Self-lubricating wear-resistant coating swash plate and technique for producing the same

A technology of self-lubricating wear-resistant and wear-resistant coatings, applied in coatings, lubricating compositions, polyether coatings, etc., can solve problems such as complex production processes, high production costs, and contamination of coating materials, and achieve simple production processes , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

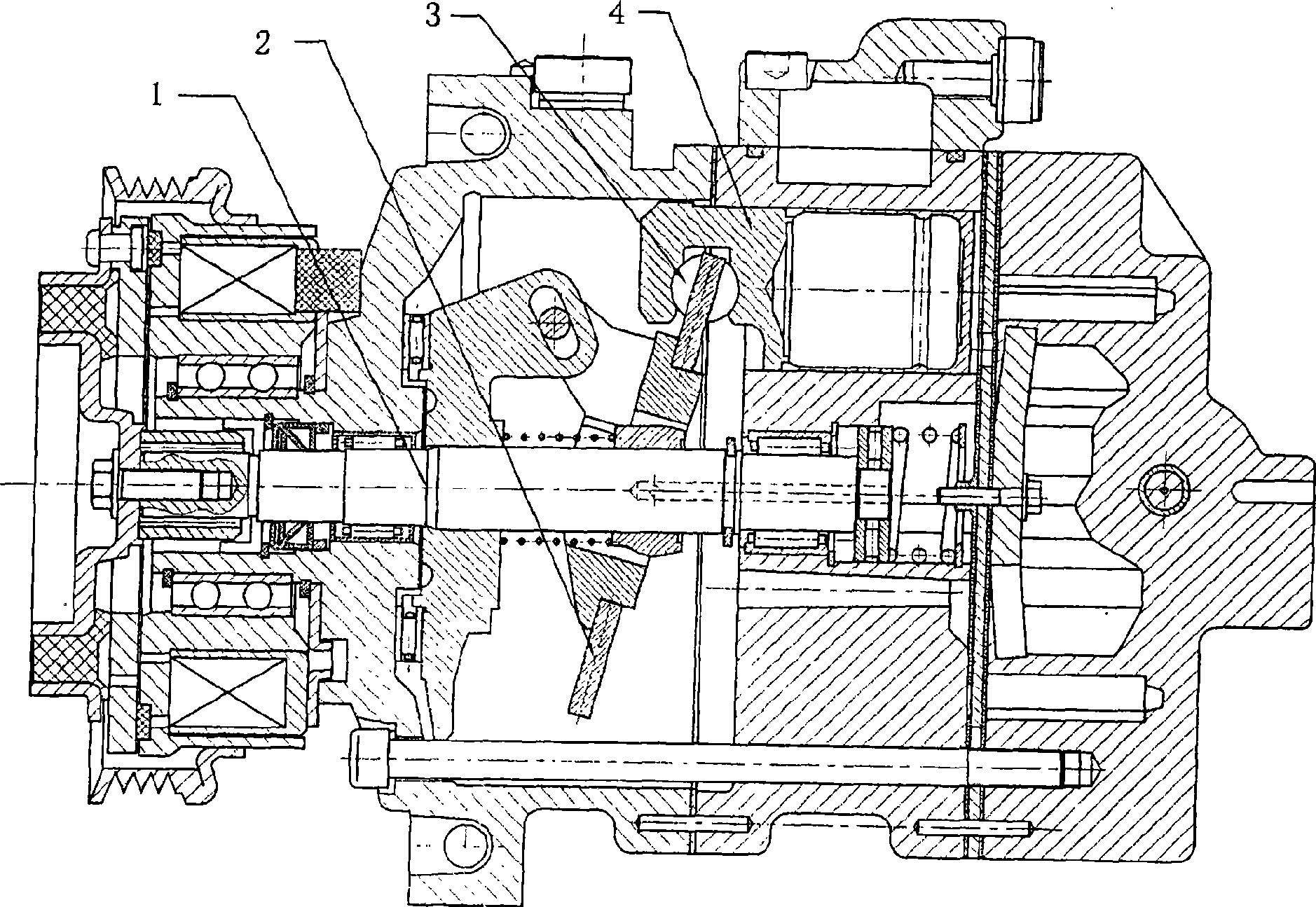

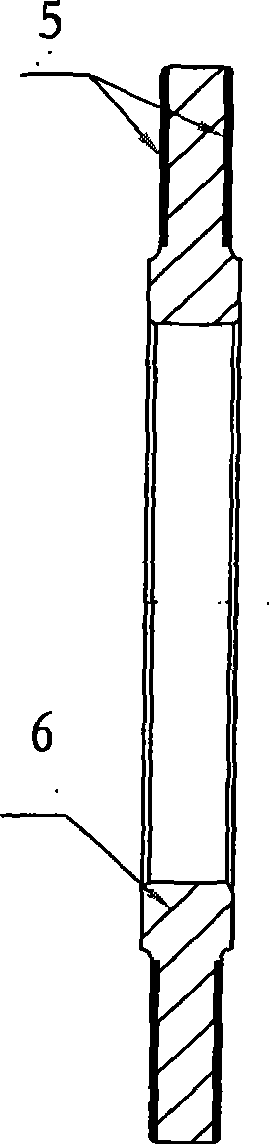

[0031] Self-lubricating wear-resistant coating coating is composed of 40% polynaphthalene polyether ketone (PPEK), 40% polyether sulfone ketone (PPESK) and 5% polytetrafluoroethylene (PTFE), 5% perfluoroethylene Propylene tetrafluoroethylene hexafluoropropylene (FEP) and 4% tungsten disulfide (WS 2 ), 4% molybdenum disulfide (MoS 2 ) and 1% aluminum oxide (Al 2 o 3 ), 1% titanium dioxide (TiO 2 ) composition, using solvent N-methylpyrrolidone as a solvent to configure the coating to be sprayed on the swash plate metal substrate 6. Dry and sinter in an oven, and then turn and grind to form a coating 5 with a thickness of 0.02-0.04mm.

Embodiment 2

[0033] The self-lubricating wear-resistant coating is composed of 38% polynaphthalene polyether ketone (PPEK), 38% polyether sulfone ketone (PPESK) and 6% polytetrafluoroethylene (PTFE), 6% perfluoroethylene Propylene tetrafluoroethylene hexafluoropropylene (FEP) and 5% tungsten disulfide (WS 2 ), 5% molybdenum disulfide (MoS 2 ) and 1% silicon carbide (SiC), 1% aluminum oxide (Al 2 o 3 ) composition, using solvent N-methylpyrrolidone as a solvent to configure the coating to be sprayed on the swash plate metal substrate 6. Dry and sinter in an oven, and then turn and grind to form a coating 5 with a thickness of 0.02-0.04mm.

Embodiment 3

[0035] The self-lubricating wear-resistant coating paint is composed of 40% polynaphthalene polyether ketone (PPEK), 40% polynaphthalene polyether sulfone (PPES) and 5% polyvinylidene fluoride (PVDF), 5% perfluoroethylene propylene Tetrafluoroethylene hexafluoropropylene (FEP) and 4% tungsten disulfide (WS 2 ), 4% molybdenum disulfide (MoS 2 ) and 1% silicon carbide (SiC), 1% titanium dioxide (TiO 2 ) composition, using solvent N-methylpyrrolidone as a solvent to configure the coating to be sprayed on the swash plate metal substrate 6. Dry and sinter in an oven, and then turn and grind to form a coating 5 with a thickness of 0.02-0.04mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com