UL94-5VA-grade high-performance flame-retardant reinforced PC (polycarbonate)/ABS (acrylonitrile butadiene styrene) blend and preparation method thereof

A high-performance, blending technology, applied in the field of polymer materials, can solve the problems of polymers that are difficult to achieve, rarely reported, and low in heat resistance, and achieve the effects of reduced loss, low combustion smoke, and high heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

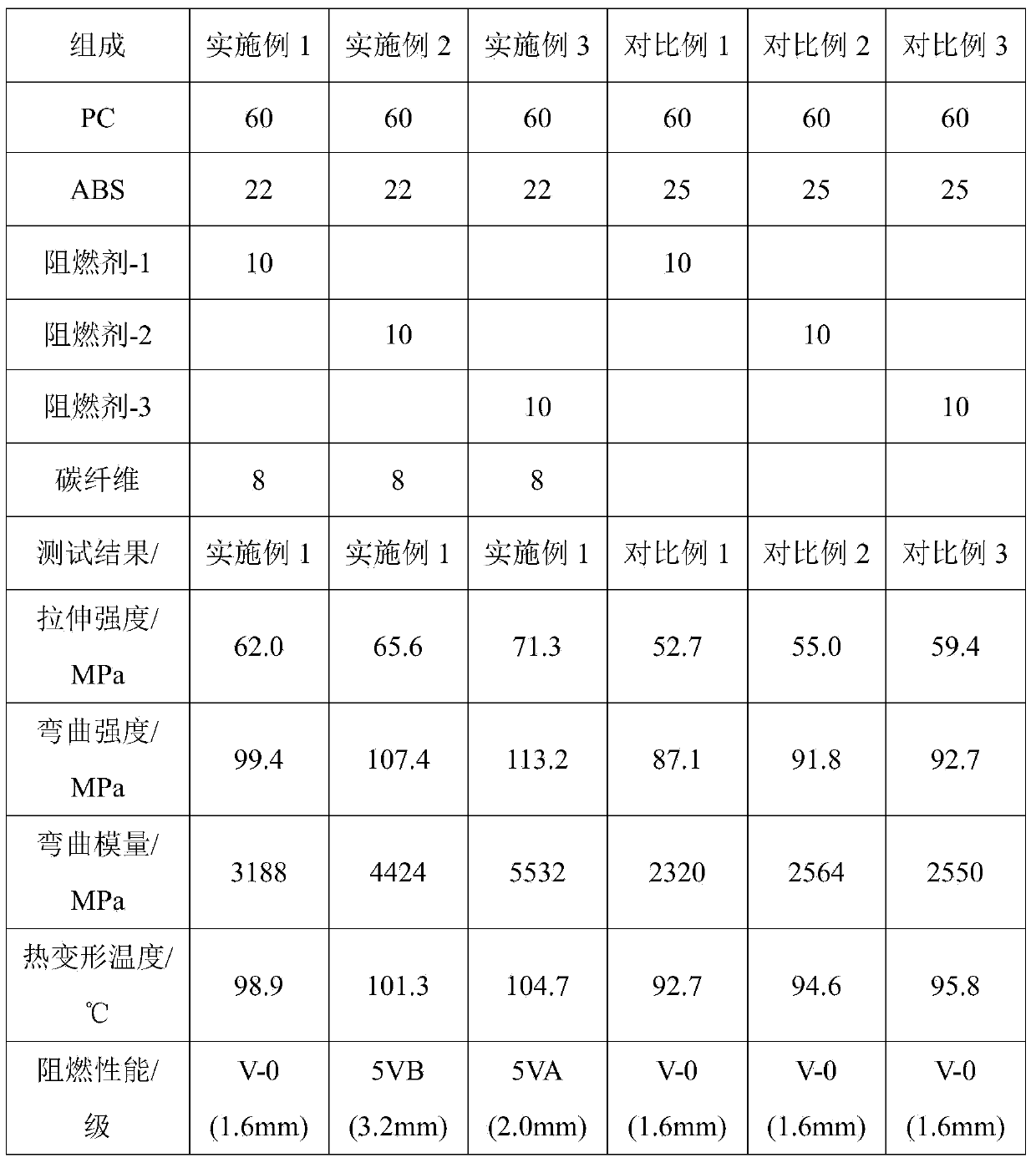

Embodiment 1~3 and comparative example 1~3

[0031] Weigh each component according to the percentages of the corresponding Examples 1-4 and Comparative Examples 1-3 in Table 1, put the carbon fiber in the side feeding bin of the twin-screw extruder, and mix the rest of the components evenly and put them into the twin-screw extruder. The main feeding bin for screw extrusion, the screw diameter is 35 mm, the length-to-diameter ratio L / D=36, the speed of the main engine is 400 rpm, and the temperature of each section of the main barrel (from the feeding port to the exit of the machine head) is 215 ° C, 220 ° C ℃, 225℃, 230℃, 230℃, 230℃, the product can be obtained after melt extrusion, granulation, drying and other processes. Standard test specimens were prepared by injection molding machine for tensile, bending, thermal deformation, flame retardancy and other properties.

[0032] Table 1

[0033]

[0034] It can be seen from Table 1 that the flame retardant system for conventional PC / ABS blend materials, whether it is ...

Embodiment 5~8 and comparative example 4

[0036] Weigh each component according to the corresponding percentages of Examples 5-8 and Comparative Example 4 in Table 2, place the carbon fiber in the side feeding bin of the twin-screw extruder, and mix the remaining components evenly before putting them into the twin-screw extruder. Out of the main feeding bin, the diameter of the screw is 35 mm, the length-to-diameter ratio L / D=36, the speed of the main machine is 400 rpm, and the temperature control of each section of the main machine barrel (from the feeding port to the outlet of the machine head) is 215 ° C, 220 ° C, 225°C, 230°C, 230°C, 230°C, the product is obtained after melt extrusion, granulation, drying and other processes. Standard test specimens were prepared by injection molding machine for tensile, bending, thermal deformation, flame retardancy and other properties.

[0037] Table 2

[0038]

[0039]

[0040] It can be seen from Table 2 that the content of carbon fiber has a direct impact on the flam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com