Production method of environment-friendly rubber oil

An environment-friendly, oil-extracting technology, applied only in the multi-stage series refining process treatment, lubricating composition, etc., can solve the problems of no novelty, difficult to achieve continuous production, large equipment investment, etc., to improve production capacity and economy. Benefit, reduced frequency and energy consumption, effect of reducing solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The PCA content of the third-line distillate produced by a refinery is 13wt%, and the benzopyrene content is 2ppm. Weigh 300g of the third-line distillate oil in the laboratory, add 600g of furfural as a solvent, then stir and heat to 90°C, settle and separate layers, the upper layer is the refined liquid, and the lower layer is the extracted liquid, add 100g of extracted oil to the extracted liquid, and heat The lower layer is found to be divided into two layers, the upper layer is the secondary refining liquid, and the lower layer is the secondary extracting liquid. The secondary extracting liquid is evaporated to remove the solvent to obtain the extracted oil. After the secondary refining liquid is evaporated to remove the solvent, the secondary refined oil is obtained. Its PCA The content is 5.5 wt%, which is slightly higher than the EU standard, but it has been found that using this method can already reduce the PCA considerably.

Embodiment 2

[0017] Add 50g of fresh furfural to the secondary refining liquid in Example 1, and after stirring fully at 60°C, it is found that it is divided into two layers, the upper layer is the refining liquid, and the lower layer is the extraction liquid, and the secondary refining oil is obtained after the solvent is evaporated from the refining liquid , its PCA content is 1.2wt%, in line with EU standards (<3wt%). This shows that further refining with fresh solvent has a good effect.

Embodiment 3

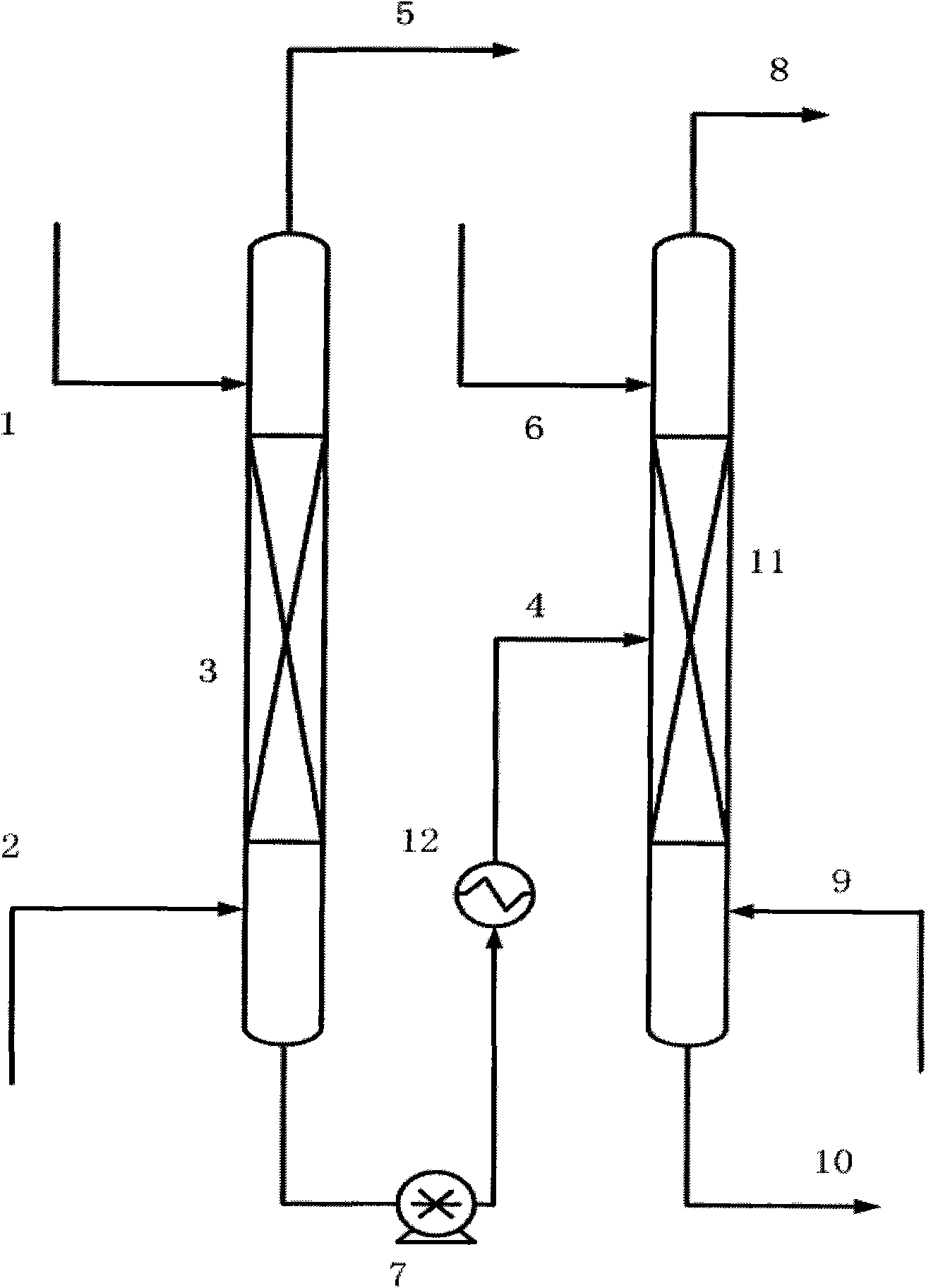

[0019] As the experimental device shown in the accompanying drawing, the extraction tower is 4m high and 10cm in diameter, and wire mesh packing is housed in the tower, and the secondary extraction tower is 4m high and 10cm in diameter. Furfural enters from the upper part of the extraction tower as the solvent, and the third-line distillate oil enters from the lower part of the tower. The furfural / oil mass ratio is 2.5:1. The temperature is 70°C, the temperature of the lower part is 60°C, the mass ratio of the feed oil extracted from the lower part of the secondary extraction tower to the third-line fraction oil is 0.6:1, and the mass ratio of fresh furfural to the extracted oil in the upper part of the secondary extraction tower is 0.5:1. After 12 hours, the secondary refined oil was obtained, the yield accounted for 32wt% of the third-line distillate oil, its PCA content was 1.3%, the benzopyrene content was 0.3ppm, and 8 kinds of carcinogen content 7ppm, C A The content is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com