Patents

Literature

153 results about "Perfluoroethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perfluoroethylene TFE. Identifiers ... Tetrafluoroethylene (TFE) is a fluoromonomer with chemical formula C 2 F 4. It belongs to the family of fluorocarbons and is the simplest perfluorinated alkene. This gaseous species is used primarily in the industrial preparation of polymers

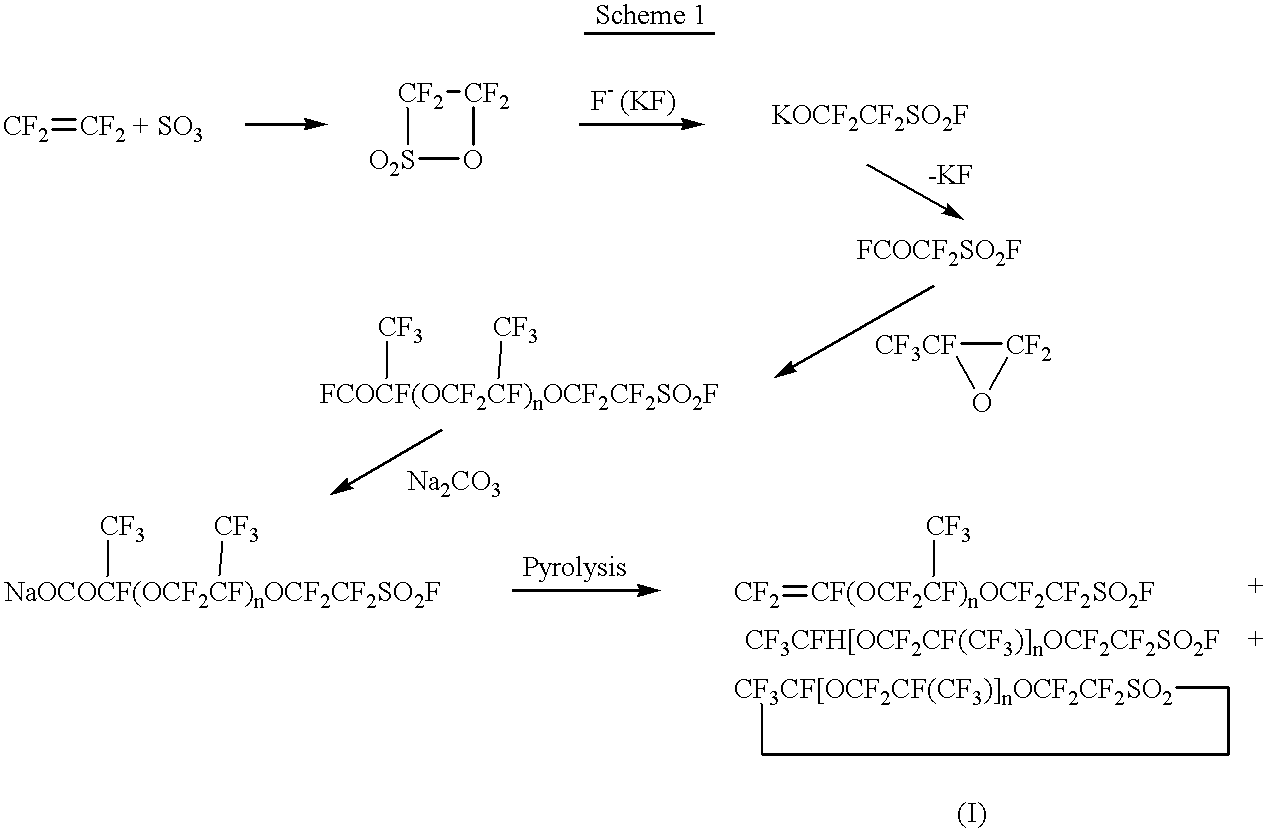

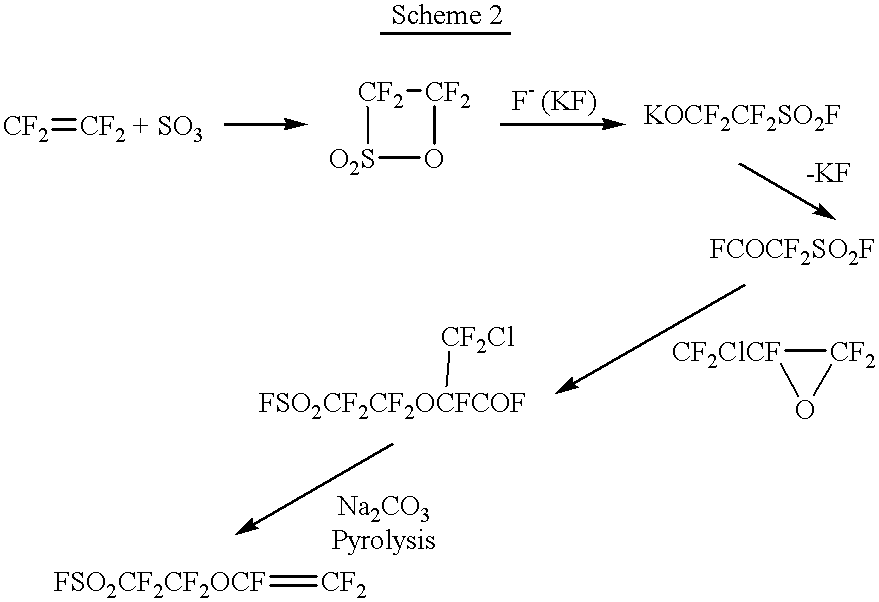

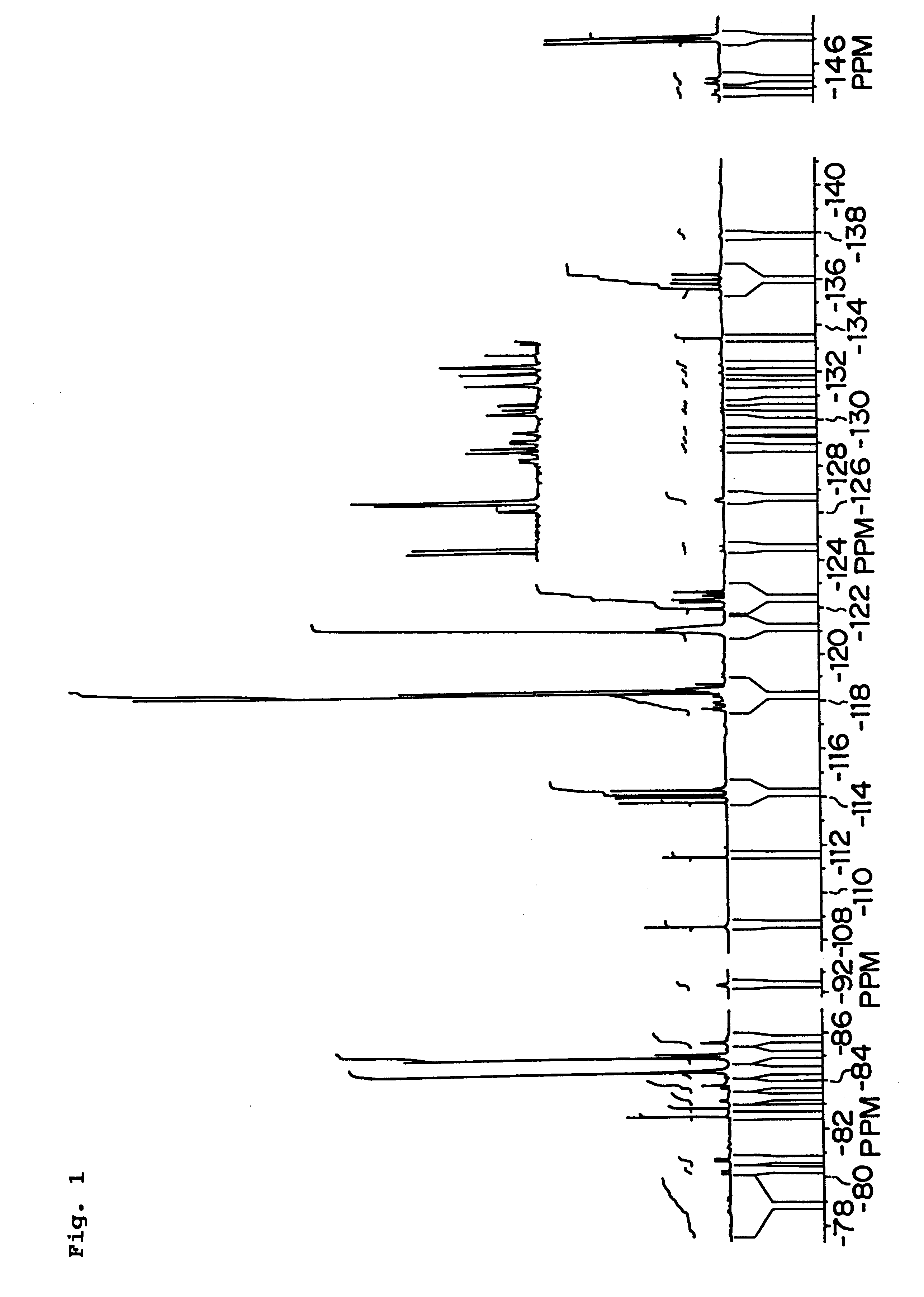

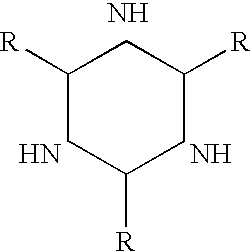

Process for the producing perfluorovinyl ethersulfonic acid derivatives and copolymer of the same

InactiveUS6274677B1Organic compound preparationSulfonic acid preparationAlkaline earth metalAcid derivative

A compound of the formula (1): FSO2CFXCF2O(CFXCF2O)nCF-(CF2Y)COF in which X is a fluorine atom, a chlorine atom or a trifluoromethyl group, Y is a fluorine atom, a chlorine atom, a bromine atom or an iodine atom, and n is a number of 0 to 5, preferably 0, 1 or 2, is converted to a compound of the formula (2): MOSO2CFXCF2O(CFXCF2O)2CF(CF2Y)COOM1 in which X, Y and n are the same as defined above, and M and M1 independently represent an alkali metal atom or an alkaline earth metal atom, and then a compound of the formula (2) is pyrolyzed at a temperature of 150 to 250° C. to obtain a compound of the formula (3): ASO2CFXCF2O(CFXCF2O)nCF=CF2 in which A is MO-, a hydroxyl group or a fluorine atom, and X and n are the same as defined above.

Owner:DAIKIN IND LTD

Perfluoroelastomers having a low glass transition temperature and method of making them

InactiveUS6730760B2The polymerization reaction is fastDesirable mechanical propertyVinyl etherVitrification

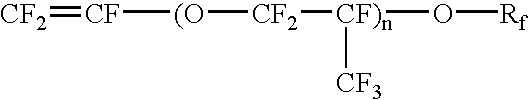

A method of making a curable fluoroelastomer is disclosed. The method comprises the steps ofpreemulsifying at least one perfluorovinylether in water, andcopolymerizing the preemulsified perfluorovinylether with a gaseous fluorinated monomer in the presence of a cure site monomer. The method provides a fluoroelastomer having a glass transition temperature of less than -10° C. Also disclosed is a fluoroelastomer that consists essentially of a perfluorovinylether of formula (I) as defined below, a cure site component, perfluoromethylvinylether, and tetrafluoroethylene and / or chlorotrifluoroethylene.

Owner:3M INNOVATIVE PROPERTIES CO

High-temperature resistant PTC electroconductive composition, high-temperature resistant PTC device containing composition and manufacturing method thereof

ActiveCN101560325ALower resistanceImprove PTC StrengthCurrent responsive resistorsPositive temperature coefficient thermistorsMetallurgyOrganic polymer

The invention relates to a high-temperature resistant PTC electroconductive composition, which comprises 20 to 70 percent of organic polymers, 25 to 75 percent of electroconductive filler, 1 to 30 percent of inorganic filler and 0.1 to 10 percent of additive, wherein the preferred melting point of the organic polymers is more than 150 DEG C; the organic polymers are one or more crystalline or semi-crystalline polymers and made of one or more of nylon 11, nylon 12, polyvinylidene fluoride, soluble poly(tetrafluoroethylene), ethylene-tetrafluoroethylene copolymers, perfluoroethylene-propylene, ethylene-chlorotrifluoroethylene and copolymers thereof. The invention also provides a high-temperature resistant PTC device containing the composition and a manufacturing method thereof. The high-temperature resistant PTC device containing the composition has low resistance, high PTC strength and superior resistance stability, so that the high-temperature resistant PTC device can be used for overcurrent protection of circuits in high-temperature environments such as automobile motors and the like. Moreover, the high-temperature resistant PTC device is simple and convenient to manufacture and has high efficiency.

Owner:SHANGHAI KETER POLYMER MATERIAL

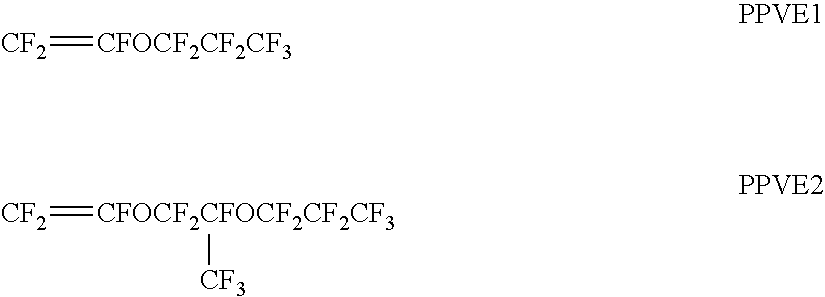

Fluoroelastomers having low glass transition temperature

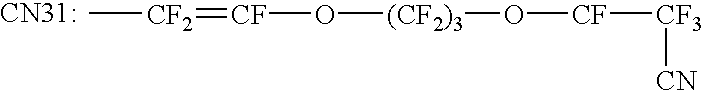

Fluoroelastomers are disclosed which have a glass transition temperature less than −10° C. The elastomers contain copolymerized units of a perfluorovinylpolyether that is derived from a trimer or tetramer of hexafluoropropylene oxide.

Owner:DUPONT PERFORMANCE ELASTOMERS L L C

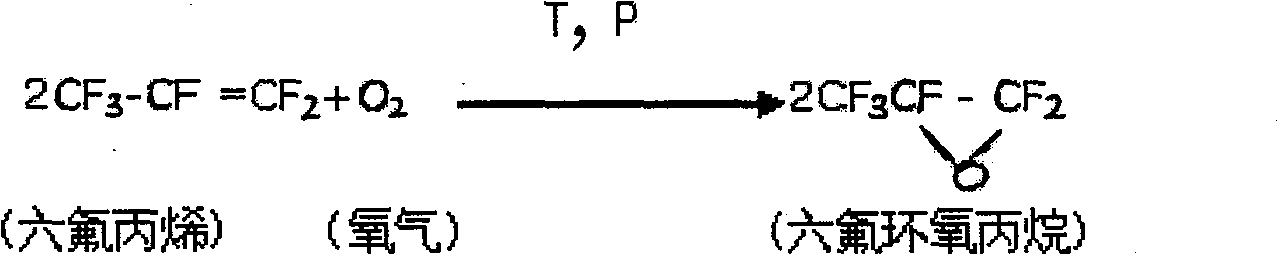

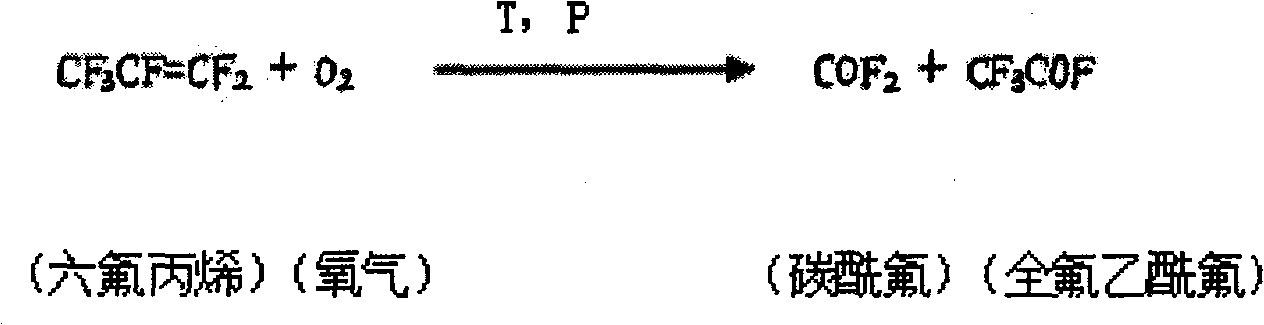

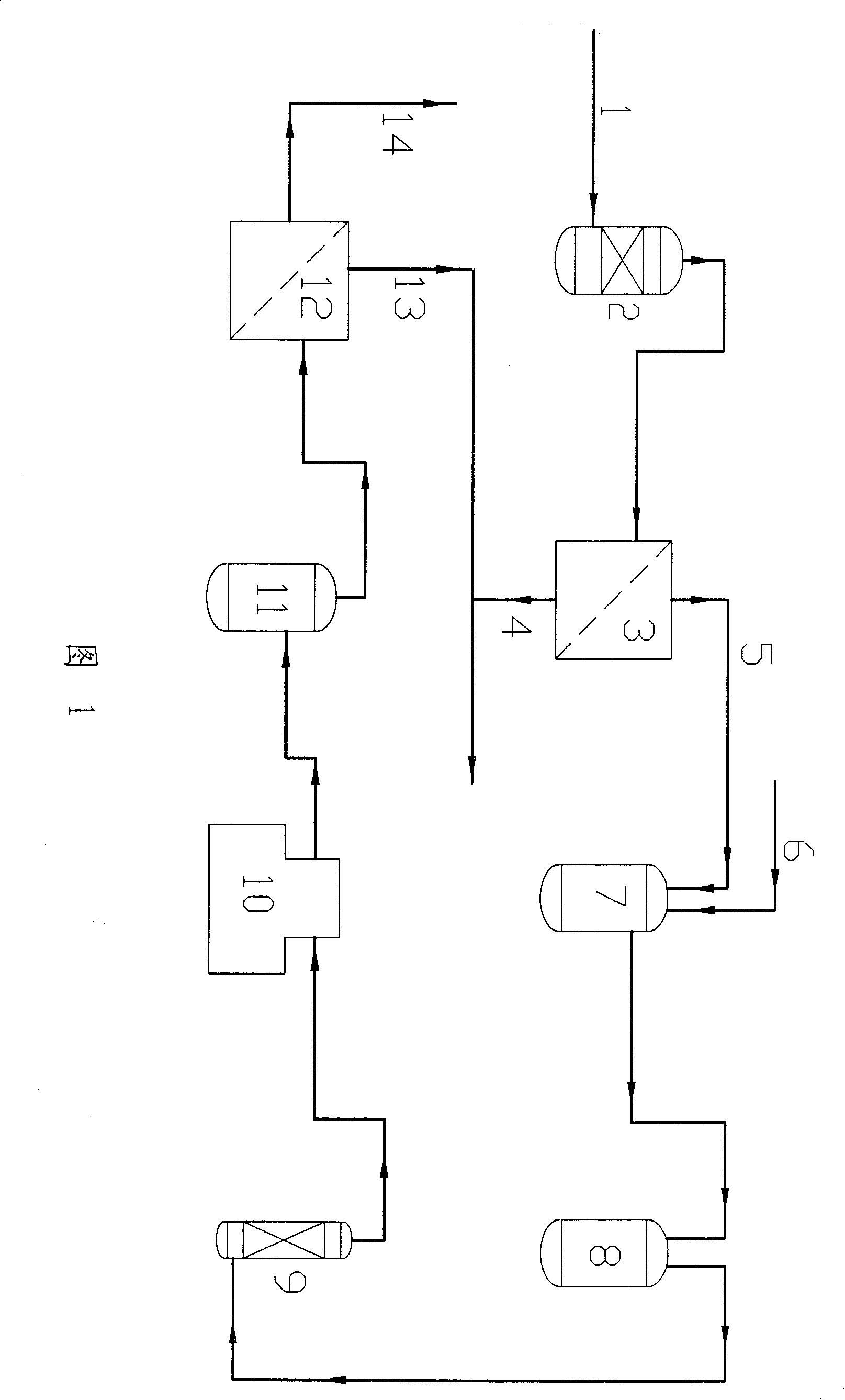

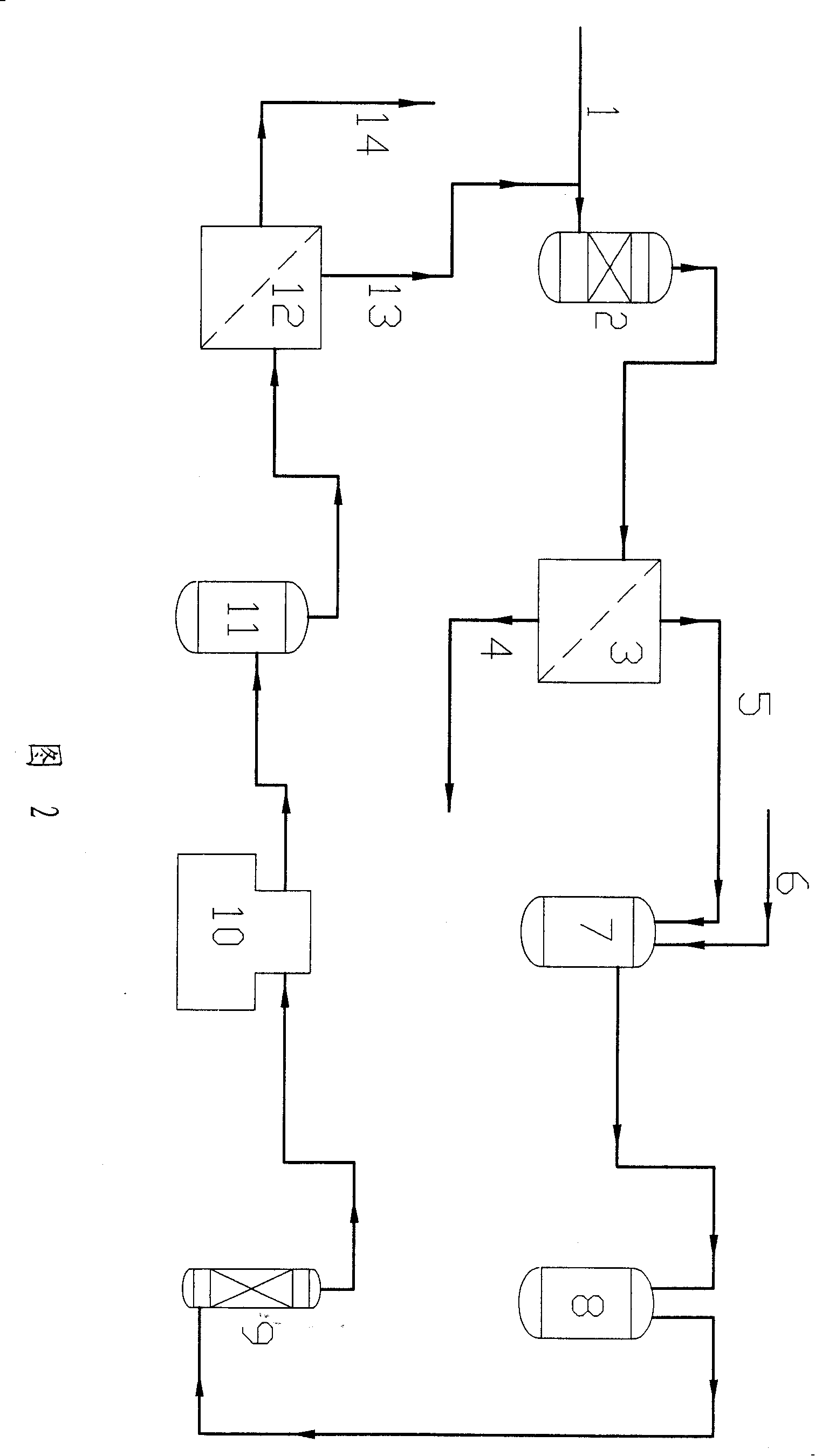

Method for producing hexafluoropropane oxide and coproducing perfluorovinyl ether

ActiveCN101817728ATake advantage ofAvoid pollutionOrganic chemistryOrganic compound preparationHexafluoropropylenePerfluoropolyether

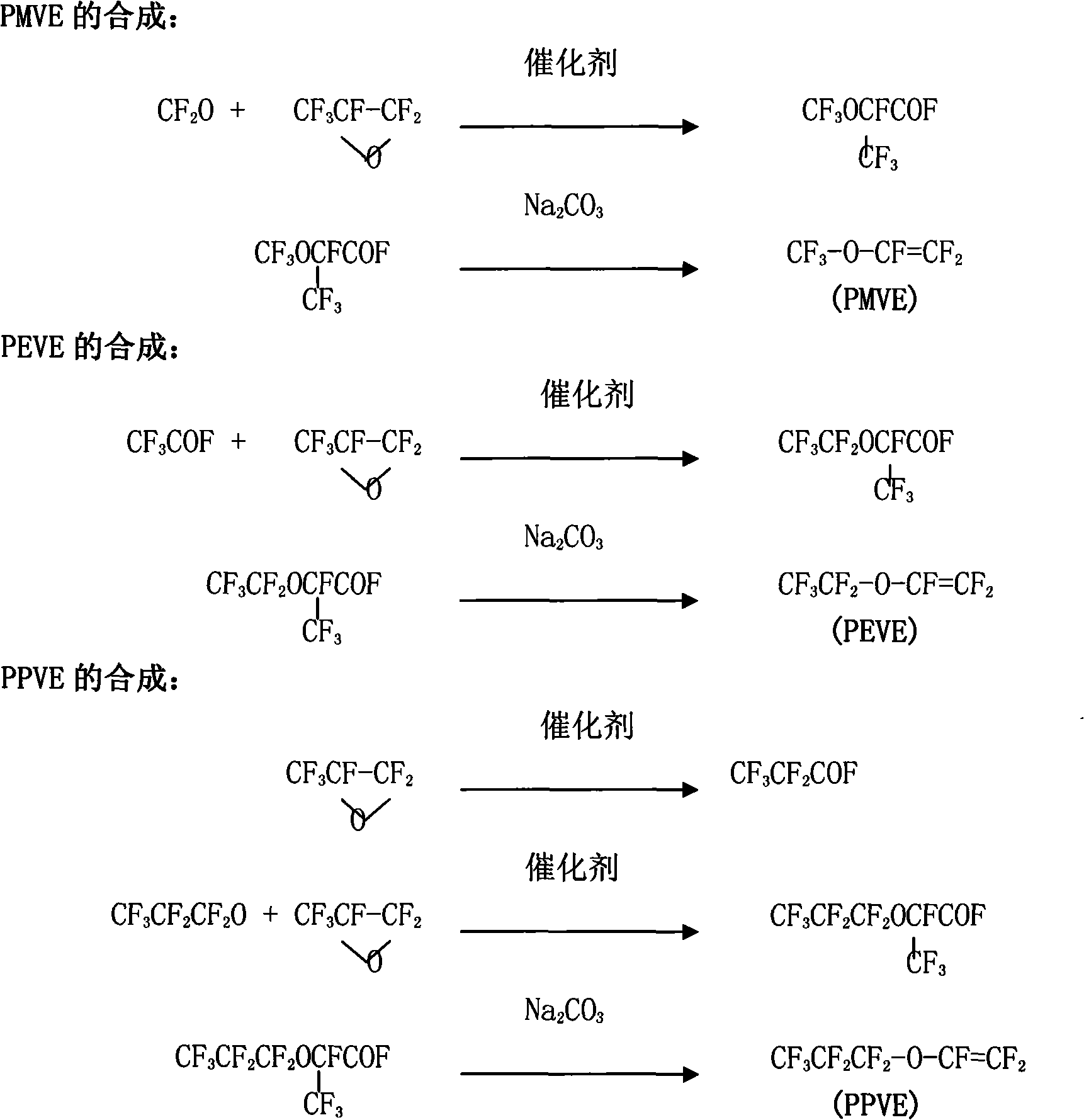

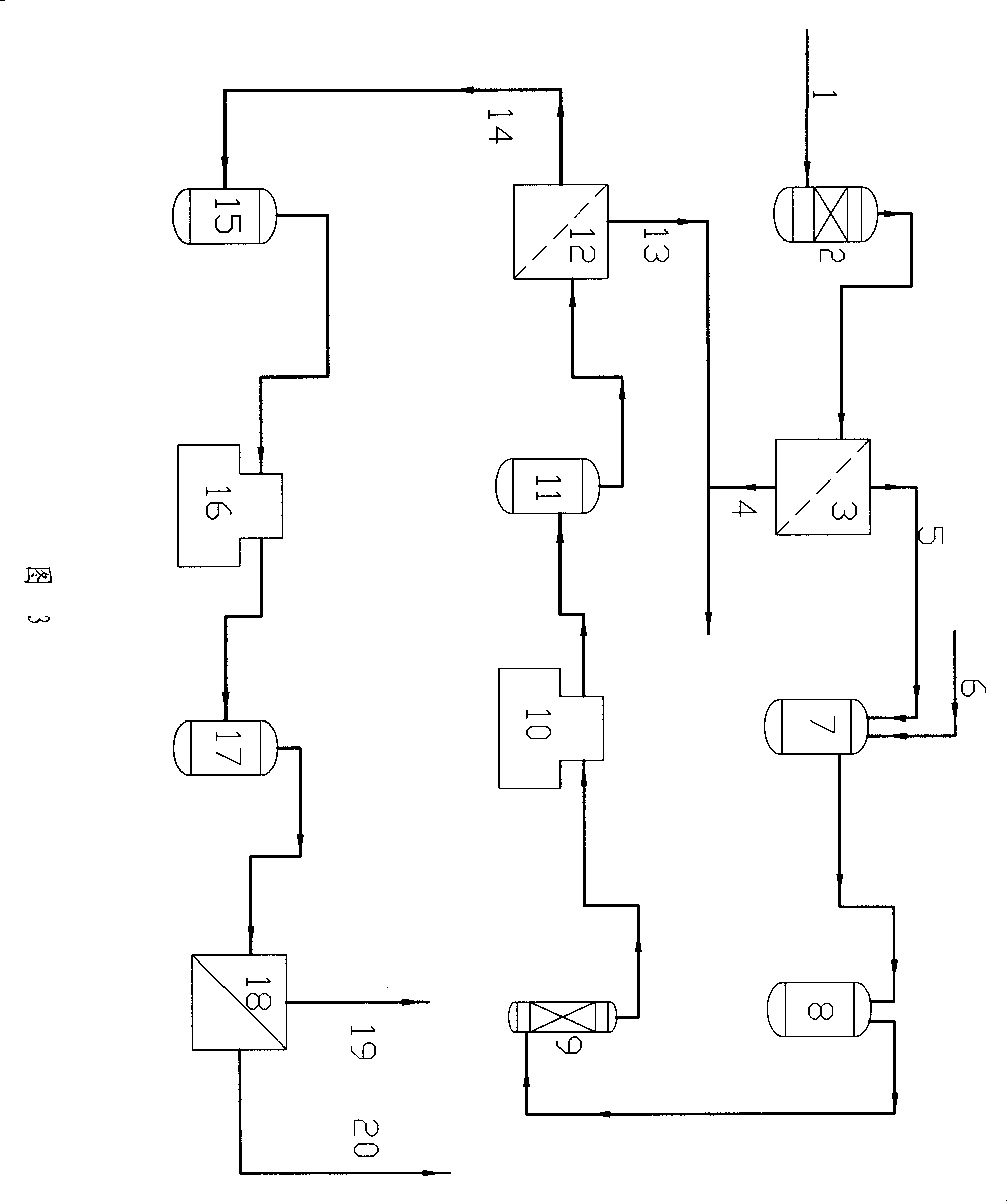

The invention relates to a method for producing hexafluoropropane oxide and coproducing perfluorovinyl ether, which comprises the following steps of: performing reaction of oxidizing hexafluoropropylene to synthesize the hexafluoropropylene oxide to obtain mixed gas, introducing the mixed gas into a coarse fractionating tower, and rectifying and purifying the separated heavy component to obtain hexafluoropropylene oxide; making the separated light component enter a rectifying tower to remove non-condensable gas to obtain mixed gas of fluorophosgene and perfluacetylfluoride, and introducing the hexafluoropropylene oxide for polymerization to obtain a corresponding perfluoroalkylpolyether mixture; in the presence of sodium carbonate, performing cracking reaction at the temperature of between 150 and 300 to obtain a perfluorovinyl ether mixture; and separating by using the rectifying tower to respectively obtain three kinds of perfluorovinyl ether, namely PMVE, PEVE, PPVE. The method fulfills the aim of producing the hexafluoropropane oxide, and fully utilizes a byproduct, namely perfluorovinyl ether with high added-value generated by the reaction, and has the advantages of reasonable process and industrial application.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

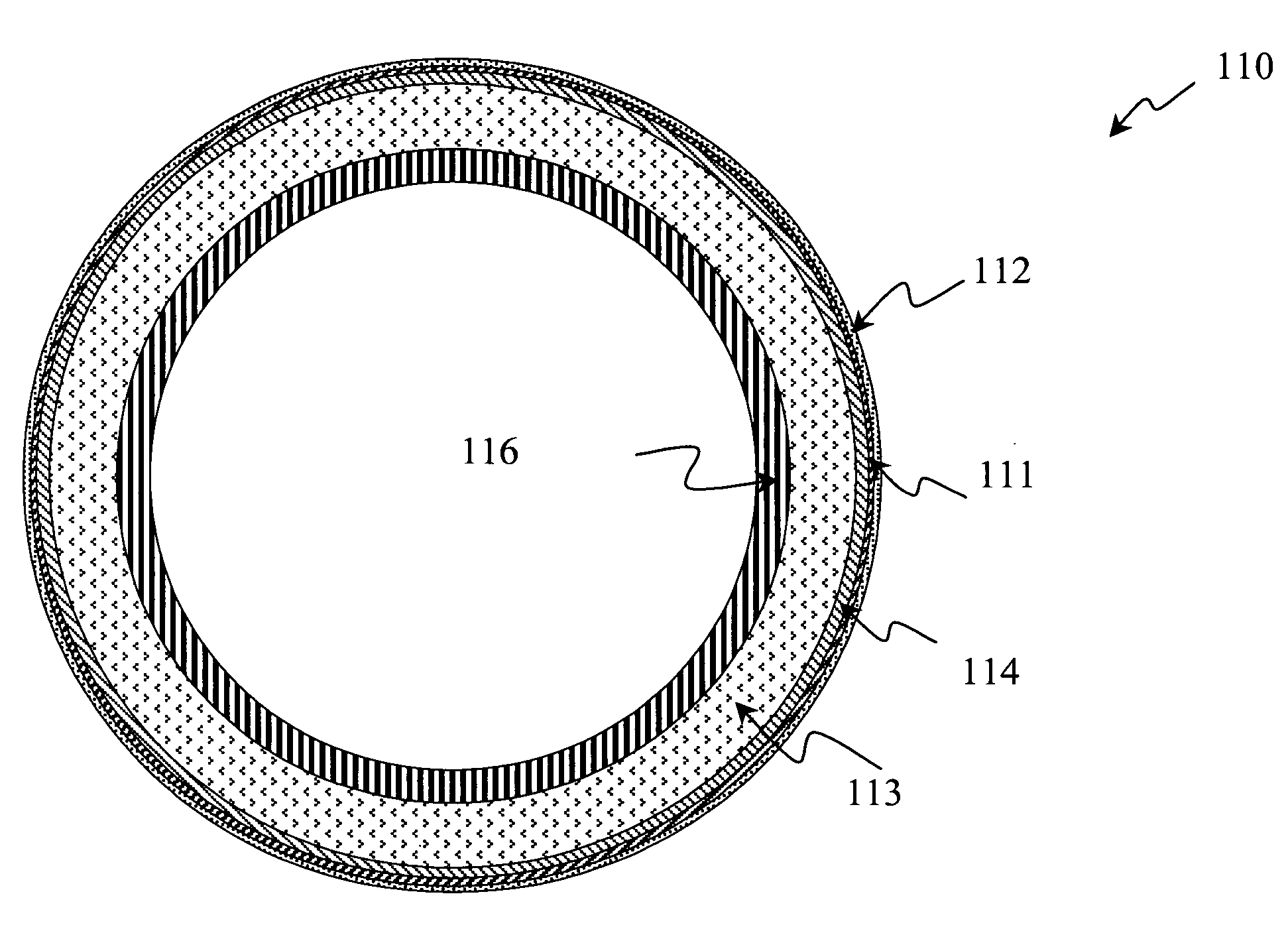

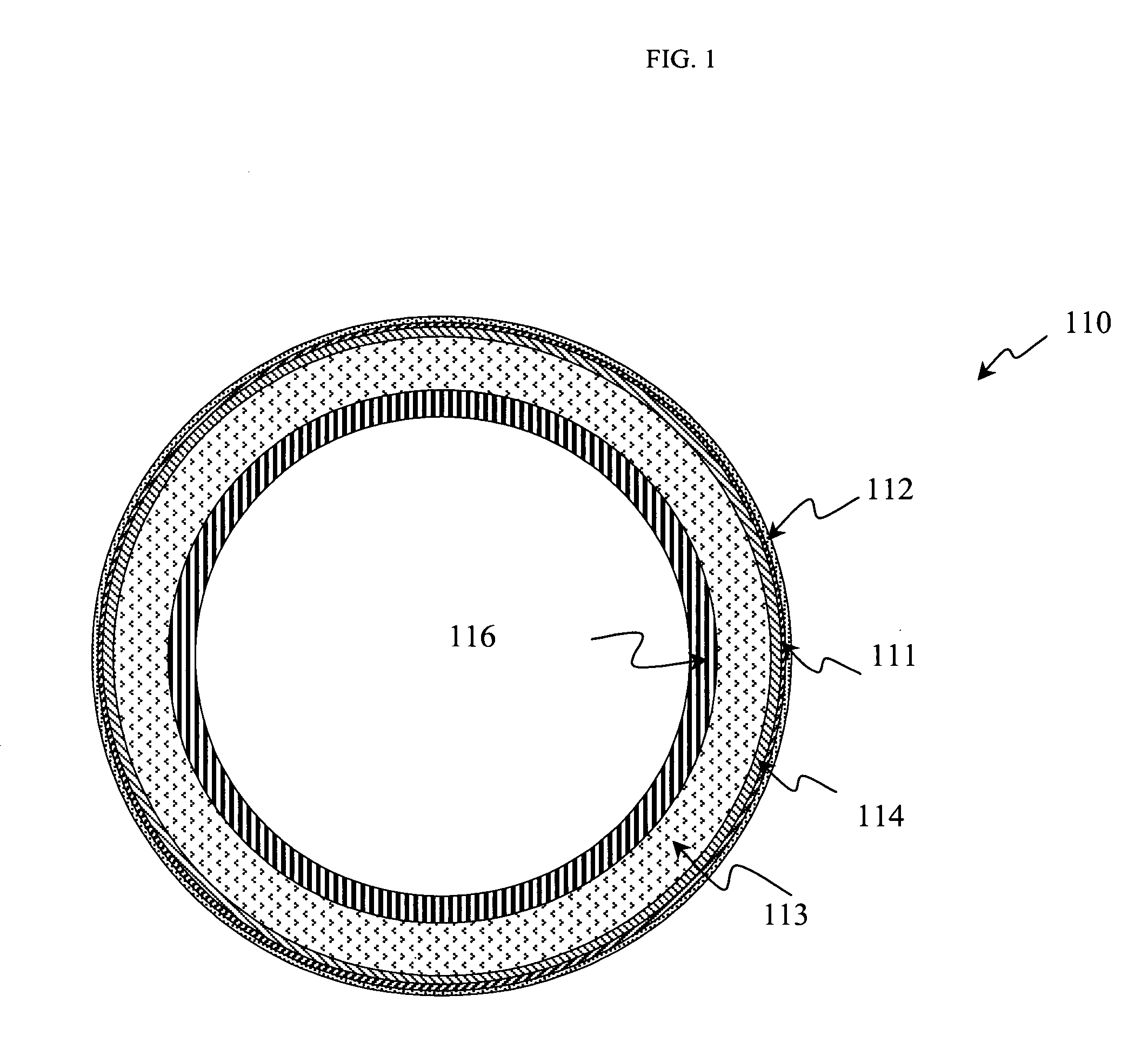

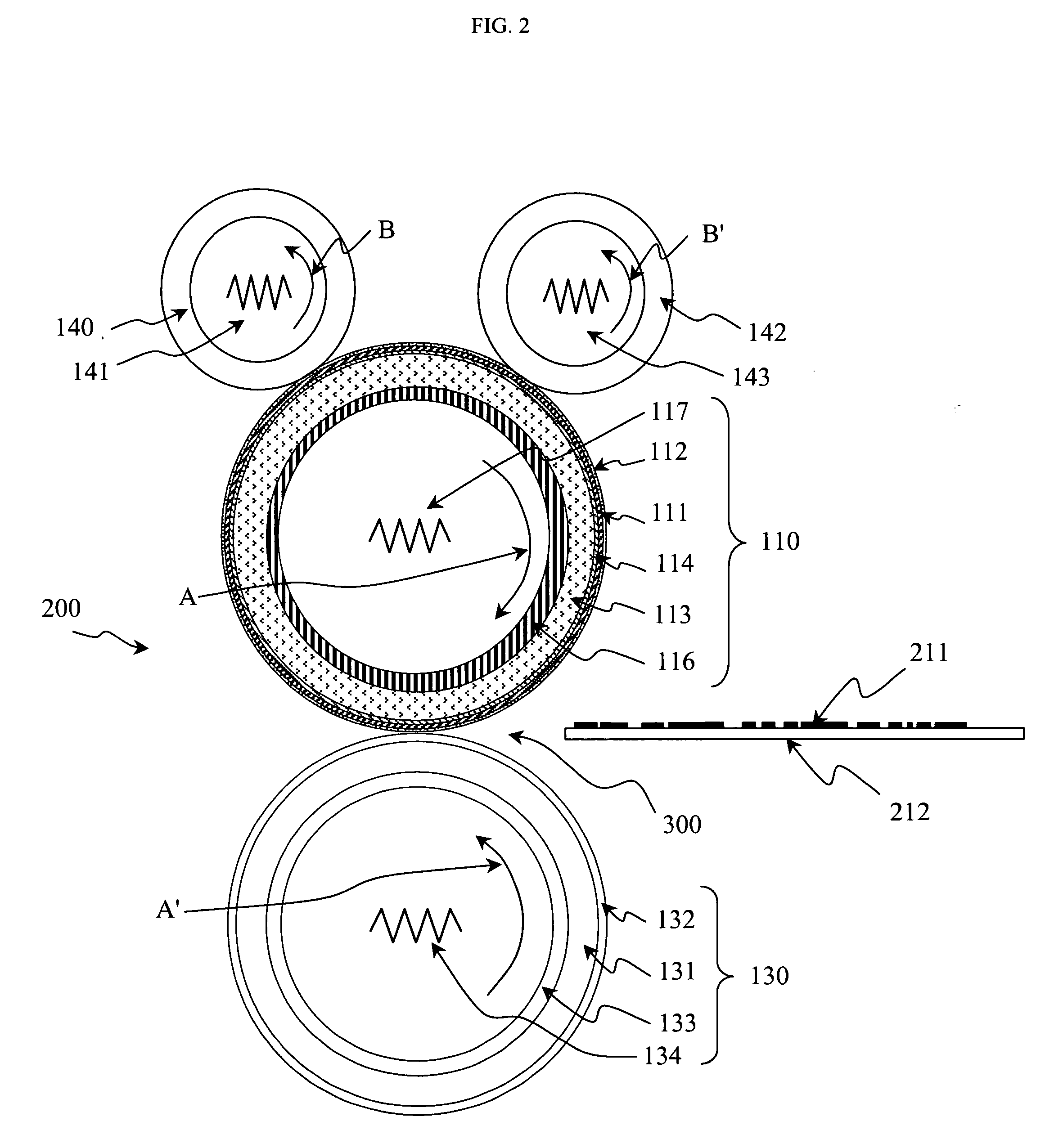

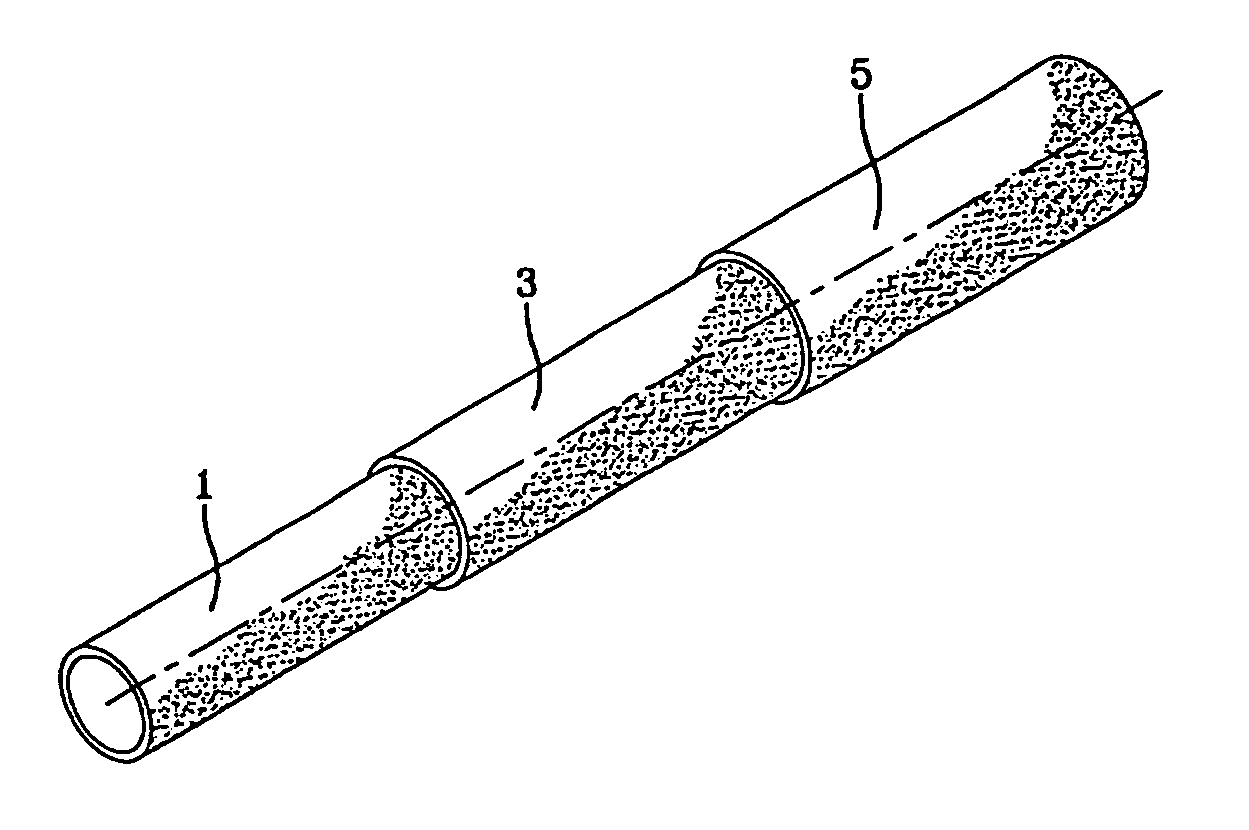

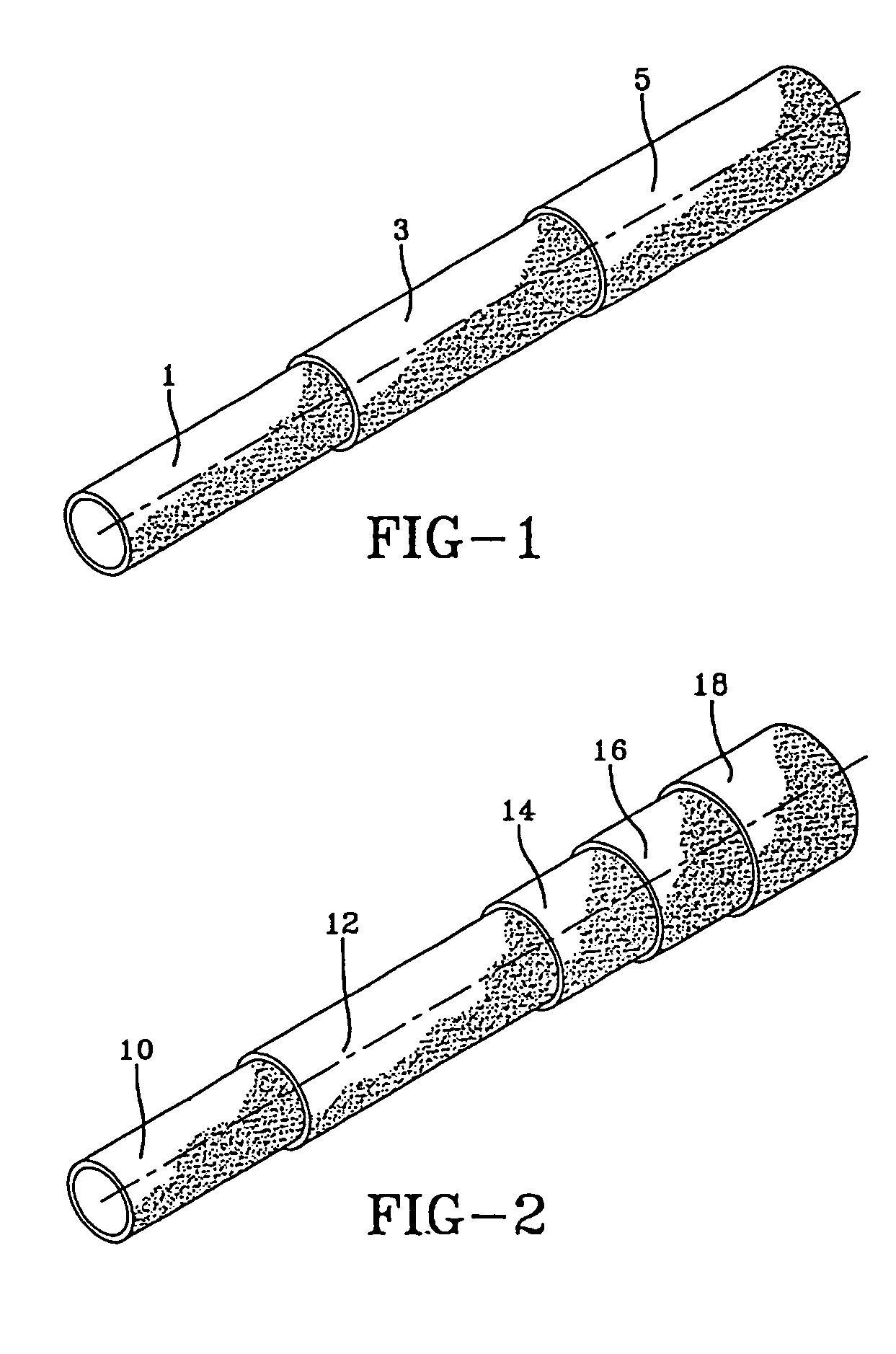

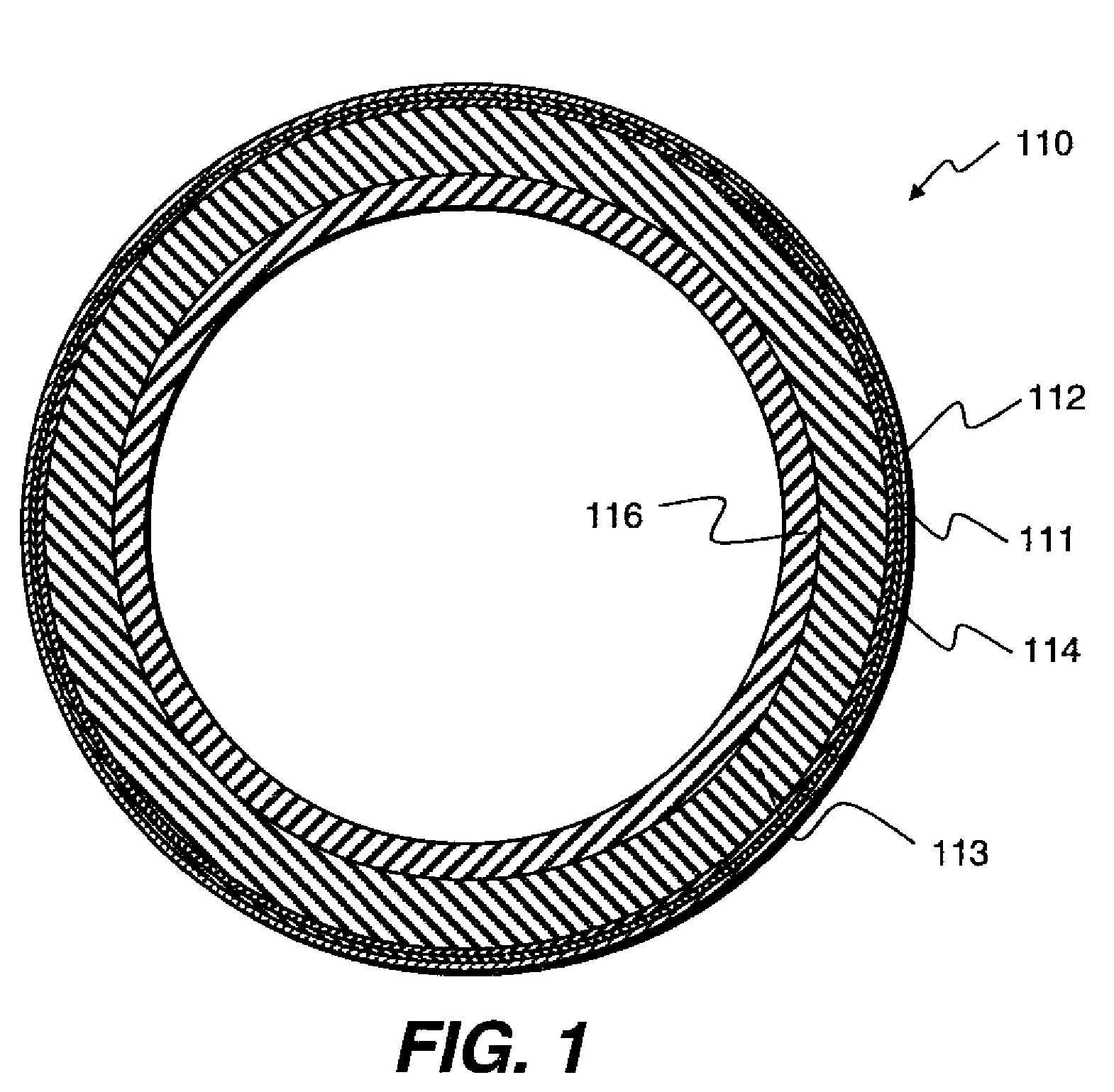

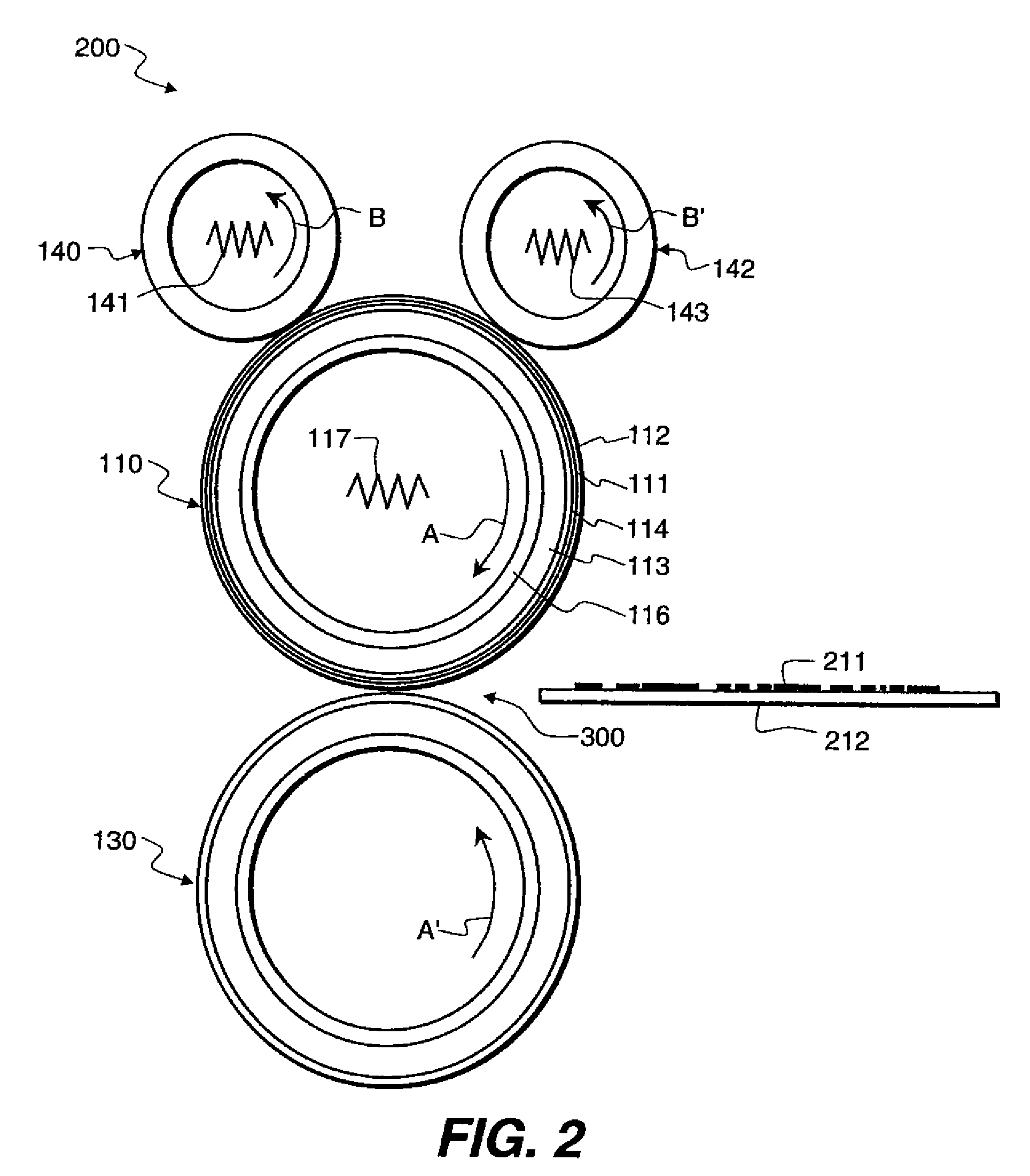

Fuser member

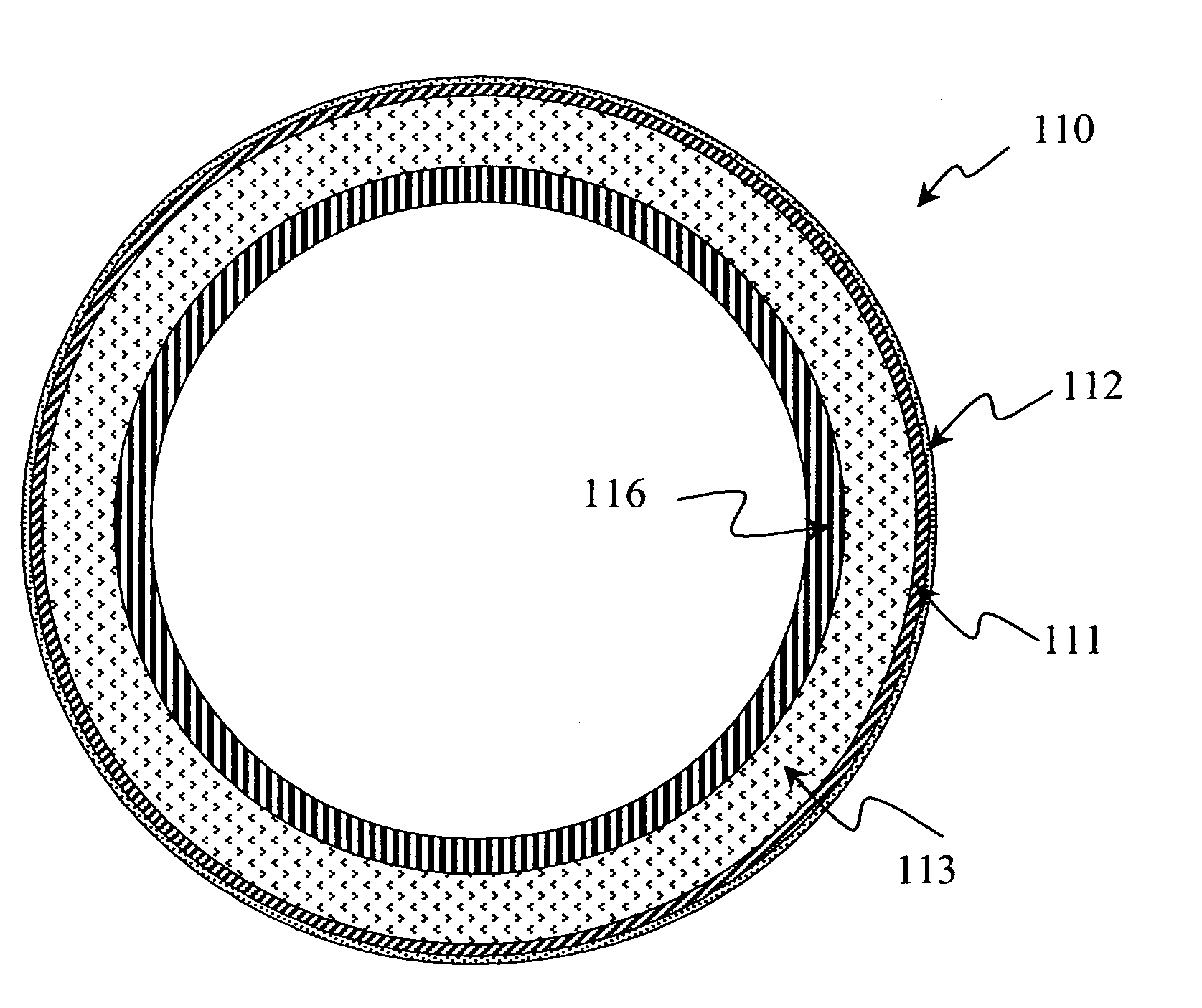

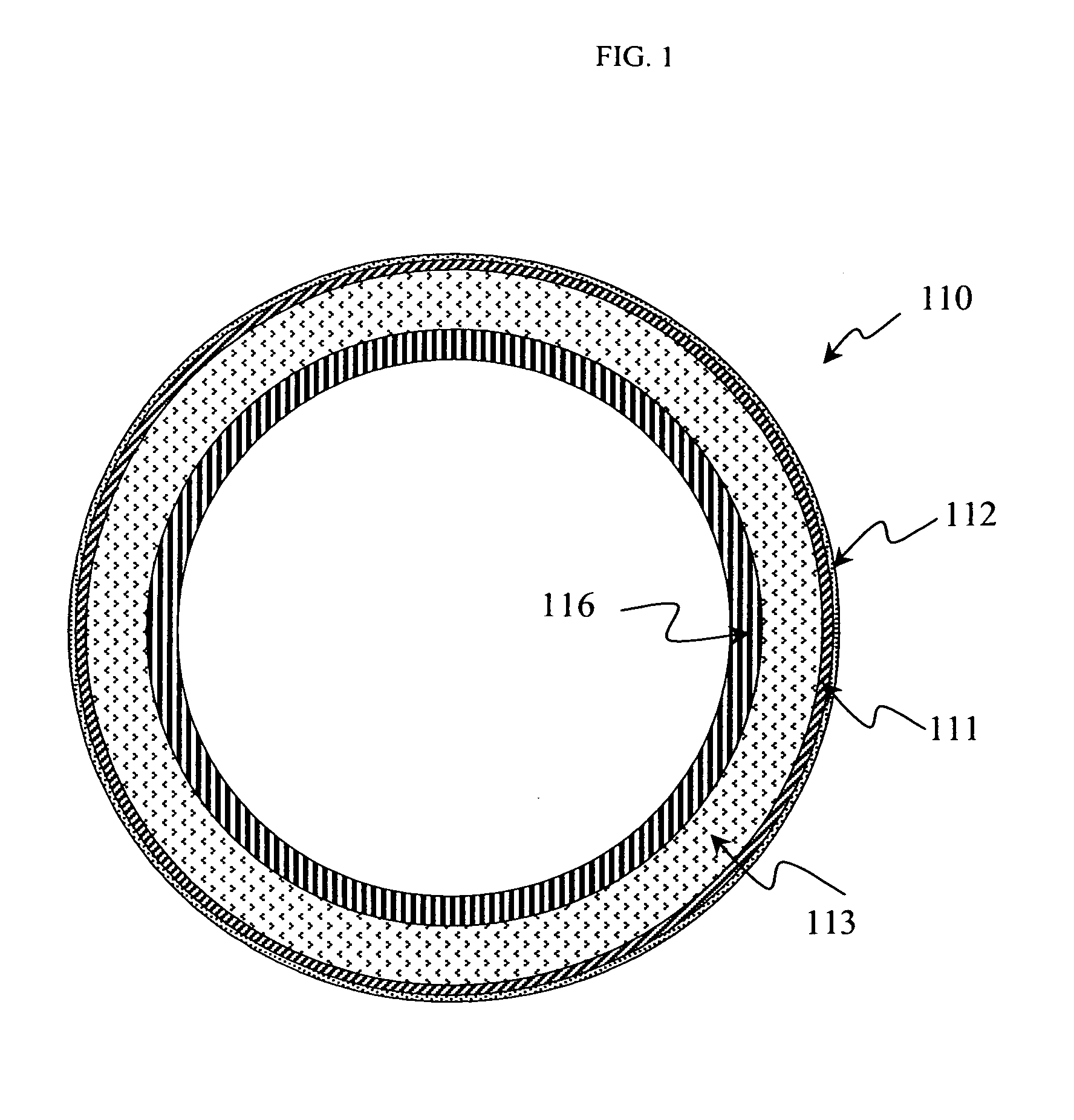

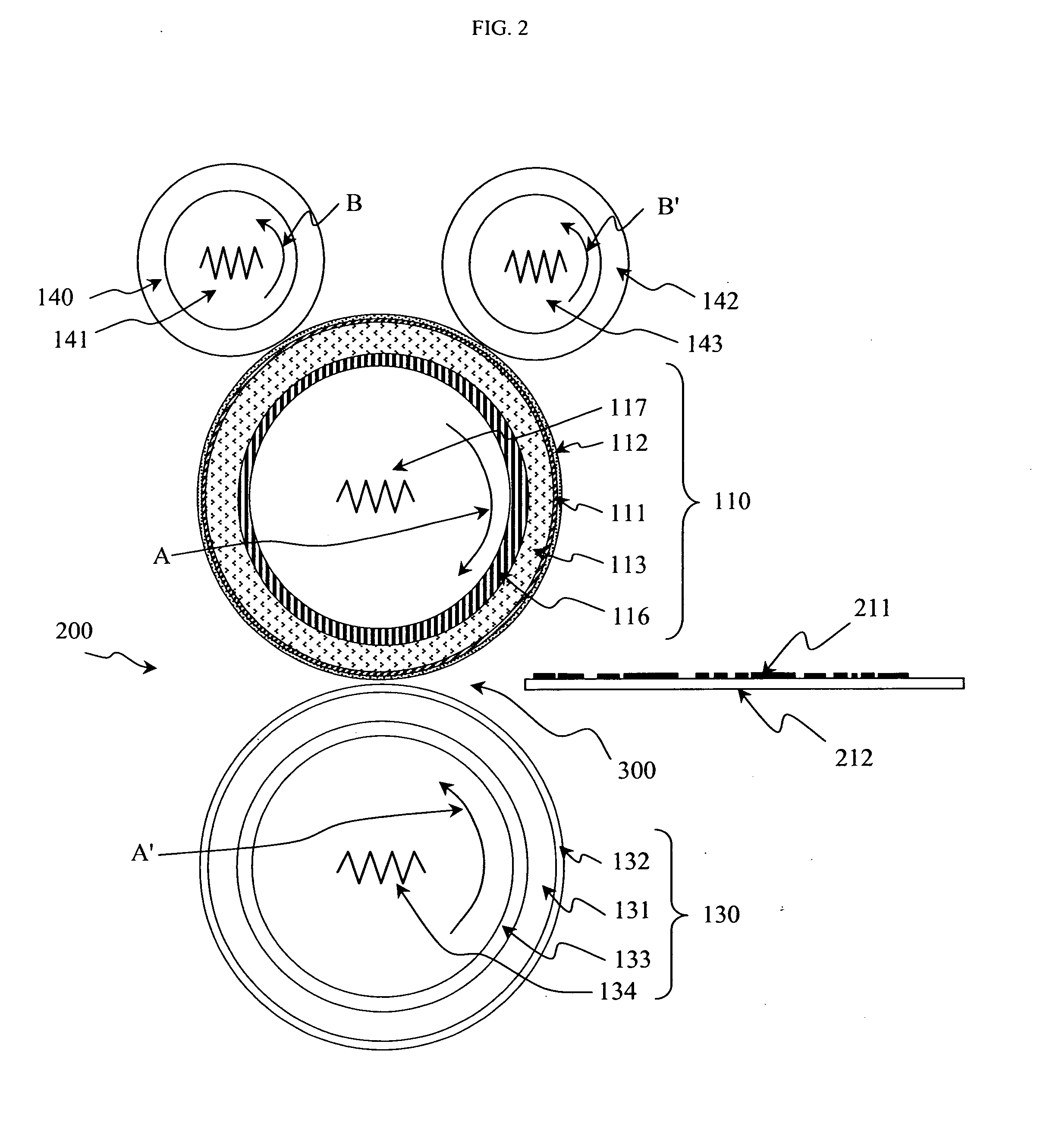

ActiveUS20070298252A1Synthetic resin layered productsRecord information storageElastomerTetrafluoroethylene

The present invention is a fuser member that includes a core member having a rigid outer surface. A resilient layer made of an elastomer is disposed on outer surface. A primer layer of perfluoroalkoxy resin and trifluoroethylene-perfluoroethylvinyl ether-perfluoroethylene vinyl phosphate or a mixture of perfluoroalkoxy resin and trifluoroethylene-perfluoroethylvinyl bonds the resilient layer and an outer layer. The outer layer comprises fluoropolymer resin selected from the group consisting of polytetrafluoroethylene, polyperfluoroalkoxy-tetrafluoroethylene, polyfluorinated ethylene-propylene, and blends thereof.

Owner:EASTMAN KODAK CO

Fuser member

InactiveUS20070298217A1Good non-adhesiveness to tonerImprove heat resistanceSynthetic resin layered productsRecord information storageVinyl etherSilanes

The fuser members of this invention include a core member that includes a rigid outer surface. An adhesion promoter layer comprising silane or epoxy silane coupling is disposed on the outer surface of the core member. A resilient layer comprising an elastomer is disposed on the adhesion promoter layer. A tie layer is disposed on the resilient layer, the tie layer being made of fluoropolymers, fluoroelastomers, fluorocarbon thermoplastic copolymers and mixtures thereof. A primer layer, disposed on the tie layer, comprising perfluoroalkoxy resin and trifluoroethylene-perfluoroethyl vinyl ether-perfluoroethylene vinyl phosphate or a mixture of perfluoroalkoxy resin and trifluoroethylene-perfluoroethylvinyl ether; and an outer layer of fluoropolymer resin made from polytetrafluoroethylene, polyperfluoroalkoxy-tetrafluoroethylene, polyfluorinated ethylene-propylene and blends thereof is disposed on the primer layer.

Owner:MIDWEST ATHLETICS & SPORTS ALLIANCE LLC

Radiation crosslinking modified ethylene-tetrafluoroethylene insulated wire cable

ActiveCN1866411ASimple processEasy to controlPlastic/resin/waxes insulatorsInsulated cablesCross-linkEngineering

The invention discloses an insulating wire cable of irradiation cross-linking modified ethane-perfluoroethylene polymer (X-ETFE) with metal screening layer and protecting layer, which is characterized by the following: the insulating thickness is 0.01-0.25 mm, which improves insulating wire heatproof grade; the product satisfies the aviation cable need under kinds of terrible climates.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

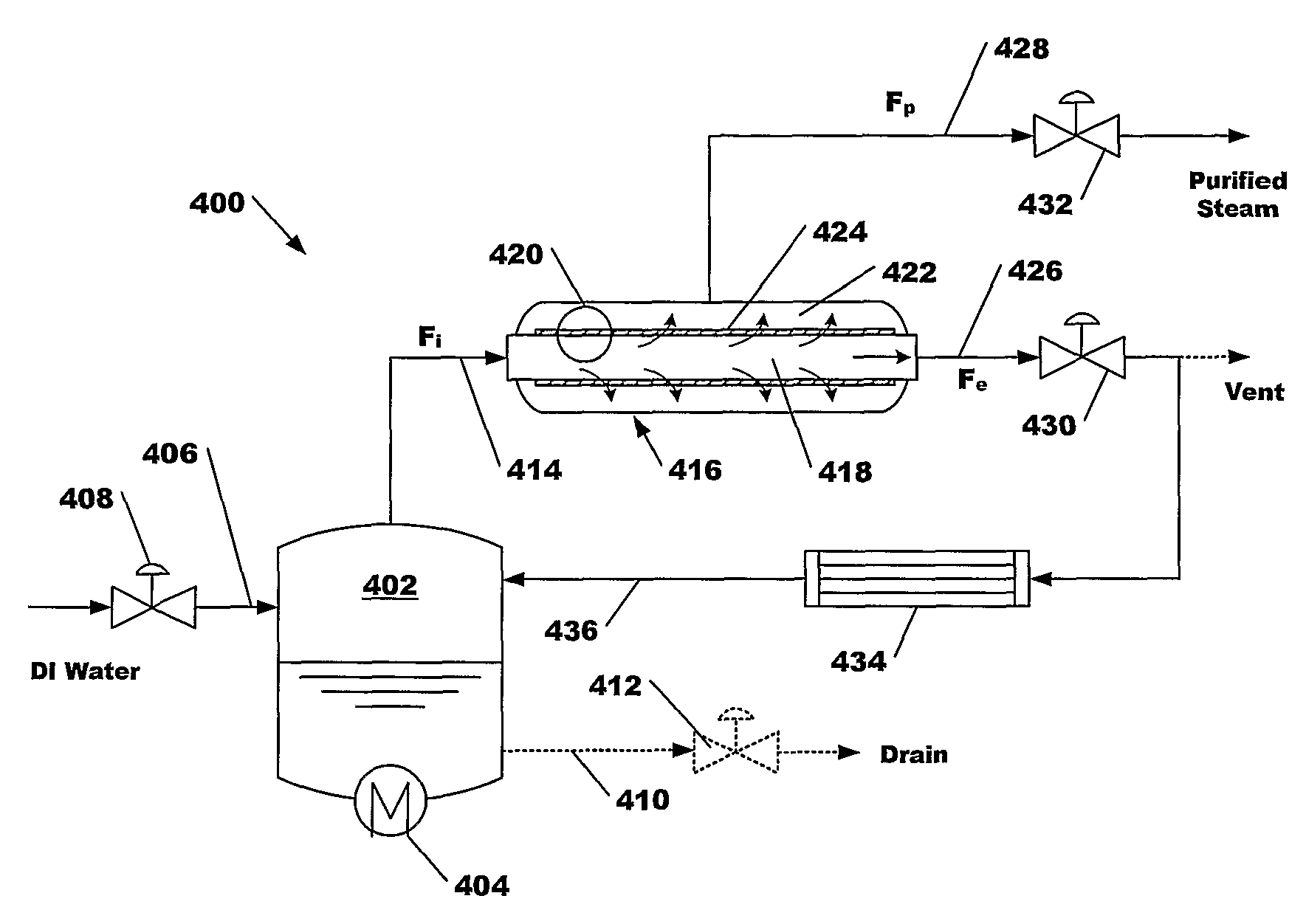

Method of producing high purity steam

ActiveUS8282708B2Maximize flow rateCombination devicesAuxillary pretreatmentIonomerTetrafluoroethylene

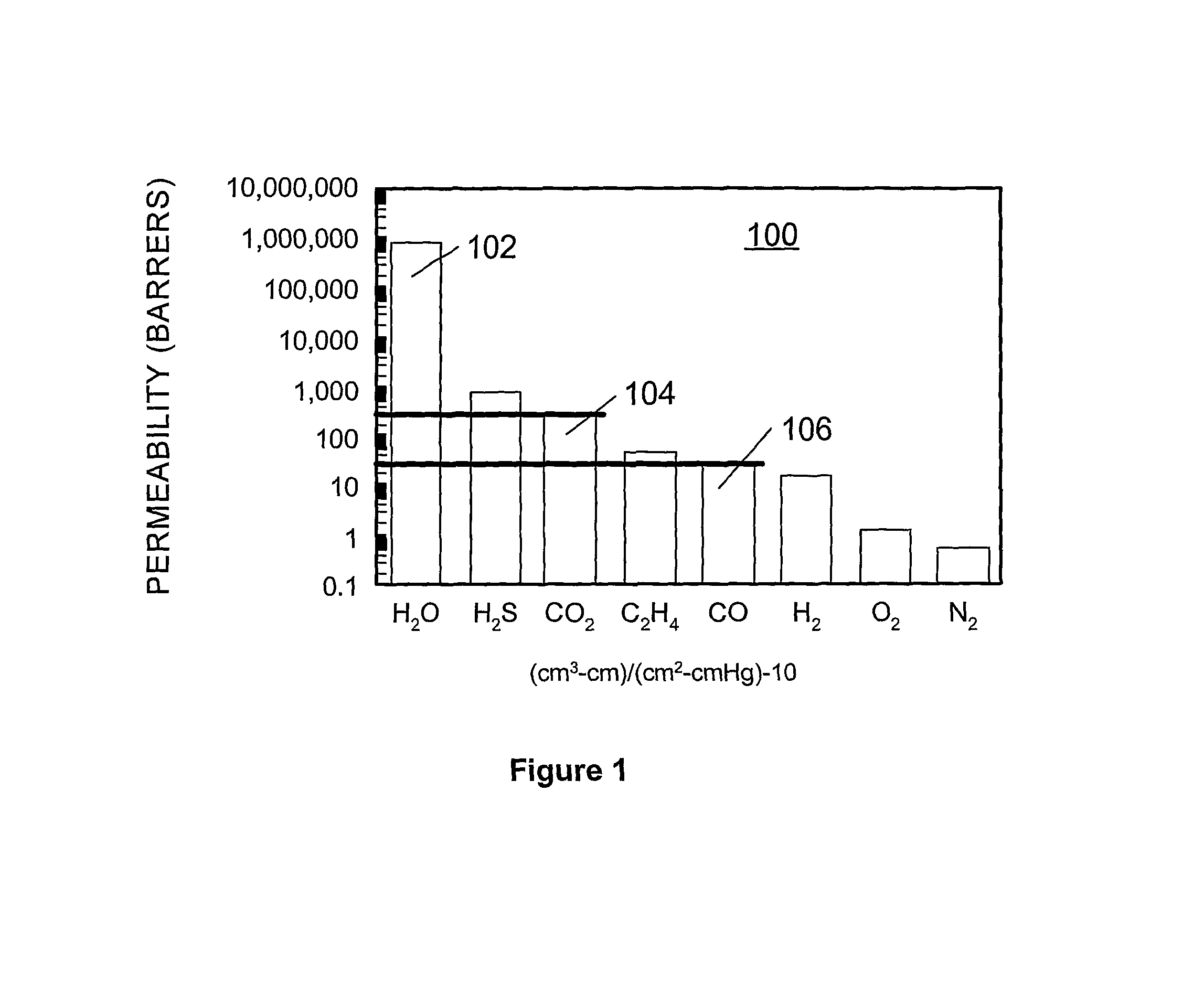

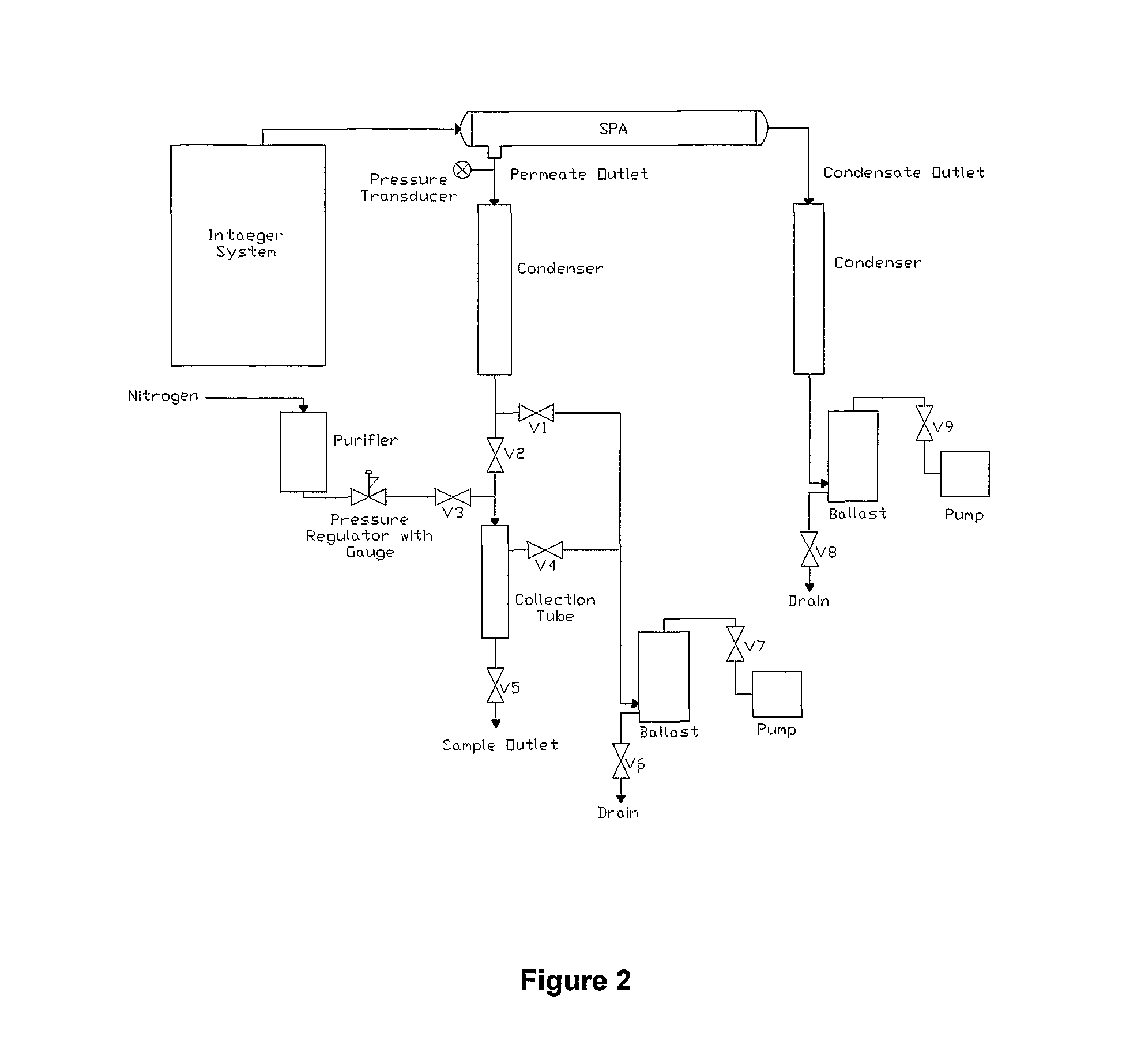

Methods for the purification of steam, systems for purifying steam, methods for measuring and / or controlling steam flow rates, and uses for purified steam are provide. Also provided are substantially gas-impermeable membranes, such as perfluorinated ionomers (e.g., perfluoroethylene-sulfonic-acid / tetrafluoroethylene membranes), having a high ratio of water vapor permeation relative to gas permeation through the membrane. Also provided are methods of operation of such membranes at relatively high operating temperatures for the purification of steam and for operation of such membranes at relatively low temperature and sub-atmospheric pressures for the purification of steam. In a preferred embodiment, the system 400 for purifying steam comprises heater 404 for creating a source of a steam feed, and a purification device 416 for housing a substantially gas-impermeable membrane 424. In the operation of system 400, water, such as deionized water, is added to vessel 402 to provide a source of the steam feed.

Owner:RASIRC

Silicon fluoride super-amphiphobic non-stick coating material

The invention relates to a non-sticking paint containing fluorine-silicon materials, which comprises a coating material portion and a curing agent portion, wherein the amount of the curing agent is 6.5-12% of the coating material portion, the coating material portion mainly comprises fluorocarbon resin, 10-20% of organosilicon resin, 3-30% of color filler, 1-5% of silicon micronized quartz powder and 3-10% of fluorine micronized powder, the curing agent is at least one of biuret, HDI trimer and organotin, the fluorocarbon resin is prepared from perfluoroethylene monomer, alkyl vinyl ester and functional monomers through copolymerization, wherein the fluorine content is greater than 35wt%, the solid content is greater than 50%, the organosilicon resin is end monohydric organosilicon resin.

Owner:ZIBO YINGQIANG CHEM TECH

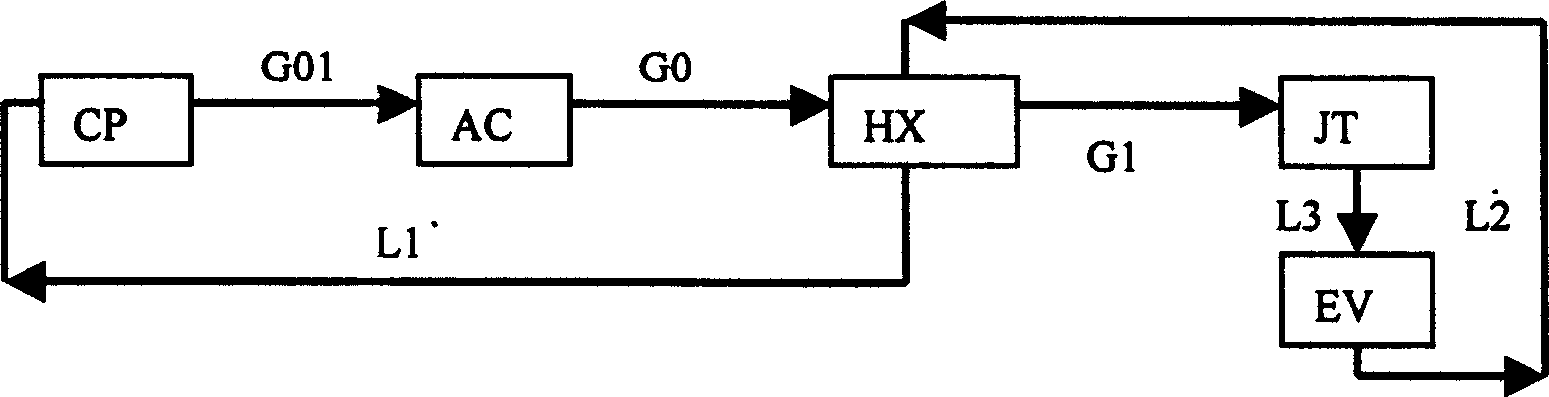

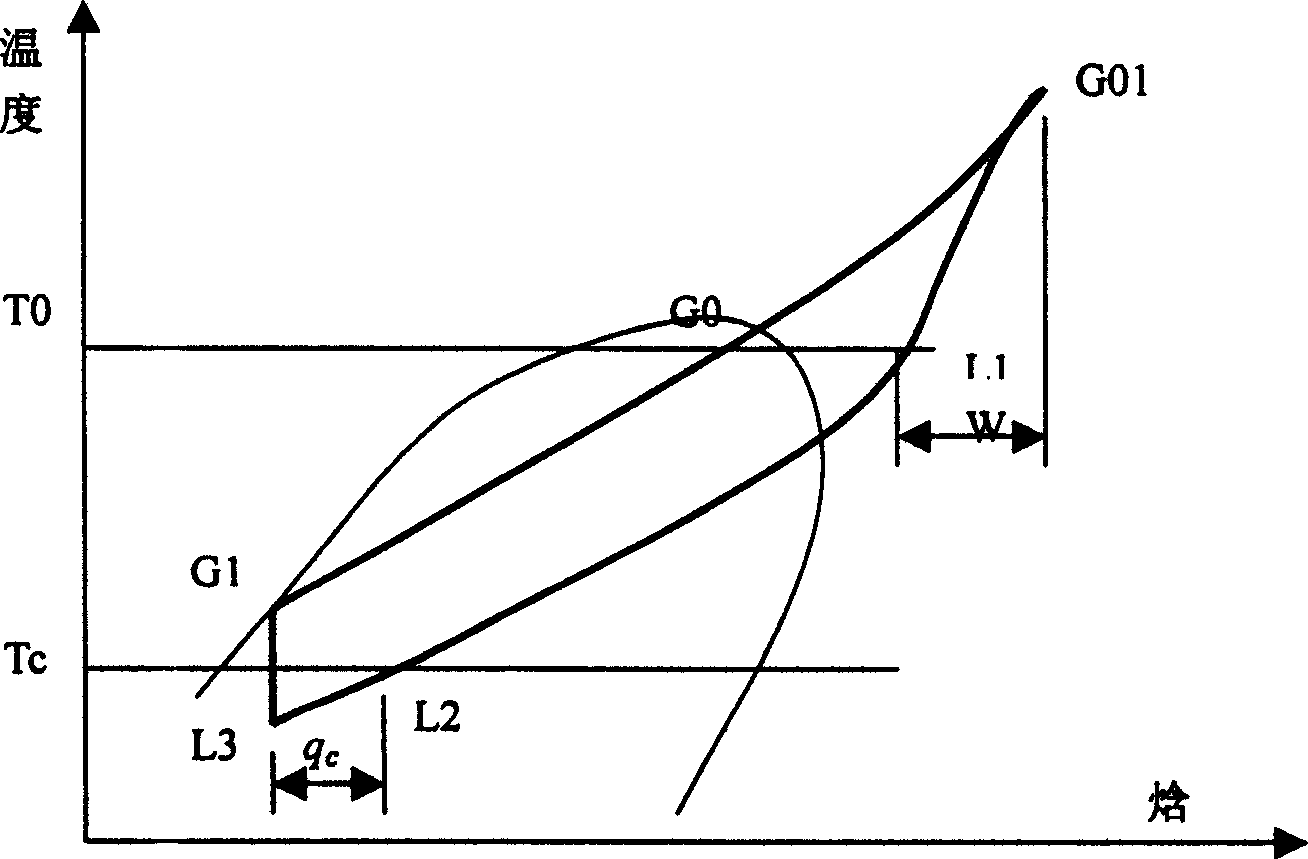

Multicomponent mixed work medium throttling refrigerant applicable to 200-204K refrigerating temperature zone

The multicomponent mixed work medium throttling refrigerating agent applicable to 200-240 k temp. zone includes four groups of substances, respectively are: first group includes tetrafluoromethane, nitrogen trifluoride or mixture; second group includes ethylene, ethane, fluoroform, xenon, fluromethane, perfluoroethylene, fluoroethylene, perfluoroethane or their any two, three and several kinds or mixture of all them; fourth group includes 1-butylene, isobutane, 2-methyl butane, 1-pentene, 3-methyl-1-butylene, 2-methylpentane, 2-butylene, cyclobutane, isobutylene, n-butane, pefluorobutane, n-pentane, perfluoropentane or their two, three, several kinds ormixture of all the them; and third group includees propylene, propane, perfluoropropane, 1,1,1-trifluoroethane, 1,1,-bifluoroethane.

Owner:中科赛凌(北京)科技有限公司

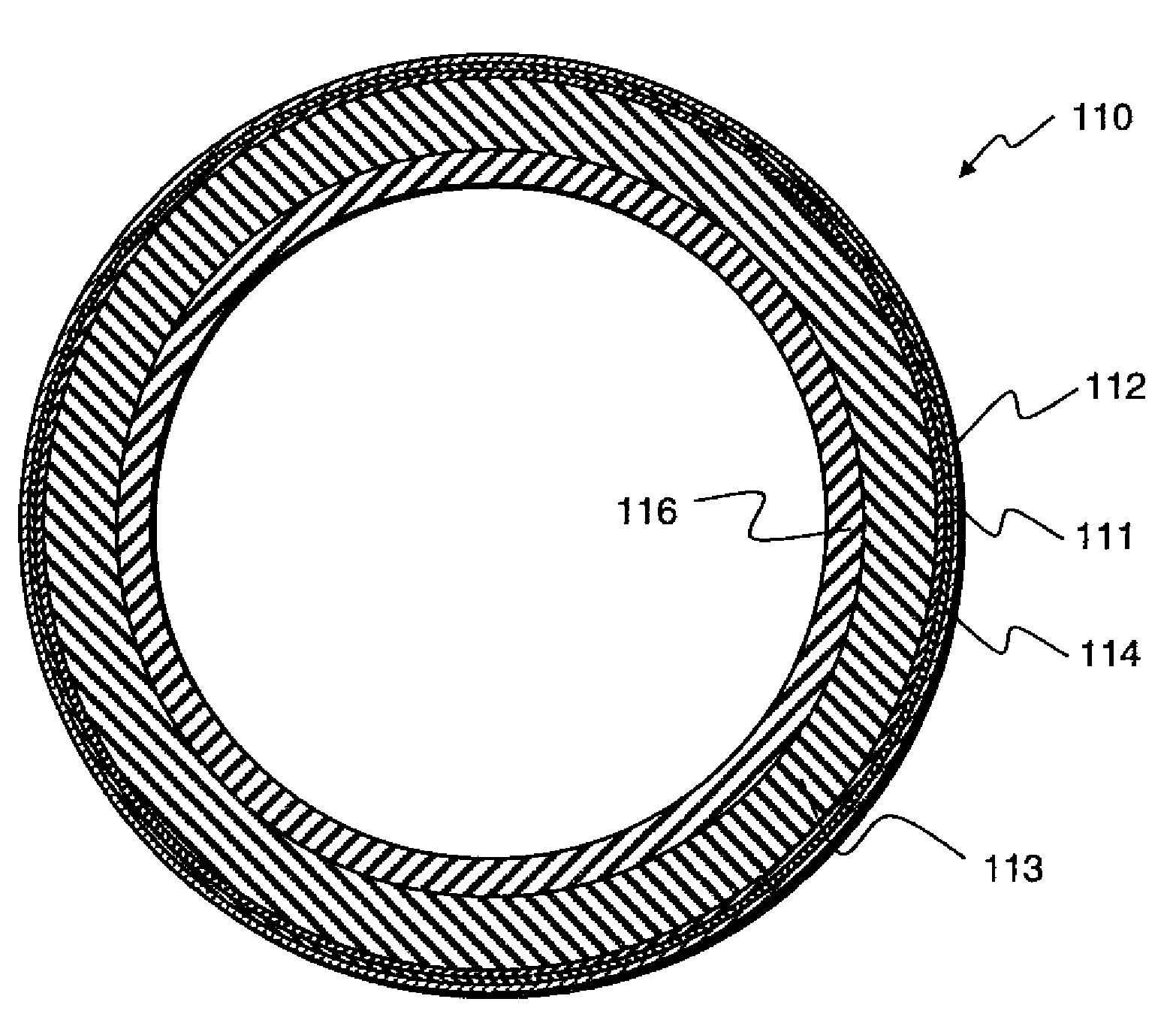

Hose construction containing NBR elastomer composition and fluoroplastic barrier

InactiveUS20060127619A1Improve penetration resistanceSynthetic resin layered productsFlexible pipesElastomerHexafluoropropylene

There is disclosed a hose comprising first and second layers in direct mutual contact; the first layer comprising a thermoplastic quadpolymer derived from tetrafluoroethylene, hexafluoropropylene, vinylidene fluoride, and a perfluorovinyl ether; the second layer comprising: 100 parts by weight of an acrylonitrile-butadiene rubber (NBR), said acrylonitrile rubber comprising from about 20 to about 65 percent by weight of bound acrylonitrile; from about 3 to about 20 parts by weight, per 100 parts by weight of the NBR, of at least one acid acceptor; from about 1 to about 10 parts by weight, per 100 parts by weight of the NBR, of at least one organophosphonium salt; and from about 0.25 to about 10 parts by weight, per 100 parts by weight of the NBR, of at least one amidine.

Owner:VEYANCE TECH

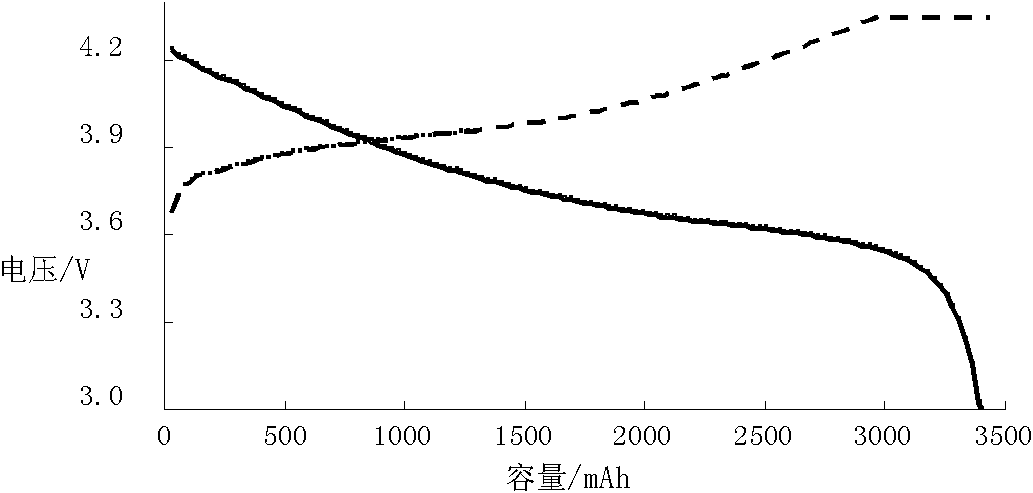

Electrolyte and lithium ion battery

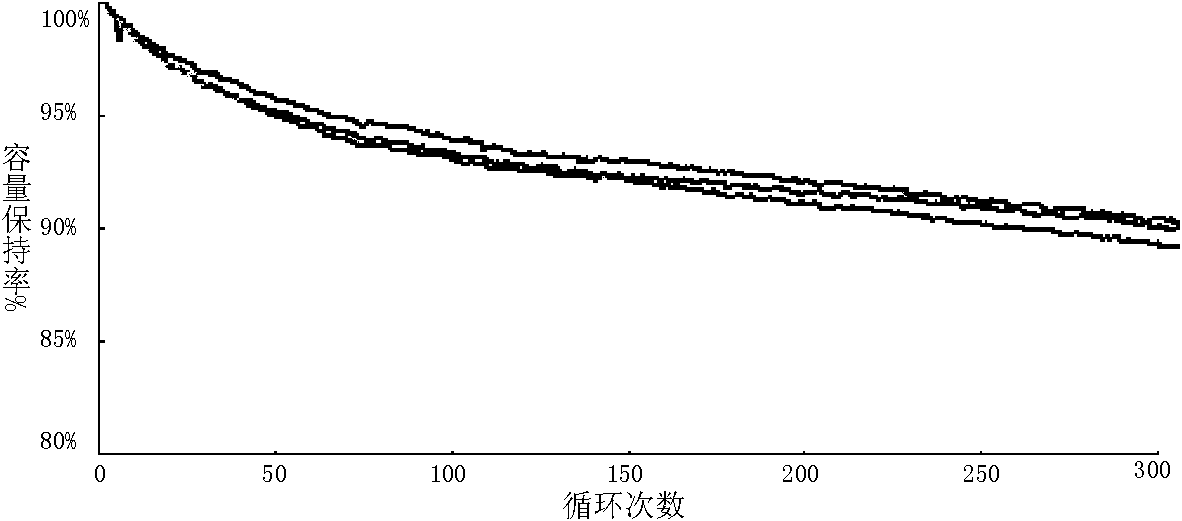

ActiveCN102593510AIncrease capacityIncrease the charge cut-off voltageSecondary cellsCapacitanceBattery charge

The invention discloses an electrolyte and a lithium ion battery and belongs to the field of lithium ion batteries. The electrolyte solves the problem that the existing lithium ion battery has a low capacity and when charging voltage is higher than 4.2V, the existing lithium ion battery produces gas and expands so that cycling performances are poor and a service life is influenced. The electrolyte comprises lithium hexafluorophosphate, solvents and additives. The additives comprise a benzotriazole compound and perfluoroethylene carbonate The electrolyte can reduce a gas production amount in battery formation, prevent gas production and expansion of a battery, and improve a battery service life, a battery capacity and cycling performances. The lithium ion battery adopts the electrolyte so that charge cut-off voltage of the lithium ion battery is improved to 4.35V; a capacitance is improved by 15% and after 300 cycles, a capacitance is still 90% of the initial capacitance; the thickness of the lithium ion battery is changed by below 3%; and a service life is improved.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Method for preparing microemulsion of fluorinated ethylene propylene powder

The invention discloses a microemulsion polymerization method of perfluoroethylene and hexafluoropropene copolymer, which uses monomer medium liquefied hexafluoropropene as organic phase, adds monomer medium liquefied hexafluoropropene, emulsifier and co-emulsifier into water, to form O / W type microemulsion, feeds perfluoroethylene and hexafluoropropylene initial mixture gas and complement mixture gas, uses oil-soluble free radical initiator to initialize reaction, after the reaction, heats to separate and recover liquefied hexafluoropropene, discharges water, heats obtained polymer powder, to remove non-decomposed initiator, decomposition product, and residual water and foreign materials. The product powder of the invention has uniform and small size, non block. And the invention uses liquefied hexafluoropropene as organic phase to avoid organic solvent pollution on product and environment.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

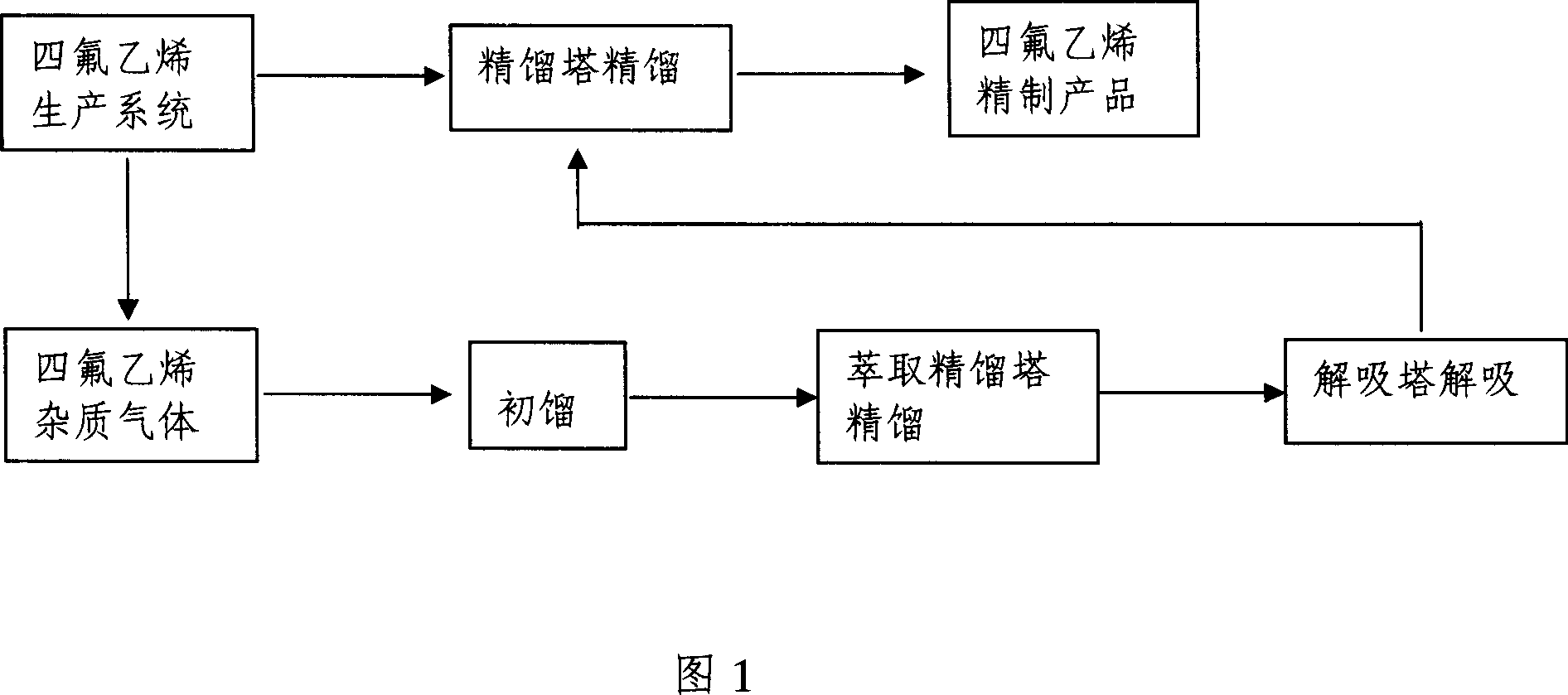

Method for removing impurity of tetrafluoroethylene

ActiveCN1962585ALow boiling pointLow priceHalogenated hydrocarbon separation/purificationOctafluorocyclobutaneKetone

The invention discloses an impurity removing method in the perfluoroethylene, which comprises the following steps: distilling perfluoroethylene gas with impurity in the degassing tower; controlling certain quantity to rectify in the extracting rectifying tower; adopting oligomer solvent of alcohols, ketones, chloroform and octafluorocyclobutane as extractant; combusting fluoride impurity gas on the top of rectifying tower; adsorbing the component from extracting rectifying tower autoclave; returning the component to rectifying unit directly to obtain the product.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

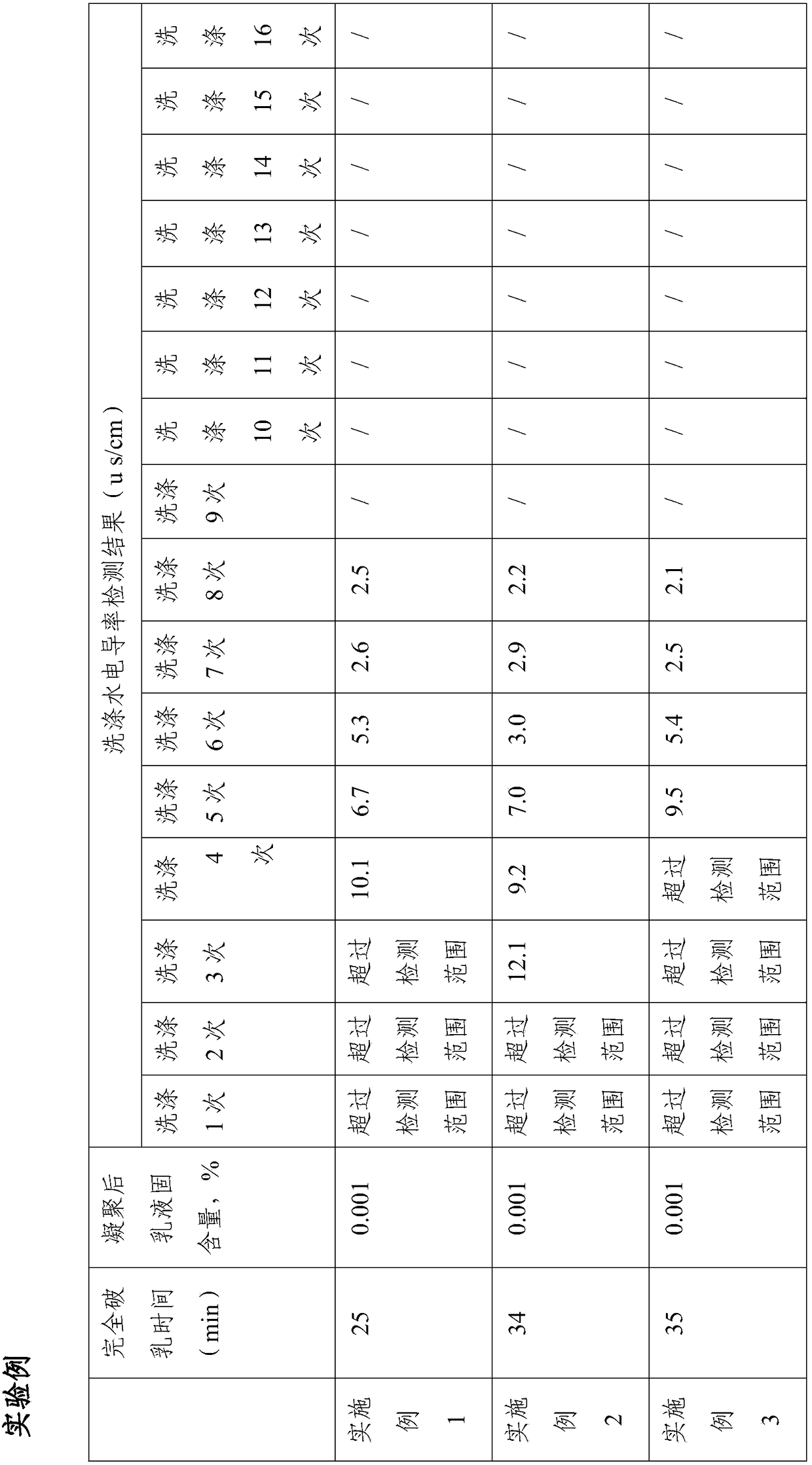

Agglomeration washing method of fluorinated ethylene propylene

This invention discloses a method for condensing and washing perfluoroethylene-perfluoropropylene copolymer prepared by emulsion polymerization. The method comprises: (1) adding 1-10 deg.C deionized water to perfluoroethylene-perfluoropropylene copolymer emulsion, stirring, demulsifying, and washing the precipitate with 40-80 deg.C deionized water for 2-6 times (1-5 min for each time). The method can largely increase the equipment productivity, lower the consumption of pure water, save the raw materials, and shorten the treatment period.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Preparation method of perfluorovinyl ether sulfonyl fluoride

ActiveCN108863854AMild conditions for fluorination reactionEasy post-processingSulfonic acid preparationEtherSulfonyl fluoride

The invention belongs to the technical field of perfluorinated resin, and particularly relates to a preparation method of Perfluorovinyl ether sulfonyl fluoride. A CF2=CF(OCF2CFX)mO(CF2)nSO2F productis directly generated from perfluorovinyl ether sulfonate CF2=CF(OCF2CFX)mO(CF2)nSO2OM by a one-step reaction under the action of a fluorinating reagent CHClFCF2N(C2H5)2,CF3CHFCF2N(C2H5)2. The preparation method has the advantages of simple process, easiness in operation, low reagent cost, avoidance of the production of waste acid gas and waste liquid as well as the increase of multi-step wastageand by-products; reaction steps are reduced, and the use of high-toxicity and high-risk reagents is avoided at the same time, and the yield can be up to 80 percent or more.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Fuser member

The fuser members of this invention include a core member that includes a rigid outer surface. An adhesion promoter layer comprising silane or epoxy silane coupling is disposed on the outer surface of the core member. A resilient layer comprising an elastomer is disposed on the adhesion promoter layer. A tie layer is disposed on the resilient layer, the tie layer being made of fluoropolymers, fluoroelastomers, fluorocarbon thermoplastic copolymers and mixtures thereof. A primer layer, disposed on the tie layer, comprising perfluoroalkoxy resin and trifluoroethylene-perfluoroethyl vinyl ether-perfluoroethylene vinyl phosphate or a mixture of perfluoroalkoxy resin and trifluoroethylene-perfluoroethylvinyl ether; and an outer layer of fluoropolymer resin made from polytetrafluoroethylene, polyperfluoroalkoxy-tetrafluoroethylene, polyfluorinated ethylene-propylene and blends thereof is disposed on the primer layer.

Owner:MIDWEST ATHLETICS & SPORTS ALLIANCE LLC

Fluorine-containing copolymer

InactiveUS7105619B2Easy to useSuitable for usePlastic/resin/waxes insulatorsVinyl etherElectrical conductor

A fluorine-containing copolymer obtained by copolymerizing tetrafluoroethylene, hexafluoropropylene and perfluoro vinyl ether as component monomers, wherein a weight ratio of tetrafluoroethylene, hexafluoropropylene and perfluoro vinyl ether units constituting the fluorine-containing copolymer is 70 to 95: 5 to 20: 0 to 10, respectively; the fluorine-containing copolymer having: a melt flow rate of 30 (g / 10 minutes) or more; a volatile content index of 0.2% by weight or less; and a stress relaxation modulus G(t) (unit: dyn / cm2) which satisfies the following formula at t=0.1 second when measured at a temperature of 310° C.:G(0.1)>7×106×X−1.62−3000where X denotes the melt flow rate (unit: g / 10 minutes). Also disclosed is an insulating material composed of the fluorine-containing copolymer and an insulated cable having a core conductor coated with the fluorine-containing copolymer.

Owner:DAIKIN IND LTD

Method for recovering tail gas generated by tetrafluoroethylene

InactiveCN101168116ANo pollution in the processLow priceDispersed particle separationHalogenated hydrocarbon separation/purificationTetrafluoroethyleneRecovery method

The invention relates to a method for recycling exhaust gas produced by perfluoroethylene. The invention employs the separating process of two-stage films or multi-stage films. Admixture of gas with TFE passes through a first-stage gas separation film component in gaseous state, the infiltration gas further recycles TFE, and the infiltration gas enters a second-stage film separation component after the concentration of the infiltration gas is adjusted by materials which are easy to be separated, such as carbon dioxide and the like and after being deoxidized. The infiltration gas of the second-stage film separation component further recycles TFE or enables the infiltration to be directly return a first-stage film separator of which the existing circulating recycles TFC and separates CO. The infiltration gas of the second film is discharged in upper air or is further treated. Or the first-stage infiltration gas directly enters the second film separating component, and the infiltration gas of the second-stage film separating component further recycles TFC, and then the second film infiltration gas is discharged in upper air. Compared with the existing technology, the method of the invention has the advantages of simple procedure, high recycle rate of TFC, no utilization of fusing agent, low cost and the like.

Owner:阳光乐程(北京)网络科技有限公司 +4

Fluorine-containing material preparation method, and application of fluorine-containing material prepared through using method

The invention discloses a fluorine-containing material preparation method, and an application of a fluorine-containing material prepared through using the method. The fluorine-containing material preparation method comprises the following steps: adding deionized water to a reaction kettle, and reserving 1 / 3-1 / 2 of the space of the reaction kettle; adding parts of polymerization monomers to the reaction kettle, sequentially adding 0.01-1 part by weight of an emulsifier, 0.015-0.3 parts by weight of a pH adjusting agent and 0.001-0.02 parts by weight of an initiator to every 100 parts of deionized water, and reacting; maintaining the oxygen content in the reaction kettle to be smaller than 30ppm, the pressure to be 2.5-4.5MPa and the temperature to be 30-65DEG C in the reaction process, and adding other polymerization monomers until the reaction ends, wherein 50-70 parts by weight of the polymerization monomers are totally added; and processing a dispersion obtained after the reaction to form the fluorine-containing material, wherein the polymerization monomers comprise at least two of vinylidene fluoride, trifluorochloroethylene, tetrafluoroethylene, hexafluoropropene, perfluorovinyl ether and monoolefin. The characteristic viscosity of the fluorine-containing material prepared through the fluorine-containing material preparation method is greater than 7.5g / 100ml, and the number-average molecular weight is greater than 1,200,000.

Owner:SHENZHEN VICTORY ON TRUST NEW MATERIAL TECHCO LTD

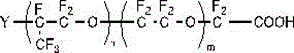

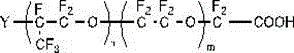

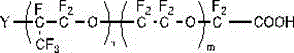

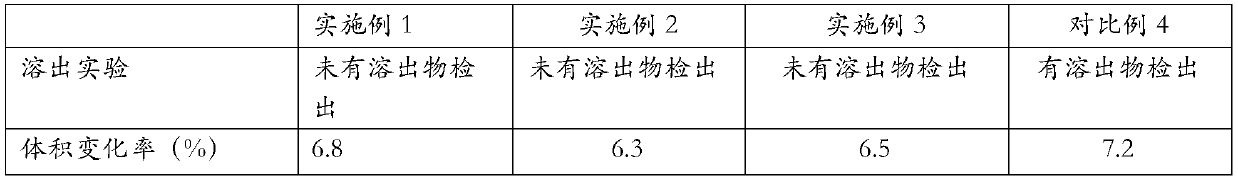

Fluorine-containing polymer, cation exchange membrane, and electrolysis vessel

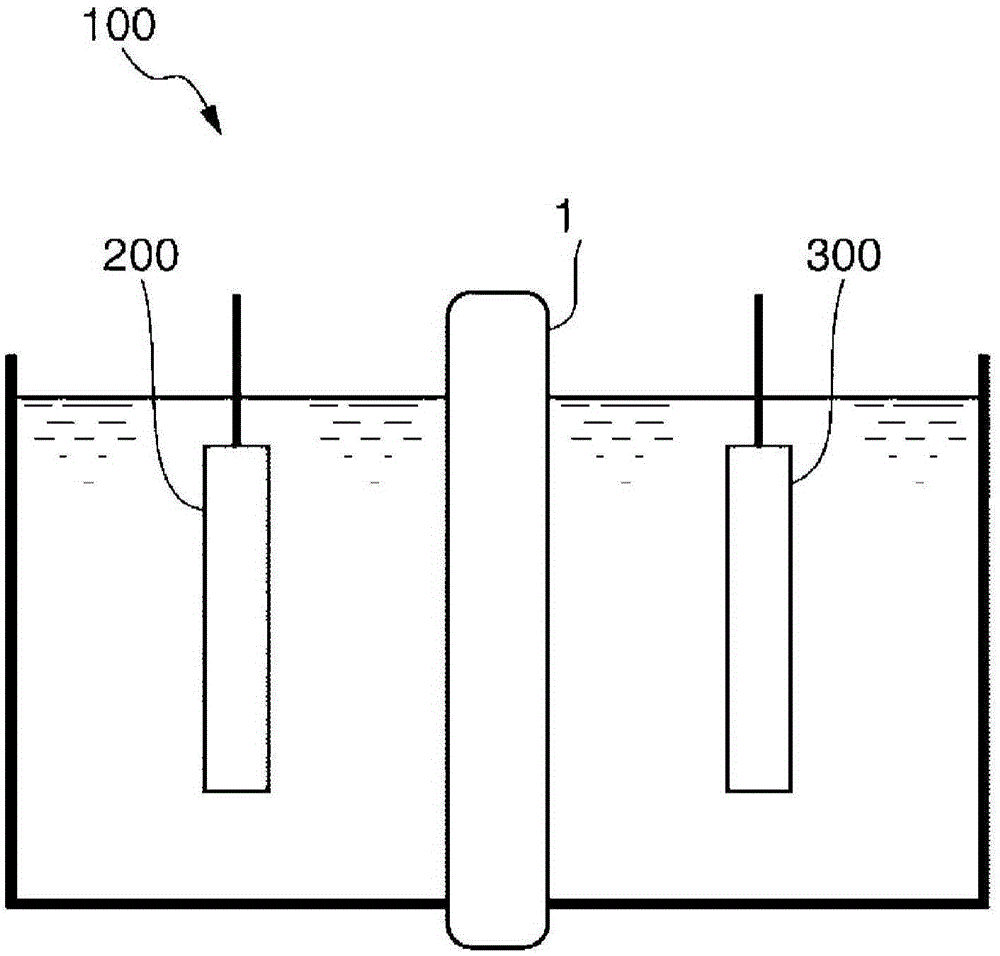

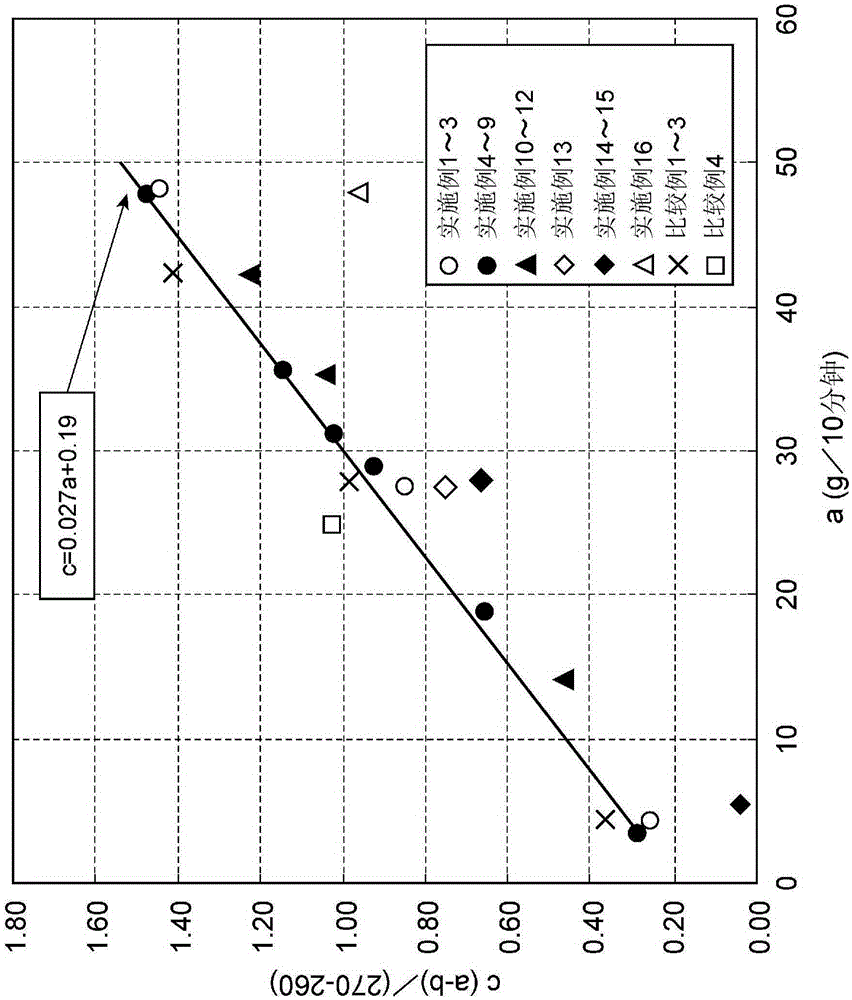

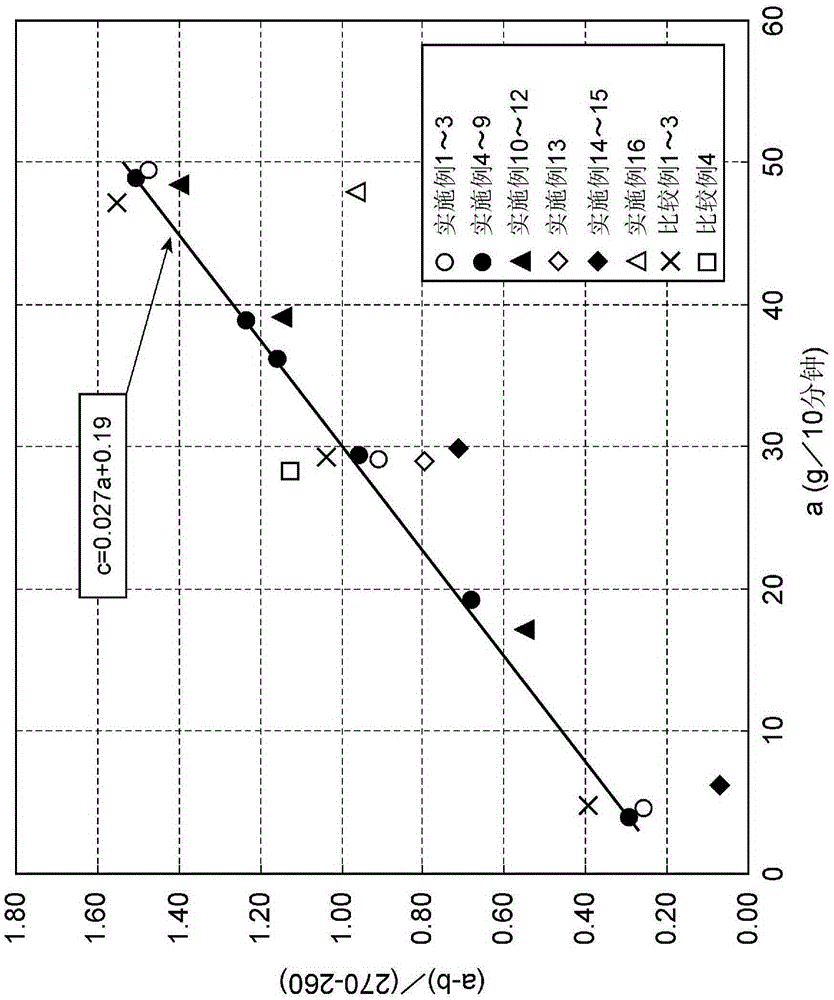

ActiveCN105308217AStable Current EfficiencyThe electrolyzer hasCellsCation exchanger materialsTetrafluoroethyleneElectrolysis

The present invention relates to a cation exchange membrane including a fluorine-containing polymer which includes tetrafluoroethylene units, and perfluoroethylene units having carboxylic acid ion exchange groups. The melt index (a) of the fluorine-containing polymer obtained by methyl esterifying the carboxylic acid ion exchange groups, said melt index (a) being measured under conditions in which the temperature is 270 not C, the load is 2.16 kg, and the orifice internal diameter is 2.09 mm, is 3-50 g / 10 min. Furthermore, the melt index (a), and the melt index (b) of the fluorine-containing polymer obtained by methyl esterifying the carboxylic acid ion exchange groups, said melt index (b) being measured under conditions in which the temperature is 260 not C, the load is 2.16 kg, and the orifice internal diameter is 2.09 mm, satisfy the relationship represented by formula (1), namely (a-b) / (270-260) <= 0.027a +0.19.

Owner:ASAHI KASEI KK

Solid acid complex catalyst and its preparing process

InactiveCN1569335AWarrantyWon't be lostOrganic-compounds/hydrides/coordination-complexes catalystsPhosphoric acidSolid acid

The invention is a solid acid compound catalyst whose component is: 10-80% sulfuric acid or phosphoric acid, 1-10% fluosulfonic acid resin and oxide of silicon, aluminum, titanium or zirconium; the fluosulfonic acid resin the polymer of perfluoroethylene and sulfonated perfluoroethylene, its average molecular weight is 300-500 thousands, the sulfonating rate is 1-5%. The mol rate of carbon element and fluorin element is 1:2. The catalyst blends the liquid acid and solid acid into a compound evenly, it maintains the nature of the liquid acid and the solid acid, and it has higher acid intensity and acid center quantity, the distribution of the acid center is even, the liquid acid will not be lost in the reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

A high-temperature macromolecule PTC thermal resistor and its making method

InactiveCN1996512AMeet the latest standardsMeet the needs of secondary protectionPositive temperature coefficient thermistorsPolymer scienceHeat sensitive

This invention relates to one high temperature macromolecule PTC heat sensitive resistance, which is made of conductive macromolecule materials by press, wherein, the materials is added with heat fluro-resin and the layer silicon salt clay through surface process; the formula is as: macromolecule polymer for 30 to 60 percent; carbon for 30 to 55 percent; heat fix fluro-resin for 0.5 to 20 percent; layer silicon salt for 25 to 25 percent; process aid for 0.1 to 10 percent; the macromolecule polymer is of polyvinylidene fluoride, melt politef, ethene perfluoroethylene polymer, nylon 11 and 12, fluorinated ethylenepropylene copolymer and chlorotrifluoroethylene.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

Condensation and washing method of perfluoroethylene propylene resin

The invention relates to a condensation and washing method of perfluoroethylene propylene resin. The condensation and washing method comprises the following steps: 1) adding room-temperature de-ionized water into perfluoroethylene propylene emulsion and adjusting the emulsion ratio to be 1.03 to 1.20; starting to stir and carrying out physical emulsion breaking on the emulsion for 15 to 60 min under the condition of 500 to 2000 r / min; 2) adding a condensation agent ammonium bicarbonate with the resin solid content of 1 to 5 percent into the emulsion and continually stirring until the perfluoroethylene propylene emulsion is completely broken; 3) repeatedly washing perfluoroethylene propylene, which is separated through the emulsion breaking, by utilizing the room-temperature de-ionized water until the detection is qualified. The method provided by the invention is used for carrying out the emulsion breaking and can be used for completely separating out the resin in the perfluoroethylenepropylene emulsion; compared with other methods, the subsequent dosage of washing water is not increased. The method provided by the invention is simple in steps and environmentally friendly, and industrialized large-scale production is facilitated.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

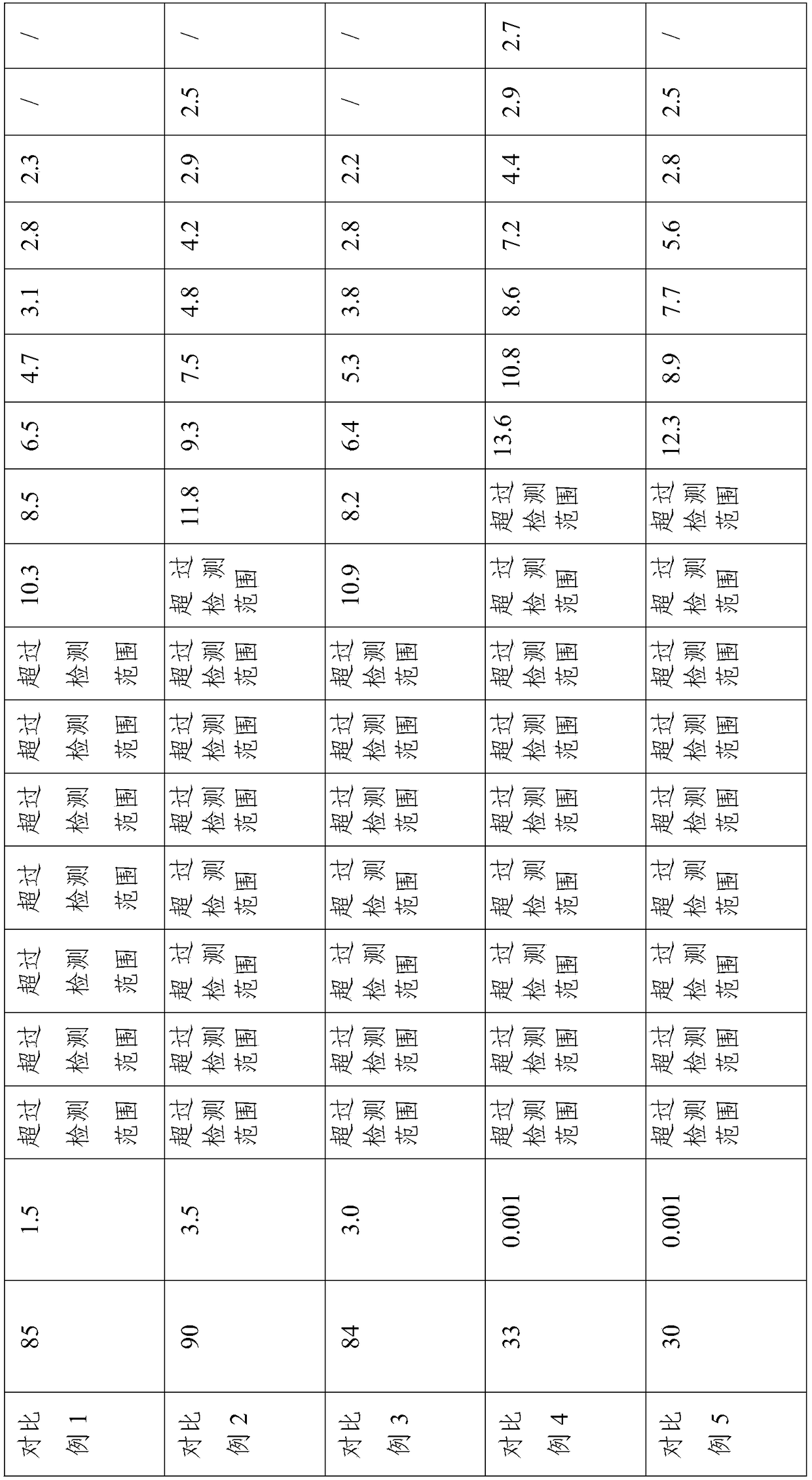

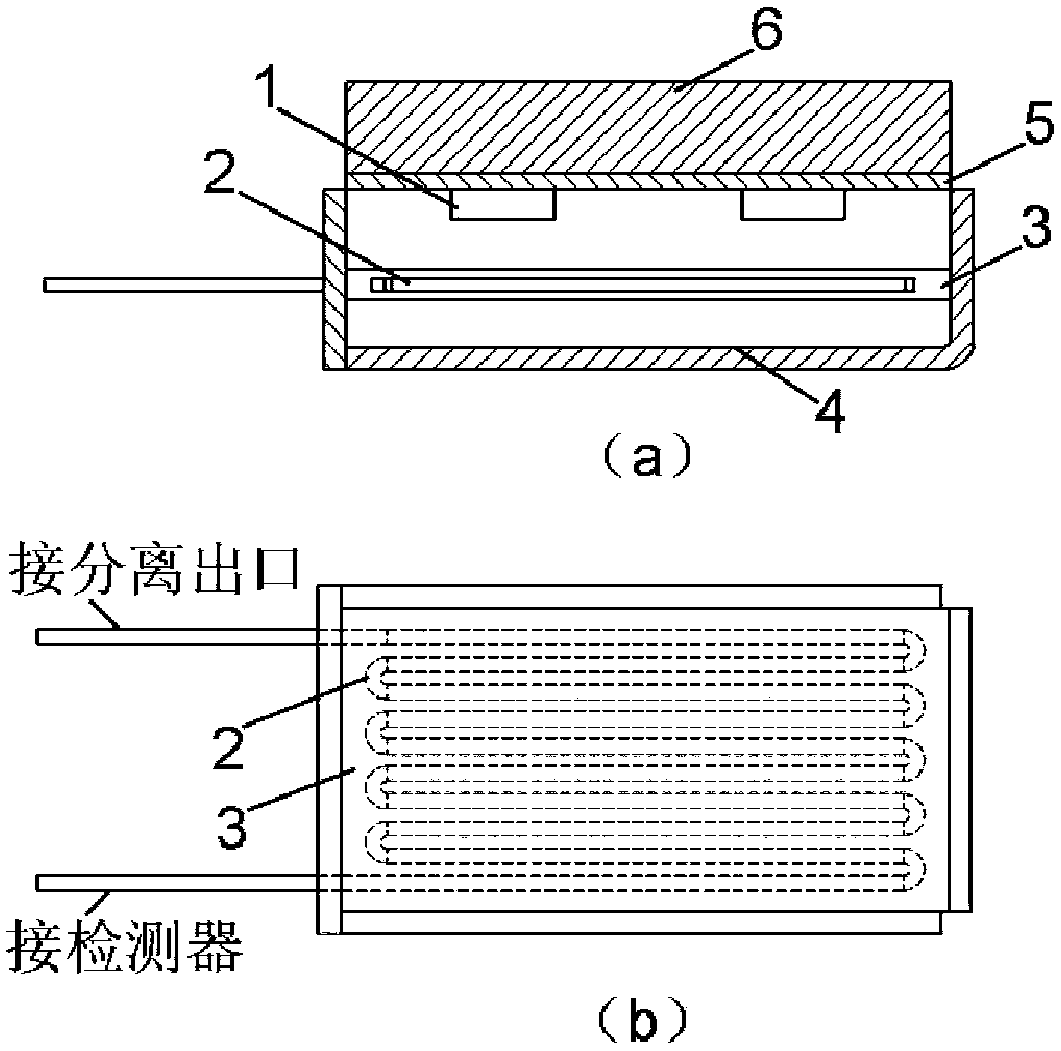

Chip type light derivatizer for aflatoxins and sulfonamides

ActiveCN108088822AImprove photoderivatization efficiencyLow costComponent separationFluorescence/phosphorescenceSulfur drugFlow injection analysis

The present invention discloses a chip type light derivatizer for aflatoxins and sulfonamides. An ultraviolet light-emitting diode (LED) having a center wavelength between 280 and 380 nm as an excitation light source, high-transparent quartz, ultraviolet-transmitting glass, PDMS (Polydimethylsiloxane) or perfluoroethylene propylene copolymer (FEP) is used as a chip substrate, a rectangular or trapezoidal groove path having a width of 10 to 500 mu m, a depth of 10 to 260 mu m, and a length of 5 to 500 mm is fabricated on the chip substrate as a derivation reaction tank, the groove path is in linear or comb-like or sine-wave shaped arrangement, the volume of the derivation reaction tank is 5nL to 75mu L, and is only 1 / 13 to 1 / 100000 of the volume of the derivation reaction tank of a conventional derivatizer. The chip type light derivatizer improves the fluorescence intensity of aflatoxin B1 by 6.5 times, and is suitable for post-column light derivation of chip capillary electrophoresis,chip microfluidic analysis, capillary liquid chromatography, microcolumn liquid chromatography, ultrahigh pressure liquid phase chromatography and normal liquid chromatography, and micro flow injection analysis / small flow injection analysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of perfluorooctanoic acid-free fluorine-containing surfactant and its preparation method and process system

ActiveCN105170018BSolve pollutionPromote decompositionPreparation from carboxylic acid halideTransportation and packagingProcess systemsPerfluorooctanoic acid

The invention discloses a fluorine-containing surfactant without perfluorooctanoic acid and its preparation method and process system. A repeating structural unit with a carboxyl group or a carboxylate at one end formed by one or more combinations of radicals and oxygen perfluorovinyl groups. The fluorine-containing surfactants involved in the present invention have a C-O-C ether bond structure Fluoropolymer is the main structure. It can be seen from the indicators that this fluorosurfactant does not contain perfluorooctanoic acid and its salts with an 8-carbon linear structure. It is easily decomposed in nature and has been proven to be harmless to the human body. , the peroxide value satisfies 0.001-1%, the surface tension satisfies 10-30mN / m, and has the amphiphilic structure of surfactant.

Owner:成都晨光博达新材料股份有限公司

Solvent-resistant inert resin coated fluororubber sealing rubber plug and manufacturing method thereof

PendingCN111231455ABarrier migrationBarrier dissolutionSynthetic resin layered productsFlat articlesVinyl etherRubber material

The invention discloses a solvent-resistant inert resin coated fluororubber sealing rubber plug and a manufacturing method thereof. The sealing rubber plug comprises the following raw materials: fluororubber, a reinforcing agent, a filling agent, a processing aid, an acid acceptor and a cross-linking agent system, wherein the sealing rubber plug further comprises a fluorine resin film which coversthe neck part of the sealing rubber plug and is subjected to corona discharge treatment; the thickness of the fluorine resin film is 5-100 [mu]m, and the fluorine resin film is one of an ethylene-tetrafluoroethylene copolymer film, a tetrafluoroethylene-perfluoropropyl perfluorovinyl ether copolymer film, a chlorotrifluoroethylene polymer film and a polyvinylidene fluoride film. The preparation method comprises the following steps: rubber material mixing, primary sheet discharging, fluorine film slicing, primary laminating vulcanization, primary punching, secondary sheet discharging, secondary vulcanization and secondary punching. The surface, in contact with a solvent, of the sealing rubber plug is coated with a layer of an inert film, low-molecular-weight organic matters in rubber can be prevented from migrating to the solvent end, the influence of dissolved matters on an organic solvent is avoided, and inaccuracy of a detection result is avoided.

Owner:烟台鑫汇包装有限公司

Preparation method of binder for dry electrode for lithium ion battery, and binder

InactiveCN111718452AImprove adhesionImprove performanceCell electrodesSecondary cellsVinyl etherElectrical battery

The invention relates to a preparation method of a binder for a dry electrode of a lithium ion battery, and the binder. The preparation method comprises the following steps: dissolving a vinyl fluoride monomer, an acrylic acid monomer or a sulfonic perfluorovinyl ether monomer into an organic solvent to form a mixed solution, and stirring for full reaction in a nitrogen protection atmosphere; precipitating the prepared copolymer with excessive methanol, filtering, thoroughly cleaning with distilled water, and removing the residual solvent, monomer and homopolymer; and completely drying to obtain the vinyl fluoride-acrylic acid-sulfovinylfluoride block copolymer. According to the method, acrylic acid molecules are embedded into a molecular chain to realize chemical bond combination with thesilicon negative electrode, so the bonding force between the binder and the electrode is effectively enhanced; and sulfonic perfluorovinyl ether is added, a good conductive network can be formed between the sulfonic perfluorovinyl ether and an active substance by utilizing the conductivity of a polymer of the sulfonic perfluorovinyl ether, and the electron and ion conductivity of the electrode isfurther improved, so that the comprehensive performance of the binder is improved.

Owner:SHENZHEN XINYUREN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com