Equipment for extracting gold and silver from lead/bismuth base alloy

A bismuth-based alloy and equipment technology, applied in the field of non-ferrous metallurgy, can solve the problems of small output of staged vacuum distillation, large amount of soot and slag, and high energy consumption of ash blowing method, and achieve the improvement of production environment, large processing capacity and significant environmental benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

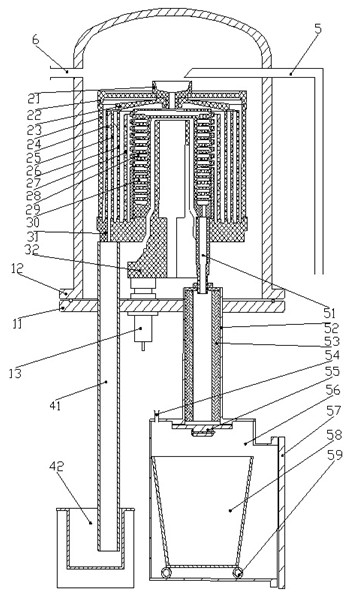

[0033] Embodiment 1: as Figure 1-3 shown, a lead from / Equipment for extracting gold and silver from bismuth-based alloys, including a vacuum furnace body, an evaporation system, a volatile matter discharge system, a crude silver alloy discharge system, a feed pipe 5 and an exhaust pipe 6. The vacuum furnace body is equipped with an evaporation system, the bottom of the evaporation system is respectively connected with the volatile matter discharge system and the coarse silver alloy discharge system, the feed pipe 5 passes through the furnace shell of the vacuum furnace body to the top of the evaporation system, and the exhaust pipe 6 passes through The furnace shell of the vacuum furnace body communicates with its inner cavity.

[0034] The vacuum furnace body includes a furnace chassis 11 , a furnace shell 12 and a water-cooled electrode 13 . The furnace bottom plate 11 is sealed and connected to the bottom end of the furnace shell 12 , and the water-cooled electrode 13 ...

Embodiment 2

[0046] Embodiment 2: as Figure 1-3 shown, a lead from / Equipment for extracting gold and silver from bismuth-based alloys, including a vacuum furnace body, an evaporation system, a volatile matter discharge system, a crude silver alloy discharge system, a feed pipe 5 and an exhaust pipe 6. The vacuum furnace body is equipped with an evaporation system, the bottom of the evaporation system is respectively connected with the volatile matter discharge system and the coarse silver alloy discharge system, the feed pipe 5 passes through the furnace shell of the vacuum furnace body to the top of the evaporation system, and the exhaust pipe 6 passes through The furnace shell of the vacuum furnace body communicates with its inner cavity.

[0047] The vacuum furnace body includes a furnace chassis 11 , a furnace shell 12 and a water-cooled electrode 13 . The furnace bottom plate 11 is sealed and connected to the bottom end of the furnace shell 12 , and the water-cooled electrode 13 ...

Embodiment 3

[0059] Embodiment 3: as Figure 1-3 shown, a lead from / Equipment for extracting gold and silver from bismuth-based alloys, including a vacuum furnace body, an evaporation system, a volatile matter discharge system, a crude silver alloy discharge system, a feed pipe 5 and an exhaust pipe 6. The vacuum furnace body is equipped with an evaporation system, the bottom of the evaporation system is respectively connected with the volatile matter discharge system and the coarse silver alloy discharge system, the feed pipe 5 passes through the furnace shell of the vacuum furnace body to the top of the evaporation system, and the exhaust pipe 6 passes through The furnace shell of the vacuum furnace body communicates with its inner cavity.

[0060] The vacuum furnace body includes a furnace chassis 11 , a furnace shell 12 and a water-cooled electrode 13 . The furnace bottom plate 11 is sealed and connected to the bottom end of the furnace shell 12 , and the water-cooled electrode 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com