Friction welding method of aluminum guide rod and steel claw

A technology of friction welding and aluminum guide rods, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of large consumption, high resistivity of the contact interface, and harsh working conditions, so as to reduce resistance, Good process stability and continuous molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

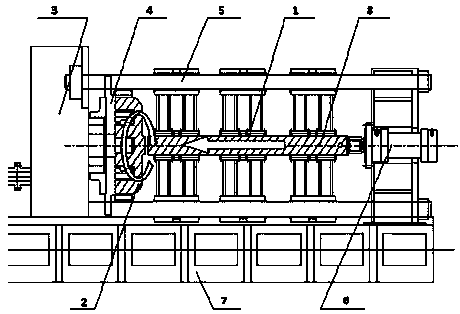

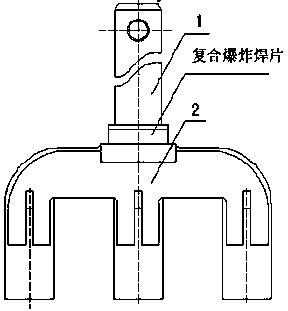

[0017] Aiming at the problem that large-section aluminum and steel friction pairs can quickly realize the high-temperature plastic metal sealing the entire friction surface at the friction boundary and avoid huge mechanical vibration and excessive friction shortening, friction heating adopts four-stage variable spindle speed, feed speed and friction heating. The time parameter of the heating method. The four-stage friction heating includes: the first stage of friction is applied to the initial friction stage using a friction time of 10 seconds to reduce and eliminate the mechanical vibration of the local contact of the workpiece at a lower rotation speed of 70 rpm; the second stage of friction is applied to the initial friction stage using friction The time is 40 seconds, at a low rotation speed of 70 rpm and a low working speed of 0.1-0.3mm / s, the temperature of the workpiece end face shaft and radial direction increases and reaches an unstable friction stage with a uniform te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com