Solvent-resistant inert resin coated fluororubber sealing rubber plug and manufacturing method thereof

A sealing rubber plug and inert resin technology, applied in rubber layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as loss of sealing performance, intolerance to organic solvents, complex components, etc., to ensure accurate Good performance, avoid impact, good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

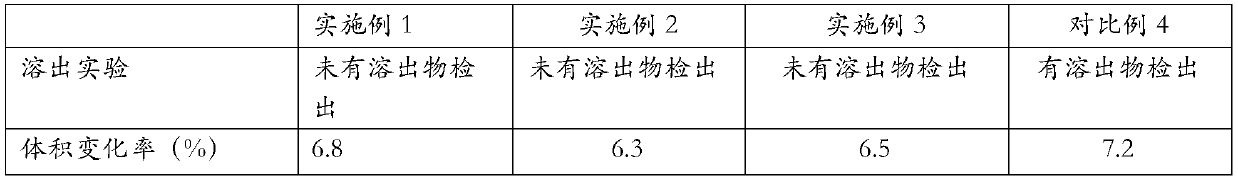

Examples

Embodiment 1

[0035] A solvent-resistant inert resin-coated fluororubber sealing rubber plug is provided, which contains the following components by weight:

[0036] 100 parts by weight of fluororubber 23 (vinylidene fluoride-chlorotrifluoroethylene copolymer), 20 parts by weight of reinforcing agent carbon black N990, 20 parts by weight of filler talcum powder, 5 parts by weight of processing aid higher fatty acid, acid absorbing agent calcium hydroxide 6 parts by weight, 3 parts by weight of magnesium oxide, 2.5 parts by weight of bisphenol A, and 0.4 parts by weight of BPP (benzyltriphenylphosphine chloride).

[0037] The manufacture method of solvent-resistant inert resin film-coated fluororubber sealing rubber plug in embodiment 1 comprises the following steps:

[0038](11) Mixing of rubber materials: put the fluororubber raw rubber in an internal mixer, knead for 3 minutes, add reinforcing agent, filler, processing aid and one-half of the acid absorbing agent and continue kneading for...

Embodiment 2

[0047] A solvent-resistant inert resin-coated fluororubber sealing rubber plug is provided, which contains the following components by weight:

[0048] 100 parts by weight of fluorine rubber 26 (vinylidene fluoride-hexafluoropropylene copolymer), 15 parts by weight of reinforcing agent carbon black N990, 20 parts by weight of filler talcum powder, 5 parts by weight of processing aid higher fatty acid, acid absorbing agent calcium hydroxide 6 parts by weight, 3 parts by weight of magnesium oxide, 2.5 parts by weight of bisphenol A, and 0.4 parts by weight of BPP (benzyltriphenylphosphine chloride).

[0049] The manufacture method of solvent-resistant inert resin film-coated fluororubber sealing rubber plug comprises the following steps in embodiment 2:

[0050] (21) Mixing of rubber materials: put the fluororubber raw rubber in an internal mixer, knead for 4 minutes, add reinforcing agent, filler, processing aid and one-half of the acid absorbing agent and continue kneading for...

Embodiment 3

[0059] A solvent-resistant inert resin-coated fluororubber sealing rubber plug is provided, which contains the following components by weight:

[0060] Fluororubber 246 (vinylidene fluoride-tetrafluoroethylene-hexafluoropropylene copolymer) 100 parts by weight, reinforcing agent carbon black N990 20 parts by weight, filler talcum powder 20 parts, processing aid high fatty acid 5 parts by weight, acid absorbing agent 6 parts by weight of calcium hydroxide, 3 parts by weight of magnesium oxide, 2.5 parts by weight of bisphenol A, and 0.4 parts by weight of BPP (benzyltriphenylphosphine chloride).

[0061] The manufacture method of solvent-resistant inert resin film-coated fluororubber sealing rubber plug comprises the following steps in embodiment 3:

[0062] (31) Mixing of rubber materials: put the fluororubber raw rubber in the internal mixer, knead for 5 minutes, add reinforcing agent, filler, processing aid and one-half of the acid absorbing agent and continue kneading for 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com