Anti-PID coating for photovoltaic module glass and preparation and use methods thereof

A photovoltaic module and coating technology, applied in the field of anti-PID coating solution, can solve the problems of complex steps, high cost, long preparation time, etc., and achieve the effects of simple use steps, reduced content, and guaranteed comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

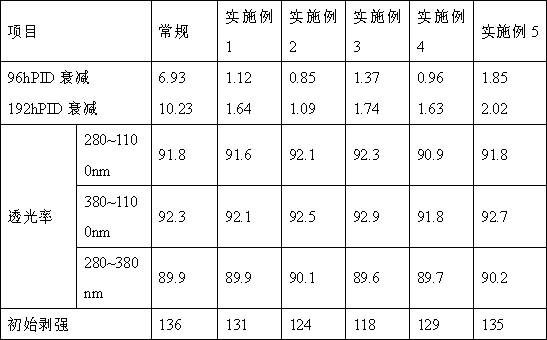

Examples

Embodiment 1

[0017] An anti-PID coating for solar photovoltaic module glass, its raw materials include: 20 parts of butyl acrylate, 20 parts of HDDA, 20 parts of curing agent (TPO), 35 parts of polyethylacrylate resin with a molecular weight of 10,000 and 5 parts of maleic anhydride .

[0018] Put the above-mentioned raw materials into a container, stir and mix evenly, and prepare an anti-PID coating solution for solar photovoltaic module glass.

[0019] When in use, first apply the coating solution evenly on the inner side of the conventional glass of the photovoltaic module, and the coating amount is 300g per square glass;

Embodiment 2

[0021] An anti-PID coating for solar photovoltaic module glass, the raw materials of which include: 50 parts of methyl acrylate, 20 parts of curing agent (907), 30 parts of polymethyl acrylate resin with a molecular weight of 1000 and 3 parts of zinc acrylate.

[0022] Put the above-mentioned raw materials into a container, stir and mix evenly, and prepare an anti-PID coating solution for solar photovoltaic module glass.

[0023] When in use, first apply the coating solution evenly on the inner side of the conventional glass of the photovoltaic module, and the coating amount is 250g per square glass; then irradiate the inner side of the glass evenly with ultraviolet light with a wavelength of 350nm for 15 minutes.

Embodiment 3

[0025] An anti-PID coating for solar photovoltaic module glass, the raw materials of which include: 40 parts of TMPTA, 30 parts of curing agent (15 parts each of 184 and 659), 30 parts of polybutylacrylate resin with a molecular weight of 5300 and 0.5 parts of zinc acrylate.

[0026] Put the above-mentioned raw materials into a container, stir and mix evenly, and prepare an anti-PID coating solution for solar photovoltaic module glass.

[0027] When in use, first apply the coating solution evenly on the inner side of the conventional glass of the photovoltaic module, and the coating amount is 200g per square glass;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com