Carbon deposit detergent for gasoline direct injection engine combustion chamber

A gasoline in-cylinder direct injection and carbon deposit cleaning agent technology, which is applied to engine components, machines/engines, detergent compositions, etc. Road sealing performance and service life, inability to clean the combustion chamber of the direct injection engine, etc., to achieve the effect of restoring the atomization effect, low cost, and improving power

Active Publication Date: 2018-10-16

GUANGDONG YUEFU AUTOMOTIVE SUPPLIES

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Polyetheramine (PEA) can also clean carbon deposits, but the cost is higher

However, the current commercially available solvent-based cleaning agents have a certain swelling effect on the rubber and plastic parts of the pipeline, which will affect the sealing performance and service life of the oil circuit; the cost of commercially available cleaning agents is relatively high; the cleaning effect is not good, and the cleaning efficiency is low; In particular, existing commercially available cleaning agents are harmful to the three-way catalyst (such as attaching or covering the three-way catalyst, or deactivating the three-way catalyst), which affects the ser

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

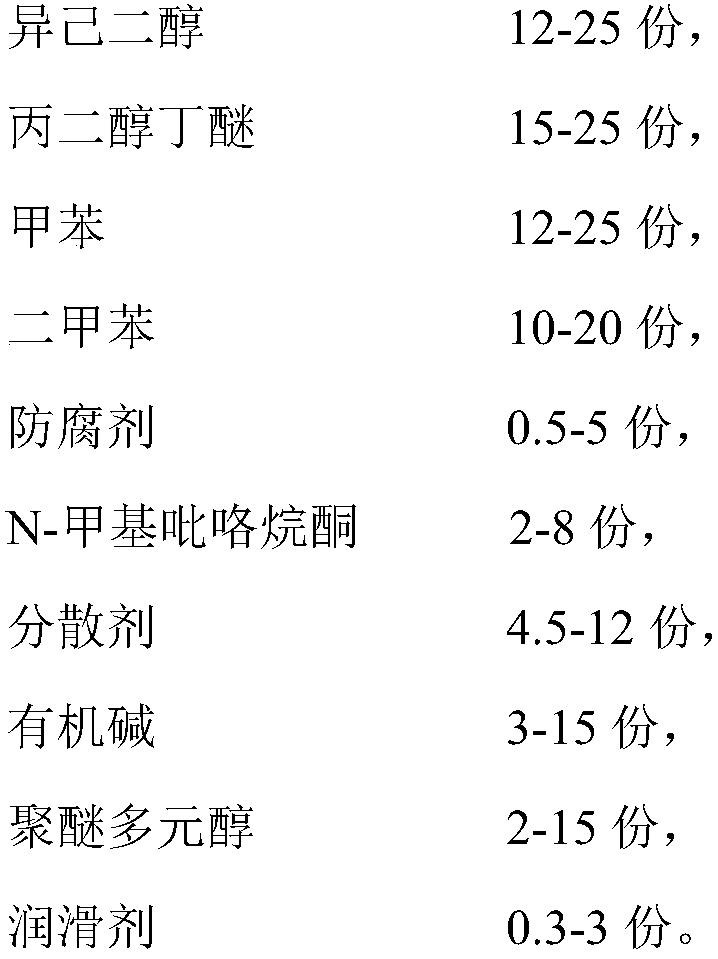

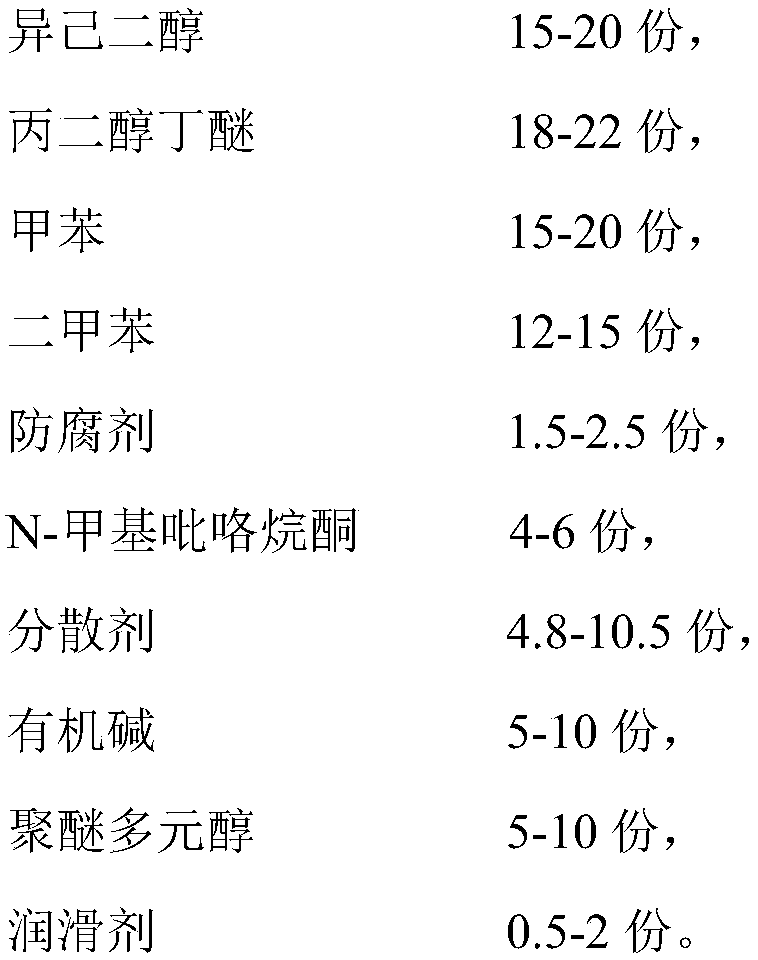

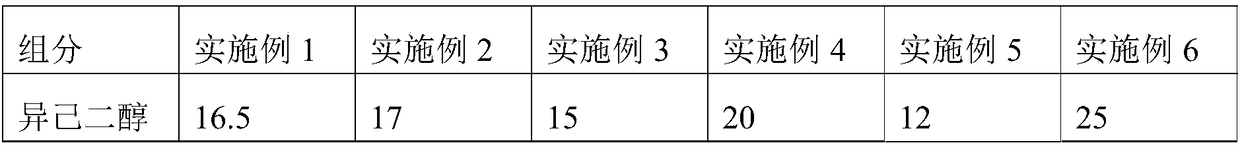

The invention discloses a carbon deposit detergent for a gasoline direct injection engine combustion chamber. The carbon deposit detergent is prepared from the following components in parts by weight:12 to 25 parts of 2-methyl-2,4-pentendiol, 15 to 25 parts of propanediol butyl ether, 12 to 25 parts of methylbenzene, 10 to 20 parts of xylene, 0.5 to 5 parts of preservative, 2 to 8 parts of N-methyl pyrrolidone, 4.5 to 12 parts of dispersing agent, 3 to 15 parts of organic alkali, 2 to 15 parts of polyether polyols, and 0.3 to 3 parts of lubricating agent. The carbon deposit detergent for thegasoline direct injection engine combustion chamber is good in cleaning effect, high in cleaning efficiency, harmless to a ternary catalytic converter, and capable of effectively cleaning the carbon deposit in the combustion chamber, optimizing the air inlet amount, improving the utilization efficiency of the fuel oil and improving the current situation of difficulty in cold starting.

Description

technical field [0001] The invention belongs to the technical field of automobile carbon deposit cleaning, and in particular relates to a carbon deposit cleaning agent used in a combustion chamber of a direct injection engine in a gasoline cylinder. Background technique [0002] A gasoline direct injection engine (GDI, Gasoline Direct Injection engine) or a gasoline direct injection engine (T-GDI) equipped with a turbocharger directly injects gasoline into the combustion chamber without passing through the intake port. In the daily use of the vehicle, although the design is very sophisticated, due to the differences in the quality of oil products in various gas stations in various regions of China, and other external factors such as forced ventilation of the engine crankcase, exhaust gas recirculation and other systems, the combustion chamber of the direct injection engine cannot Avoid carbon deposits. Carbon deposits in the fuel injector will lead to poor atomization effec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11D7/32C11D7/26C11D7/24C11D3/37C11D7/60C11D11/00F02B77/04

CPCC11D3/3707C11D7/24C11D7/247C11D7/261C11D7/263C11D7/32C11D7/3218C11D7/3281C11D11/0041F02B77/04

Inventor 林壮

Owner GUANGDONG YUEFU AUTOMOTIVE SUPPLIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com