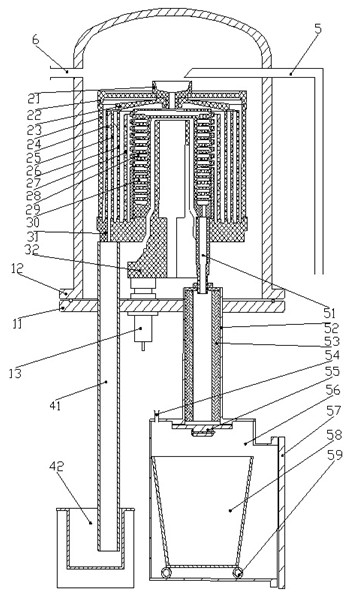

Equipment for extracting gold and silver from lead/bismuth base alloy

InactiveCN102676828AEmission reductionSaving blowing fuelProcess efficiency improvementSlagPollutant emissions

The invention relates to equipment for extracting gold and silver from lead / bismuth base alloy, and belongs to the technical field of nonferrous metallurgy. The equipment comprises a vacuum furnace body, a vaporization system, a volatile substance discharging system, a crude silver alloy discharging system, a feed pipe and an exhaust pipe, wherein the vaporization system is arranged in the vacuum furnace body; the bottom of the vaporization system is communicated with the volatile substance discharging system and the crude silver alloy discharging system; the feed pipe penetrates through the vacuum furnace body to reach the top of the vaporization system; and the exhaust pipe is communicated with the vacuum furnace body. By the equipment, 70 percent of lead, antimony, arsenic and bismuth can be transformed into alloy to be removed and recovered in the vacuum distillation stage, blowing fuel is greatly saved, the labor intensity is reduced, the production environment is improved and pollution emission is greatly reduced; and the equipment has high treatment capacity, low energy consumption and high metal recovery rate, does not generate smoke or oxidizing slag, is stable and reliable, and is environment-friendly energy-saving emission-reducing equipment.

Owner:KUNMING UNIV OF SCI & TECH +1

Frictional heat self-sintering antifriction material

InactiveCN101205457AStable coefficient of frictionSmall fluctuationOther chemical processesFiberTO-18

The invention belongs to the friction material field of friction stopping devices used in transport machinery and various engineering operation machineries, and relates to a friction heat self-sintering friction-resistant material. The material comprises the following raw materials by weight percent: 10 to 16 percent of adhesive, 8 to 20 percent of modified framework material, 10 to 20 percent of friction stabilizer, 10 to 25 percent of plasticizing fiber, 5 to 15 percent of various auxiliary agents, 3 to 13 percent of sintering material, 8 to 18 percent of friction-increasing agent, 2 to 8 percent of chopped glass fiber, 3 to 16 percent of petroleum coke and 4 to 16 percent of coke dust. The invention is characterized in that: ceramic-like material is converted into compound with low melting point by utilization of the heat on a friction surface; moreover, the conversion ensures that grains are refined and compact and distributed more evenly. Test result shows that the friction material has stable friction coefficient, small fluctuation, not more than +-0.035 deviation, less abrasion loss, long service life, no braking noise, no smoke and spark and no dust; moreover, the outstanding characteristic of the friction material lies in that the material does not cause damages on a brake drum (disc).

Owner:信义集团公司

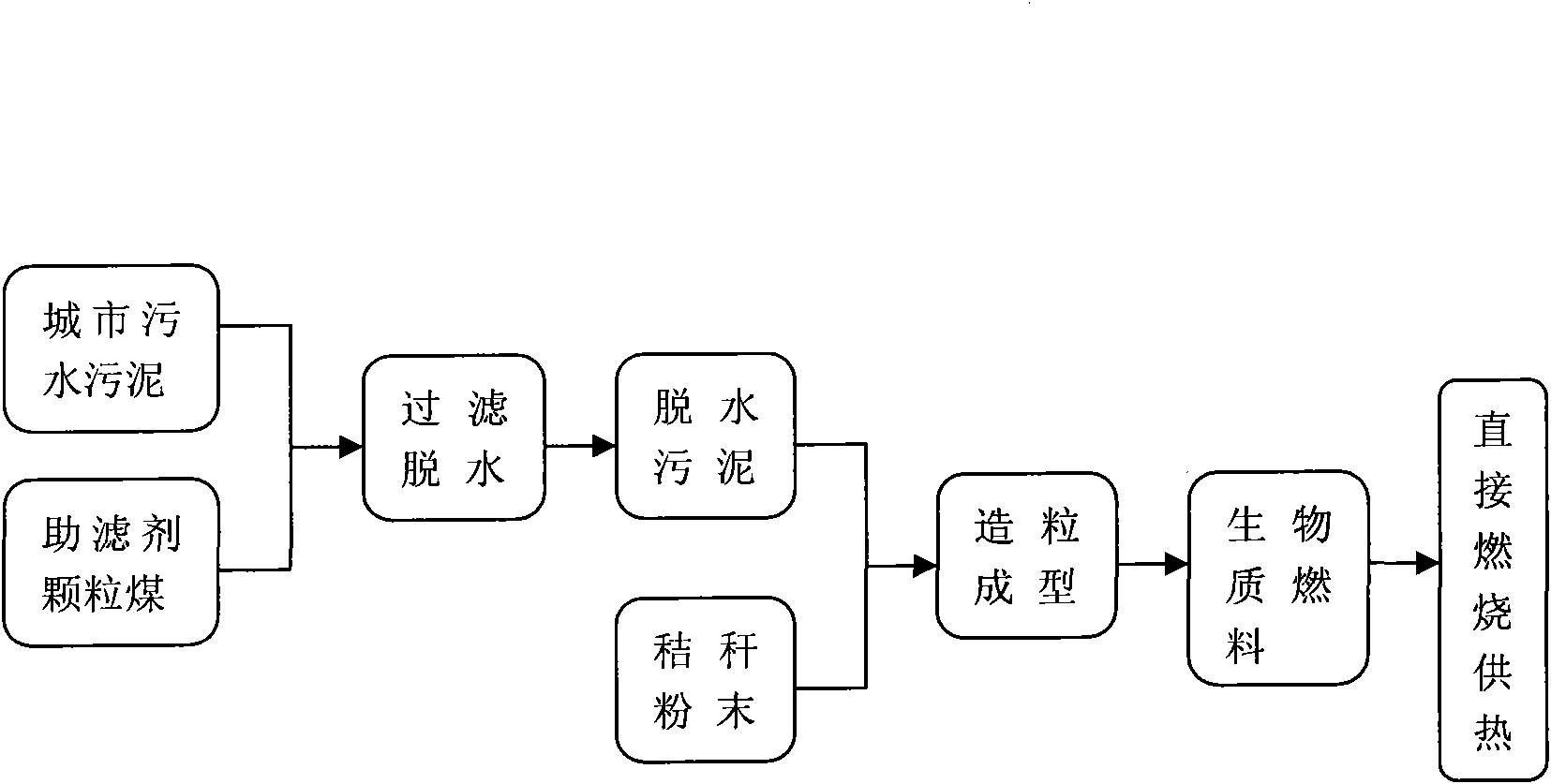

Preparation method of sludge straw biomass fuel

InactiveCN101928623AMake full use of the calorific value of combustionTake advantage of adhesionBiofuelsSolid fuelsAlternative fuelsResource utilization

The invention provides a preparation method of a sludge straw biomass fuel, which comprises the following steps: firstly mixing the excess sludge with the moisture content more than 96% from a municipal wastewater treatment plant with particle coal with the particle size of 0.15-0.18mm based on the mass ratio of 1:1-2; then filtering and dehydrating to obtain dewatered sludge with the moisture content of 40-60%; smashing the crop straws into crop powers to mix with the dewatered sludge based on the mass ratio of 1-10:90-99; and prilling and molding by a comminutor to prepare the sludge straw biomass fuel. The fuel can be used as an alternative fuel of the coal to directly be burnt for heat supply, is free of black smoke in the burning process, and can be applied in boilers or daily life cookware. The invention sufficiently utilizes the higher calorific value of the municipal sludge and the crop straws, realizes resource utilization of the fuel, and solves the treatment problem of the excess sludge from the municipal wastewater treatment plant and the crop straws.

Owner:卢秉威

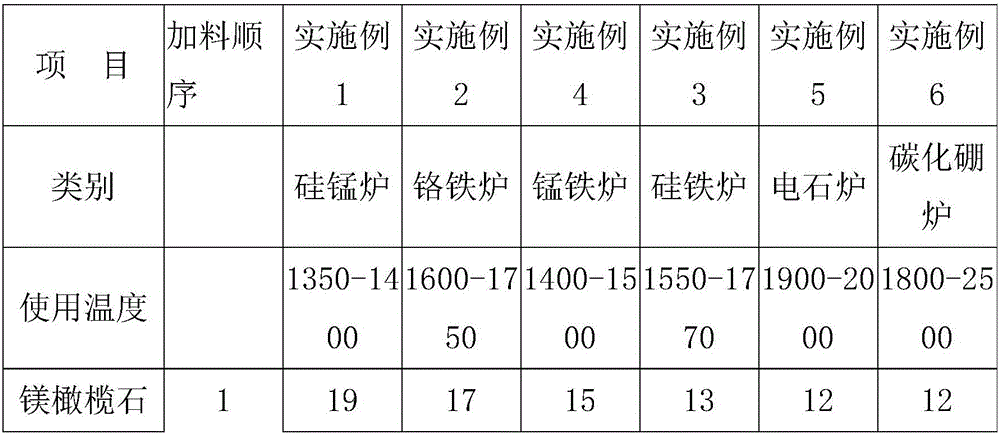

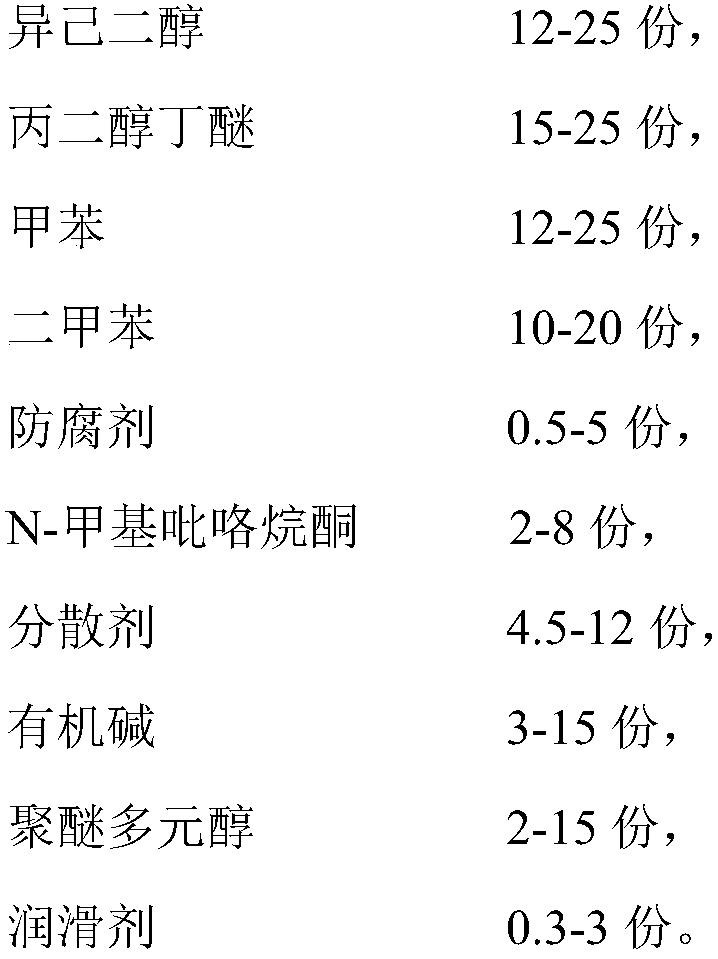

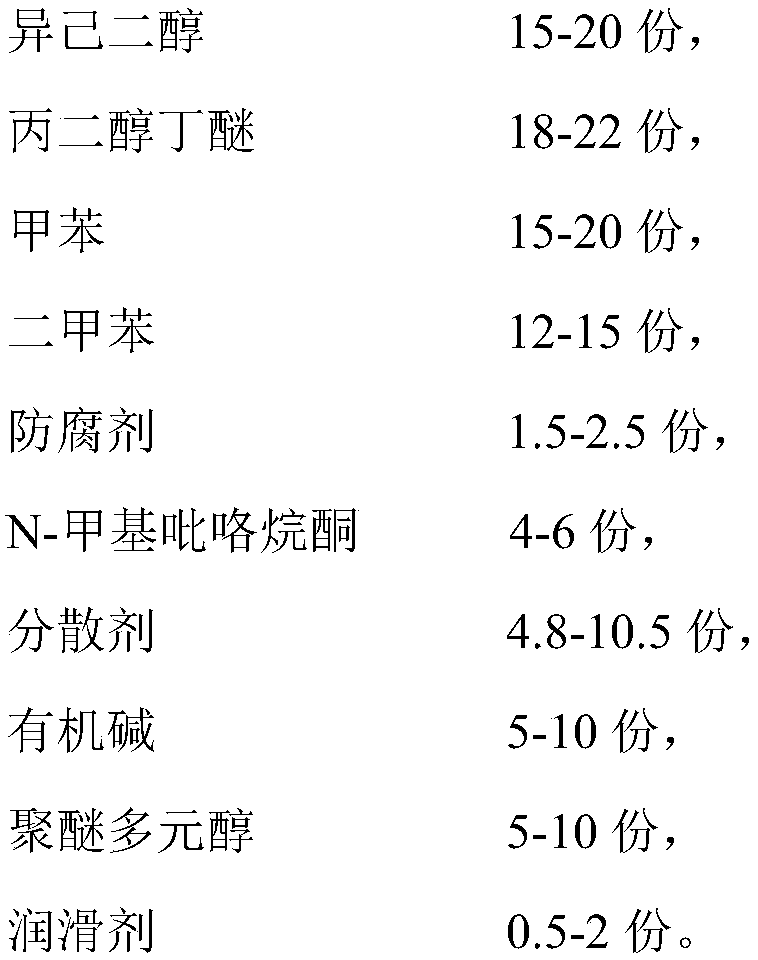

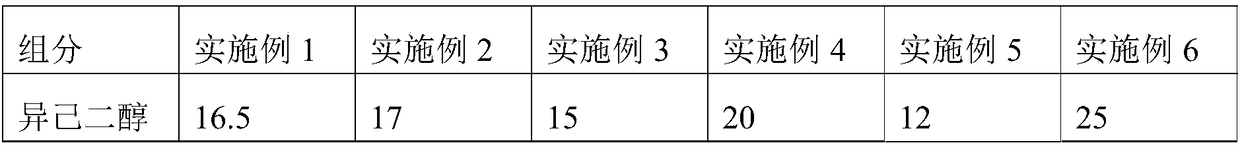

Environment-friendly anhydrous stemming for submerged arc furnace and preparation method

The invention discloses environment-friendly anhydrous stemming for a submerged arc furnace and a preparation method of the environment-friendly anhydrous stemming. The environment-friendly anhydrous stemming is prepared from the following raw materials in parts by weight: 10 to 20 parts of forsterite, 10 to 45 parts of magnesia, 10 to 20 parts of silicon carbide, 10 to 25 parts of coke, 5 to 15 parts of asphalt, 10 to 20 parts of clay, 5 to 15 parts of nitride, 3 to 10 parts of kyanite, 0 to 15 parts of quartz powder, 12 to 20 parts of carbon black oil, 2 to 8 parts of anthracene oil and 0.5 to 2 parts of plasticizer, wherein the nitride is one or a mixture of ferro silicon nitride, silicon nitride, aluminum nitride and titanium nitride, and the carbon black oil and the anthracene oil are premixed to form a composite environment-friendly binding agent for standby use; raw materials are weighed and added into a mixing mill to be dry-mixed; the binding agent is added, mixed and milled; the plasticizer is added and stirred; and the mixture is extruded and molded. The environment-friendly anhydrous stemming is safe to the human body and environment, high in performance, low in consumption, and good in slag erosion resistance and scouring resistance.

Owner:CHINA JINGYE ENG +1

Environmental-friendly water-based fire extinguishing agent and its preparation method

InactiveCN102350032ANot easy to cause pollutionLeave quicklyFire extinguisherWater basedAntiseptic Agent

The invention relates to an environmental-friendly water-based fire extinguishing agent, which comprises: deionized water, an antiseptic agent, a metal antirust agent, a halogen-free fire retardant, a hydrocarbon surfactant, a high efficiency chelating agent, 2-5 parts of an osmotic agent and a high efficiency corrosion inhibitor. The preparation method of the water-based fire extinguishing agentconsists of the steps of: adding deionized water into a dispersing cylinder according to the weight part, then adding the antiseptic agent, the metal antirust agent, the halogen-free fire retardant and the hydrocarbon surfactant, and stirring the mixture uniformly till completely salvation of the mixture; then adding the high efficiency chelating agent, the osmotic agent and the high efficiency corrosion inhibitor, stirring them uniformly till semi-clarity, thus obtaining the finished product. Containing a halogen free fire retardant, the fire extinguishing agent of the invention can be biologically degraded 100%, thus having no pollution to surrounding equipment and space. Containing an osmotic agent, the fire extinguishing agent in the invention can penetrate articles in fire hazards ofclass A, and can penetrate into the inside of combustible articles, so that even if the fire is not completely put out due to a large fire, the part injected with the agent can effectively block a fire source and control the spreading speed of a fire. Therefore, the fire extinguishing agent provided in the invention has excellent flame resistance.

Owner:广东卫斯理化工科技有限公司

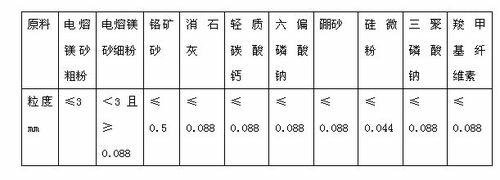

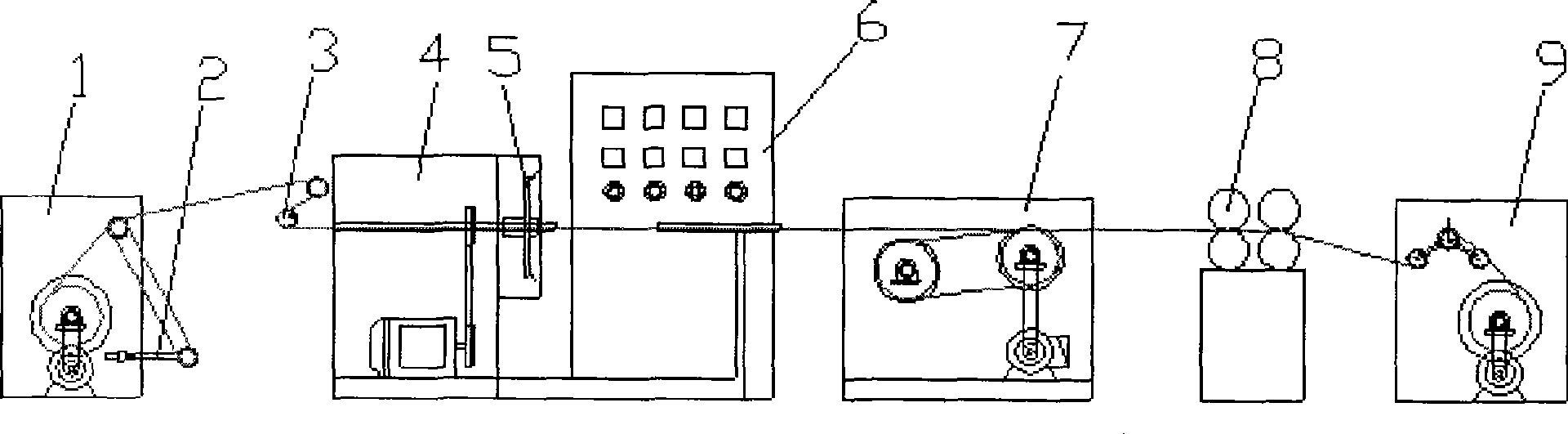

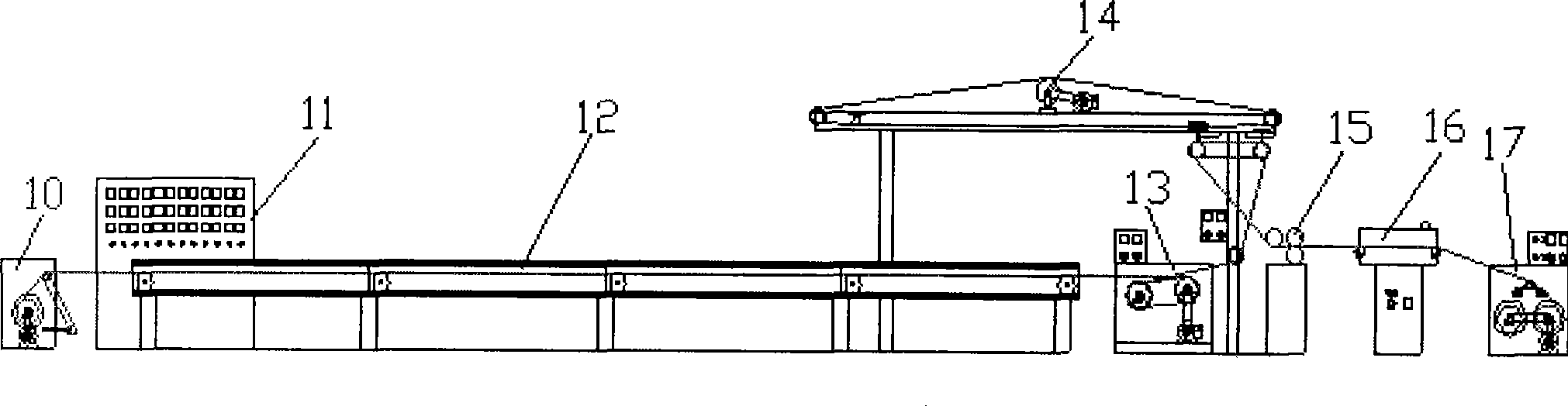

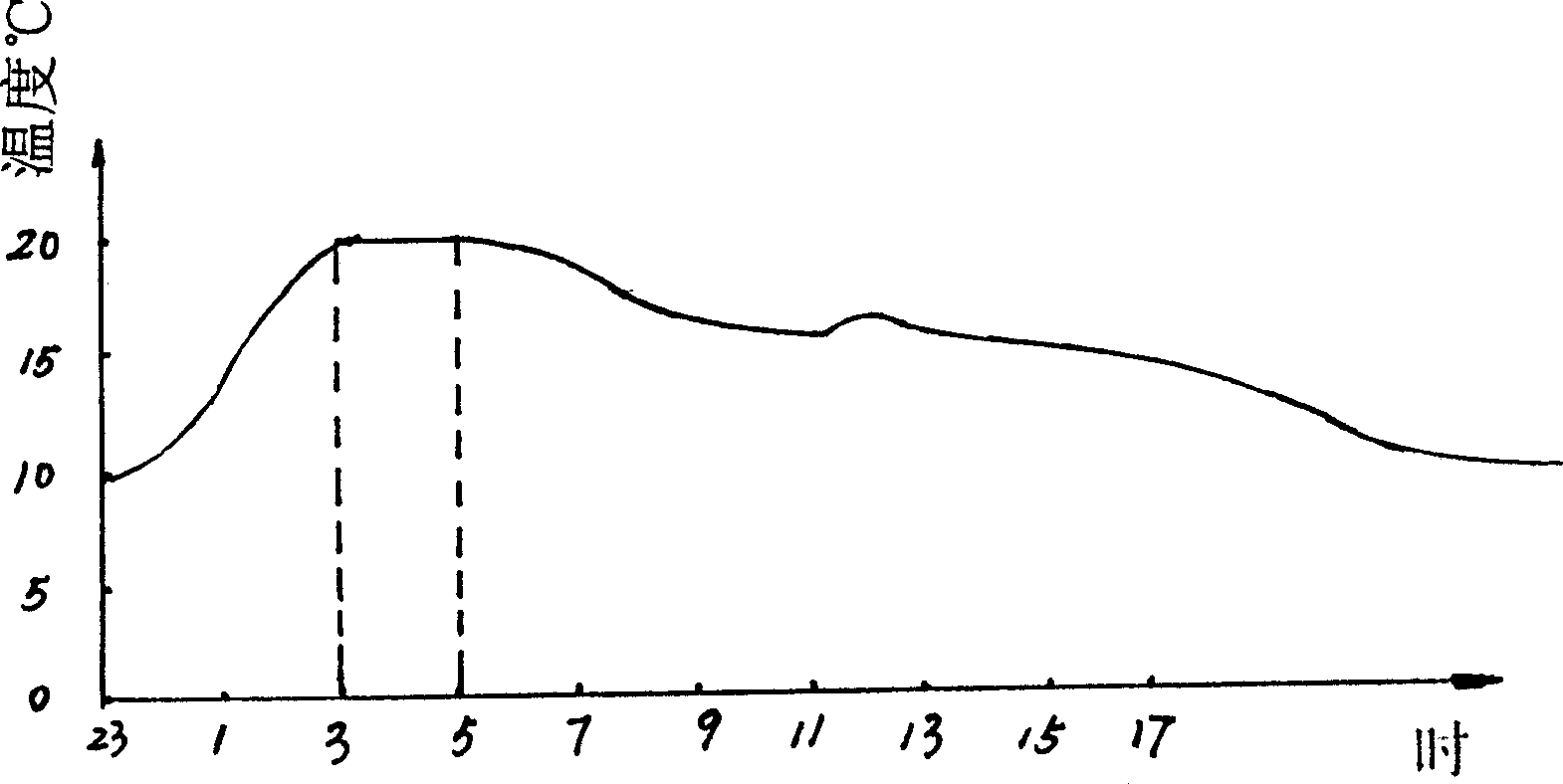

Device and process for baking dark tea

ActiveCN102302064AImprove drying qualityMellow tastePre-extraction tea treatmentAgricultural engineeringBULK ACTIVE INGREDIENT

The invention discloses a device and a process for baking dark tea, and relates to equipment and a process for drying the dark tea. The device for baking the dark tea is provided with a drying chamber, wherein a ventilated interlayer is arranged in the middle of the drying chamber; the lower part of the drying chamber is provided with a baking chamber and a seven-star stove; a closed hot air circulation chamber covers the drying chamber; an air blower is arranged inside or outside the hot air circulation chamber; air inlet and outlet pipes of the air blower are communicated with the circulation chamber and the baking chamber respectively; and one side of the circulation chamber is provided with a dehumidifier. The process for baking the dark tea comprises the following steps of: uniformlyspreading tea which is fermented and retwisted into the interlayer of the drying chamber at one time during baking, burning charcoal or aerating carbon dioxide hot air in the seven-star stove, starting the air blower to promote the hot air to circulate, starting the dehumidifier and dehumidifying, and controlling the temperature in the circulation chamber to 60 to 70 DEG C. The baking temperatureand humidity can be effectively controlled, so that inclusions of the tea can be fully transformed into active ingredients such as theaflavin, thearubigins, tea polysaccharide and the like; the production efficiency is high and the labor intensity is low; and the tea has good drying quality and does not have smoke taste, the baked dark tea has pure mouthfeel, and the soup color is red, yellow andperfectly clear, and has tangy fragrance.

Owner:湖南安化芙蓉山茶业有限责任公司

Glass fiber reinforced halogen-free flame-retardant polybutylene terephthalate (PBT)

ActiveCN102321349AEnvironmental protection is goodImprove heat resistanceEnvironmental resistanceAntioxidant

The invention relates to glass fiber reinforced halogen-free flame-retardant polybutylene terephthalate (PBT), which is characterized by being prepared from the following raw materials in part by mass: 40 to 50 parts of PBT, 10 to 20 parts of halogen-free flame retardant, 2 to 8 parts of acrylate copolymer, 1 to 5 parts of nano-scale polyethylene terephthalate (PET), 1 to 5 parts of antioxidant and 20 to 40 parts of glass fibers, wherein the halogen-free flame retardant is melamine salt. Products prepared from the glass fiber reinforced halogen-free flame-retardant PBT are low-smoke, environment-friendly, hard to break and easy to process and form.

Owner:JIANGYIN LONGSHAN SYNTHETIC MATERIAL

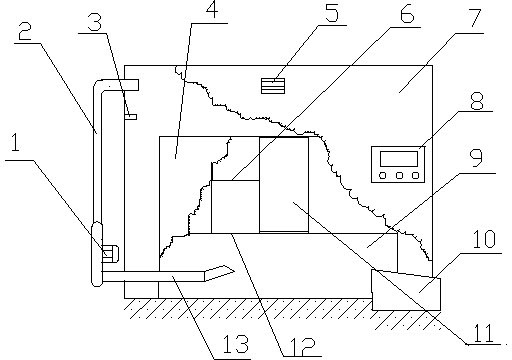

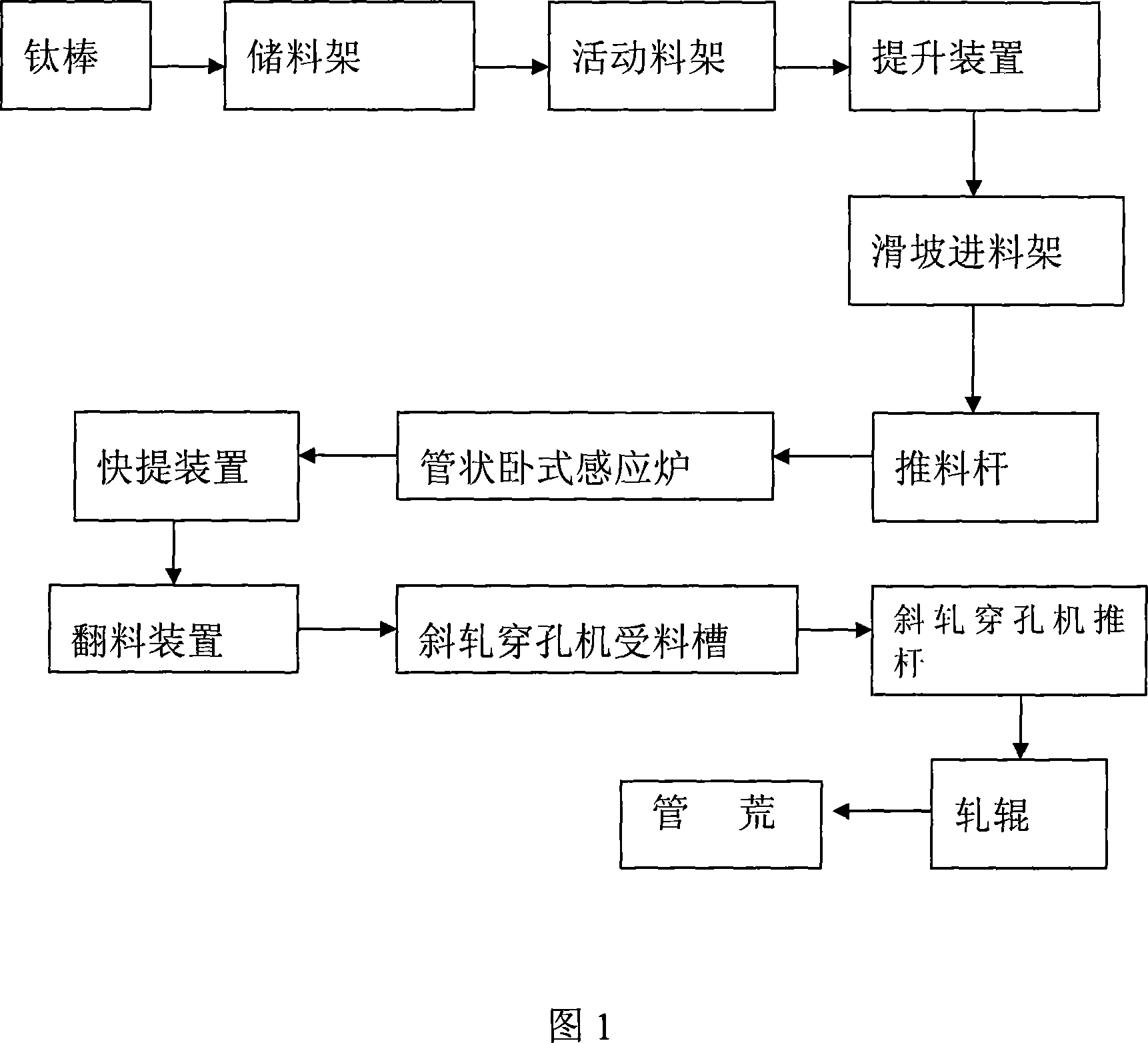

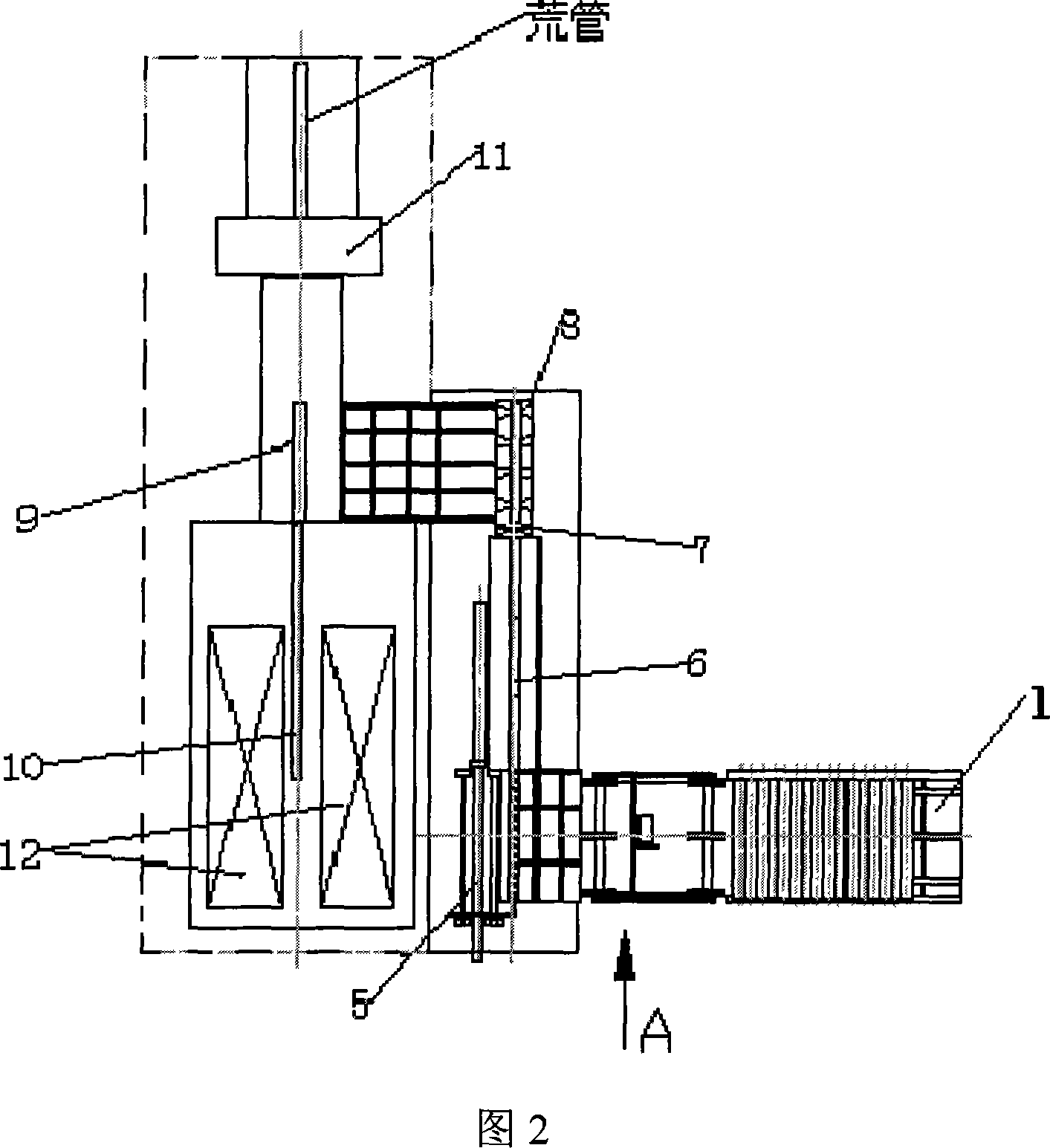

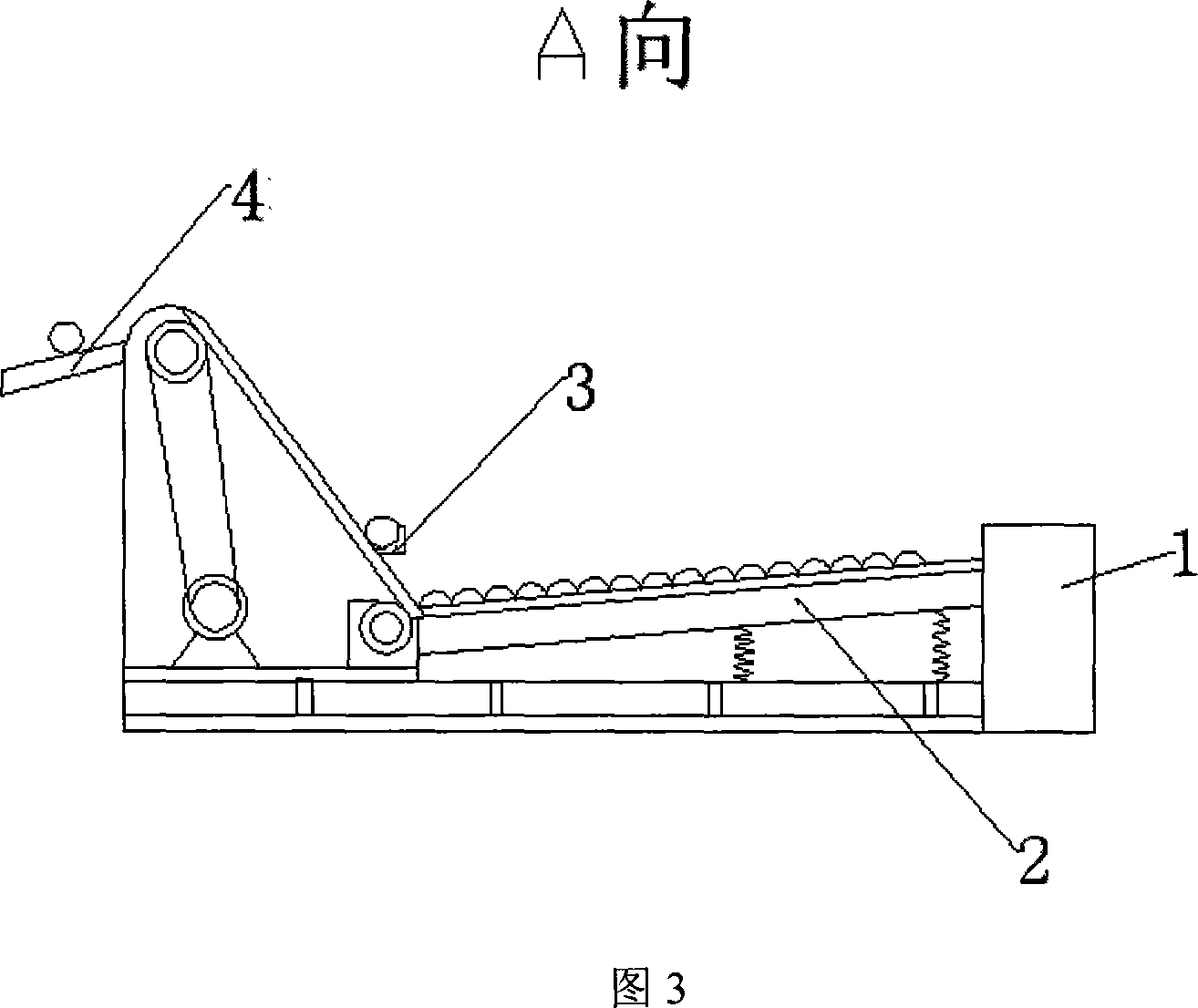

Process for heating titanium oblique perforating rod ingot

InactiveCN101029348AHeating fastReduce oxidationTemperature control deviceFurnace typesPunchingMonitoring system

Process for heating titanium-oblique rolling punch rod blank adopts horizontal step-by-step medium-frequency induction heating finance as tool. The heating furnace consists of automatic skip mechanism, core-watch temperature differential monitoring system and fast-extraction discharge mechanism. The process is carried out by hoisting titanium rod onto bedding rack by overhead traveling crane, arranging on movable bedding rack paralleled, lifting titanium-rod onto charge rack on slop by production beat, entering into horizontal step-by-step medium-frequency induction heating furnace successively, moving titanium-rod forwardly by step-by-step mode, raising temperature while homogeneous heating, discharging, entering into blow tank of oblique-rolling punch, nipping and punching to raw pipe. It's simple, safe and cheap and has no environmental pollution.

Owner:WESTERN TITANIUM TECH

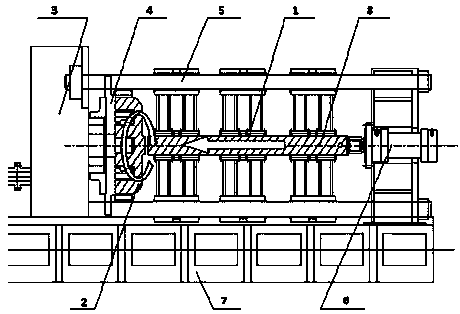

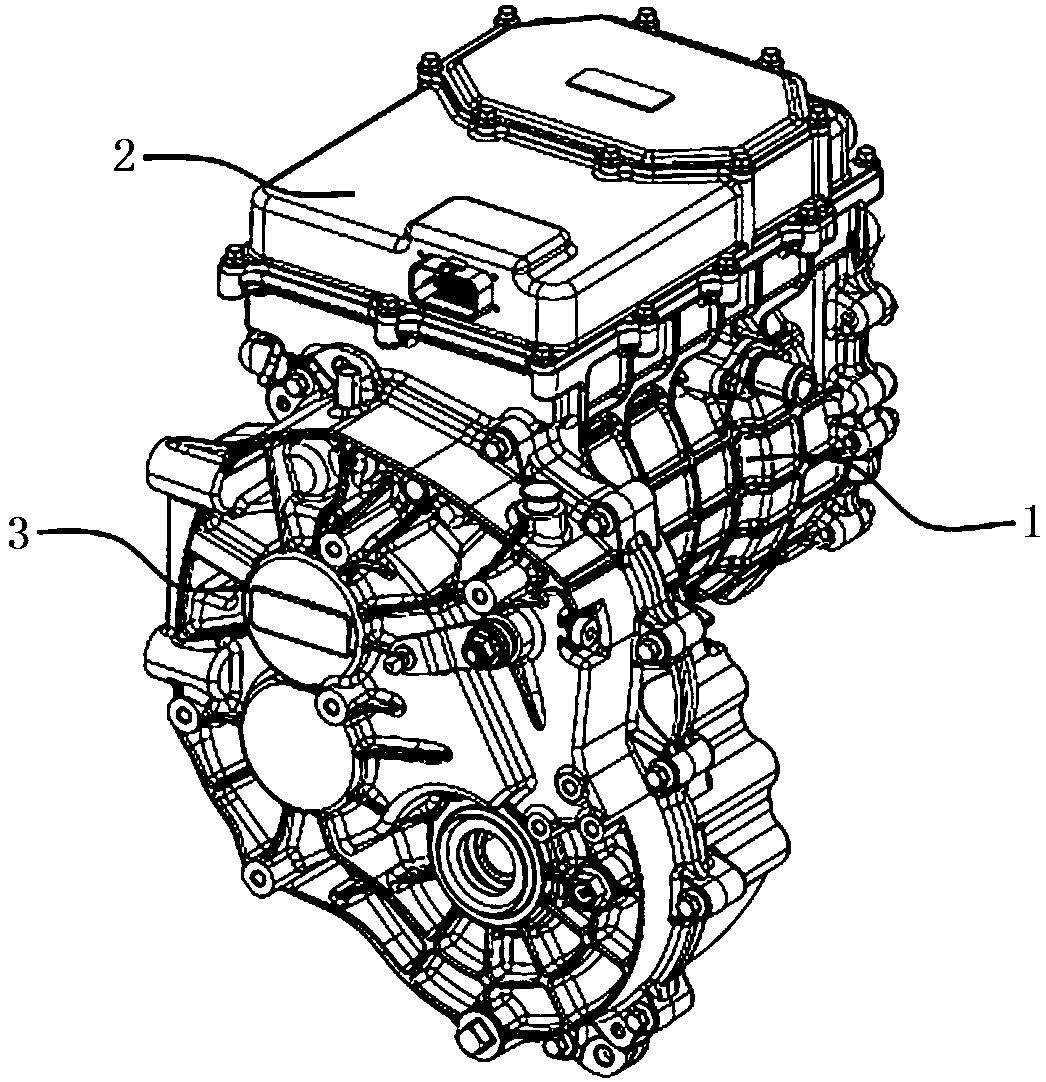

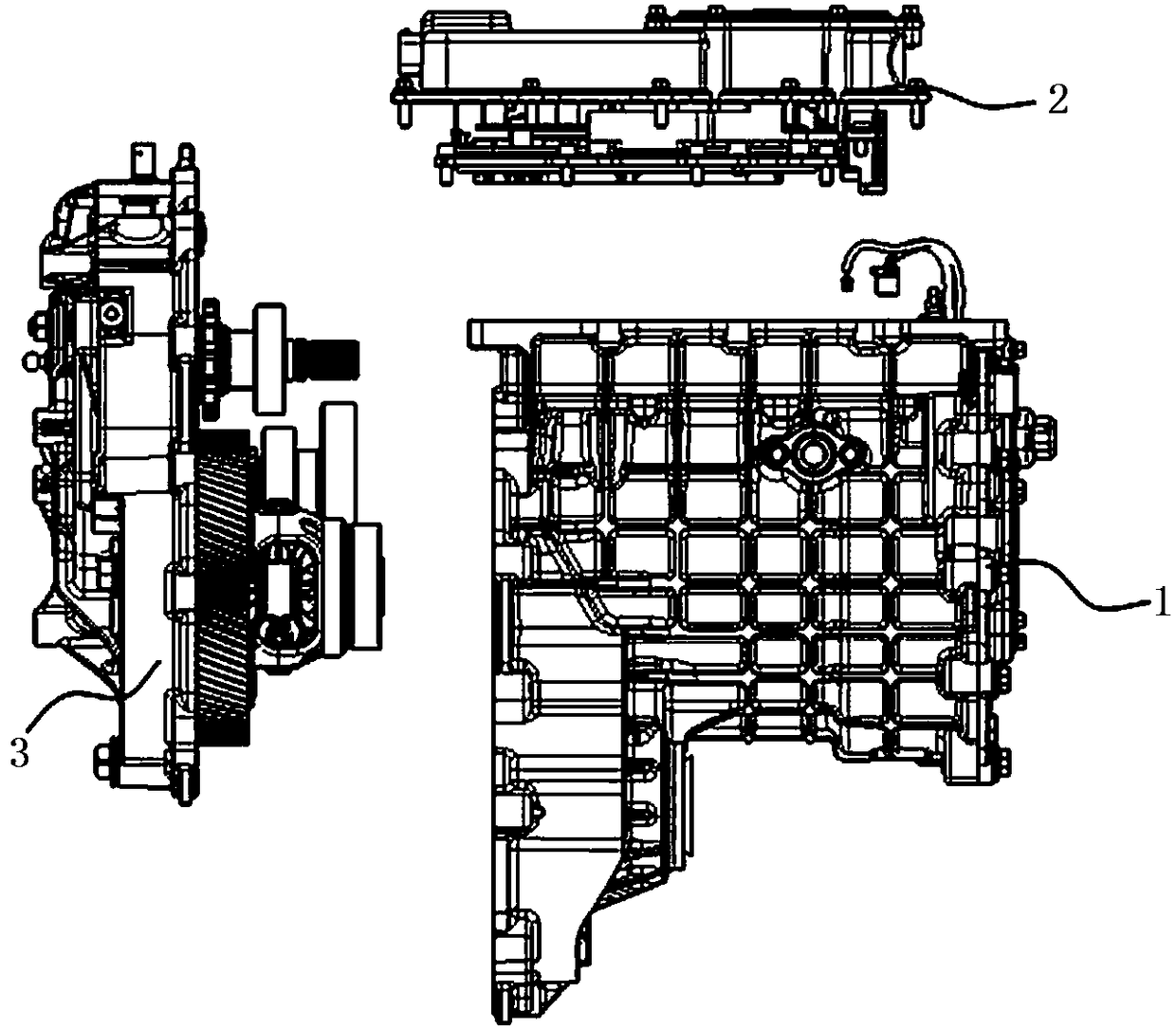

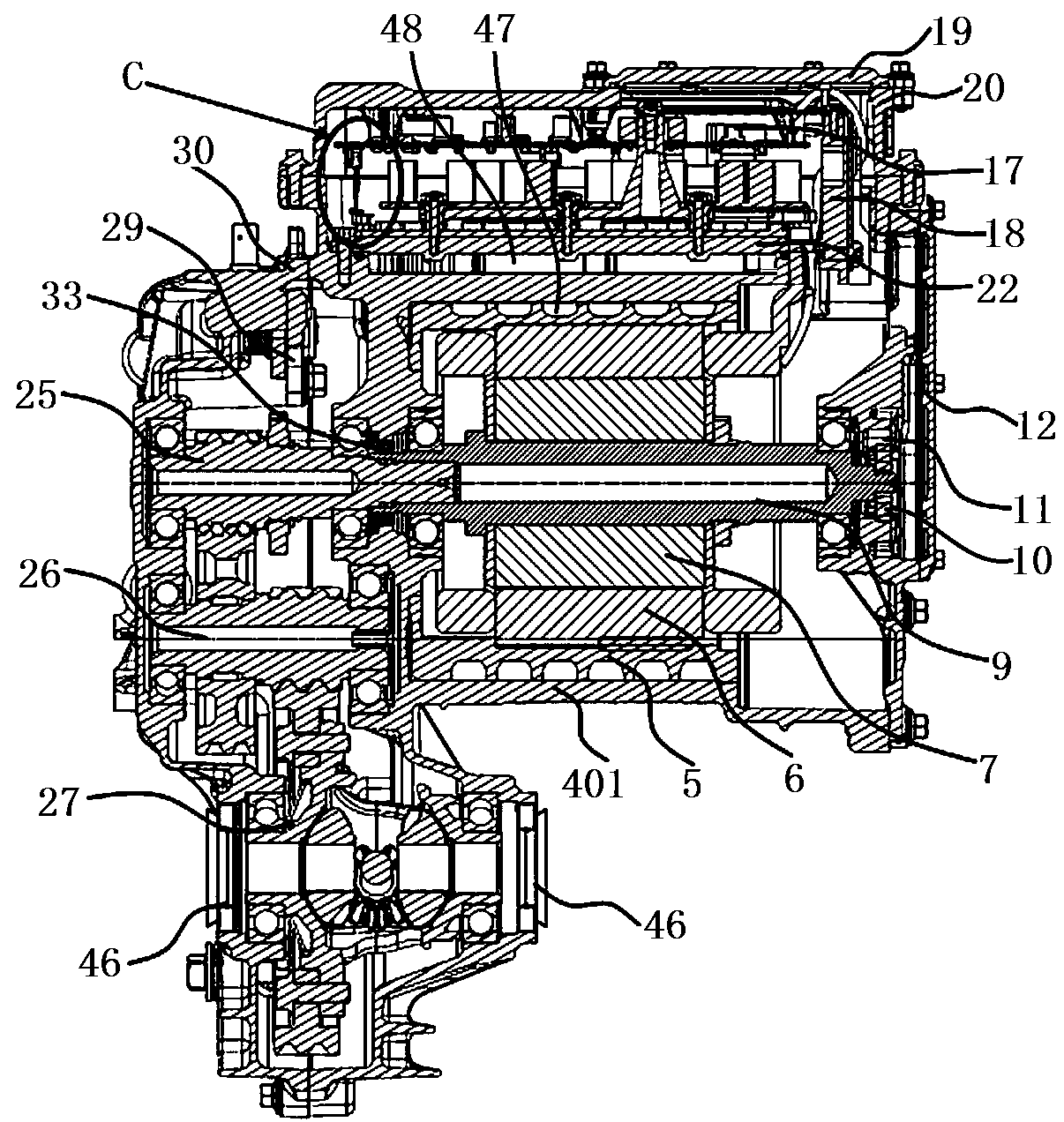

Deeply integrated electric drive system

PendingCN109378945AReduce residual stressAvoid deformationAssociation with control/drive circuitsMechanical energy handlingMOSFETLow voltage

Disclosed is a deeply integrated electric drive system. The deeply integrated electric drive system includes a motor module, a motor controller module and a gearbox module which are integrated. A motor shell of the motor module is formed by stirring, rubbing and welding a motor water jacket outer sleeve and a motor water jacket inner sleeve. The motor controller module includes a MOSFET module, adirect current filter module, a MOSFET water cooling board, a control board, a three-phase copper bar and a motor controller cover assembly. The gearbox module includes an input shaft assembly, an intermediate shaft assembly, a differential assembly, a parking mechanism and a gearbox cover assembly. The motor module and the motor controller module adopt integrated cooling water channels. The electric drive system integrates a motor, a motor controller and a gearbox. The motor controller is integrated with the MOSFET module, and so the size is reduced. The motor and the motor controller are connected by the three-phased copper bar which are internally arranged, and adopt integrated cooling water channels without external connection of a high and low voltage wiring harness and a cooling water pipe. The deeply integrated electric drive system has the advantages of high reliability, low cost and convenient logistics transportation.

Owner:上海伊控动力系统有限公司

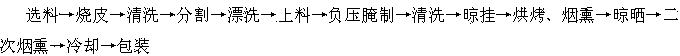

Making method of negative-pressure marinated bacon

ActiveCN104172222AEvenly saltedShort marinating timeMeat/fish preservationClimate change adaptationBurned skinLean meat

The invention belongs to the field of processing of foods and particularly relates to a making method of negative-pressure marinated bacon. The making method is characterized by comprising the following steps: selecting materials, burning skin, washing, cutting, rinsing, loading, marinating, washing, airing, hanging, baking, smoking, airing, then cooling and packaging, wherein the marinating is negative-pressure marinating, namely rough meat after loading is placed into a negative-pressure container and laminated tidily, then, the container is vacuumized till 0.08-0.085MPa, then the container is closed, a vacuum state is always maintained for 4 days for marinating, and the temperature of a marinating environment is 2-6 DEG C. The bacon made by the making method provided by the invention has a clean and sanitary surface and no smoke and dust, and is convenient to eat, safe and healthy; the strip-like shape is complete, the skin color is golden and bright, and lean meat is in rose red; the marinated taste is unique, oily but not greasy, delicious and tasty.

Owner:SICHUAN RUNYU FOOD

Carbon deposit detergent for gasoline direct injection engine combustion chamber

ActiveCN108659993AEasy to cleanImprove cleaning efficiencyOrganic detergent compounding agentsDetergent mixture composition preparationCombustion chamberFuel oil

Owner:GUANGDONG YUEFU AUTOMOTIVE SUPPLIES

Method for manufacturing smokeless incombustible temperature-resistant tetrafluoroethylene electric wire

InactiveCN101533688AUniform apparent densityHigh apparent densityPlastic/resin/waxes insulatorsInsulated cablesStrong acidsOxygen

The invention provides a method for manufacturing smokeless incombustible temperature-resistant tetrafluoroethylene electric wire, comprising the steps of uniformly and seamlessly winding tetrafluoroethylene colour raw material belt for winding and sintering on nickel plated copper stranded wire according to a certain winding angle, improving the apparent density of winding belt by a shaping technology, and finally sintering so as to obtain the smokeless incombustible temperature-resistant tetrafluoroethylene electric wire. The invention has the advantages that 1. the thickness is uniform, the surface is smooth, and the compactness is high; 2. the manufacturing process is simple and the operation is simple and convenient; 3. the manufacturing cost is reduced by 50% compared with the manufacturing method in a paste extrusion manner; and 4. the breakdown resistant voltage can be 6000-8000V, the used rated voltage is 600V, the temperature range for long term usage is -65 to 260 DEG C, the limited oxygen index is more than 95, and the electric wire is incombustible and resistant to strong acids, strong alkalis and aging.

Owner:四会市生料带厂有限公司

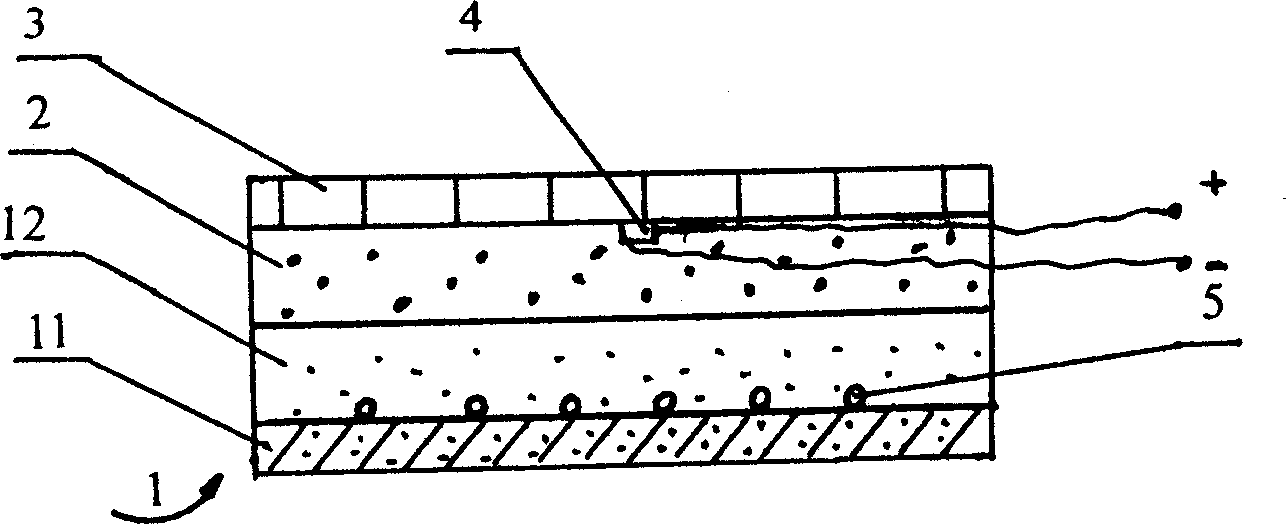

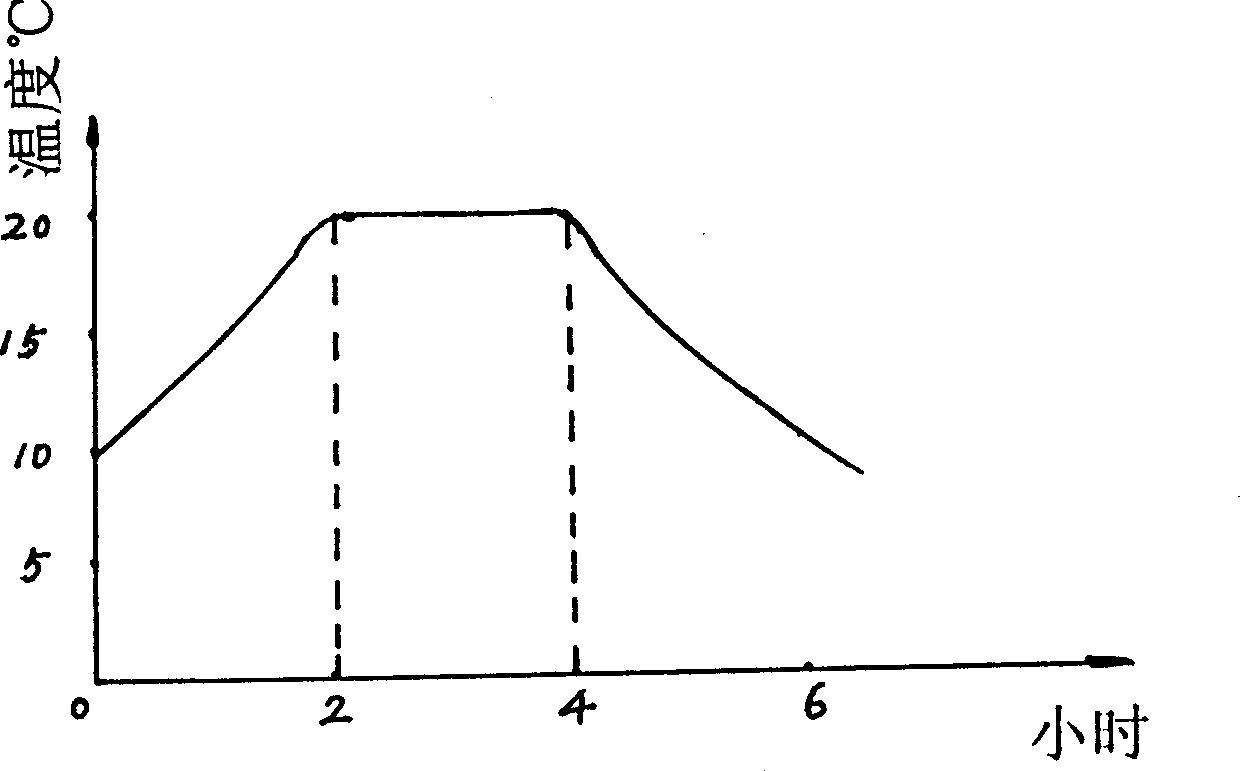

Static thermal-storage heating-amount slow-release structure and construction process and use thereof

InactiveCN1488895APreferential electricity priceLower heating costsLighting and heating apparatusElectric heating systemControl modeElectric energy

The present invention relates to a geothermic electric heating static heat-stored heating heat quantity slowly-releasing structure, its construction process and application. Its structure comprises up-down laminated heat-storing layer and heat quantity slowly-releasing layer, the geothermic cable is embedded in the heat-storing layer formed from heat-storing material whose heat-conducting coefficient is 0.3-0.79w.m(-1).k(-1), said heat-storing layer is covered with the slowly-releasing layer formed from slowly-releasing material whose heat-conducting coefficient is 0.04-0.07 w.m(-1).k(-1), and the temp. sensor is embedded in the slowly-releasing layer, and is series-connected with geothermal cable loop. Its application includes the following steps: starting power supply to supply power to geothermic cable, and storing heat energy in heat-storing layer, then slowly-releasing the heat energy to heating space by means of slowly-releasing layer.

Owner:孙侠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com