Patents

Literature

1197 results about "N methyl pyrrolidone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for preparing purified terephthalic acid

InactiveUS6013835AOrganic compound preparationCarboxylic preparation by oxidationPolyester resinSide reaction

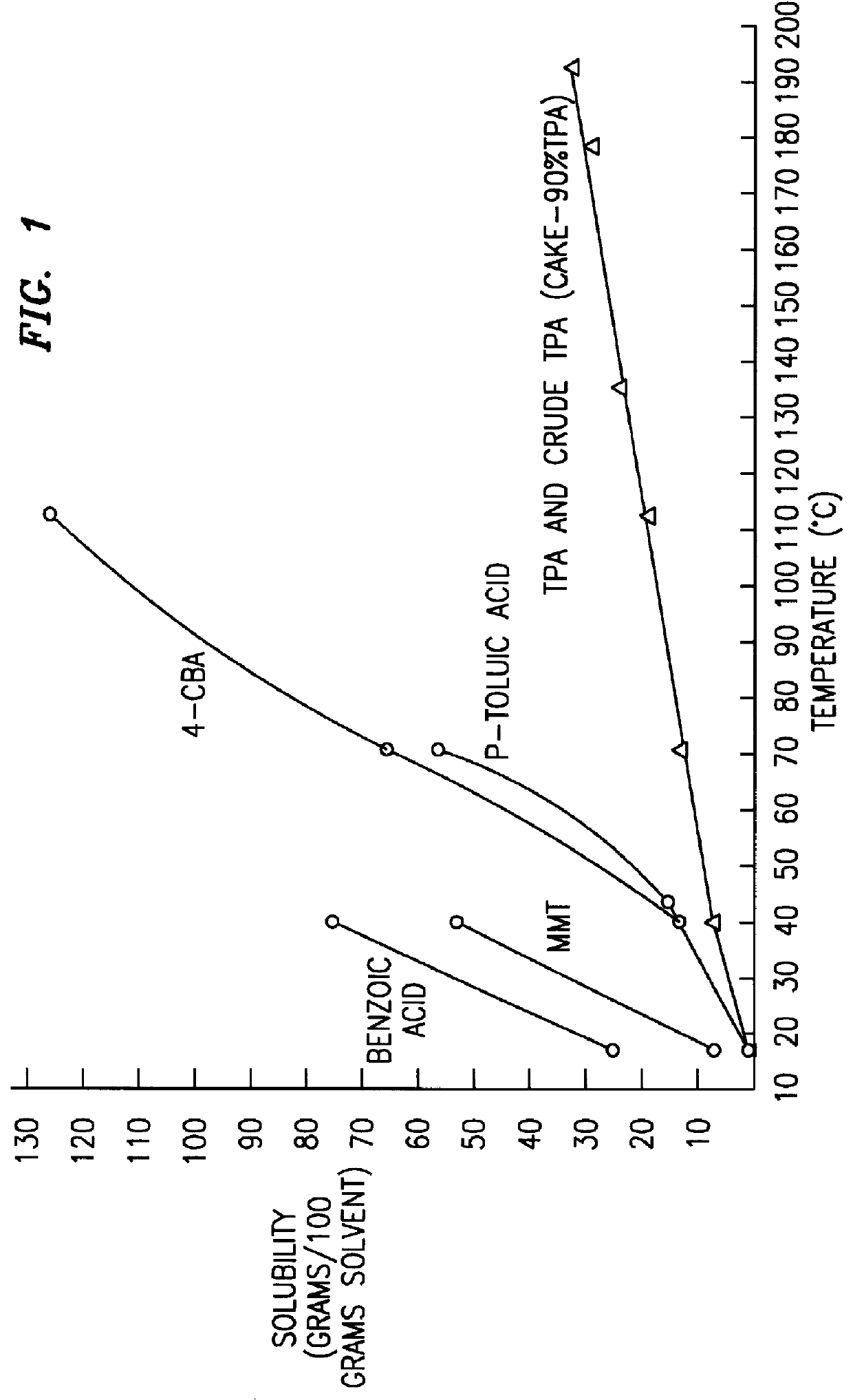

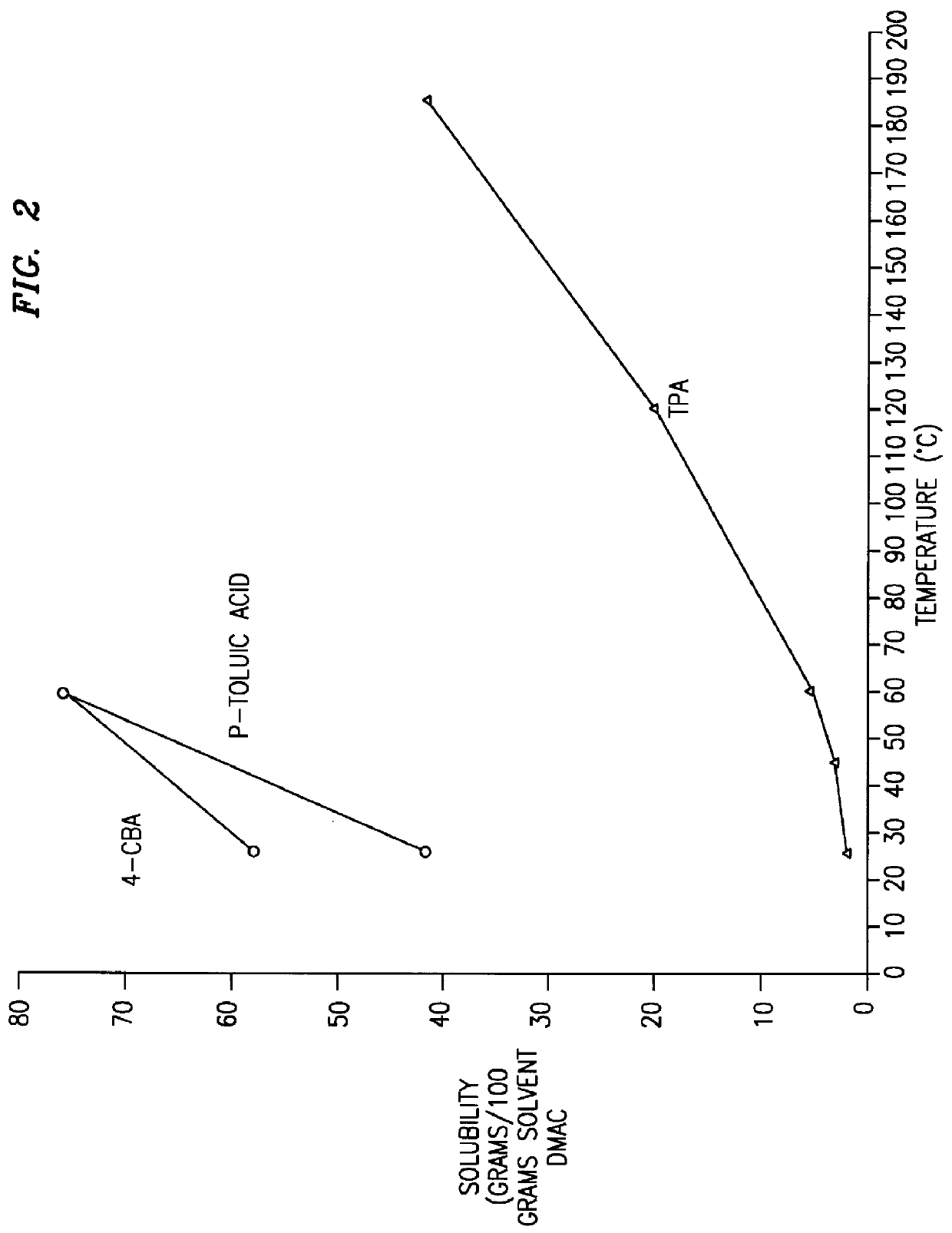

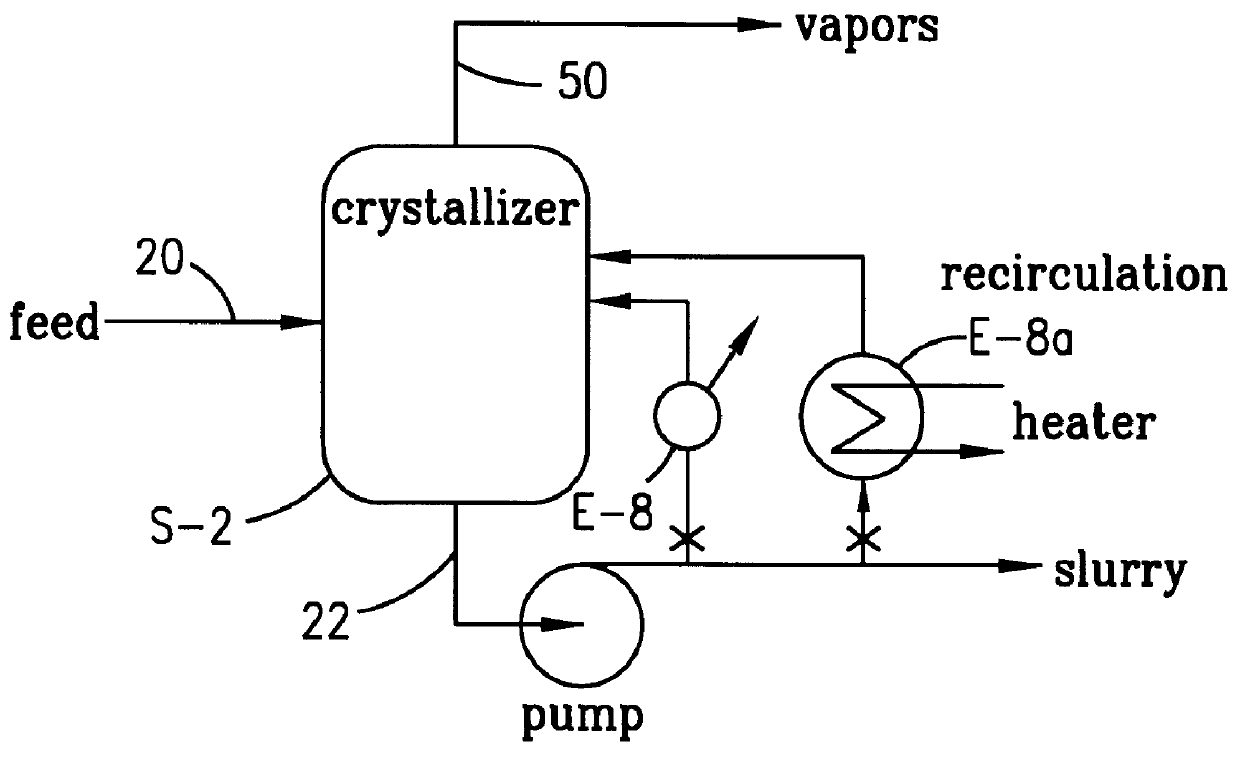

A method and apparatus for purifying crude terephthalic acid from a liquid dispersion thereof also containing impurities selected from unreacted starting materials, solvents, products of side reactions and / or other undesired materials is provided. The method comprises the steps of filtering the dispersion to form a crude terephthalic acid filter cake, dissolving the filter cake in a selective crystallization solvent at an elevated temperature to form a solution, crystallizing purified terephthalic acid from the solution in the crystallization solvent by reducing the pressure and temperature of the solution, and separating the crystallized purified terephthalic acid from the solution. According to the invention, the selective crystallization solvent is non-aqueous, non-corrosive and essentially non-reactive with terephthalic acid. Preferably, the selective crystallization solvent is N-methyl pyrrolidone. The method and apparatus produces purified terephthalic acid having a purity desired for use in forming polyester resin and other products at an economically attractive rate and at operating conditions of reduced severity which require a lower capital investment and simplified processing.

Owner:GTC TECHNOLOGY INC

Large scale process for polymerization of dapbi-containing polyaramid

A method for obtaining an aromatic polyamide crumb from an aromatic diamine and an aromatic diacid chloride, which aromatic polyamide comprises 5(6)-amino-2-(p-aminophenyl)benzimidazole terephthalamide units and has a relative viscosity ηrel of at least 3, by: (1) adding at least monomers (i)-(iii) in N-methyl pyrrolidone as solvent wherein (i) is 0-30 mole % para-phenylenediamine (PPD), (ii) is 20-50 mole % 5(6)-amino-2-(p-aminophenyl)benzimidazole (DABPI), (iii) is 49.05-50.05 mole % terephthaloyl dichloride (TDC), and optionally calcium chloride to obtain a CaCl2 / aromatic diamine molar ratio less than 0.5, and an aromatic diamine / aromatic diacid chloride ratio between 0.99 and 1.01; (2) mixing the monomers and the optional calcium chloride to a homogenous mixture having a monomer concentration of 5 to 12 wt %; followed by (3) adding calcium chloride to the homogeneous mixture to obtain a CaCl2 / aromatic diamine molar ratio 0.6-1.0; and (4) polymerizing the mixture.

Owner:TEIJIN ARAMID BV

N-methylpyrrolidone-free polyurethane dispersions based on dimethylolpropionic acid

InactiveUS20060240264A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePropanoic acid

The present invention relates to aqueous polyurethane dispersions that are free from N-methylpyrrolidone and other solvents and wherein the polyurethanes are the reaction products of A) a mixture of 25% to 90% by weight of 1-isocyanate-3,3,5,-trimethyl-5-isocyanatomethylcyclohexane (IPDI) and 10% to 75% by weight of 4,4′-diisocyanatodicyclohexylmethane, wherein the preceding percentages are based on the weight of component A), with B) one or more polyols having average molarcular weights (Mn) of 500 to 6000, C) one or more compounds which have at least one OH— or NH-functional group and contain a carboxyl and / or carboxylate group, wherein at least 50 mol % of the acid groups, based on the total moles of acid incorporated into the polyurethane, are incorporated by dimethylolpropionic acid, D) one or more polyols and / or polyamines having average molecular weights (Mn) of below 500, and E) optionally one or more monoalcohols and / or monoamines. The present invention also relates to a process for preparing the aqueous polyurethane dispersions and to the use of the polyurethane dispersions for preparing coatings or adhesives.

Owner:BAYER MATERIALSCIENCE AG

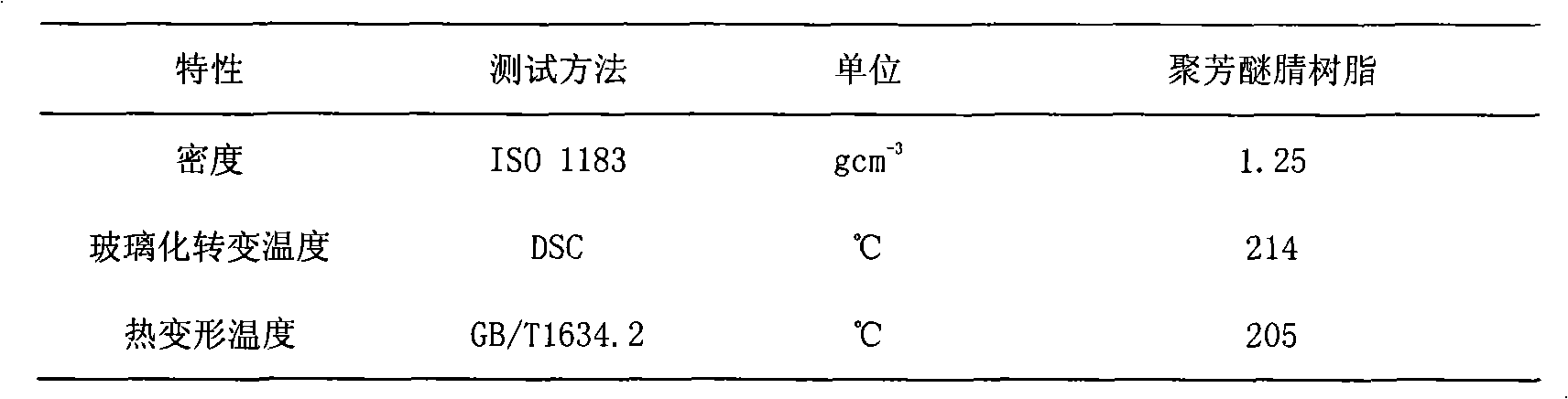

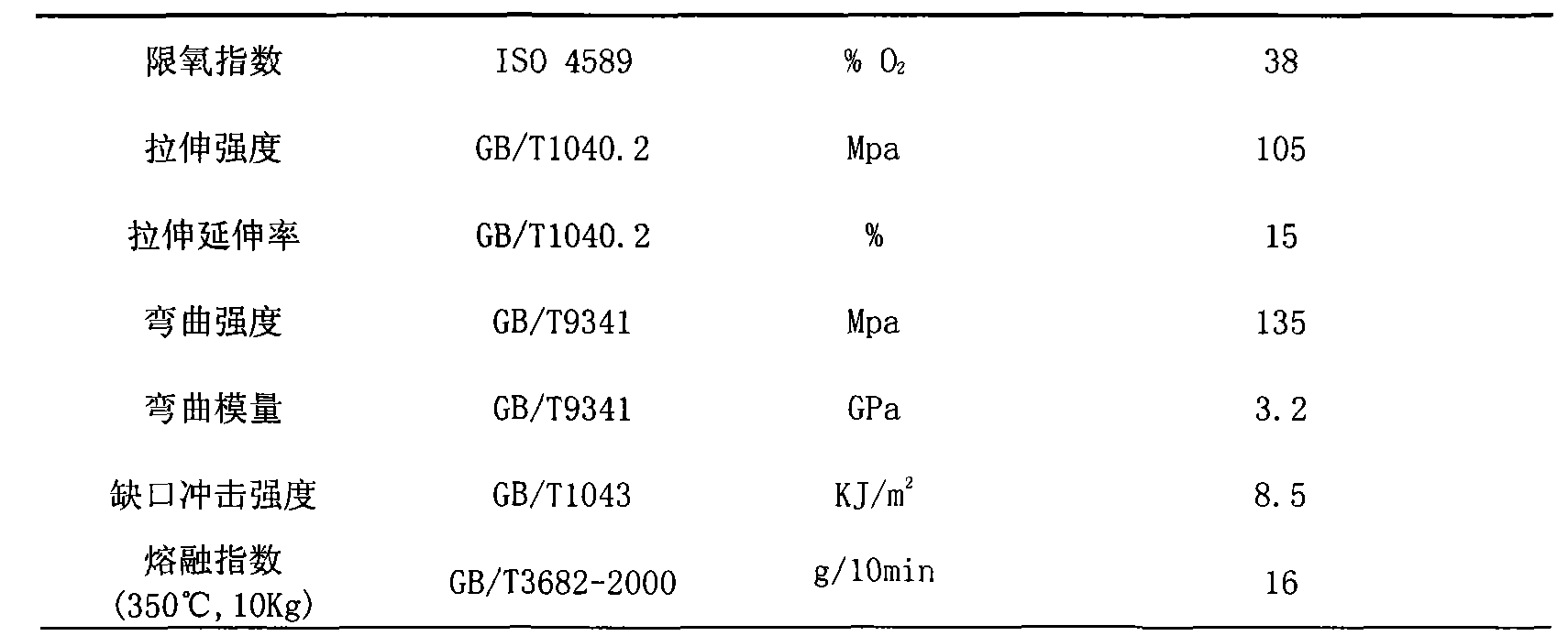

Method for preparing poly(arylene ether nitrile) resin

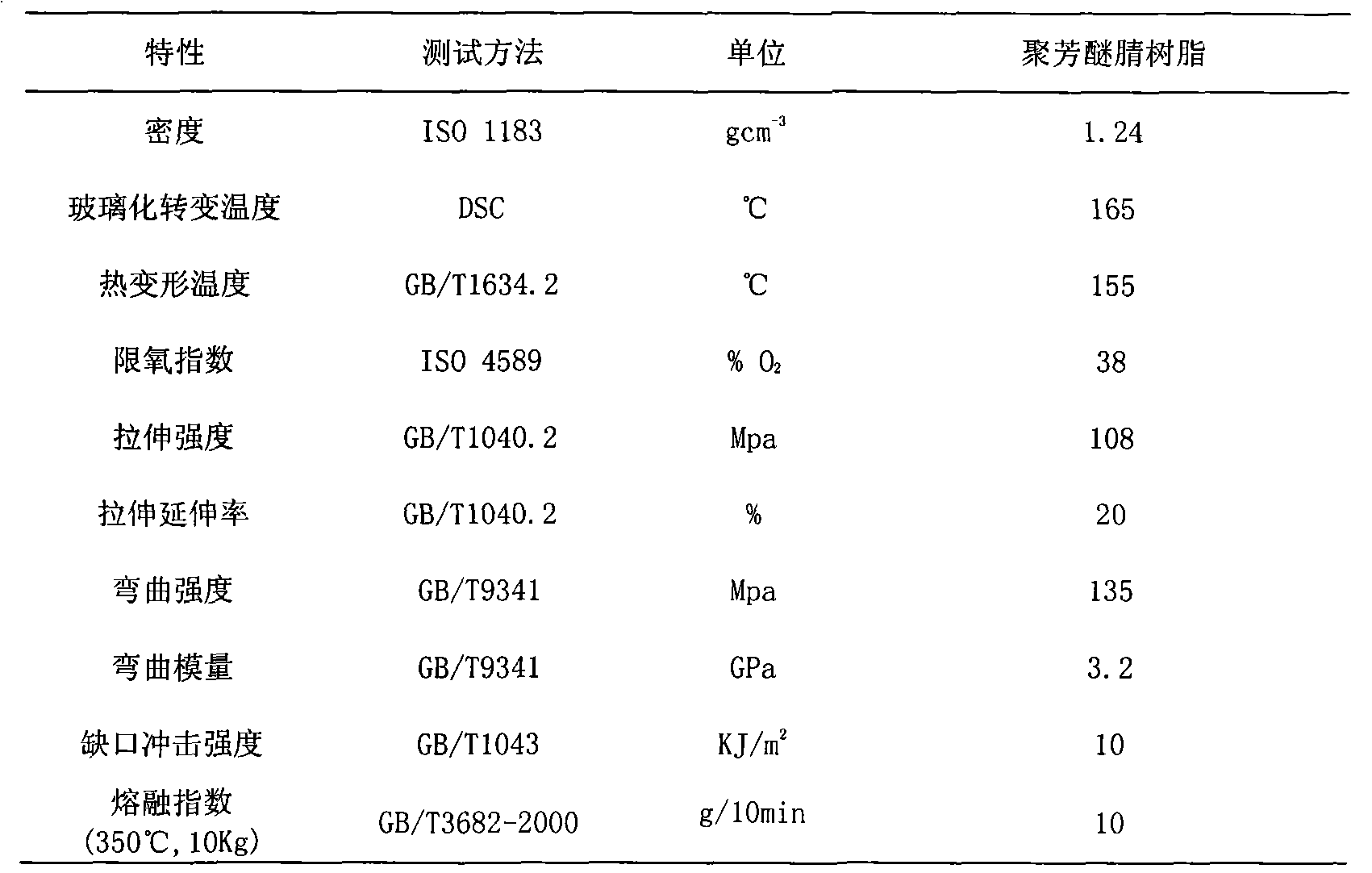

The invention discloses a method for preparing poly(arylene ether nitrile) resin, which belongs to the technical field of high polymer materials. The method comprises the following steps of: finishing a reaction in a reaction kettle under normal pressure under the actions of a catalyst and a dehydrating agent by taking 2,6-dichlorobenzonitrile and aromatic dicarboxylic phenol as raw materials and taking N-methyl pyrrolidone as a solvent; pressurizing and atomizing solution after dilution to a precipitating agent for precipitating; after heating, stirring and refluxing a precipitate and the precipitating agent to finish solvent extraction, performing solid-liquid separation by using a centrifugal machine; allowing liquid to enter a rectifying tower for rectifying and recovering the solvent; and drying solid after washing with boiling water to obtain the poly(arylene ether nitrile) resin of the invention. The method has the characteristics of easily implemented production conditions, and safe and environmentally-friendly production process. The poly(arylene ether nitrile) resin prepared by adopting the method of the invention has the characteristics of high purity and stable performance, and can be applied to the field of aerospace, electronics, machinery, medical treatment, chemical industry and the like.

Owner:SICHUAN FEIYA NEW MATERIAL

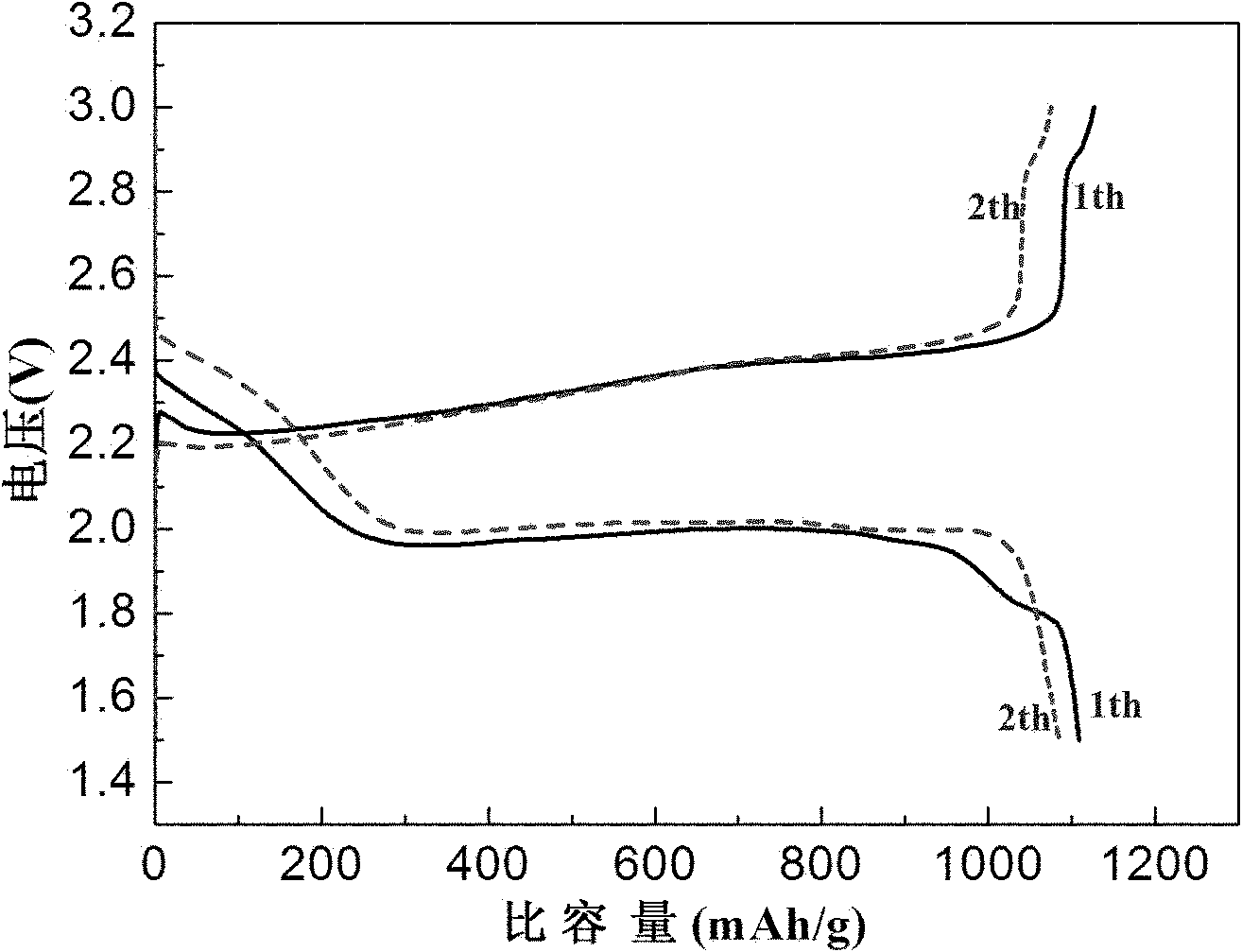

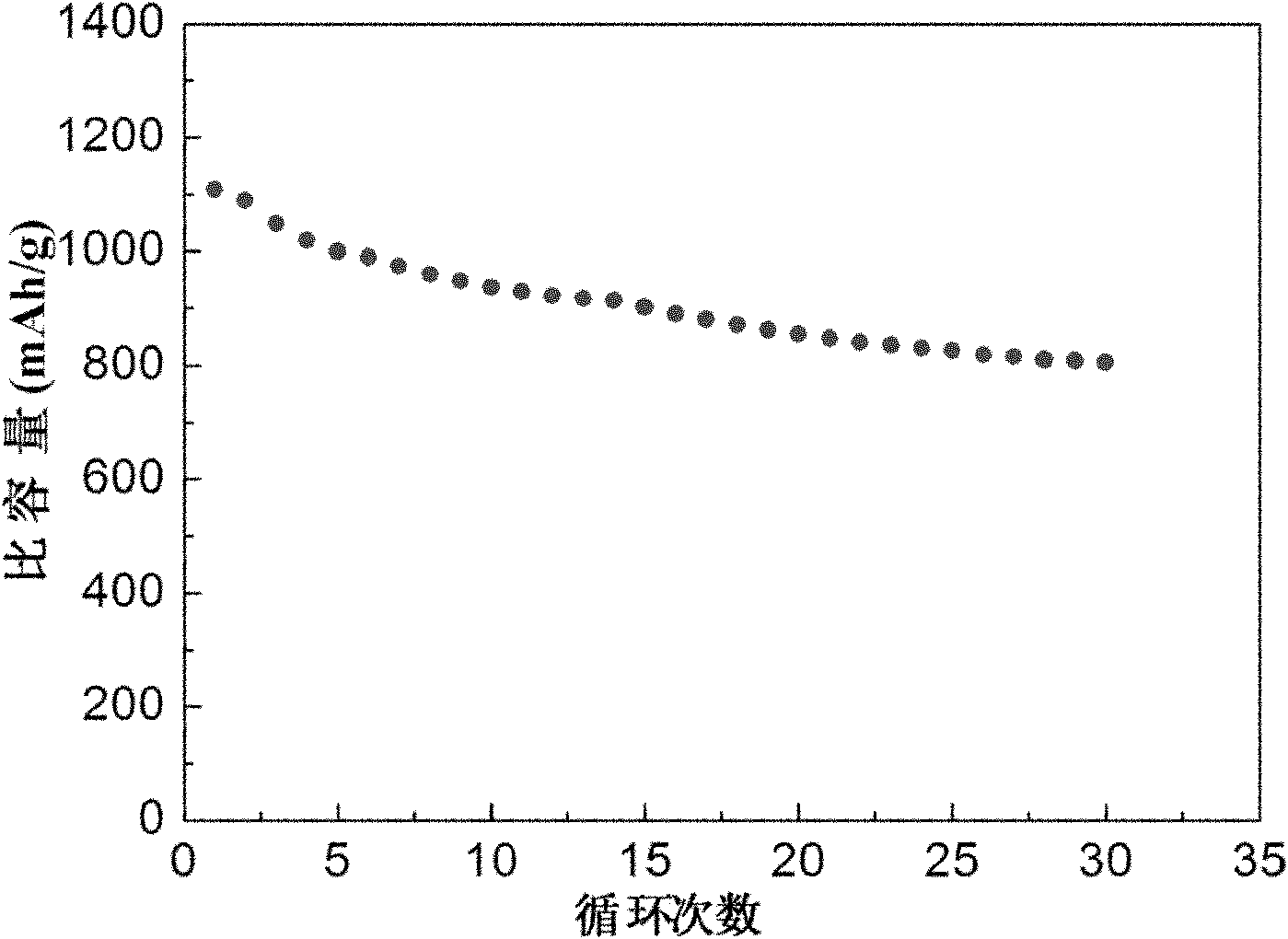

Porous nano carbon fiber material, lithium battery cathode material and cathode plate

ActiveCN102127828AEasy to operateAperture controllableFilament/thread formingSecondary cellsFiberCarbon fibers

The invention discloses a porous nano carbon fiber material, a lithium battery elemental sulfur / porous nano carbon fiber composite anode material and an anode plate which are prepared from the porous nano carbon fiber material. The lithium battery elemental sulfur / porous nano carbon fiber composite anode plate is prepared by using the method: (1) mixing lithium battery elemental sulfur / porous nano carbon fiber composite anode material shown by the right requirements 3 with acetylene black and an adhesive and uniformly stirring to obtain a mixture; and (2) adding an N-methyl pyrrolidone solution to the mixture obtained in the step (1), proportioning into paste and scraping the paste on a carbon-coated aluminum foil as a current collector and drying to obtain an elemental sulfur / porous nano carbon fiber composite anode plate. Lithium sulphur batteries made by utilizing the anode plate of the invention have greatly-improved cycle performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for producing high-arene environment-friendly rubber oil

The invention relates to a method for producing high-arene environment-friendly rubber oil. The method comprises the steps of taking heavy-solvent extract oil of a lubricating-oil solvent-refining device as raw material, adding an auxiliary agent to the raw material and then refining solvent, wherein the heavy-solvent extract oil has the flash point higher than 200 DEG C, the kinematic viscosity greater than 15.0 mm<2> / s at 100 DEG C and the CA value greater than 35.0 percent; the auxiliary agent is single-hydrocarbon or light-hydrocarbon oil with low density, low viscosity and boiling point between 80 and 300 DEG C; the solvent is N-methyl pyrrolidone, phenol or furfural; a refining tower has the temperature between 50 and 100 DEG C on the top and has the temperature between 30 and 100 DEG C on the bottom; and the mass ratio of the raw material to the auxiliary agent to the solvent is 1.0:0.1-0.5:2.0-5.0. Refined oil is high in arene content; the CA value of the refined oil is above 19.0 percent; the arene content of the refined oil is greater than 50.0 percent; the PCA content of the refined oil determined by an IP346 method is less than 3.0 percent; the benzopyrene of the refined oil is less than 1 PPM; and the total content of eight specific polyaromatic hydrocarbon is less than 10 PPM.

Owner:PETROCHINA CO LTD

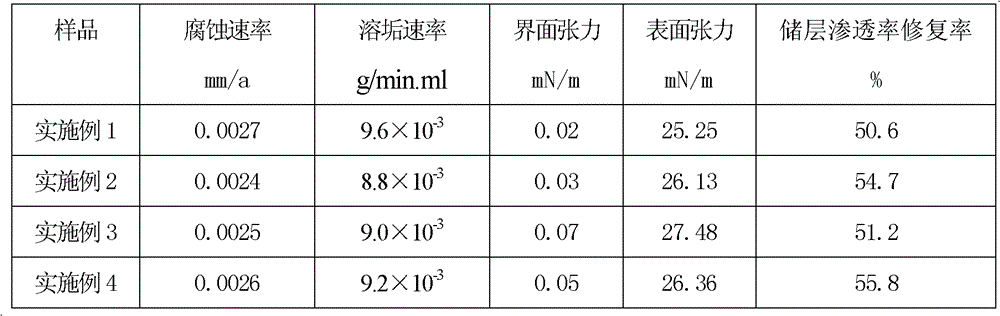

Blocking remover of gas well shaft

The invention relates to a blocking remover of a gas well shaft. The blocking remover comprises, by weight, 5-25% of an alcohol ether compound, 0.5-10% of a dispersant, 1-10% of a cleaning agent, and 0.5-5% of chelating agent, with the balance being a nitrogen-containing polar solvent, wherein the nitrogen-containing polar solvent is one selected from N,N dimethyl formamide, N,N dimethyl acetamide, and N-methyl pyrrolidone, the alcohol ether compound is one selected from glycol-ether, glycol-propyl ether, glycol-butyl ether, and diglycol-ether, the disperant whose micelle particle size is from 20nm to 100nm is a middle-phase microemulsion-type dispersant mixed by kerosene, water, a surfactant and a cosurfactant, the cleaning agent is one selected from allene diamine, acetonitrile and pentylamine, and the chelating agent is one selected from sodium citrate and EDTA. The blocking remover has the advantages that corrosivity is weak, that the speed of dissolving blockage is fast, that the product performance is stable in high temperatures, and that the blocking remover can reduce damages caused by water locking and fouling in areas close to gas wells, and can recover the permeability of storing layers.

Owner:PETROCHINA CO LTD

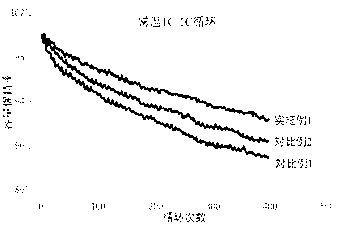

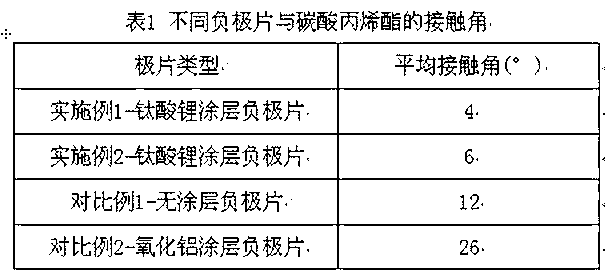

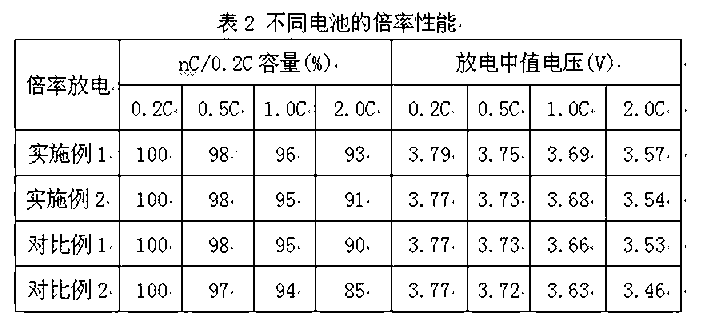

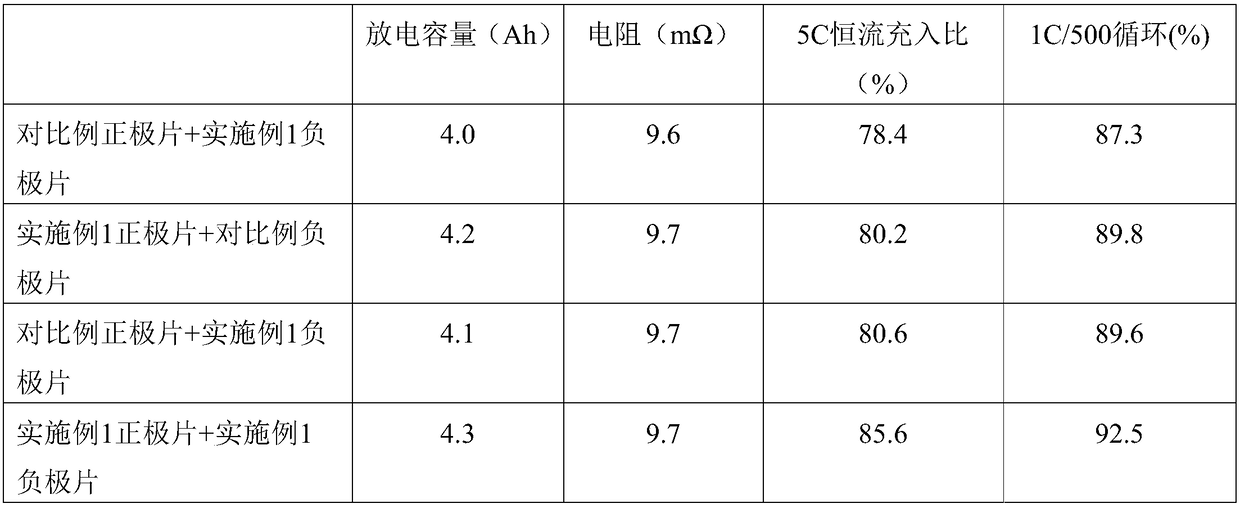

Lithium titanate coated cathode and lithium ion battery using cathode

InactiveCN103050705ADoes not affect security featuresImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesHexafluoropropyleneNano al2o3

The invention discloses a lithium titanate coated cathode and a lithium ion battery using the cathode. The lithium titanate coated cathode comprises a cathode piece and a lithium titanate coating, wherein the lithium titanate coating comprises the following components by weight ratio: 90-97% of nanomaterial and 3-10% of adhesive agent; the nanomaterial is nano lithium titanate, or a combination of nano lithium titanate and nano alumina and / or nano aluminium nitride; the adhesive agent is one of a combination of SBR (Styrene Butadiene Rubber) and CMC (Carboxyl Methyl Cellulose), PVDF (Polyvinylidene Fluoride), PVDF-HFP (Polyvinylidene Fluoride-Hexafluoropropylene), and polyacrylate; pulp of the lithium titanate coating comprises a solvent; the solvent is one of deionized water and NMP (N-Methyl Pyrrolidone); the solid content of the pulp of the lithium titanate coating is 20-60%; and the two sides of the cathode piece are coated with the pulp of the lithium titanate coating. The lithium ion battery using the lithium titanate coated cathode has better electrolyte wettability on the premise that a safety feature of the battery is unaffected, and can form a fully contacted liquid-phase interface with a diaphragm, and the multiplying power performance and the cycle performance of the battery can be improved.

Owner:TIANJIN ENERGIES

Polyurethane-acrylic ester emulsion for watersoluble wood lacquer and method of producing the same

The invention relates to a polyurethane-acrylate emulsion used for a waterborne wood lacquer. The emulsion is characterized in that: the polyurethane-acrylate emulsion for the waterborne wood lacquer comprises water, polyisocyanate, polyether polyol, small molecule polybasic alcohol, hydrophilic polybasic alcohol, hydroxyl-containing crylic acid monomer, neutralizing amine, acetone, N-methyl pyrrolidone, methyl methacrylate, adipic dihydrazide, diacetone acrylamide and azobisisobutyronitrile; the content of all components by mass percent is as follows: water: 50 percent to 60 percent, polyisocyanate: 8 percent to 15 percent, polyether polyol: 6 percent to 9 percent, small molecule polybasic alcohol: 1 percent to 2 percent, hydrophilic polybasic alcohol: 1 percent to 2 percent, hydroxyl-containing crylic acid monomer: 0.1 percent to 1 percent, neutralizing amine: 1 percent to 2 percent, acetone: 3 percent to 6 percent, N-methyl pyrrolidone: 3 percent to 6 percent, methyl methacrylate: 8 percent to 15 percent, adipic dihydrazide: 0.1 percent to 1 percent, diacetone acrylamide: 0.1 percent to 1 percent and azobisisobutyronitrile: 0.05 percent to 0.15 percent. The polyurethane-acrylate emulsion for the waterborne wood lacquer has high drying speed, good water resistance, high impact resistance and excellent abrasion performance.

Owner:佛山市顺德区巴德富实业有限公司

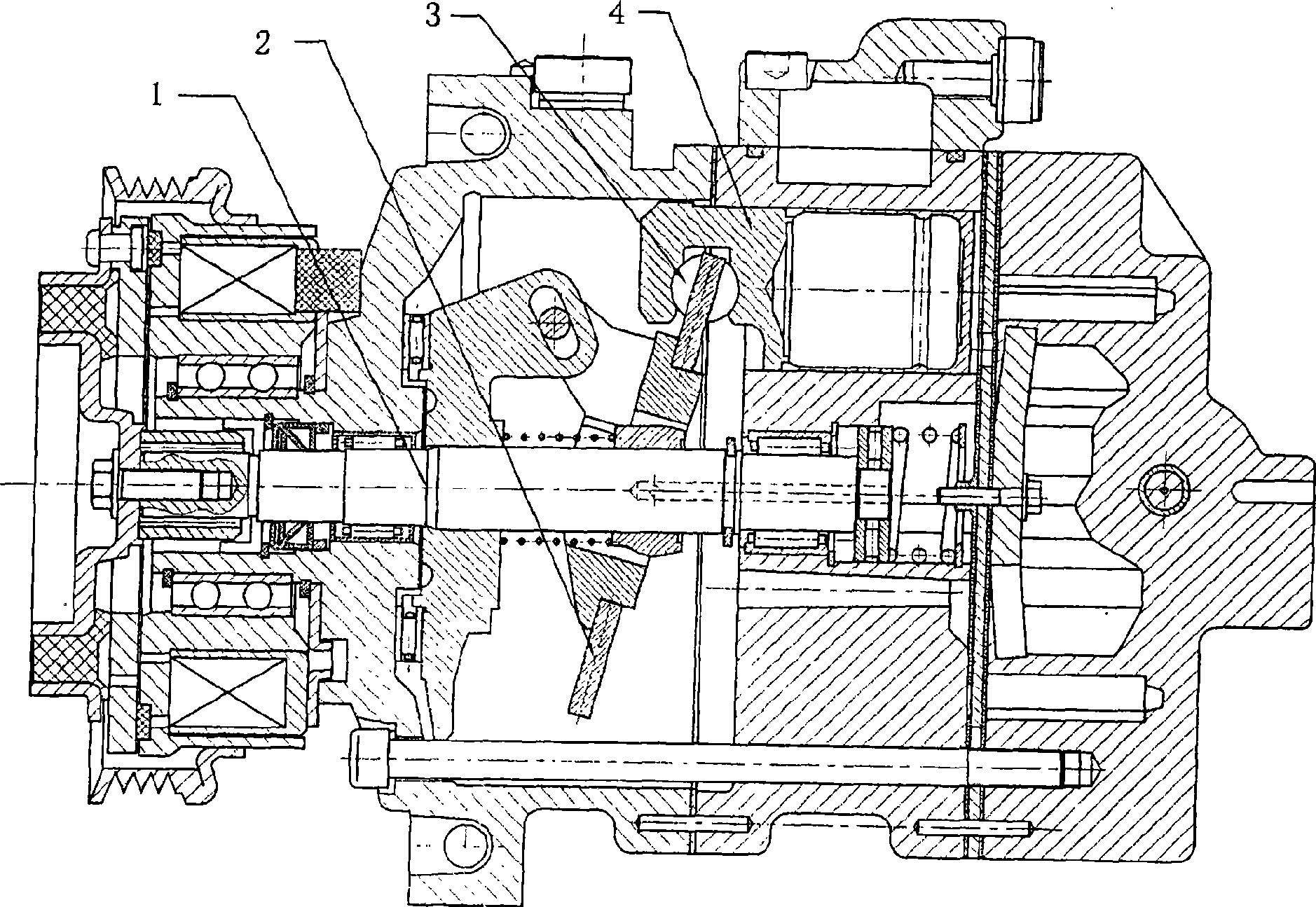

Self-lubricating wear-resistant coating swash plate and technique for producing the same

ActiveCN101503995AMeet the development requirements of lead-freeSimple production processLiquid surface applicatorsPositive displacement pump componentsWear resistantMolecular materials

The invention relates to a self-lubricating wear-resistant coating swash plate, which consists of a metallic matrix and a self-lubricating wear-resistant coating, wherein annular planes on two sides of the metallic matrix are coated with the self-lubricating wear-resistant coating, and the components of the self-lubricating wear-resistant coating comprise a main material of high molecular materials, fluoroplastics, solid lubricants and inorganic matters. A process for producing the self-lubricating wear-resistant coating swash plate comprises that: the self-lubricating wear-resistant coating is coated on the swash plate after being prepared into a liquid coating, and a method for preparing the liquid coating comprises the steps of using a solvent of N-methyl pyrrolidone or dimethyl acetamide to dissolve the main material of the high molecular materials first, and then adding the fluoroplastics, the solid lubricants and the inorganic matters into the mixture to perform sufficient stirring and dispersion so as to prepare the liquid coating with certain solid content. The swash plate has the advantages of good self-lubricating and wear-resistant performance, simple production process and low production cost, and does not contain metallic lead which is harmful to human bodies and the environment.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

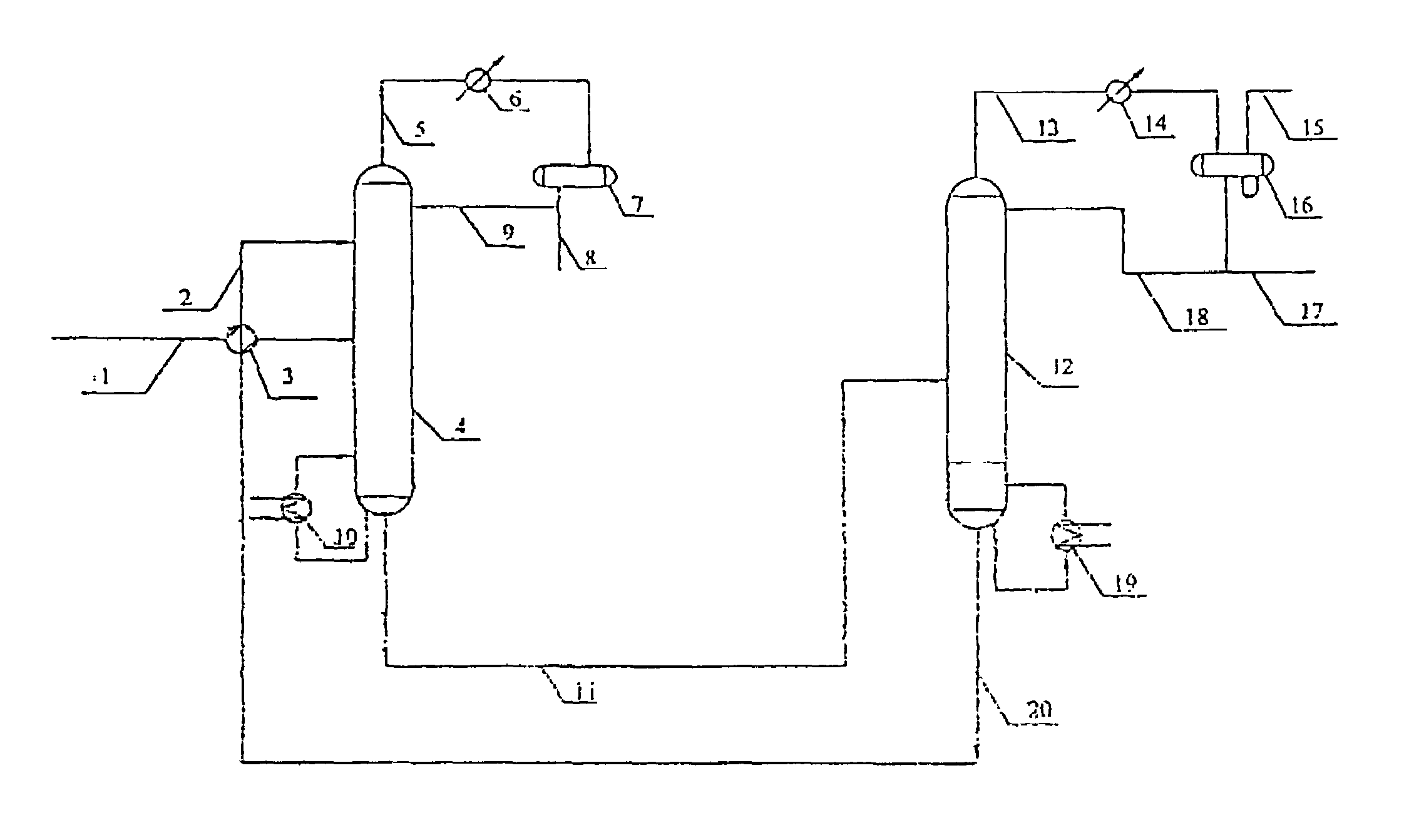

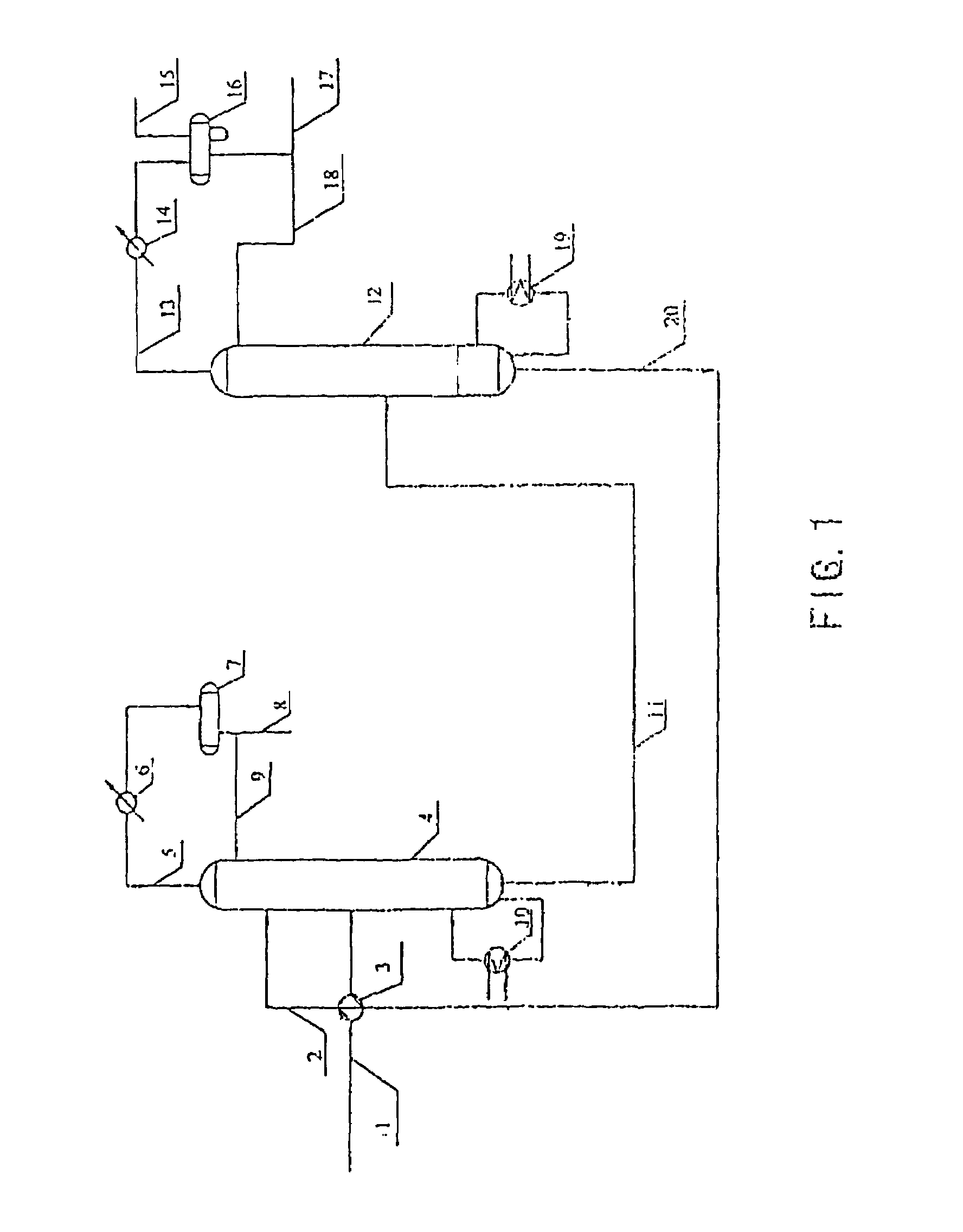

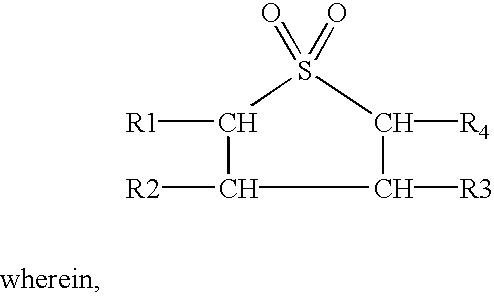

Process for separating aromatics by extractive distillation and a composite solvent used therein

InactiveUS7078580B2Improve solubilityWide boiling rangeDistillation purification/separationHydrocarbonsSulfolaneAlkalinity

This application relates to a composite solvent for separating aromatics by extractive distillation, comprising a main solvent, a solutizer and a modifier. Said solutizer is selected from any one or mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the content of which is 3–39 wt %, and the number of carbon atoms of the lowest aromatic in the solutizer should be greater than that of the highest aromatic in the aromatics to be separated. When the solutizer is selected from any one of C8–C11 aromatics, the composite solvent contains 0.01–10.0 wt % of the modifier; when the solutizer is selected from mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the composite solvent contains 0–10.0 wt % of the modifier. Said main solvent and modifier are independently selected from sulfolane derivatives, N-formyl morpholine, and N-methyl pyrrolidone, provided that the acidity and basicity of the modifier are opposite to those of the main solvent. When the composite solvent is used to recover aromatics by extractive distillation, it is possible to moderate the operation conditions of solvent recovery, increase the yield of aromatics, and make the separated aromatics to be neutral.

Owner:CHINA PETROCHEMICAL CORP +1

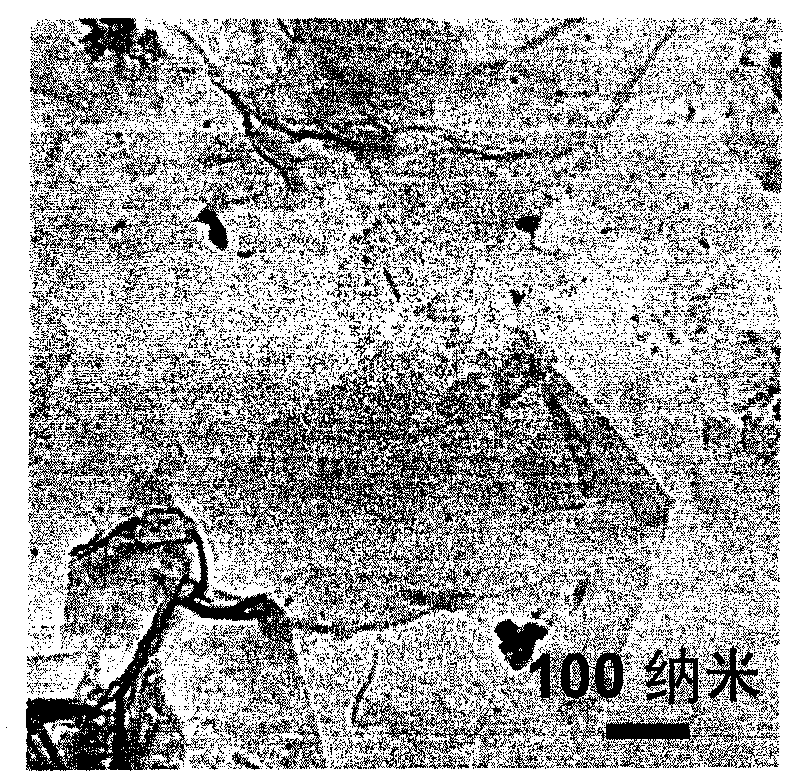

Preparation method for three-dimensional carbon nanotube/nitrogen-doped graphene/sulfur electrode slice

InactiveCN105609736AReduce Shuttle EffectImprove cycle lifeCell electrodesLi-accumulatorsSulfur electrodeCarbon nanotube

The invention provides a preparation method for a three-dimensional carbon nanotube / nitrogen-doped graphene / sulfur electrode slice. The preparation method comprises the following steps of (1) adding the carbon nanotube, graphite oxide and polyacrylonitrile to N-methyl pyrrolidone, performing an ultrasonic reaction, coating an aluminium foil with mixed paste, and performing vacuum drying to obtain the electrode slice; (2) putting the obtained electrode slice into a muffle furnace under ammonia gas protection, heating to 400-500 DEG C, and naturally cooling; and (3) enabling the electrode slice obtained in the step (2) to be fully inserted into a Na2S2O3 solution, and slowly adding hydrochloric acid to the solution in a dropwise manner until the PH value of the solution reaches 6.5-7.5, taking out the electrode slice, and drying the electrode slice to obtain a positive plate. The electrode slice prepared by the invention can be directly used for the positive electrode of a lithium-sulfur battery without requiring a conductive agent and a binder, so that the cost of the electrode is greatly lowered.

Owner:钟玲珑

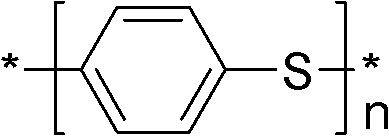

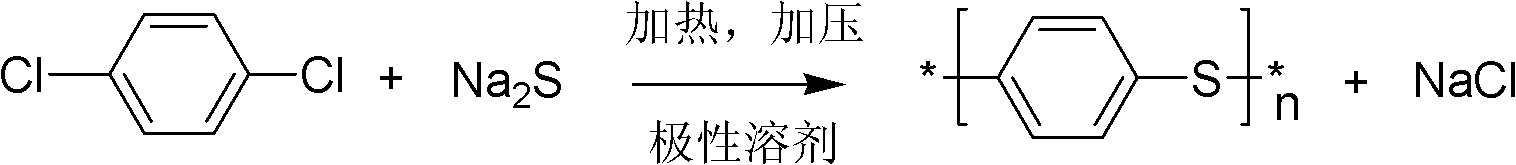

Method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin

ActiveCN103073720AThe average molecular weight is largeMolecular distribution index is smallMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin. According to the invention, sodium sulfide and p-dichlorobenzene are adopted as raw materials; N-methyl pyrrolidone, N,N-dimethyl acetamide, and the like are adopted as solvents; under the existence of a basic salt, through a four-step method comprising pre-polymerization, polymerization, chain extension and end-capping, the high-purity low-color fiber-grade polyphenylene sulfide resin is synthesized. By adjusting process parameters, polyphenylene sulfide average molecular weight and distribution index can be effectively controlled. Also, purification process can be simplified, and metal ion embedding can be reduced. Resin slice color is reduced, resin processing stability is improved, and resin performance is improved.

Owner:CHINA PETROLEUM & CHEM CORP

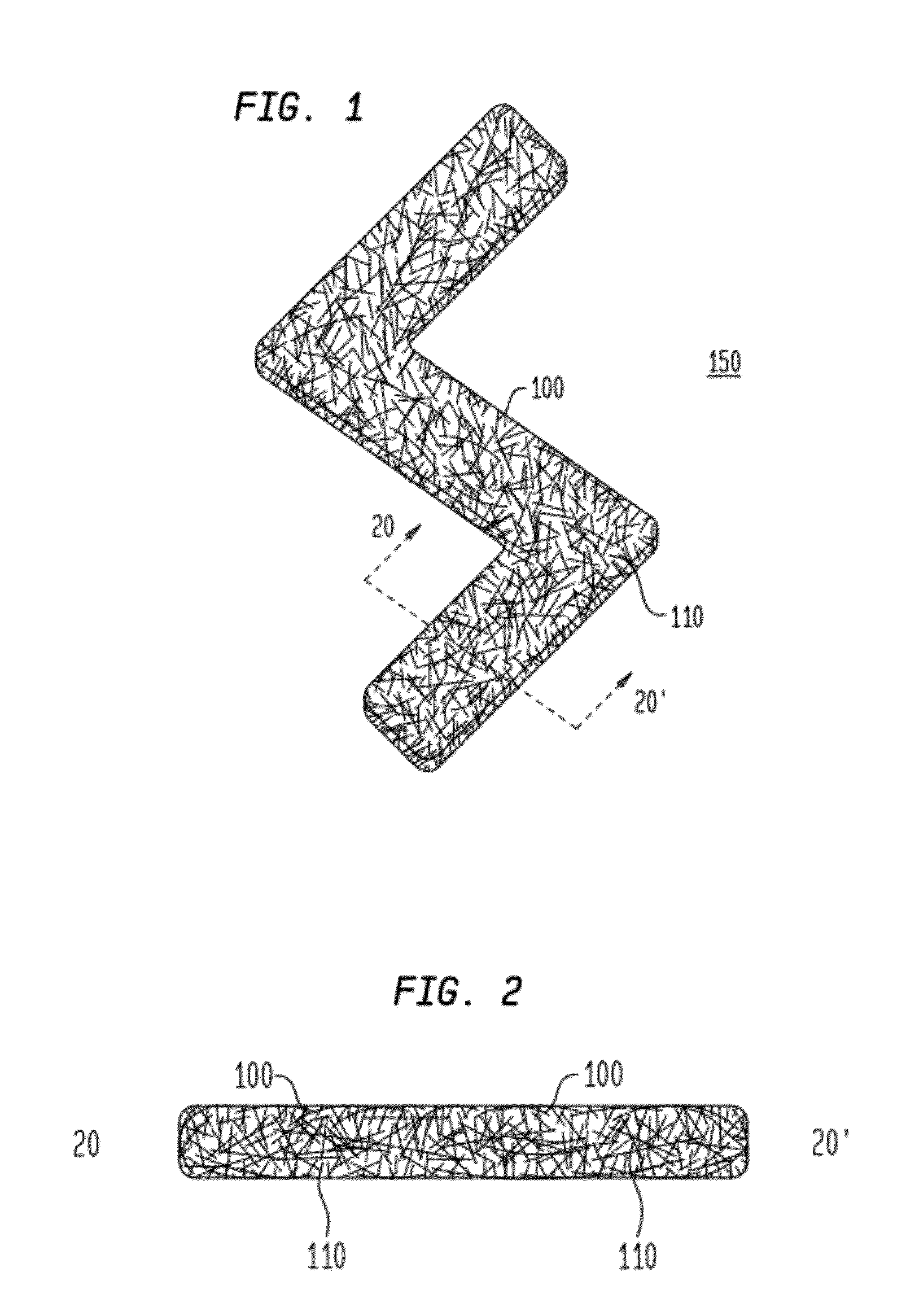

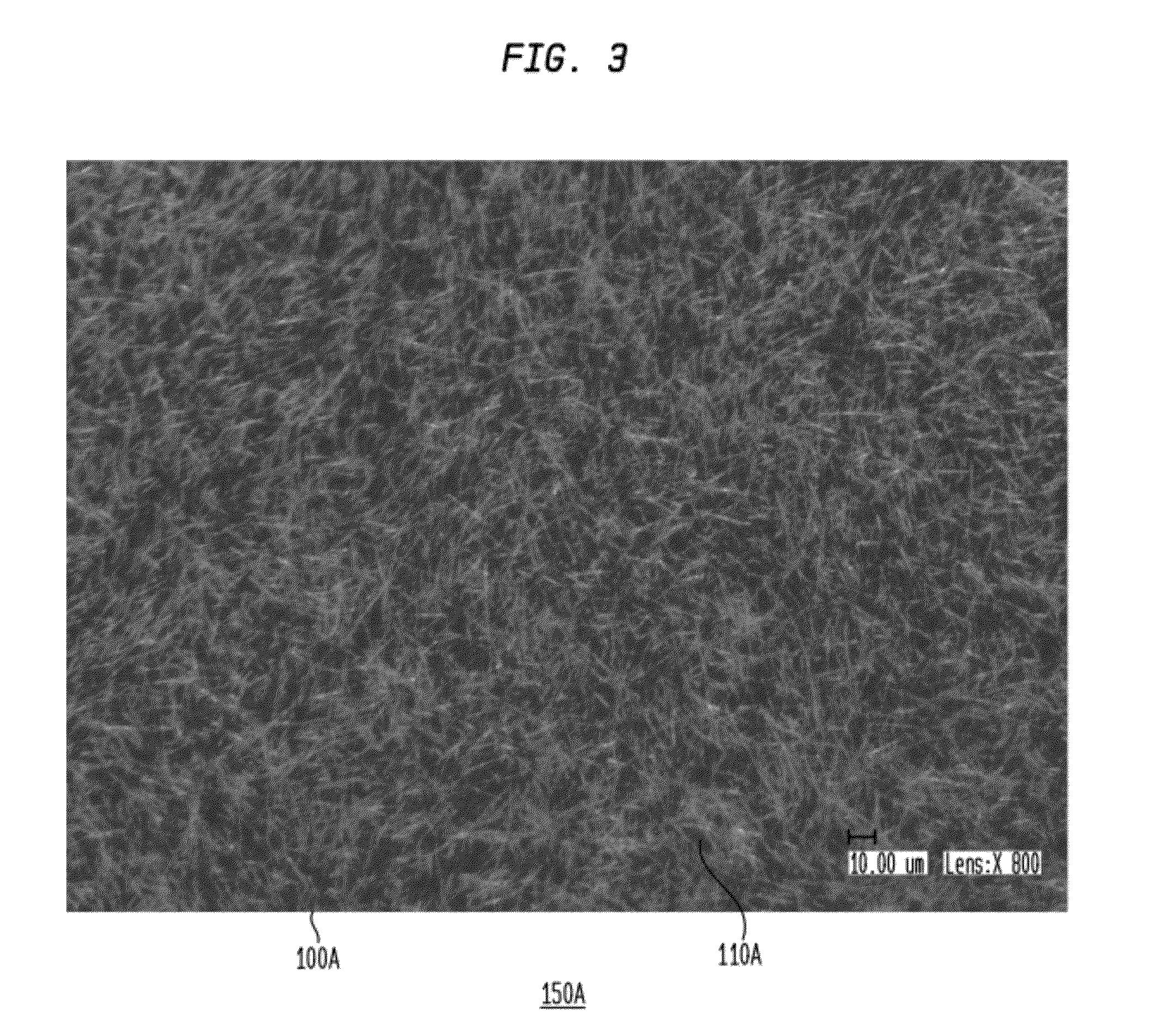

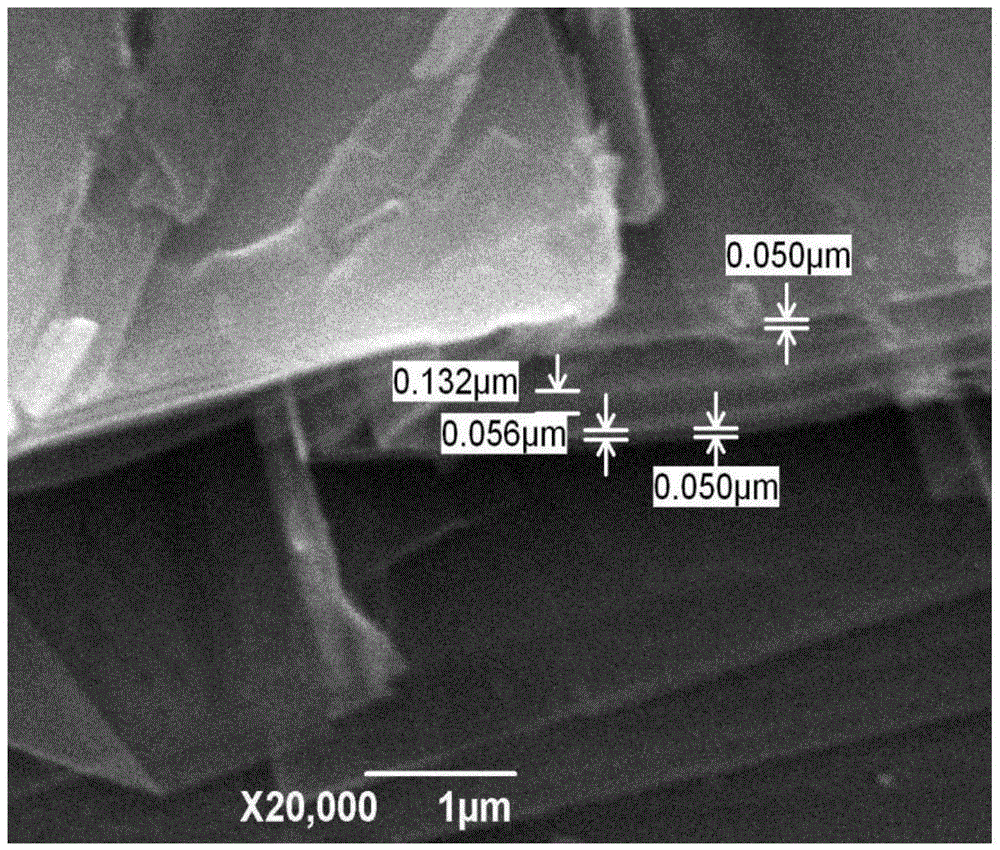

Metallic Nanofiber Ink, Substantially Transparent Conductor, and Fabrication Method

An exemplary printable composition comprises a liquid or gel suspension of a plurality of metallic nanofibers; a first solvent; and a viscosity modifier, resin, or binder. In various embodiments, the metallic nanofibers are between about 10 microns to about 100 microns in length, are between about 10 nm to about 120 nm in diameter, and are typically functionalized with a coating or partial coating of polyvinyl pyrrolidone or a similar compound. An exemplary metallic nanofiber ink which can be printed to produce a substantially transparent conductor comprises a plurality of metallic nanofibers; one or more solvents such as 1-butanol, ethanol, 1-pentanol, n-methylpyrrolidone, cyclohexanone, cyclopentanone, 1-hexanol, acetic acid, cyclohexanol, or mixtures thereof; and a viscosity modifier, resin, or binder such as polyvinyl pyrrolidone or a polyimide, for example.

Owner:NTHDEGREE TECH WORLDWIDE

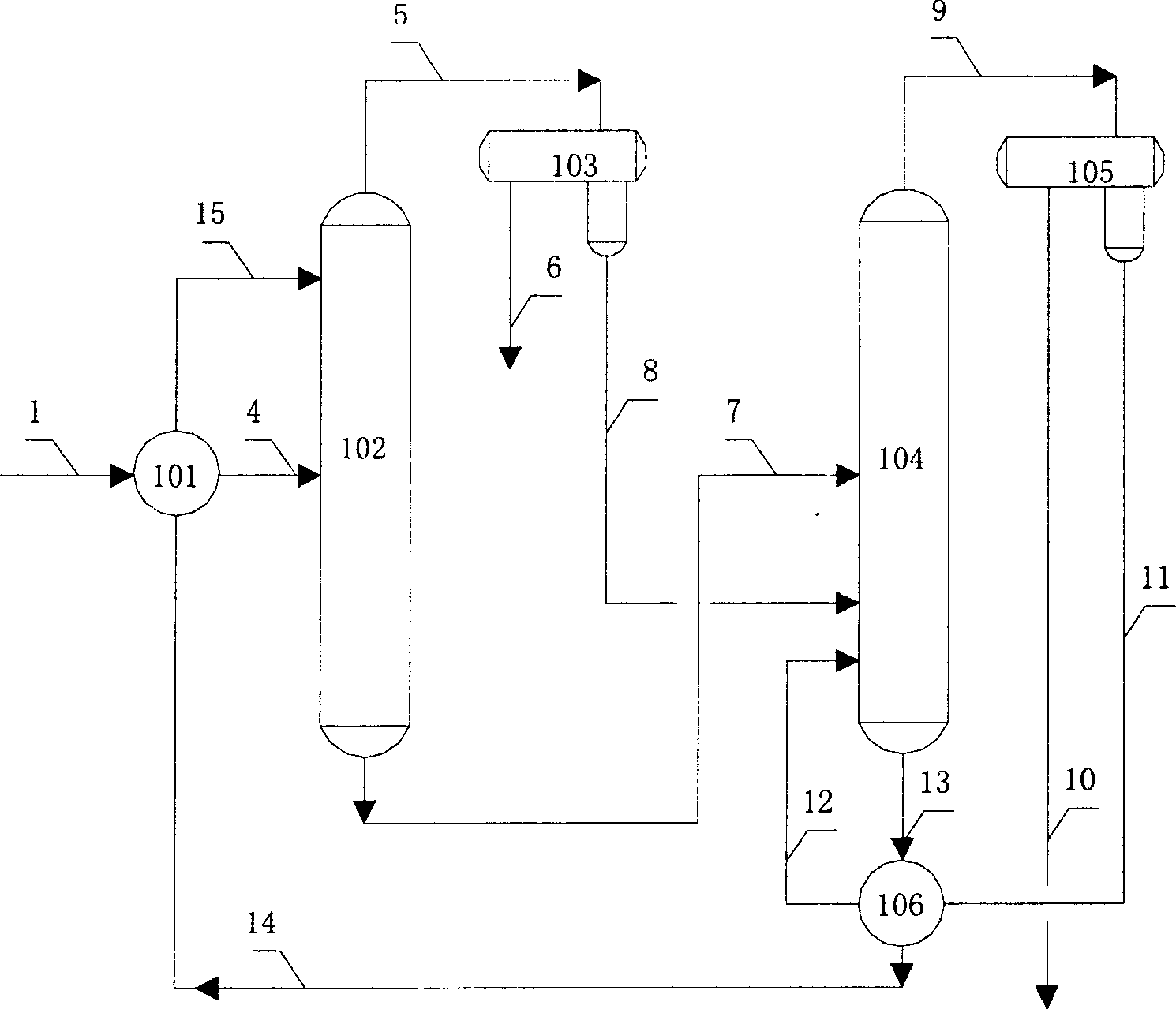

Solvent and catalyst recovery technology in polyphenyl thioether production

InactiveCN102675683AReduce manufacturing costSave raw materialsChemical recyclingLithium chloridePowder mixture

The invention relates to a solvent and catalyst recovery technology in polyphenyl thioether production, which comprises the steps of: after polycondensation reaction is finished, firstly adding 1-3mol / mol Na2S and fresh NMP (N-methyl pyrrolidone) solvent as a diluting agent, diluting the reaction system with NMP to obtain another mixture, and further treating the mixture by filtering, extraction, evaporation and spiral evaporator to respectively obtain a mixed solution containing NMP and water and a powder mixture containing a cosolvent and byproducts; and evaporating the mixed solution containing NMP and water to remove water to obtain NMP solvent containing certain impurities, further rectifying and purifying the NMP solvent by a rectifying tower to obtain NMP solvent with the purity of 99.98% and the recovery rate of 96-98%to be recycled for polyphenyl thioether resin synthesis, and treating the powder mixture containing the cosolvent and byproducts to obtain catalyst lithium chloride with the purity of 99.95-99.98% and the recovery rate of 98-99%.

Owner:SICHUAN DEYANG ENG PLASTIC DEV

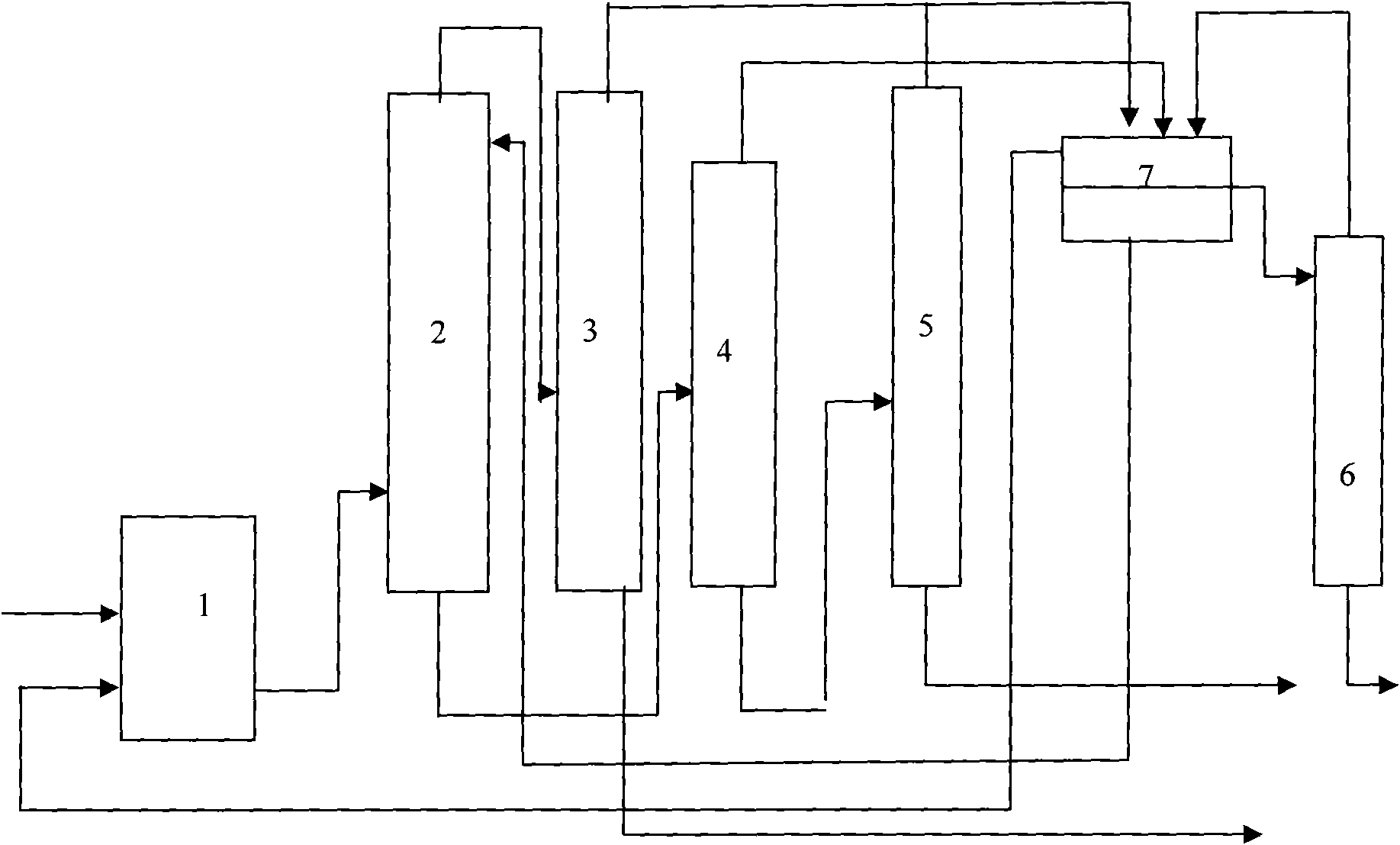

Static mixed rotational flow separation and extraction process of regenerative base oil N-methyl pyrrolidone

The invention relates to a static mixed rotational flow separation and extraction process of regenerative base oil N-methyl pyrrolidone, comprising the following steps in sequence: (a) carrying out sedimentation of used oil and removing moisture and solid impurities; (b) filtering by a filter, and removing tiny solid particles and colloids; (c) adding sodium hydroxide solution and flocculating; (d) removing floccules and residual sodium hydroxide solution; (e) carrying out reduced pressure distillation by a distiller, and collecting distillate oil; (f) mixing the distillate oil with organic solvent by a static mixer on line; (g) separating out raffinate oil and raffinate oil containing organic solvent from mixed liquor by a swirler; (h) carrying out the reduced pressure distillation on the raffinate oil by a climbing film evaporator, and removing the organic solvent in the raffinate oil; and (i) carrying out the reduced pressure distillation by a molecule (short range) distiller, removing residual organic solvent and peculiar smell gas, and obtaining the regenerative base oil. The separation and extraction process provided by the invention has the advantages of conciseness in procedure, safety in operation, less equipment investment, high product yield, energy conservation, environmental friendliness and the like.

Owner:ANHUI GUOFU LUBRICANT IND

Water-soluble single component aliphatic polyurethane floor coatings and manufacturing method thereof

InactiveCN101362922AGood anti-sinking effectSolve the problem of difficult film formationPolyurea/polyurethane coatingsEmulsion paintsPolymer scienceUltra fine

The invention provides a waterborne single-component aliphatic polyurethane floor coating, relating to the technical field of polyurethane coating. The waterborne single-component aliphatic polyurethane floor coating consists of waterborne single-component aliphatic polyurethane latex, deionized water, waterborne dispersant, polyether modified siloxane defoamer, no-dissolve polyurethane associative thickener, filling material, pigment, waterborne antiseptic, cosolvent compounded by propylene glycol methyl ether and N-methyl pyrrolidone according to the proportion of 1:1, pH regulator and ultra-fine SiO2 extinction powder compatibility, is a floor coating type of high performance, high performance / price ratio and friendly environment, has more excellent wearability and weathering resistance performance correspondingly to coatings such as epoxy, and the like, and can achieve and exceed the mechanical performance and chemical medium resistance of the products such as epoxy, etc.

Owner:无锡市南雅化工有限公司

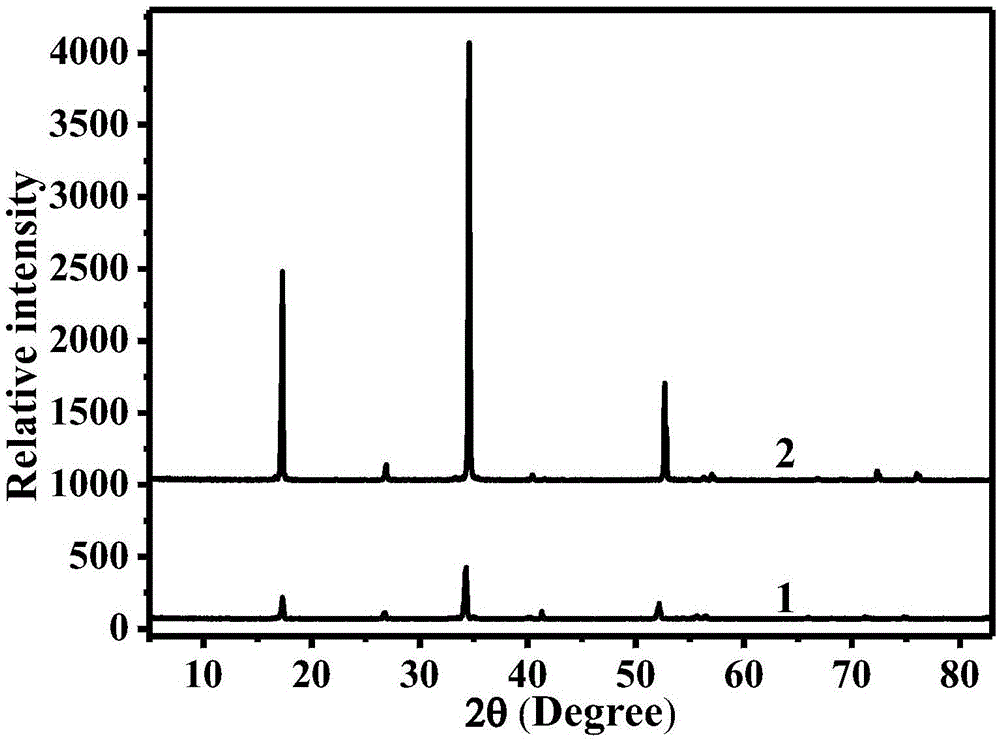

Black phosphorus and phosphinidene preparing methods

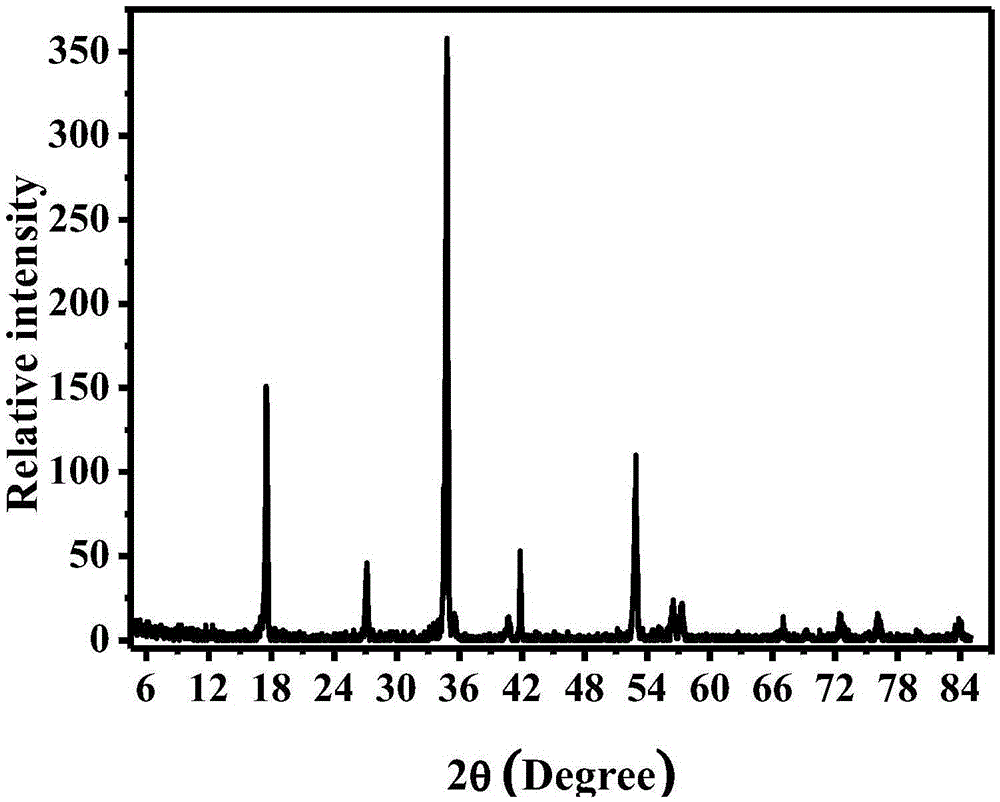

The invention relates to black phosphorus and phosphinidene preparing methods. According to the black phosphorus preparing method, tin tetraiodide, tin and red phosphorus are used as raw materials to prepare black phosphorus through reaction. According to the phosphinidene preparing method, the prepared black phosphorus is treated in N-methyl pyrrolidone, absolute ethyl alcohol or N-cyclohexyl-2-pyrrolidone for a proper period of time under the stirring and ultrasonic condition at 20-50 DEG C. Reasonable preparing raw materials and reaction conditions are adopted, and synthesis can be achieved within 21-32 h only. Few-layer black phosphorus is prepared successfully by means of the liquid-phase stripping method. According to the preparing methods, the technology is simple, raw materials are cheap, and repeatability is high.

Owner:NORTHWEST UNIV(CN)

Anode slurry of high-rate lithium ion battery and fabrication method of anode slurry

ActiveCN103035924ASmall particle sizeLarge specific surface areaCell electrodesMixing materials pretreatmentHigh rateMass ratio

The invention discloses anode slurry of a high-rate lithium ion battery and a fabrication method of the anode slurry. The fabrication method comprises the steps of mixing a binder, a conductive agent and a lithium iron phosphate active substance uniformly at a mass ratio of 1:(0.8-1.2):(18-23) with a mixer at a rotating speed of 19-21r / min for 2-4h, adding the uniformly mixed raw materials into an air blowing oven for baking at 80-90 DEG C for 8-12h, turning off the air blowing oven, cooling the mixed raw materials naturally to below 45 DEG C for use, adding the raw materials into a stirring barrel containg NMP (N-Methyl Pyrrolidone) in three times, stirring with a planetary stirrer, controlling the solid content of the slurry to be 30%-40%, stirring for 5-10min at a low speed and 1-1.5h at a high speed when the mixed raw materials are added in the first time and the second time, stirring for 5-10min at the low speed and 2-3h at the high speed when the mixed raw materials are added in the third time, adding NMP to adjust viscosity, controlling the viscosity to be 5000-10000MPa*s, stirring at the low speed to conduct vacuum defoaming, and filtering the slurry with a screen with 200 meshes.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Prepn process of water thinned polyurethane emulsion

The preparation process of water thinned polyurethane emulsion includes the reaction of polyester polyols, polyether polyols and isophorone diisocyanate in the molar ratio between isophorone diisocyanate and the sum of polyester polyols and polyether polyols equal to 2.7-3.2 in the presence of dibutyl tin laurate catalyst at 75-80 deg.c for 1 hr to obtain pre-polymer; adding dihydroxymethyl propionic acid containing hydrophilic group and co-solvent N-methyl pyrrolidone to reaction for further 2 hr; neutralizing with triethylamine, dropping into water while adding amine chain expander, defoaming, and filtering to obtain the water thinned polyurethane emulsion. The water thinned polyurethane emulsion has solid content of 30-35 wt%, pH value of 6.5-8.0, viscosity of 10-50 MPa.S, etc.

Owner:SHANGHAI PLASTICS RES INST CO LTD

Production method of environment-friendly rubber oil

ActiveCN101870886AReduce the number of timesReduce energy consumptionTreatment with plural serial refining stagesLubricant compositionEvaporationPolyaromatic hydrocarbon

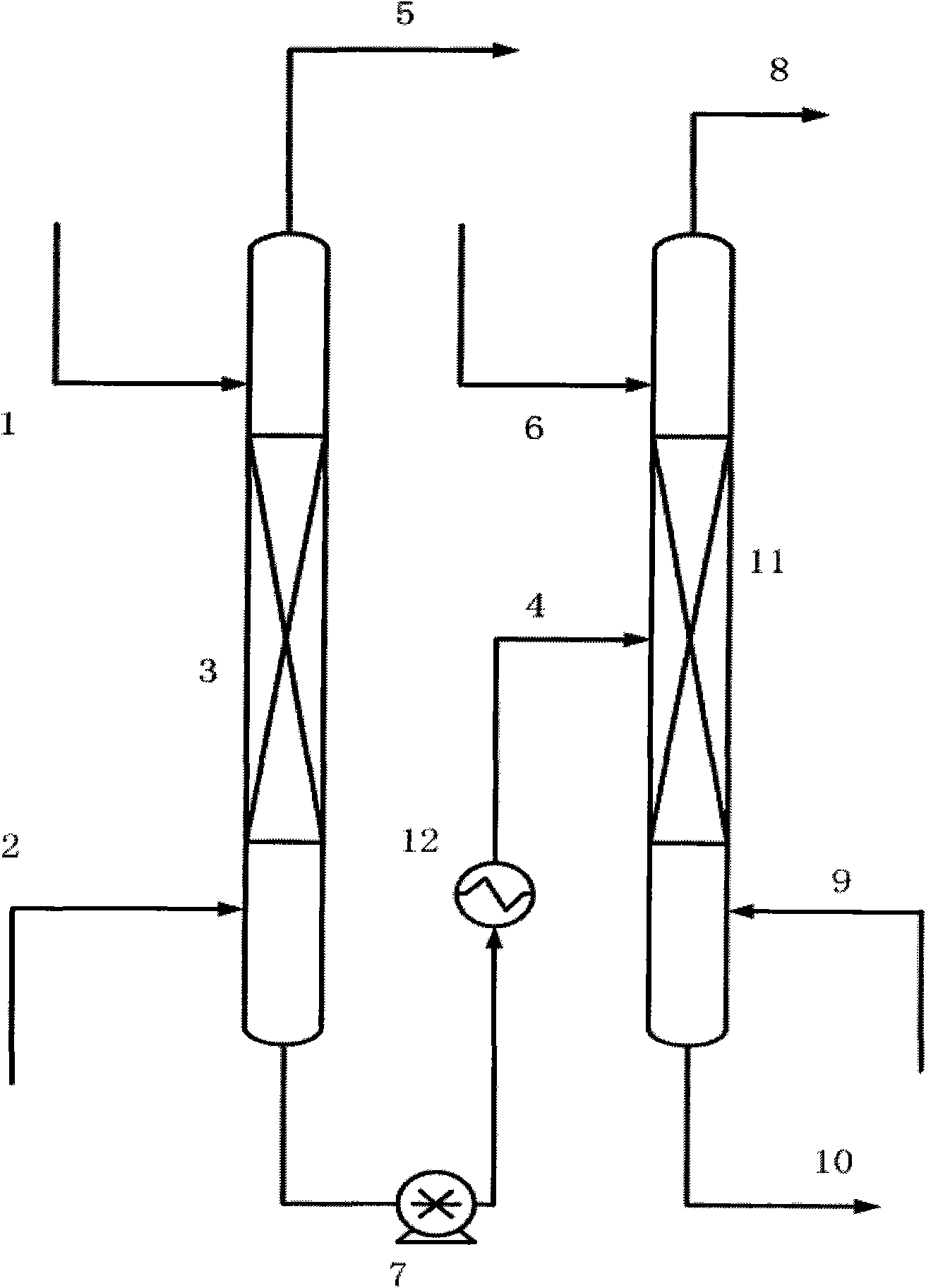

The invention relates to a method for refining vacuum gas oil, which can be used for producing environment-friendly rubber extending oil with a high content of aromatic hydrocarbon and a low content of polyaromatic hydrocarbon. The method is characterized in that furfural, N-methyl pyrrolidone, phenol and dimethyl sulfoxide are used as solvent for extraction in an extraction tower, the solvent is fed in from the upper part of the extraction tower, vacuum distillate is fed in from the lower part of the extraction tower, the solvent and the vacuum distillate are in countercurrent contact, then refined solution flows out of the top of the extraction tower, and refined oil can be obtained after solvent recovery through evaporation and stripping; and primary extract solution on the tower bottom is fed into the middle upper part of a secondary extraction tower, extract oil is fed into the lower part of the secondary extraction tower, fresh solvent is fed into the upper part of the secondary extraction tower, then secondary refined solution flows out of the top of the secondary extraction tower, secondary refined oil can be obtained after solvent recovery through evaporation and stripping and can be used as the environment-friendly rubber extending oil with a high content of aromatic hydrocarbon, secondary extract solution flows out of the bottom of the secondary extraction tower, extract oil can be obtained after solvent recovery through evaporation and stripping, part of the extract oil returns to the lower part of the secondary extraction tower, and the rest of the extract oil is thrown out as the product.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method of surface self-assembly of graphene/polyimide transparent electric conduction film

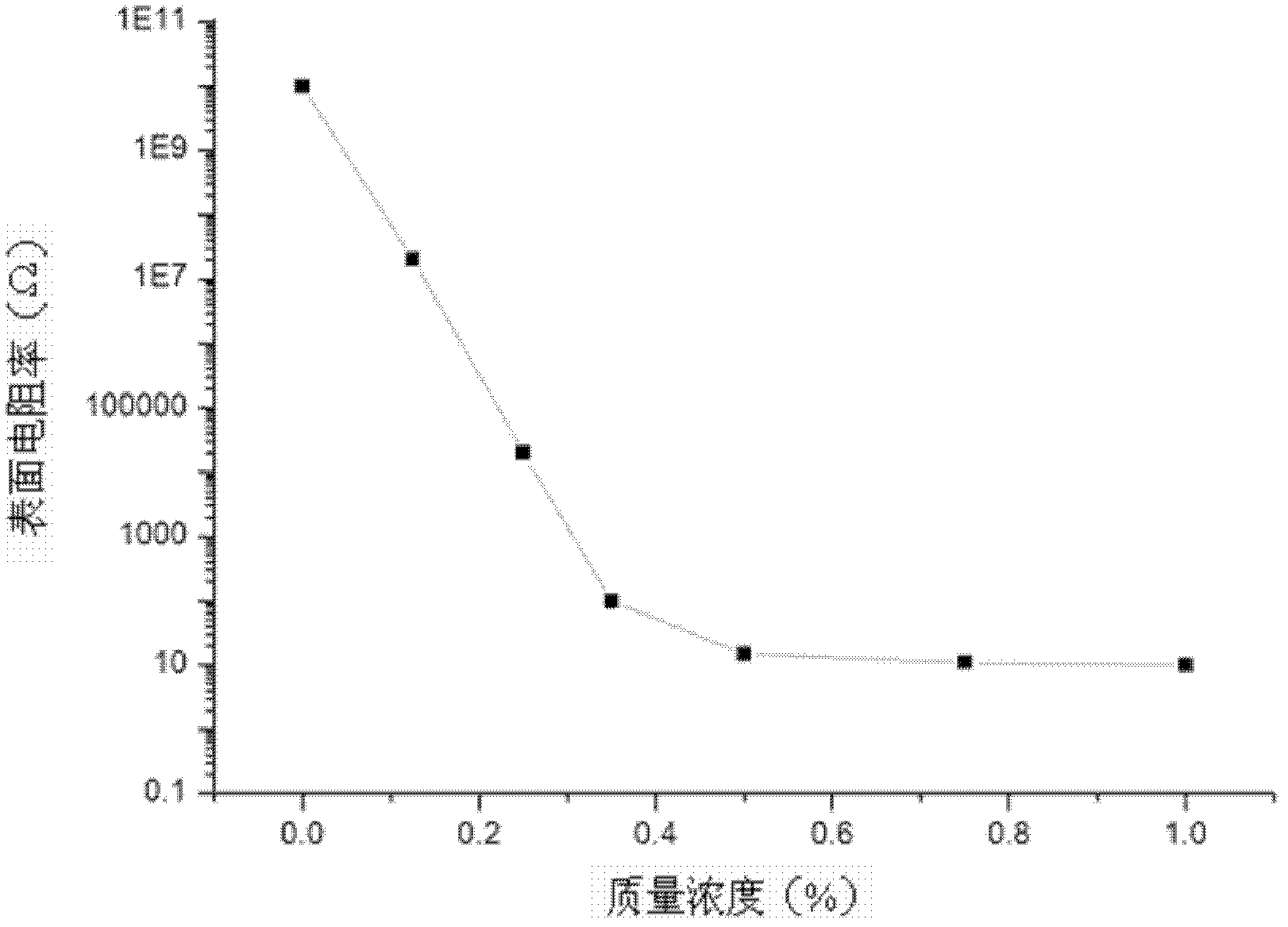

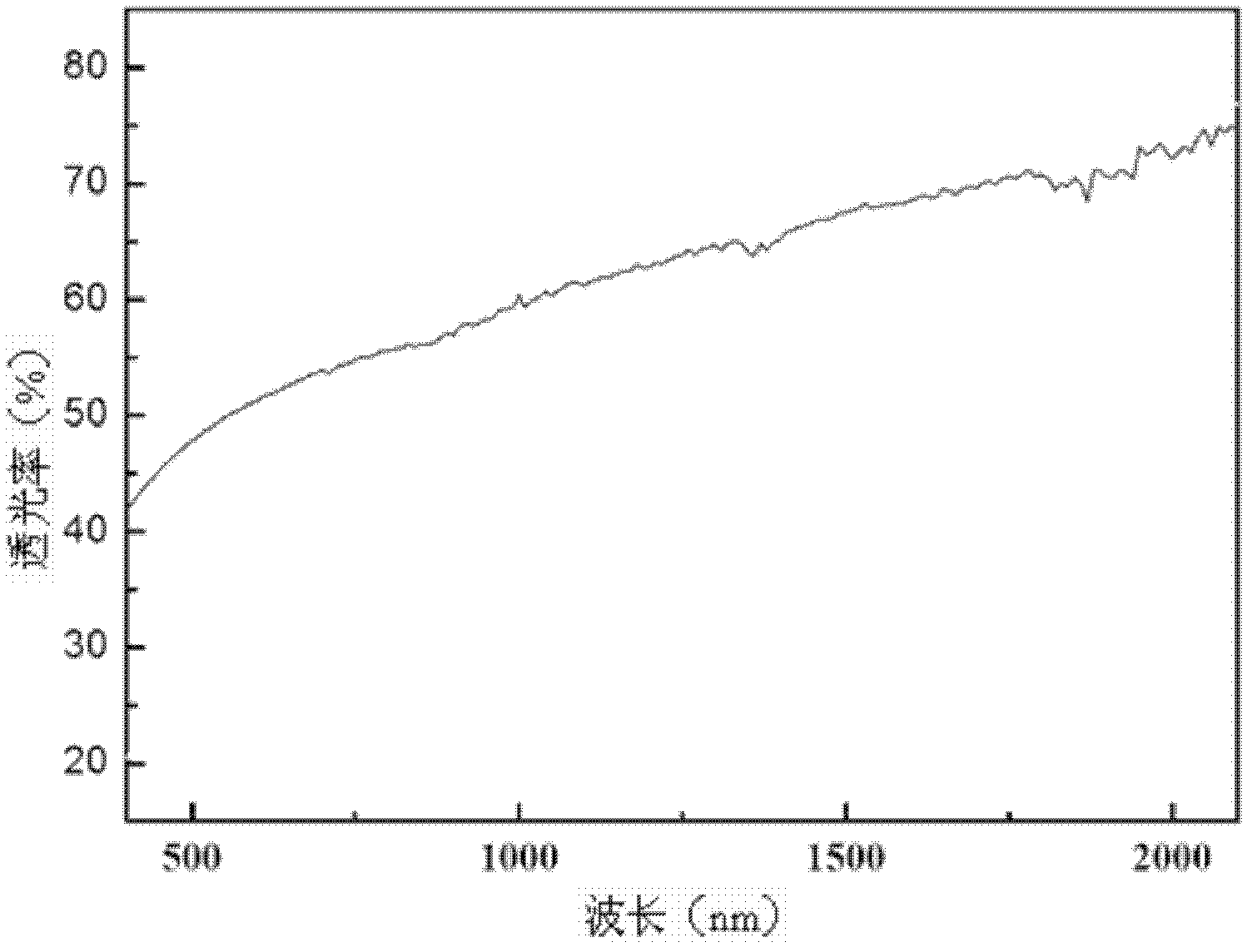

ActiveCN102592749AImprove incompatibilitySimple processConductive layers on insulating-supportsCable/conductor manufactureOmegaUltrasonic dispersion

The invention relates to a method of surface self-assembly of graphene / polyimide transparent electric conduction film, and relates to a preparation method of the graphene / polyimide transparent electric conduction film. The invention aims to solve the technical problems that the adhesive force of a flexible substrate and a settled layer in the existing flexible electric conduction film is weak, and an inorganic electric conduction layer and an organic base are incompatible. The method comprises the following steps: firstly, placing graphite oxide respectively in N,N-dimethyl acetamide or N-methyl pyrrolidone, carrying out ultrasonic dispersion, adding a reducing agent, and carrying out reduction reaction, thereby obtaining a graphene organic solution system; secondly, adding a dianhydride monomer and a diamine monomer in N, N-dimethyl acetamide, and stirring in an inert atmosphere, thereby obtaining a PAA (poly acrylic acid) solution; and thirdly, mixing and stirring the graphene organic solution system and the PAA solution, then coating on a clean and dry glass plate, volatilizing the solvent and curing. The surface resistance of the graphene / polyimide transparent electric conduction film prepared by the method provided by the invention is 10-20 omega, and the graphene / polyimide transparent electric conduction film has favorable light transmissivity at the visible light wave band and the near-infrared wave band.

Owner:HARBIN INST OF TECH

Waterborne polyurethane emulsion and preparation method thereof

InactiveCN104974327AImprove performanceKeep hydrophilicPolyurea/polyurethane coatingsLeather surface finishingPolymer scienceEmulsion

The invention discloses a waterborne polyurethane emulsion and a preparation method thereof. The preparation method comprises the following steps: firstly carrying out vacuum dehydration on polymer polyol, a hydrophilic chain extender, isosorbide and N-methyl pyrrolidone at 90 DEG C for 1-2 hours, reducing the temperature to 80-90 DEG C, adding diisocyanate and reacting for 2.5-3 hours until NCO% reaches the theoretical value; then reducing the temperature, adding a neutralizer to an NCO-terminated polyurethane prepolymer and reacting at 60 DEG C for 0.5 hour until the neutralization degree is 95-100%; finally dispersing the polyurethane prepolymer containing isosorbide into deionized water under the high-speed shearing action of an agitator and dropwise adding a mixture of diamine and water after dispersing for a period of time, thus obtaining the waterborne polyurethane emulsion. Isosorbide is successfully introduced into the waterborne polyurethane emulsion, thus obviously improving the glossiness of waterborne polyurethane films.

Owner:JINCHUANGJING NEW MATERIAL TECH SHANGHAI

Method for preparing composite material of graphene and graphene poly-p-phenylenediamine

The invention relates to a method for preparing a composite material of graphene and graphene poly-p-phenylenediamine, which comprises the following steps of: dissolving p-phenylenediamine in N,N-dimethylformamide, and then adding the mixture into an oxidized graphite colloid treated by ultrasonic de-bonding; treating the mixture in an oil bath, and filtering an obtained colloid; washing the colloid with acetone, and then dispersing the obtained wet powder into ethanol, glycol, N-methyl pyrrolidone and the N,N-dimethylformamide to obtain a stable graphene colloid; adding a K2S2O8 hydrochloric acid aqueous solution into the unfiltered and unwashed graphene colloid; treating the mixture in an ice bath; and washing the mixture with acetone, hydrochloric acid and water to obtain graphene poly-p-phenylenediamine composite powder. The composite material of the graphene colloid and the graphene poly-p-phenylenediamine prepared by the method has good dispersity and simple preparation process.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

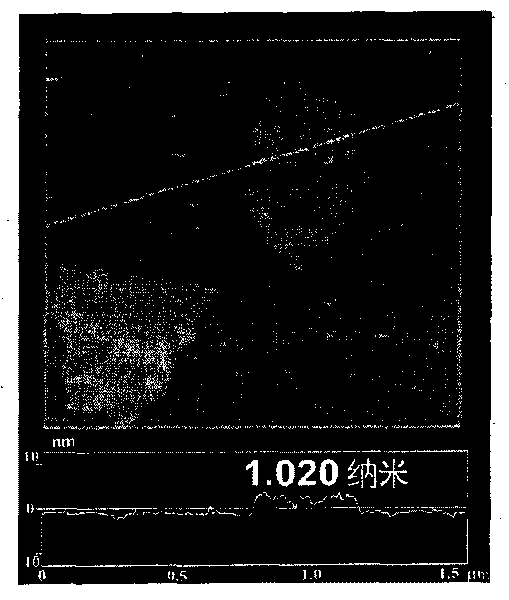

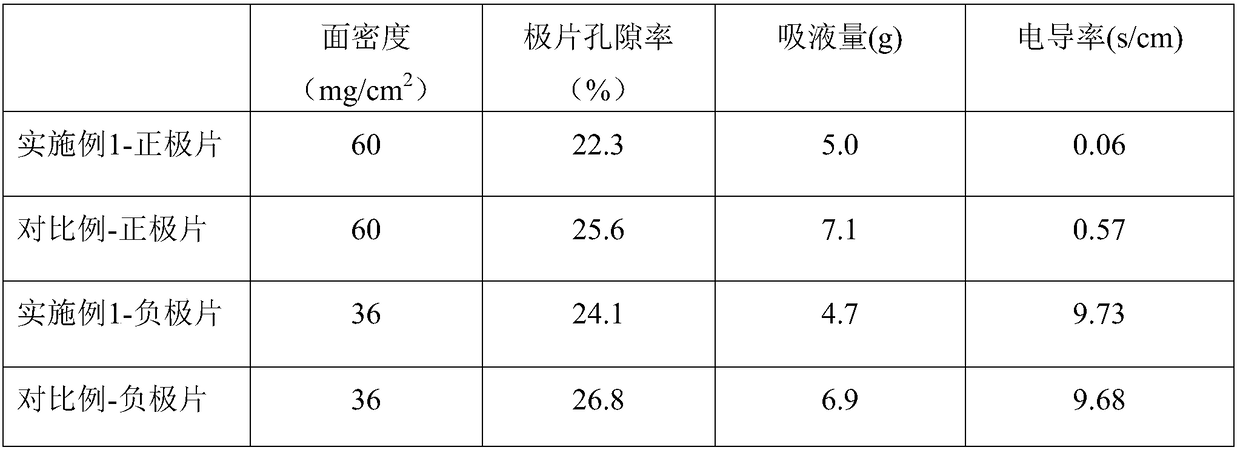

A preparation method of a porous lithium ion electrode sheet with high energy density and a lithium ion battery

ActiveCN109167020AHigh porosityImprove electrical performanceSecondary cellsElectrode collector coatingPorosityDecomposition

The invention provides a preparation method of a porous lithium ion electrode sheet with high energy density and a lithium ion battery. S1, A glue liquid is prepared by dissolving a binder in a N-methyl pyrrolidone solution, and the glue liquid is uniformly mixed with an active substance and a conductive agent to obtain a slurry; S2, respectively coating the mixed slurry on the current collector to obtain pole pieces; S3, cold pressing the coated pole piece, then coating the pore-forming agent on the surface of the cold-pressed pole piece, uniformly coating the pore-forming agent on the surface of the cold-pressed pole piece by means of a coating machine, drying while coating, and setting the drying temperature to be higher than the decomposition temperature of the pore-forming agent to obtain the porous lithium ion pole piece with high energy density. The invention improves the porosity of the thick electrode sheet and improves the electric performance by preparing a thick electrode with high surface density and coating a pore-forming agent on the surface of the electrode sheet after cold pressing.

Owner:TIANJIN ENERGIES

Composite solvent in use for extracting, rectifying and separating arene and method of application

ActiveCN1660970AReduce dosageImprove solubilityExtraction purification/separationHydrocarbon oils refiningChemical LinkageMorpholine

A composite solvent for extraction, rectification and separation of arylhydrocarbon contains proportionally the primary solvent chosen from sulfone compound, glycol compound, N-formacyl morpholine and N-methyl pyrrolidone, the secondary solvent chosen from hydrocarbon compound with two benzene rings, and water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing high-viscosity polyphenylene terephthalamide

The invention relates to a method for synthesizing high-viscosity polyphenylene terephthalamide, and belongs to the technical field of polymer synthesis. The method comprises the following steps of: adding dissolution-helping salt into N-methyl pyrrolidone first, adding p-phenylenediamine for dissolution, adding paraphthaloyl chloride for polymerization, and washing and drying an obtained reaction product to obtain the polyphenylene terephthalamide. An acid absorbent used by the synthesis method is calcium hydride, the calcium hydride can react with hydrogen chloride produced in a polymerization reaction, and generated calcium chloride is a cosolvent in a solvent system and is favorable for the stability of a reaction system; and the calcium hydride can remove trace water in the reaction system, so that the influence of water on polyphenylene terephthalamide (PPTA) polymerization is eliminated. Moreover, the unreacted calcium hydride can be easily removed in the subsequent washing step after the PPTA polymerization is finished.

Owner:TSINGHUA UNIV

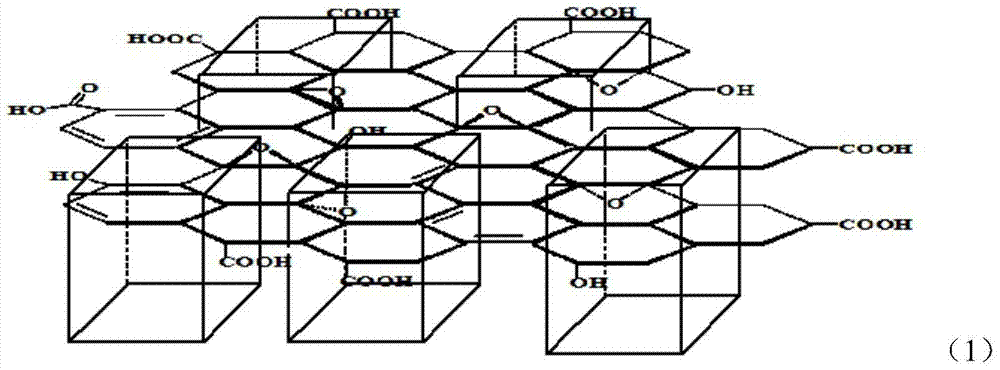

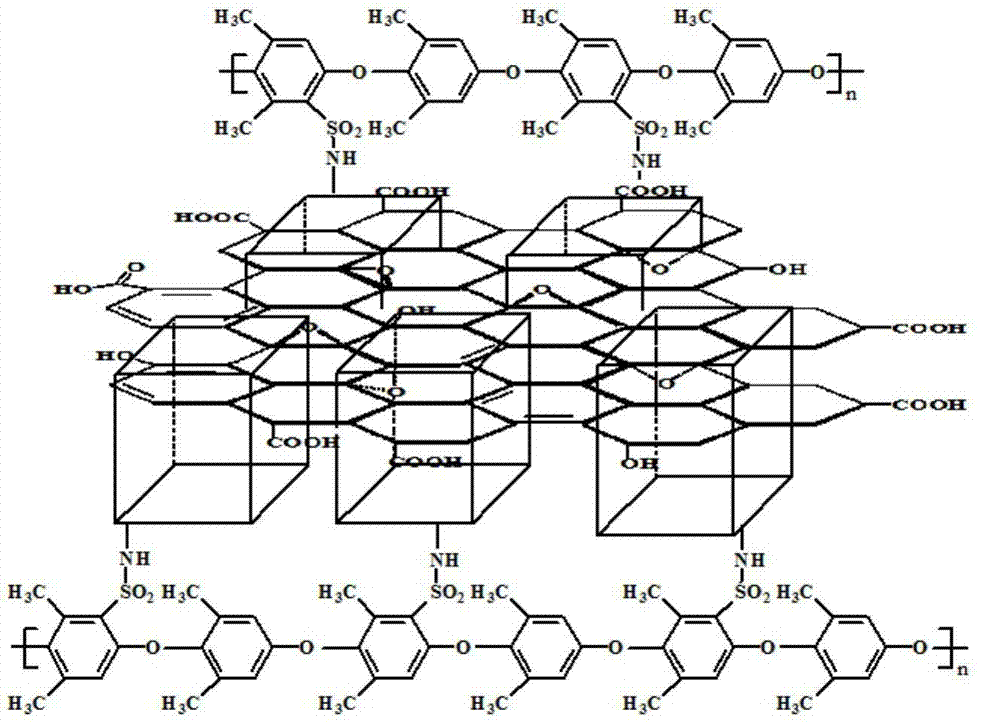

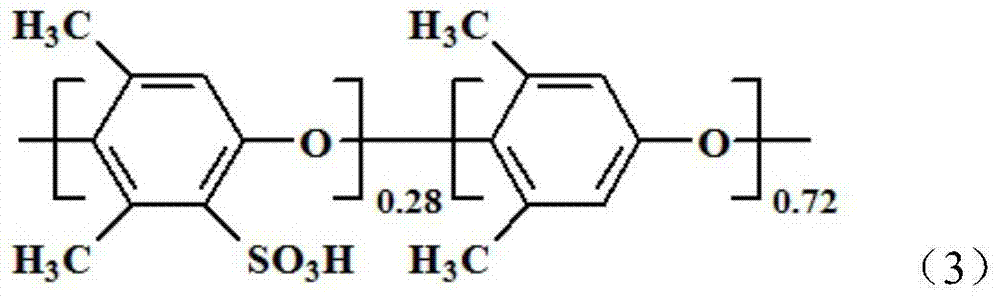

Method for preparing high-temperature proton exchange membrane

ActiveCN103779597AImprove conductivityImprove oxidation resistanceFinal product manufactureSolid electrolyte fuel cellsSodium hydroxidePolyphenylene oxide

The invention discloses a method for preparing a high-temperature proton exchange membrane. The method is characterized by comprising the following steps: introducing a precursor composition with a metal organic frame into oxidized graphene to form a coexisting body of the oxidized graphene and the metal organic frame, subsequently adding the coexisting body together with a sodium hydroxide solution into an N-methyl pyrrolidone solution of sulfonyl chlorination polyphenyl ether to perform Hinsberg reaction to obtain polymer membrane casting liquid with the coexisting body, coating and drying so as to obtain the high-temperature proton exchange membrane. According to the method, the metal organic frame is introduced into the oxidized graphene by using a hydrothermal method to form the coexisting body, and is further prepared into the high-temperature proton exchange membrane together with sulfonated polyphenyl ether in a chemical bond mode, the membrane is good in mechanical strength, thermal stability and excellent high-temperature proton conductivity and oxidative resistance, and can be applied to high-temperature proton exchange membrane fuel batteries.

Owner:UNIV OF SCI & TECH OF CHINA

High intensity PVC hollow fiber hyperfiltration membrane and method of preparing the same

InactiveCN101254422AHigh strengthExtended service lifeSemi-permeable membranesHollow fibrePolymer science

The invention discloses a high-strength polyvinyl chloride hollow fiber ultrafiltration film which is made from a film-casting liquid containing the following components at the following weight percentages: polyvinyl chloride 13-19%, reinforcing agent 1-55, hydrophilic agent 0.4-2%, pore-forming agent 3-18% and solvent 56-79%. The reinforcing agent is a terpolymer mainly composed of methyl methacrylate, butadiene and styrene, the hydrophilic agent is a copolymer mainly composed of vinyl chloride and a carboxyl-containing compound, the pore-forming agent is the mixture of polyethylene glycol and polyvinylpyrrolidone, and the solvent is mainly N-methyl pyrrolidone. The ultrafiltration film is prepared by the following steps: (1) preparing the film-casting liquid from the components at the given ratio; (2) stirring the film-casting liquid intensively at 45-85 DEG C to debubble; and (3) extruding the film-casting liquid into a tubular hollow fiber spinning sprayer, traveling vertically 5-50 cm in the air and then going into a curing bath, followed by film forming of different phases respectively.

Owner:深圳市诚德来实业有限公司

Separation and purification method for solution containing N-methyl pyrrolidone (NMP)

InactiveCN102115454AReduce energy consumptionHigh recovery rateOrganic chemistryPurification methodsAramid

The invention discloses a separation and purification method for the solution containing N-methyl pyrrolidone (NMP), which is applied to, the purification of NMP in aramid polymer powder washing mother liquor. The separation and purification method comprises the following steps: I, acidic solution containing NMP is neutralized, and the pH value of the solution is controlled between 5.5 and 7.0; II, chloroform as an extracting solvent is sufficiently mixed with neutral solution containing NMP at normal temperature according to the weight ratio of 1 to 8, then the mixed solution stands, and the fractional extraction in more than one stage is carried out; an aqueous solution containing inorganic salts is formed on the upper layer of a stratified solution system obtained after each stage of extraction, and chloroformic solution containing N-methyl pyrrolidone (NMP) is formed on the lower layer of the stratified solution system obtained after each stage of extraction; and III, the chloroformic solution containing NMP obtained through extraction and separation is purified by a rectification method. The extraction rate of NMP can reach more than 99 percent, the stratified solution of chloroform is rectified to obtain reusable NMP with purity higher than 99.95 percent, and the separation and purification method has the advantages of low energy conservation and high recovery ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com