Method for preparing composite material of graphene and graphene poly-p-phenylenediamine

A poly-p-phenylenediamine and composite material technology is applied in the field of preparation of graphene colloid and graphene-poly-p-phenylene diamine composite material, and can solve the problems of high reaction temperature, high equipment requirements, unfavorable large-scale application and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

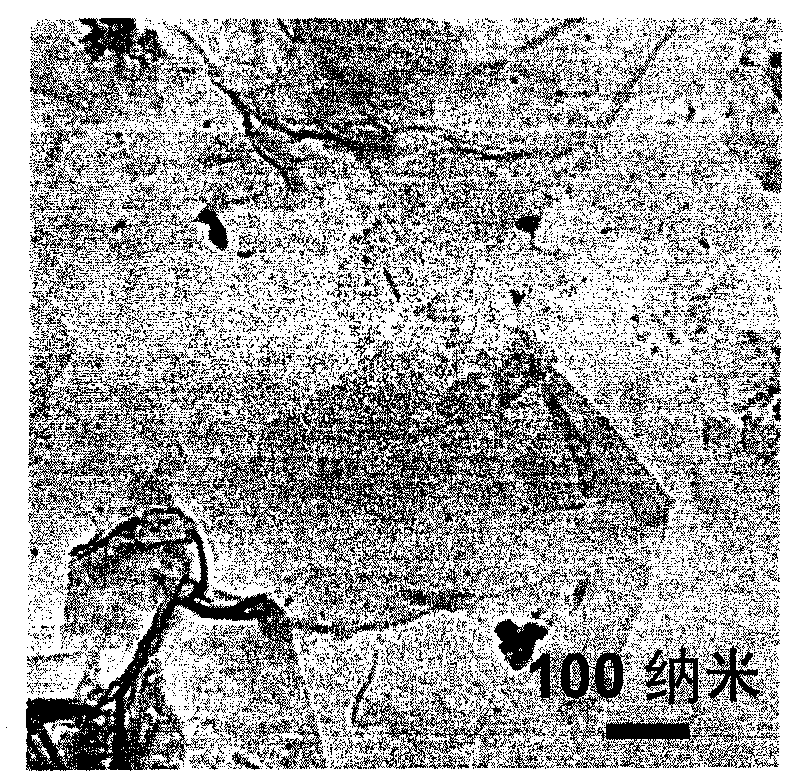

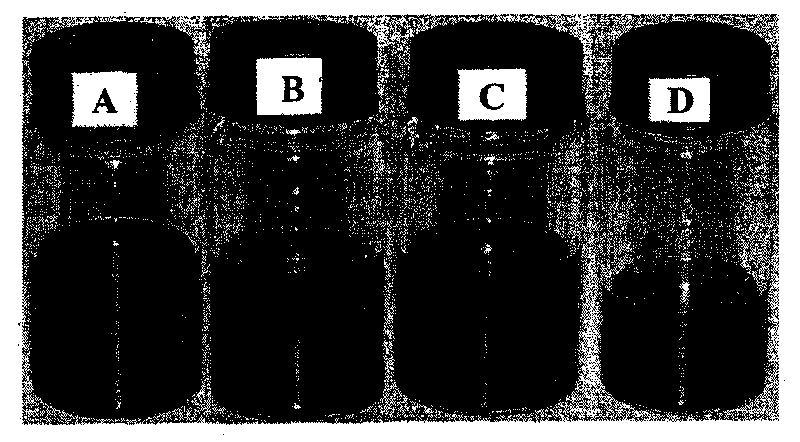

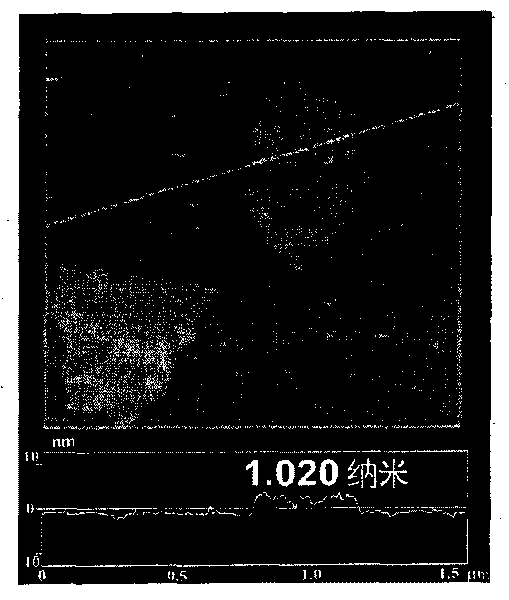

[0018] 0.1 g of graphite oxide was dissolved in 100 ml of water, and then ultrasonically dispersed for 2 hours to form a graphene oxide colloid with a mass concentration of 1 mg / ml. 0.9 g of p-phenylenediamine was dissolved in 100 ml of N,N-dimethylformamide to form an aqueous solution of p-phenylenediamine with a mass concentration of 9 mg / ml. The prepared graphene oxide colloid and p-phenylenediamine aqueous solution were mixed and then poured into a round-bottomed flask and boiled and refluxed at 90° C. for 24 hours. The obtained red graphene colloid was filtered and washed with acetone to obtain a graphene wet powder. Get 0.05g graphene wet powder and transfer to 100ml ethanol, make the graphene colloid that concentration is 0.5mg / ml.

[0019] 0.1 g of graphite oxide was dissolved in 100 ml of water, and then ultrasonically dispersed for 2 hours to form a graphene oxide colloid with a mass concentration of 1 mg / ml. 0.9 g of p-phenylenediamine was dissolved in 100 ml of N,...

Embodiment 2

[0022] 0.1 g of graphite oxide was dissolved in 100 ml of water, and then ultrasonically dispersed for 1 hour to form a graphene oxide colloid with a mass concentration of 1 mg / ml. 0.9 g of p-phenylenediamine was dissolved in 100 ml of N,N-dimethylformamide to form an aqueous solution of p-phenylenediamine with a mass concentration of 9 mg / ml. Mix the prepared graphene oxide colloid and p-phenylenediamine aqueous solution, pour it into a round bottom flask and boil and reflux at 90°C for 24 hours, filter the resulting red graphene colloid, wash with acetone to obtain a graphene wet powder, and take 0.05g of graphite Graphene wet powder is transferred to 100ml ethanol, and prepared concentration is the graphene colloid of 0.5mg / ml.

[0023]0.1 g of graphite oxide was dissolved in 100 ml of water, and then ultrasonically dispersed for 1 hour to form a graphene oxide colloid with a mass concentration of 1 mg / ml. 0.9 g of p-phenylenediamine was dissolved in 100 ml of N,N-dimethyl...

Embodiment 3

[0025] 0.1 g of graphite oxide was dissolved in 100 ml of water, and then ultrasonically dispersed for 1.5 hours to form graphene oxide colloids with a mass concentration of 1 mg / ml. 0.9 g of p-phenylenediamine was dissolved in 100 ml of N,N-dimethylformamide to form an aqueous solution of p-phenylenediamine with a mass concentration of 9 mg / ml. Mix the prepared graphene oxide colloid and p-phenylenediamine aqueous solution, pour it into a round bottom flask and boil and reflux at 90°C for 24 hours, filter the resulting red graphene colloid, wash with acetone to obtain a graphene wet powder, and take 0.05g of graphite Graphene wet powder is transferred to 100ml ethanol, and prepared concentration is the graphene colloid of 0.5mg / ml.

[0026] 0.1 g of graphite oxide was dissolved in 100 ml of water, and then ultrasonically dispersed for 1.5 hours to form graphene oxide colloids with a mass concentration of 1 mg / ml. 0.9 g of p-phenylenediamine was dissolved in 100 ml of N,N-dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com